Page 1

DCS550

Manual

DCS550 Drives (20 A to 1000 A)

ABB

Page 2

DCS550 Manuals

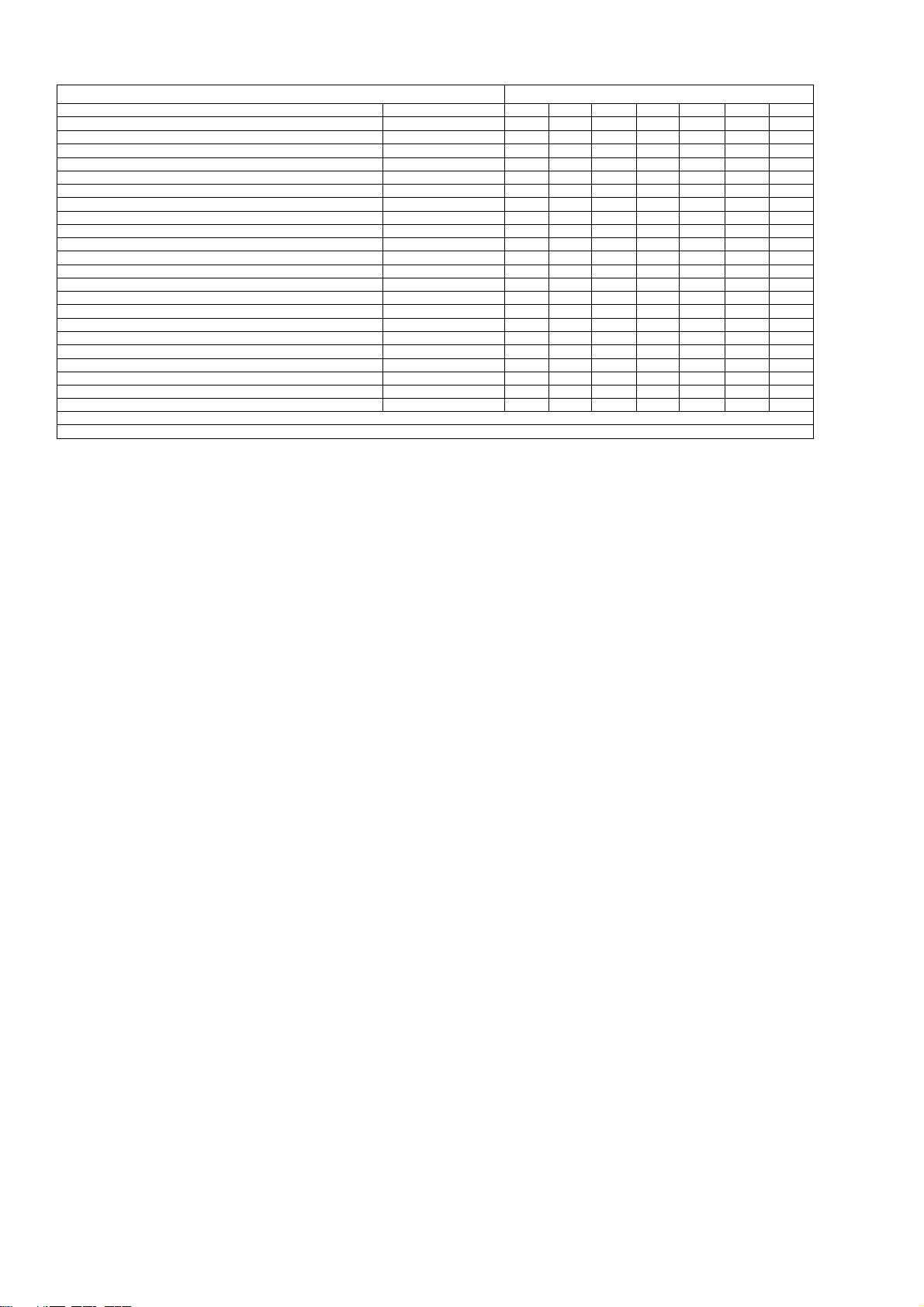

Public. number E D I ES F CN RU

Quick Guide

DCS550 Tools & Documentation CD

DCS550 Modules

DCS550 Flyer 3ADW000374 x x

DCS550 Technical Catalogue 3ADW000378 p

DCS550 Manual 3ADW000379 x

DCS550 Service Manual 3ADW000399 p

Installation according to EMC 3ADW000032 x

Technical Guide 3ADW000163 x

Extension Modules

RAIO-01 Analogue IO Extension 3AFE64484567 x

RDIO-01 Digital IO Extension 3AFE64485733 x

Serial Communication

RPBA-01 PROFIBUS 3AFE64504215 x

RCAN-01 CANopen 3AFE64504231 x

RCNA-01 ControlNet 3AFE64506005 x

RDNA-01 DeviceNet 3AFE64504223 x

RMBA-01 MODBUS 3AFE64498851 x

RETA-01 Ethernet 3AFE64539736 x

x -> existing p -> planned

Status 05.2011

DCS550 Drive Manuals-List_d.doc

3ADW000395 x x x x x

3ADW000377 x

Language

Page 3

Safety instructions

Chapter overview

This chapter contains the safety instructions you must follow when installing, operating and servicing the drive.

If ignored, physical injury or death may follow, or damage may occur to the drive, the motor or driven

equipment. Read the safety instructions before you work on the unit.

To which products this chapter applies

The information is valid for the whole range of the product DCS550.

Usage of warnings and notes

There are two types of safety instructions throughout this manual: warnings and notes. Warnings caution you

about conditions, which can result in serious injury or death and/or damage to the equipment, and advice on

how to avoid the danger. Notes draw attention to a particular condition or fact, or give information on a

subject. The warning symbols are used as follows:

Dangerous voltage warning warns of high voltage, which can cause physical injury or death

and/or damage to the equipment.

General danger warning warns about conditions, other than those caused by electricity, which

can result in physical injury or death and/or damage to the equipment.

3

Electrostatic sensitive devices warning warn of electrostatic discharge, which can damage

the equipment.

Installation and maintenance work

These warnings are intended for all who work on the drive, motor cable or motor. Ignoring the instructions can

cause physical injury or death and/or damage to the equipment.

WARNING!

1. Only qualified electricians are allowed to install and maintain the drive!

Never work on the drive, motor cable or motor when main power is applied. Always ensure

by measuring with a multimeter (impedance at least 1 Mohm) that:

1. Voltage between drive input phases U1, V1 and W1 and the frame is close to 0 V.

2. Voltage between terminals C+ and D- and the frame is close to 0 V.

Do not work on the control cables when power is applied to the drive or to the external

control circuits. Externally supplied control circuits may cause dangerous voltages inside the

drive even when the main power on the drive is switched off.

Do not make any insulation resistance or voltage withstand tests on the drive or drive

modules.

Isolate the motor cables from the drive when testing the insulation resistance or voltage

withstand of the cables or the motor.

When reconnecting the motor cable, always check that the C+ and D- cables are connected

with the proper terminal.

Note:

The motor cable terminals on the drive are at a dangerously high voltage when the main

power is on, regardless of whether the motor is running or not.

Depending on the external wiring, dangerous voltages (115 V, 220 V or 230 V) may be

present on the relay outputs of the drive system (e.g. RDIO).

DCS550 with enclosure extension: Before working on the drive, isolate the whole drive

system from the supply.

Safety instructions

3ADW000379R0301 DCS550 Manual e c

Page 4

4

Grounding

These instructions are intended for all who are responsible for the grounding of the drive. Incorrect grounding

can cause physical injury, death and/or equipment malfunction and increase electromagnetic interference.

Printed circuit boards and fiber optic cables

These instructions are intended for all who handle the circuit boards and fiber optic cables. Ignoring the

following instructions can cause damage to the equipment.

WARNING!

Ground the drive, motor and adjoining equipment to ensure personnel safety in all

circumstances, and to reduce electromagnetic emission and pick-up.

Make sure that grounding conductors are adequately sized and marked as required by safety

regulations.

In a multiple-drive installation, connect each drive separately to protective earth (PE ).

Minimize EMC emission and make a 360° high frequency grounding (e.g. conductive

sleeves) of screened cable entries at the cabinet lead-through plate.

Note:

Power cable shields are suitable as equipment grounding conductors only when adequately

sized to meet safety regulations.

As the normal leakage current of the drive is higher than 3.5 mA

or 10 mADC (stated by EN

AC

50178, 5.2.11.1), a fixed protective earth connection is required.

WARNING!

The printed circuit boards contain components sensitive to electrostatic discharge. Wear a

grounding wristband when handling the boards. Do not touch the boards unnecessarily.

Use grounding strip:

ABB order no.: 3ADV050035P0001

WARNING!

Handle the fiber optic cables with care. When unplugging optic cables, always grab the

connector, not the cable itself. Do not touch the ends of the fibers with bare hands, as the fiber

is extremely sensitive to dirt. The minimum allowed bend radius is 35 mm (1.38 in.).

Safety instructions

3ADW000379R0301 DCS550 Manual e c

Page 5

Mechanical installation

These notes are intended for all who install the drive. Handle the unit carefully to avoid damage and injury.

WARNING!

DCS550 size F4: The drive is heavy. Do not lift it alone. Do not lift the unit by the front cover.

Place it only on its back.

Make sure that dust from drilling does not enter the drive when installing. Electrically

conductive dust inside the unit may cause damage or lead to malfunction.

Ensure sufficient cooling.

Do not fasten the drive by riveting or welding.

Operation

These warnings are intended for all who plan the operation of the drive or operate the drive. Ignoring the

instructions can cause physical injury or death and/or damage to the equipment.

WARNING!

Before adjusting the drive and putting it into service, make sure that the motor and all driven

equipment are suitable for operation throughout the speed range provided by the drive. The

drive can be adjusted to operate the motor at speeds above and below the base speed.

Do not control the motor with the disconnecting device (disconnecting mains); instead, use

5

the control panel keys

Mains connection

You can use a disconnect switch (with fuses) to disconnect the electrical components of the

drive from the mains for installation and maintenance work. The type of disconnect switch

used must be as per EN 60947-3, Class B, so as to comply with EU regulations, or a circuitbreaker type which switches off the load circuit by means of an auxiliary contact causing the

breaker's main contacts to open. The mains disconnect must be locked in its "OPEN"

position during any installation and maintenance work.

EMERGENCY STOP buttons must be installed at each control desk and at all other control

panels requiring an emergency stop function. Pressing the STOP button on the control panel

of the drive will neither cause an emergency stop of the motor, nor will the drive be

disconnected from any dangerous potential.

To avoid unintentional operating states, or to shut the unit down in case of any imminent

danger according to the standards in the safety instructions it is not sufficient to merely shut

down the drive via signals "RUN", "drive OFF" or "Emergency Stop" respectively "control

panel" or "PC tool".

Intended use

The operating instructions cannot take into consideration every possible case of

configuration, operation or maintenance. Thus, they mainly give such advice only, which is

required by qualified personnel for normal operation of the machines and devices in industrial

installations.

If in special cases the electrical machines and devices are intended for use in non-industrial

installations - which may require stricter safety regulations (e.g. protection against contact by

children or similar) - these additional safety measures for the installation must be provided by

the customer during assembly.

Note:

When the control location is not set to Local (L not shown in the status row of the display),

the stop key on the control panel will not stop the drive. To stop the drive using the control

and , or commands via the I/O board of the drive.

panel, press the LOC/REM key and then the stop key

.

Safety instructions

3ADW000379R0301 DCS550 Manual e c

Page 6

6

Table of contents

DCS550 Manuals.................................................................................................................................................2

Safety instructions................................................................................................................................................ 3

Table of contents ................................................................................................................................................. 6

Introduction.......................................................................................................................................................... 8

The DCS550........................................................................................................................................................ 9

General...................................................................................................................................................... 9

Overview Main circuit and control............................................................................................................ 11

Environmental Conditions........................................................................................................................ 12

Type code................................................................................................................................................ 13

Voltage ratings......................................................................................................................................... 13

Current ratings......................................................................................................................................... 14

Dimensions and weights.......................................................................................................................... 16

Mechanical installation....................................................................................................................................... 19

Cabinet installation .................................................................................................................................. 20

Planning the electrical installation......................................................................................................................21

Drive connection and wiring example...................................................................................................... 22

Installation components........................................................................................................................... 24

Cabling..................................................................................................................................................... 29

⑥ Cooling fans ........................................................................................................................................ 32

Electrical installation .......................................................................................................................................... 33

Power connections .................................................................................................................................. 34

Drive interfaces........................................................................................................................................ 36

Installation checklist................................................................................................................................. 38

Electronic board details......................................................................................................................................39

Terminal locations ................................................................................................................................... 39

Table of used boards............................................................................................................................... 40

Control board SDCS-CON-F ................................................................................................................... 41

Power Interface board SDCS-PIN-F........................................................................................................ 44

OnBoard field exciters SDCS-BAB-F01 and SDCS-BAB-F02 ................................................................ 46

Accessories........................................................................................................................................................ 49

① Line reactors (L1)................................................................................................................................ 49

② Semiconductor fuses (F1)................................................................................................................... 55

③ EMC filters (E1)................................................................................................................................... 57

④ Auxiliary transformer (T2) for converter electronics and fan............................................................... 57

Start-up.............................................................................................................................................................. 58

Commissioning ........................................................................................................................................ 58

Macros ..................................................................................................................................................... 62

Firmware description..........................................................................................................................................73

Start / stop sequences............................................................................................................................. 73

Excitation ................................................................................................................................................. 74

Table of contents

3ADW000379R0301 DCS550 Manual e c

Page 7

DC-breaker...............................................................................................................................................76

Dynamic braking.......................................................................................................................................77

Digital I/O configuration............................................................................................................................79

Analog I/O configuration...........................................................................................................................83

Serial field bus communication...........................................................................................................................87

CANopen communication with fieldbus adapter RCAN-01......................................................................87

ControlNet communication with fieldbus adapter RCNA-01 ....................................................................91

DeviceNet communication with fieldbus adapter RDNA-01.....................................................................94

Ethernet/IP communication with fieldbus adapter RETA-01....................................................................97

Modbus (RTU) communication with fieldbus adapter RMBA-01 ...........................................................100

Modbus/TCP communication with fieldbus adapter RETA-01...............................................................102

Profibus communication with fieldbus adapter RPBA-01.......................................................................103

ProfiNet communication with fieldbus adapter RETA-02.......................................................................107

Switch on sequence ...............................................................................................................................108

Data set table .........................................................................................................................................108

AP (Adaptive Program).....................................................................................................................................109

What is AP?............................................................................................................................................109

DWL AP..................................................................................................................................................113

Function blocks ......................................................................................................................................118

Winder ..............................................................................................................................................................130

7

Winder blocks.........................................................................................................................................130

Winder macros .......................................................................................................................................136

Winder commissioning ...........................................................................................................................145

Signal and parameter list..................................................................................................................................148

Parameter group list...............................................................................................................................149

Signals....................................................................................................................................................151

Parameters.............................................................................................................................................176

DCS Control Panel...........................................................................................................................................264

Fault tracing......................................................................................................................................................270

Converter protection...............................................................................................................................270

Motor protection .....................................................................................................................................273

Display of status, fault messages and error codes ................................................................................279

Fault signals (F)......................................................................................................................................280

Alarm signals (A)....................................................................................................................................288

Notices ...................................................................................................................................................295

Appendix A: Quick start-up diagrams...............................................................................................................296

Drive configuration with reduced components .......................................................................................296

I/O connections ......................................................................................................................................298

Appendix B: Firmware structure diagrams.......................................................................................................299

Appendix C: Index of signals and parameters..................................................................................................303

Table of contents

3ADW000379R0301 DCS550 Manual e c

Page 8

8

Introduction

Chapter overview

This chapter describes the purpose, contents and the intended use of this manual.

Before You Start

The purpose of this manual is to provide you with the information necessary to control and program the drive.

Study carefully the Safety instructions

the drive. Read this manual before starting-up the drive.

Note:

This manual describes the standard DCS550 firmware.

What this manual contains

The Safety instructions are at the beginning of this manual.

Introduction

The DC

Mechanical installation

Planning the electrical installation

Electrical installation

Electronic board details

Accessories

Start-up

Firmware description

Serial field bus communication

AP (Adaptive Program)

Winder

Signal and parameter list

DCS Control Panel

Fault tracing

Appendix A: Quick start-up diagrams

Appendix B: Firmware structure diagrams

Appendix C: Index of signal and parameters

, the chapter you are currently reading, introduces you to this manual.

S550, this chapter describes the basic properties of the DCS550.

, this chapter describes the mechanical installation of the DCS550.

, this chapter describes the electrical installation of the DCS550.

, this chapter describes the electronics of the DCS550.

, this chapter describes the accessories for the DCS550.

, this chapter describes the basic start-up procedure of the DCS550.

, this chapter describes how to control the DCS550 with standard firmware.

, this chapter describes the communication capabilities of the DCS550.

, this chapter describes the basics of AP and instructs how to build an application.

, this chapter describes the winder and instructs how to use the winder blocks of the DCS550.

, this chapter contains all signals and parameters.

, this chapter describes the handling of the DCS Control Panel.

, this chapter describes the protections and fault tracing of the drive.

at the beginning of this manual before attempting any work on or with

, this chapter describes how to plan the electrical installation of the DCS550.

Introduction

3ADW000379R0301 DCS550 Manual e c

Page 9

The DCS550

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Chapter overview

This chapter describes the basic properties of the DCS550.

General

ABB Drive Service

In order to offer the same after sales service to our customer around the

world, ABB has created the DRIVE SERVICE CONCEPT. ABB’s after

sales service is globally consistent due to common targets, rules and the

way of operation. This means for our customers simply visit the ABB

drive service homepage at www.abb.com/drivesservices

DC drives worldwide Service Network

Country Local ABB Service Town Service Phone No.

rgentina

ustralia

ustria

Belgium

Brazil

Canada

China

Czech Republic ABB S.R.O. PRAHA +42 02 34 32 23 60

Finland

Finland

Finland

France

Germany

Greece

Ireland

Italy

Korea, Republic ABB Ltd., Korea CHONAN +82 (0) 4 15 29 22

Malaysia

Mexico

Netherlands

New Zealand

Poland

Russia

Switzerland

Singapore

Slovakia

South Africa

Spain

Taiwan

Thailand

Turkey

USA

Venezuela

sea Brown Boveri S.A. BUENOS AIRES +54 (0) 12 29 55 00

BB NOTTING HILL +61 (0) 3 85 44 00 00

BB AG WIEN +43 1 60 10 90

BB N.V. ZAVENTEM

BB Ltda. OSASCO +55 (0) 11 70 84 91 11

BB Inc. SAINT-LAURENT +1800 865 7628

BB China Ltd BEIJING +86 40 08 10 88 85 - 24h service

BB Oy Service KUUSANKOSKI +35 8 10 22 51 00

BB Oy Product Service HELSINKI +35 8 10 22 20 00

BB Oy Service NOKIA +35 8 10 22 51 40

BB Automation

BB Process Industry

BB Process Industries MANNHEIM +49 18 05 22 25 80

BB SA METAMORPHOSSIS +30 69 36 58 45 74

BB Ireland Ltd. TALLAGHT +35 3 14 05 73 00

BB MILAN +39 02 90 34 73 91

BB Malaysia Sdn. Bhd. KUALA LUMPUR +60 3 56 28 42 65

BB Sistemas S.A. DE C.V. TLALNEPANTLA +52 53 28 14 00

BB B.V. ROTTERDAM +31 1 04 07 88 66

BB Service ltd

BB Centrum IT Sp.zo.o

BB Automation LLC MOSCOW +74 95 96 0

BB AG DÄTTWIL +41 5 85 86 87 86

BB Industry Pte Ltd SINGAPORE +65 67 76 57 11

BB Elektro s.r.o. BANSKA BYSTRICA +42 19 05 58 12 78

BB South Africa (Pty) Lt JOHANNESBURG +27 1 16 17 20 00

BB Automation Products BARCELONA +34 9 37 28 73 00

BB Ltd. TAIPEI 105 +88 62 25 77 60 90

BB Limited SAMUTPRAKARN +66 27 09 33 46

BB Elektirk Sanayi A.S ISTANBUL +90 2 16 36 52 90

BB Industrial Products NEW BERLIN

BB S.A. CRCS +58 (0) 22 38 24 11 / 12

MONTLUEL

from abroad France

UCKLAND +64 92 76 60 16

WROCLAW

LODZ

.

+32 27 18 64 86

+32 27 18 65 00 - 24h service

+33 1 34 40 25 81

+0810 02 00 00

+48 42 61 34 96 2

+48 42 29 93 91 39 5

+1 26 27 85 32 00

+1 262 435 7365

9

The DCS550

3ADW000379R0301 DCS550 Manual e c

Loading...

Loading...