Page 1

Catalog

ABB DC Drives

DCS550, 20 A to 1000 A

Page 2

©

2

0

1

1

A

B

B

A

u

t

o

m

a

t

i

o

n

P

r

o

d

u

t

G

m

b

H

-

A

l

l

R

i

g

h

t

R

e

e

r

e

d

3ADW 000 377 R0201 / April 2011

System configuration

WINDOWS 98, NT, 2000, XP

Acrobat Reader 4.0 or higher

Internet Explorer 5.0 or higher

I

f

t

h

e

C

D

R

O

M

w

o

n

’

t

s

t

a

r

t

a

u

t

o

m

a

t

i

c

a

l

l

y

p

l

e

a

s

e

e

x

e

c

u

t

e

S

T

A

R

T

.

B

A

T

System confirmation

Win2000, WinXP

Before installation of PC tools

remove previous version by

CONTROL PANEL of your

PC

Read more details in

Quick Guide 3ADW000191

Content

This CD ROM provides

information about DCS550 and

contains PC tools:

DWL 2.93 for DC drives

+Commissioning Wizard 1.0

+DWL AP 2.2

FDT 2.2 Firmware

download kit

+ workspace

Firmware 1.1

DCS550

Ver.: 1.10

System confirmation

Win7, Win2000, WinXP

Before installation of PC tools

remove previous version by

CONTROL PANEL of your PC

Flexibly geared to all the requirements of modern-day machinery

manufacturers

c

s

s

s

Startup and

maintenance software

Used from drive startup

and configuration to daily

use and process tuning

v

UR fuses Three phase line chokes

Assistant control panel

The assistant control panel

features a multilingual alphanumeric display for easy drive

programming. The control

panel has various assistants

and a built-in help function to

guide the user.

Adaptive Programming

Adaptive Programming

is easy and fast because

there is a graphical support.

2 3ADW000378R0101 | DCS550 Technical catalog e a

Page 3

Fieldbus adapter

modules

The pluggable fieldbus

options allow connection to most automation

systems.

A single cable replaces

complex conventional

cabling.

With its compact dimensions and robust

technology, the DCS550 is an ideal drive

solution for machinery manufacturers – both in

new installations or as a replacement for older

analog devices.

Integrated “winder”, high-performance

field supply and various interfaces provide

machinery manufacturers with a maximum of

flexibility in terms of machine integration.

DC motor

Interface extension modules

The pluggable I/O modules

extend the basic I/Os.

On-board field exciter

Integrated on-board field

exciter reduces hardware and installation

work.

Integrated macros

Most frequent parameter settings covered

by macros for easy

commissioning.

Contents

Overview 2

Contents 3

Designed for essential requirements 4

Flexibility for different applications 5

Smart human-drive interface 6

Standard firmware 7

PC tool for easy start-up and maintenance 8

Winder function required? 9

How to select a drive 10

Standard interface and extensions 11

How to select the motor voltage 12

Technical data, dimensions and weights 13

Line reactors L1 14

Fuse connections 15

Environmental conditions 16

Service 17

DCS family - the range for all demands 18

Notes 19

DCS550 Technical catalog e a | 3ADW000378R0101 3

Page 4

Designed to meet the essential requirements of machinery

manufacturers

DCS550 – The highlights

– Compact dimensions

For installations with limited space

– Integrated high performance three phase field exciter up to 35 A

Fits all available motors without additional installations

– “Winder” with commissioning assistant

For easy and fast adaptation to different applications

– Different fieldbus interfaces (incl. EtherCAT, Profinet…)

For easy integration into automation

– Additional PID-controller

For overriding control functions (e. g. pressure or

level control)

– Adaptive programming with Drive AP, ABB’s graphical PC-tool

For easy implementation of additional functions

– Various start-up assistants and auto-tune functions

For fast commissioning

– Large control panel

For straight forward and self-explanatory operation

– Rugged design

For rough environments, high reliability

– Worldwide service

Local service in more than 60 countries

Easy to use

The basic version of the DCS550 is already equipped with a

large number of standard hardware interfaces like an encoder,

an analog tachogenerator and four analog input devices.

Since the basic unit includes all important functions almost all

applications are covered – options are not necessary.

The single-volume documentation provides comprehensive

information on the unit, firmware and hardware. The guided

start-up and complementary support functions reduce startup times to a minimum. The grouped structure of the parameters provides easy and clearly arranged navigation within the

various features and functions. Error messages and help texts

are displayed in plaintext in the user’s native language. The reduced need for training is an additional advantage created by

the synergies and similarities with ABB’s DCS800 converter

and ABB AC-drives.

Fieldexciter connection

DCS550 Control panel

Analog output, 2 x AO

Analog input, 4 x AI

Tacho input /10 ... 270 V

Armature Connection

4 3ADW000378R0101 | DCS550 Technical catalog e a

R-Fieldbus module

R-IO extension module

R-IO extension module

Encoder interface

Digital input, 8 x DI

Digital output, 4 x D0

Digital output, Relay

AC Connection

DCS550 converter module

Page 5

Flexibility for different applications

DCS550 – Extensive applications

– Extruders

– Sugar centrifuges

– Wire drawing machines

– Coating lines

– Printing machines

– Presses

– Tools machines main drives

– Food processing machines

– Woodworking (wooden products and MDF industry)

– Retrofit of analog DC-technology

Modern DC-drives – More up-to-date than ever

Today, DC-drive technology is more up-to-date than ever.

Their attractive cost-performance ratio and functional advantages such as high torque at low speed, light weight and low

power loss, turn DC-drives into the preferred solution for many

applications. As far as innovation is concerned ABB’s DCdrives match the same high standards as ABB’s AC-drives.

Easy upgrade of installed older converters

The machines are frequently still in very good condition, but

spare parts and know-how for the installed power electronics

are no longer available.

With the DCS550, existing machines can be kept in operation

by replacing the old drive.

Short downtimes and low costs for the retrofit are additional

advantages of an upgrade of existing machinery.

DCS550 Technical catalog e a | 3ADW000378R0101 5

Page 6

Smart human-drive interface

General

All units are equipped with the DCS550 Control Panel. It can

be snapped into place on the power converter module or

installed in the switchgear cubicle door by means of a mounting kit.

Control panel: high level of convenience included

The assistant control panel is part of the basic unit. It offers

a multi-language alphanumeric display (EN, DE, ES, FR, IT)

with a multilingual help function. The large graphic display

allows the user to freely select actual and set values. Another

additional advantage: the user can call up a list of all changed

parameters. The control panel can also store parameters as a

security backup or copy them for use in other converters.

Panel mounting kits

To attach the control panel to the outside of a larger enclosure, two panel mounting kits are available. A simple and

cost-efficient installation is possible with the ACS/H-CP-EXT

kit, while the JPMP-01 kit provides a more user-friendly solution, including a panel platform that enables the panel to be

removed in the same way as a drive-mounted panel. The

panel mounting kits include all hardware required, including

3 m extension cables and installation instructions.

– Startup Assistant

– Fault logger function

– Plain text for fault logger, faults and alarms

– Shows actual values in physical units

– Backup and Copy function for parameter

– Compare function for parameters

– Real time clock

- Help function

- Multilingual

6 3ADW000378R0101 | DCS550 Technical catalog e a

Page 7

Standard Firmware for scalable control and functionality

α

≥

Basic firmware

DCS550 firmware includes the basic functions of speed

control, armature current, field current and motor voltage. The

design of the drive logic enables a drive reaction defined by

Profibus standard, but can also configured to adapt classic

command structures.

Macros

The DCS550 is equipped with seven different macros to cover

the most frequent parameter settings.

Macros are pre-programmed parameter sub-sets. During

start-up, the drive can be configured easily without changing individual parameters. The functions of all inputs and

several outputs and of allocations in the control structure are

influenced by the selection of a macro. The means whether

the drive is speed-controlled or torque-controlled, whether

supplementary references are processed, which actual values

are available at the analog outputs, which reference value

sources are used etc. is already defined in the macro.

Functions of basic firmware

– Different speed ramp function

– Speed control

– Torque control

– Armature current control

– Field current control

– Automatic field weakening

– E-stop function according to Profibus standard

– Interface for fieldbus

– Programmable digital and analogue outputs

– 16 blocks Adaptive Program

– Converter protection (temperature, voltage,...)

Motor protection features

– Stall protections

– Thermal motor model

– Klixon supervision

– Speed feedback error

– Over speed

– Armature current ripple

– Armature over current

– Minimum field current

Example: STANDARD macro

DCS550 Technical catalog e a | 3ADW000378R0101 7

Page 8

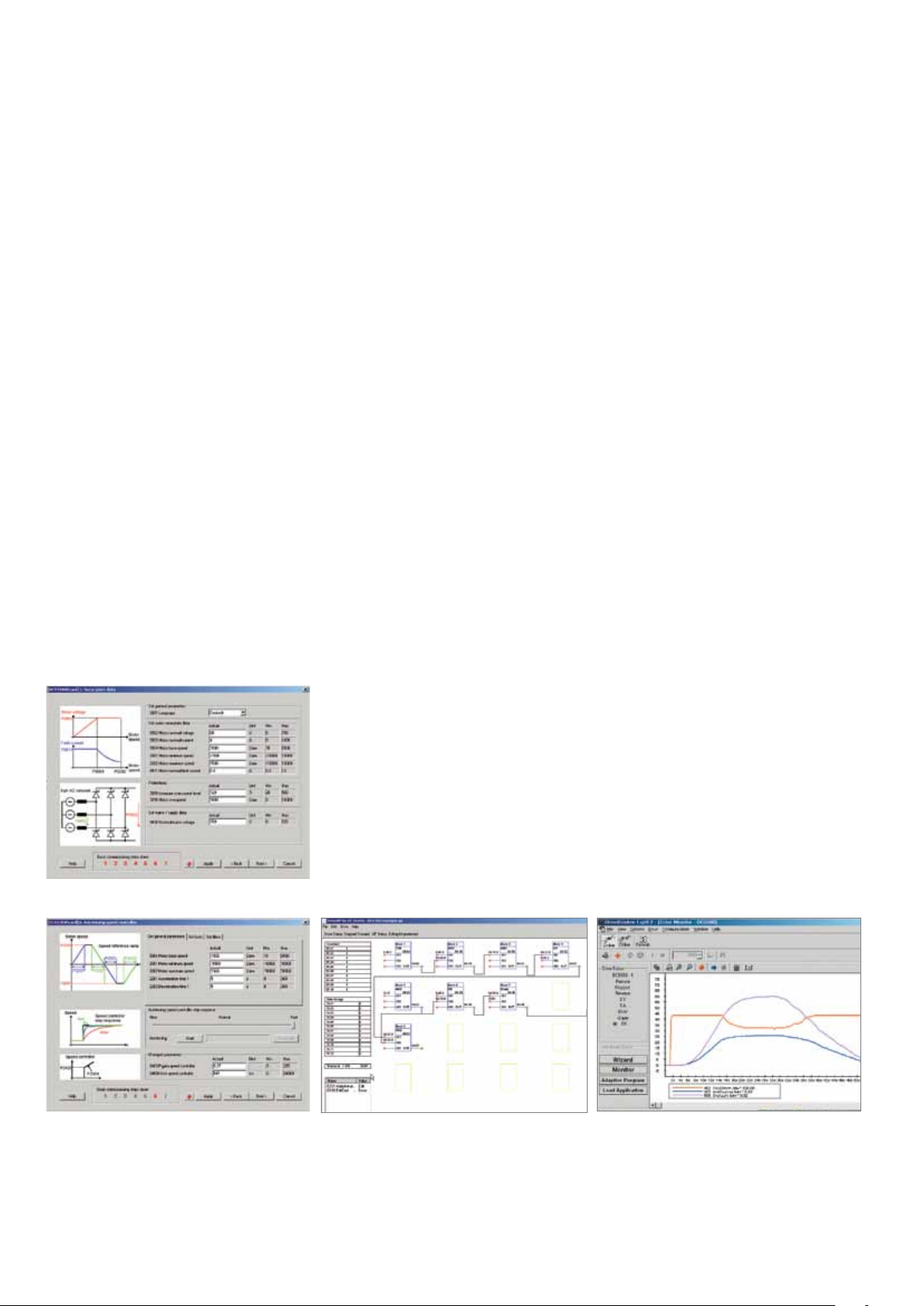

PC tool for easy start-up and maintenance

Useful features

DriveWindow Light

The user-friendly start-up and maintenance tool for the world

of ABB-drives supports both ABB’s DC-drives and AC-drives.

DriveWindow Light is a PC software package for easy and

fast start-up and maintenance of DCS550 converters and is

part of the basic package. In offline-mode, all parameters can

be set from the user’s office desk. The parameter browser

can both display and save parameters on the computer. A

comparison feature can compare and align current values with

a stored set of parameters. With the “Local”-feature, the drive

can be controlled as well. At the same time, up to four display

values can be visualized graphically. DriveWindow Light also

includes an assistant for guided start-up, winder functions as

well as the AP-tool for block programming.

Start-up assistant

The DriveWindow Light start-up assistant for the DCS550

provides valuable support during commissioning via an interactive dialog. The individual steps of the start-up process

are pre-defined in the right order and all required parameters

are displayed. The “Basic”-feature captures motor and connection data and adjusts the controller automatically. The

“Advanced”-feature supports the start-up of serial communication (fieldbus) and winder functions. The context-sensitive

help function is always available.

Adaptive Programming (AP):

Adaptive Programming is included in the basic package.

With the help of 16 functional blocks users can develop, test

and document their own programs easily in graphical mode.

The „Adaptive Programming“ (AP) function allows the implementation of additional features.

Modifications can be configured with either the control panel

or with the help of the graphical interface of DriveWindow

Light AP.

The main features of DriveWindow Light AP are:

– 16 programmable function blocks

– Available functions:

– Logical: AND, OR and XOR

– Mathematical: ADD, MUL, DIV, ABS, MAX and MIN

– Other: timer, switch, comparator, filter, SR, PI and

user-defined warnings or faults

– Freely definable execution order

– Easy documentation

Start-up Assistant

Speed Controller Autotuning

Adaptive Programming

Content CD:

The CD ROM provides information about DCS550

and contains PC tools:

– DriveWindow Light for DC drives +

Commissioning Wizard + DWL AP

– FDT Firmware download kit + workspace

– Firmware

Trending

8 3ADW000378R0101 | DCS550 Technical catalog e a

Page 9

Winder function required?

F

T

D

F

T

D

Integrated winder functions

The DCS550 is equipped with a winder function featuring

pre-defined macros for the four most commonly used winder

types:

Velocity control

Calculates the diameter and rotation speed setpoint value.

The diameter is used to adjust the speed controller to all

winding sizes. There is no tension control. All other macros

are included in this basic structure.

Indirect tension control

Controls the tension with the help of preset charts for friction

and moment of inertia (open loop).

This structure provides a very robust control behavior because no physical tension measurement is required.

Dancer control

Controls the tension with the weight of the dancer roll

(closed loop).

The dancer has to be kept in the right position with additional

speed set values. The PID-controller of the DCS550 can also

control the positioning of the dancer roll. The position of the

dancer roll is transmitted to the controller as an analog actual

value.

Commissioning assistant

For an easy winder set-up, all different winder types can be

configured and commissioned using a graphical assistant.

The assistant is part of DriveWindows Light PC-tool.

The rating for friction and inertia can be determined by auto

tuning.

Direct tension control

Closed loop for physical value of tension

The tension is measured with a load cell and transferred to

the drive as an analog actual value. The DCS550 is equipped

with a free PID-controller that can be integrated into the control loop with the “Tension Control” macro.

Example: direct tension control (closed loop)

Winder MacrosWinder Assistant

DCS550 Technical catalog e a | 3ADW000378R0101 9

Page 10

How to select a drive

Many of the features for DCS550 drives are built-in as standard providing easy selection.

Every drive is equipped with

– Assistant Control panel

– CD ROM with PC commissioning assistant and DWL/ AP

programming PC tool (PC requires COM port)

– Quickguide manual in 5 language En,DE,IT,FR,ES

– Marking CE and cUlus

– ON board field exciter, rating see table

The control board and power interface board are coated.

Cable marking C and tin plated Cu bars inside, Protection

class IP00.

Available as options

– R-fieldbus modules

– additional R I/O modules

– semiconductor fuses

– line reactors

– EMC Filters

To choose the right drive for your application, please refer to

the ratings table on page 12. The selected drive has a unique

type designation, which identifies the drive by construction,

power and voltage range.

Type designation: DCS550 - S0y - xxxx - 05

DCS550-S0y-xxxx-05

– DCS550 = Product series

– S0 = DC drive converter module

– y = 1 = single bridge/ motor operation

= 2 = double bridge motor + regen operation

– xxxx = rated current (main bridge armature circuit) double check

suitable duty cycles rated field current, see table

– 05 = 230 V

Options are ordered via Id code of the price list.

... 525 VAC supply

AC

10 3ADW000378R0101 | DCS550 Technical catalog e a

Page 11

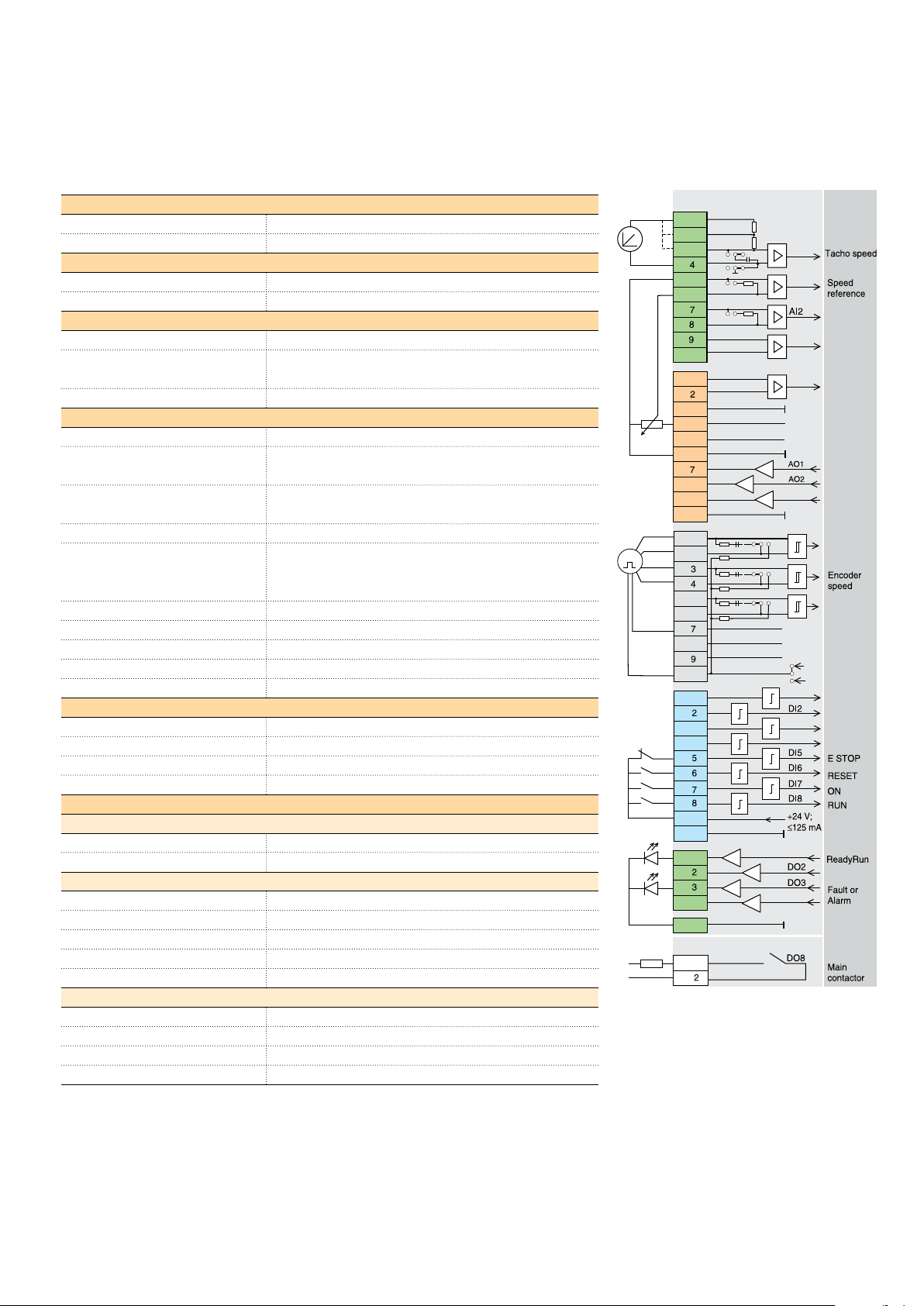

Standard interface and extensions for comprehensive connectivity

Mains connection

Mains 3-phase 230 VAC - 525 VAC; -15 % / +10 %

Rated frequency 50 Hz or 60 Hz

Field exciter

Supply voltage Internally connected to the mains

Hardware Completely integrated 3-phase OnBoard field exciter

Operating conditions

Degree of protection IP 00

EMC Fulfilling EN 61800-3 in accordance with

3ADW 000 032

Compliance CE, cULus

Control interfaces

Auxiliary voltages 115 V

, 230 VAC, 230 V

AC

DC

PC-tools DriveWindow Light, DWL AP, start-up assistant, winder as-

sistant, help function

DCS550 Control Panel As standard, several languages, start-up assistant, help

function

Status display Seven-segment display as standard

Analog I/O 4 AI (15 bit + sign);

3 AO (11 bit + sign; two are freely programmable, one is

fixed for armature current)

Digital I/O 8 DI, 5 DO (one for mains breaker)

Motor temperature 1 PTC

Analog tacho input As standard

Encoder input As standard for 5 V and 24 V encoders

Option slots two slots for analog and digital I/O plug-in options

Special firmware functions

Adaptive Program 16 freely programmable function blocks

PID controller Freely usable PID controller

Macros 10 pre-defined macros for fast commissioning

winder macros 4 pre-defined winder macros

Control and communication options

Analog & digital plug-in options

1 * RAIO 2 AI, 2 AO

2 * RDIO 3 DI, 2 DO each

Classic fieldbusses

RCAN-01 CANopen

RCNA-01 ControlNet

RDNA-01 DeviceNet

RMBA-01 Modbus (RTU)

RPBA-01 Profibus

Ethernet fieldbuses

RECA-01 EtherCat

RETA-01 Ethernet/IP and Modbus/TCP

RETA-02 Profinet

t

230V

E

K1

SDCS-CON-F

±90...±270 V

X1:1

±

30...±90 V

2

±

8...±30 V

3

S1

3

S1

6

5

S2

3

4

6

S3

3

4

10

X2:1

3

4

5

6

8

9

10

X3:1

121

100nF

2

10k

121

100nF

10k

5

121

100nF

6

10k

8

10

Sense 0 V

Sense 5 V

Power

X4:1

3

4

9

10

1

X5:

4

8

SDCS-PIN-F

X96:1

Firmware

-

ATACH

1

+

4

-

AI1

250

+

-

250

+

-

AI3

+

-

AI4

+

GND

+10V

-10V

GND

I-act

GND

ChA

+

S4

3

2

1

ChA

-

ChB

+

S4

6

5

4

ChB

-

ChZ

+

9

7S48

ChZ

-

GND

S4

10

5V

11

24V

12

DI1

DI3

DI4

DO1

DO4

GND

B22_001_0_a.dsf

DCS550 Technical catalog e a | 3ADW000378R0101 11

Page 12

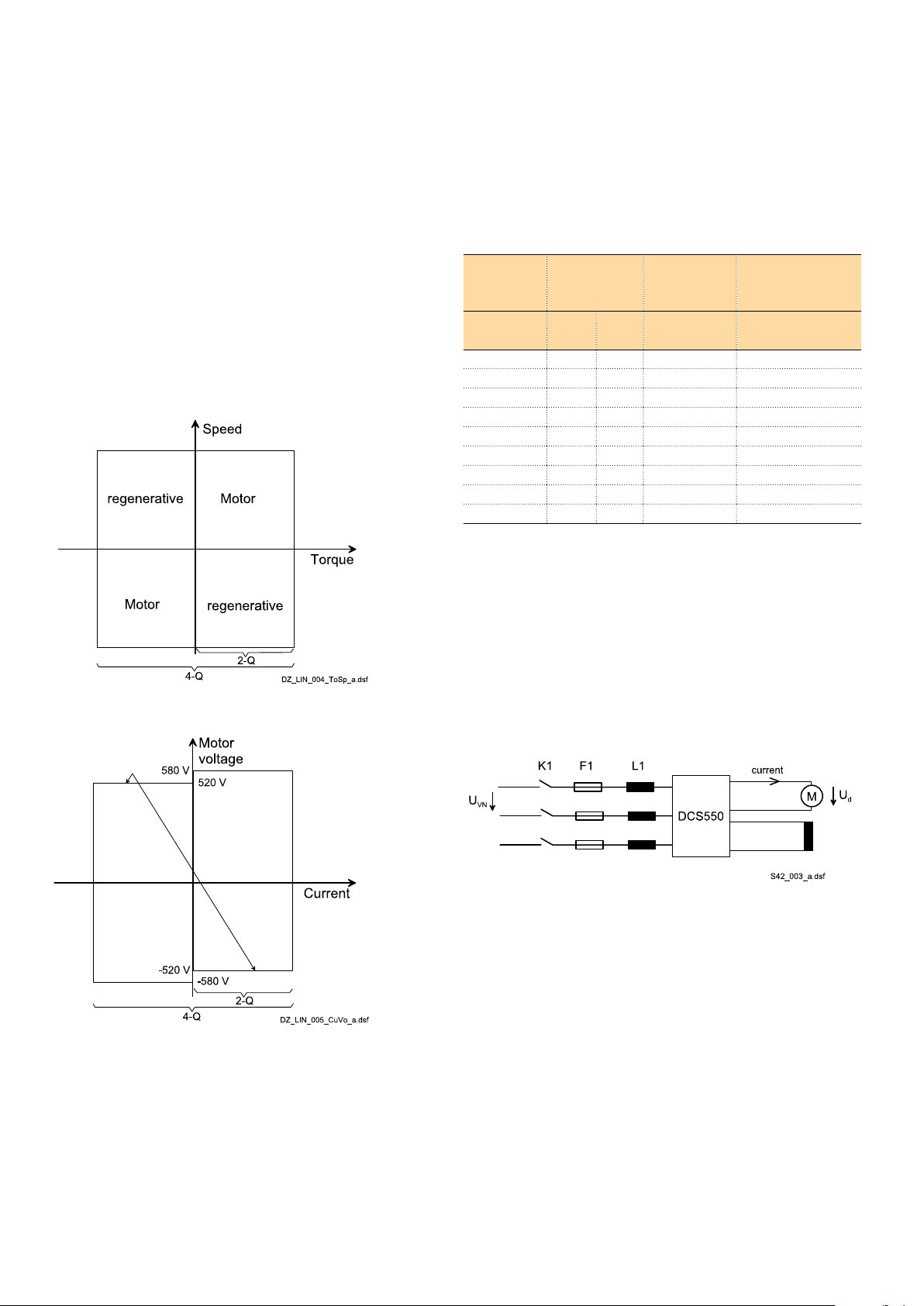

How to select the motor voltage

Reference variables

The voltage characteristics are shown in the table beside. The

DC voltage characteristics have been calculated using the following assumptions:

= rated input terminal voltage, 3-phase

– U

VN

– Voltage tolerance ±10 %

– Internal voltage drop approx. 1 %

– If a deviation or a voltage drop has to be taken into con-

sideration in compliance with IEC and VDE standards, the

output voltage or the output current must be reduced in

accordance with the table on the right.

The bridge type 2-Q or 4-Q has an influence on the maximum

motor voltage. See table below.

System

connection

voltage

U

[V]

230 265 240 310 05

380 440 395 510 05

400 465 415 540 05

415 480 430 560 05

440 510 455 590 05

460 530 480 620 05

480 555 500 640 05

500 580 520 670 05

525 610 545 700 05

VN

DC voltage

(recommended)

U

dmax 2-Q

[V]

U

dmax 4-Q

[V]

Ideal DC

voltage with-

out load

U

di0

[V]

Recommended

DCS800

voltage class

motor and regenerative operation

If armature voltages higher than recommended are requested,

please check carefully whether your system is still working

under safe conditions.

The maximum output voltage of a 4-Q drive can be increased

up to the level of U

. Thus the torque reversal from mo-

dmax 2-Q

toring mode to generating mode increases up to 300 ms. This

lowers the dynamics of the drive and is only recommended for

non-dynamic applications (e.g. E-Stop function).

Example: maximum motor voltage U

for 500 VAC supply voltage U

dmax

VN

The power section of the converters is available as a single

(2-Q) bridge or double (4-Q) bridge. 4-Q drives are required

for regenerative breaking.

12 3ADW000378R0101 | DCS550 Technical catalog e a

Page 13

Technical data, dimensions and weights

Single bridge (2-Q Drive), 230 - 525 V -15 / +10 %

[A] IF [A] Fan supply Dimensions

I

A

20 1 - 12 no fan 370 x 270 x 220 11 9 12 0,18 DCS550-S01-0020-05 F1

45 internal 21 26 0,28 DCS550-S01-0045-05

65 internal 30 38 0,32 DCS550-S01-0065-05

90 internal 42 52 0,39 DCS550-S01-0090-05

135 1 - 18 115 / 230 V 370 x 270 x 270 16 63 78 0,58 DCS550-S01-0135-05 F2

180 115 / 230 V 84 104 0,76 DCS550-S01-0180-05

225 115 / 230 V 105 131 0,90 DCS550-S01-0225-05

270 115 / 230 V 126 157 1,00 DCS550-S01-0270-05

315 2 - 25 115 / 230 V 459 x 270 x 310 25 146 183 1,12 DCS550-S01-0315-05 F3

405 115 / 230 V 188 235 1,38 DCS550-S01-0405-05

470 115 / 230 V 219 273 1,66 DCS550-S01-0470-05

610 2 - 35 230 V 644 x 270 x 345 38 284 354 1,94 DCS550-S01-0610-05 F4

740 230 V 344 429 2,38 DCS550-S01-0740-05

900 230 V 419 522 2,95 DCS550-S01-0900-05

h x w x d [mm]

Weight

[kg]

Power 400 V

[kW]

Power 525 V

[kW]

Losses

[kW]

Type code Size

Double bridge (4-Q Drive), 230 - 525 V -15 / +10 %

[A] IF [A] Fan supply Dimensions

I

A

25 1 - 12 no fan 370 x 270 x 220 11 10 13 0,20 DCS550-S02-0025-05 F1

50 internal 21 26 0,31 DCS550-S02-0050-05

75 internal 31 39 0,36 DCS550-S02-0075-05

100 internal 42 52 0,42 DCS550-S02-0100-05

150 1 - 18 115 / 230 V 370 x 270 x 270 16 62 78 0,64 DCS550-S02-0150-05 F2

200 115 / 230 V 83 104 0,84 DCS550-S02-0200-05

250 115 / 230 V 104 130 1,00 DCS550-S02-0250-05

300 115 / 230 V 125 156 1,10 DCS550-S02-0300-05

350 2 - 25 115 / 230 V 459 x 270 x 310 25 145 182 1,22 DCS550-S02-0350-05 F3

450 115 / 230 V 187 234 1,54 DCS550-S02-0450-05

520 115 / 230 V 216 270 1,85 DCS550-S02-0520-05

680 2 - 35 230 V 644 x 270 x 345 38 282 354 2,15 DCS550-S02-0680-05 F4

820 230 V 340 426 2,64 DCS550-S02-0820-05

1000 230 V 415 520 3,31 DCS550-S02-1000-05

h x w x d [mm]

Weight

[kg]

Power 400 V

[kW]

Power 525 V

[kW]

Losses

[kW]

Type code Size

IAC = IA * 0.82 + IF * 0.82

Size: F1 F2 F3 F4

DCS550 Technical catalog e a | 3ADW000378R0101 13

Page 14

Line reactors L1

Size Converter type (2-Q) Converter type (4-Q) Line choke 1 %

relative voltage drop

F1 DCS550-S01-0020 DCS550-S02-0025 ND01 1 ND401 4

DCS550-S01-0045 DCS550-S02-0050 ND02 1 ND402 4

DCS550-S01-0065 DCS550-S02-0075 ND04 1 ND403 5

DCS550-S01-0090 DCS550-S02-0100 ND06 1 ND404 5

F2 DCS550-S01-0135 DCS550-S02-0150 ND06 1 ND405 5

DCS550-S01-0180 DCS550-S02-0200 ND07 2 ND406 5

DCS550-S01-0225 DCS550-S02-0250 ND07 2 ND407 5

DCS550-S01-0270 DCS550-S02-0300 ND09 2 ND408 5

F3 DCS550-S01-0315 DCS550-S02-0350 ND09 2 ND408 5

DCS550-S01-0405 DCS550-S02-0450 ND10 2 ND409 5

DCS550-S01-0470 DCS550-S02-0520 ND10 2 ND410 5

F4 DCS550-S01-0610 DCS550-S02-0680 ND12 2 ND411 5

DCS550-S01-0740 DCS550-S02-0820 ND13 3 ND412 5

DCS550-S01-0900 DCS550-S02-1000 ND13 3 ND413 5

Design

fig.

Line choke 4 %

relative voltage drop

Design

fig.

Fig. 1 Fig. 2 Fig. 3

Fig. 4 Fig. 5

14 3ADW000378R0101 | DCS550 Technical catalog e a

Page 15

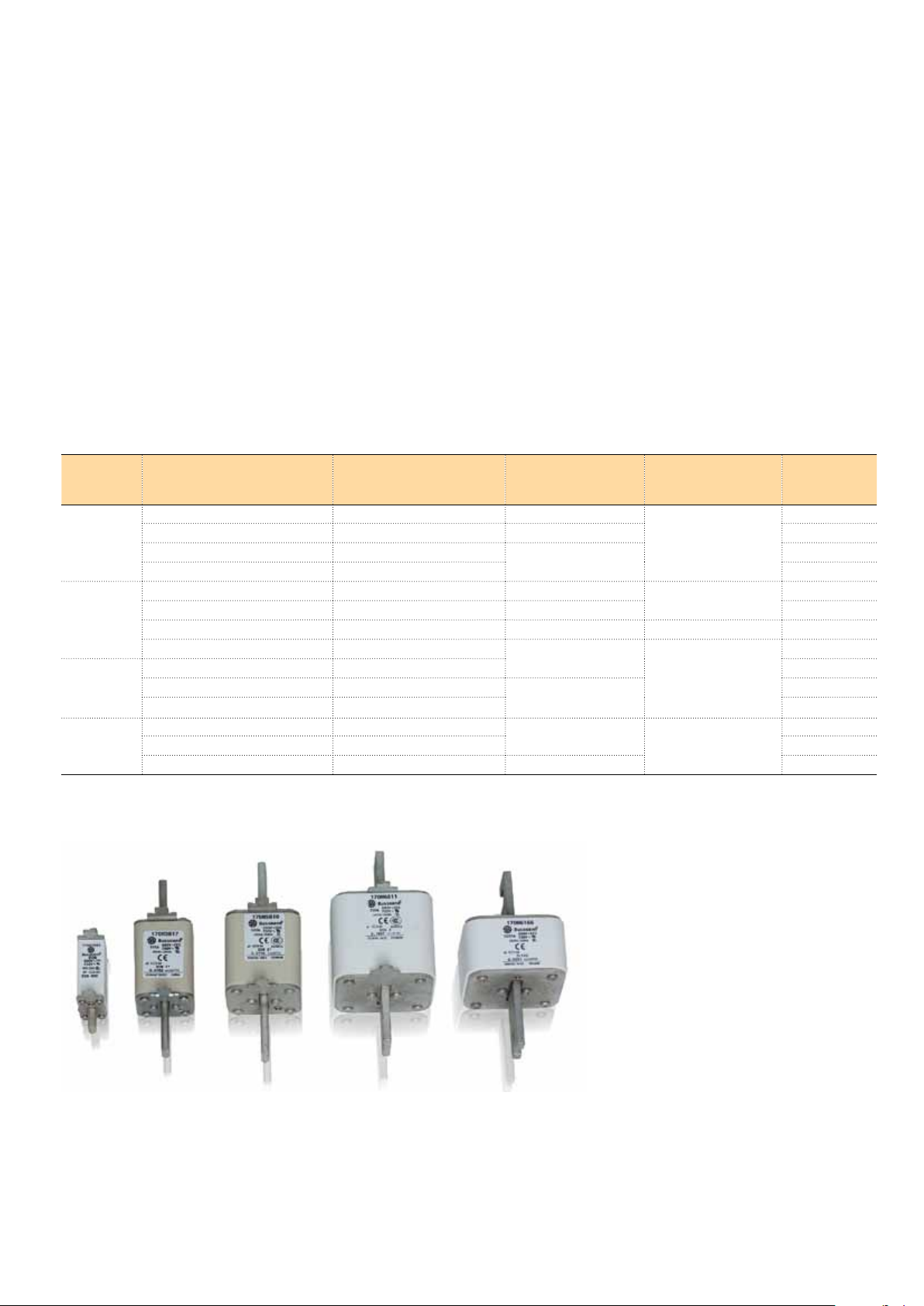

Fuse connections

Semiconductor fuses and fuse holders for AC and DC power lines

The DCS550 converter sizes F1, F2, F3 and F4 with rated

currents up to 1000 A require external line fuses for armature

bridge.

The table assigns the AC fuse types to the converter types

involved. In case the converter needs to be equipped with DC

Recommended fuse connections

Size Converter type (2-Q) Converter type (4-Q) Fuse Type Fuse holder Design

F1 DCS550-S01-0020 DCS550-S02-0025 50A 660V UR OFAX 00 S3L 1

DCS550-S01-0045 DCS550-S02-0050 63A 660V UR 1

DCS550-S01-0065 DCS550-S02-0075 125A 660V UR 1

DCS550-S01-0090 DCS550-S02-0100 1

F2 DCS550-S01-0135 DCS550-S02-0150 200A 660V UR OFAX 1 S3 2

DCS550-S01-0180 DCS550-S02-0200 250A 600V UR 2

DCS550-S01-0225 DCS550-S02-0250 315A 660V UR OFAX 2 S3 2

DCS550-S01-0270 DCS550-S02-0300 500A 660V UR OFAX 3 S3 3

F3 DCS550-S01-0315 DCS550-S02-0350 3

DCS550-S01-0405 DCS550-S02-0450 700A 660V UR 4

DCS550-S01-0470 DCS550-S02-0520 4

F4 DCS550-S01-0610 DCS550-S02-0680 900A 660V UR 3 x 170H 3006 5

DCS550-S01-0740 DCS550-S02-0820 5

DCS550-S01-0900 DCS550-S02-1000 1250A 660V UR 5

fuses according to the instructions use the same type of fuse

used on the AC side now in the plus and minus line (only for

sizes F1...F4). Blade type fuses are used for all the converters of construction type F1...F4 except the converters (610 A,

680 A, 740 A, 820 A, 900 A, 1000 A).

fig.

Fig. 1 Fig. 2 Fig. 3 Fig. 4 Fig. 5

DCS550 Technical catalog e a | 3ADW000378R0101 15

Page 16

Environmental conditions

System connection

Voltage, 3-phase: 230 to 525 V acc. to IEC 60038

Voltage deviation: ±10% continuous; ±15 % short-time *

Rated frequency: 50 Hz or 60 Hz

Static frequency deviation: 50 Hz ±2 %; 60 Hz ±2 %

Dynamic: frequency range: 50 Hz: ±5 Hz; 60 Hz: ± 5 Hz

df/dt: 17 % / s

* = 0.5 to 30 cycles.

Please note: Special consideration must be given to voltage deviation in

regenerative mode.

Degree of protection

Converter module and options

(line chokes, fuse holder, field

supply unit, etc.):

Paint finish

Converter module: RAL 9002

IP 00

Sound pressure level

Size Sound pressure level LP (1 m distance) Vibration

as module enclosed conv. as module

F1 55 dBA 68 dBA

F2 55 dBA 72 dBA

F3 60 dBA 78 dBA

F4 66...70 dBA,

depending on fan

77 dBA

0.5 g, 5...55 Hz

Environmental limit values

Permissible cooling air temperat.

- at converter module air inlet: 0 to +55°C

with rated DC current: 0 to +40°C

w. different DC current +30 to +55°C

- Options: 0 to +40°C

Relative humidity (at 5...+40°C): 5 to 95 %, no condensation

Relative humidity (at 0...+5°C): 5 to 50 %, no condensation

Change of the ambient temp.: < 0.5°C / minute

Storage temperature: -40 to +55°C

Transport temperature: -40 to +70°C

Pollution degree (IEC 60664-1, IEC

60439-1):

Site elevation

<1000 m above M.S.L.: 100%, without current reduction

>1000 m above M.S.L.: with current reduction

2

Product compliance

– CE

– Low Voltage Directive 2006/95/EC — conformity EN61800-5-1 EN60146-1-1

– Machinery Directive 2006/42/EC — in cooperation EN60204-1

– EMC Directive 2004/108/EC — conformity EN61800-3

– Quality assurance system ISO 9001 and Environmental system ISO 14001

– RoHS

– C-Tick

– Pending: UL, cUL 508A or 508C and CSA C22.2 NO. 14-95, GOST R

EMC according to EN 61800-3 (2004)

– Categories C2, C3 or C4 with external EMC filtering or dedicated transformer

16 3ADW000378R0101 | DCS550 Technical catalog e a

Page 17

Service

ABB drive life cycle management model

Maximizing return on investment

At the heart of ABB’s services is its drive life cycle

management model. All services available for ABB low

voltage drives are planned according to this model. For

customers it is easy to see which services are available at

which phase.

Drive specific maintenance schedules are also based on

this four-phase model. Thus, a customer knows precisely

One of the most efficient ways to improve productivity and to

maximize process uptime is to establish a contract which can

include a combination of individual services such as training,

technical support and preventive and corrective maintenance.

Reduced environmental impact

Before purchasing a drive, ABB offers an energy appraisal

to determine which applications can benefit from the use of

drives. During operation and maintenance, tuning of the drive

maximizes its energy savings. Additionally, when the drive life

cycle is complete, ABB can ensure that the drive is disposed

of in a way that meets all local environmental regulations.

Enhanced safety

Seeking advice from ABB at the selection and dimensioning

stage helps ensure that the right drive is chosen with the

correct safety features. Helpful safety advice continues into

the installation and commissioning stage.

Throughout the drive’s lifetime, services such as remote

monitoring help protect the safety of the plant by rapidly

diagnosing and rectifying faults.

the timing of the part replacements plus all other

maintenance related actions. The model also helps the

customer when deciding about upgrades, retrofits and

replacements.

Professional management of the drive’s life cycle maximizes

the return on any investment in ABB low voltage drives.

The ABB DriveHelp service is ABB‘s globally operating

process for handling LV drives warranty claims. It

has been exclusively tailored for international OEM

customers, who have purchased LV drives manufactured

by ABB for their production machinery and equipment.

The service covers all LV drives manufactured by ABB,

that are delivered to International machine manufacturers

builder.

Efficient service

As indicated by its name, the new ABB DriveHelp service targets at supporting International machine manufacturer builder

customers at all times by offering them an efficiently operating warranty service that enables them to run their business

operations at an optimum maximum level. The ABB DriveHelp

service defines clear procedures, which advise the machine

builder customers whom to contact in case any of their ABB

LV drives fails during the warranty period in order to get assistance as soon as possible from the nearest local ABB service

provider.

The ABB DriveHelp team can be reached 24 hours a day and

is committed to ensureing that the machine builder customers

have a competent, local person available to assist them within

the shortest possible time whenever help is needed.

A well defined operations model

The target of the ABB DriveHelp service is to quickly locate

the official ABB service provider, which is closest to the

customer. In the event a case of an LV drive failure, the enduser informs the OEM agent in his counrtry, who forwards the

message with product and customer information to the seller

of the drive. After having checked the warranty, he will send

a warranty claim with all necessary information to the ABB

DriveHelp team.

The ABB DriveHelp team will process the warranty claim,

choose the best suitable service provider, follow up the response time to the end user and finalize the case. The service

ABB drive life cycle management model

provider allocated to the case will contact the end customer

within 24 hours of receiving information from the ABB DriveHelp team. The ABB service provider takes care of the warranty service request and sends a service and warranty report

to the ABB DriveHelp team as well as the original ABB drives

sales company.

Training

Throughout the value chain, from pre-purchase to replacement and recycling of a drive, ABB offers product, application

and general technical training both in classrooms and over the

internet.

Classroom training typically comprises theoretical presentations and hands-on exercises.

To meet its customers’ growing interest in self-learning, ABB

offers several e-learning modules for DCS550 available in the

Internet. The training content includes product features, applications, installation and start-up procedures, programming,

PC tools, maintenance and trouble-shooting fault finding.

The majority of training is delivered by ABB training centre’s.

Versatile training services are also offered by local ABB sales

and service companies and their channel partners. Some

courses are organized at the customer’s location. Benefits of

professional training include enhanced personnel and plant

safety, reduced downtime, improved productivity and increased employee motivation. More information about ABB’s

training centre’s and the courses can be found from the ABB

University at www.abb.com/abbuniversity.

- The drive, with complete life cycle

services, is available for purchase.

Complete life cycle services

To ensure the availability of complete life cycle services, a drive must be in the Active

or Classic phase. A drive can be kept in the Active or Classic phase by upgrading,

retrofi tting or replacing.

ABB follows a four-phase model for managing drive life cycles, which brings enhanced customer support and improved effi ciency.

Examples of life cycle services are: selection and dimensioning, installation and commissioning, preventive and corrective maintenance, remote services, spare part services,

training and learning, technical support, upgrade and retrofi t, replacement and recycling.

- The drive, with complete life cycle

services, is available for plant extensions.

Limited ObsoleteActive Classic

- Spare part, maintenance and repair

services are available as long as

materials can be obtained.

Limited life cycle services

Caution! A drive entering the Limited or Obsolete phase has limited repair options.

This may result in unpredictable process downtime. To avoid this possibility, the drive

should be kept in the Active or Classic phase.

DCS550 Technical catalog e a | 3ADW000378R0101 17

- ABB cannot guarantee availability of life

cycle services for technical reasons or

within reasonable cost.

Page 18

DCS family - the range for all demands

DCS550-S modules

The compact drive for

machinery application

20 … 1,000 A

0 … 610 V

230 … 525 V

DC

DC

AC

IP00

DCS800-S modules

The versatile drive for

processindustry

20 … 5,200 A

0 … 1,160 V

230 … 1,000 V

DC

DC

AC

IP00

DCS800-A enclosed

converters

Complete drive solutions

20 … 20,000 A

0 … 1,500 V

230 … 1,200 V

DC

DC

AC

IP21 – IP54

– Compact

– Robust design

– Adaptive and winder program

– High field exciter current

– Compact

– Highest power ability

– Simple operation

– Comfortable assistants, e.g. for commissioning or

fault tracing

– Scalable to all applications

– Free programmable by means of integrated

IEC61131-PLC

– Individually adaptable to customer requirements

– User-defined accessories like external PLC or

automation systems can be included

– High power solutions in 6- and 12-pulse up to

20,000 A, 1,500 V

– In accordance to usual standards

– Individually factory load tested

– Detailed documentation

DCS800-E series

Pre-assembled drive-kits

20 … 2,000 A

0 … 700 V

230 … 600 V

DC

DC

AC

IP00

DCS800-R Rebuild Kit

Digital control-kit for

existing powerstacks

20 … 20,000 A

0 … 1,160 V

230 … 1,200 V

DC

DC

AC

IP00

– DCS800 module with all necessary accessories

mounted and fully cabled on a panel

– Very fast installation and commissioning

– Squeezes shut-down-times in revamp projects to

a minimum

– Fits into Rittal cabinets

– Compact version up to 450 A and Vario version up

to 2,000 A

– Proven long life components are re-used, such

as power stacks, (main) contactors, cabinets and

cabling / busbars, cooling systems

– Use of up-to-date communication facilities

– Increase of production and quality

– Very cost-effective solution

– Open Rebuild Kits for nearly all existing DC drives

– tailor-made solutions for…

•BBCPxD •BBCSZxD

•ASEATYRAK •othermanufacturers

18 3ADW000378R0101 | DCS550 Technical catalog e a

Page 19

Notes

DCS550 Technical catalog e a | 3ADW000378R0101 19

Page 20

Contact us

ABB Automation Products GmbH

Motors and Drives

Wallstadter Straße 59

D-68526 Ladenburg

Germany

Phone: +49 (0) 6203 717 608

Fax: +49 (0) 6203 717 609

dc-drives@de.abb.com

www.abb.com/motors&drives

© Copyright 2012 ABB. All rights reserved. 3ADW000378R0101 Rev A 01.2012 Specifications subject to change without notice.

Loading...

Loading...