Page 1

UL & CSA Technical data

1

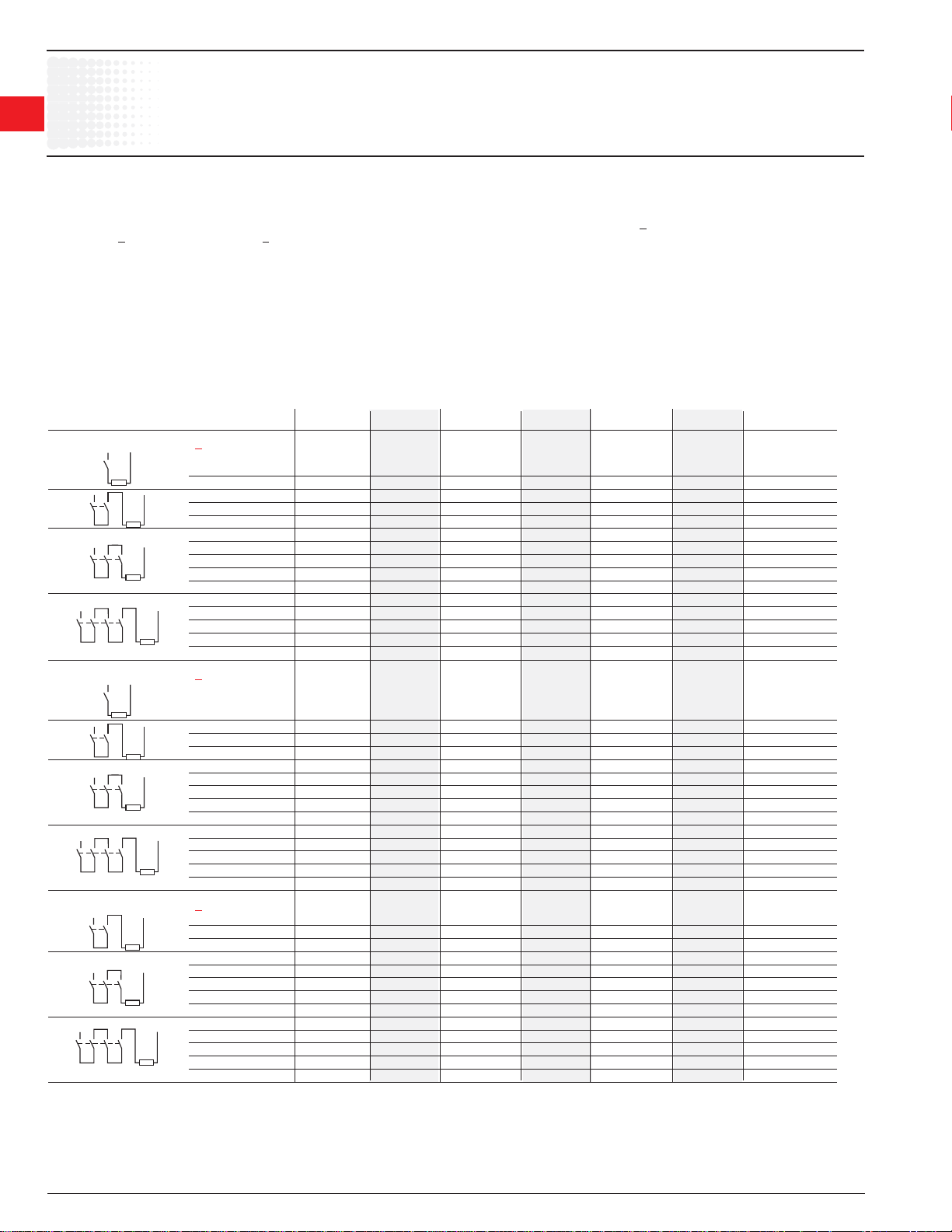

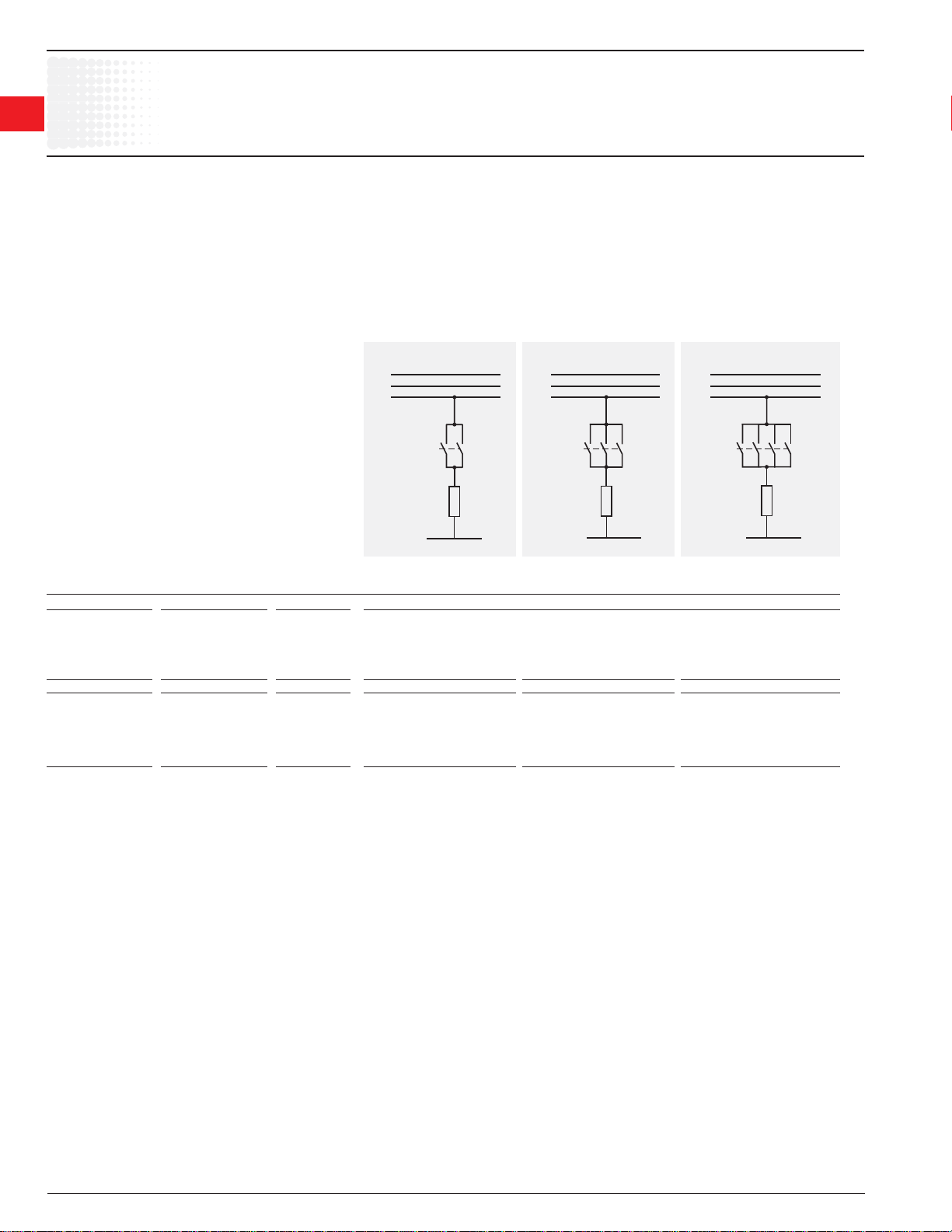

Across the line

1

contactors

ABB contactor frame size A/AE/AL A/AE/AL A/AE/AL A/AE/AL A/AE/AL A/AE/AL A/AE/AF A/AE/AF A/AE/AF A/AE/AF A/AE/AF A/AE/AF

9 12 16 26 30 40 45 50 63 75 95 110

NEMA size 00 — 0 1 1P — — 2 — 3 — —

Number of poles 3 OR 4 3 3 OR 4 3 OR 4 3 3 4 3 OR 4 3 3 OR 4 3 3

AC rating information

NEMA cont. amp rating thermal current 9 — 18 27 36 — — 45 — 90 — —

NEMA maximum H.P. ratings 1 phase

115 VAC 1/3 — 1 2 3 — — 3 — — — —

230 VAC 1 — 2 3 5 — — 7.5 — — — —

NEMA maximum H.P. ratings 3 phase

200 VAC 1.5 — 3 7.5 — — — 10 — 25 — —

230 VAC 1.5 — 3 7.5 — — — 15 — 30 — —

460/575 VAC 2 — 5 10 — — — 25 — 50 — —

U.L. general purpose current 40°C 21 25 30 40 50 60 65 80 90 105 125 140

Max. 3 Ph Switching motor loads A 9 11 17 28 34 42 — 54 65 80 95 110

U.L. maximum H.P. ratings 1 phase

115 VAC 1/2 3/4 1.5 2 3 3 — 3 5 7.5 7.5 10

230 VAC 2 2 3 5 7.5 7.5 — 7.5 10 15 20 25

U.L. maximum H.P. ratings 3 phase

200-208 VAC 2 3 5 7.5 10 10 — 15 20 25 30 30

220-240 VAC 2 3 5 10 10 15 — 20 25 30 30 40

440-480 VAC 5 7.5 10 20 25 30 — 40 50 60 60 75

550-600 VAC 7.5 10 15 25 30 40 — 50 60 75 75 100

U.L. maximum H.P. ratings

120 VDC 1 1.5 2 3 3 5 — 7.5 10 10 — —

240 VDC 2 3 3 5 7.5 10 — 15 20 25 — —

Lighting — ballast and incandescent 600VAC 15 15 20 1 35 50 60 65 65 85 105 120 —

Resistive heating applications 600VAC 15 15 20 35 50 60 65 65 85 105 — —

CSA Elevator ratings

220 – 240VAC 3 phase — — 5 — — 10 — 15 — 20 20 —

440 – 480VAC 3 phase — — 10 — — 20 — 30 — 30 40 —

550 – 600VAC 3 phase — — 10 — — 20 — 30 — 40 50 —

230VAC 1 phase — — 2 — — 5 — 7.5 — 10 10 —

Auxiliary contacts

NEMA rating AC A600 A600 A600 A600 A600 A600 — A600 A600 A600 A600 A600

AC rated voltage VAC 600 600 600 600 600 600 — 600 600 600 600 600

AC thermal rated current A 10 10 10 10 10 10 — 10 10 10 10 10

AC maximum volt-ampere making VA 7200 7200 7200 7200 7200 7200 — 7200 7200 7200 7200 7200

AC maximum volt-ampere breaking VA 720 720 720 720 720 720 — 720 720 720 720 720

NEMA rating DC P600 P600 P600 P600 P600 P600 — P600 P600 P600 P600 P600

DC rated voltage VDC 600 600 600 600 600 600 — 600 600 600 600 600

DC thermal rated current A 5 5 5 5 5 5 — 5 5 5 5 5

DC Maximum make-break A 0.2 0.2 0.2 0.2 0.2 0.2 — 0.2 0.2 0.2 0.2 0.2

Approximate weight

Contactor lbs. 0.7 0.7 0.7 1.01 1.2 2.25 2.25 2.25 2.25 2.25 3.5 5

Starter lbs. 1.04 1.04 1.04 1.35 1.54 3 — 3 3 3 6 7

Terminal wire range AWG 18-10 18-10 18-10 12-8 8-4 8-4 8-1 8-1 8-1 8-1 6-2/0 6-2/0

Number of wires per phase 2 2 2 2 2 2 1 1 1 1 1 1

Maximum short circuit ratings

MCCB,MCP, Amps/kA 480VAC 50/35 50/35 50/35 100/35 150/65 150/65 — 150/85 250/85 250/85 250/85 250/85

MCCB,MCP, Amps/kA 600VAC 10/35 10/35 10/35 100/35 150/25 150/25 — — — — 250/35 250/35

Fuse,Amps — type/kA 600VAC 30J/200 30J/200 30J/200 60J/200 60J/200 100J/200 — 100J/200 200J/200 200J/200 200J/200 200J/200

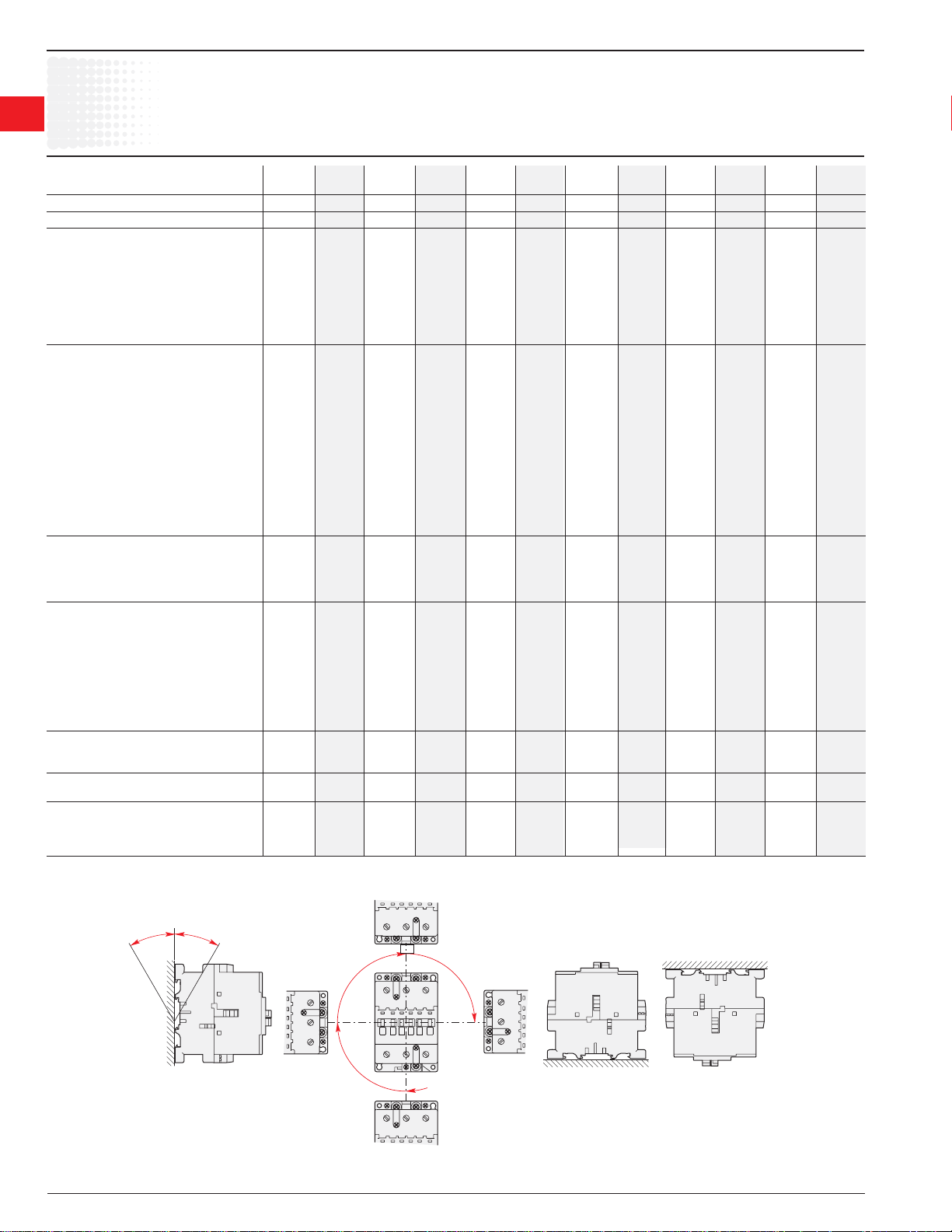

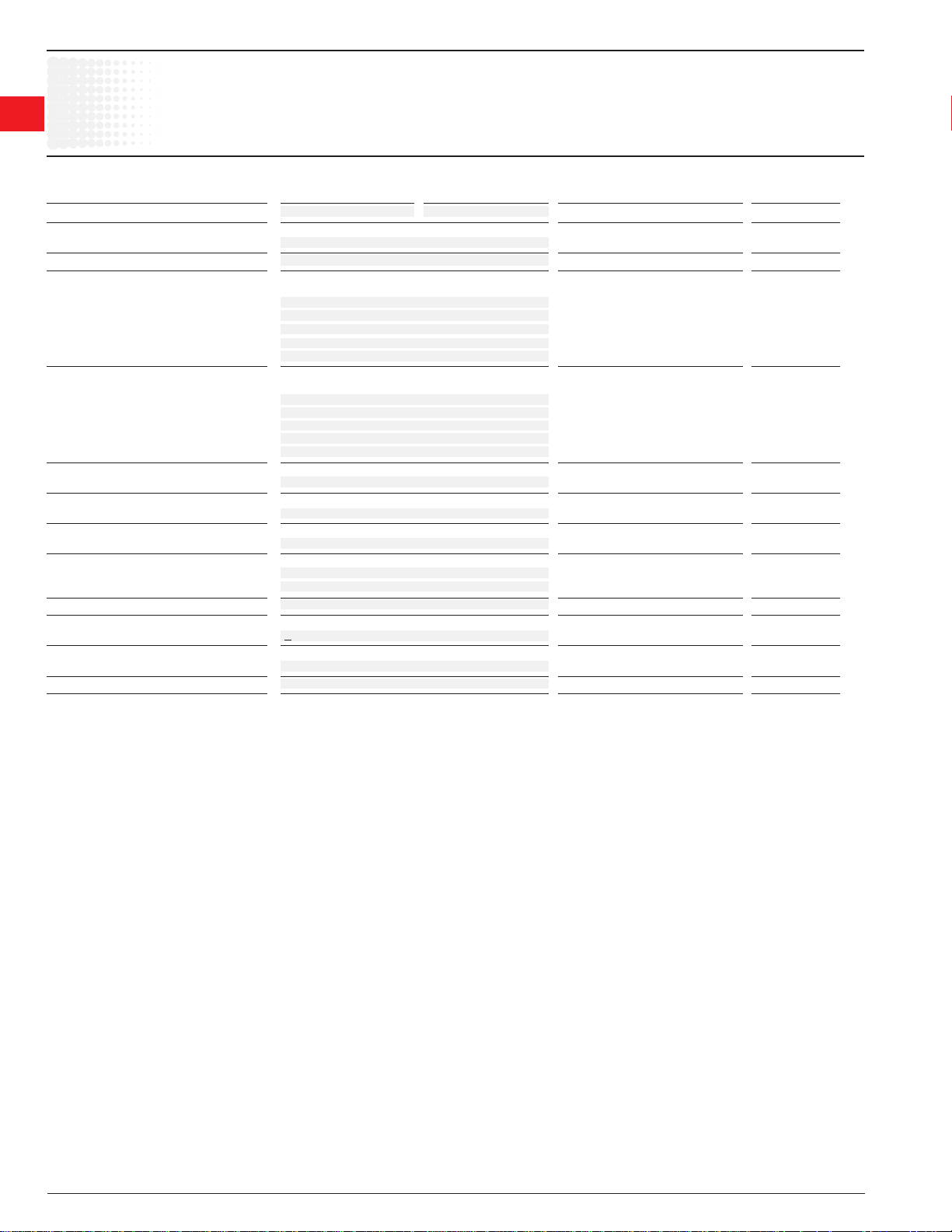

A/AE9 – A/AE/AF110, AL9 – AL40

AC & DC operated

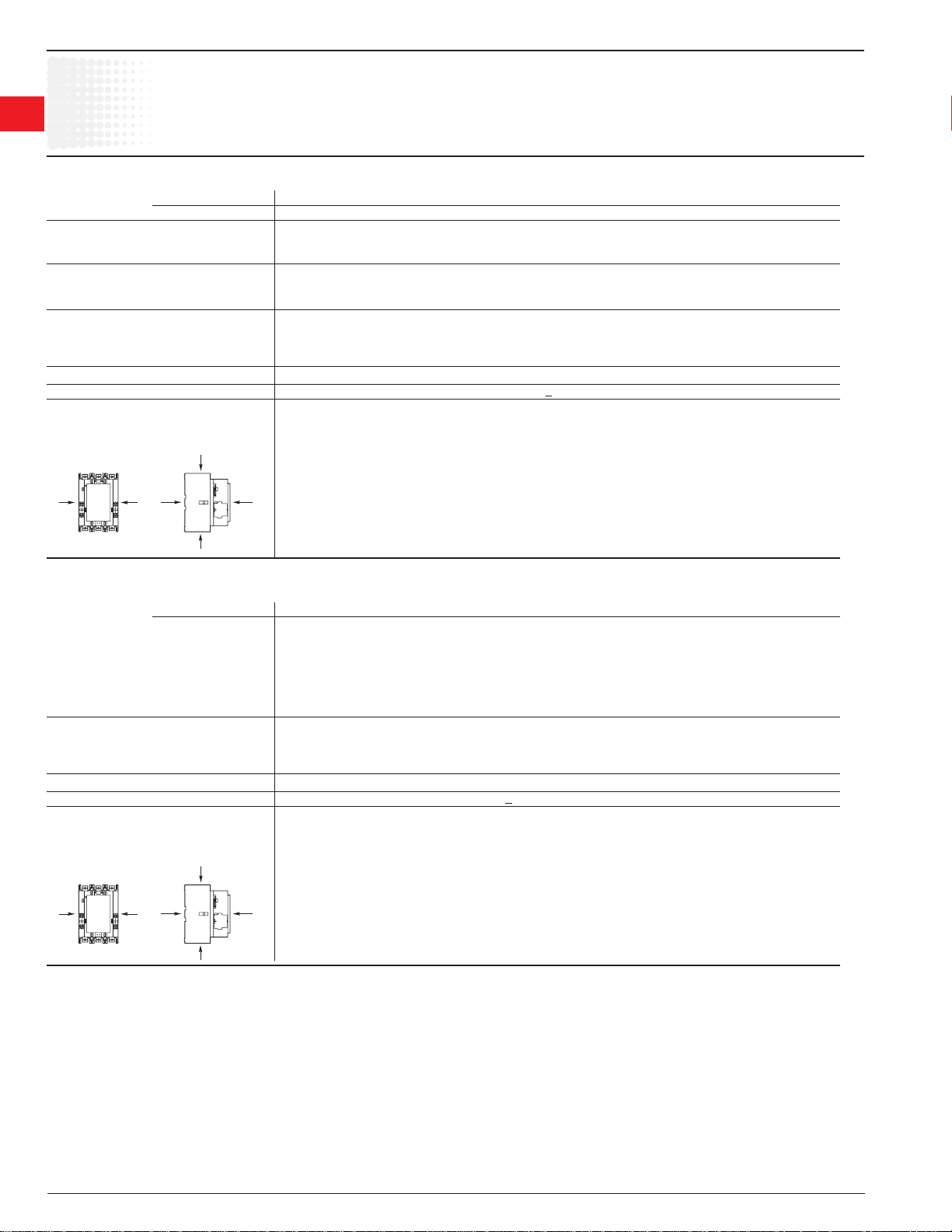

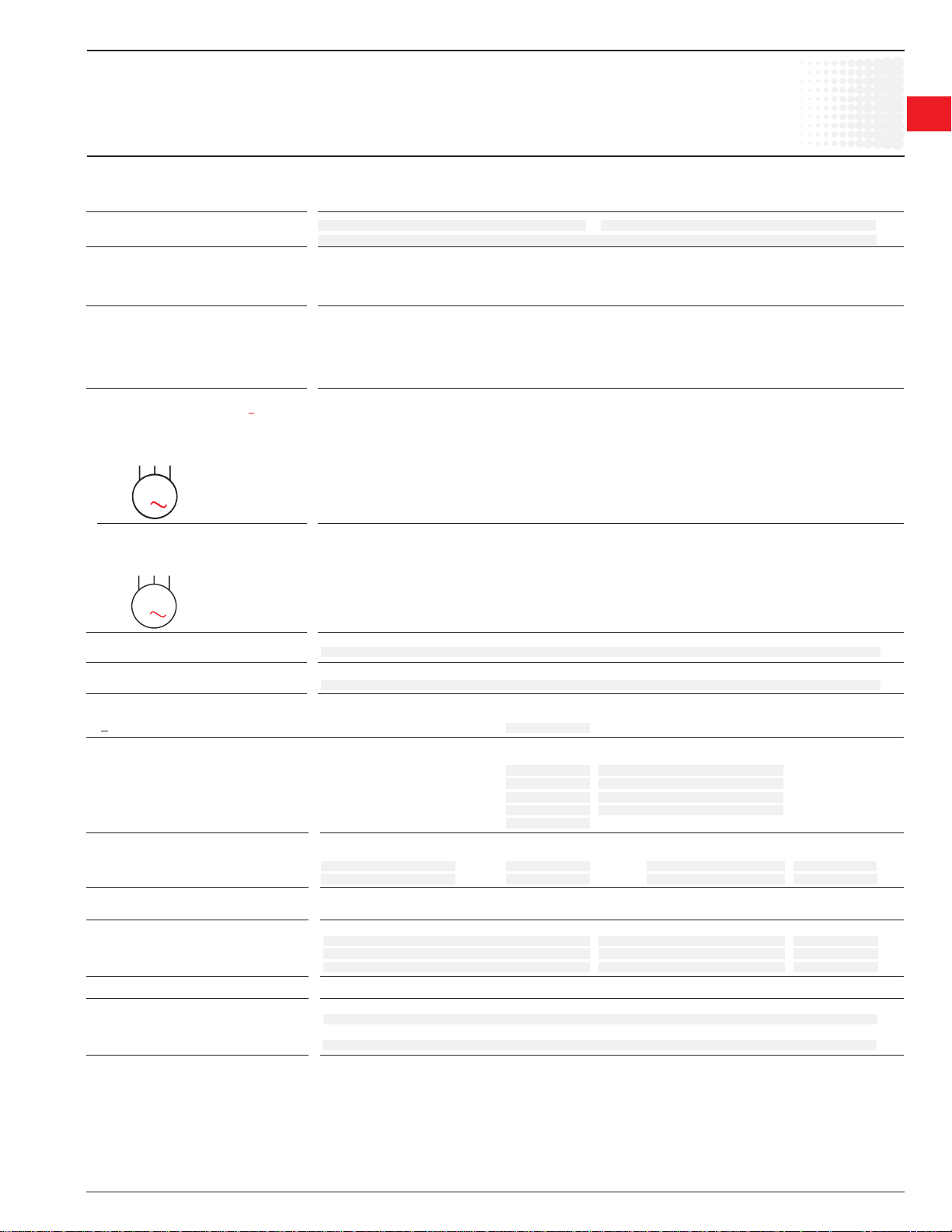

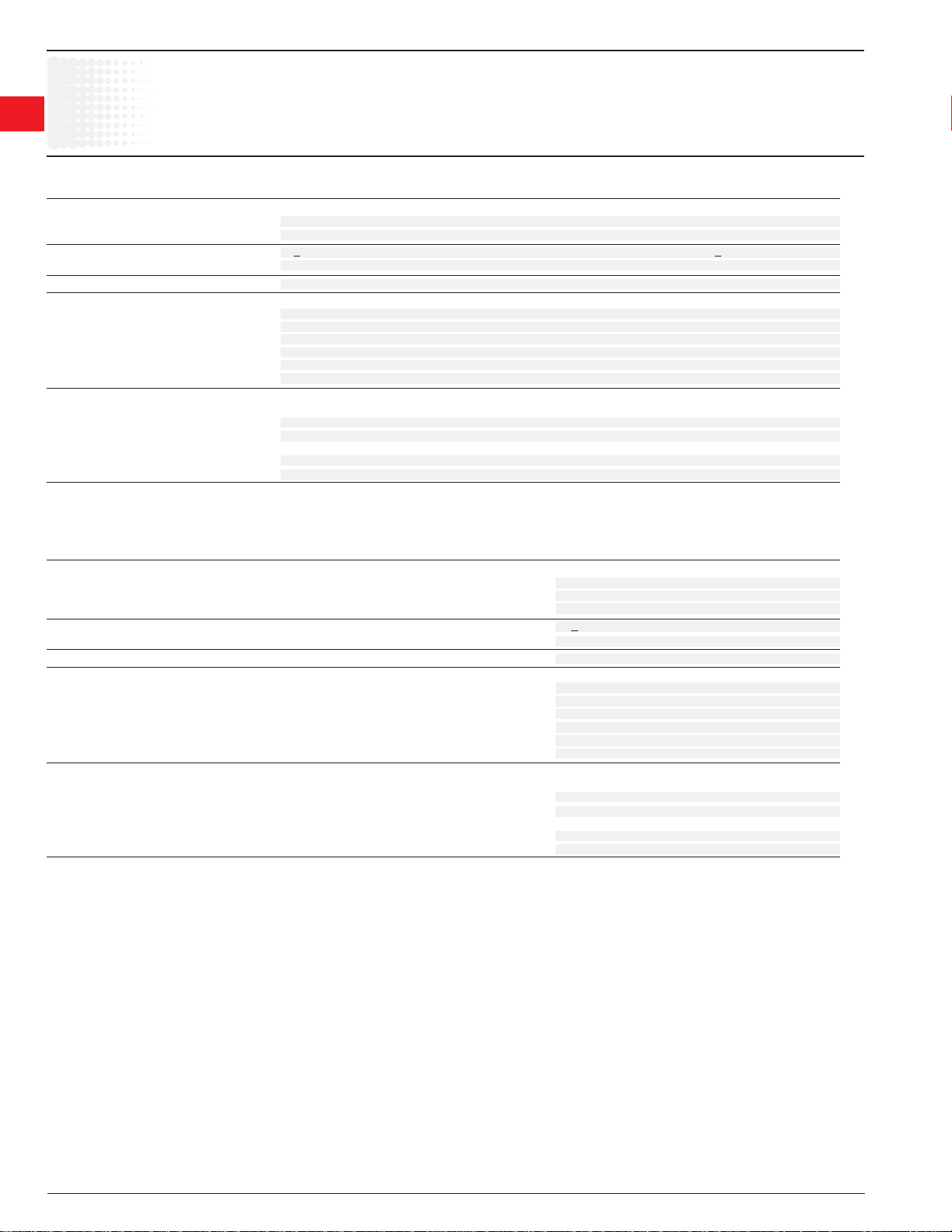

Mounting positions

Pos. 2

ABB

30°

1 30A Ballast

1.36 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

30°

Pos. 1 ± 30°

ABB

ABB

ABB

Pos. 1

ABB

Pos. 3Pos. 4

Pos. 5

Pos. 6

(AL unauthorized)

Page 2

Across the line

UL & CSA Technical data

contactors

A/AF145 – AF750

AC & DC operated

ABB contactor frame size A/AF A/AF A/AF A/AF A/AF AF AF AF AF

145 185 210 260 300 400 460 580 750

NEMA size 4 — — 5 — — 6 — 7

Number of poles 3 3 3 3 3 3 3 3 3

AC rating information

NEMA maximum H.P. ratings 3 phase

200 VAC 40 — — 75 — — 150 — —

230 VAC 50 — — 100 — — 200 — 300

460/575 V 100 — — 200 — — 400 — 600

U.L. general purpose current 40°C 230 250 300 350 400 550 650 750 900

Max. 3 Ph switching motor loads Amps 130 156 192 248 302 414 480 590 720

U.L. maximum H.P. ratings 1 phase

115 VAC 10 15 — — — — — — —

230 VAC 25 30 40 50 — — — — —

U.L. maximum H.P. ratings 3 phase

200—208 VAC 40 50 60 75 100 125 150 200 250

220—240 VAC 50 60 75 100 100 150 200 250 300

440—480 VAC 100 125 150 200 250 350 400 500 600

550—600 VAC 125 150 200 250 300 400 500 600 700

Lighting – ballast and incandescent 600VAC 200 — 300 — 400 — — — —

CSA Elevator ratings

220 – 240VAC 3 phase 40 50 60 — — — —

240 – 480VAC 3 phase Consult Consult 75 100 125 — — — —

550 - 600VAC 3 phase factory factory 100 125 150 — — — —

230VAC 1 phase — — — — — — —

Auxiliary contacts

NEMA rating AC A600 A600 A600 A600 A600 A600 A600 A600 A600

AC rated voltage VAC 600 600 600 600 600 600 600 600 600

AC thermal rated current A 10 10 10 10 10 10 10 10 10

AC maximum volt—ampere making VA 7200 7200 7200 7200 7200 7200 7200 7200 7200

AC maximum volt—ampere breaking VA 720 720 720 720 720 720 720 720 720

NEMA rating DC P600 P600 P600 P600 P600 P600 P600 P600 P600

DC rated voltage VDC 600 600 600 600 600 600 600 600 600

DC thermal rated current A 5 5 5 5 5 5 5 5 5

DC Maximum make—break A 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2

Approximate weight

Contactor lbs. 7.1 7.1 13 13 13 26 26 33 33

Starter lbs. 9.11 9.11 17.67 17.67 17.67 35 35 45 45

Terminal wire range

Number of wires per phase 1 1 1 1 2 2 2 2 3

Maximum short circuit ratings

MCCB,MCP,amps/kA 480VAC 400/85 400/85 800/85 800/85 800/85 800/80 800/80 1200/42 1200/42

MCCB,MCP,amps/kA 600VAC 400/35 400/35 800/35 800/35 800/35 800/42 800/42 — —

Fuse, amps—Type/kA 600VAC 400J/200 400J/200 600J/200 600J/200 600J/200 1000L/80 1000L/80 1200L/80 1200L/80

AWG 6-250MCM 6-250MCM 4-400MCM 4-400MCM 4-500MCM 250-500MCM 250-500MCM 2/0-500MCM 2/0-500MCM

1

1

Low Voltage Products & Systems 1.37

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 3

UL & CSA Technical data

1

Across the line

1

contactors

ABB contactor frame size AF AF

1350 1650

NEMA size — 8

Number of poles 3 3

AC rating information

NEMA maximum H.P. ratings 3 phase

200 VAC — —

230 VAC — 450

460/575 V — 900

U.L. general purpose current 40°C 1350 1650

Max. 3 Ph switching motor loads Amps 960 1080

U.L. maximum H.P. ratings 1 phase

115 VAC — —

230 VAC — —

U.L. maximum H.P. ratings 3 phase

200—208 VAC — —

220—240 VAC 400 450

440—480 VAC 800 900

550—600 VAC 900 1000

Auxiliary contacts

NEMA rating AC A600 A600

AC rated voltage VAC 600 600

AC thermal rated current A 10 10

AC maximum volt—ampere making VA 7200 7200

AC maximum volt—ampere breaking VA 720 720

NEMA rating DC P600 P600

DC rated voltage VDC 600 600

DC thermal rated current A 5 5

DC Maximum make—break A 0.2 0.2

Approximate weight

Contactor lbs. 75 75

Starter lbs. — —

Terminal wire range AWG 1/0-750 MCM 1/0-750 MCM

Number of wires per phase 4 6

Maximum short circuit ratings

MCCB,MCP,amps/kA 480VAC 2000/42 2000/42

MCCB,MCP,amps/kA 600VAC — —

Fuse, amps—Type/kA 600VAC 1600L/82 2000L/82

AF1350 – AF1650

AC & DC operated

1.38 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 4

Across the line

C

UL/CSA & IEC Technical data

contactors

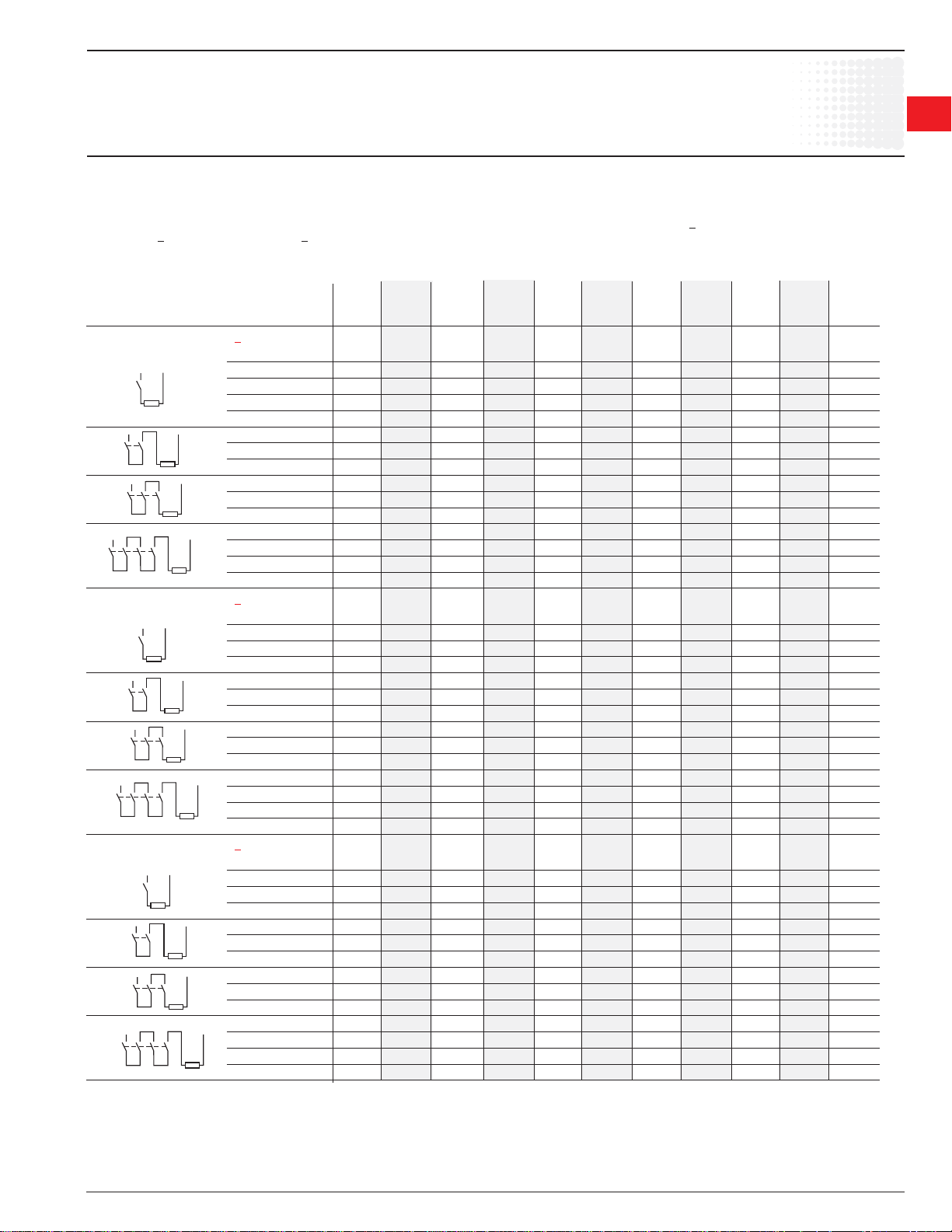

A/AE9 – A/AE/AF/TAE110

Contactor types: A..., AE... 9 12 16 26 30 40 45 50 63 75 95 110

AF..., TAE... – – – – – – 45 50 63 75 95 110

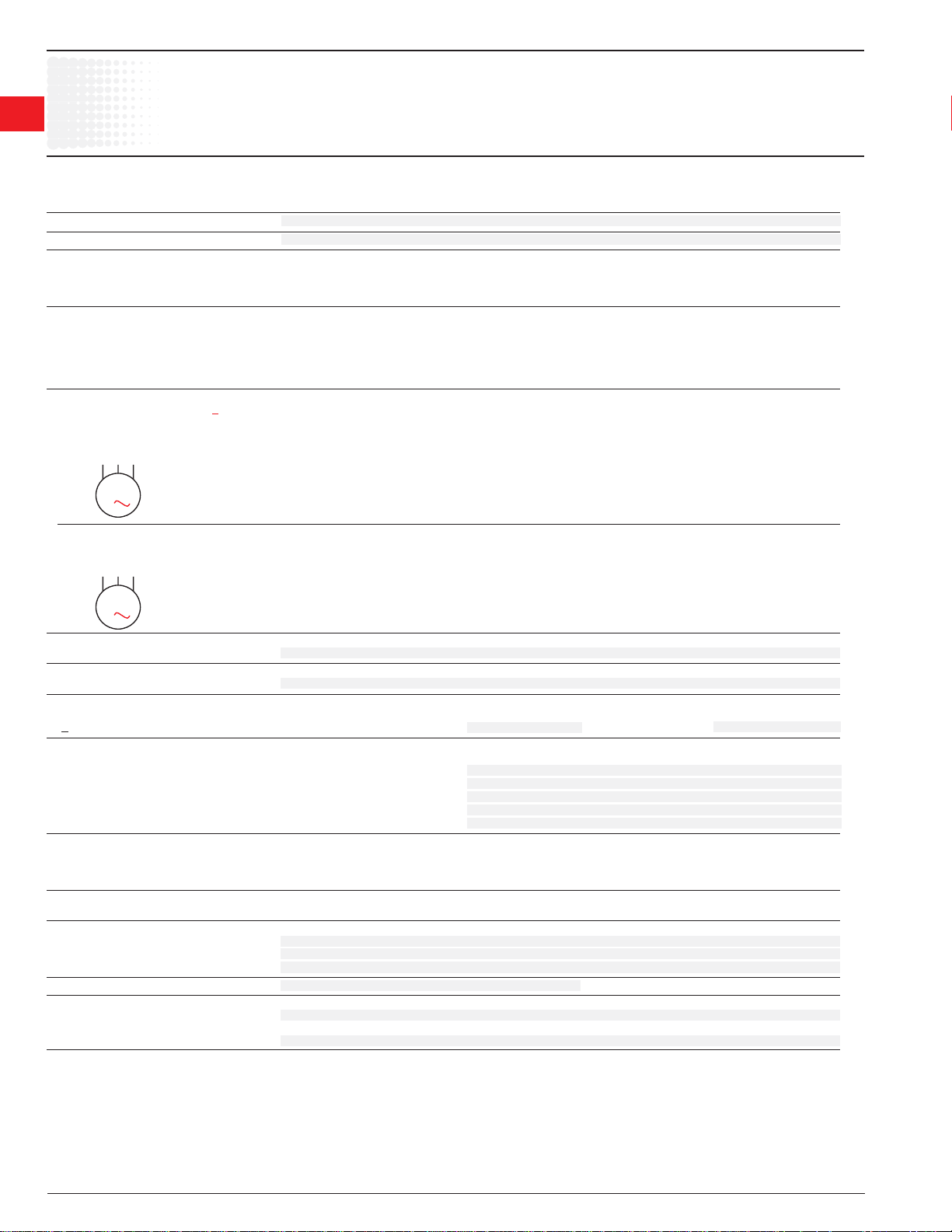

Rated insulation voltage U

according to IEC 60947-4-1 V 1000

according to UL/CSA V 600

Rated impulse withstand voltage U

Standards Devices complying with international standards IEC 60947-1 / 60947-4-1

and European standards EN 60947-1 / 60947-4-1

Air temperature close to contactor see "Conditions for use" page 1.50, for control voltage limits and authorized mounting positions

– fi tted with thermal O/L relay °C -25 to +55

– without thermal O/L relay °C -40 to +70 (55 max. for TAE... contactors)

– for storage °C -60 to +80 -40 to +70

Climatic withstand acc. to IEC 60068-2-30 and 60068-2-11 - UTE C 63-100 specifi cation II

30

Operating altitude m < 3000

Shock withstand

acc. IEC 60068-2-27 and EN 60068-2-27

Mounting position 1 (see page 1.50) 1/2 sinusoidal shock for 11 ms: no change in contact position

Shock direction Making position Breaking position

A 20 g 20 g

B1 10 g 5 g 1

B2 15 g 2 15 g 2

A

C1 20 g 20 g

C2 20 g 20 g

i

kV 8

imp.

acc. to IEC 68-2-

C1

B1

A

B2

2

mounting

Not valid for DIN-rail

1

1

1 3 g for AF 45-22, AE 45-22, AF 75-22 and AE 75-22.

2 10 g for AF 45-22, AE 45-22, AF 75-22 and AE 75-22.

Low Voltage Products & Systems 1.39

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 5

UL/CSA & IEC Technical data

1

Across the line

1

contactors

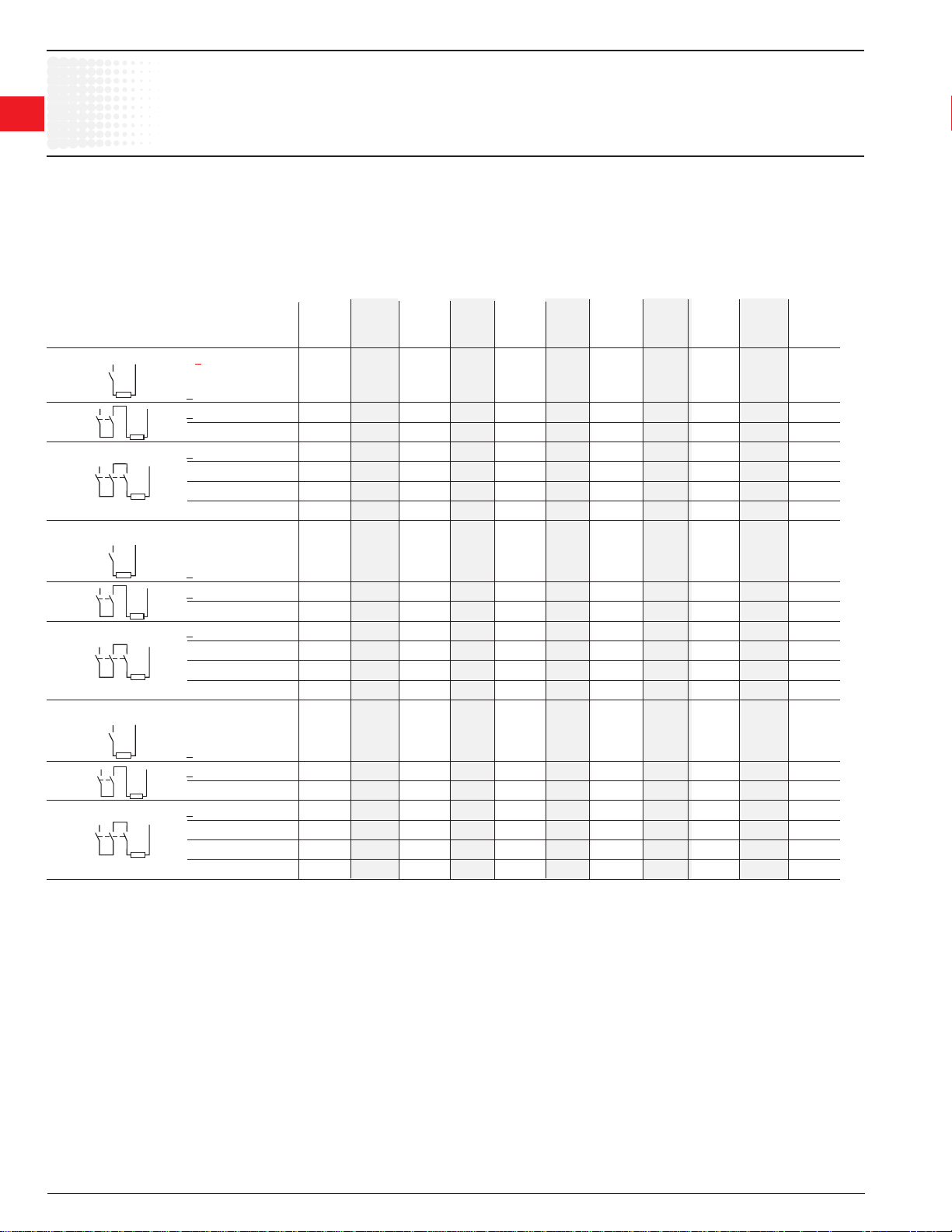

A/AF145 – AF750

Contactor types: A... 145 185 210 260 300 – – – –

AF... 145 185 210 260 300 400 460 580 750

Rated insulation voltage Ui

according to IEC 60947-4-1 V 1000

according to UL/CSA V600

Rated impulse withstand voltage U

Standards Devices complying with international standards IEC 60947-1 / 60947-4-1

and European standards EN 60947-1 / 60947-4-1

Air temperature close to contactor see "Conditions for use" page 1.51 , for control voltage limits and authorized mounting positions

– fi tted with thermal O/L relay °C -25 to +55

– without thermal O/L relay °C -40 to +70

– for storage °C -40 to +70

Climatic withstand acc. to IEC 60068-2-30

Operating altitude m < 3000

Shock withstand

acc. IEC 60068-2-27 and EN 60068-2-27

Mounting position 1 (

5 g in all directions (A, B1, B2, C1, C2)

see

imp.

page 1.51) 1/2 sinusoidal shock for 30 ms: no change in contact position

A/AF145 – AF1650

kV 8

C1

ABB

A

B1

A

B2

C2

AF1350 – AF1650

Contactor types: AF... 1350 1650

Rated insulation voltage Ui

according to IEC 60947-4-1 1000

according to UL/CSA V 600

Rated impulse withstand voltage U

Standards Devices complying with international standards IEC 60947-1 / 60947-4-1

and European standards EN 60947-1 / 60947-4-1

Air temperature close to contactor see "Conditions for use" page 1.51 , for control voltage limits and authorized mounting positions

– fi tted with thermal O/L relay °C-25 to +55

– without thermal O/L relay °C-40 to +70

– for storage °C-40 to +70

Climatic withstand acc. to IEC 60068-2-30

Operating altitude m < 3000

Shock withstand

acc. IEC 60068-2-27 and EN 60068-2-27

Mounting position 1 (See page 1.51) 1/2 sinusoidal shock for 30 ms: no change in contact position

5 g in all directions (A, B1, B2, C1, C2)

ABB

A

A

imp.

B1

kV 8

C1

B2

C2

1.40 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 6

Across the line

IEC Technical data

contactors

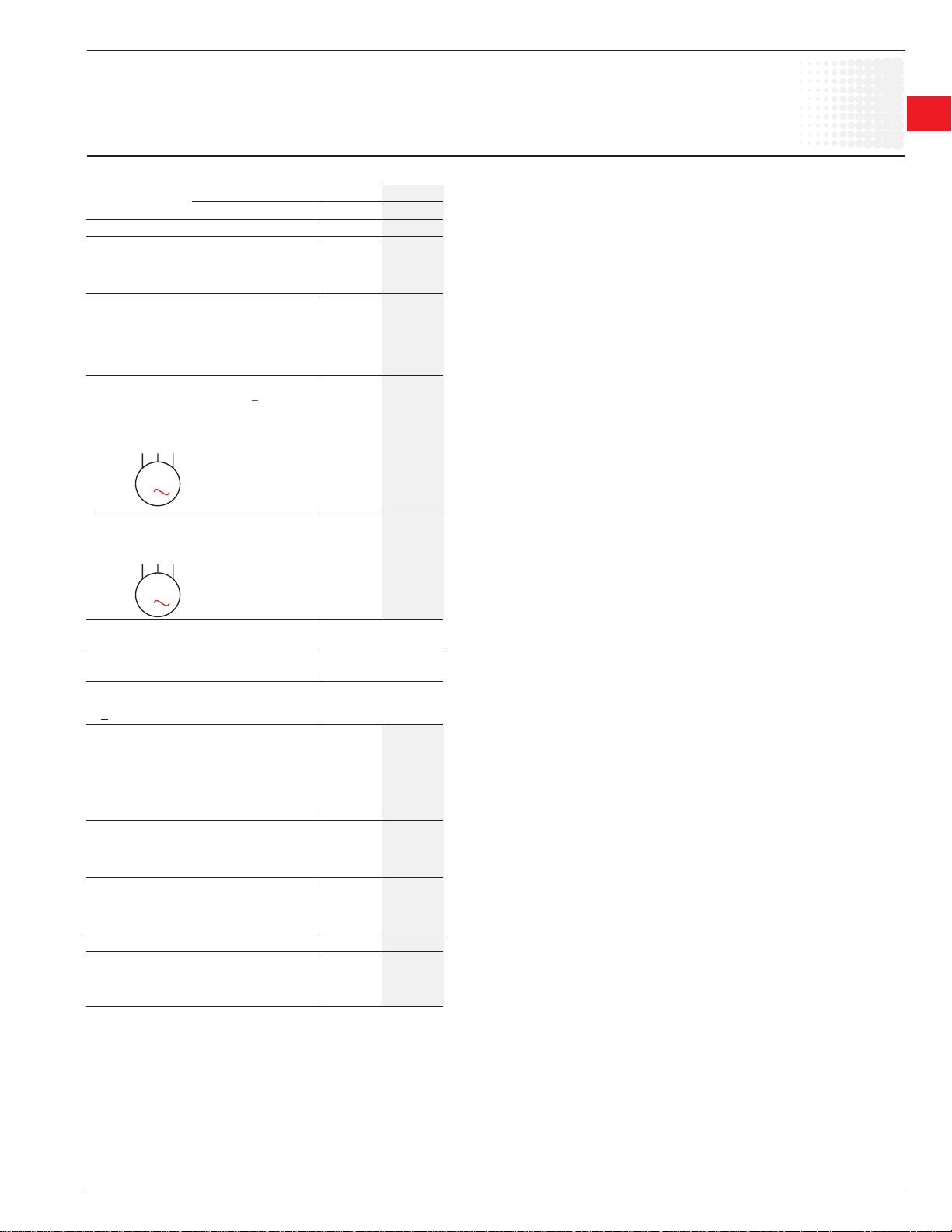

DC circuit switching

A/AE9 – GAE75

General

The arc switching on d.c. is more diffi cult than on a.c.

• For selecting a contactor it is essential to determine the current, the voltage and the L/R time constant of the controlled load.

• For information, typical time constant values are quoted hereafter: non inductive loads such as resistance furnaces (L/R ~ 1 ms), inductive loads such as shunt

motors (L/R ~ 2 ms) or series motors (L/R ~ 7.5 ms).

• The addition of a resistor in parallel with an inductive winding helps in the elimination of the arcs.

• All the poles required for breaking must be connected in series between the load and the source polarity not linked to earth (or chassis).

a.c. operated contactors A9 A12 A16 A26 A30 A40 A45 A50 A63 A75 GA75

a.c. / d.c. operated (electronic coil interface) – – – – – – AF45 AF50 AF63 AF75 –

d.c. operated contactors AE9 AE12 AE16 AE26 AE30 AE40 AE45 AE50 AE63 AE75 GAE75

Utilization category DC-1, L/R < 1 ms

≤ 72 V A 25 27 30 45 55 60 70 100 110 120 120

110 V A 10 15 20 – – – – – – – 120

220 V A – – – – – – – – – – 120

440 V A – – – – – – – – – – 100

600 V A – – – – – – – – – – 75

≤ 72 V A 25 27 30 45 55 60 70 100 110 120 –

110 V A 25 27 30 45 55 60 70 100 110 120 –

220 V A 10 15 20 – – – – – – – –

≤ 72 V A 25 27 30 45 55 60 70 100 110 120 –

110 V A 25 27 30 45 55 60 70 100 110 120 –

220 V A 25 27 30 45 55 60 70 100 110 120 –

≤ 72 V A 25 27 30 45 – – 70 100 – 120 –

110 V A 25 27 30 45 – – 70 100 – 120 –

220 V A 25 27 30 45 – – 70 100 – 120 –

440 V A 10 15 20 – – – – – – – –

Utilization category DC-3, L/R < 2 ms

≤ 72 V A 25 27 30 45 55 60 70 100 110 120 120

110 V A 6 7 8 – – – – – – – 120

220 V A – – – – – – – – – – 100

440 V A – – – – – – – – – – 85

≤ 72 V A 25 27 30 45 55 60 70 100 110 120 –

110 V A 25 27 30 45 55 60 70 100 110 120 –

220 V A 6 7 8 – – – – – – – –

≤ 72 V A 25 27 30 45 55 60 70 100 110 120 –

110 V A 25 27 30 45 55 60 70 100 110 120 –

220 V A 25 27 30 45 55 60 70 100 110 120 –

≤ 72 V A 25 27 30 45 – – 70 100 – 120 –

110 V A 25 27 30 45 – – 70 100 – 120 –

220 V A 25 27 30 45 – – 70 100 – 120 –

440 V A 6 7 8 – – – – – – – –

Utilization category DC-5, L/R < 7.5 ms

≤ 72 V A 9 12 16 25 30 40 50 50 63 75 85

110 V A 4 4 4 – – – – – – – 85

220 V A – – – – – – – – – – 85

440 V A – – – – – – – – – – 35

≤ 72 V A 25 27 30 45 55 60 70 100 110 120 –

110 V A 10 15 20 30 45 50 70 80 90 100 –

220 V A 4 4 4 – – – – – – – –

≤ 72 V A 25 27 30 45 55 60 70 100 110 120 –

110 V A 25 27 30 45 55 60 70 100 110 120 –

220 V A 9 12 16 25 30 40 50 50 63 75 –

≤ 72 V A 25 27 30 45 – – 70 100 – 120 –

110 V A 25 27 30 45 – – 70 100 – 120 –

220 V A 10 15 20 30 – – 70 70 – 100 –

440 V A 4 4 4 – – – – – – – –

1

1

Low Voltage Products & Systems 1.41

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 7

IEC Technical data

1

Across the line

1

contactors

Technical Data

• The tables indicate for the standard contactors the Ie max. operating currents depending on: the utilization category (i.e. L/R) DC-1, DC-3, DC-5 as defi ned in the

IEC 60947-4-1 publication, the operating voltage Ue and the pole coupling details. See page 1.81.

Ampere values quoted in the tables below are valid for a -25 … +70 °C temperature close to the contactors, as long as the AC-1 Ampere values (see pages 1.45

- 146) for the corresponding ambient temperature are not exceeded.

• Max. switching frequency: 300 ops/h.

• For switching higher d.c. ratings, we recommend the use of bar mounted contactors, R series (63 … 2000 A).

The selection table for AE 50 ... AE 110 contactors can be used for the TAE 50 ... TAE 110 types.

a.c. operated contactors A95 A110 A145 A185 A210 A260 A300 – – – –

a.c. / d.c. operated (electronic coil interface) AF95 AF110 AF145 AF185 AF210 AF260 AF300 AF400 AF460 AF580 AF750

d.c. operated contactors AE95 AE110 – – – – – – – – –

Utilization category DC-1, L/R < 1 ms

DC circuit switching

A/AF/AE95 – AF750

<110 V A 145 160 250 275 350 400 450 600 700 800 1050

220 V A – – – – – – – 600 700 800 1050

<110 V A 145 160 250 275 350 400 450 600 700 800 1050

220 V A 145 160 250 275 350 400 450 600 700 800 1050

440 V A – – – – – – – 600 700 800 1050

600 V A – – – – – – – 600 700 800 1050

Utilization category DC-3, L/R ≤ 2.5 ms

<110 V A 145 160 250 275 350 400 450 600 700 800 1050

220 V A – – – – – – – 600 700 800 1050

<110 V A 145 160 250 275 350 400 450 600 700 800 1050

220 V A 145 160 250 275 350 400 450 600 700 800 1050

440 V A – – – – – – – 600 700 800 1050

600 V A – – – – – – – 600 700 800 1050

Utilization category DC-5, L/R ≤ 15 ms

<110 V A 145 160 250 275 350 400 450 600 700 800 1050

220 V A – – – – – – – 600 700 800 1050

<110 V A 145 160 250 275 350 400 450 600 700 800 1050

220 V A 145 160 250 275 350 400 450 600 700 800 1050

440 V A – – – – – – – 600 700 800 1050

600 V A – – – – – – – 600 700 800 1050

<110 V A – – – – – – – 600 700 800 1050

<110 V A – – – – – – – 600 700 800 1050

<110 V A – – – – – – – 600 700 800 1050

1.42 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 8

Across the line

IEC Technical data

contactors

DC circuit switching

AL9 — AL40

General

The arc switching on d.c. is more diffi cult than on a.c.

• For selecting a contactor it is essential to determine the current, the voltage and the L/R time constant of the controlled load.

• For information, typical time constant values are quoted hereafter: non inductive loads such as resistance furnaces (L/R ~ 1 ms), inductive loads such as shunt

motors (L/R ~ 2 ms) or series motors (L/R ~ 7.5 ms).

• The addition of a resistor in parallel with an inductive winding helps in the elimination of the arcs.

• All the poles required for breaking must be connected in series between the load and the source polarity not linked to earth (or chassis).

A.C. operated contactors AL9 AL12 AL16 AL26 AL30 AL40

Utilization category DC-1, L/R < 1 ms

≤ 72 V A 25 27 30 45 55 60

110 V A 10 15 20 – – –

220 V A – – – – – –

440 V A – – – – – –

600 V A – – – – – –

≤ 72 V A 25 27 30 45 55 60

110 V A 25 27 30 45 55 60

220 V A 10 15 20 – – –

≤ 72 V A 25 27 30 45 55 60

110 V A 25 27 30 45 55 60

220 V A 25 27 30 45 55 60

≤ 72 V A 25 27 30 45 – –

110 V A 25 27 30 45 – –

220 V A 25 27 30 45 – –

440 V A 10 15 20 – – –

Utilization category DC-3, L/R < 2 ms

≤ 72 V A 25 27 30 45 55 60

110 V A 6 7 8 – – –

220 V A – – – – – –

440 V A – – – – – –

≤ 72 V A 25 27 30 45 55 60

110 V A 25 27 30 45 55 60

220 V A 6 7 8 – – –

≤ 72 V A 25 27 30 45 55 60

110 V A 25 27 30 45 55 60

220 V A 25 27 30 45 55 60

≤ 72 V A 25 27 30 45 – –

110 V A 25 27 30 45 – –

220 V A 25 27 30 45 – –

440 V A 6 7 8 – – –

Utilization category DC-5, L/R < 7.5 ms

≤ 72 V A 9 12 16 25 30 40

110 V A 4 4 4 – – –

220 V A – – – – – –

440 V A – – – – – –

≤ 72 V A 25 27 30 45 55 60

110 V A 10 15 20 30 45 50

220 V A 4 4 4 – – –

≤ 72 V A 25 27 30 45 55 60

110 V A 25 27 30 45 55 60

220 V A 9 12 16 25 30 40

≤ 72 V A 25 27 30 45 – –

110 V A 25 27 30 45 – –

220 V A 10 15 20 30 – –

440 V A 4 4 4 – – –

1

1

Low Voltage Products & Systems 1.43

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 9

IEC Technical data

1

Across the line

1

contactors

General

The arc switching on d.c. is more diffi cult than on a.c.

• For selecting a contactor it is essential to determine the current, the voltage and the L/R time constant of the controlled load.

• For information, typical time constant values are quoted hereafter: non inductive loads such as resistance furnaces (L/R ~ 1 ms), inductive loads such as shunt

motors (L/R ~ 2 ms) or series motors (L/R ~ 7.5 ms).

• The addition of a resistor in parallel with an inductive winding helps in the elimination of the arcs.

• All the poles required for breaking must be connected in series between the load and the source polarity not linked to earth (or chassis).

Technical Data

• The tables indicate for the standard contactors the Ie max. operating currents depending on: the utilization category (i.e. L/R) DC-1, DC-3, DC-5 as defi ned in the

IEC 60947-4-1 publication (see page 1.75 for more details), the operating voltage Ue and the pole coupling details.

Ampere values quoted in the tables below are valid for a -25 … +70 °C temperature close to the contactors, as long as the AC-1 Ampere values (see page 1.61)

for the corresponding ambient temperature are not exceeded.

• Max. switching frequency: 300 ops/h.

• For switching higher d.c. ratings, we recommend the use of bar mounted contactors, R series (63 … 2000 A).

Selection Table

a.c. / d.c. operated contactors EK110 EK150 EK175 EK210 EK370 EK550 EK1000

Utilization category DC-1, L/R < 1 ms

≤ 72 V A 120 145 210 210 370 550 –

110 V A 120 145 210 210 370 550 –

≤ 72 V A 200 200 300 300 550 800 –

110 V A 200 200 300 300 550 800 –

220 V A 200 200 300 300 550 800 –

≤ 72 V A 200 200 300 300 550 800 –

110 V A 200 200 300 300 550 800 –

220 V A 200 200 300 300 550 800 –

440 V A – – 210 210 450 650 –

600 V A – – – – 450 650 –

≤ 72 V A 200 200 300 300 550 800 –

110 V A 200 200 300 300 550 800 –

220 V A 200 200 300 300 550 800 –

440 V A 200 200 260 300 450 650 –

600 V A – – 260 300 450 650 –

Utilization category DC-3, L/R < 2 ms

DC circuit switching

EK110 — EK1000

≤ 72 V A 120 145 210 210 370 550 –

≤ 72 V A 135 145 210 210 450 650 –

110 V A 135 135 210 210 450 650 –

220 V A 135 135 210 210 450 650 –

≤ 72 V A 135 145 210 210 450 650 –

110 V A 135 135 210 210 450 650 –

220 V A 135 135 210 210 450 650 –

440 V A – – 210 210 450 650 –

600 V A – – – – 450 650 –

≤ 72 V A 135 145 210 210 450 650 –

110 V A 135 135 210 210 450 650 –

220 V A 135 135 210 210 450 650 –

440 V A 135 135 210 210 450 650 –

600 V A – – 170 210 450 650 –

Utilization category DC-5, L/R < 7.5 ms

≤ 72 V A 135 145 210 210 450 650 –

110 V A 135 135 210 210 450 650 –

220 V A 135 135 210 210 450 650 –

≤ 72 V A 135 145 210 210 450 650 –

110 V A 135 135 210 210 450 650 –

220 V A 135 135 210 210 450 650 –

440 V A – – 210 210 450 650 –

600 V A – – – – 450 650 –

≤ 72 V A 135 145 210 210 450 650 –

110 V A 135 135 210 210 450 650 –

220 V A 135 135 210 210 450 650 –

440 V A 135 135 210 210 450 650 –

600 V A – – 170 210 450 650 –

1.44 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 10

Across the line

IEC Technical data

contactors

A/AE9 — A/AE/AF/TAE110

1

Main Pole - Utilization Characteristics

Contactor types: A..., AE... 9 12 16 26 30 40 45 50 63 75 95 110

AF..., TAE... – – – – – – 45 50 63 75 95 110

Rated operational voltage Ue max. V 690 1000 (690 for AF... contactors)

Rated frequency limits Hz 25-400

Conventional free-air thermal current Ith

acc. to IEC 60947-4-1,

open contactors ø ≤ 40 °C A 26 28 30 45 65 65 100 100 125 125 145 160

with conductor cross-sectional area mm2 4 4 4 6 16 16 35 35 50 50 50 70

Rated operational current I

for air temperature close to contactor

ø ≤ 40 °C A 25 27 30 45 55 60 70 100 115 125 145 160

Ue max. 690 V ø ≤ 55 °C A 22 25 27 40 55 60 60 85 95 105 135 145

ø ≤ 70 °C 3 A 18 20 23 32 39 42 50 70 80 85 115 130

with conductor cross-sectional area mm2 2.5 4 4 6 10 16 25 35 50 50 50 70

Utilization categorie AC-3

for air temperature close to contactor < 55 °C

Rated operational current Ie AC-3 1

220-230-240 V A 9 12 17 26 33 40 40 53 65 75 96 110

3-phase motors 380-400 V A 9 12 17 26 32 37 37 50 65 75 96 110

415 V A 9 12 17 26 32 37 37 50 65 72 96 110

440 V A 9 12 16 26 32 37 37 45 65 70 93 100

500 V A 9 12 14 22 28 33 33 45 55 65 80 100

690 V A 7 9 10 17 21 25 25 35 43 46 65 82

1000 V A – – – – – – – 23 2 25 2 28 2 30 2 30 2

Rated operational power AC-3 1

1500 r.p.m. 50 Hz

1800 r.p.m. 60 Hz

3-phase motors 415 V kW 4 5.5 9 11 15 18.5 18.5 25 37 40 55 59

440 V kW 4 5.5 9 15 18.5 22 22 25 37 40 55 59

500 V kW 5.5 7.5 9 15 18.5 22 22 30 37 45 55 59

690 V kW 5.5 7.5 9 15 18.5 22 22 30 37 40 55 75

1000 V kW – – – – – – – 30 2 33 2 37 2 40 2 40 2

Rated making capacity AC-3

according to IEC 60947-4-1 10 x I

Rated breaking capacity AC-3

according to IEC 60947-4-1 8 x I

Short-circuit protection for contactors

without thermal O/L relay - Motor protection excluded

Ue < 500 V a.c. - gG type fuse A 25 32 32 50 63 80 100 125 160 160 200

Rated short-time withstand current I

at 40 °C ambient temp., in free air,

from a cold state 1 s A 250 280 300 400 600 1000 1320 1320

10 s A 100 120 140 210 400 650 800 800

30 s A 60 70 80 110 225 370 500 500

1 min A 50 55 60 90 150 250 350 350

15 min A 26 28 30 45 65 110 110 135 135 160 175

Maximum breaking capacity

cos ø = 0.45 (cos ø = 0.35 for I

at 440 V A 250 420 820 900 1300 1160

at 690 V A 90 170 340 490 630 800

Heat dissipation per pole

I

Max. electrical switching frequency

– for AC-1 cycles/h 600 600 (300 for AF..., AE... TAE...) 300

– for AC-3 cycles/h 1200 (600 for AE...) 600 (300 for AF..., AE... TAE...) 300

– for AC-2, AC-4 cycles/h 300 150 150

Electrical durability see pages 1.70 - 1.73

Mechanical durability

– millions of operating cycles 10 (5 for AE... and TAE... contactors)

– max. mechanical switching

frequency cycles/h 3600 (300 for AF... contactors)

M

M

3

3

220-230-240 V kW 2.2 3 4 6.5 9 11 11 15 18.5 22 25 30

380-400 V kW 4 5.5 7.5 11 15 18.5 18.5 22 30 37 45 55

M

3

/ AC-1

e

{

AC-3

e

AC-3

e

cw

> 100 A)

e

Ie / AC-1 W 0.8 1 1.2 1.8 2.5 3 2.5 5 6.5 7 6.5 7.5

/ AC-3 W 0.1 0.2 0.35 0.6 0.9 1.3 0.65 1.3 1.5 2 2.7 3.6

e

1

1 For the corresponding hp/A values of 1500 r.p.m., 50Hz, 3-phase motors, see page 1.76.

2 AF... contactors excluded

3 Unauthorized for TAE... contactors.

Low Voltage Products & Systems 1.45

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 11

IEC Technical data

1

Across the line

1

contactors

Main Pole - Utilization Characteristics

Contactor types: A... 145 185 210 260 300 – – – –

AF... 145 185 210 260 300 400 460 580 750

Rated operational voltage Ue max. V 690

Rated frequency limits Hz 25 ... 400

Conventional free-air thermal current Ith

acc. to IEC 60947-4-1,

open contactors ø ≤ 40 °C A 250 275 350 400 500 600 700 800 1050

with conductor cross-sectional area 1 mm2 120 150 185 240 300

Rated operational current Ie / AC-1

for air temperature close to contactor

ø ≤ 40 °C A 250 275 350 400 500 600 700 800 1050

Ue max. 690 V ø ≤ 55 °C A 230 250 300 350 400 500 600 700 800

ø ≤ 70 °C A 180 180 240 290 325 400 480 580 720

with conductor cross-sectional area mm2 120 150 185 240 300

Utilization categorie AC-3

for air temperature close to contactor < 55 °C

Rated operational current Ie AC-3

220-230-240 V A 145 185 210 260 305 400 460 580 750

3-phase motors 380-400 V A 145 185 210 260 305 400 460 580 750

415 V A 145 185 210 260 300 400 460 580 750

440 V A 145 185 210 240 280 400 460 580 750

500 V A 145 170 210 240 280 400 460 580 750

690 V A 120 170 210 220 280 350 400 500 650

1000 V A – – – – – – – – –

Rated operational power AC-3

1500 r.p.m. 50 Hz

1800 r.p.m. 60 Hz

3-phase motors 415 V kW 75 90 110 140 160 220 250 355 425

440 V kW 75 90 110 140 160 220 250 355 450

500 V kW 90 110 132 180 200 250 315 400 520

690 V kW 110 132 160 200 250 315 355 500 600

1000 V kW – – – – – – – – –

Rated making capacity AC-3

according to IEC 60947-4-1 10 x I

Rated breaking capacity AC-3

according to IEC 60947-4-1 8 x I

Short-circuit protection for contactors

without thermal O/L relay - Motor protection excluded

Ue < 500 V a.c. - gG type fuse A 315 355 400 500 630 800 1000

Rated short-time withstand current I

at 40 °C ambient temp., in free air,

from a cold state 1 s A 1800 2000 2500 3500 4600 7000

10 s A 1200 1500 1700 2400 4400 6400

30 s A 800 1000 1200 1500 3100 4500

1 min A 600 800 1000 1100 2500 3500

15 min A 280 320 400 500 840 1300

Maximum breaking capacity

cos ø = 0.45 (cos ø = 0.35 for I

at 440 V A 1500 2000 2300 2600 3000 4000 5000 6000 7500

at 690 V A 1200 1600 2000 2400 2500 3500 4500 5000 7000

Heat dissipation per pole

I

Max. electrical switching frequency

– for AC-1 cycles/h 300 300 300 300

– for AC-3 cycles/h 300 300 300 300

– for AC-2, AC-4 cycles/h 150 150 60 60

Electrical durability see pages 1.65 ... 1.69 – – – –

Mechanical durability

– millions of operating cycles 5 3

– max. mechanical switching

frequency cycles/h 3600 (300 for AF... contactors) 300

M

3

M

3

{

220-230-240 V kW 45 55 59 80 90 110 132 160 220

380-400 V kW 75 90 110 140 160 200 250 315 400

e

Ie / AC-1 W 13 16 18 25 32 30 42 32 50

e

A/AF145 – AF750

3

2 x 185 2 x 240 2 x 240

3

2 x 185 2 x 240 2 x 240

AC-3

e

AC-3

e

cw

> 100 A)

/ AC-3 W 5 8 9 14 18 16 21 17 28

2 x 80 x 5 2

2 x 80 x 5 2

1 Conductors with preparation.

2 Dimensions of the bars (in mm).

3 For currents above 450A, use terminal extension / enlargement pieces LX 300 / LW 300 see page 1.31).

1.46 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 12

IEC Technical data

AF1350 – AF1650

Main Pole - Utilization Characteristics

Contactor types: AF... 1350 1650

Rated operational voltage U

Rated frequency limits Hz 25-400 25-400

Conventional free-air thermal current Ith

acc. to IEC 60947-4-1,

open contactors ø ≤ 40 °C A 1350 1650

with conductor cross-sectional area1

Rated operational current I

for air temperature close to contactor

ø ≤ 40 °C A 1350 1650

Ue max. 690 V ø ≤ 55 °C A 1150 1450

ø ≤ 70 °C A 1000 1270

with conductor cross-sectional area mm2

Utilization categorie AC-3

for air temperature close to contactor < 55 °C

Rated operational current Ie AC-3

220-230-240 V A 860 1050

3-phase motors 380-400 V A 860 1050

415 V A 860 1050

440 V A 860 1050

500 V A — —

690 V A — —

1000 V A — —

Rated operational power AC-3

1500 r.p.m. 50 Hz

1800 r.p.m. 60 Hz

3-phase motors 415 V kW 500 600

440 V kW 560 670

500 V kW — —

690 V kW — —

1000 V kW — —

Rated making capacity AC-3

according to IEC 60947-4-1

Rated breaking capacity AC-3

according to IEC 60947-4-1

Short-circuit protection for contactors

without thermal O/L relay - Motor protection excluded

Ue < 500 V a.c. - gG type fuse A

Rated short-time withstand current I

at 40 °C ambient temp., in free air,

from a cold state 1 s A 10,000 12,000

10 s A 8000 10,000

30 s A 6000 7500

1 min A 4500 5500

15 min A 1600 2200

Maximum breaking capacity

cos ø = 0.45 (cos ø = 0.35 for I

at 440 V A 10,000 12,000

at 690 V A — —

Max. electrical switching frequency

– for AC-1 cycles/h 60 60

– for AC-3 cycles/h

– for AC-2, AC-4 cycles/h

Electrical durability 50,000 50,000

Mechanical durability

– millions of operating cycles 500,000 500,000

– max. mechanical switching

frequency cycles/h 60 60

M

3

220-230-240 V kW 257 315

380-400 V kW 475 560

M

3

max. V 1000 1000

e

mm2 2/100x5 3/100x5

/ AC-1

e

{

cw

> 100 A)

e

2 x 80 x 51

Product coordination

with ABB circuit breaker

2 x 80 x 51

10 x I

, AC-3

e

8 x I

, AC-3

e

Consult factory

Across the line

contactors

1

1

1 Dimensions of the bars (in mm).

Low Voltage Products & Systems 1.47

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 13

IEC Technical data

1

Across the line

1

contactors

Magnet System Characteristics for A... Contactors

Contactor types: A... 9 12 16 26 30 40 45 50 63 75 95 110

Rated control circuit voltage U

– at 50 Hz V 20 ... 690

– at 60 Hz V 24 ... 600

Coil operating limits ø < 55 °C ø < 70 °C

according to IEC 60947-4-1 0.85 ... 1.1 x U

Drop-out voltage in % of Uc roughly 40 ... 65 %

Coil consumption

Average pull-in value 50 Hz VA 70 120 180 350

60 Hz VA 80 140 210 450

50/60 Hz 1 VA/VA 74/70 125/120 190/180 410/365

Average holding value 50 Hz VA/W 8/2 12/3 18/5.5 22/6.5

60 Hz VA/W 8/2 12/3 18/5.5 26/8

50/60 Hz 1

Operating time

between coil energization and:

– N.O. contact closing ms 10 ... 26 8 ... 21 8 ... 27 10 ... 25

– N.C. contact opening ms 7 ... 21 6 ... 18 7 ... 22 7 ... 22

between coil de-energization and:

– N.O. contact opening ms 4 ... 11 4 ... 11 4 ... 11 7 ... 15

– N.C. contact closing ms 9 ... 16 7 ... 14 7 ... 14 10 ... 18

c

Magnet System Characteristics for AF... Contactors

Contactor types: AF... – – – – – – 45 50 63 75 95 110

Rated control circuit voltage Uc

– at 50 Hz V 48 ... 250 48 ... 250

– at 60 Hz V 48 ... 250 48 ... 250

– d.c. V 20 ... 250 20 ... 250

Coil operating limits ø < 70 °C

according to IEC 60947-4-1 0.85 ... 1.1 x U

Drop-out voltage in % of U

Coil consumption

Average pull-in value 50 Hz VA 210 350

60 Hz VA 210 350

d.c. W 190 400

Average holding value 50 Hz VA/W 7/2.8 7/3.5

60 Hz VA/W 7/2.8 7/3.5

d.c. W 2.8 2

Operating time

between coil energization and:

– N.O. contact closing ms 30 ... 100 30 ... 80

– N.C. contact opening ms 27 ... 95 27 ... 77

between coil de-energization and:

– N.O. contact opening ms 30 ... 110 55 ... 125

– N.C. contact closing ms 35 ... 115 60 ... 130

55 %

c

A/AF9 — AF110

0.85 ... 1.1 x U

c

VA/W 8/2 12/3 18/5.5 27/7.5

c

c

1 50/60 Hz coils: voltage codes 8 0 to 8 8.

1.48 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

page 1.28.

see

Page 14

Across the line

IEC Technical data

contactors

A145 — AF750

Magnet System Characteristics for A... Contactors

Contactor types: A... 145 185 210 260 300 – – – –

Rated control circuit voltage Uc

– at 50 Hz V 24 ... 690

– at 60 Hz V 24 ... 690

Coil operating limits ø < 70 °C

according to IEC 60947-4-1 0.85 ... 1.1 x U

Drop-out voltage in % of U

Coil consumption

Average pull-in value 50 Hz VA 550 1350

60 Hz VA 600 1550

50/60 Hz 1 VA/VA 700/650 1700/1550

Average holding value 50 Hz VA/W 35/11 60/16

60 Hz VA/W 40/12 65/19

50/60 Hz 1 VA/W 44/13 80/21

Operating time

between coil energization and:

– N.O. contact closing ms 13 ... 27 17 ... 35

– N.C. contact opening ms 8 ... 22 12 ... 30

between coil de-energization and

– N.O. contact opening ms 5 ... 10 7 ... 13

– N.C. contact closing ms 9 ... 13 10 ... 16

roughly 25 ... 65 %

c

c

1

1

Magnet System Characteristics for AF... Contactors

Contactor types: AF... 145 185 210 260 300 400 460 580 750

Rated control circuit voltage U

– at 50 Hz V 48 ... 250

– at 60 Hz V 48 ... 250

– d.c. V 24 ... 250

Coil operating limits ø < 70 °C

according to IEC 60947-4-1 0.85 ... 1.1 x U

Drop-out voltage in % of U

Coil consumption

Average pull-in value 50 Hz VA 430 470 890 850

60 Hz VA 430 470 890 850

d.c. W 500 520 990 950

Average holding value 50 Hz VA/W 12/3.5 10/2.5 12/4 12/4.5

60 Hz VA/W 12/3.5 10/2.5 12/4 12/4.5

d.c. W 2 2 4 4.5

Operating time

between coil energization and:

– N.O. contact closing ms 30 ... 115 50 ... 120

– N.C. contact opening ms 30 ... 115 50 ... 120

between coil de-energization and

– N.O. contact opening ms 25 ... 80 40 ... 70

– N.C. contact closing ms 25 ... 80 40 ... 70

c

55 %

c

c

1 50/60 Hz coils: voltage codes 8 0 to 8 8. see page 1.28.

Low Voltage Products & Systems 1.49

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 15

IEC Technical data

1

Across the line

1

contactors

Magnet System Characteristics for AF... Contactors

Contactor types: AF... 1350 1650

Rated control circuit voltage U

– at 50 Hz V 100 - 250

– at 60 Hz V 100 - 250

– d.c. V 100 - 250

Coil operating limits ø < 70 °C

according to IEC 60947-4-1 0.85 ... 1.1 x U

Drop-out voltage in % of U

Coil consumption

Average pull-in value 50 Hz VA 1900

60 Hz VA 1900

d.c. W 1700

Average holding value 50 Hz VA/W 48/17

60 Hz VA/W 48/17

d.c. W 16

Operating time

between coil energization and:

– N.O. contact closing ms 50 - 80

– N.C. contact opening ms 50 - 80

between coil de-energization and

– N.O. contact opening ms 35 - 55

– N.C. contact closing ms 35 - 55

With PLC

between coil energization and

– N.O. contact opening ms 40 - 65

– N.C. contact closing ms 40 - 65

between coil de-energization and

– N.O. contact opening ms 10 - 30

– N.C. contact closing ms 10 - 30

c

55 %

c

AF1350 — AF1650

c

1 50/60 Hz coils: voltage codes 8 0 to 8 8. see page 1.28.

1.50 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 16

Across the line

IEC Technical data

contactors

AE9 — AE110

TAE45 — TAE110

Magnet System Characteristics for AE... Contactors

Contactor types: AE... 9 12 16 26 30 40 45 50 63 75 95 110

Rated control circuit voltage U

V d.c. 12 ... 250

Coil operating limits ø < 55 °C ø < 70 °C

according to IEC 60947-4-1 0.85 ... 1.1 x U

Drop-out voltage in % of U

Coil consumption - Average values

– pull-in value W 90 110 200 400

– holding value W 2 2.5 4 2.4

Coil time constant

– open L/R ms 2 3 3 6

– closed L/R ms 9 16 15 30 ... 40

Operating time

between coil energization and:

– N.O. contact closing ms 10 ... 16 13 ... 21 13 ... 30 15 ... 25

– N.C. contact opening ms 8 ... 12 11 ... 16 10 ... 27 12 ... 22

between coil de-energization and

– N.O. contact opening ms 5 ... 14 1 6 ... 12 1 5 ... 15 1 15 ... 20 1

– N.C. contact closing ms 11 ... 17 1 8 ... 16 1 8 ... 18 1 18 ... 23 1

Magnet System Characteristics for TAE... Contactors

Contactor types: TAE... – – – – – – 45 50 – 75 95 110

Rated control circuit voltage U

V d.c. 17 ... 264

Coil operating limits ø < 55 °C

according to IEC 60947-4-1 U

Drop-out voltage in % of U

Coil consumption

values for U

– pull-in value W 120 ... 250 300 ... 1000

– holding value W 1.7 ... 6.5 2 ... 7

Coil time constant

– open L/R ms 3 6

– closed L/R ms 15 40

Operating time

between coil energization and:

– N.O. contact closing ms 13 ... 30 15 ... 25

– N.C. contact opening ms 10 ... 27 12 ... 22

between coil de-energization and

– N.O. contact opening ms 5 ... 15 2 15 ... 20 2

– N.C. contact closing ms 8 ... 18 2 18 ... 23 2

min. ... Uc max.

c

c

c

c

max. roughly 20 ... 35 %

c

roughly 10 ... 30 % roughly 15 ... 40 %

c

min. ... Uc max.

c

1

1

1 The use of surge suppressors increases the opening time on a scale of 1.1 to 1.5 for a varistor suppressor and on a scale of 4 to 8 for a diode suppressor.

AE 9 ... AE 40 contactors and U

2 The use of surge suppressors increases the opening time on a scale of 1.1 to 1.5 for a varistor suppressor and on a scale of 4 to 8 for a diode suppressor.

Low Voltage Products & Systems 1.51

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

> 110 V: table values for contactors with RV 5 surge suppressor (factory mounted).

c

Page 17

IEC Technical data

1

Across the line

1

contactors

Built-in Auxiliary Contacts - Utilization Characteristics

Contactor types: A... 9 12 16 26 30 40 45 50 63 75 95 110

Rated operational voltage Ue

Conventional free air thermal

current I

Rated frequency limits Hz 25 ... 400 – – – – – –

Rated operational current I

according to IEC 60947-5-1

24-127 V 50/60 Hz A 6 – – – – – –

220-240 V 50/60 Hz A 4 – – – – – –

380-440 V 50/60 Hz A 3 – – – – – –

500 V 50/60 Hz A 2 – – – – – –

690 V 50/60 Hz A 2 – – – – – –

Rated operational current I

according to IEC 60947-5-1

24 V d.c. A / W 6 / 144 – – – – – –

48 V d.c. A / W 2.8 / 134 – – – – – –

72 V d.c. A / W 2 / 144 – – – – – –

125 V d.c. A / W 1.1 / 138 – – – – – –

250 V d.c. A / W 0.55 / 138 – – – – – –

Rated making capacity

acc. to IEC 60947-5-1 10 x I

Rated breaking capacity

acc. to IEC 60947-5-1 10 x I

Short-circuit protection

gG type fuse A 10 – – – – – –

Rated short-time withstand current I

for 1.0 s A 100 – – – – – –

for 0.1 s A 140 – – – – – –

Minimum switching capacity V / mA 17 / 5 – – – – – –

Non-overlapping time between

N.O. and N.C. contacts ms > 2 – – – – – –

Insulating resistance at 500 V d.c.

after durability test MOhm 5 – – – – – –

Heat dissipation per pole at 6 A W 0.10 – – – – – –

- ø ≤ 40 °C A 16 – – – – – –

th

max.

/ AC-15

e

/ DC-13

e

A9 — A110

V 690 – – – – – –

/ AC-15 – – – – – –

e

/ AC-15 – – – – – –

e

cw

1.52 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 18

Across the line

IEC Technical data

contactors

A/AE9 — AF/TAE110

1

Mounting characteristics

Contactor types: A..., AE... 9 12 16 26 30 40 45 50 63 75 95 110

AF..., TAE... – – – – – – 45 50 63 75 95 110

Mounting positions see "Conditions for use"

Mounting distances The contactors can be assembled side by side

Mounting

on DIN rail 35 x 7.5 mm 35 x 15 mm

according to IEC 715 and EN 50022 / EN 50023

by screws (not supplied) 2 x M4 2 x M6

Conditions for Use

Sustainable utilization conditions for contactors involving at the same time the Mounting position, Ambient temperature and Control voltage operating limits are

summarized in the table below.

Contactors Mounting position Ambient temperature Control voltage

A 9 ... A 110, AE 9 ... AE 110

> 55 °C unauthorized –

AF 45 ... AF 110

6 unauthorized – –

TAE 45 ... TAE 110 > 55 °C unauthorized –

6 unauthorized – –

Notes for 4-pole contactors

Whatever the coil voltage: Pos. 5 unauthorized for A 45-22-00, AE 45-22-00, A 75-22-00, AE 75-22-00 contactors.

For 60 Hz coil voltage: (only for devices fi tted with CA 5-.. and CAL 5-11 auxiliary contacts or TP timer)

– A 45-40-00, A 50-40-00 and A 75-40-00 contactors

Mounting positions 1 to 5 and ambient temperature < 55 °C: tolerance reduced to 0.9 ... 1.1 U

– A 45-22-00 and A 75-22-00 contactors

Mounting positions 1 to 4 (pos. 5 unauthorized) and ambient temperature < 55 °C: tolerance reduced to 0.9 ... 1.1 Uc (instead of 0.85 ... 1.1 Uc) for coil voltage

codes 7 and 8 .

For mounting position 6 or ambient temperature of 55 to 70 °C the information given on this page remains applicable.

55 ... 70 °C U

1, 1 + 30°, 2, 3, 4, 5 < 70 °C 0.85 U

35 x 15 mm 75 x 25 mm 75 x 25 mm

1, 1 + 30°, 2, 3, 4, 5

< 55 °C 0.95 ... 1.1 x U

6

1, 1 + 30°, 2, 3, 4, 5

< 55 °C 0.85 ... 1.1 x U

c

< 55 °C U

(instead of 0.85 ... 1.1 Uc) for coil voltage codes 7 and 8 .

c

min. ... Uc max.

c

c

c

min. ... 1.1 x Uc max.

c

1

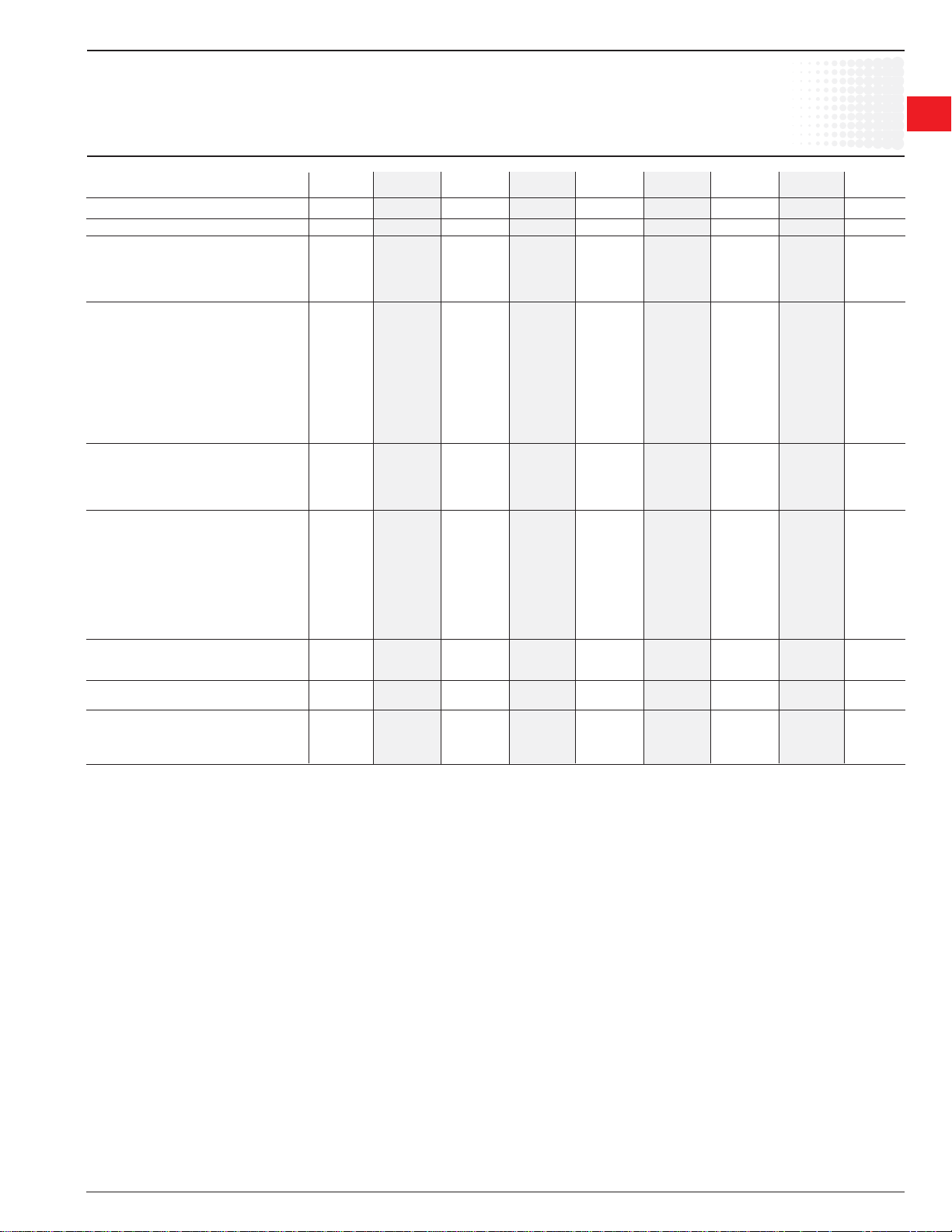

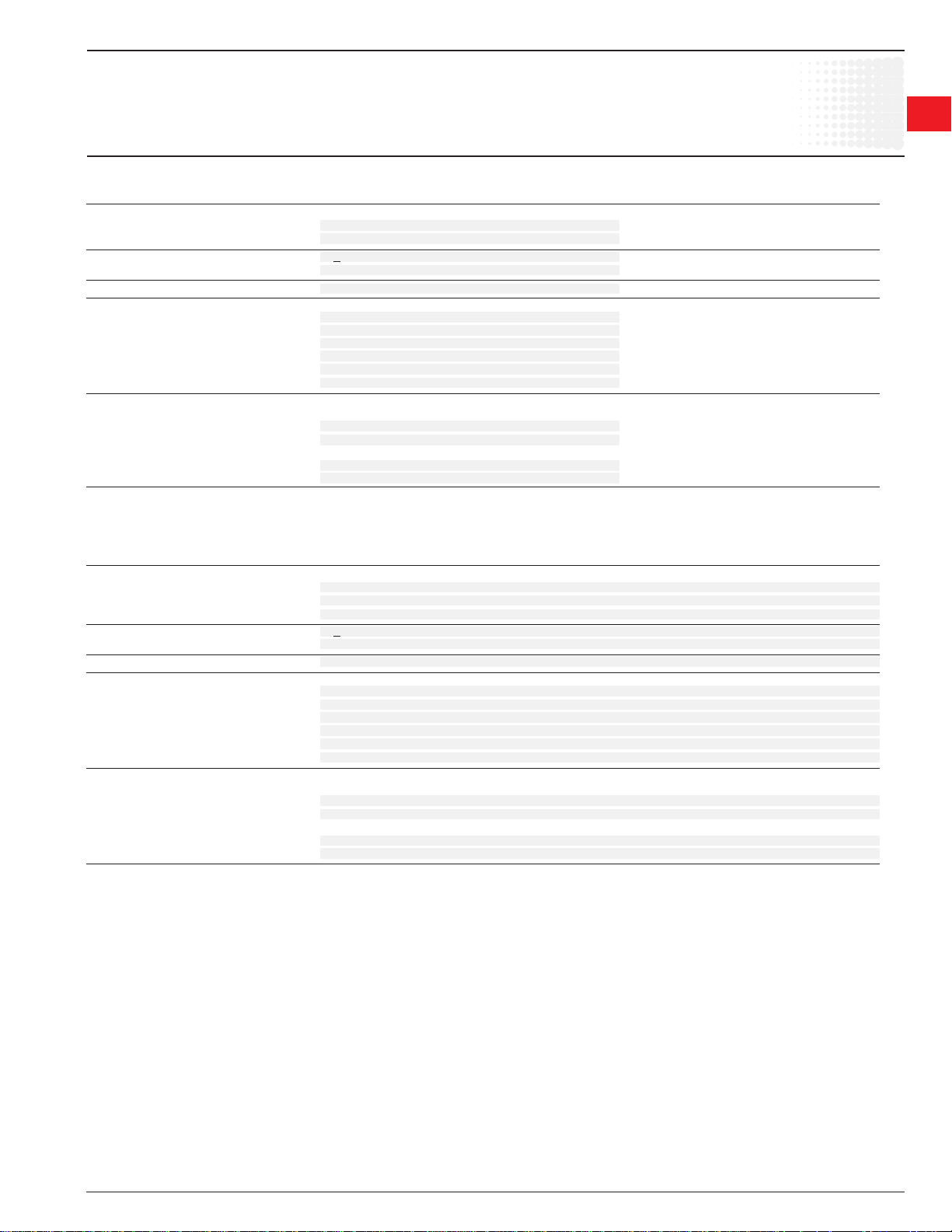

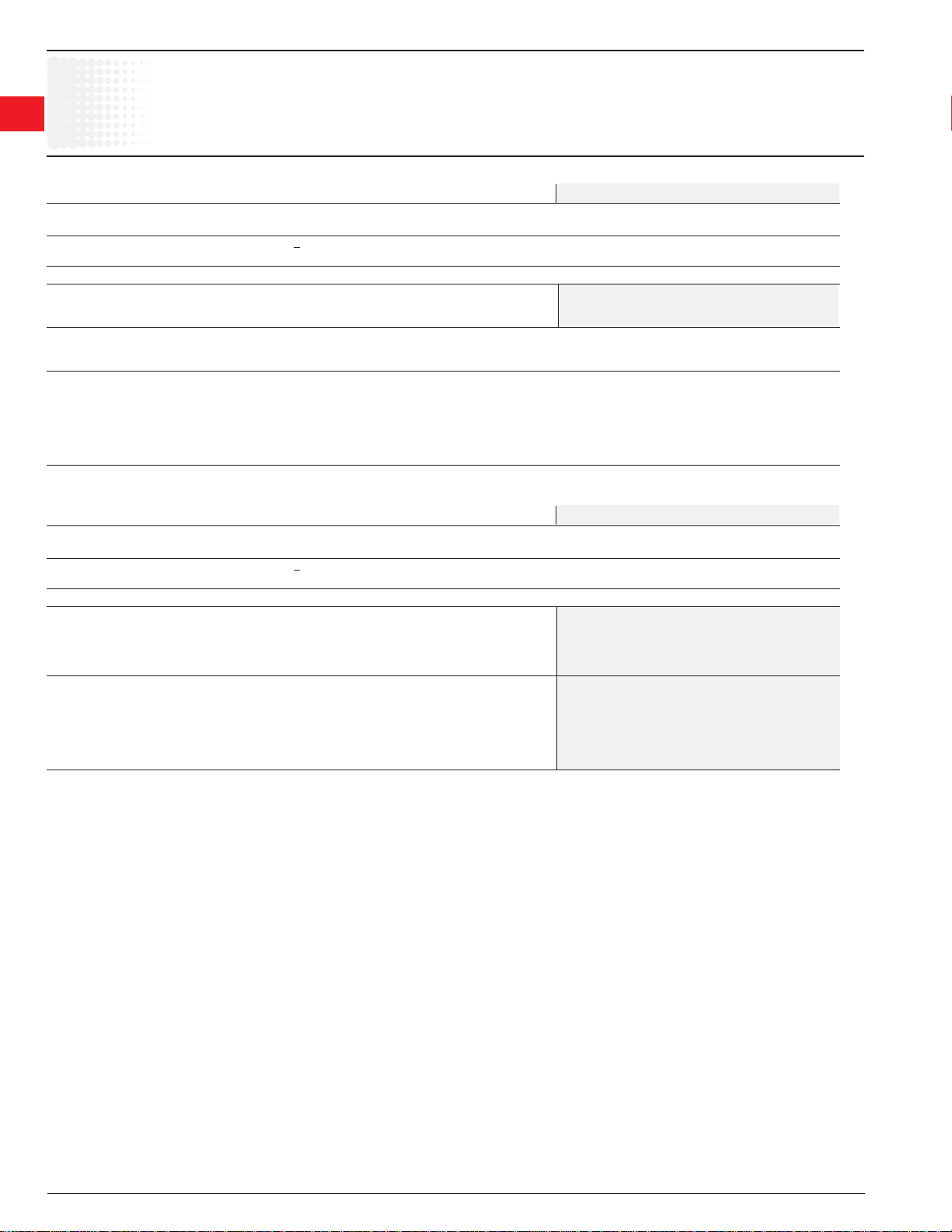

Mounting Positions (see the above table for authorized positions)

Position

2

ABB

Position 4

ABB

ABB

Position 1

ABB

-30°

Position 3

Position 1 ± 30°

+30°

Position 5

Position 6

Low Voltage Products & Systems 1.53

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 19

IEC Technical data

1

Across the line

1

contactors

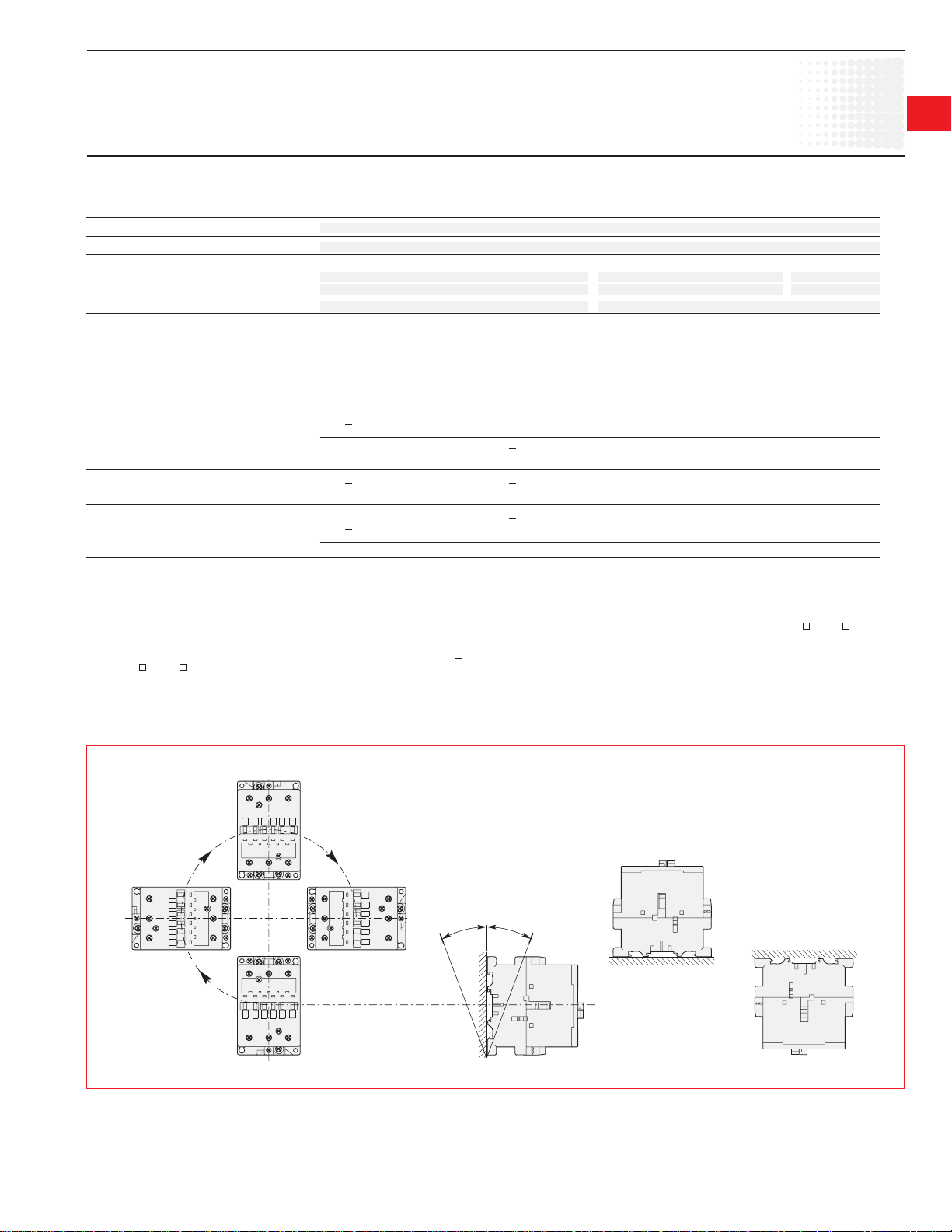

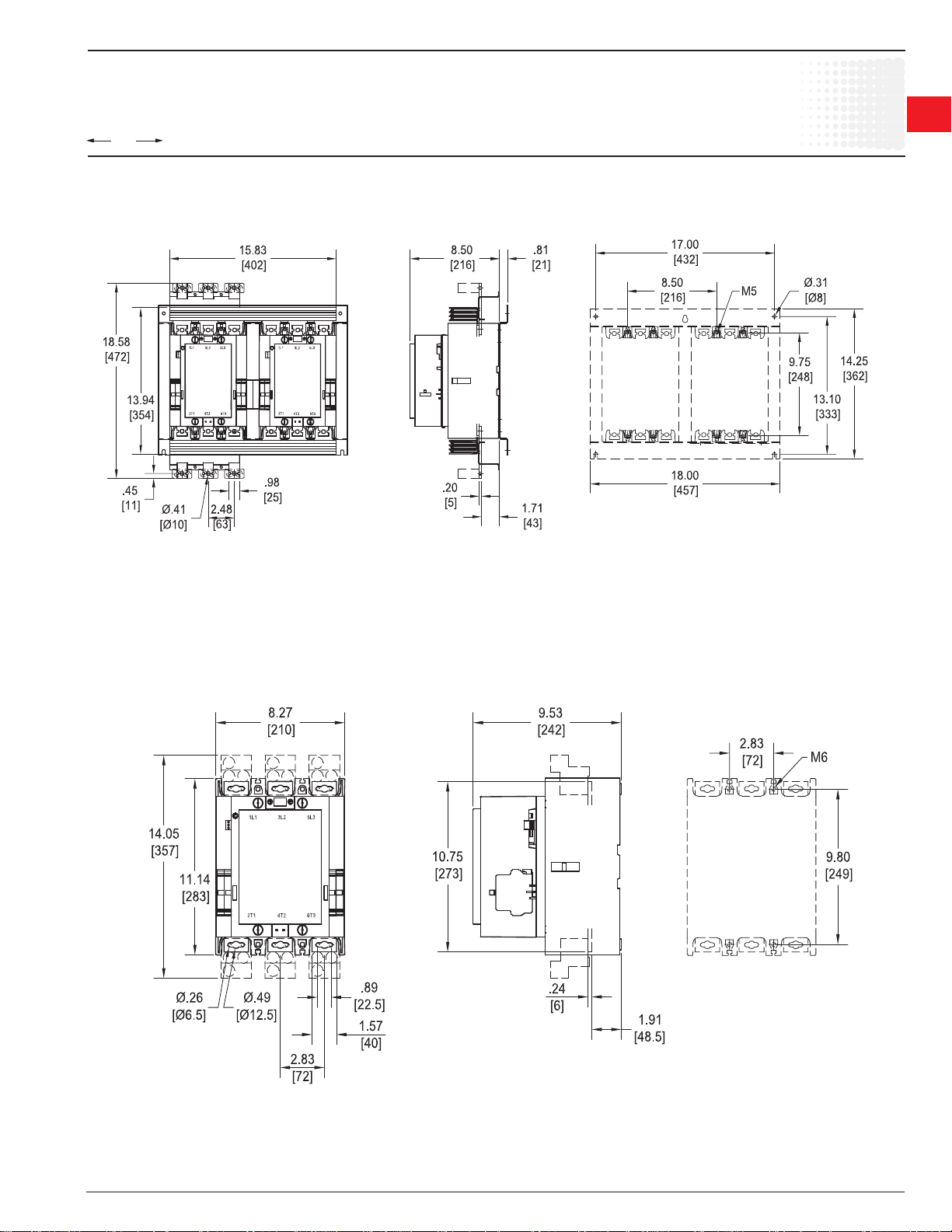

Mounting Characteristics — A/AF145 — AF750

Contactor types: A... 145 185 210 260 300 – – – –

AF... 145 185 210 260 300 400 460 580 750

Mounting positions see "Condition for use"

Mounting distances The contactors can be assembled side by side

Fixing

on DIN rail – – – – – – – – –

according to IEC 715 and EN 50022 / EN 50023

by screws (not supplied) 4 x M5 4 x M6

Mounting Characteristics — AF1350 — AF1650

Contactor types: AF 1350 1650

Mounting positions see "Condition for use"

Mounting distances The contactors can be assembled side by side

Fixing

on DIN rail – –

according to IEC 715 and EN 50022 / EN 50023

by screws (not supplied) 4 x M8

Conditions for Use

Sustainable utilization conditions for contactors involving at the same time the Mounting position, Ambient temperature and Control voltage operating limits are

summarized in the table below.

Contactors Mounting position Ambient temperature Control voltage

A 145 ... A 300

6 unauthorized – –

AF 145 ... AF 750

6 unauthorized – –

1, 1 + 30°, 2, 3, 4, 5 < 70 °C 0.85 ... 1.1 x U

1, 1 + 30°, 2, 3, 4, 5 < 70 °C 0.85 x U

A/AF145 — AF1650

c

min. ... 1.1 x Uc max.

c

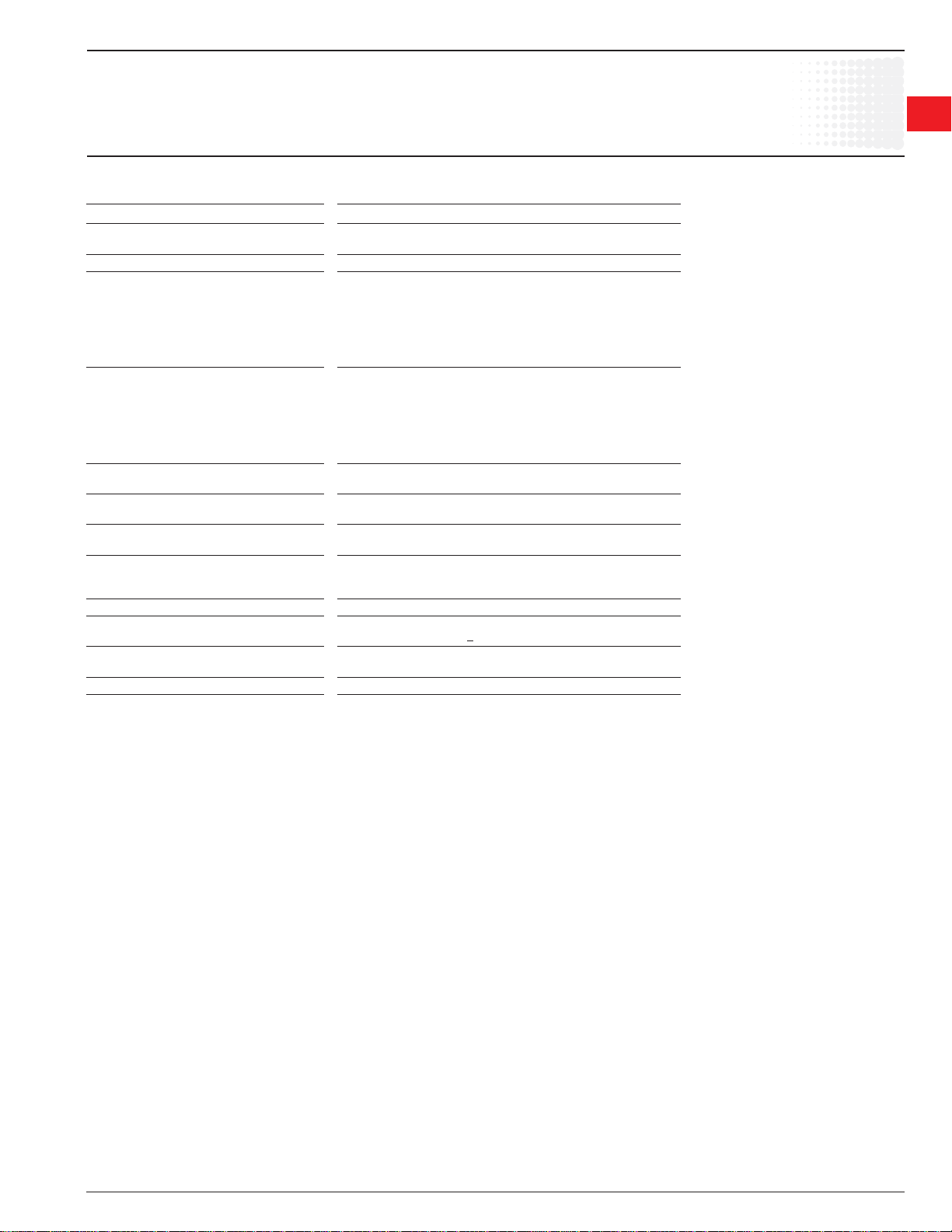

Mounting Positions (see the above table for authorized positions)

Position 2

ABB

Position 4

ABB

ABB

Position 3

ABB

Position 1

-30°

+30°

Position 5

Position 6

Position 1 ± 30°

1.54 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 20

Across the line

IEC Technical data

contactors

A/AE9 — AF/TAE110

Connecting Characteristics

Contactor types: A..., AE... 9 12 16 26 30 40 45 50 63 75 95 110

AF..., TAE... – – – – – – 45 50 63 75 95 110

Main terminals

1

1

with cable clamp with double with single connector with single

connector

Connecting capacity (min. ... max.)

Main conductors (poles)

Rigid: solid (≤ 4 mm

stranded (≥ 6 mm2) 2 x mm2 1 ... 4 1.5 ... 6 2.5 ... 16 6 ... 16 6 ... 35

Rigid with connector

single for Cu cable mm

single for Al/Cu cable mm2 – – – – – – – – – – – –

double for Al/Cu cable mm2 – – – – – – – – – – – –

Flexible with cable end 1 x mm

2 x mm2 0.75 ... 2.5 0.75 ... 4 2.5 ... 10 6 ... 25 6 ... 35

Bars or lugs L mm ≤ 8 10 – – – – – – 30 2

l mm > 3.7 4.2 – – – – – – 6

Auxiliary conductors

(built-in auxiliary terminals + coil terminals)

Rigid solid 1 x mm

2 x mm2 1 ... 4 0.75 ... 2.5

Flexible with cable end 1 x mm

2 x mm2 0.75 ... 2.5

Lugs L mm ≤ 8 1 8

l mm > 3.7 1 3.7

Degree of protection acc. to IEC 60947-1 / Protection against direct contact acc. to VDE 0106 - Part. 100

EN 60947-1 and IEC 60529 / EN 60529

– Main terminals IP 20 IP 10

– Coil terminals IP 20

– Built-in auxiliary terminals IP 20 – – – – – –

Screw terminals (delivered in open position, screws of unused terminals must be tightened)

Main terminals (+,-) pozidriv 2 screws hexagon socket

M3.5 M4 M5 M6 M8 (s = 4 mm)

Coil terminals M3.5 (+,-) pozidriv 2 screws with cable clamp

Built-in auxiliary terminals (+,-) pozidriv 2 screws with cable clamp – – – – – –

M3.5 M4 M5 – – – – – –

Tightening torque

Main pole terminals

– recommended Nm / lb.in 1.00 / 9 1.7 / 15 2.30 / 20 4.00 / 35 6.00 / 53

– max. Nm 1.20 2.20 2.60 4.50 6.50

Coil terminals

– recommended Nm / lb.in 1.00 / 9

– max. Nm 1.20

Built-in auxiliary terminals

– recommended Nm / lb.in 1.00 / 9 1.7 / 15 1.00 / 9 – – – – – –

– max. Nm 1.20 2.20 1.20 – – – – – –

Terminal marking and positioning see pages 1.34

2

) 1 x mm2 1 ... 4 1.5 ... 6 2.5 ... 16 6 ... 50 10 ... 95

}

2

– – – – – – – – – – – –

2

0.75 ... 2.5 0.75 ... 4 2.5 ... 10 6 ... 35 10 ... 70

L

l

2

1 ... 4 0.75 ... 2.5

2

0.75 ... 2.5 1 ... 2.5 0.75 ... 2.5

L

l

2 x (5.6 x 6.5 mm) (14 x 14 mm)

(13 x 10 mm) connector

1 L < 8 and l > 3.7 for coil terminal - L < 10 and l > 4.2 for built-in auxiliary terminals.

2 With LW 110 enlargement piece. See page 1.31.

Low Voltage Products & Systems 1.55

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 21

IEC Technical data

1

Across the line

1

contactors

Connecting Characteristics

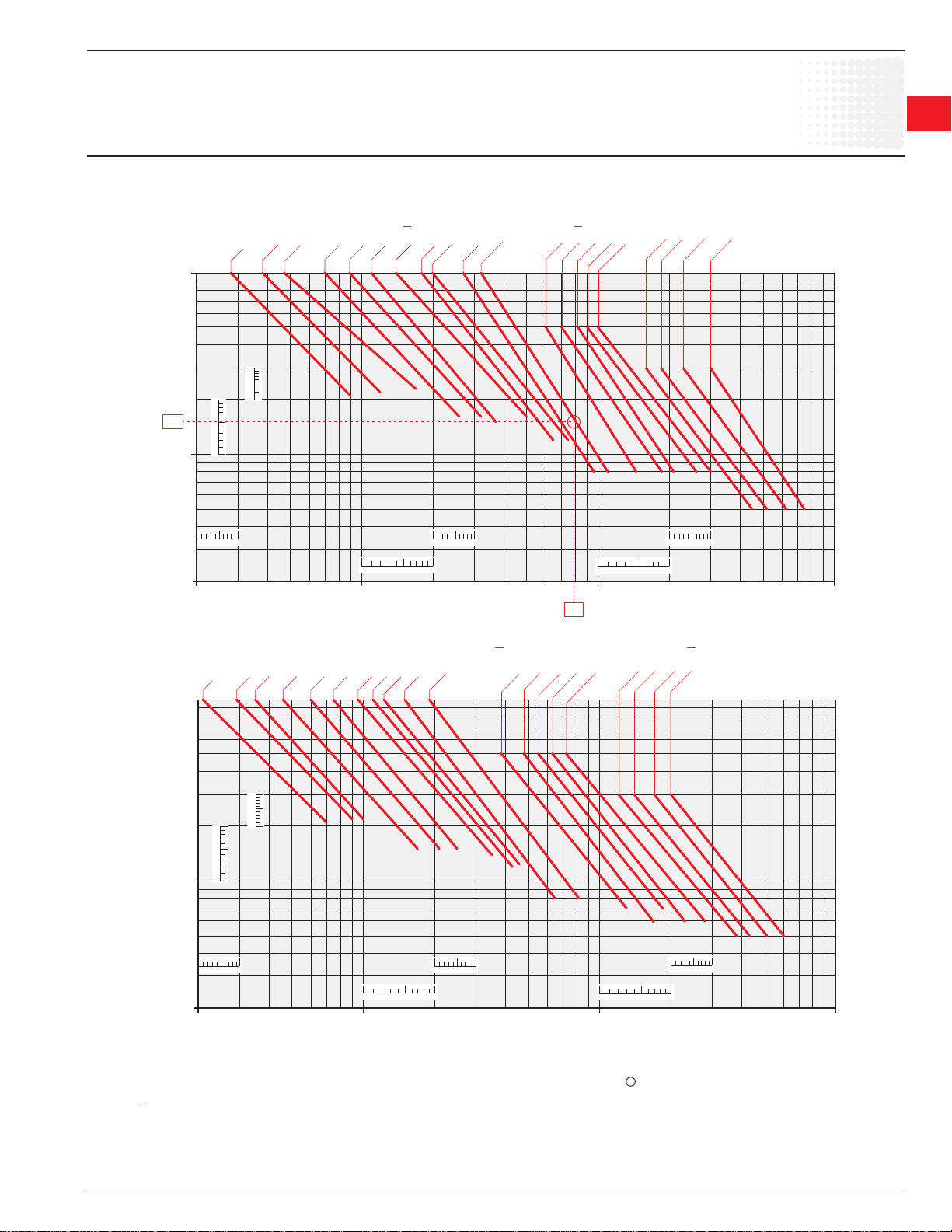

Contactor types: A... 145 185 210 260 300 – – – –

AF... 145 185 210 260 300 400 460 580 750

Main terminals

Flat type

A/AF145 — AF750

17.5

5

20

5

25

6

22.5

6

40

22.5

ø8.5

Connecting capacity (min. ... max.)

Main conductors (poles)

Rigid: 1 x mm

Rigid with connector

single for Cu cable mm2 6 ... 185 16 ... 240 240 300

single for Al/Cu cable mm2 25 ... 150 120 ... 240 240 300

double for Al/Cu cable mm2 – 2 x 95 ... 120 2 x 240 3 x 185

Flexible

1 x mm2 – – – – – – – – –

2 x mm2 – – – – – – – – –

Bars or lugs L mm ≤ 24 32 47 / 45 52 / 50

Ø mm > 8 10 10 12

Auxiliary conductors

(coil terminals)

Rigid solid 1 x mm

2 x mm2 1 ... 4

Flexible with cable end

Lugs L mm ≤ 8

l mm > 3.7

Degree of protection acc. to IEC 60947-1 / Protection against direct contact acc. to VDE 0106 - part 100

EN 60947-1 and IEC 60529 / EN 60529

– Main terminals IP 00

– Coil terminals IP 20

– Built-in auxiliary terminals –

Screw terminals

Main terminals Screws and bolts

M8 M10 M10 M12

Coil terminals (delivered in open position) M3.5 (+,-) pozidriv 2 screws with cable clamp

Built-in auxiliary terminals – – – – – – – – –

– – – – – – – – –

Tightening torque

Main pole terminals

– recommended

– max.

Coil terminals

– recommended

– max.

Built-in auxiliary terminals

– recommended

– max.

Terminal marking and positioning see pages 1.36 & 1.37

ø

1 x mm2 0.75 ... 2.5

L

l

2

2 x mm2 – – – – – – – – –

L

2 x mm2 0.75 ... 2.5

Nm / lb.in 18 / 160 28 / 240 40 / 354 45 / 443

Nm / lb.in 1.00 / 9

Nm / lb.in – – – – – – – – –

– – – – – – – – –

2

1 ... 4

Nm 20 30 44 49

Nm 1.20

Nm – – – – – – – – –

ø 10.2

ø6.5

ø10.5

ø 6.5

ø 12.5

1.56 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 22

IEC Technical data

AF1350 — AF1650

Connecting Characteristics

Contactor types: AF... 1350 1650

Main terminals

Flat type

Connecting capacity (min. ... max.)

Main conductors (poles)

Rigid: 1 x mm

Rigid with connector

single for Cu cable mm

single for Al/Cu cable mm

double for Al/Cu cable mm2

Flexible

1 x mm2

2 x mm2

Bars or lugs L mm ≤ 100 100

Ø mm > 12 12

Auxiliary conductors

(coil terminals)

Rigid solid 1 x mm

2 x mm2 1...4 1...4

Flexible with cable end

Lugs L mm ≤ 8 8

l mm > 3.7 3.7

Degree of protection acc. to IEC 60947-1 /

EN 60947-1 and IEC 60529 / EN 60529

– Main terminals IP 00 IP 00

– Coil terminals IP 20 IP 20

– Built-in auxiliary terminals

Screw terminals Screw and bolts

Main terminals M12

Coil terminals (delivered in open position) M3.5 (+,-) pozidriv 2 screws with cable clamp

Built-in auxiliary terminals — —

Tightening torque

Main pole terminals

– recommended

– max.

Coil terminals

– recommended

– max.

Built-in auxiliary terminals

– recommended

– max.

ø

1 x mm2 0.75...2.5 0.75...2.5

L

l

2 —

2 — —

2 x mm

2 — —

2 — —

— —

— —

— —

L

2

1...4 1...4

2 x mm2 0.75...2.5 0.75...2.5

Nm / lb.in

Nm / lb.in

Nm / lb.in — —

45/443 45/443

Nm

49 49

1.00 / 9

Nm

1.20 1.20

Nm

— —

—

1.00 / 9

Across the line

contactors

1

1

Low Voltage Products & Systems 1.57

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 23

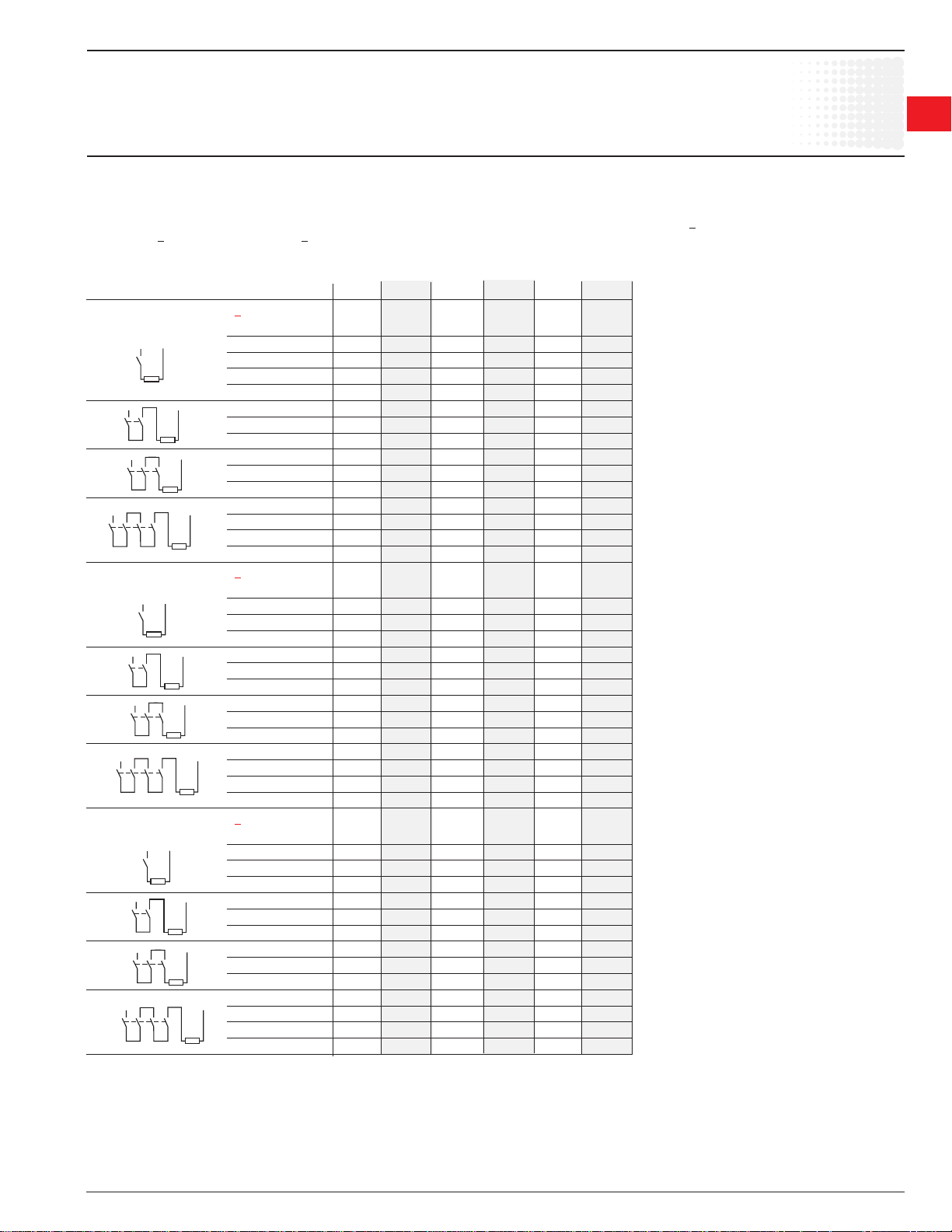

C

UL/CSA & IEC Technical data

1

Across the line

1

contactors

Contactor types: AL AL9 AL12 AL16 AL26 AL30 AL40

Rated insulation voltage Ui

according to IEC 60947-4-1 V 1000

according to UL/CSA V 600

Rated impulse withstand voltage U

Standards Devices complying with international standards IEC 60947-1 / 60947-4-1

and European standards EN 60947-1 / 60947-4-1

Air temperature close to contactor see "Conditions for use" page 1.50, for control voltage limits and authorized mounting positions

– fi tted with thermal O/L relay °C -25 to +55

– without thermal O/L relay °C -40 to +70 (55 max. for TAE... contactors)

– for storage °C -60 to +80

Climatic withstand acc. to IEC 60068-2-30 and 60068-2-11 - UTE C 63-100 specifi cation II

Operating altitude m < 3000

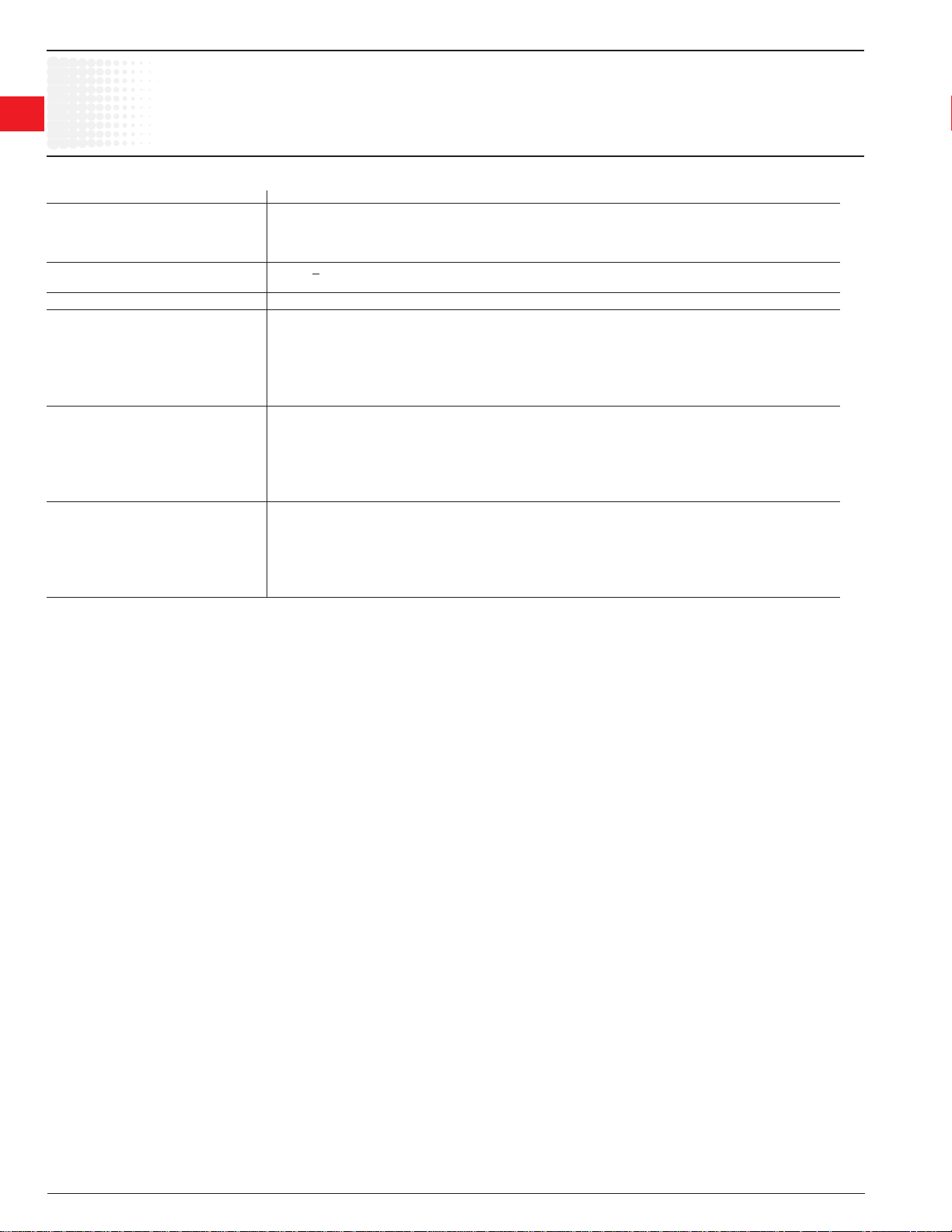

Shock withstand

acc. IEC 60068-2-27 and EN 60068-2-27

Mounting position 1 (see page 1.50) 1/2 sinusoidal shock for 11 ms: no change in contact position

Shock direction Making position Breaking position

A 20 g 20 g

B1 10 g 5 g

A

B2 15 g 15 g

C1 20 g 20 g

C2 20 g 20 g

B1

A

imp.

C1

2

AL9 — AL40

kV 8

B2

1.58 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 24

IEC Technical data

AL9 — AL40

Main Pole - Utilization Characteristics

Contactor types: AL AL9 AL12 AL16 AL26 AL30 AL40

Rated operational voltage Ue max. V 690

Rated frequency limits Hz 25-400

Conventional free-air thermal current Ith

acc. to IEC 60947-4-1,

open contactors ø ≤ 40 °C A 26 28 30 45 65 65

with conductor cross-sectional area mm2 4 4 4 6 16 16 35

Rated operational current I

for air temperature close to contactor

ø ≤ 40 °C A 25 27 30 45 55 60

Ue max. 690 V ø ≤ 55 °C A 22 25 27 40 55 60

ø ≤ 70 °C 3 A 18 20 23 32 39 42

with conductor cross-sectional area mm2 2.5 4 4 6 10 16

Utilization categorie AC-3

for air temperature close to contactor < 55 °C

Rated operational current Ie AC-3 1

220-230-240 V A 9 12 17 26 33 40

3-phase motors 380-400 V A 9 12 17 26 32 37

415 V A 9 12 17 26 32 37

440 V A 9 12 16 26 32 37

500 V A 9 12 14 22 28 33

690 V A 7 9 10 17 21 25

1000 V A – – – – – –

Rated operational power AC-3 1

1500 r.p.m. 50 Hz

1800 r.p.m. 60 Hz

3-phase motors 415 V kW 4 5.5 9 11 15 18.5

440 V kW 4 5.5 9 15 18.5 22

500 V kW 5.5 7.5 9 15 18.5 22

690 V kW 5.5 7.5 9 15 18.5 22

1000 V kW – – – – – –

Rated making capacity AC-3

according to IEC 60947-4-1 10 x I

Rated breaking capacity AC-3

according to IEC 60947-4-1 8 x I

Short-circuit protection for contactors

without thermal O/L relay - Motor protection excluded

Ue < 500 V a.c. - gG type fuse A 25 32 32 50 63

Rated short-time withstand current I

at 40 °C ambient temp., in free air,

from a cold state 1 s A 250 280 300 400 600

10 s A 100 120 140 210 400

30 s A 60 70 80 110 225

1 min A 50 55 60 90 150

15 min A 26 28 30 45 65

Maximum breaking capacity

cos ø = 0.45 (cos ø = 0.35 for I

at 440 V A 250 — — 420 820

at 690 V A 90 — — 170 340

Heat dissipation per pole

I

Max. electrical switching frequency

– for AC-1 cycles/h 600

– for AC-3 cycles/h 1200

– for AC-2, AC-4 cycles/h 300

Mechanical durability

– millions of operating cycles 10

– max. mechanical switching

frequency cycles/h 3600

M

M

3

3

220-230-240 V kW 2.2 3 4 6.5 9 11

380-400 V kW 4 5.5 7.5 11 15 18.5

M

3

/ AC-1

e

{

AC-3

e

AC-3

e

cw

> 100 A)

e

Ie / AC-1 W 0.8 1 1.2 1.8 2.5

/ AC-3 W 0.1 0.2 0.35 0.6 0.9

e

Across the line

contactors

1

1

Low Voltage Products & Systems 1.59

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 25

IEC Technical data

1

Across the line

1

contactors

Magnet system characteristics for AL contactors

Contactor types: AL AL9 AL12 16 26 30 40

Rated control circuit voltage U

V d.c. 12 ... 240 (24V & 48V for AL...Z)

Coil operating limits ø < 55 °C

according to IEC 60947-4-1 0.85 ... 1.1 x U

Drop-out voltage in % of U

Coil consumption - Average values

– pull-in value W 3 (2.4 for AL9Z - AL16Z) 3.5

– holding value W 3 (2.4 for AL9Z - AL16Z) 3.5

Coil time constant

– open L/R ms 40

– closed L/R ms 90

Operating time

between coil energization and:

– N.O. contact closing ms 50 ... 75

– N.C. contact opening ms 45 ... 70

between coil de-energization and

– N.O. contact opening ms 15 ... 30

– N.C. contact closing ms 17 ... 32

c

roughly 15 ... 30 %

c

Magnet System Characteristics for TAL... Contactors

Contactor types: TAL TAL9 TAL12 TAL16 TAL26 TAL30 TAL40

Rated control circuit voltage U

V d.c. 9 ... 264

Coil operating limits ø < 55 °C

according to IEC 60947-4-1 0.85 ... 1.1 x U

Drop-out voltage in % of U

Coil consumption

values for U

– Uc max. DC W 8.5 9

– Uc min. DC W 2.5 2.7

– Uc DC W 5 5.4

Operating time

between coil energization and:

– N.O. contact closing ms 50 ... 100 55 ... 110

– N.C. contact opening ms 20 ... 70 25 ... 75

between coil de-energization and

– N.O. contact opening ms 10 ... 17 1 12 ... 18 1

– N.C. contact closing ms 16 ... 27 1 18 ... 28 1

max. and 20 °C

c

c

max. roughly 20... 35 %

c

AL9 — AL40, TAL9 – TAL40

c

c

1 The use of surge suppressors increases the opening time on a scale of 1.1 to 1.5 for a varistor suppressor and on a scale of 4 to 8 for a diode suppressor.

1.60 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 26

IEC Technical data

AL9 — AL40

Built-in Auxiliary Contacts - Utilization Characteristics

Contactor types: AL AL9 AL12 AL16 AL26 AL30 AL40

Rated operational voltage Ue

Conventional free air thermal

current I

- ø ≤ 40 °C A 16

th

Rated frequency limits Hz 25 ... 400

Rated operational current I

according to IEC 60947-5-1

24-127 V 50/60 Hz A 6

220-240 V 50/60 Hz A 4

380-440 V 50/60 Hz A 3

500 V 50/60 Hz A 2

690 V 50/60 Hz A 2

Rated operational current I

according to IEC 60947-5-1

24 V d.c. A / W 6 / 144

48 V d.c. A / W 2.8 / 134

72 V d.c. A / W 2 / 144

125 V d.c. A / W 1.1 / 138

250 V d.c. A / W 0.55 / 138

Rated making capacity

acc. to IEC 60947-5-1 10 x I

Rated breaking capacity

acc. to IEC 60947-5-1 10 x I

Short-circuit protection

gG type fuse A 10

Rated short-time withstand current I

for 1.0 s A 100

for 0.1 s A 140

Minimum switching capacity V / mA 17 / 5

Non-overlapping time between

N.O. and N.C. contacts ms > 2

Insulating resistance at 500 V d.c.

after durability test MOhm 5

Heat dissipation per pole at 6 A W 0.10

max.

V 690

/ AC-15

e

/ DC-13

e

cw

/ AC-15

e

/ AC-15

e

Across the line

contactors

1

1

Low Voltage Products & Systems 1.61

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 27

IEC Technical data

1

Across the line

1

contactors

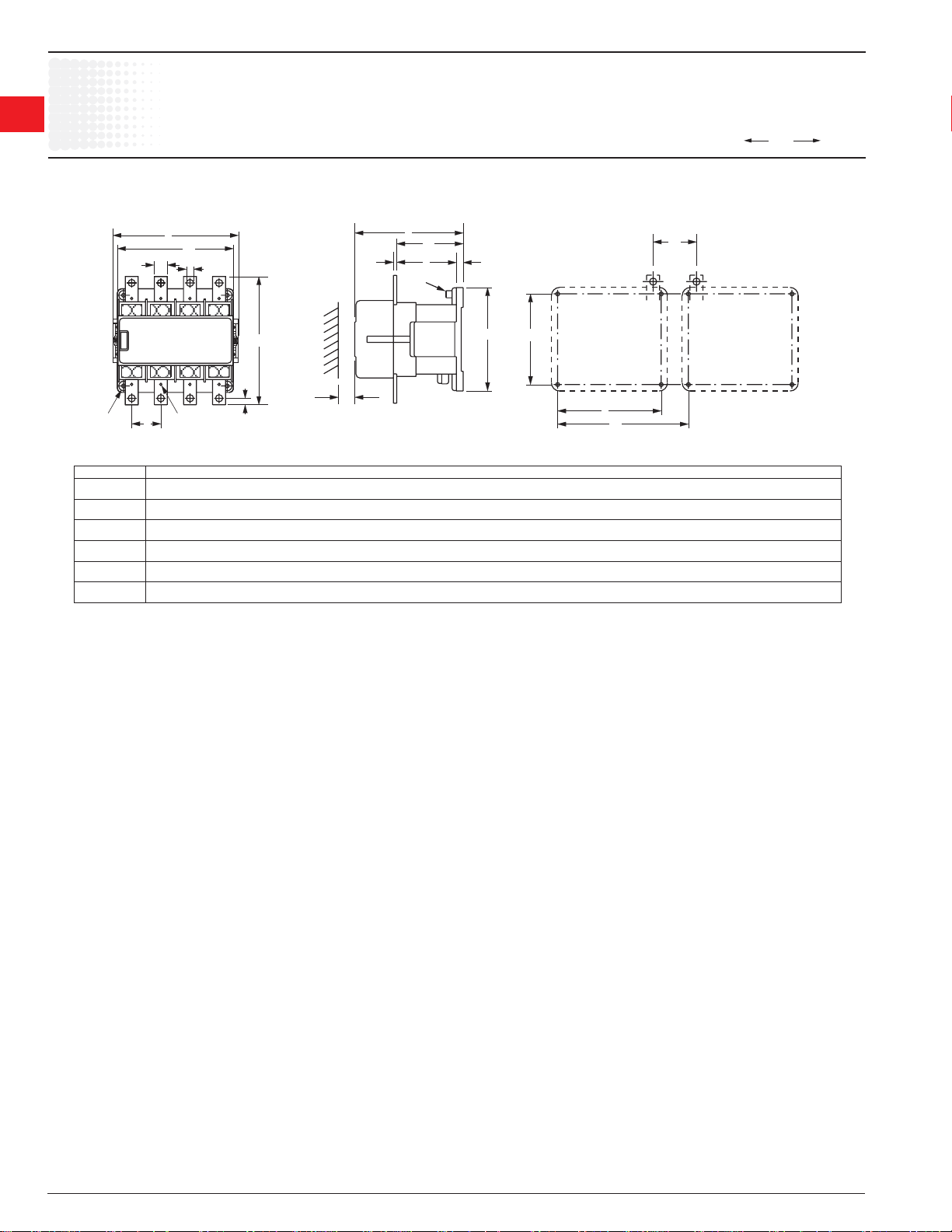

Mounting characteristics

Contactor types: AL AL9 AL12 AL16 AL26 AL30 AL40

Mounting positions see "Conditions for use"

Mounting distances The contactors can be assembled side by side

Mounting

on DIN rail 35 x 7.5 mm

according to IEC 715 and EN 50022 / EN 50023

by screws (not supplied) 2 x M4

Conditions for Use

Sustainable utilization conditions for contactors involving at the same time the Mounting position, Ambient temperature and Control voltage operating limits are

summarized in the table below.

Contactors Mounting position Ambient temperature Control voltage

AL9 – AL40

55 ... 70 °C U

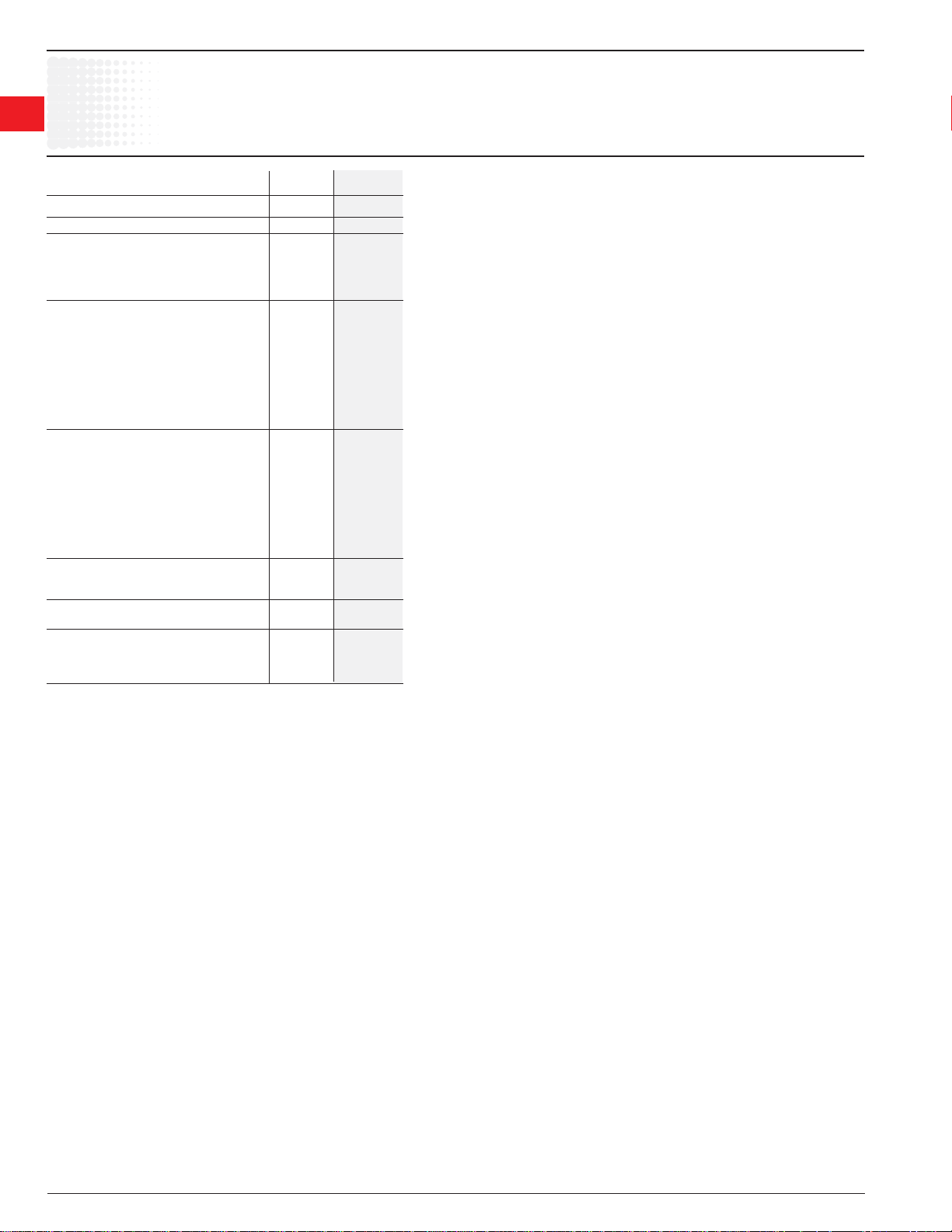

Mounting Positions (see the above table for authorized positions)

AL9 — AL40

Position

2

35 x 15 mm

1, 1 + 30°, 2, 3, 4, 5

6 (Unauthorized)

< 55 °C 0.85 ... 1.1 x U

c

c

Position 4

ABB

ABB

Position 1

ABB

ABB

Position 3

-30°

+30°

Position 1 ± 30°

Position 5

Position 6

1.62 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 28

Across the line

IEC Technical data

contactors

AL9 — AL40

Connecting Characteristics

Contactor types: AL AL9 AL12 AL16 AL26 AL30 AL40

Main terminals

with cable clamp with double

connector

Connecting capacity (min. ... max.)

Main conductors (poles)

Rigid: solid (≤ 4 mm

stranded (≥ 6 mm2) 2 x mm2 1 ... 4 1.5 ... 6 2.5 ... 16

Rigid with connector

single for Cu cable mm

single for Al/Cu cable mm2 – – – – – –

double for Al/Cu cable mm2 – – – – – –

Flexible with cable end 1 x mm

2 x mm2 0.75 ... 2.5 0.75 ... 4 2.5 ... 10

Bars or lugs L mm ≤ 8 10 – –

l mm > 3.7 4.2 – –

Auxiliary conductors

(built-in auxiliary terminals + coil terminals)

Rigid solid 1 x mm

2 x mm2 1 ... 4

Flexible with cable end 1 x mm

2 x mm2 0.75 ... 2.5

Lugs L mm ≤ 8 1 8

l mm > 3.7 1 3.7

Degree of protection acc. to IEC 60947-1 / Protection against direct contact acc. to VDE 0106 - Part. 100

EN 60947-1 and IEC 60529 / EN 60529

– Main terminals IP 20

– Coil terminals IP 20

– Built-in auxiliary terminals IP 20

Screw terminals (delivered in open position, screws of unused terminals must be tightened)

Main terminals (+,-) pozidriv 2 screws

M3.5 M4 M5

Coil terminals M3.5 (+,-) pozidriv 2 screws with cable clamp

Built-in auxiliary terminals (+,-) pozidriv 2 screws with cable clamp

M3.5 M4 M5

Tightening torque

Main pole terminals

– recommended Nm / lb.in 1.00 / 9 1.7 / 15 2.30 / 20

– max. Nm 1.20 2.20 2.60

Coil terminals

– recommended Nm / lb.in 1.00 / 9

– max. Nm 1.20

Built-in auxiliary terminals

– recommended Nm / lb.in 1.00 / 9 1.7 / 15 1.00 / 9

– max. Nm 1.20 2.20 1.20

Terminal marking and positioning see pages 1.35

2

) 1 x mm2 1 ... 4 1.5 ... 6 2.5 ... 16

}

2

– – – – – –

2

0.75 ... 2.5 0.75 ... 4 2.5 ... 10

L

l

2

1 ... 4

2

0.75 ... 2.5

L

l

2 x (5.6 x 6.5 mm)

1

1

1 L < 8 and l > 3.7 for coil terminal - L < 10 and l > 4.2 for built-in auxiliary terminals.

2 With LW 110 enlargement piece. See page 1.31.

Low Voltage Products & Systems 1.63

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 29

IEC Technical data

1

Across the line

1

contactors

General Technical Data

Contactor types: EK... 110 150 175 210 370 550 1000

Rated insulation voltage Ui

according to IEC 60947-4-1

according to UL/CSA

Rated impulse withstand voltage U

Standards Devices complying with international standards IEC 60947-1 / 60947-4-1

and European standards EN 60947-1 / 60947-4-1

Air temperature close to contactor see "Conditions for use" page 1.63, for control voltage limits and authorized mounting positions

– fi tted with thermal O/L relay °C -25 to +55

– without thermal O/L relay °C -40 to +70

– for storage °C -50 to +70

Climatic withstand acc. to IEC 60068-2-30

Operating altitude m < 3000

Shock withstand

acc. IEC 60068-2-27 and EN 60068-2-27

Mounting position 1 (see page 1.63) 1/2 sinusoidal shock for 15 ms: no change in contact position

Contactor in making or breaking position

Shock direction: A, C1, C2: 10 g

B1: 10 g

ABB

A AB1

B2: 10 g

V 1000

V 600

imp.

EK110 — EK1000

kV 8

C1

B2

C2

1.64 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 30

Across the line

IEC Technical data

contactors

EK110 — EK1000

Main Pole - Utilization Characteristics

Contactor types: EK... 110 150 175 210 370 550 1000

Rated operational voltage Ue max. V 1000 690

Rated frequency limits Hz 25 ... 400

Conventional free-air thermal current Ith

acc. to IEC 60947-4-1,

open contactors ø ≤ 40 °C A 200 250 300 350 550 800 1000

with conductor cross-sectional area mm2 95 150 185 240 2 x 185 2 x 240 2 x 300

Rated operational current I

for air temperature close to contactor

ø ≤ 40 °C A 200 250 300 350 550 800 1000

Ue max. 690 V ø ≤ 55 °C A 180 230 270 310 470 650 800

ø ≤ 70 °C A 155 200 215 250 400 575 720

with conductor cross-sectional area mm2 95 150 185 240 2 x 185 2 x 240 2 x 300

Utilization categorie AC-3

for air temperature close to contactor < 55 °C

Rated operational current Ie AC-3

220-230-240 V A 120 145 210 400 550 –

3-phase motors 380-400 V A 120 145 210 400 550 –

415 V A 120 145 210 400 550 –

440 V A 120 145 210 370 550 –

500 V A 120 145 210 370 550 –

690 V A 120 120 210 370 550 –

1000 V A 64 80 113 155 175 –

Rated operational power AC-3

1500 r.p.m. 50 Hz 220-230-240 V kW 30 45 59 110 160 –

1800 r.p.m. 60 Hz 380-400 V kW 55 75 110 200 280 –

3-phase motors 415 V kW 55 75 110 220 315 –

440 V kW 59 75 110 220 315 –

500 V kW 75 90 132 250 400 –

690 V kW 110 110 160 355 500 –

1000 V kW 90 110 160 220 250 –

Rated making capacity AC-3

according to IEC 60947-4-1 10 x I

Rated breaking capacity AC-3

according to IEC 60947-4-1 8 x I

Short-circuit protection for contactors

without thermal O/L relay - Motor protection excluded

Ue < 500 V a.c. - gG type fuse A 250 355 630 800 1000

Rated short-time withstand current I

at 40 °C ambient temp., in free air,

from a cold state 1 s A 1700 1800 2300 5500 6800

10 s A 900 1200 1680 5300 6400

30 s A 600 700 1000 3700 4400

1 min A 450 550 800 3000 3400

15 min A 210 250 320 1000 1200

Maximum breaking capacity

cos ø = 0.45 (cos ø = 0.35 for I

at 440 V A 1400 1500 2000 5000 5400 –

at 690 V A 1100 1200 1700 5000 5400 –

Heat dissipation per pole

I

Max. electrical switching frequency

– for AC-1 cycles/h 300 300

– for AC-3 cycles/h 300 –

– for AC-2, AC-4 cycles/h 150 120 –

Electrical durability see pages 1.75

Mechanical durability

– millions of operating cycles 10 5

– max. mechanical switching

frequency cycles/h 3600 3600

M

3

M

3

/ AC-1

e

{

AC-3 –

e

AC-3 –

e

cw

> 100 A)

e

Ie / AC-1 W 10 13 18 40 60 80

/ AC-3 W 3 5 9 15 25 –

e

1

1

Low Voltage Products & Systems 1.65

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 31

IEC Technical data

1

Across the line

1

contactors

Magnet System Characteristics for EK... Contactors - a.c. Operated

Contactor types: EK... 110 150 175 210 370 550 1000

Rated control circuit voltage U

– at 50 Hz V 24 ... 500 48 ... 500

– at 60 Hz V 24 ... 600 110 ... 600

Coil operating limits ø < 70 °C

according to IEC 60947-4-1 0.85 ... 1.1 x U

Drop-out voltage in % of Uc roughly 45 ... 65 %

Coil consumption

Average pull-in value 50 Hz1 VA 800 1100 3500

60 Hz1 VA 900 1200 4000

50/60 Hz2

Average holding value 50 Hz1 VA/W 44/15 52/18 125/50

60 Hz1 VA/W 52/18 65/22 140/60

50/60 Hz2

Operating time

between coil energization and:

– N.O. contact closing ms 20 ... 401 / 30 ... 502 30 ... 60

– N.C. contact opening ms 15 ... 351 / 25 ... 452 25 ... 55

between coil de-energization and:

– N.O. contact opening ms 7.5 ... 151 / 95 ... 1202 10 ... 20

– N.C. contact closing ms 10 ... 181 / 100 ... 1252 13 ... 23

c

Magnet System Characteristics for EK... Contactors - d.c. Operated

Contactor types: EK... 110 150 175 210 370 550 1000

Rated control circuit voltage U

V d.c. 12 ... 220 24 ... 220

Coil operating limits ø < 70 °C

according to IEC 60947-4-1 0.85 ... 1.1 x U

Drop-out voltage in % of U

Coil consumption - Average values

– pull-in value W 500 630 1100

– holding value W 2.5 2.5 20

Coil time constant

– open L/R ms 8 12

– closed L/R ms 50 60

Operating time

between coil energization and:

– N.O. contact closing ms 30 ... 50 60 ... 80

– N.C. contact opening ms 27 ... 47 55 ... 75

between coil de-energization and:

– N.O. contact opening ms 10 ... 35

– N.C. contact closing ms 13 ... 38

c

c

EK110 — EK1000

c

VA/VA 500/500 630/630 3800/3400

VA/W 2.5/2.5 2.5/2.5 140/60

roughly 15 ... 50 %

c

1 "A" coil voltage codes see page 1.29.

2 50/60 Hz "E" coil voltage codes see page 1.29.

1.66 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 32

Across the line

IEC Technical data

contactors

EK110 — EK1000

1

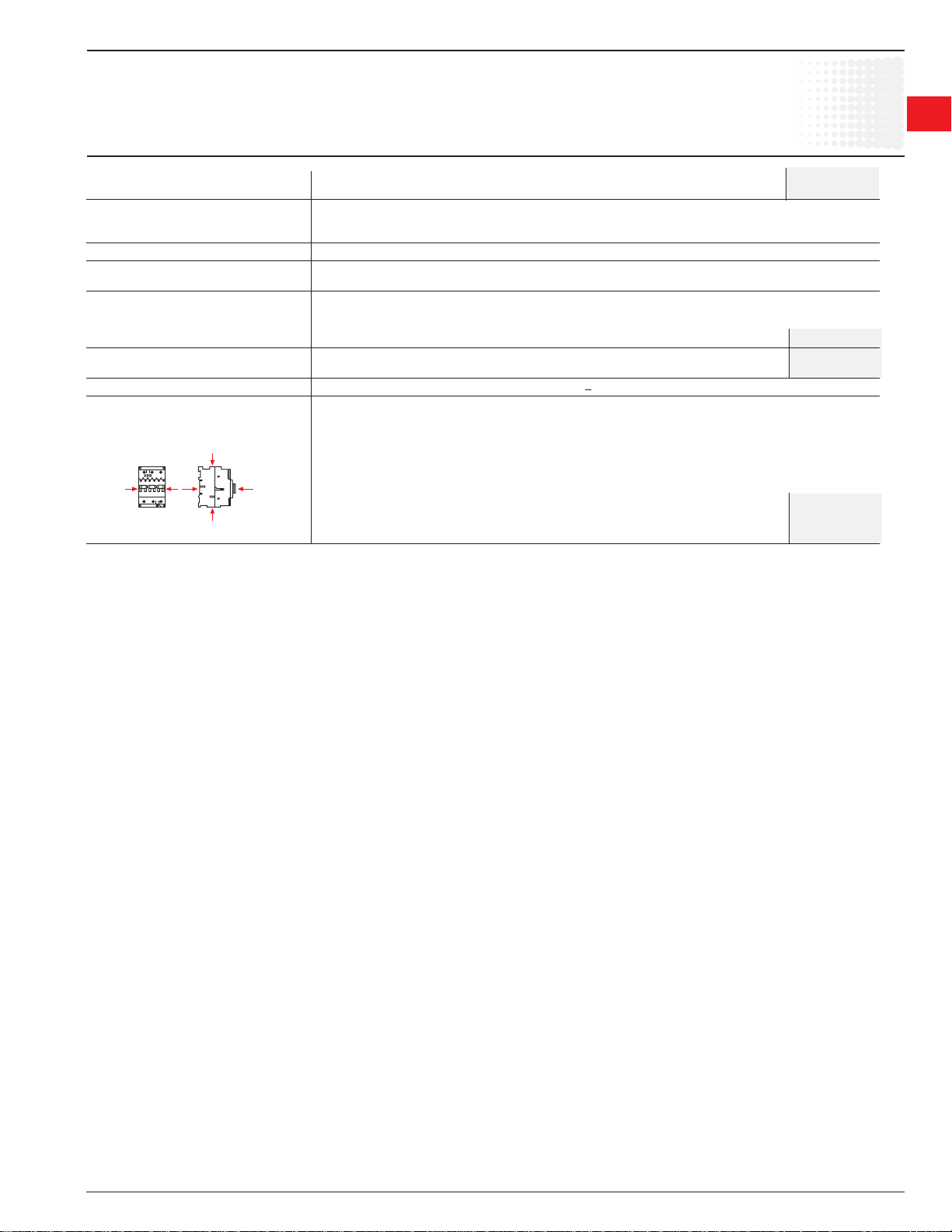

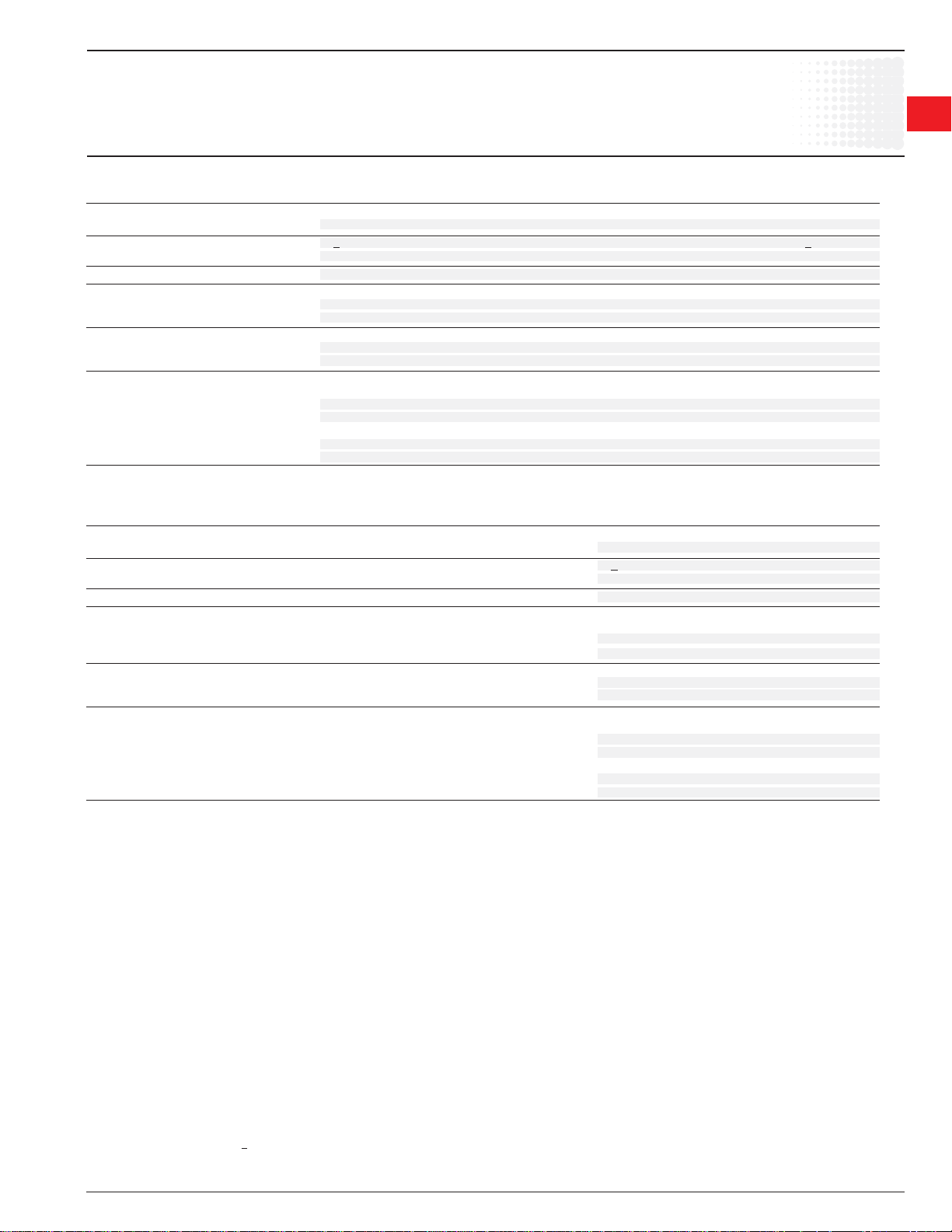

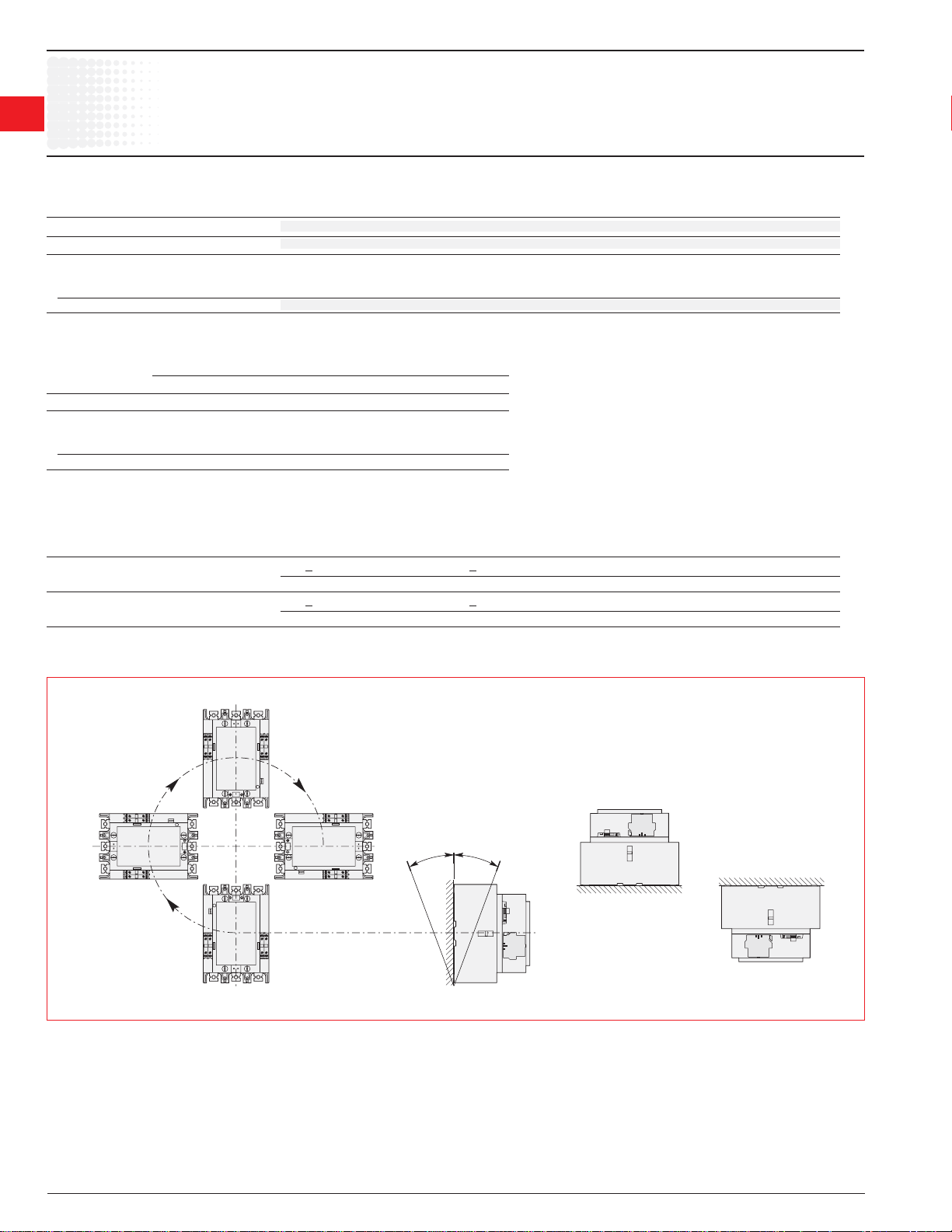

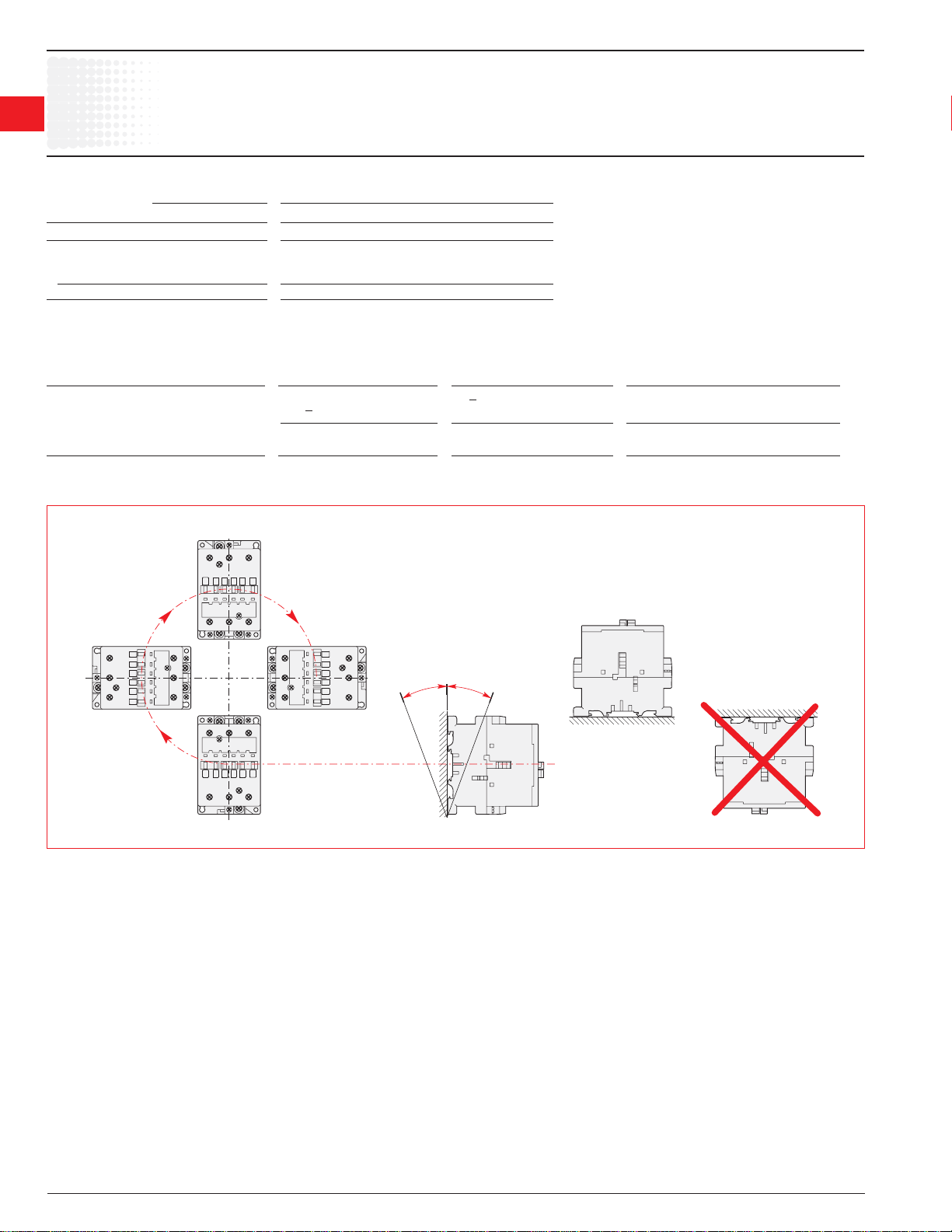

Mounting Characteristics

Contactor types: EK... 110 150 175 210 370 550 1000

Mounting positions see "Conditions for use"

Fixing

by screws (supplied) 4 x M6 4 x M6 (1)

Conditions for Use

Sustainable utilization conditions for contactors involving at the same time the Mounting position, Ambient temperature and Control voltage operating limits are

summarized in the table below.

Contactors Mounting position Ambient temperature Control voltage

E110 ... EK210 1, 1 + 30°, 3, 4, 5 < 70 °C 0.85 ... 1.1 x U

E370 ... EK1000 1, 1 + 30°, 2, 3, 4, 5 < 70 °C 0.85 ... 1.1 x U

6 unauthorized

2, 6 unauthorized

Mounting Positions (see the above table for authorized positions)

Position 2

c

c

1

Position 4

ABB

ABB

Position 1

ABB

ABB

Position 3

-30°

+30°

Position 5

Position 6

Position 1 ± 30°

1 Damping elements are supplied

Low Voltage Products & Systems 1.67

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU 000 023 C0201

Page 33

IEC Technical data

1

Across the line

1

contactors

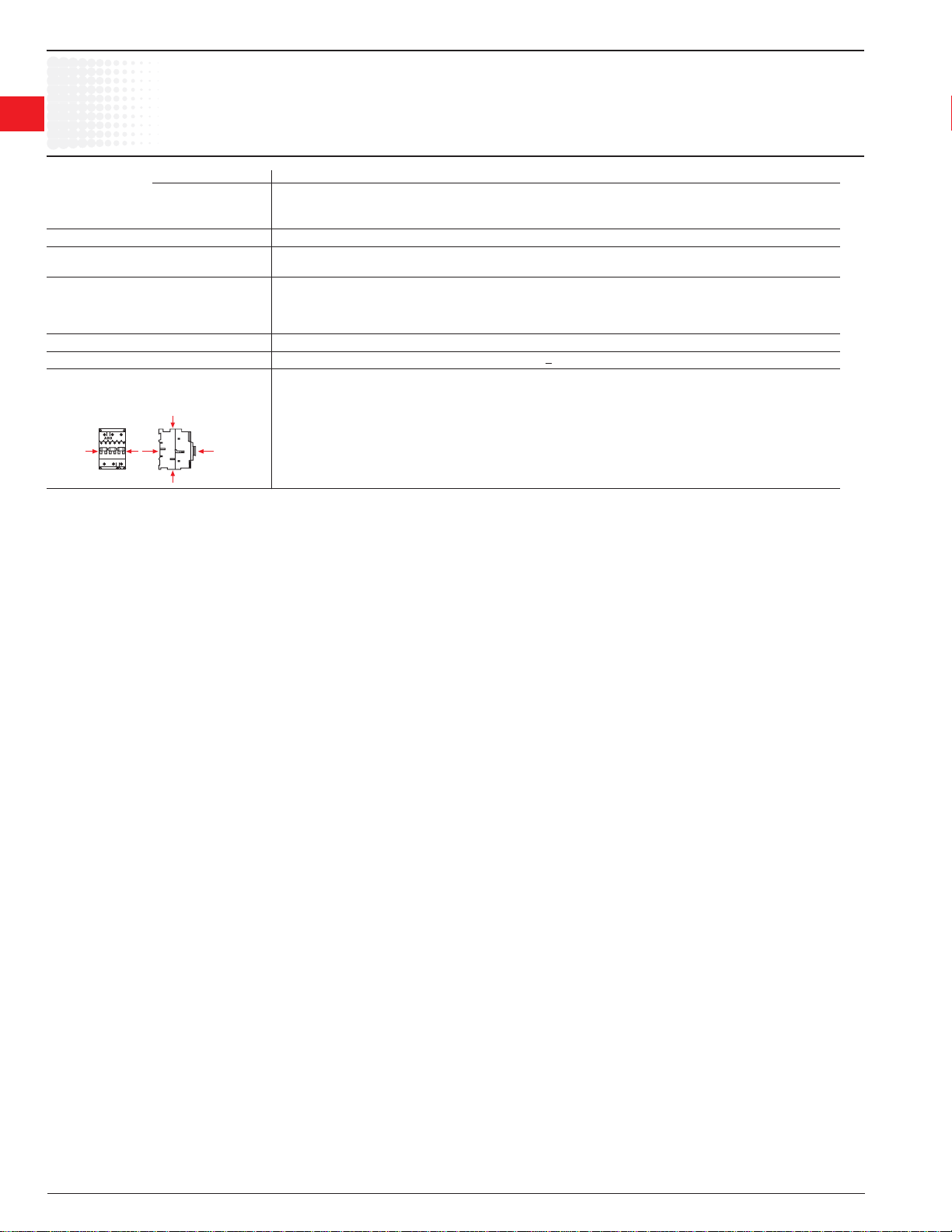

Connecting Characteristics

Contactor types: EK... 110 150 175 210 370 550 1000

Main terminals

Flat type

Connecting capacity (min. ... max.)

Main conductors (poles)

Rigid: 1 x mm

2 x mm2 – –

Rigid with connector

single for Cu cable mm

single for Al/Cu cable mm2 10 ... 70 35 ... 120 70 ... 300 95 ... 300

double for Al/Cu cable mm2 – – 2 x 35 ... 185 2 x 95 ... 300

Flexible

1 x mm2 – – – – – – –

2 x mm2 – – – – – – –

Bars or lugs L mm ≤ 30 30 33 55

Ø mm > 6 10 10 10

Auxiliary conductors

(coil terminals)

Rigid solid 1 x mm

2 x mm2 0.5 ... 2.5

Flexible with cable end

Lugs L mm ≤ 8

l mm > 3.7

Degree of protection acc. to IEC 60947-1 / Protection against direct contact acc. to VDE 0106 - Part. 100

EN 60947-1 and IEC 60529 / EN 60529

– Main terminals IP 00

– Coil terminals IP 20

Screw terminals

Main terminals Screws and bolts

M6 M10

Coil terminals (delivered in open position) M3.5 (+,-) pozidriv 2 screws with cable clamp

Tightening torque

Main pole terminals

– recommended

– max.

Coil terminals

– recommended

– max.

2

1 x mm2 0.5 ... 2.5

2 x mm2 0.5 ... 2.5

Nm / lb.in 5 / 44 18 / 160

Nm 6 22

Nm / lb.in 1.00 / 9

Nm 1.20

EK110 — EK1000

15

4.5

ø 6.6

2

– – – – – – –

25 ... 120 25 ... 185 70 ... 300 –

ø

L

2

0.5 ... 2.5

L

l

20

4

ø11

–

5

ø11

20

6

ø11

–

–

25

–

40

8

ø11

–

1.68 Low Voltage Products & Systems

1SXU 000 023 C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Page 34

Across the line

IEC Technical data

contactors

Contactor electrical durability

and Utilization categories

General

Utilization categories determine the current making and breaking conditions relating to the characteristics of the loads to be controlled by the contactors. International standard IEC 60947-4-1 and European standard EN 60947-4-1 are the standards to be referred to.

If I

is the current to be broken by the contactor and Ie the rated operational current normally drawn by the load, then:

c

• Categories AC-1 and AC-3: I

• Category AC-2: Ic = 2.5 x I

• Category AC-4: Ic = 6 x I

Generally speaking Ic = m x Ie where m is a multiple of the load operational current.

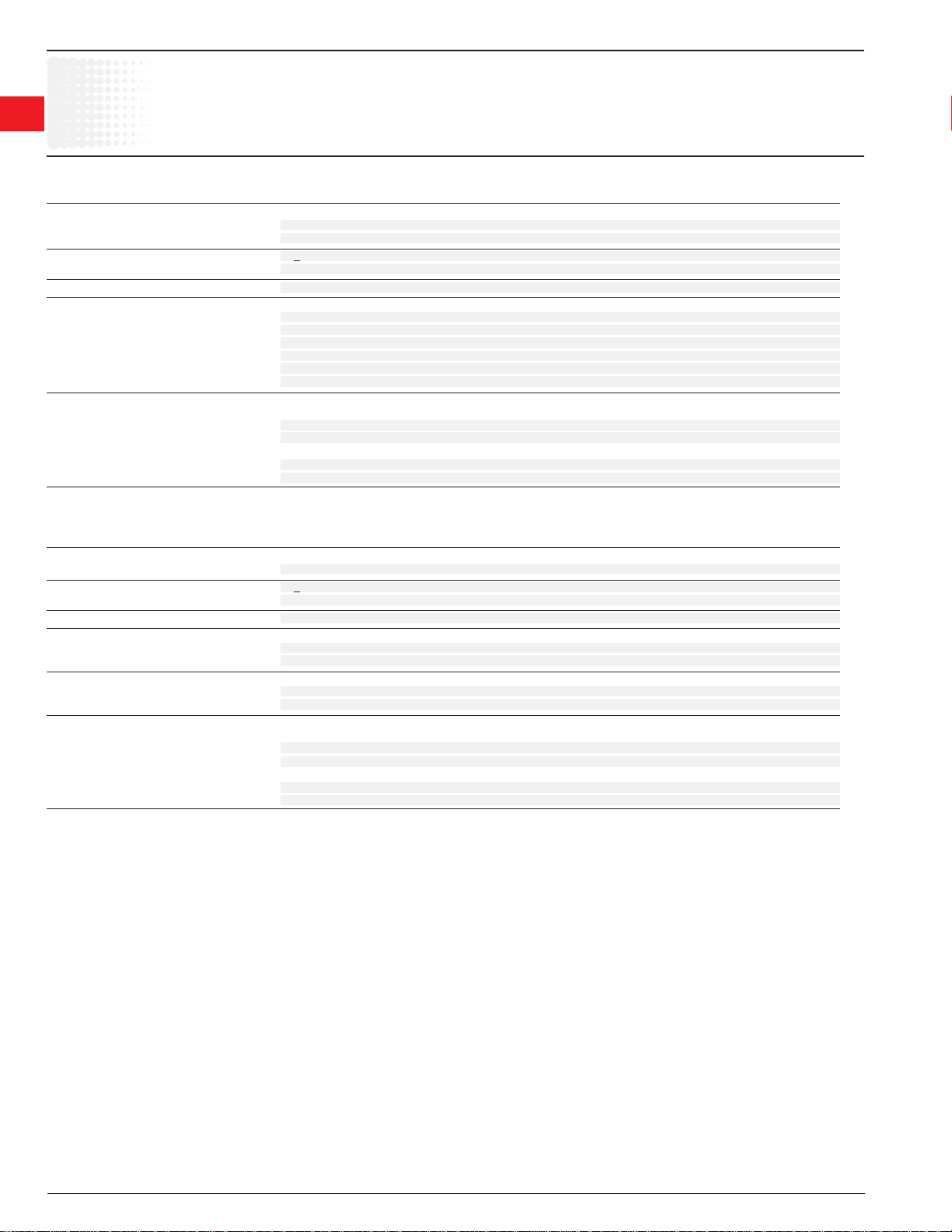

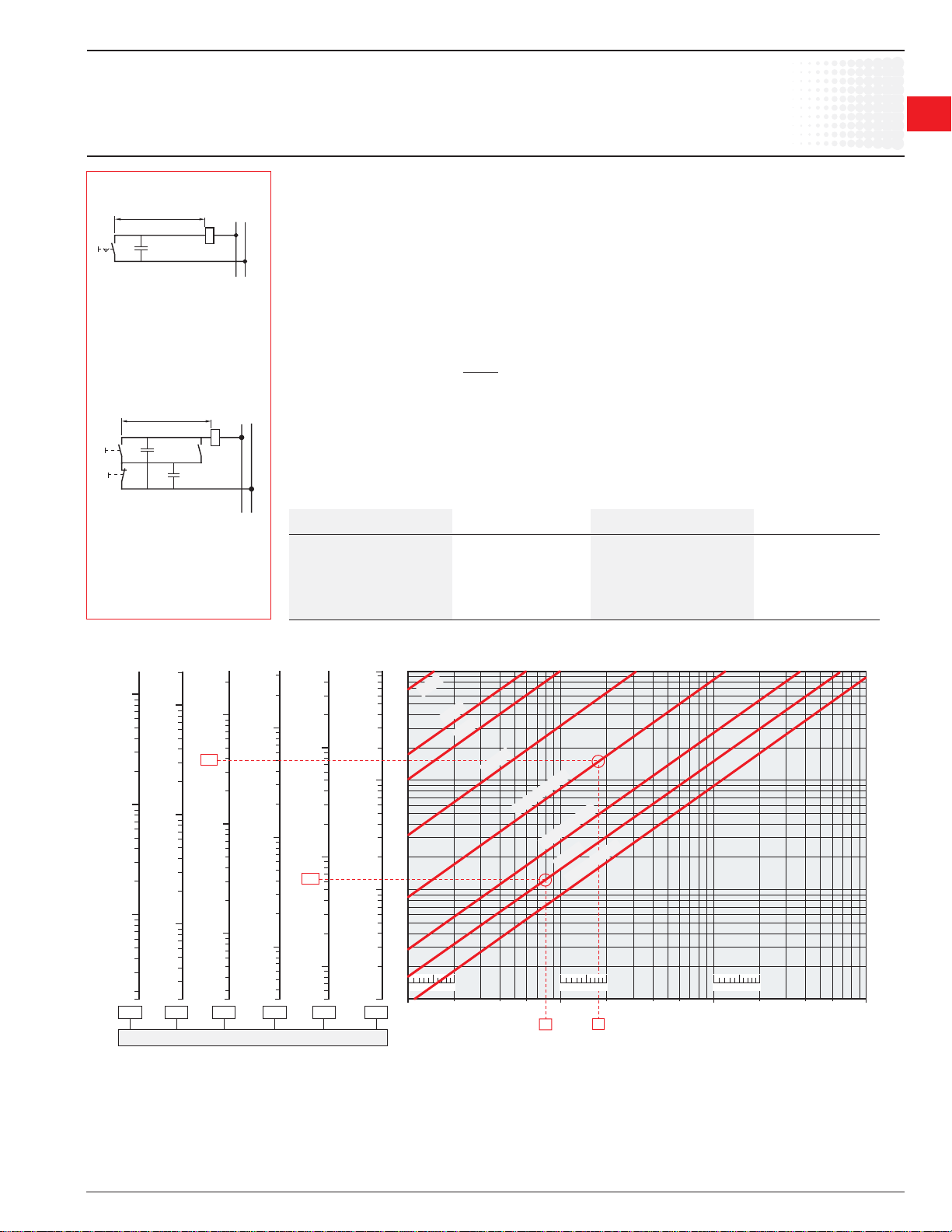

On pages 1.66 - 1.71, the curves corresponding to categories AC-1, AC-2, AC-3 and AC-4 represent the electrical durability variation of standard contactors in

relation to the breaking current Ic .

Electrical durability is expressed in millions of operating cycles.

These curves have been plotted for 400 V - 50 Hz 3-phase currents but remain valid up to 690 V - 40 ... 60 Hz provided that a check is carried out to make sure

that at the operational voltage Ue , the current Ie normally drawn by the load does not exceed the value of the contactor rated operational current: Ie / AC-1 for

category AC-1 and Ie / AC-3 for categories AC-3 and AC-4. The values are given for each type of contactor in pages 1.44, 1.45, 1.54, and 1.61 (Technical Data).

Curve Utilization Mode

Electrical durability forecast and contactor selection for categories AC-1, AC-2, AC-3 or AC-4

• Note the characteristics of the load to be controlled:

– Operational voltage ............................................................................................U