Page 1

Page 2

41-151.1H Type D-3 Direct Current Relay

Sketch

205342

182A787

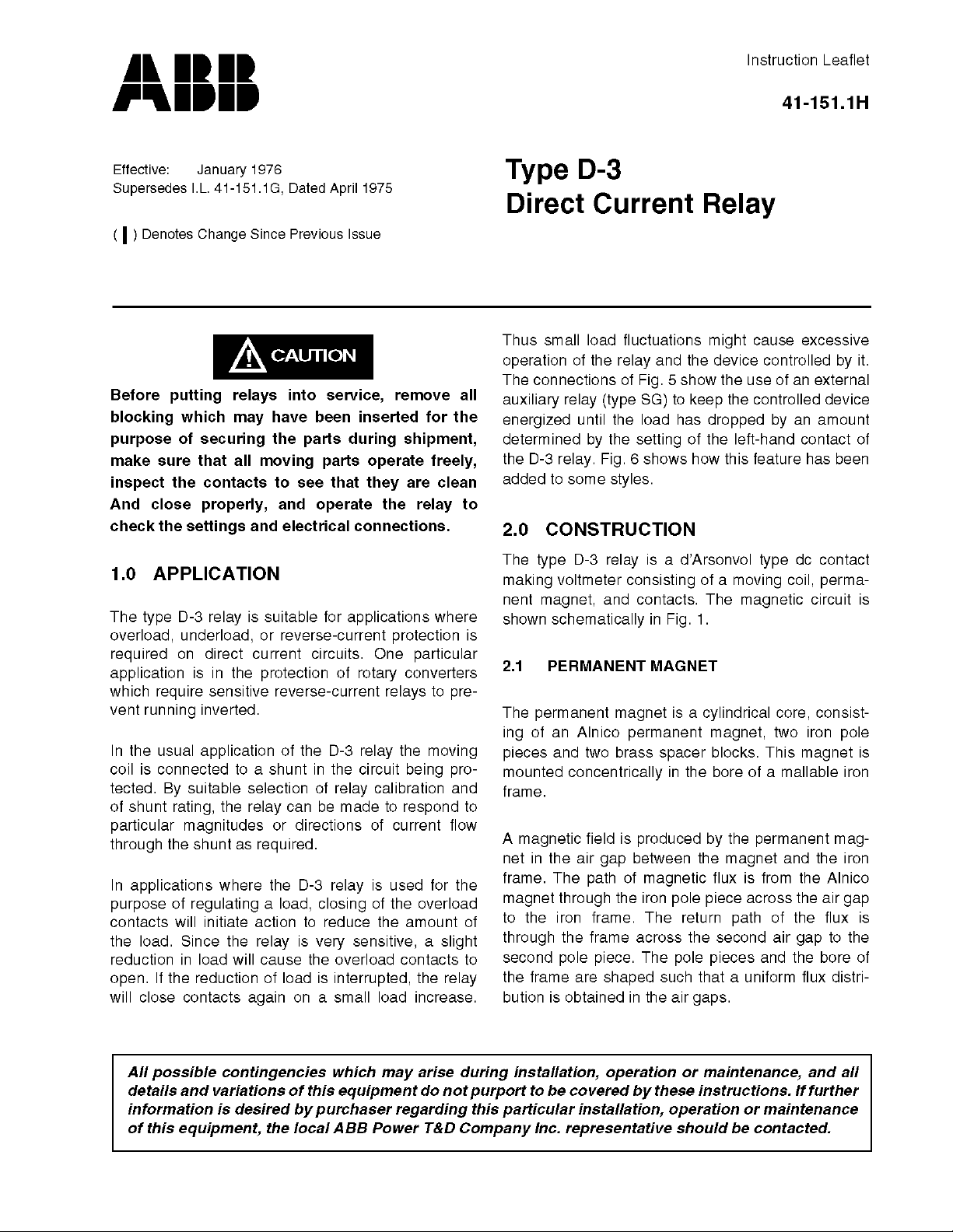

Figure 1: Schematic Drawing of Magnetic Circuit of Type

D-3 Relay (Top View). Moving Coil Bearing Supports, Springs and Contacts Omitted.

2.2 MOVING COIL

The moving coil rotates in the air gap between the

core and the iron frame. Electrical connections are

made to the coil through two springs located at the

top of the element. One end of each spring is connected through a lever am to a head of the coil.

cache other end of each spring is fastened to posts

mounted in a circular insulation plate. This plate can

be rotated to permit adjustment of the zero position

of the moving element.

A third spiral spring located at the bottom of the element provides a current path to the moving contact.

2.3 AUXILIARY SWITCH (CS-1) (WHEN USED)

The auxiliary switch is a small solenoid type switch. A

cylindrical plunger with a silver disc mounted on its

lower end moves in the core of the solenoid. As the

plunger travels upward the disc bridges three silver

stationary contacts.

2.4 OPERATION INDICATOR (WHEN USED)

The operation indicator consists of a small solenoid

coil mounted in a steel frame, a spring restrained

armature and a white flag. The indicator is reset by a

push rod in the cover.

Figure 2: Internal Schematic of the Type D-3 Relay in the

Type FT-21 Case.

3.0 OPERATION

The D-3 relay operates on the principle of a current

carrying conductor (moving coil) located in a magnetic field (permanent magnet). When a current is

applied to the coil of the relay, a torque is produced

that rotates the moving coil until the electrical torque

is equal to the torque of the restraining spring. The

moving contact will assume a position in its travel

that is proportional to the current applied to the moving coil.

The direction of movement of the moving coil is

determined by the polarity of the current applied to

the roil. In the “left zero” and “suppressed zero” D-3

relays, the contacts will move to the right when a current of the proper magnitude and polarity is applied

to the relay. On the other hand, the contact of the

“center zero” relay will move either left or right

depending on the polarity and magnitude of the

applied current.

4.0 CHARACTERISTICS

The type D-3 relay is supplied in the standard ranges

listed in the table below. The numbers on the scale

indicate in millivolts the potential required at the relay

base terminals to operate the moving element to the

indicated scale position.

2

Page 3

Type D-3 Direct Current Relay 41-151.1H

183A342

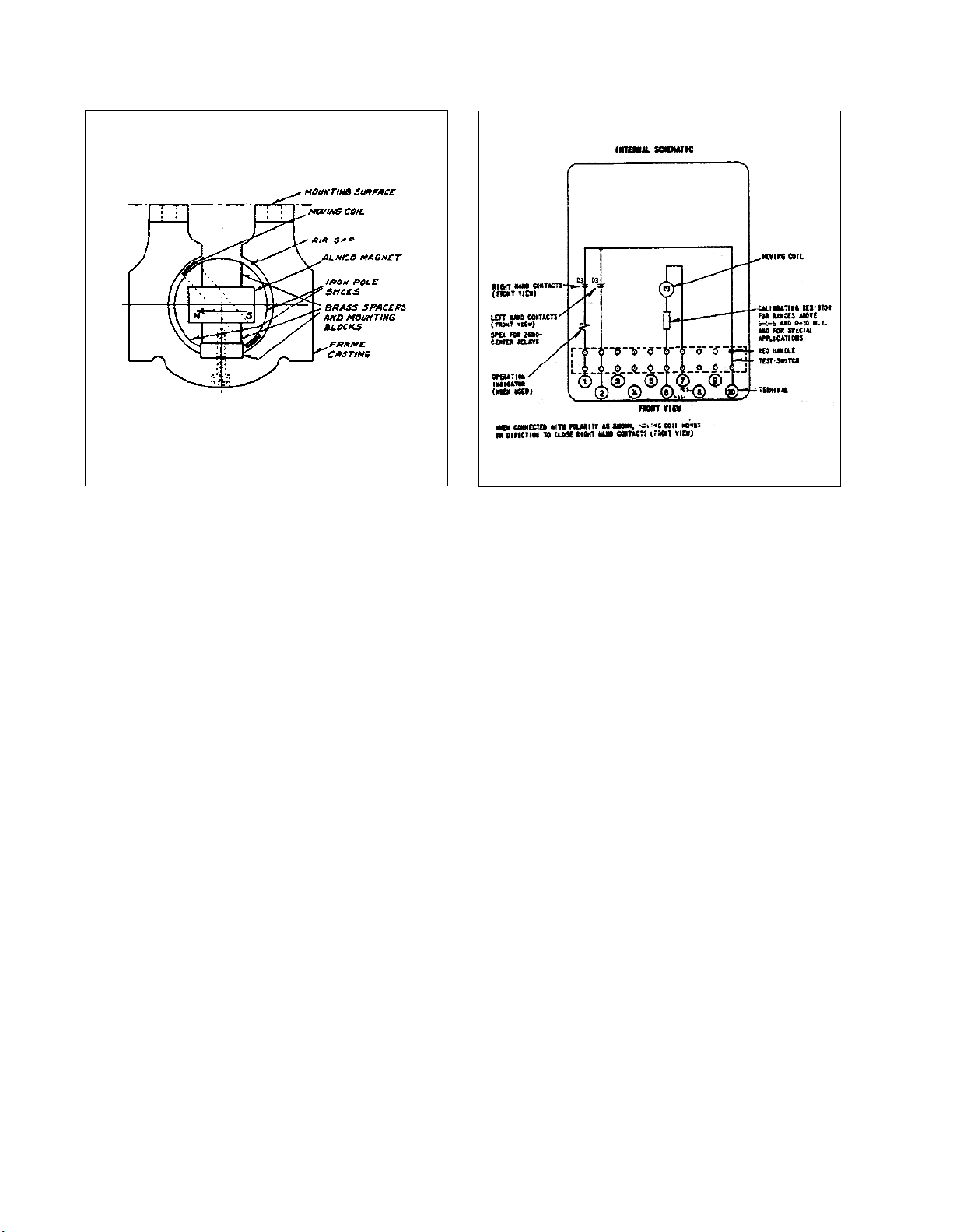

Figure 3: External Schematic Diagram for Overload or Re-

verse Current Protection, using the Type D-3 Relay.

MOVING COIL CIRCUIT

Ranges in

Millivolts, dc

Resistance in Ohms at 25°C

0-10

5-0-5

40-80

100-0-100

0-200

* Other ranges can also be supplied.

Average

0.3

0.3

1.2

6.0

6.0

As shown in the above Table, the D-3 relay is available with a “left zero,” “suppressed zero” and “center

zero” scale. In the “left zero” and the “suppressed

zero” relays the moving contact is located in the

extreme left hand position of the scale when the

relays are deenergized. The “suppressed zero” relay

is held in this position with considerable more force

than the “left zero” relay. When the relays are energized with voltages of the proper magnitude and

polarity, the moving contact moves to the right.

183A343

Figure 4: External Schematic Diagram for Overload Protec-

tion where Trip Currents in Excess of One Ampere

Rating Require Use of an Auxiliary Relay.

In the “center zero” relay, the moving contact is

located in the center of the scale when the relay is

deenergized. When the relay is energized, the contact will move either to the right or left depending

upon the polarity of the applied voltage.

A modification of the D-3 relay, in which a rectifier is

mounted internally, makes it suitable for ac operation. Full scale deflection can be obtained with 6 milliamperes ac Relays modified for AC volts can also be

supplied.

The relay has a slight time-delay, with inverse characteristics. In the usual application the moving coil

terminals are connected across a shunt, and this

results in longer delay for both operating and reset

times. When a shunt is used the operating time for

full scale travel at 125% of the full scale operating

current is about 4 seconds, while at 1000% it is about

.25 second. In applications where no shunt is used,

the operating times for the same conditions are about

1.25 and .15 second respectively. When the relay is

deenergized, the time required for it to reset from the

full scale position to the 10% position is approxi-

3

Page 4

41-151.1H Type D-3 Direct Current Relay

183A344

Figure 5: External Schematic Diagram for Use of External

Auxiliary Relay to Prevent Pumping of the Type D3 Relay when used for Overload Protection.

mately 5 seconds when a shunt is used, and 2 seconds when there is no shunt.

Continuous maximum overload is approximately

1500% of full scale.

The minimum setting which D-3 Relay can accommodate is 5% of the full scale.

5.0 SETTINGS

For reverse-current protection a sensitivity of 2 per

cent is obtained when using a standard 50 milli-volt

shunt and setting the relay at 1 millivolt. A 10 per

cent sensitivity is obtained by setting the relay at 5

millivolts. These values of sensitivity can be doubled

by using a 100 millivolt shunt.

For overload protection the relay is set at the index

setting which, with respect to the millivolt drop of the

shunt, will operate at desired per cent of overload.

182A785

Figure 6: Internal Schematic of the Type D-3 Relay in the

Type FT-21 Case with Self-Contained Auxiliary

Relay used to Prevent Pumping on Overload Protection.

5.1 TRIP CIRCUIT

Amperes contacts will:

(non-inductive load)

Contacts

D-3 relay

contactor switch

(when supplied)

dc control

voltage open close

125 V

250 V

125 V

250 V

0.04

0.02

3.5

1.0

1.0

1.0

3.0

3.0

carry

continuously

-------------

-------------

5.0

5.0

6.0 INSTALLATION

The relays should be mounted on switchboard panels or their equivalent in a location free from dirt,

moisture, excessive vibration, and heat. Mount the

relay vertically by means of the four mounting holes

on the flange for semi-flush mounting or by means of

the rear mounting stud or studs for projection mounting. Either a mounting stud or the mounting screws

may be utilized for grounding the relay. The electrical

4

Page 5

Type D-3 Direct Current Relay 41-151.1H

182A786

Figure 7: Internal Schematic of the Type D-3 in the Type

FT-21 Case with Two Self-Contained Auxiliary

Relays used to Increase Contact Capacity.

connections may be made directly to the terminals by

means of screws for steel panel mounting or to the

terminal studs furnished with the relay for thick panel

mounting. The terminal studs may be easily removed

or inserted by locking two nuts on the stud and then

turning the proper nut with a wrench.

For detailed FT. case information refer to Instruction

Leaflet 41-076.

Standard D-3 relays are calibrated in millivolts measured at the relay terminals. Hence, the resistance of

the leads between the relay and the ammeter shunt

must be sufficiently low to avoid introducing an

excessive error in the relay indication. With the 0-10

or 5-0-5 millivolt relays, leads 8 feet long of 910 B&S

gauge copper wire will reduce the relay indication by

approximately 5%. if the lead length is less or the

conductor size is larger, the error will be correspondingly reduced. Relays with higher millivolt ranges

have proportionally greater internal resistances, and

consequently error due to lead resistance is reduced.

For example, a 0-100 millivolt relay with leads as

described above would have an error of 0.5% due to

lead resistance.

182A788

Figure 8: Internal Schematic of the Type D-3 Relay in the

Type FT-21 Case, Modified for ac Operation.

basis of 1000 amp. per square inch, at .20°C, 6 feet

of copper bus-bar will give 50 millivolts drop.

7.0 ADJUSTMENTS AND MAINTENANCE

The proper adjustments to insure correct operations

have been made at the factory. Upon receipt of the

relay, no customer adjustments, other than those

covered under “SETTINGS” should be required.

7.1 ACCEPTANCE CHECK

Check the scale markings by setting either of the two

adjustable contacts at a value marked on the scale.

Then alternately apply this voltage plus and minus

3%. The contacts should make and break.

Remove the adjustable contact from the setting and

set the second adjustable contact at the same point

on the scale. Alternately -apply this voltage plus and

minus 3%. The contacts should make and break.

7.2 ROUTINE MAINTENANCE

The use of standard ammeter shunts may be

avoided by connecting the moving element leads

over an equivalent length of bus-bar or cable. On a

All contacts should be cleaned periodically. A contact

burnisher S#182A836H0I is recommended for this

purpose. The use of abrasive material for cleaning

5

Page 6

41-151.1H Type D-3 Direct Current Relay

contacts is not recommended because of the danger

of embedding small particles in the face of the soft

silver and thus impairing the contact.

If the moving element should be removed, the bearing end-play should be checked when replacing it.

This should be from .020 inch to .025 inch, and can

be measured by inserting a feeler gauge between the

upper bearing screw and the shoulder on the moving

element shaft.

The core and moving coil assembly should not be

removed from the frame casting of the D-3 relay

unless a keeper having the same radius on the core

is placed on the core in such manner as to bridge the

iron pole pieces as the core is withdrawn from the

bore of the casting. It is necessary also to insert

spacers in the air gap so that the core will remain

approximately centered when the mounting screws

are removed, to prevent damaging the coil winding

when sliding the assembly out of the casting.

7.3 AUXILIARY SWITCH (CS-1)

Adjust the stationary core of the switch for a clearance between the stationary core and the moving

core when the switch is picked up. This can be done

by turning the relay upside-down. Then screw up the

core screw until the moving core starts rotating. Now

back off the core screw until the moving core stops

rotating. This indicates the points when the play in

the assembly is taken up, and where the moving core

just separates from the stationary core screw. Back

off the core screw approximately one turn and lock in

place. This prevents the moving core from striking

and sticking to the stationary core because of residual magnetism. Adjust the contact clearance for

3/64” by means of the two small nuts on either side of

the Micarta disc.

Block main contacts closed and energize trip circuit

with rated voltage. Contacts of auxiliary switch

(CS-1) should make.

7.4 OPERATION INDICATOR

The operation indicator (when used) consists of a

small solenoid coil mounted in a steel frame, a spring

restrained armature and a white flag. The indicator is

reset by a push rod in the cover. Block the CS-1 auxiliary relay contacts closed and pass 0.2 amperes AC

or DC through the indicator. The white target should

fall into view.

The coil has a dc resistance of approximately 2.8

ohms and a continuous current carrying capacity of

0.6 amperes.

8.0 REPAIRS AND RENEWAL PARTS

Repair work can be done most satisfactorily at the

factory. However, interchangeable parts can be furnished to the customers who are equipped for doing

repair work. When ordering parts, always give the

complete nameplate data.

6

Page 7

Type D-3 Direct Current Relay 41-151.1H

Figure 9: Type D-3 Relay without case. 1- Moving Coil. 2 - Current-carrying restraining springs. 3- Permanent Magnet.

4- Iron-Frame. 5- Scale. 6- Moving Contact. 7- Stationary Contacts.

7

Page 8

Loading...

Loading...