Page 1

DCS Thyristor power converter

for DC drive systems

20 to 1000 A

9 to 522 kW

Manual

DCS 400

II K 1-1

Page 2

This manual is valid for DCS 400 Rev A including software version 108.0

List of contents

MANUAL

1 DCS 400 - the compact-size DC drive ........ II K 1-3

2 System overview of DCS 400 .................... II K 2-1

2.1 Environmental conditions .............................................

2.2 DCS 400 power converter modules ............................

2.3 DCS 400 overload withstand capability ......................

2.4 Control and Display Units of the DCS 400 .................

3 Technical Data ............................................ II K 3-1

3.1 Module Dimensions .......................................................

3.2 Cross-sectional areas - Tightening torques ..................

3.3 Power losses .................................................................

3.4 Power section cooling ...................................................

3.5 Control board SDCS-CON-3A ......................................

3.6 Power interface board SDCS-PIN-3A ...........................

3.7 Field exciter SDCS-FIS-3A .........................................

3.8 Circuit diagrams ..........................................................

4 Overview of software.................................. II K 4-1

4.1 General inormation about application Macros ..............

4.2 Application Macros ........................................................

4.3 Digital and analogue Inputs/Outputs ...........................

4.4 Drive Logic ..................................................................

4.5 Regulator functions .....................................................

4.6 Software Structure ......................................................

4.7 Parameter list ..............................................................

II K

II K

II K

II K

II K

II K

II K

II K

II K

II K

II K

II K

II K

II K

II K

II K

II K

II K

II K

2-2

2-3

2-4

2-5

3-1

3-3

3-5

3-6

3-7

3-9

3-10

3-12

4-2

4-4

4-22

4-24

4-27

4-42

4-44

5 Installation ................................................... II K 5-1

5.1 Safety instructions .........................................................

5.2 EMC Compliant Installation and Configuration for PDS

5.3 Connection Examples ................................................. II K 5-17

II K

II K

5-2

5-4

6 Operating Instructions ............................... II K 6-1

6.1 Panel .............................................................................

6.2 Guided Commissioning .................................................

6.3 Useful hints for commissioning ...................................

6.4 Troubleshooting ..........................................................

II K

II K

II K

II K

6-2

6-7

6-20

6-24

7 Serial interfaces .......................................... II K 7-1

7.1 Panel-port ......................................................................

7.2 RS232-port ....................................................................

7.3 Fieldbus interface ..........................................................

II K

II K

II K

7-6

7-7

7-8

Appendix

A Accessories .......................................................................

Line chokes ...................................................................

Fuses .............................................................................

EMC filter .......................................................................

B Declaration of conformity ..................................................

C Quick Installation & Commissioning guide .......................

D Examples for basic parameter programming ...................

II K

II K

II K

II K

II K

II K

II K

A-1

A-1

A-4

A-6

B-1

C-1

D-1

Index

II K 1-2

Page 3

1 DCS 400 - the compact-size DC drive

DCS 400 is a new generation of DC drives, which

is rated from 9 to 522 KW and for use on all line

supply voltages from 230 to 500 V.

Total ease of use

designers. The result is a DC drive that meets the

needs of machine builders. It is:

I

as easy to handle as an analogue drive but with

all the advantages of a digital drive

I

easy to design into machine equipment, being

compact and having just the right number of

features

I

easy to install and set up

The DCS 400 is an

latest semiconductor technology together with

an advanced software which helps to reduce

maintenance, increase product reliability and

enables extremely rapid commissioning.

The DCS 400's small size brings substantial space

savings to machine builders, allowing them to

was the brief given to the drive`s

innovative design

, using the

integrate more accessories within the same space.

The compact design has been partly achieved by

a fully integrated field exciter, which includes the

field fuse and choke.

Based on

exciter, there is no need for a field voltage

adaptation transformer to match the line supply

voltage with that of the motor.

The

trol panel and the PC tool - makes start up of the

drive extremely easy, by simply guiding the user

through the start up procedure.

In addition, the DCS 400 contains

macros

user can pre-select the software structure and

the I/O connection, thus saving time and elimi-

nating any errors.

The DCS 400 carries the CE Mark and is designed

and produced according to the quality standard

ISO 9001.

new IGBT technology

commissioning wizard

. By selecting a macro from a menu, the

used for the field

-available on the con-

application

II K 1-3

Page 4

DCS 400 - the compact-size DC drive

Unit functions

Drive functions

Speed ramp function generator (S-ramp,

2 accel / decel ramps)

Speed feedback via tacho, encoder, EMF

Speed controlling

Torque / current reference processing

External torque limitation

Current controlling

Automatic field weakening

Automatic optimization for armature-circuit

current, field current, speed controller, EMF

regulator, flux adaptation

Speed monitor

On/Off control logic

Remote/local operation

Emergency stop

Automatic phase sequence detection

Motor overload detection

Internal motor potentiometer function for the

speed reference

Jog function

Configuration macros

Activation and operator-control

analogue and digital

fieldbusses

MMC

(man-machine communication) via:

Drive Window Light

(start-up and maintenance program) PC pro-

grams can be run under all commonly used

Windows® environments (3.1x, 95,98, NT):

Parameter programming

Fault detection

Feedback display and analysis

Fault logger

DCS400PAN

Removable control and display panel with

plain text display for:

Guided

Parameter programming

Fault detection

Reference and feedback display

Local operation

commissioning

inputs

and

outputs

Monitoring functions

Self-test

Fault logger

Motor monitoring

Speed feedback error

Overtemperature (PTC evaluation)

Overload (I² t)

Overspeed

Stalled motor

Armature-circuit overcurrent

Armature-circuit overvoltage

Minimum field current

Field overcurrent

Power converter protection

Overtemperature

Watchdog function

Mains voltage interruption

Thyristor diagnosis

II K 1-4

Page 5

2 System overview of DCS 400

)LHOGVXSSO\

6'&6),6$

M

U

H

W

O

L

I

&

0

(

F1

Q1

115 / 230 V AC

L1

K1

0

/HJHQG

Q

R

L

W

D

O

R

V

L

F

L

Q

D

Y

O

Q

D

J

J

Q

L

$

J

V

R

L

Q

V

W

L

&

W

9

E

L

$

E

9

W

W

X

X

W

S

S

X

W

W

W

S

X

X

X

Q

R

R

L

S

W

H

H

X

Q

X

X

L

R

J

J

O

\

R

D

R

O

O

W

D

L

O

D

D

J

H

Q

Q

L

5

D

$

G

230...500V

115...230 V AC

1

U

R

&

O

/

&

R

3

R

3

7

Fig. 2/1: System overview of DCS 400

RS232

T

$

U

1

,

H

3

Z

R

6

3

&

'

6

V

F

L

$

Q

R

U

1

W

F

2

H

O

&

H

6

O

'&6

R

&

U

W

'

Q

6

R

&

U

1

$

3

6

&

'

O

R

W

R

U

V

W

L

U

Q

\

R

K

F

7

6HULDO

LQWHUIDFHV

\

O

S

S

X

6

O

H

Q

D

S

O

R

U

W

Q

R

&

O

R

G

U

O

W

H

L

Q

R

)

F

V

W

X

S

W

X

2

V

P

W

X

µ

S

Q

,

2

82

4

optical fibre

[

[

[

[

1

T

&

V

/

X

3

E

H

G

O

K

H

W

L

R

)

W

II K 2-1

Page 6

2.1 Environmental conditions

System overview of DCS 400

Mains supply - power part

Voltage, 3-phase: 230 to 500 V in acc. with IEC 38

Voltage deviation: ±10% permanent

Rated frequency: 50 Hz or 60 Hz

Static frequency deviation: 50 Hz ±2 %; 60 Hz ±2 %

Dynamic: frequency range: 50 Hz: ±5 Hz; 60 Hz: ± 5 Hz

df/dt: 17 % / s

Mains supply - Electronics supply

Voltage, 1-phase: 115 to 230 V in acc. with IEC 38

Voltage deviation: -15% / +10%

Frequency range: 45 Hz to 65 Hz

Degree of protection

Power converter module: IP 00

Paint finish

Power converter module, cover: RAL 9002 light-grey

housing: RAL 7012 dark-grey

Current reduction to (%) for armature circuit and field supply

100

90

80

70

60

Environmental limit values

Permissible ambient temp. with rated current I

Ambient temp., power conv. module:+40°C to 55°C; s. Fig. 2.1/2

: +5 to +40°C

DC

Alteration in the ambient temp.: < 0,5°C / minute

Storage temperature: -40 to +55°C

Transport temperature: -40 to +70°C

Relative humidity: 5 to 95%, no condensation

Pollution degree: Grade 2

Site elevation:

<1000 m above M.S.L.: 100%, without current reduction

>1000 m above M.S.L.: with current reduct., s. Fig. 2.1/1

Vibration converter module: 0,5 g; 5 Hz to 55 Hz

Noises: Size as module

(1 m distance)

A1 55 dBA

A2 55 dBA

A3 60 dBA

A4 66...70 dBA, dependent on fan

Current reduction to (%) for armature circuit and field supply

110

100

90

80

50

1000 2000 3000 4000 5000

Fig. 2.1/1: Effect of the site elevation above sea level on the

power converter's load capacity

m

70

30 35 40 45 50 55

Fig. 2.1/2: Effect of the ambient temperature on the converter

module load capacity.

Compliance with standards

The power converter modules and cubicles are designed for industrial applications.

Within the EU, the components satisfy the requirements European guidelines, shown

in the table below.

European Union Directive Manufacturer’s Assurance

Machinery Directive

89/392/EEC

93/68/EEC

Low Voltage Directive

73/23/EEC

93/68/EEC

EMC Directive

89/336/EEC

93/68/EEC

Declaration of

Incorporation

Declaration of Conformity

Declaration of Conformity.

Provided that all installation

instructions concerning

cable selection, cabling and

EMC filters or dedicated

transformer are followed.

EN 60204-1

[IEC 204-1]

EN 60146-1-1

[IEC 146-1-1]

EN 50178 [IEC --]

see additional

IEC 664

EN 61800-3

[IEC 1800-3]

where limits are under consideration

EN 50081-2 / EN 50082-2 has been supplied

¥

’Installation in accordance with EMC’

The Technical Construction File to which this

Declaration relates has been assessed by

Report and Certificate from ABB EMC

Certification AB being the Competent Body

according to the EMC Directive.

Harmonized Standards

Converter module

¥

in accordance with 3ADW 000 032

under preparation

°C

Standards in North America

In North America, the system components

satisfy the requirements as listed in the

table below.

Safety for Power

conversion Equipment

≤ 600 V

Industrial control

Equipment: industrial

products ≤ 600 V

Standard for module

UL 508 C

CSA C 22.2. No.1495

Planned for 2000

Please note:

applies for power converter modules only.

II K 2-2

Page 7

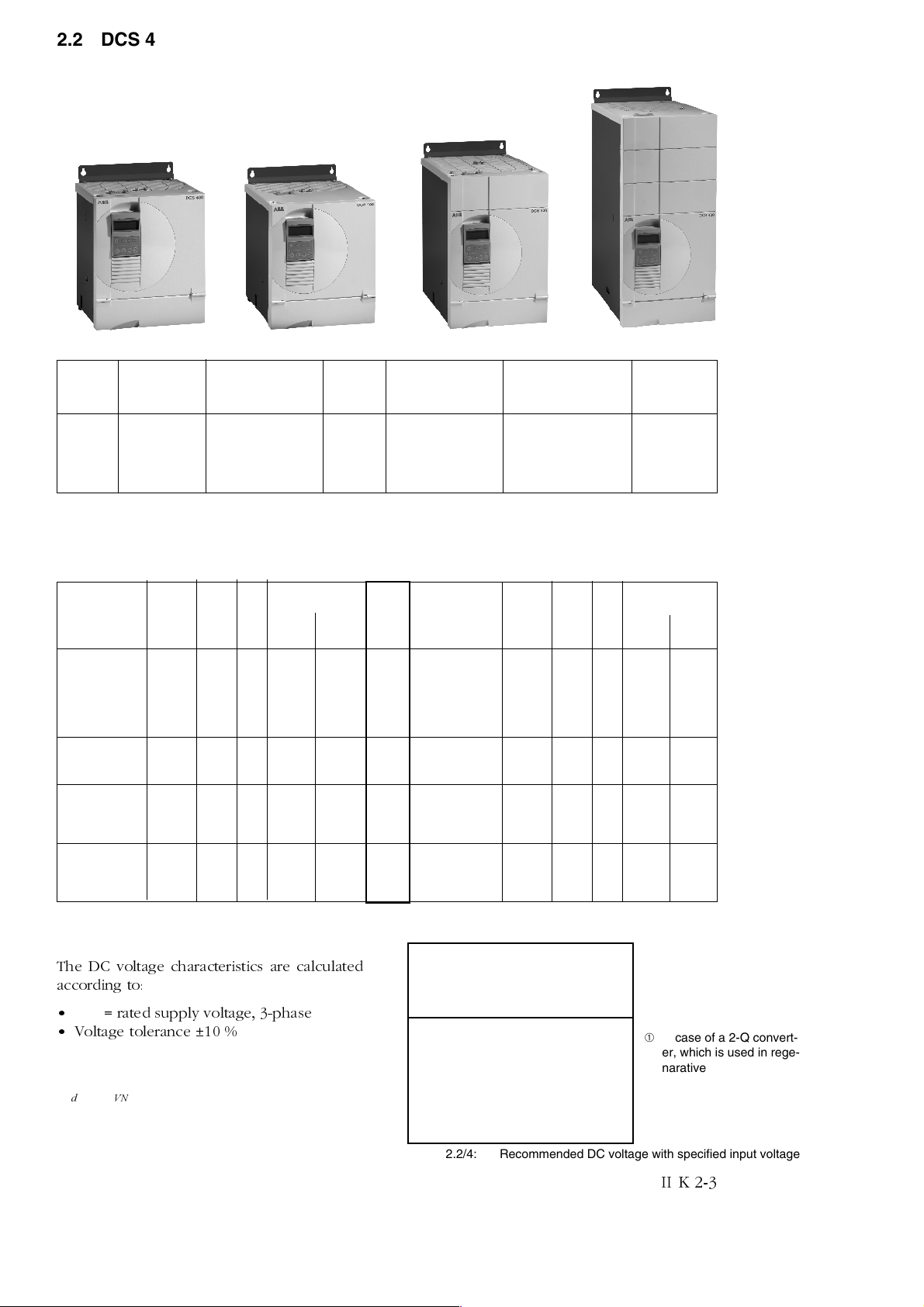

2.2 DCS 400 power converter modules

Sizes

System overview DCS 400

Size A1

Size Current Dimensions Weight Min. Clearances Fan connection Fuses

range H x W x D appr. top/butom/side

A1 20...25 A 310x270x200 11 150x100x5 - external

A1 45...140 A 310x270x200 11 150x100x5 115/230 V/1 ph external

A2 180...260 A 310x270x270 16 250x150x5 115/230 V/1 ph external

A3 315...550 A 400x270x310 25 250x150x10 115/230 V/1 ph external

A4 610...1000 A 580x270x345 38 250x150x10 ➀ 230 V/1 ph external

Table 2.2/1: Sizes of DCS 400

Size A2

[mm] [kg] [mm]

Size A3

Size A4

➀ Fan with 115 V/1 ph

available as option

Unit table

DCS 401 2-quadrant converter DCS 402 4-quadrant converter

Converter type Line voltage

I

[A] I

DC

DCS401.0020 20 16 4 9 12

DCS401.0045 45 36 6 21 26

DCS401.0065 65 52 6 31 39

DCS401.0090 90 74 6 41 52

DCS401.0125 125 102 6 58 73

DCS401.0180 180 147 16 84 104

DCS401.0230 230 188 16 107 133

[A] IF [A] P [kW] P [kW]

AC

400 V 500 V

Converter type Line voltage

Size

I

[A] I

DC

DCS402.0025 25 20 4 10 13

A1

DCS402.0050 50 41 6 21 26

A1

DCS402.0075 75 61 6 31 39

A1

DCS402.0100 100 82 6 41 52

A1

DCS402.0140 140 114 6 58 73

A1

DCS402.0200 200 163 16 83 104

A2

DCS402.0260 260 212 16 108 135

A2

[A] IF [A] P [kW] P [kW]

AC

400 V 500 V

DCS401.0315 315 257 16 146 183

DCS401.0405 405 330 16 188 235

DCS401.0500 500 408 16 232 290

DCS401.0610 610 498 20 284 354

DCS401.0740 740 604 20 344 429

DCS401.0900 900 735 20 419 522

Table 2.2/2: DCS 401 unit table

DC voltage characteristic

The DC voltage characteristics are calculated

according to:

U

= rated supply voltage, 3-phase

VN

Voltage tolerance ±10 %

()

88

91G

cos a = 0.966 (2-Q)

0.866 (4-Q)

α

cos*35.1*%10−=

DCS402.0350 350 286 16 145 182

A3

DCS402.0450 450 367 16 187 234

A3

DCS402.0550 550 448 16 232 290

A3

DCS402.0680 680 555 20 282 354

A4

DCS402.0820 820 669 20 340 426

A4

DCS402.1000 1000 816 20 415 520

A4

Table 2.2/3: DCS 402 unit table

System con- DC voltage

nection voltage (max. Motor voltage)

U

vN

230 270 240

380 460 400

400 470 420

415 490 430

440 520 460

460 540 480

480 570 500

500 600 520

Table 2.2/4: Recommended DC voltage with specified input voltage

2Q ➀ 4Q

U

d

➀ in case of a 2-Q convert-

er, which is used in regenarative mode, please

use 4-Q voltage values

II K 2-3

Page 8

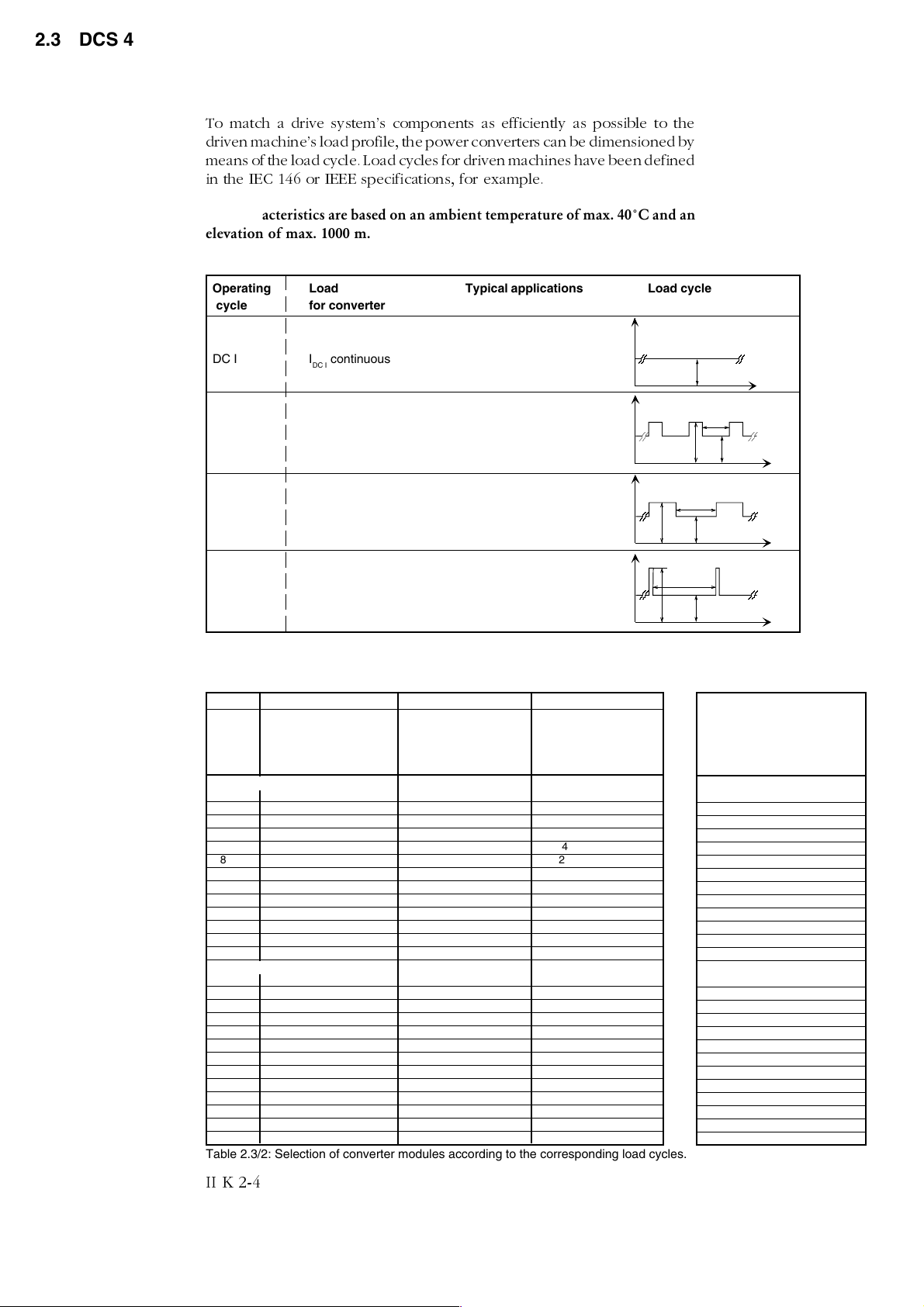

2.3 DCS 400 overload withstand capability

To match a drive systems components as efficiently as possible to the

driven machines load profile, the power converters can be dimensioned by

means of the load cycle. Load cycles for driven machines have been defined

in the IEC 146 or IEEE specifications, for example.

The characteristics are based on an ambient temperature of max. 40°C and an

elevation of max. 1000 m.

Types of load

Operating Load Typical applications Load cycle

cycle for converter

System overview of DCS 400

DC I I

DC II I

DC III I

DC IV I

continuous (IdN) pumps, fans

DC I

for 15 min and extruders, conveyor belts

DC II

1,5 * I

DC III

1,5 * I

DC IV

2 * I

for 60 s

DC II

for 15 min and extruders, conveyor belts

for 120 s

DC III

for 15 min and

for 10 s

DC IV

150%

150%

200%

Table 2.3/1: Definition of the load cycles

Load cycles of driven machines

DC I DC II DC III DC IV

I

DC I

contin- 100 % 150 % 100 % 150 % 100 % 200 %

uous 15 min 60 s 15 min 120 s 15 min 10 s

[A] [A] [A] [A]

2-quadrant applications

20 18 27 18 27 18 36

45 40 60 37 56 38 76

65 54 81 52 78 55 110

90 78 117 72 108 66 132

125 104 156 100 150 94 188

180 148 222 144 216 124 248

230 200 300 188 282 178 356

315 264 396 250 375 230 460

405 320 480 310 465 308 616

500 404 606 388 582 350 700

610 490 735 482 723 454 908

740 596 894 578 867 538 1076

900 700 1050 670 1005 620 1240

4-quadrant applications

25 23 35 22 33 21 42

50 45 68 43 65 38 76

75 66 99 64 96 57 114

100 78 117 75 113 67 134

140 110 165 105 158 99 198

200 152 228 148 222 126 252

260 214 321 206 309 184 368

350 286 429 276 414 265 530

450 360 540 346 519 315 630

550 436 654 418 627 380 760

680 544 816 538 807 492 984

820 664 996 648 972 598 1196

1000 766 1149 736 1104 675 1350

Table 2.3/2: Selection of converter modules according to the corresponding load cycles.

I

DC II

I

DC III

I

DC IV

ð

100%

15 min

100%

15 min

100%

15 min

100%

Recommended

Converter type

Converter type

2-quadrant converter

DCS 401.0020

DCS 401.0045

DCS 401.0065

DCS 401.0090

DCS 401.0125

DCS 401.0180

DCS 401.0230

DCS 401.0315

DCS 401.0405

DCS 401.0500

DCS 401.0610

DCS 401.0740

DCS 401.0900

4-quadrant converter

DCS 402.0025

DCS 402.0050

DCS 402.0075

DCS 402.0100

DCS 402.0140

DCS 402.0200

DCS 402.0260

DCS 402.0350

DCS 402.0450

DCS 402.0550

DCS 402.0680

DCS 402.0820

DCS 402.1000

II K 2-4

Page 9

2.4 Control and Display Units of the DCS 400

System overview DCS 400

For operation, commissioning, diagnosis and for

controlling the drive, there are different possibil-

ities available.

'&63$1

Panel

connection

3&

Fig. 2.4/1: Possibilities of operation

6'&6&21$

X7:

electrical

connection

(RS232)

The coupling to an overriding system (PLC) takes

place over a serial interface with a fibre-optic link

to a field bus adapter.

'&6

X6:

V800

X8:

power supply

PE SHF DG D( N) D(P)SH

X2

optical fibre

10 m

≤

RXD

Nxxx-01

TXD

xxxxxxxx

ADAPTER

XMIT

BUS

TERMINA TION

REC

ERROR

X1

PE SHF DG D( N) D(P)

+24V 0V SH

)LHOGEXV

$GDSWHU

ON

OFF

WR3/&

440V 368A 1500rpm

1500rpm

OUTPUT MENU AUTO OFF LOC <RUN>

Panel DCS 400 PAN

Features

Guided commissioning

(Panel Wizard)

Drive control

Parameter programming

Display of reference and ac-

tual values

Status information

Fault reset

Multilingual

removable during operation

7-Segment display

Features

RAM/ROM memory test error

Program is not running

Normal situation

During download sequence

Alarm

Fault

Fieldbus Adapter

Components:

plastic optical fibre

field bus adaptor

available Fieldbus adapters:

PROFIBUS

AC 31

MODBUS

MODBUS+

CAN-BUS

DeviceNet

You will find more detailed information on data

exchange in the related documentation for field

bus adapters.

II K 2-5

Page 10

System overview of DCS 400

Operation by PC

Components :

RS232 standard cable, 9-pin sub-D connector,

male-female, non-crossing

Functionality:

Software package "Drive Window Light"

System requirements/recommendation:

PC with 386 processor or higher

hard disk with 5 MB free memory

VGA monitor

Windows 3.1, 3.11, 95, 98, NT

3 1/2" floppy disk drive

CAUTION!

To avoid unintentional operating states, or to shut

the unit down in case of any imminent danger

according to the standards in the safety instructions it is not sufficient to merely shut down the

drive via signals 'RUN', drive 'OFF' or 'Emergency

Stop' respectively 'control panel' or 'PC tool'.

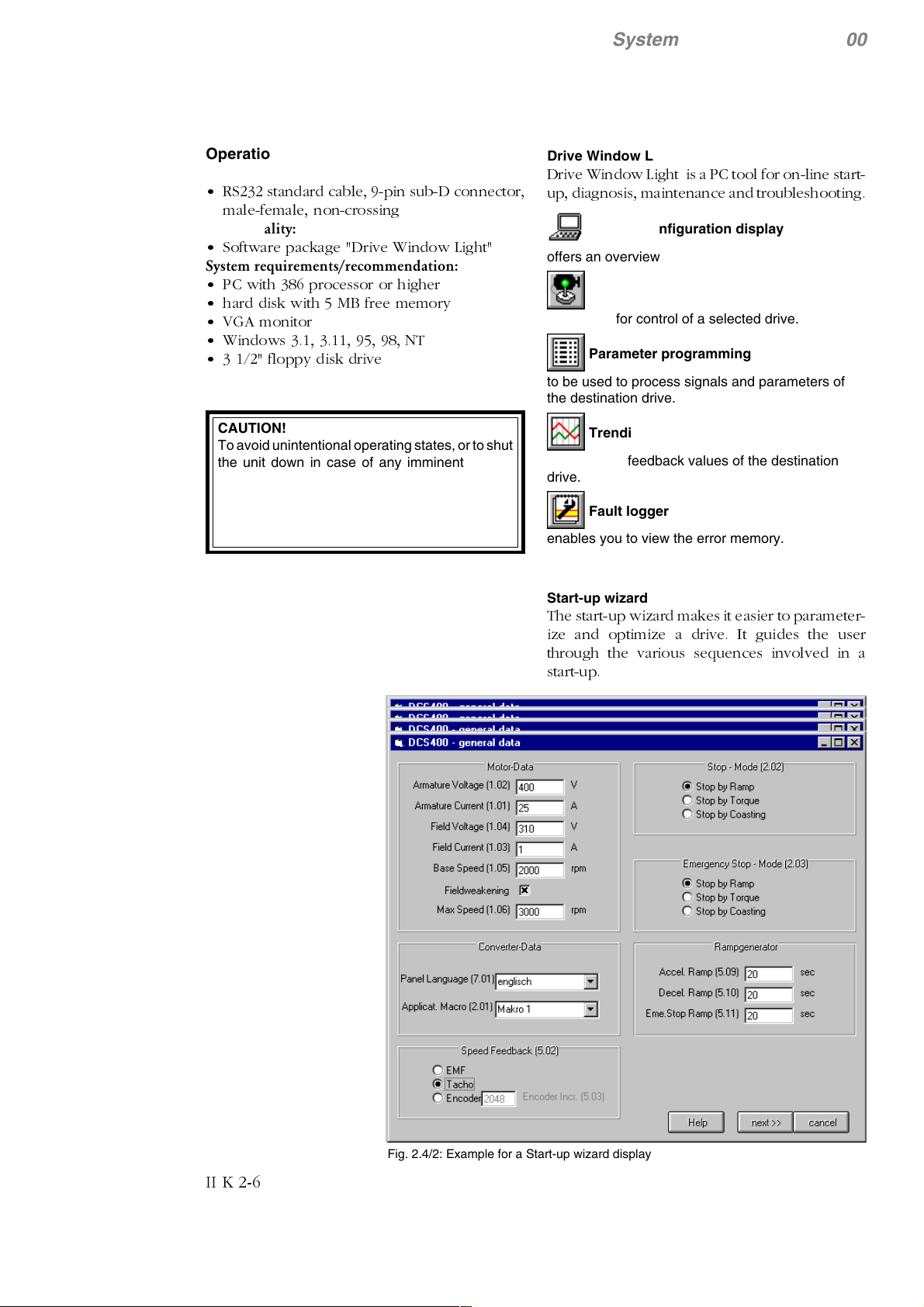

Drive Window Light

Drive Window Light is a PC tool for on-line start-

up, diagnosis, maintenance and troubleshooting.

System configuration display

offers an overview the system.

Drive control

to be used for control of a selected drive.

Parameter programming

to be used to process signals and parameters of

the destination drive.

Trending

monitors the feedback values of the destination

drive.

Fault logger

enables you to view the error memory.

Start-up wizard

The start-up wizard makes it easier to parameter-

ize and optimize a drive. It guides the user

through the various sequences involved in a

start-up.

II K 2-6

Fig. 2.4/2: Example for a Start-up wizard display

Page 11

3 Technical Data

3.1 Module dimensions

Module A1

DCS 401.0020

DCS 401.0045

DCS 401.0065

DCS 401.0090

DCS 401.0125

DCS 402.0025

DCS 402.0050

DCS 402.0075

DCS 402.0100

DCS 402.0140

Module A2

DCS 401.0180

DCS 401.0230

DCS 402.0200

DCS 402.0260

Technical data

Module A3

DCS 401.0315

DCS 401.0405

DCS 401.0500

DCS 402.0350

DCS 402.0450

DCS 402.0550

Dimensions in mm

Fig. 3.1/1: Dimension drawing A1, A2, A3-Module

II K 3-1

Page 12

Module A4

DCS 401.0610

DCS 401.0740

DCS 401.0900

DCS 402.0680

DCS 402.0820

DCS 402.1000

Dimensions in mm

Technical data

for M6

for M12

II K 3-2

Fig. 3.1/2: Dimension drawing A4-Module

Page 13

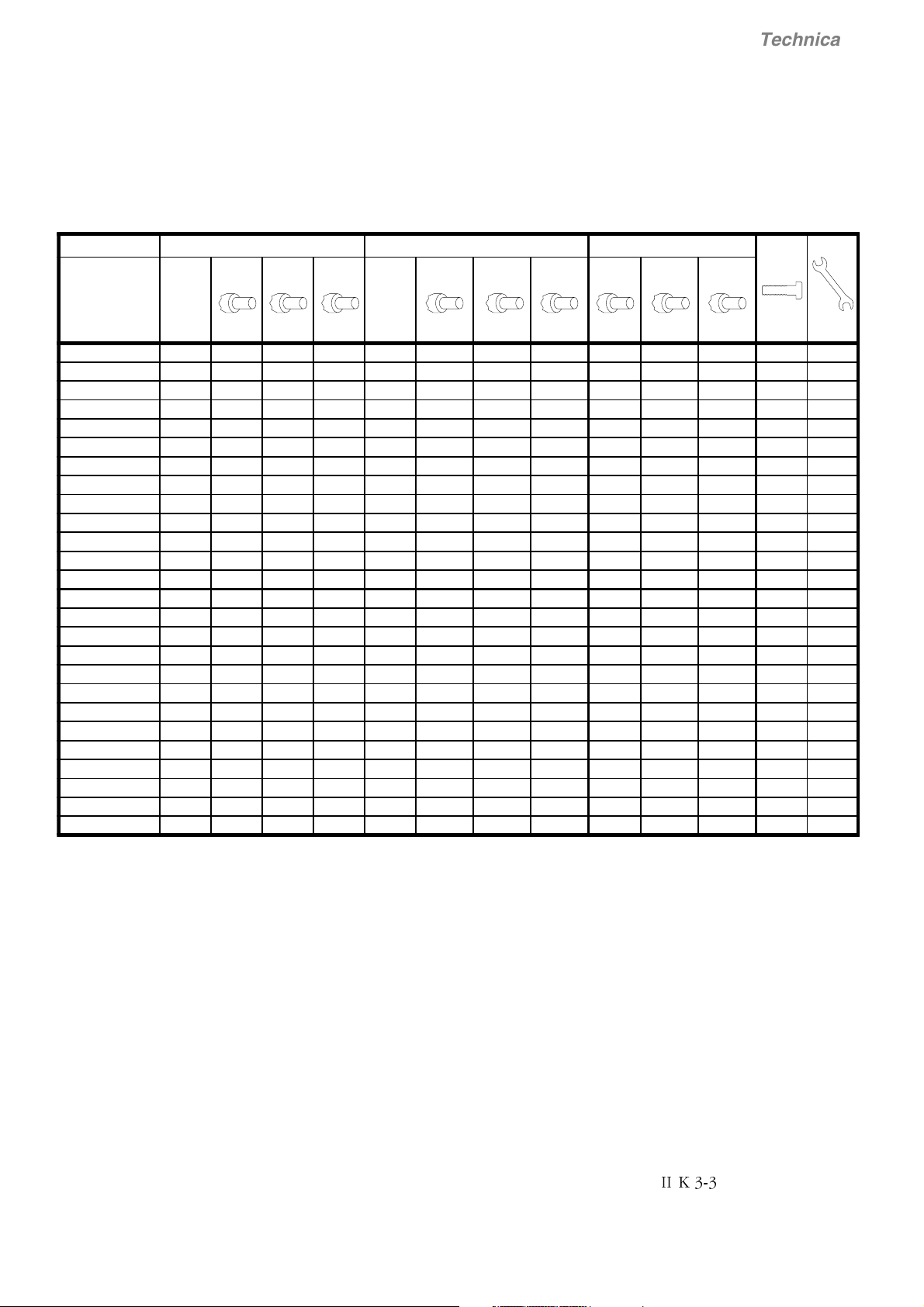

3.2 Cross-sectional areas - Tightening torques

Technical data

3.2.1 Recommended cross-sectional area to DIN VDE 0276-1000 and DIN VDE 0100-540 (PE), trefoil arrangement, up to 40°C

ambient temperature and a 90°C operating temperature of the conductor.

Unit type

IDC

[A-]

DCS 401.0020 20 1 x 2.5 1 x 1.5 1 x 1.5 16 1 x 2.5 1 x 1.5 1 x 1.5 1 x 2.5 1 x 1.5 1 x 1.5 M6 6

DCS 401.0045 45 1 x 10 1 x 6 1 x 6 36 1 x 6 1 x 6 1 x 4 1 x 6 1 x 6 1 x 4 M6 6

DCS 401.0065 65 1 x 16 1 x 10 1 x 10 52 1 x 16 1 x 10 1 x 6 1 x 16 1 x 10 1 x 6 M6 6

DCS 401.0090 90 1 x 25 1 x 16 1 x 16 74 1 x 25 1 x 16 1 x 16 1 x 16 1 x 16 1 x 16 M6 6

DCS 401.0125 125 1 x 35 1 x 25 1 x 25 102 1 x 35 1 x 25 1 x 25 1 x 16 1 x 16 1 x 16 M6 6

DCS 401.0180 180 1 x 70 1 x 50 1 x 50 147 1 x 50 1 x 50 1 x 35 1 x 25 1 x 25 1 x 16 M10 25

DCS 401.0230 230 1 x 95 1 x 70 1 x 70 188 1 x 70 1 x 70 1 x 50 1 x 35 1 x 35 1 x 25 M10 25

DCS 401.0315 315 2 x 50 1 x 95 1 x 120 257 2 x 50 1 x 95 1 x 95 1 x 50 1 x 50 1 x 50 M10 25

DCS 401.0405 405 2 x 70 2 x 50 1 x 150 330 2 x 70 2 x 50 1 x 120 1 x 70 1 x 50 1 x 70 M10 25

DCS 401.0500 500 2 x 120 2 x 70 2 x 70 408 2 x 95 2 x 70 2 x 70 1 x 95 1 x 70 1 x 70 M10 25

DCS 401.0610 * 610 2 x 150 2 x 95 2 x 95 498 2 x 150 2 x 95 2 x 70 1 x 150 1 x 95 1 x 70 M12 50

DCS 401.0740 * 740 2 x 240 2 x 150 2 x 150 604 2 x 185 2 x 120 2 x 95 1 x 185 1 x 120 1 x 95 M12 50

DCS 401.0900 * 900 2 x 240 2 x 185 2 x 185 735 2 x 240 2 x 150 2 x 150 1 x 240 1 x 150 1 x 150 M12 50

DCS 402.0025 25 1 x 2.5 1 x 2.5 1 x 2.5 20 1 x 2.5 1 x 2.5 1 x 1.5 1 x 2.5 1 x 2.5 1 x 1.5 M6 6

DCS 402.0050 50 1 x 10 1 x 6 1 x 6 41 1 x 10 1 x 6 1 x 4 1 x 10 1 x 6 1 x 4 M6 6

DCS 402.0075 75 1 x 16 1 x 10 1 x 16 61 1 x 16 1 x 10 1 x 10 1 x 16 1 x 10 1 x 10 M6 6

DCS 402.0100 100 1 x 25 1 x 16 1 x 25 82 1 x 25 1 x 16 1 x 16 1 x 16 1 x 16 1 x 16 M6 6

DCS 402.0140 140 1 x 50 1 x 35 1 x 35 114 1 x 35 1 x 25 1 x 25 1 x 16 1 x 16 1 x 16 M6 6

DCS 402.0200 200 1 x 70 1 x 50 1 x 70 163 1 x 70 1 x 50 1 x 50 1 x 35 1 x 25 1 x 25 M10 25

DCS 402.0260 260 1 x 120 1 x 70 1 x 95 212 1 x 95 1 x 70 1 x 70 1 x 50 1 x 35 1 x 35 M10 25

DCS 402.0350 350 2 x 70 1 x 120 1 x 120 286 2 x 50 1 x 120 1 x 95 1 x 50 1 x 70 1 x 50 M10 25

DCS 402.0450 450 2 x 95 2 x 70 2 x 70 367 2 x 70 2 x 70 2 x 50 1 x 70 1 x 70 1 x 50 M10 25

DCS 402.0550 550 2 x 120 2 x 95 2 x 95 465 2 x 120 2 x 70 2 x 70 1 x 120 1 x 70 1 x 70 M10 25

DCS 402.0680 * 680 2 x 185 2 x 120 2 x 120 555 2 x 150 2 x 120 2 x 95 1 x 150 1 x 120 1 x 95 M12 50

DCS 402.0820 * 820 2 x 240 2 x 150 2 x 150 669 2 x 240 2 x 150 2 x 120 1 x 240 1 x 150 1 x 120 M12 50

DCS 401.1000 * 1000 2 x 300 2 x 185 2 x 185 816 2 x 240 2 x 150 2 x 150 1 x 240 1 x 150 1 x 150 M12 50

* Busbar connection 5 x 40 mm is recommended

C1, D1 U1, V1, W1 PE

HO7V

[mm²]

NSGA

FÖU

[mm²]

N2XY

[mm²]Iv[A~]

HO7V

[mm²]

NSGA

FÖU

[mm²]

N2XY

[mm²]

HO7V

[mm²]

NSGA

FÖU

[mm²]

❶

N2XY

[mm²]

1 x M.. [Nm]

Table 3.2/1: Cross-sectional areas - tightening torques DCS 400

❶

You will find instructions on how to calculate the PE

conductor’s cross-sectional area in VDE 0100 or in

equivalent national standards. We would remind you

that power converters may have a current-limiting

effect. This can lead to other values than recommended.

Definition of the recommended cables above:

H07V: DIN-VDE 0281-1; Polyvinyl chloride insulated cables

NSGAFÖU: DIN-VDE 0250-602; Special rubber-insulated single-core cables

N2XY: DIN-VDE 0276-604; Power cable with special fire performance

II K 3-3

Page 14

3.2.2 Cross-sectional areas for UL installations

• The DCS 400 should be installed in an enclosure

that is minimum 150% of the dimensions of converter.

• The DCS 400 is suitable for use in a circuit capable

of delivering not more than 18 kA rms Symetrical

amperes, 500 V AC maximum. Recommended

fuses must be used to provide short circuit protection.

Technical data

Unit type

DCS 401.0020 20 1 x 10 16 1 x 14 12 M6 6

DCS 401.0045 45 1 x 4 36 1 x 6 10 M6 6

DCS 401.0065 65 1 x 3 52 1 x 4 8 M6 6

DCS 401.0090 90 1 x 1/0 74 1 x 2 8 M6 6

DCS 401.0125 125 1 x 2/0 102 1 x 2/0 6 M6 6

DCS 401.0180 180 1 x 4/0 147 1 x 4/0 6 M10 25

DCS 401.0230 230 1 x 350 188 1 x 300 4 M10 25

DCS 401.0315 315 2 x 3/0 257 2 x 3/0 3 M10 25

DCS 401.0405 405 2 x 250 330 2 x 250 2 M10 25

DCS 401.0500 500 2 x 400 408 2 x 350 2 M10 25

DCS 401.0610 610 * 498 * 0 M12 50

DCS 401.0740 740 *604* 0M1250

DCS 401.0900 900 * 735 * ??? M12 50

DCS 402.0025 25 1 x 8 20 1 x 12 10 M6 6

DCS 402.0050 50 1 x 4 41 1 x 6 10 M6 6

DCS 402.0075 75 1 x 2 61 1 x 3 10 M6 6

DCS 402.0100 100 1 x 1/0 82 1 x 1 8 M6 6

DCS 402.0140 140 1 x 2/0 114 1 x 2/0 6 M6 6

DCS 402.0200 200 1 x 250 163 1 x 250 6 M10 25

DCS 402.0260 260 2 x 2/0 212 1 x 400 4 M10 25

DCS 402.0350 350 2 x 4/0 286 2 x 4/0 3 M10 25

DCS 402.0450 450 2 x 300 367 2 x 300 2 M10 25

DCS 402.0550 550 2 x 500 465 2 x 400 1 M10 25

DCS 402.0680 680 *555* 0M1250

DCS 402.0820 820 * 669 * 2/0 M12 50

DCS 401.1000 1000 * 816 * ??? M12 50

* Busbar connection 5 x 40 mm required

C1, D1 U1, V1, W1 PE

IDC

[A-]

Wire

size

[AWG or

MCM]Iv[A~]

Wire

size

[AWG]

Under preparation

Under preparation

Wire

size

[AWG]

1 x M.. [Nm]

Note: 60°C wire up to 100 A, 75°C wire over 100 A

Note: Use UL listed ring terminals for connections to drives

Table 3.2/2: Cross-sectional areas for UL installations of DCS 400

II K 3-4

Page 15

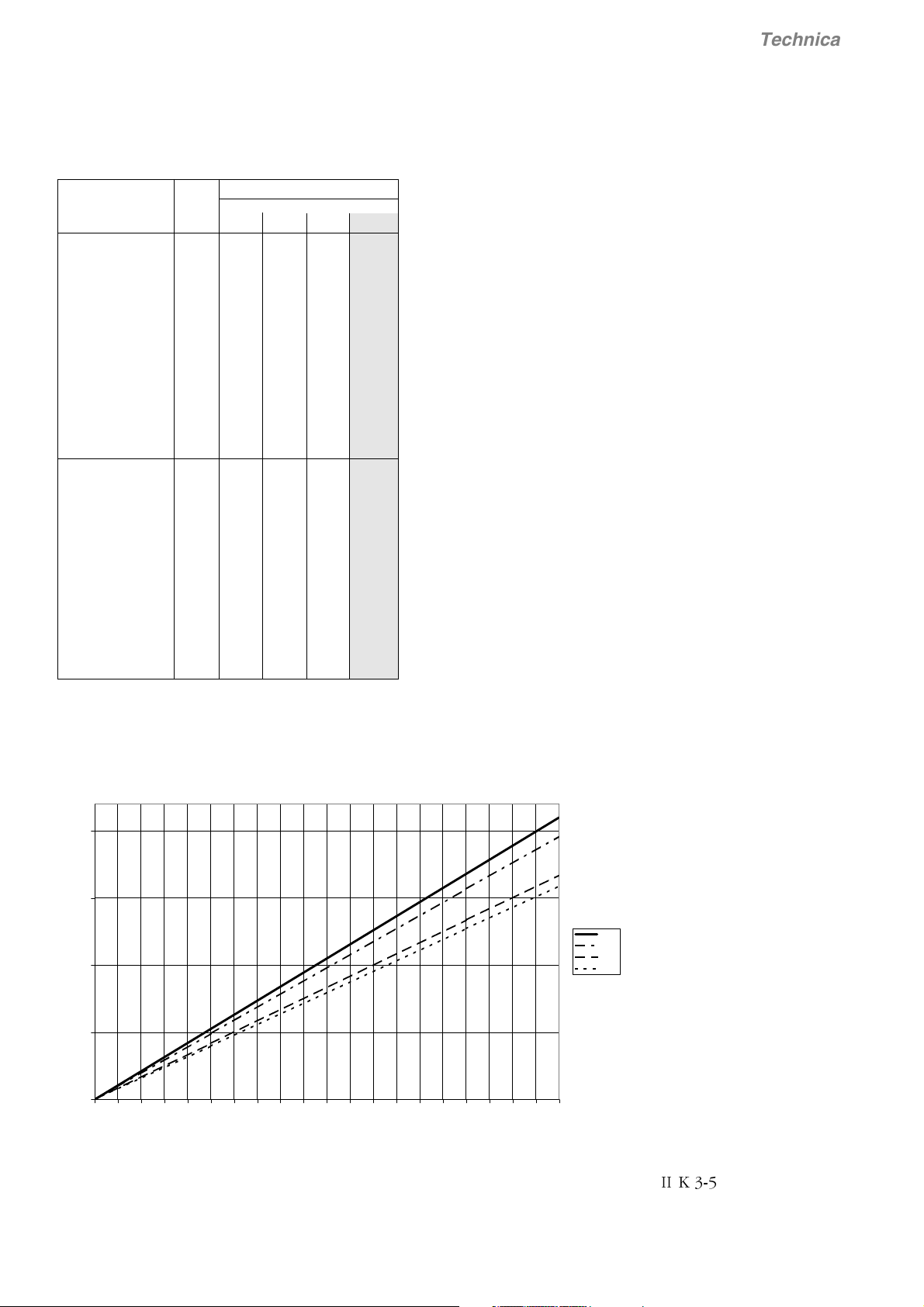

3.3 Power losses

DCS 400 armature circuit

Technical data

Converter type Power losses PL [W]

Load

I

[A] 25% 50% 75% 100%

DC

DCS401.0020 20 10 22 35 49

DCS401.0045 45 25 57 95 145

DCS401.0065 65 38 80 128 181

DCS401.0090 90 48 103 166 236

DCS401.0125 125 65 138 220 311

DCS401.0180 180 96 210 341 490

DCS401.0230 230 116 254 413 594

DCS401.0315 315 163 339 526 726

DCS401.0405 405 218 444 697 969

DCS401.0500 500 236 513 830 1188

2-Quadrant4-Quadrant

DCS401.0610 610 312 653 1025 1427

DCS401.0740 740 380 799 1259 1758

DCS401.0900 900 467 993 1578 2222

DCS402.0025 25 13 28 46 65

DCS402.0050 50 28 65 109 162

DCS402.0075 75 44 95 152 217

DCS402.0100 100 53 116 188 270

DCS402.0140 140 73 157 252 357

DCS402.0200 200 108 238 389 562

DCS402.0260 260 133 293 481 696

DCS402.0350 350 182 265 591 818

DCS402.0450 450 237 499 785 1096

DCS402.0550 550 262 573 933 1342

DCS402.0680 680 349 736 1160 1622

DCS402.0820 820 423 895 1416 1986

DCS402.1000 1000 522 1116 1786 2527

Table 3.3/1: DCS 400 Power losses of armature circuit

Remarks on the table

• The values stated are are maximum values obtained under the most unfavourable conditions.

DCS 400 field supply

P

L

200

[W]

150

100

50

0

01234567891011121314151617181920

Fig. 3.3/1: DCS 400 Power losses of field supply

[A]

440V

350V

150V

50V

I

II K 3-5

Page 16

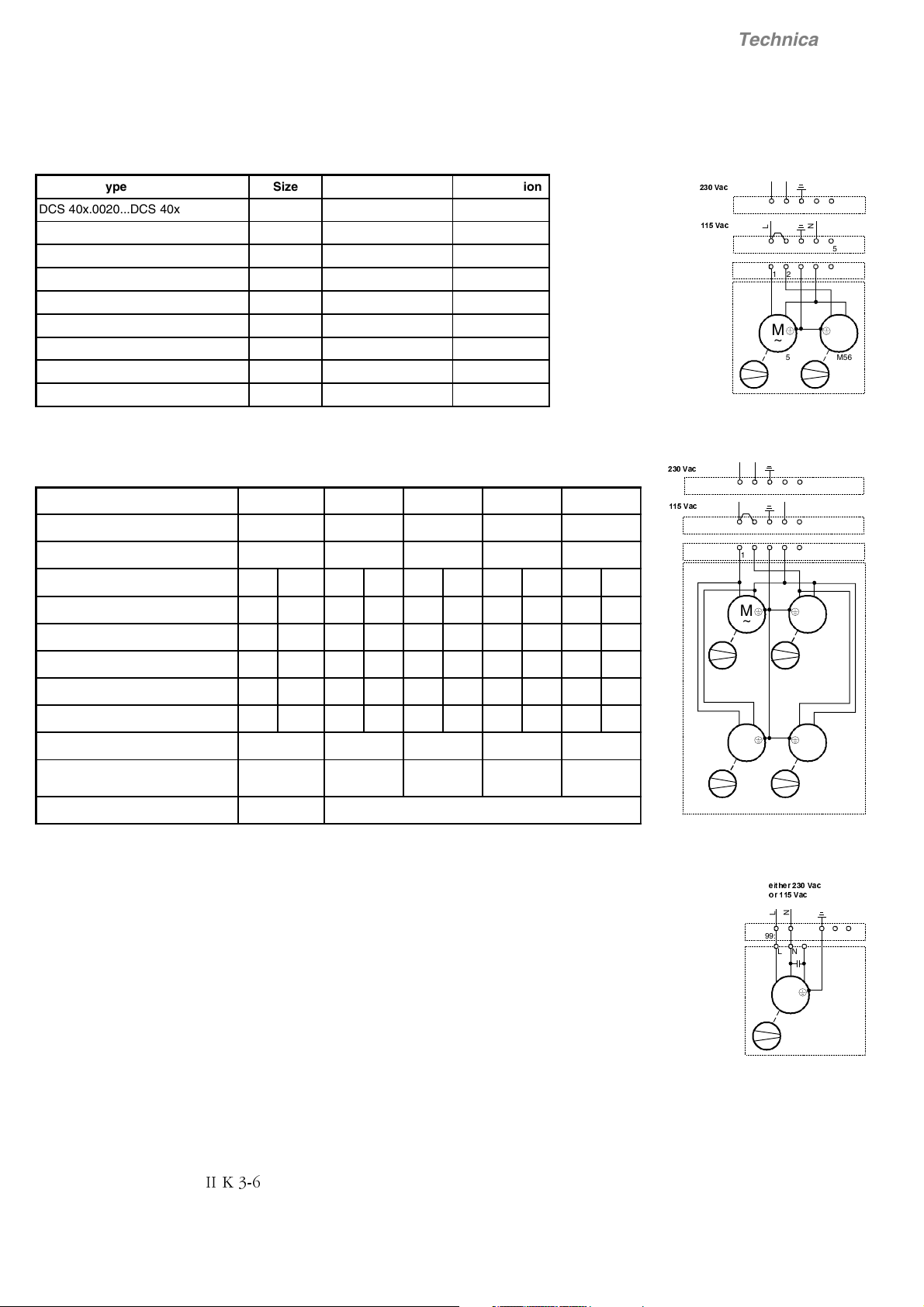

3.4 Power section cooling

Technical data

Fan assignment for DCS 400

Converter type Size Fan type Configuration

DCS 40x.0020...DCS 40x.0025 A1 no Fan -

DCS 40x.0045...DCS 40x.0140 A1 2x CN2B2 1

DCS 40x.0180...DCS 40x.0260 A2 2x CN2B2 1

DCS 40x.0315...DCS 40x.0350 A3 2x CN2B2 1

DCS 40x.0405...DCS 40x.0550 A3 4x CN2B2 2

DCS 40x.0610...DCS 40x.0820 A4 1x W2E200 (230 V) 3

DCS 40x.0610. 2...DCS 40x.0820. 2 A4 1x W2E200 (115 V) 3

DCS 40x.0900...DCS 40x.1000 A4 1x W2E250 (230 V) 3

DCS 40x.0900. 2...DCS 40x.1000. 2 A4 1x W2E250 (115 V) 3

Table 3.4/1: Fan assignment for DCS 400

Fan data for DCS 400 (data per fan)

Fan type

Rated voltage [V] 115; 1~ 230; 1~ 115; 1~ 115; 1~ 230; 1~

Tolerance [%] ±10 +6/-10 +6/-10 ±10 +6/-10

Frequency [Hz] 50 60 50 60 50 60 50 60 50 60

CN2B2 W2E200 W2E200 W2E250 W2E250

Fan connection for DCS 400

L

9DF

9DF

N

12 3X99: 45

L

N

12 3X99: 45

12 3X99:

45

M

~

M55 M5 6

M

Configuration 1

L

9DF

9DF

N

12 3X99: 45

L

N

12 3X99: 45

12 3X99:

45

~

Power consuption [W] 16 13 64 80 64 80 120 165 135 185

Current consumption [A] 0.2 0.17 0.29 0.35 0.6 0.7 1.06 1.44 0.59 0.82

Stall current [A] < 0.3 < 0.26 < 0.7 < 0.8 <1.5 <1.8 <1.8 <1.8 <0.9 <0.9

3

Air volume, freely blowing [m

/h] 156 180 925 1030 925 1030 1835 1940 1860 1975

Noise levelt [dBA] 44 48 59 61 59 61 66 67 68 70

Max. ambient temperature [° C] < 60 < 75 < 75 60 60

Useful lifetime of fan

appr. 40000

h/60°

appr. 45000

h/60°

appr. 45000

h/60°

appr. 40000 h appr. 40000 h

Protection Stall Overtemperature

Table 3.4/2: Fan data for DCS 400

Monitoring the DCS 400 power section

The power sections are monitored by an electrically

isolated PTC thermistor detector. First an alarm will

be outputted, and - if the temperature continues to

rise - an error message. This will switch off the unit

in a controlled manner.

M

~

M55 M5 6

M

~

M57 M5 8

M

M

~

~

Configuration 2

HLWKHU9DF

RU9DF

L

N

12 345X99:

LN

M

~

M55

II K 3-6

Configuration 3

Page 17

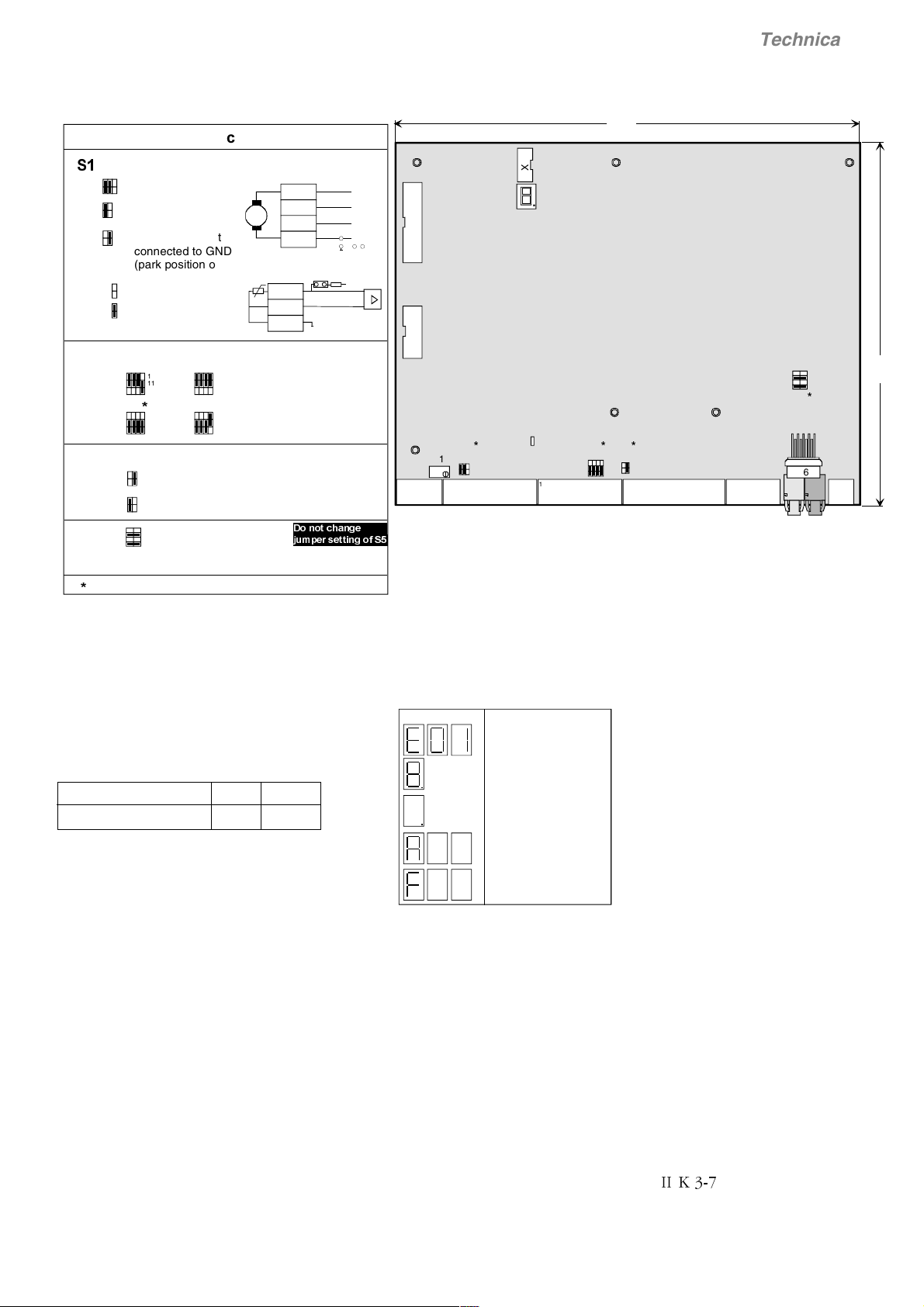

3.5 Control Board SDCS-CON-3A

Technical data

-XPSHUFRGLQJ

Tacho and PTC

6

6

2

*

15

2

Tacho signal

1

connected to GND

2

Tacho signal not

1

connected to GND

-

T

+

(park position only)

6

5

6

5

Pulse encoder

6

single ended:

differential:

Firmware download

6

6

default value

AI2 as ref input

AI2 used for temp.

measurement via PTC

5 V 24 V

31112

2

1

5 V

31112

2

1

4

2

3

1

42

13

78

12

31112

2

10

10

Normal operation

Firmware download via RS232

Note: change Jumper position only if electronics is switched off

For firmware download via RS232

S5:1-2 and 5-6 have to be jumpered

S5:5-6 int.Micro-controller Flash Prom

S5:1-2 Boot Mode

1

24 V

31112

2

1

10

10

X2:3

Fig. 3.5/1 Layout of the control board SDCS-CON-3A

-

X1:1

-

2

-

3

4

4

5

'RQRWFKDQJH

MXPSHUVHWWLQJRI6

-

+

GND

S1:

56PTC

S1

2

+

1

34

GND

22 K

+10V

233.5

X7

X12X13

78

12

All supports are conductive

connected to GND

S1

R115

6

2

1

5

41 91 81 101 5 1

X1 X2 X3 X4 X5 X8

Meas. point

I

A act

3

2

1

S2

S4

12

2

4

11

3

1

10

S5

X6

V800

DDCS

190

RS232

2

Control functions (Watchdog)

The control board has an internal watchdog. The

watchdog trip has the following effects:

- Thyristor firing control is reset and disabled.

- Digital outputs are forced to '0 V'.

Supply voltage monitoring

Supply voltage +5 V Mains

Undervoltage tripping level +4.50 V £97 VAC

If +5 V drops under the tripping level, it causes a

master reset by hardware. All I/O registers are forced

to 0 and the firing pulses are suppressed.

If mains monitor trips, firing pulses are forced to

inverter stability limit.

Serial interfaces

The control board SDCS-CON-3A has three serial

communication channels:

• X7: is a serial communication channel which is

used for

- DCS 400 PAN

- Adapter (3AFE 10035368)

• X6: is a standard RS232 serial communication

channel. It is a 9-pin D-Sub female connector

• V800 is an integrated channel and can be used

for Fieldbus Adapter by using optical fibre

Seven segment display

A seven segment display is located on the control

board and it shows the state of drive.

0.7s 0.7s 0.7s

RAM/ROM memory test error

Program is not running

Normal situation

Alarm

Fault

Fig. 3.5/2 Seven segment display of the SDCS-CON-3A

II K 3-7

Page 18

Digital and analogue I/O connection of the SDCS-CON-3A

Technical data

6'&6&21

-

X1:1

X2:1

90-270 V

30-90 V

2

-

3

4

2

3

4

8-30 V

+

-

+

S1:

22 K

56

-

+

5

6

7

8

9

X3:1

120

Ω

2

3

120

Ω

4

5

120

Ω

6

7

8

X4:1

2

+5V +24V

4.75k

10k

3

4

5

6

7

8

9

10

1

X5:

2

3

4

5

123

45

78

10 11 12

470k

A

+10V

S2

22n

R115

3

4

6

9

2

1

GND

+5/+24V

+5/+24V

+5/+24V

100k

S1

100k 100k

+10V

-10V

100µ

100n

ChA +

ChA -

ChB +

ChB ChZ +

ChZ -

GND

Power-Source

100k

1n

1n

0V

47.5

+24 V/ ≤50 mA

100

µ

47n

0 V

Software

AITAC

AI1

AI2

AO1

AO2

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

+24V

DO1

DO2

DO3

DO4

Reso- Input/output Scaling Load Common Remarks

lution values by mode

[bit] Hardware range

±90...270 V

11 + sign ±30...90 V R 115/ ±20 V ➀ ➁

±8...30 V Software

11 + sign -11...0...+11 V Software ±20 V ➀ ➁

11 + sign -11...0...+11 V Software ±40 V ➀ ➁

£10* mA for external use

£10* mA e.g. reference pot.

11 + sign -11...0...+11 V Software £5 * mA

11 + sign -11...0...+11 V Software £5 * mA

Encoder supply Remarks

Inputs not isolated

max. frequency £300 kHz

5V/ 24V £ 200 mA* Selectable with jumper S2: 10-12

Input value Signal definition Remarks

by

0...+5 V Software

+15...+30 V

^

= "0" status

^

= "1" status

Output value Signal definition Remarks

by

50 * mA Software Current limit for all 4 outputs =

160 mA

The terminal connectors X1: ... X5: are removable. They cannot be

interchanged

Fig. 3.5/3 Terminal connection of the SDCS-CON-3A board

II K 3-8

➀ total smoothing time £2 ms

➁ -20...0...+20 mA by external 500 W resistor

* short circuit proof

Note

Unless otherwise stated, all signals are

referenced to a 0 V potential. On all PCBs,

this potential is firmly connected to the

unit's casing by means of plating-through

at the fixing points.

Page 19

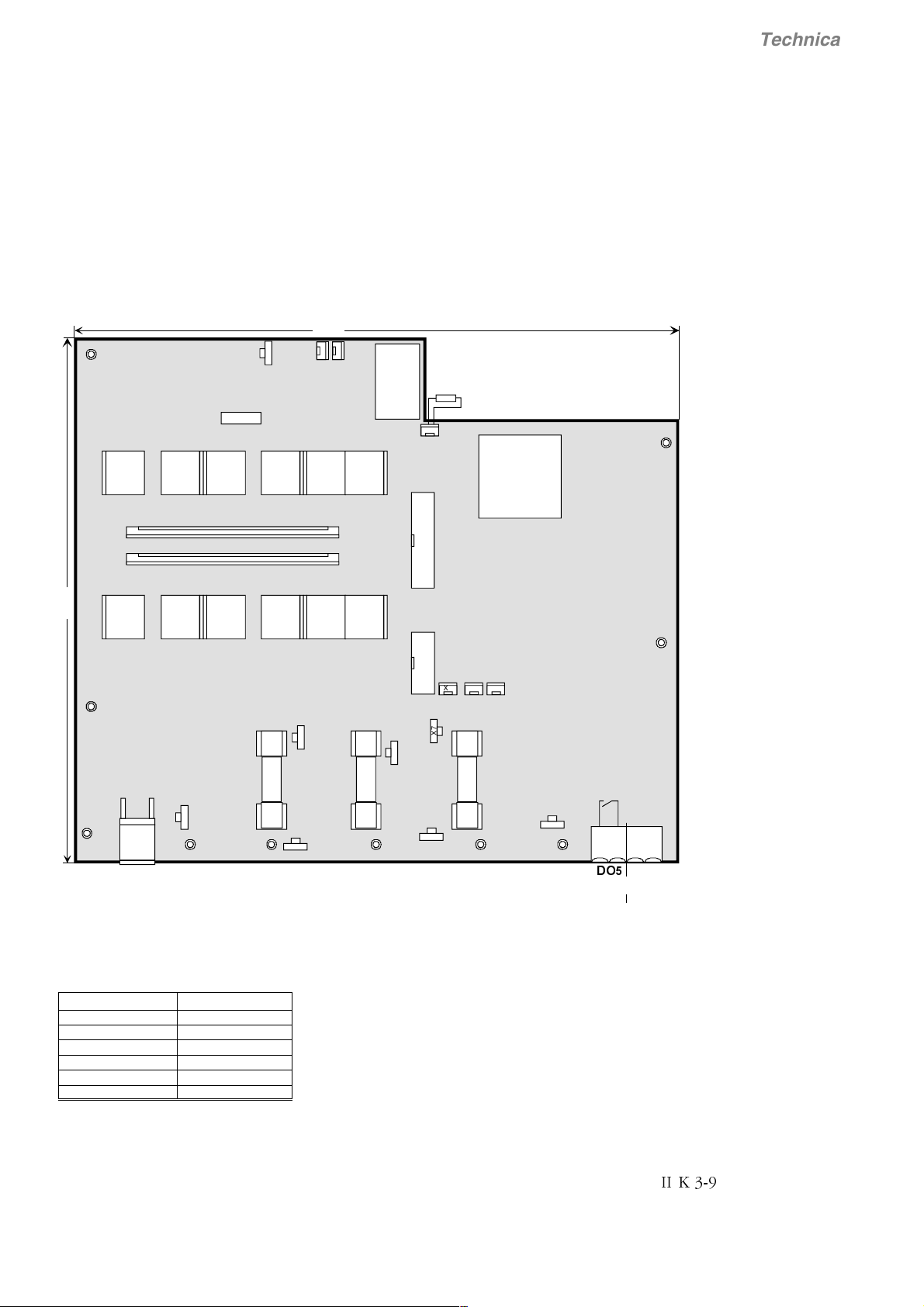

3.6 Power Interface Board SDCS-PIN-3A

The power interface board SDCS-PIN-3A is used

for all converter modules model A1...A4.

Functions:

- firing pulse circuits

- measurement of the armature current

- snubber circuit

- AC and DC voltage measurement

- heat sink temperature measurement

X6

258

X14

X11

- power supply for complete converter electronics

- fuses for field supply. Fuse data F100...F102:

T2

Technical data

Bussmann KTK-15A (600V)

PTC

X100

T24 T22 T26 T11 T15 T13

X15

X16

225

T14 T12 T16 T21 T25 T23

X1

F100

X24

X10

12

F+

to motor field

Fig. 3.6/1 Layout of the SDCS-PIN-3A board.

C1 U1 V1 W1 D1

X21

F-

X22

T1

X12X13

X3 X4 X5

X7

X2

F101

X23

F102

X20

X98

1234

Electronic

'2

supply

115...230 V

AC Supply voltage (X98:3-4)

Supply voltage 115...230 V AC

Tolerence -15%/+10%

Frequency 45 Hz ... 65 Hz

Power consumption 120 VA

Power loss £60 W

Inrush current 20 A/10 A (20 ms)

Mains buffering min 30 ms

Output X98:1-2 (DO5)

Potential isolated by relay (N.O. contact)

MOV- element (275 V)

Contact rating: AC: £250 V~/ £3 A~

DC: £24 V-/ £3 A-

or £115/230 V-/ £0.3 A-)

II K 3-9

Page 20

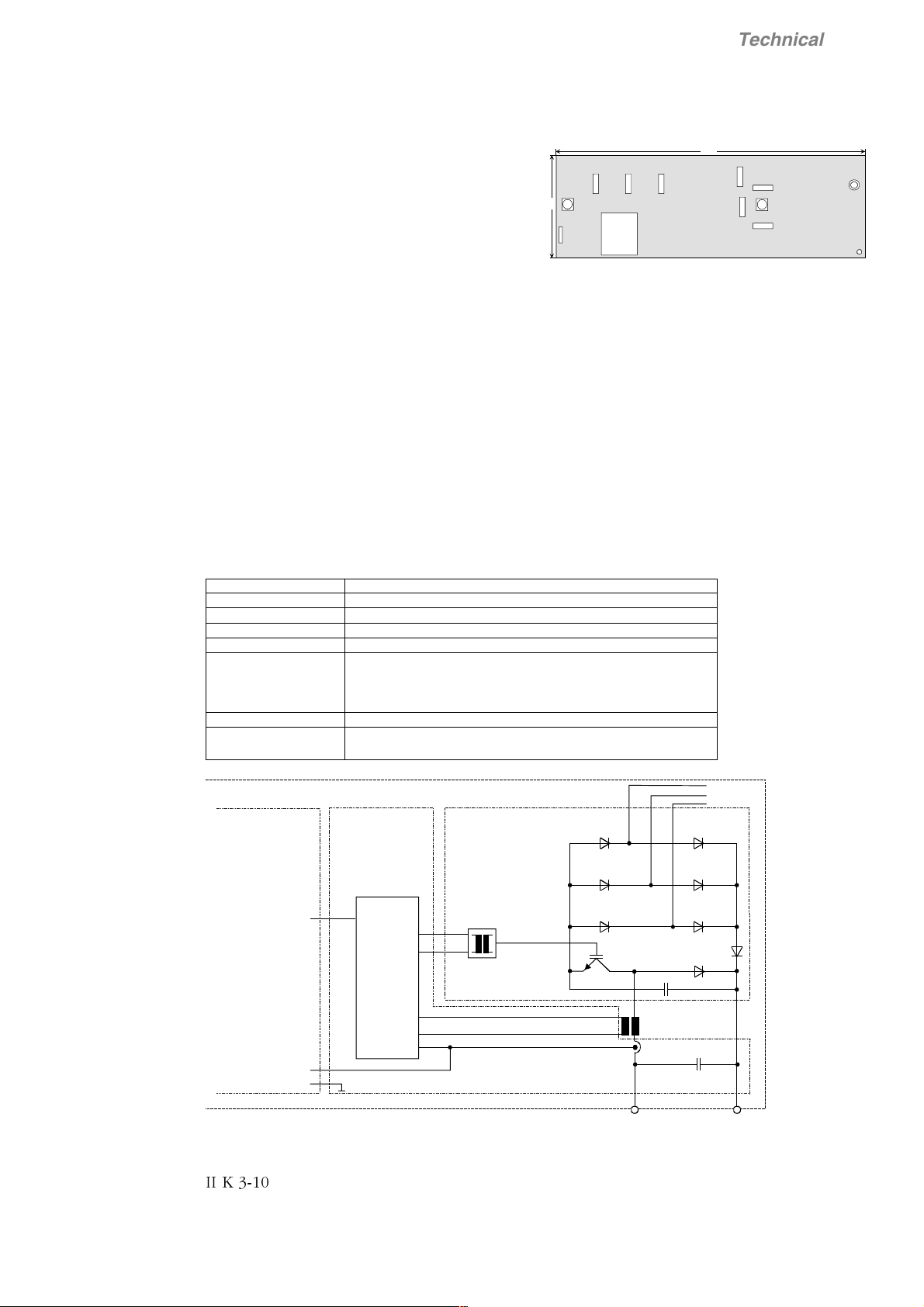

3.7 Field exciter SDCS-FIS-3A

Technical data

The DCS 400 converter has an build-in three-phase

field exciter with the following features:

X7

X2

X1

• smoothed field voltage

- better commutation of the motor

- increased brush life

45

T100

X14

• less heat generation in the motor

• less effort of cabling

Remark:

Fig. 3.7/1 Layout of the SDCS-FIS-3A field exciter

board

The DC link capacitor of the IGBT based field exciter

serves as an overvoltage protection for the armature

converter.

Overloading of the DC link capacitor is prevented by

the connected motor field winding.

The energy of glitches caused by the commutation of

the armature converter is no longer waste energy but

is used by the field exciter.

The overvoltage protection only works if a field winding is connected.

Therefore DCS400 can not be used with disconnected field.

Electrical data of SDCS-FIS-3A

AC input voltage: 230 V...500 V ±10%; three-phase

DC output voltage 50...440 V programmable

AC input current: £ output current

AC isolation voltage: 600 V

Frequency: same as DCS converter module

DC output current: 0.1 A...4 A for armature converter modules from 20 A to 25 A

Power loss see chapter 3.3

Terminal X10:1,2 on SDCS-PIN-3A

Cross sectional area 4 mm²

0.1 A...6 A for armature converter mod. from 45 A to 140 A

0.3 A...16 A for armature converter mod. from 180 A to 550 A

0.3 A...20 A for armature converter mod. for ³ 610 A

145

SDCS-FIS-3A

X6

X5

X4

X3

SDCS-CON-3A

FPWM

SDCS-PIN-3A SDCS-FIS-3A

X12: X12:

26

26

low level

control

3

1

X14:

Converter

8

IFM

989

GND

Fig. 3.7/2 Diagram of the field exciter unit

II K 3-10

U1

V1

X2 X7

X1

3

1

X14:

X11:2

3

X100:1-2 X6:1-3

X10:2 X10:1

(for motor field)

W1

X6X4X3

DC Output

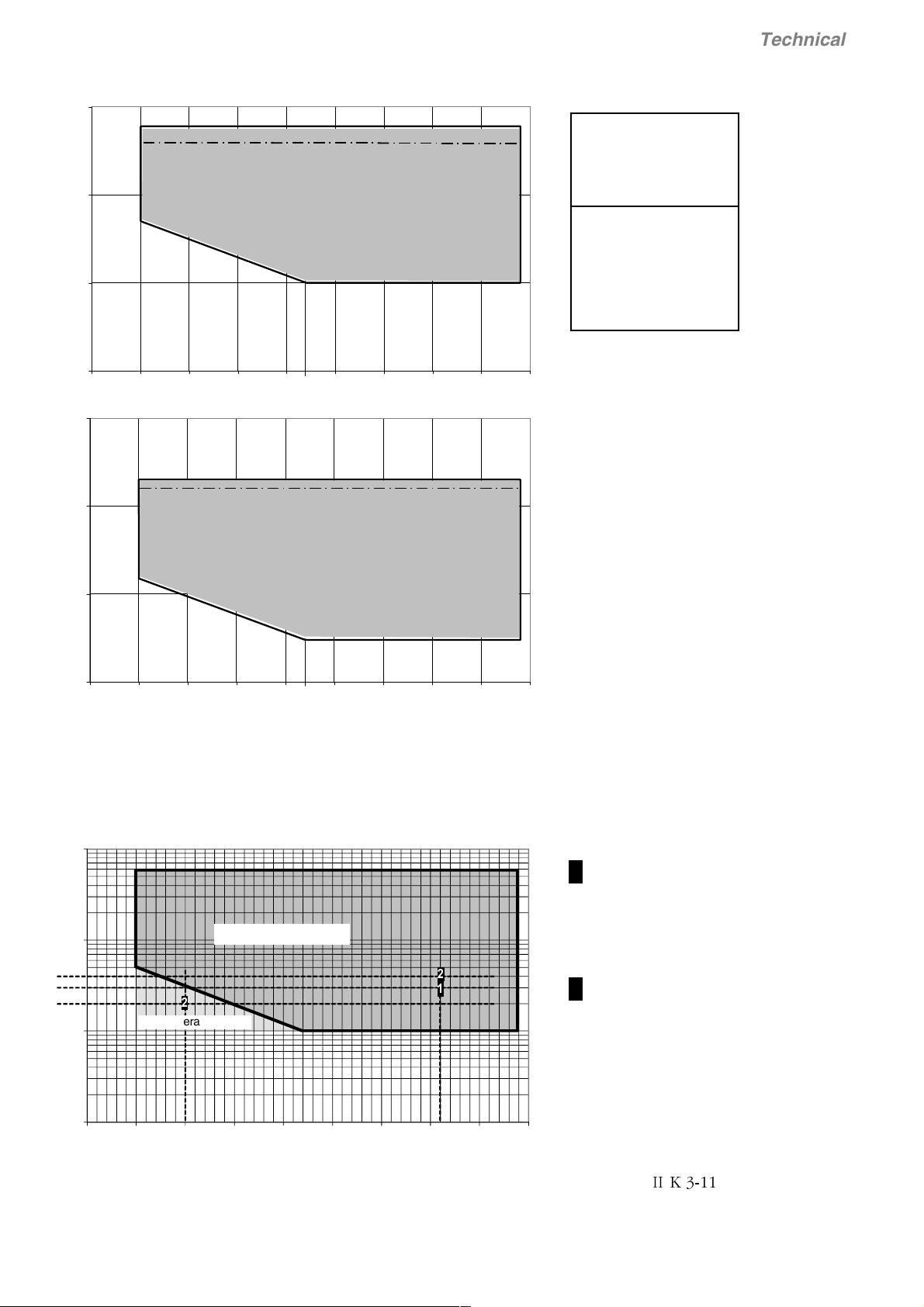

Page 21

Technical data

I

[A]

0,1

0,01

10

F

1

6

4

0.5

0 50 100 150 200 250 300 350 400 450

DCS 40x.0020...DCS 40x.0140

0.1

220

Fig. 3.7/3 Operating area of field exciter 0.1...6 A

100

I

F

[A]

20

10

16

DCS 40x.0180...DCS 40x.1000

System con- Field

nection voltage

range

U

Line

[V~] [V-]

230 50...237

380 50...392

400 50...413

415 50...428

440 50...440

460 50...440

480 50...440

500 50...440

Table 3.7/1:

Field voltage range related to

U

[V]

F

specified input voltage

1

0,1

1.5

0.3

0 50 100 150 200 250 300 350 400 450

220

Fig. 3.7/4 Operating area of field exciter 0.3...20 A

Important note:

Nominal field voltage and field current of the motor has to be within the field

controller operating range. For application with constant field it is easy to

check:

Transfer values of field current and field voltage to the diagram and check

that the point of intersection is within the operating range.

10

I

F

[A]

2SHUDWLQJUDQJH

0,1

1

out of operating range

U

[V]

F

Example:

For field weakening application do that check with

nominal values and minimal values. Both points of

intersection have to be within the operating range.

Depend on the converter use the right diagram

1

(6 A or 20 A)

e.g. DCS401.0045

Ue 310 V / Ie 0.3 A

è 6A diagram è ok

Depend on the converter use the right diagram

2

(6 A or 20 A)

e.g. DCS402.0050

Ue

310 V / Ie

nom

è 6A diagram è ok

nom

0.4 A

0,01

0 50 100 150 200 250 300 350 400 450

Fig. 3.7/5 Example of Field exciter operating range

Ue

100 V / Ie

min

è 6A diagram è not ok, not to realize !

U

[V]

F

0.2 A

min

II K 3-11

Page 22

3.8 Ciruit diagrams

F

D

9

/

1

;

Technical data

F

D

9

/

1

;

0

F

F

D

D

9

9

/

1

;

0

0

:

/

9

/

6

6

/

.

8

/

7

(

3

$

6

6

/

.

7

6

6

/

.

7

2

5

'

5

$

2

%

(

&

$

)

5

(

7

1

,

5

(

:

2

3

;

;

;

$

1

,

3

7

7

;

;

;

;

;

'

9

9

.

.

*

**

9

9

.

..

*

*

9

9

.

*

0

9

.

.

*

7

;

.*.*.*

7

;

*.*.

7

7

7

;

;

;

;

9

**

.*.*

7

;

9

9

.

..

*

*

'

5

$

2

%

(

&

$

)

5

(

7

1

,

'

/

(

,

$

)

*

.*.**.

7

;

7

7

7

;

;

;

9

9

.

*

&

;

;

$

;

6

,

;

)

.*.

;

;

;

;;

;

;

/

;;

;

;

7

;

;

)

/

;

.

98

&

:

;

;

)

)

&

'

;

;

(

/

8

'

2

0

5

(

7

5

(

9

1

2

&

'

5

$

2

%

$

/

2

5

1

7

1

2

2

&

$

&

;

;

;

;

;

;

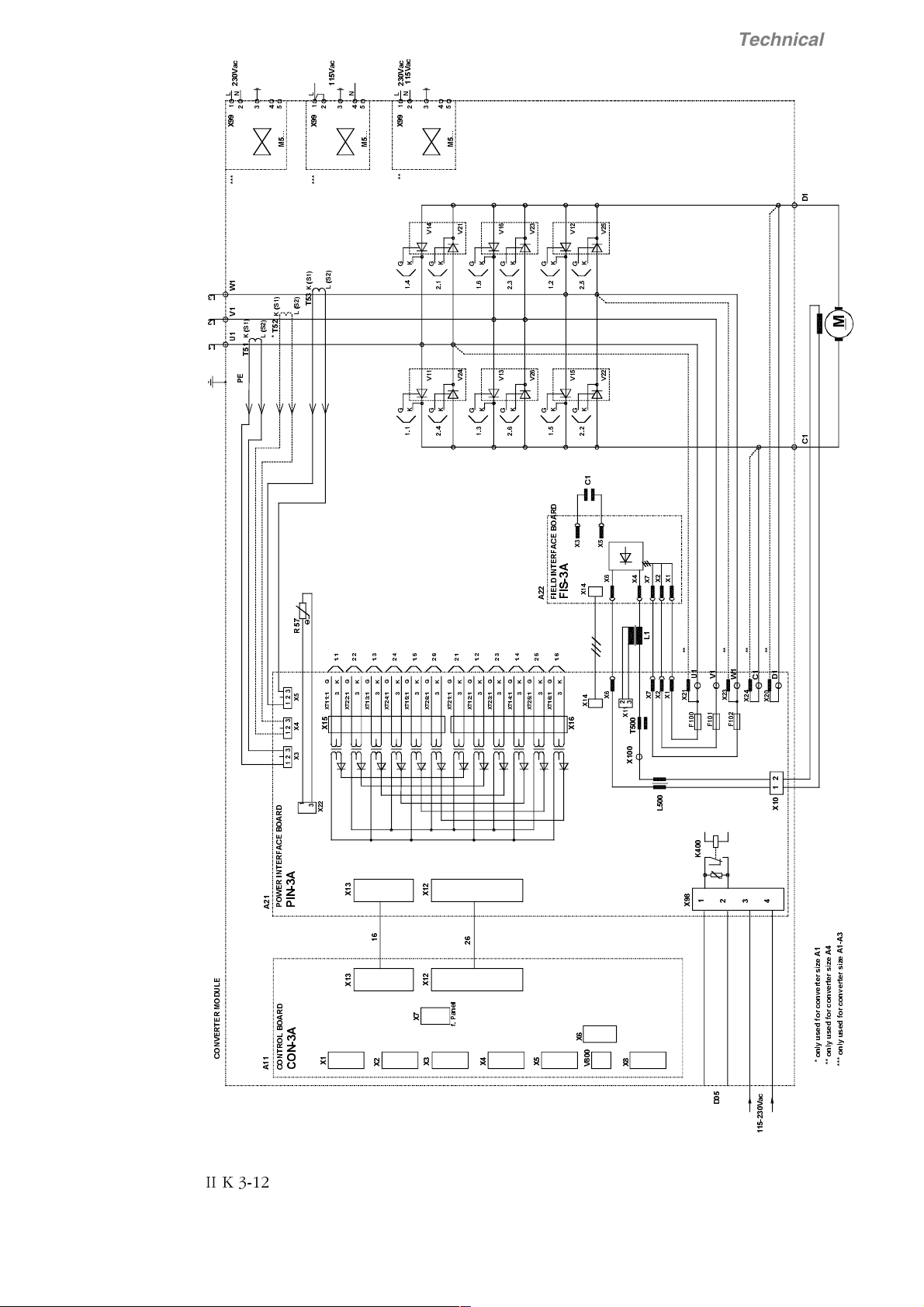

Fig. 3.8/1 Circuit diagram 4-Q converter

II K 3-12

O

H

Q

D

3

I

;

;

;

9

;

F

D

'

9

$

$

$

$

H

H

H

]

]

L

]

L

L

V

V

V

U

U

U

H

H

W

H

W

W

U

U

U

H

H

H

Y

Y

Y

Q

Q

Q

R

R

R

F

F

F

U

U

U

R

R

I

R

I

I

G

G

G

H

H

H

V

V

V

X

X

X

\

\

O

\

O

O

Q

Q

Q

R

R

R

Page 23

F

D

9

/

1

;

Technical data

F

D

9

/

1

0

;

F

F

D

D

9

9

/

1

0

;

0

:

/

9

/

6

6

/

.

8

/

7

(

3

6

6

/

.

7

6

6

/

.

7

2

5

;

;

;

'

5

$

2

%

(

&

$

)

5

(

7

1

,

$

5

(

:

1

,

2

3

3

$

7

7

;

;

;

;

;

'

9

.

*

9

.

*

9

.

*

0

9

.

*

7

;

.*.*.*

7

;

*.*.

7

7

;

;

;

9

.

*

.*.*

7

7

7

;

;

;

9

.

*

&

'

5

$

2

%

(

&

$

)

5

(

7

1

,

'

/

(

,

)

$

*

.*.**.

7

7

7

;

;

;

;

;

$

;

6

,

;

)

.*.

;

;

;

;;

;

;

/

8

9

&

;;

;

;

7

;

;

/

;

:

;

;

)

)

)

.

&

'

;

;

(

/

8

'

2

0

5

(

7

5

(

9

1

2

&

'

5

$

2

%

$

/

2

5

1

7

1

2

2

&

&

$

;

;

;

;

;

;

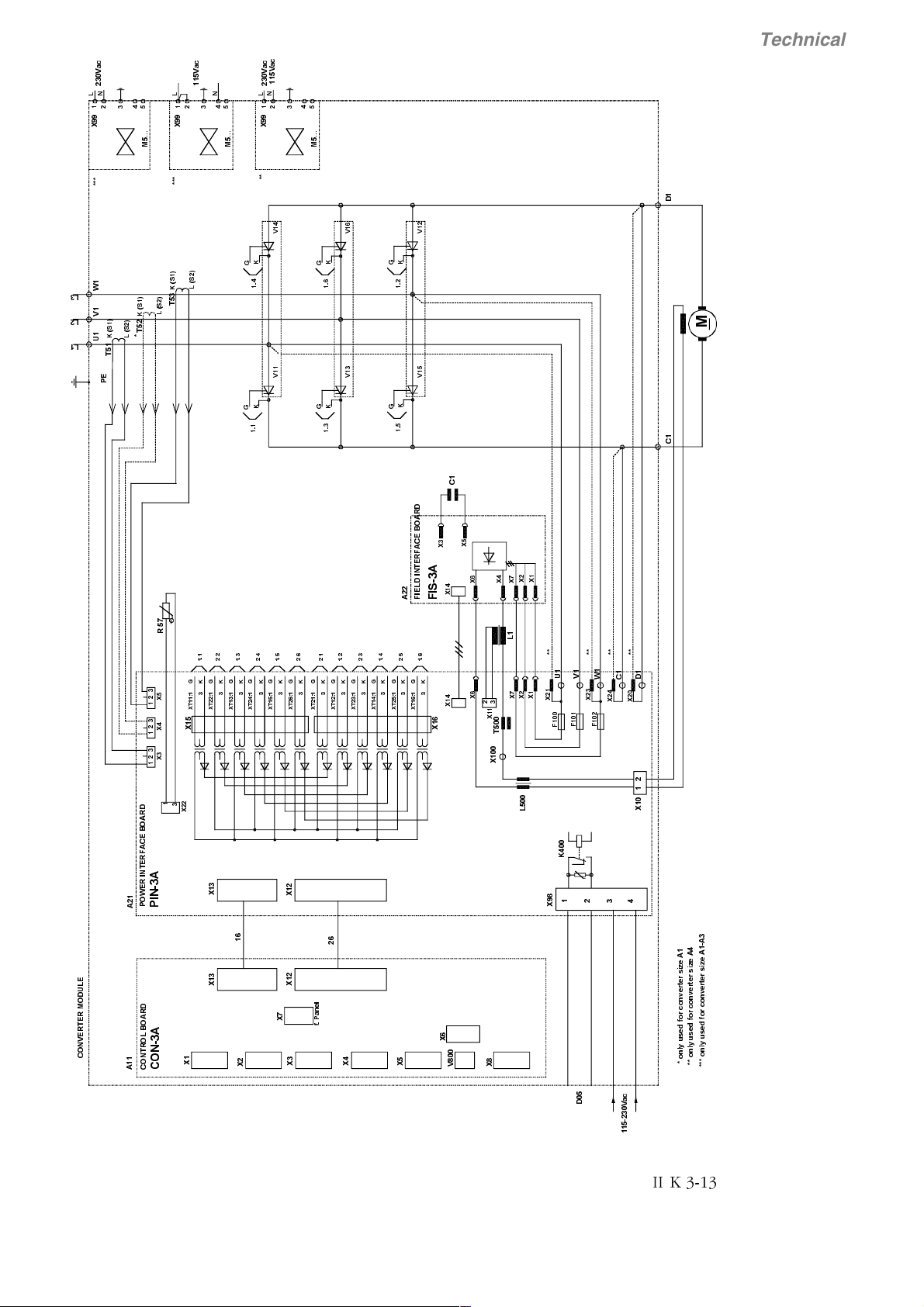

Fig. 3.8/2 Circuit diagram 2-Q converter

O

H

Q

D

3

I

;

;

;

9

;

F

D

'

9

$

$

$

$

H

H

H

]

]

L

]

L

L

V

V

V

U

U

U

H

H

W

H

W

W

U

U

U

H

H

H

Y

Y

Y

Q

Q

Q

R

R

R

F

F

F

U

U

U

R

R

I

R

I

I

G

G

G

H

H

H

V

V

V

X

X

X

\

\

O

\

O

O

Q

Q

Q

R

R

R

II K 3-13

Page 24

Technical data

II K 3-14

Page 25

4 Overview of software

(The software delivered may contain minor changes to the product described here.)

Overview of Software

Parameter

The parameters of the converter are subdivided into

functional groups. These groups are listed in the table

below.

Parameter group Functions

1 - Motor Settings Motor settings, actual line

values, auto reclosing

2 - Operating Mode Macro selection, behaviour

during switching on/off, control/status information, control location

3 - Armature Actual value signals, high

current dosage, controller

settings, stall protection, reference sources

4 - Field Actual value signals, con-

troller settings, overcurrent/

undercurrent tripping, flux

adaptation, field heating

5 - Speed Controller Reference sources, actual

value acquisition, controller

settings, ramp generator,

constant speeds, alternative

settings, speed monitoring,

actual value filtering

6 - Input/Output Scaling and allocation of the

analog and digital inputs and

outputs, display selection for

the control panel, field bus

allocation, actual value signals

7 - Maintenance Language selection, service

procedures, diagnostics,

fault and alarm information,

square-wave generator

8 - Field Bus Serial communication via the

field bus, RS232 or panel

adapter

9 - Macro Adaptation Re-configure digital inputs

DI1...DI4 of macros 1, 5, 6,

7, and 8.

Parameter saving

Any changes of the parameters are stored automatically in the FlashProm of the converter. The

storage is executed in a time interval of approx. 5

seconds.

Function menu

Special functions of the control panel are listed in the

table below.

Menu function Significance

Set Typecode Typecode adaptation for re-

placement of SDCS-CON-3

Read Faultlogger Read / Clear the last 16

Faults or Alarms

Factory Settings Reset all parameters to fac-

tory values (default values)

Copy to Panel Parameter uploading from

drive to control panel

Copy to Drive Parameter downloading

from control panel to drive

Long/Short Par List Some parameter visible / in-

visible

Panel Lock Lock the control panel for

maloperation

LCD Contrast Contrast of cotrol panel dis-

play

Commissioning Guided commissioning via

control panel

Continual parameter writing destroys the FlashProm

Parameter are saved automatically in a background

routine. This is done approx. every 5 seconds, when:

• parameters are altered by means of the control

panel.

• parameters are transmitted by means of PC Tool

Drive Window Light, irrespective of whether the

content of the parameter has changed.

• parameters are transmitted by means of PLC

communication via one of the three serial ports

Field bus adapter or RS232-Port or PanelPort, irrespective of whether the parameter’s

content has changed.

Continual transmission of a parameter with the

same content will entail continual saving in the

background routine, i.e. even if the value of the

parameter does not change, the save routine will still

be activated.

A FlashProm of the present-day generation can be

written on and erased up to 100,000 times. This

means 100,000 x 5 seconds = approx. 6 days.

Continual transmission of parameters may destroy this FlashProm after approx. 6 days, which

is why parameters should only be transmitted if

the values involved have changed.

II K 4-1

Page 26

4.1 General information about application Macros

Overview of Software

Macros are pre-programmed parameter sets. During start-up, the

drive can be configured easily without changing individual parameters.

The functions of all inputs and outputs and of allocations in the

control structure are influenced by the selection of a macro. Any

allocation which can be set manually with a “selector” (parameter) is

preset by the selection of a macro. The means, whether the drive is

speed-controlled or torque-controlled, whether supplementary references are processed, which actual values are available at the

Selector Remark

Cmd Location (2.02) Control location

Cur Contr Mode (3.14) Current controller operating mode

Torque Ref Sel (3.15) Torque reference source

Speed Ref Sel (5.01) Speed reference source

Alt Par Sel (5.21) Switching event for alternative speed

control parameters

Aux Sp Ref Sel (5.26) Auxiliary reference source

AO1 Assign (6.05) Actual value output at analog output AO1

AO2 Assign (6.08) Actual value output at analog output AO2

DO1 Assign (6.11) Signal output at digital output DO1

DO2 Assign (6.12) Signal output at digital output DO2

DO3 Assign (6.13) Signal output at digital output DO3

DO4 Assign (6.14) Signal output at digital output DO4

DO5 Assign (6.15) Signal output at digital output DO5

MSW bit 11 Ass (6.22) Signal transmission in bit 11 of the status

word

MSW bit 12 Ass (6.23) Signal transmission in bit 12 of the status

word

MSW bit 13 Ass (6.24) Signal transmission in bit 13 of the status

word

MSW bit 14 Ass (6.25) Signal transmission in bit 14 of the status

word

Jog 1 (9.02) Jogging 1 function via Fixed Speed 1

(5.13)

Jog 2 (9.03) Jogging 2 function via Fixed Speed 2

(5.14)

COAST (9.04) Coast stop function

User Fault (9.05) external User Fault event

User Fault Inv (9.06) external User Fault (invers) event

User Alarm (9.07) external User Alarm event

User Alarm Inv (9.08) external User Alarm (inverse) event

Dir of Rotation (9.09) Direction of Rotation only for speed con-

trolled drive

Mot Pot Incr (9.10) Motor Potentiometer Increment to in-

crease speed ref.

Mot Pot Decr (9.11) Motor Potentiometer Decrement to de-

crease speed ref.

analog outputs, which reference value sources are used, etc. is

already defined in the macro.

A macro is selected in the Macro Select (2.01) parameter. After

selection a function is assigned to each of the digital inputs DI1…DI8.

The functions are described in the chapter Application Macros.

The following “selectors” (parameters) are predefined when you are

selecting the macro provided that these parameters have their

default settings or are set to Macro Depend:

Selector Remark

MotPotMinSpeed (9.12) Motor Potentiometer Minimum Speed ref.

Ext Field Rev (9.13) external Field Reversal via external field

reversing switch

AlternativParam (9.14) switch over between Standard Parame-

ter Set and Alternative Parameter Set

Ext Speed Lim (9.15) external Speed Limitation via Fixed Speed

1 (5.13)

Add AuxSpRef (9.16) additional aux. speed ref.

Curr Lim 2 Inv (9.17) second current limitation via Arm Cur Lim

2 (3.24)

Speed/Torque (9.18) switch over between speed controlled

and torque controlled drive

Disable Bridge1 (9.19) block thyristor bridge 1

Disable Bridge2 (9.20) block thyristor bridge 2

Then the allocations will be dependent on the selected macro, see

chapter

The user can

are no longer “

allows the flexible, user-friendly adaptation to special requirements.

In addition to analog and digital outputs some of the digital inputs are

re-configurable. The digital inputs DI1…DI4 in macros 1+5+6+7+8

can be set individually via parameter group 9 - MacroAdaptation.

Macros 2+3+4 are fixed, not re-configurable.

Example of MacroAdaptation:

• Set parameter „Dir of Rotation" (9.09) from Macro depend to

• Set parameter „AlternativParam" (9.14) from Macro depend to

• Set standard parameter set (5.07…5.10) and alternative

Application Macros

change

Macro Depend

macro 6 - MotorPot should be selected

digital input DI1 should be re-defined from "direction of rotation"

to "alternativ parameter set" for using ramp 1 / 2

Disable

DI1

parameter set (5.22…5.25) to values as required

.

the allocations manually any time. Then they

”. Hence the macro technique also

II K 4-2

Page 27

Overview of Software

Overview of factory settings of macro-dependent parameters:

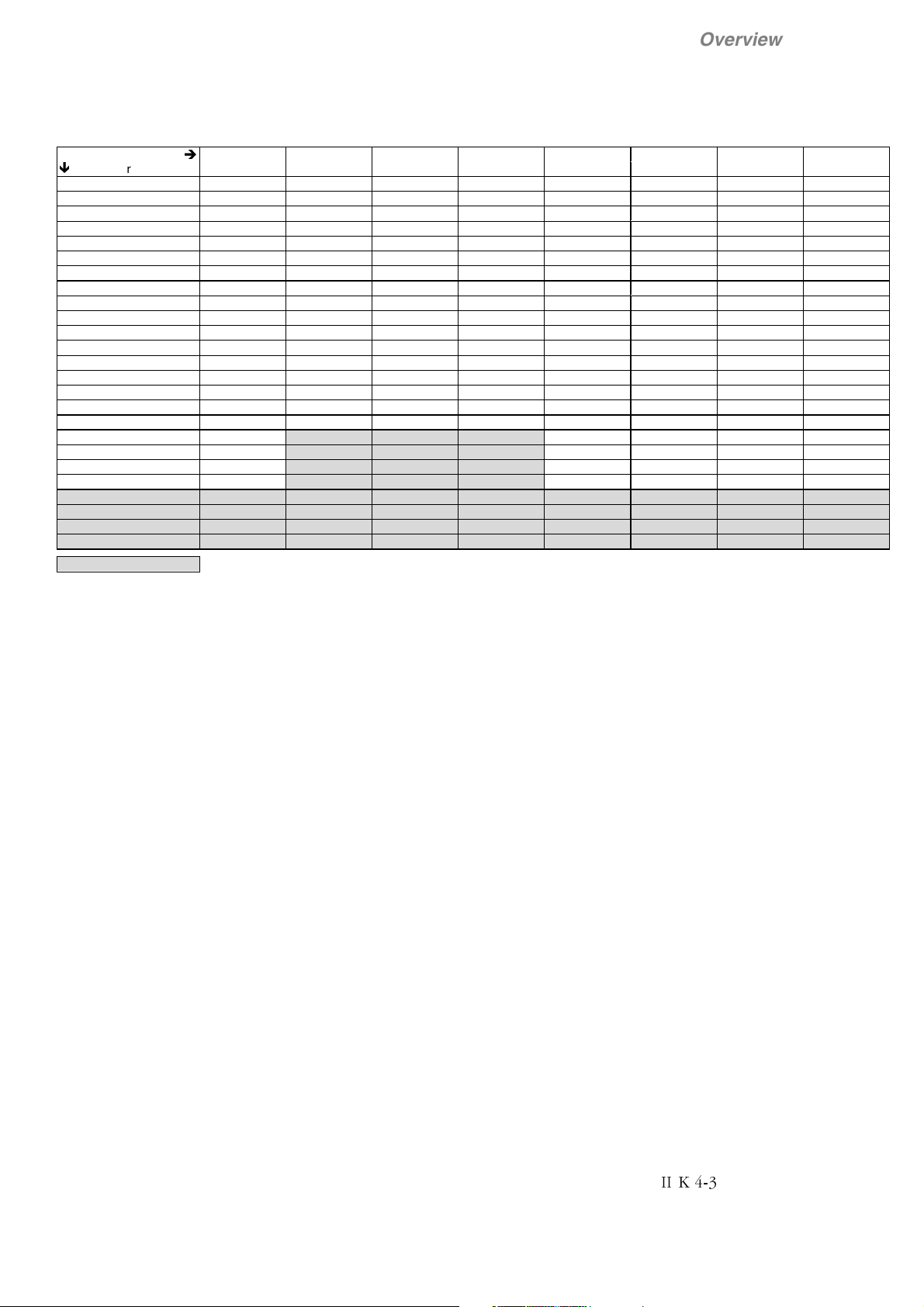

Macro

Ï

Parameter Standard Man/Const Sp Hand/Auto Hand/MotPot Jogging Motor Pot ext Field Rev Torque Ctrl

Cmd Location (2.02) Terminals Terminals Terminals Terminals Terminals Terminals Terminals Terminals

Cur Contr Mode (3.14) Speed Contr Speed Contr Speed Contr Speed Contr Speed Contr Speed Contr Speed Contr Torque Contr

Torque Ref Sel (3.15) AI2 AI2 Const Zero AI2 Const Zero AI2 AI2 AI1

Speed Ref Sel (5.01) AI1 AI1 AI1 AI1 AI1 Const Zero AI1 Const Zero

Alt Par Sel (5.21) Sp < Lev1 Digital Input 4 Sp < Lev1 Sp < Lev1 Sp < Lev1 Sp < Lev1 Sp < Lev1 Sp < Lev1

Aux Sp Ref Sel (5.26) Const Zero Const Zero Const Zero Const Zero AI2 Const Zero Const Zero Const Zero

AO1 Assign (6.05) Speed Act Speed Act Speed Act Speed Act Speed Act Speed Act Speed Act Speed Act

AO2 Assign (6.08) Arm Volt Act Arm Cur Act Arm Cur Act Arm Cur Act Torque Act Arm Volt Act Arm Volt Act Torque Act

DO1 Assign (6.11) Rdy for Run Rdy for On Rdy for On Rdy for On Rdy for Run Rdy for Run Rdy for Run Rdy for Run

DO2 Assign (6.12) Running Running Running Running Zero Speed Speed Level 1 Running Running

DO3 Assign (6.13) Zero Speed Fault Fault Fault At Setpoint Speed Level 2 Field Rev Act Zero Speed

DO4 Assign (6.14) Flt or Alarm Zero Speed Zero Speed Zero Speed Flt or Alarm Flt or Alarm Flt or Alarm Flt or Alarm

DO5 Assign (6.15) Main Cont On Main Cont On Main Cont On Main Cont On Main Cont On Main Cont On Main Cont On Main Cont On

MSW Bit11 Ass (6.22) none none none none none none none none

MSW Bit12 Ass (6.23) none none none none none none none none

MSW Bit13 Ass (6.24) none none none none none none none none

MSW Bit14 Ass (6.25) none none none none none none none none

Assignment of DI1 Jog 1 Start

Not re-configurable

Í

DI2 Jog 2 Stop Hand/Auto Jog 1 Jog 1 Incr. Speed Jog 1 not used

DI3 External Fault Direc of Rotat. Direc of Rotat. Direc of Rotat. Jog 2 Decr. Speed External Fault External Fault

DI4 External Alarm Ramp 1 / 2 AI1/Fixed Sp 1 AI1/MotPot not used Min Speed External Alrm External Alrm

DI5 Emerg. Stop Emerg. Stop Emerg. Stop Emerg. Stop Emerg. Stop Emerg. Stop Emerg. Stop Emerg. Stop

DI6 Reset Reset Reset Reset Reset Reset Reset Reset

DI7 On/Off Fixed Speed 1 Direc of Rotat. Incr. Speed On/Off On/Off On/Off On/Off

DI8 Run Fixed Speed 2

12345678

Start/Stop Hand

Start/Stop Auto

Start/Stop Direc of Rotat. Direc of Rotat. Ext Field Rev Coast

Decr. Speed Run Run Run Run

II K 4-3

Page 28

4.2 Application Macros

The following application macros are available:

Overview of Software

Macro 1: Standard

Drive switch-on/switch-off and enable via 2

digital inputs.

Speed reference via analog input.

External torque limiting via analog input.

Jogging via 2 digital inputs.

2 digital inputs for external events (fault/

alarm).

2 digital inputs for emergency stop and fault

acknowledgement.

Macro 2: Man/Const Sp

Starting and stopping of the drive via 2 digital

inputs.

Speed reference via analog input.

Reversal of rotational direction via 1 digital input.

2 ramp sets selectable via 1 digital input.

Selection of speed reference or 2 fixed

speeds via 2 digital inputs.

2 digital inputs for emergency stop and fault

acknowledgement.

Macro 3: Hand/Auto

Switchover between manual and auto. control

effected via 1 digital input.

Manual control:

Starting and stopping of the drive via 1 digital input.

Speed reference via analog input 1.

Selection of speed reference or 1 fixed

speed via 1 digital input.

Reversal of rotational direction via 1 digital input.

Automatic control:

Starting and stopping of the drive via 1 digital input.

Speed reference via analog input 2.

Reversal of rotational direction via 1 digi-

tal input.

2 digital inputs for emergency stop and fault

acknowledgement.

Macro 4: Hand/MotPot

Starting and stopping of the drive via 1 digital

input.

Jogging via 1 digital input.

Speed reference via analog input.

Reversal of rotational direction via 1 digital input.

Motor potentiometer function via 2 digital inputs.

Selection of speed reference or motor pot via

1 digital input.

2 digital inputs for emergency stop and fault

acknowledgement.

Macro 5: Jogging

Drive switch-on/switch-off and enable via 2 digital inputs.

Speed reference via analog input 1.

Additional reference via analog input 2.

Jogging via 2 digital inputs.

Reversal of rotational direction via 1 digital input.

2 digital inputs for emergency stop and fault

acknowledgement.

Macro 6: Motor Pot

Drive switch-on/switch-off and enable via 2 digital inputs.

Reversal of rotational direction via 1 digital input.

Minimum speed can be activated via 1 digital

input.

Motor pot function via 2 digital inputs.

2 digital inputs for emergency stop and fault

acknowledgement.

Macro 7: ext Field Rev

Drive switch-on/switch-off and enable via 2 digital inputs.

Speed reference via analog input 1.

External torque limiting via analog input 2.

Jogging via 1 digital input.

External field reversal can be activated via 1

digital input.

2 digital inputs for external events (fault/

alarm).

2 digital inputs for emergency stop and fault

acknowledgement.

Macro 8: Torque Ctrl

Drive switch-on/switch-off and enable via 2 digital inputs.

Torque reference via analog input.

Coast Stop via 1 digital input.

2 digital inputs for external events (fault/

alarm).

2 digital inputs for emergency stop and fault

acknowledgement.

II K 4-4

Page 29

Overview of Software

II K 4-5

Page 30

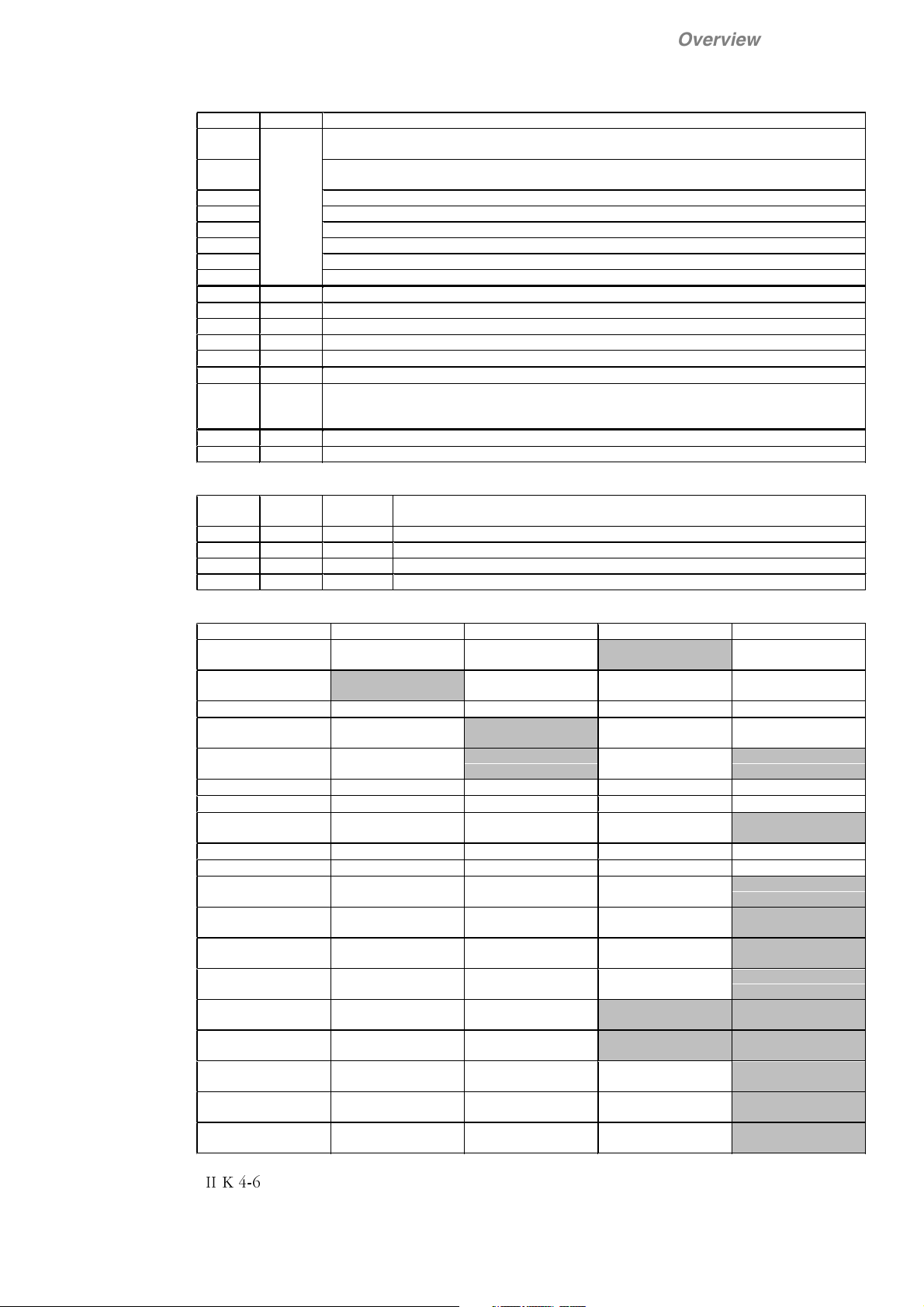

4.2.1 Macro 1 - Standard

Description of I/O’s functionality

I/O Param Function

DI1 Jog speed 1. Speed can be defined in parameter 5.13.

DI2 Jog speed 2. Speed can be defined in parameter 5.14.

DI3 2.01 External fault signal. Triggers a fault response and trips the drive

DI4 External alarm signal. Triggers a warning in DCS400

DI5 Emergency stop. Closed-circuit principle, must be closed for operation

DI6 Reset. Faultacknowledgement, reset faults signaled by the drive

DI7 Drive ON / OFF. DI7=0=OFF , DI7=1=ON

DI8 Drive START / STOP. DI8=0=STOP , DI8=1=START

DO1 6.11 Ready for Run. Converter switched ON, but not yet STARTed

DO2 6.12 Running. Drive is STARTed (Current controller enabled)

DO3 6.13 Zero-speed signal. Motor at standstill

DO4 6.14 Group fault signal. Common signal for all faults or alarms

DO5 6.15 Main contactor on. Controlled by ON command (DI7)

AI1 5.01 Speed reference

AI2 3.15 External torque limitation possible. First the parameter Cur Contr Mode 3.14 has to be changed

AO1 6.05 Speed actual

AO2 6.08 Armature voltage actual

Inter locking of Jog speed 1 – Jog speed 2 – Drive START

Jog 1

DI1

Overview of Software

Accel/Decel Ramp for Jogging can be defined in parameter 5.19/5.20.

Accel/Decel Ramp for Jogging can be defined in parameter 5.19/5.20.

from Macro depend to Lim Sp Ctr. Without changes the factory settings for torque limitation is

effective (100%).

Jog 2

DI2

0 0 0 Drive is STOPped (Current controller disabled)

1 0 0 Drive STARTed via DI1 , speed reference=parameter 5.13

x 1 0 Drive STARTed via DI2 , speed reference=parameter 5.14

x x 1 Drive STARTed via START command (DI8) , speed reference via analog input AI1

START

DI8

Drive is ON (DI7=1)

Parameter settings, shaded areas are set by macro - all others are set during commissioning

1 - Motor Settings 2 - Operation Mode 3 - Armature 5 - Speed Controller 6 - Input/Output

1.01 Arm Cur Nom 2.01 Macro Select

[Standard]

1.02 Arm Volt Nom 2.02 Cmd Location

[Terminals]

1.03 Field Cur Nom 2.03 Stop Mode 3.08 Torque Lim Neg 5.03 Encoder Inc 6.03 AI2 Scale 100%

1.04 Field Volt Nom 2.04 Eme Stop Mode 3.14 Cur Contr Mode

1.05 Base Speed 3.15 Torque Ref Sel

1.06 Max Speed 3.17 Stall Torque 5.11 Eme Stop Ramp 6.06 AO1 Mode

3.04 Arm Cur Max 5.01 Speed Ref Sel

[AI1]

3.07 Torque Lim Pos 5.02 Speed Meas

Mode

5.09 Accel Ramp 6.04 AI2 Scale 0%

[Speed Contr]

5.10 Decel Ramp

[AI2]

3.18 Stall Time 5.12 Ramp Shape 6.07 AO1 Scale 100%

5.13 Fixed Speed 1 6.08 AO2 Assign

5.14 Fixed Speed 2 6.09 AO2 Mode

5.15 Zero Speed Lev 6.10 AO2 Scale 100%

5.16 Speed Level 1 6.11 DO1 Assign

5.17 Speed Level 2 6.12 DO2 Assign

5.19 Jog Accel Ramp 6.13 DO3 Assign

5.20 Jog Decel Ramp 6.14 DO4 Assign

5.21 Alt Par Sel

[Sp < Lev1]

5.26 Aux Sp Ref Sel

[Const Zero]

6.01 AI1 Scale 100%

6.02 AI1 Scale 0%

6.05 AO1 Assign

[Speed Act]

[Arm Volt Act]

[Rdy for Run]

[Running]

[Zero Speed]

[Flt or Alarm]

6.15 DO5 Assign

[Main Cont On]

6.22 MSW Bit 11 Ass

[none]

6.23 MSW Bit 11 Ass

[none]

6.24 MSW Bit 11 Ass

[none]

6.25 MSW Bit 11 Ass

[none]

II K 4-6

Page 31

Overview of Software

_

1.03 / 1.04

unit

Field exciter

1.05 / 1.06

1.01 / 1.02

400V 50H z

F1

1

L1 N L1 L2 L3

115...230V 50 Hz

2

135

K1

246

U1 W 1V1 PE

L1

F5

module type and on the supply voltage

the connection of the fan depends on the

module

Converter

5.02

~

M

5.03

Fan

6.14

6.13

6.12

6.11

1

2

F4

4 A

Main contactor ON

98:2

1

98:1

2

F6

K1

12 34 45X99: 1 2 3

X98:

Power supply

6.15

DO5

2.01

0V

0V0V

+

X10: 1 2

_

C 1 D 1

+

U

S

0 V

Z-

Z+

B-

B+

A-

A+

1 2345678

X3:

Emergenc y stop

Fault or Alar m

Zero-speed

Running

Ready for Run

Run

On/Off

Reset

User alarm

User fault

Jogging 2

Jogging 1

**

mode!

regenerative

* only required in

Q

R

L

W

D

W

S

D

G

$

R

U

F

D

re-configu rable in

parameter group 9

0

M

for motor operation

the po larities are shown

+

T

_

T

(optical)

RXD

X2

PE SHF DG D(N) D(P)SH

8.01 ... 8.16

IN

DDCS

ON

OFF

BUS

TERMINA TION

Nxxx-01

xxxxxxxx

ADAPTER

TXD

XMIT

REC

ERROR

+24V 0V SH

PE SHF DG D(N) D(P)

X1

Control board

'&6

OUT

6.08 / 6.09 / 6.10

6.05 / 6.06 / 6.07

6.03 / 6.04

6.01 / 6.02

5.02

+24 V

X6:

X7:

X8:

RS232

&

3

AI2

0V

AITAC AI1

Parameter

+10V -10V AO1 AO2 DI1 DI2 DI3 DI4 DI5 DI6 DI7 DI8 +24V DO1DO2 DO3 DO4

++

__

2

1

X2:

S1

+

_

X1:1234 1234 567 8 9 X4:12345678910X5:12345

DCS 400 P AN

U

a act

n

act

T

ref

n

ref

Fig. 4.2/1: Connection example application-Macro 1 - Standard

II K 4-7

Page 32

4.2.2 Macro 2 - Man/Const Sp

Description of I/O’s functionality

I/O Param Function

DI1 Drive is started by closing digital input DI1 (DI=1). Switches the drive ON and START

DI2 Drive is stopped by opening digital input DI2 (DI2=0). DI2 has a higher priority than DI1, i.e. if DI2 is

DI3 2.01 Direction of rotation. DI3=0=forward, DI3=1=reverse

DI4 2 ramp sets selectable.

DI5 Emergency stop. Closed-circuit principle, must be closed for operation

DI6 Reset. Faultacknowledgement, reset faults signaled by the drive

DI7 Fixed speed 1, speed can be defined in parameter 5.13 (Ramp 5.19/5.20)

DI8 Fixed speed 2, speed can be defined in parameter 5.14 (Ramp 5.19/5.20)

DO1 6.11 Ready for On. Elektronics powered up, no fault signals present

DO2 6.12 Running. Current controller enabled

DO3 6.13 Fault signal. Converter tripped

DO4 6.14 Zero-speed signal. Motor at standstill

DO5 6.15 Main contactor on. Controlled by START command (DI1)

AI1 5.01 Speed reference

AO1 6.05 Speed actual

AO2 6.08 Armature current actual

Overview of Software

open the drive can not be started. Stop the drive in according to parameter Stop-Mode and

afterwards switch the drive off.

DI4=0=Ramp 1

Accel Ramp 5.09 / Decel Ramp 5.10 / Speed Reg KP 5.07 / Speed Reg TI 5.08

DI4=1=Ramp 2

Alt Accel Ramp 5.24 / Alt Decel Ramp 5.25 / Alt Speed KP 5.22 / Alt Speed TI 5.23

Selection of speed reference or 2 fixed speed via DI7 and DI8

DI7 DI8 Drive is STARTed (DI1=1)

00• Man Speed; Speed reference via analog input AI1

10• Const Speed; Fixed speed 1, speed can be defined in parameter 5.13 (Ramp 5.19/5.20)

x1• Const Speed; Fixed speed 2, speed can be defined in parameter 5.14 (Ramp 5.19/5.20)

Parameter settings, shaded areas are set by macro - all others are set during commissioning

1 - Motor Settings 2 - Operation Mode 3 - Armature 5 - Speed Controller 6 - Input/Output

1.01 Arm Cur Nom 2.01 Macro Select

[Man/Const Sp]

1.02 Arm Volt Nom 2.02 Cmd Location

[Terminals]

1.03 Field Cur Nom 2.03 Stop Mode 3.08 Torque Lim Neg 5.03 Encoder Inc 6.03 AI2 Scale 100%

1.04 Field Volt Nom 2.04 Eme Stop Mode 3.14 Cur Contr Mode

1.05 Base Speed 3.15 Torque Ref Sel

1.06 Max Speed 3.17 Stall Torque 5.11 Eme Stop Ramp 6.06 AO1 Mode

3.04 Arm Cur Max 5.01 Speed Ref Sel

[AI1]

3.07 Torque Lim Pos 5.02 Speed Meas

Mode

5.09 Accel Ramp 6.04 AI2 Scale 0%

[Speed Contr]

5.10 Decel Ramp

[AI2]

3.18 Stall Time 5.12 Ramp Shape 6.07 AO1 Scale 100%

5.13 Fixed Speed 1 6.08 AO2 Assign

5.14 Fixed Speed 2 6.09 AO2 Mode

5.15 Zero Speed Lev 6.10 AO2 Scale 100%

5.16 Speed Level 1 6.11 DO1 Assign

5.17 Speed Level 2 6.12 DO2 Assign

5.19 Jog Accel Ramp 6.13 DO3 Assign

5.20 Jog Decel Ramp 6.14 DO4 Assign

5.21 Alt Par Sel

[DI4]

5.24 Alt Accel Ramp 6.22 MSW Bit 11 Ass

5.25 Alt Decel Ramp 6.23 MSW Bit 12 Ass

5.26 Aux Sp Ref Sel

[Const Zero]

6.01 AI1 Scale 100%

6.02 AI1 Scale 0%

6.05 AO1 Assign

[Speed Act]

[Arm Cur Act]

[Rdy On]

[Running]

[Fault]

[Zero Speed]

6.15 DO5 Assign

[Main Cont On]

[none]

[none]

6.24 MSW Bit 13 Ass

[none]

6.25 MSW Bit 14 Ass

[none]

II K 4-8

Page 33

Overview of Software

_

1.03 / 1.04

unit

Field exciter

1.05 / 1.06

1.01 / 1.02

400V 50H z

F1

1

L1 N L1 L2 L3

115...230V 50 Hz

2

135

K1

246

U1 W 1V1 PE

L1

F5

module type and on the supply voltage

the connection of the fan depends on the

module

Converter

~

M

5.03

5.02

Fan

6.14

6.13

6.12

6.11

1

2

F4

4 A

Main contactor ON

98:2

1

98:1

2

F6

K1

12 34 45X99: 1 2 3

X98:

Power supply

6.15

DO5

2.01

C 1 D 1

0V

0V0V

+

X10: 1 2

_

+

U

S

0 V

Z-

Z+

B-

B+

A-

A+

1 2345678

X3:

Zero-speed

Running

Ready for ON

Fixed s peed 2

Fixed s peed 1

Emergenc y stop

Ramp 1 / Ramp 2

Direction of ro tation

**

Fault

Reset

Stop

Start

M

mode!

regenerative

* only required in

not re-confi gurable

for motor operation

the po larities are shown

+

T

_

T

RXD

X2

PE SHF DG D(N) D(P)SH

8.01 ... 8.16