ABB CP630-x-WEB, CP620-x-WEB, CP635-F, CP635-x-WEB, CP651 Operating Instructions Manual

...Page 1

Page 2

Content

Introduction ........................................................................................................................ 3

Before You Start ................................................................................................................ 4

Safety Notices ............................................................................................................................. 4

Markups ....................................................................................................................................... 4

Product Overview .............................................................................................................. 5

Standards and Approvals ................................................................................................. 6

Product Identification ................................................................................................................ 6

Technical Specifications ........................................................................................................... 7

Environmental Conditions ......................................................................................................... 7

CP635-Fx: ................................................................................................................................ 8

Electromagnetic Compatibility (EMC) ...................................................................................... 9

Durability Information .............................................................................................................. 10

Technical Data ................................................................................................................. 11

Dimensions ............................................................................................................................... 15

Installation Environment ......................................................................................................... 16

Applying the Gasket ............................................................................................................... 16

Installation Procedure .............................................................................................................. 17

Connections ..................................................................................................................... 19

Serial Port ................................................................................................................................. 20

Ethernet Port ............................................................................................................................. 20

Power Supply, Grounding and Shielding ...................................................................... 21

Battery .............................................................................................................................. 22

Cleaning Faceplates ........................................................................................................ 23

Getting Started ................................................................................................................. 24

System Settings ............................................................................................................... 25

Dedicated LED Indicators ............................................................................................... 27

Unpacking and Packing Instructions ............................................................................. 28

2 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 3

Introduction

The operational guidelines described below is information which relates to the device, place of employment, transportation, storage, assembly, use and maintenance.

This Operating Instruction describes the main features of the CP600 Control Panels. The Operating Instructions refers to the following models:

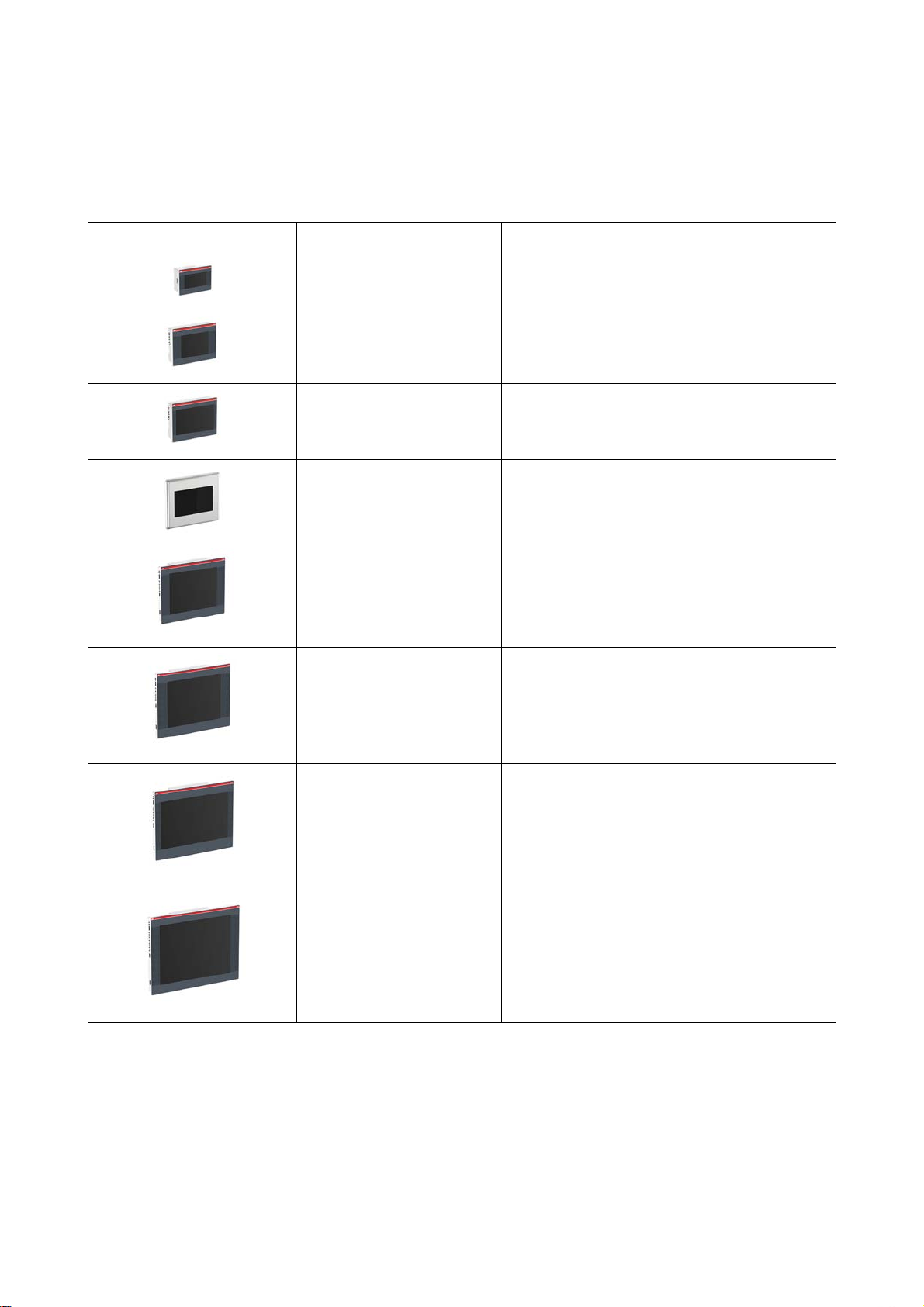

Picture Type Description

CP620-x, CP620-x-WEB Control panel with TFT color 4.3” widescreen

CP630-x, CP630-x-WEB Control panel with TFT color 5.7” display

CP635-x, CP635-x-WEB Control panel with TFT color 7” widescreen

CP635-Fx Control panel with TFT color 7” widescreen

display touchscreen

touchscreen

display touchscreen

display touchscreen

CP651-x, CP651-x-WEB Control panel with TFT color 10.4” display

touchscreen

CP661-x, CP661-x-WEB Control panel with TFT color 12.1” display

touchscreen

CP665-x, CP665-x-WEB Control panel with TFT color 13.3” widescreen

display touchscreen

CP676-x, CP676-x-WEB Control panel with TFT color 15” display

touchscreen

3

CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 4

Before You Start

Safety Notices

Indicates an imminent risk. It will lead to death or serious injury if not avoided.

DANGER!

Indicates a possible risk. It may lead to death or serious injury if not avoided.

WARNING!

Indicates a possible risk. It may lead to light or slight injury or material damage if not avoided.

CAUTION!

Markups

Enumeration.

Precondition for an operation instruction or a description.

Operation instruction with one step.

1. Operation instruction with several steps.

Result of an operation.

Helpful information with background information or an emphasized notice.

NOTE

Application tips or other useful information and suggestions.

TIP

4 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 5

Product Overview

The Control Panels combine state-of-the-art features and top performance with an outstanding design.

They are the ideal choice for all demanding HMI applications including factory and building automation.

These Control Panels have been designed to run the PB610 Panel Builder 600 software.

PB610 Panel Builder 600 Runtime included. Full compatibility with PB610 Panel Builder 600.

Full vector graphic support. Native support of SVG graphic objects. Transparency and alpha blend-

ing.

Full object dynamics: Control visibility and transparency, move, resize, rotate any object on screen.

Change properties of basic and complex objects.

TrueType fonts.

Multilanguage applications. Easily create and manage your applications in multiple languages to

meet global requirements. Far East languages are supported. Tools available in PB610 Panel Builder

600 support easy third-party translations and help reducing development and maintenance costs of

the application.

Data display in numerical, text, bargraph, analog gauges and graphic image formats.

Rich set of state-of-the-art HMI features: Data acquisition, alarm handling, scheduler and timed ac-

tions (daily and weekly schedulers, exception dates), recipes, users and passwords, e-mail and RSS

feeds, rotating menus.

Includes support for a set of communication drivers.

Multiple drivers communication capability.

Remote monitoring and control. Client-Server functionality.

Offline and online Simulation with PB610 Panel Builder 600.

Powerful scripting language for automating HMI applications. Script debugging improves efficiency in

application development.

Rich gallery of vector symbols and objects.

Project templates.

5 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 6

Standards and Approvals

The Control Panels have been designed for installation and use in an industrial environment in compliance with the 2004/108/EC EMC Directive.

The products have been designed in compliance with:

EN 61000-6-4:2007+A1:2011 EN 55011 Class A

EN 61000-6-2:2005 EN 61000-4-2

EN 61000-4-3

EN 61000-4-4

EN 61000-4-5

EN 61000-4-6

The installation of these devices into the residential, commercial and light-industrial environments is allowed only in the case that special measures are taken in order to get ensure conformity

to EN 61000-6-3.

The products are in compliance with the Restrictions on Certain Hazardous Substances (RoHS) Directive

2011/65/EU. In compliance with the above regulations the products are CE marked.

If the mounting surface is not plane and robust enough, the degree IP69K is not guaranteed.

A special mounting flange is included to provide the necessary support.

NOTE

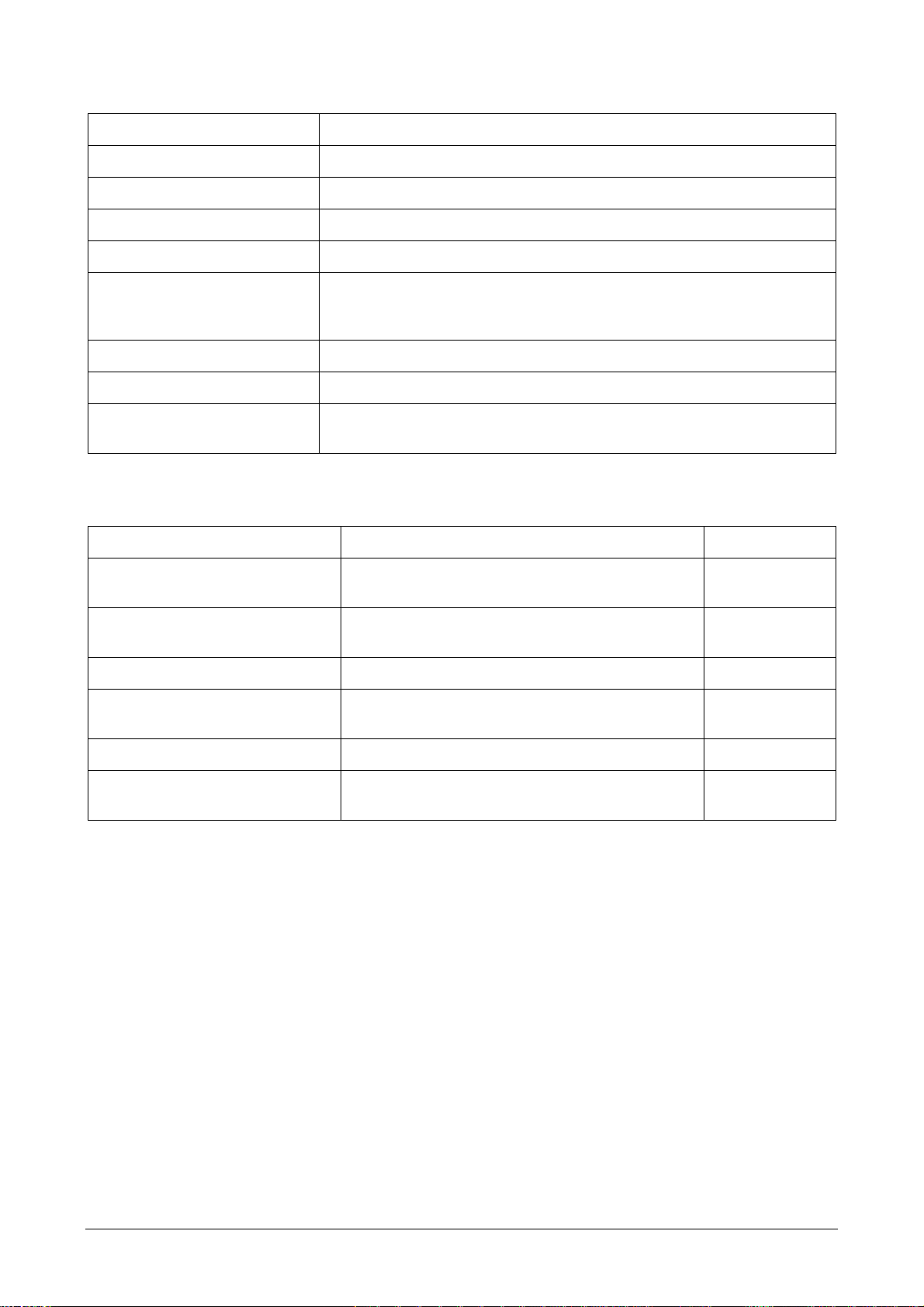

Product Identification

The Control Panel products are identified by a product label. The label reports several information, including the model name, the part number, the power supply, the date of production (in the following format:

ywwy) and two barcodes. The first code is the version code, the second one the serial number (S.N.).

Example of product label

Information on type plate (example) Description

CP620 Product type

1SAP520200R0001 Product part number

1231 ywwy – week and year of production

09994971497 Serial number

040100A01000140 Version number of the product

WEB 1.5.15.117 Version number of the MicroBrowser

(only valid for CP6xx-x-WEB)

6 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 7

Technical Specifications

Parameter Value

Touchscreen technology Resistive

Back-up battery 3V 50mAh Lithium, rechargeable, not user-replaceable, model VL2330

Fuse Automatic

Serial Port RS-232, RS-485, RS-422 software configurable

User memory Flash 128 MB for CP620, CP630, CP635 including –x, -x-WEB

Flash 256 MB for CP635-Fx,

Flash 256 MB for CP651, CP661, CP665, CP676 including –x, -x-WEB

Recipe memory Flash

Hardware clock Clock/calendar with back-up battery

Accuracy RTC

(at 25 °C operating)

< 100 ppm

Environmental Conditions

Parameter Value According to

Operating temperature

(surrounding air temperature)

Storage temperature -20 °C … +70 °C

Operating and storage humidity 5 % … 85 % RH not-condensing EN 60068-2-30

Vibrations 5 Hz … 9 Hz, 7 mm

Shock ± 50 g, 11 ms, 3 pulses per axis EN 60068-2-27

Protection class IP66 front panel *

*) The front face of the Control Panel unit, installed in a solid panel, has been tested using conditions

equivalent to the standards shown in the ”Environmental Conditions”. Even though the CP600 unit’s level

of resistance is equivalent to these standards, oils that should have no effect on the control panel can

possibly harm the unit. This can occur in areas where either vaporized oils are present, or where low viscosity cutting oil are allowed to adhere to the unit for long periods of time. If the control panel’s front face

protection sheet becomes peeled off, these conditions can lead to the ingress of oil into the control panel

and separate protection measures are suggested.

0 °C … +50 °C

for CP635-Fx: -20 °C … +60 °C

for CP635-Fx: -40 °C … +85 °C

p-p

9 Hz … 150 Hz, 1 g

for CP635-Fx: IP69K

EN 60068-2-14

EN 60068-2-14

EN 60068-2-6

EN 60529

If the installation gasket is used for a long period of time, or if the unit and its gasket are removed from the

panel, the original level of the protection cannot be guaranteed.

7 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 8

CP635-Fx:

Main Features

Stainless steel bezel 316/1.440l

Food-compatible gasket

Food standard sealing compliant with FDA 21 CFR 177.2006

PCAP touchscreen, can be operated with gloves for food areas

Designated according to DIN EN 1672-2

Designated according to the EHEDG Guideline

Chemical Resistance

Protective front foils are made with high-quality polyester. Polyester withstands exposure of more than

24 h duration under DIN 42 115 Part 2 to wide range of chemicals without visible change.

Sodium hydroxide 50 %

Ammonia < 32 %

Sulphuric acid 30 %

Acetic acid < 50 %

IP69K standard

Water temperature 80 °C (176 °F)

Pressure 8 … 10 MPa (80 … 100 bar) (1160 … 1450 psi)

Flow rate 14 … 16 l/m (3.7 … 4 gal/m)

Nozzle distance 10 … 15 cm (4 … 6 inch)

Angles 0° 30° 60° 90°

Timing 30 s/each angle

8 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 9

Electromagnetic Compatibility (EMC)

Test executed on the 230 V AC side of the Power Supply (EN 61000-4-11).

Parameter Value According to

Radiated disturbance test Class A EN 55011

Electrostatic discharge immunity test

Radiated, radio-frequency,

electromagnetic field immunity test

Burst immunity test ± 2 kV DC power port

Surge immunity test ± 0.5 kV DC power port (line to earth)

Immunity to conducted disturbances inducted by radiofrequency field

Voltage dips, short interruptions and voltage variations

immunity test

8 kV (air electrostatic discharge)

4 kV (contact electrostatic discharge)

80 MHz … 1 GHz, 10 V/m

1.4 GHz … 2 GHz, 3 V/m

2 GHz … 2.7 GHz, 1 V/m

± 1 kV signal line

± 0.5 kV DC power port (line to line)

± 1 kV signal line (line to earth)

0.15 … 80 MHz, 10 V EN 61000-4-6

Port: AC mains. Level:

100 % / duration: 1 cycle and 250 cycles (50 Hz);

40 % / duration: 10 cycles (50 Hz);

70 % / duration: 25 cycles (50 Hz);

Phase: 0°-180°

EN 61000-4-2

EN 61000-4-3

EN 61000-4-4

EN 61000-4-5

9 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 10

Durability Information

Parameter Value of CP600 Value of CP635-Fx

Backlight service life

(LED type)

MTBF value: 40,000 h

(time of continuous operation until the brightness of the backlight reaches

50 % of the rated value when the surrounding temperature reach 25 °C),

1

see

Battery lifetime 10 years if the surrounding temperature is 25 °C

5 years if the surrounding temperature is 40 °C

Front foil (without directly

10 years if the surrounding temperature is 25 °C

expose to sunlight or UV ray)

UV Resistance Indoor applications: After 300 h cycled humidity in QUV accelerated

weathering, some yellowing and brittleness may be present.

Touch panel

(resistive film, analog)

1,000,000 or more of activations,

2

see

Not applicable

(capacitive touchscreen with no

mechanical stress), see

3

Touchscreen reliability > 1 million operations Not applicable

(capacitive touchscreen with no

mechanical stress)

1

Extended use in environments where the surrounding air temperature is 40 °C or higher may degrade

backlight quality/reliability/durability.

2

Solvent resistance:

Contact for ½ hour at 21 °C, no visible effect: Acetone, Butyl Cellosolve, Cyclohexanone, Ethyl Acetate,

Hexane, Isopropyl Alcohol, MEK, Methylene Chloride, Toluene, Xylene

Contact for 24 hours at 49 °C, no visible effect: Coffee, Ketchup, Lemon Juice, Mustard (slight yellow stain),

Tea, Tomato Juice.

3

Solvent resistance:

Contact of more than 24 hours, no visible effect: Acetone, Acetic acid <50%, Ammonia <32%, Hydrochloric

acid <10%, Hydrogen peroxide <25%, Potassium Hydroxide (Caustic Potash) <2%, Sodium hydroxide 50%,

Sodium hypochlorite <20%, Sulphuric Acid 30%, Toluene

10 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 11

Technical Data

Model CP620-x (-WEB) CP630-x (-WEB)

Display/Backlight TFT Color / LED TFT Color / LED

Colors 64 K 64 K

Resolution 480 x 272 320 x 240

Diagonal (inches) 4.3” 5.7“

Dimming Yes Yes

Touchscreen Yes Yes

User memory flash 128 MB 128 MB

SC card slot Yes Yes

Recipe memory Yes. Flash memory storage limited

only by available memory

Serial Port RS-232, RS-485, RS 422, DB9

female, software configurable

Ethernet port 2 x 10/100 Mbit/s with integrated

switch

USB port 1 x host interface, version 2.0 and

1.1

Expansion slot for future

optional plugin modules

Battery Rechargeable Rechargeable

Real-time clock Yes Yes

Voltage 18 … 32 V DC *) 18 … 32 V DC *)

Current rating (at 24 V DC) 0.4 A 0.65 A

Weight 1 kg 1 kg

*) For applications not requiring compliance with EN 61131-2 and specifically in reference to 10 ms voltage

dips, the minimum power supply voltage is 10 V DC.

1 x 2 x

Yes. Flash memory storage limited

only by available memory

RS-232, RS-485, RS 422, DB9

female, software configurable

2 x 10/100 Mbit/s with integrated

switch

2 x host interface,

1 version 2.0 and 1.1,

1 version 2.0

11 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 12

Model CP635-Fx CP635-x (-WEB)

Display/Backlight TFT Color / LED TFT Color / LED

Colors 64 K 64 K

Resolution 800 x 480 800 x 480

Diagonal (inches) 7“ widescreen 7“ widescreen

Dimming Yes Yes

Touchscreen Yes Yes

User memory flash 256 MB 128 MB

SC card slot Yes Yes

Recipe memory Yes. Flash memory storage limited

only by available memory

Serial Port RS-232, RS-485, RS 422, DB9

female, software configurable

Ethernet port 2 x 10/100 Mbit/s with integrated

switch

USB port 2 x host interface,

1 version 2.0 and 1.1,

1 version 2.0

Expansion slot for future

- 2 x

Yes. Flash memory storage limited

only by available memory

RS-232, RS-485, RS 422, DB9

female, software configurable

2 x 10/100 Mbit/s with integrated

switch

2 x host interface,

1 version 2.0 and 1.1,

1 version 2.0

optional plugin modules

Battery Rechargeable Rechargeable

Real-time clock Yes Yes

Voltage 18 … 32 V DC *) 18 … 32 V DC *)

Current rating (at 24 V DC) 0.9 A 0.7 A

Weight 1.5 kg 1 kg

*) For applications not requiring compliance with EN 61131-2 and specifically in reference to 10 ms voltage

dips, the minimum power supply voltage is 10 V DC.

12 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 13

Model CP651-x(-WEB) CP661-x(-WEB)

Display/Backlight TFT Color / LED TFT Color / LED

Colors 64 K 64 K

Resolution 800 x 600 800 x 600

Diagonal (inches) 10.4” 12.1“

Dimming Yes Yes

Touchscreen Yes Yes

User memory flash 256 MB 256 MB

SC card slot Yes Yes

Recipe memory Yes. Flash memory storage limited

only by available memory

Serial Port RS-232, RS-485, RS-422, DB9

female, software configurable

Ethernet port 2 x 10/100 Mbit/s

with integrated switch

USB port 2 x host interface,

1 version 2.0 and 1.1,

1 version 2.0

Expansion slot for future

2 x 2 x

Yes. Flash memory storage limited

only by available memory

RS-232, RS-485, RS-422, DB9

female, software configurable

2 x 10/100 Mbit/s

with integrated switch

2 x host interface,

1 version 2.0 and 1.1,

1 version 2.0

optional plugin modules

Battery Rechargeable Rechargeable

Real-time clock Yes Yes

Voltage 18 … 32 V DC *) 18 … 32 V DC *)

Current rating (at 24 V DC) 1 A 1.2 A

Weight 2.1 kg 2.8 kg

*) For applications not requiring compliance with EN 61131-2 and specifically in reference to 10 ms voltage

dips, the minimum power supply voltage is 10 V DC.

13 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 14

Model CP665-x(-WEB) CP676-x(-WEB)

Display/Backlight TFT Color / LED TFT Color / LED

Colors 64 K 64 K

Resolution 1280 x 800 1024 x 768

Diagonal (inches) 13.3” 15“

Dimming Yes Yes

Touchscreen Yes Yes

User memory flash 256 MB 256 MB

SC card slot Yes Yes

Recipe memory Yes. Flash memory storage limited

only by available memory

Serial Port RS-232, RS-485, RS-422, DB9

female, software configurable

Ethernet port 2 x 10/100 Mbit/s

with integrated switch

USB port 2 x host interface,

1 version 2.0 and 1.1,

1 version 2.0

Expansion slot for future

optional plugin modules

Battery Rechargeable Rechargeable

Real-time clock Yes Yes

Voltage 18 … 32 V DC *) 18 … 32 V DC *)

Current rating (at 24 V DC) 1.2 A 1.4 A

Weight 2.8 kg 3.5 kg

*) For applications not requiring compliance with EN 61131-2 and specifically in reference to 10 ms voltage

dips, the minimum power supply voltage is 10 V DC.

2 x 2 x

Yes. Flash memory storage limited

only by available memory

RS-232, RS-485, RS-422, DB9

female, software configurable

2 x 10/100 Mbit/s

with integrated switch

2 x host interface,

1 version 2.0 and 1.1,

1 version 2.0

14 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 15

Dimensions

CP620 CP630, CP635, CP651, CP661, CP665, CP676

including –x(-WEB) including –x(-WEB), CP635-Fx

Model A B C H L F

mm inches mm inches mm inches mm inches mm inches mm inches

CP620-x(-WEB) 136 5.35” 96 3.78” 52 2.05” 107 4.21” 147 5.78” 4 0.16”

CP630-x(-WEB) 176 6.93” 136 5.35” 47 1.85” 147 5.79” 187 7.36” 4 0.16”

CP635-x(-WEB) 176 6.93” 136 5.35” 47 1.85” 147 5.79” 187 7.36” 4 0.16”

CP635-Fx 176 6.93” 136 5.35” 44 1.73” 177 6.96” 217 8.54” 4 0.16”

CP651-x(-WEB) 276 10.87” 221 8.70” 56 2.20” 232 9,13” 287 11.30” 4 0.16”

CP661-x(-WEB) 326 12.83” 256 10.08” 56 2.20” 267 10.51” 336 13.23” 4 0.16”

CP665-x(-WEB) 326 12.83” 256 10.08” 56 2.20” 267 10.51” 336 13.23” 4 0.16”

CP676-x(-WEB) 381 15.00” 296 11.65” 60 2.36” 307 12.09” 392 15.43” 4 0.16”

Model CSD: Minimum compass safe distance of

standard compass

mm inches mm inches

CSD2: Minimum compass safe distance of

steering compass, standby steering

compass and emergency compass

CP620-x(-WEB) 350 13.78” 200 7.87”

CP630-x(-WEB) 350 13.78” 200 7.87”

CP635-x(-WEB) 450 17.72” 250 9.84”

CP635-Fx N.A. N.A. N.A. N.A.

CP651-x(-WEB) 600 23.62” 400 15.75”

CP661-x(-WEB) 250 9.84” 150 5.91”

CP665-x(-WEB) 500 19.69” 150 5.91”

CP676-x(-WEB) 550 21.65” 300 11.81”

15 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 16

Installation Environment

The equipment is not intended for continuous exposure to direct sunlight. This might accelerate the aging

process of the front panel film.

The equipment is not intended for installation in contact with corrosive chemical compounds. Check the

resistance of the front panel film to a specific compound before installation.

Do not use tools of any kind (screwdrivers etc.) to operate the touchscreen of the panel.

In order to meet the front panel protection classifications, proper installation procedure must be followed:

The borders of the cutout must be flat.

The cutout for the panel must be of the dimensions indicated in this manual.

Screw up each fixing screw until the plastic bezel corner get in contact with the panel.

The IP66 is guaranteed only if:

Maximum deviation from the plane surface to the cut-out: 0.5 mm

Thickness of the plate the equipment is mounted: 1.5 mm to 6 mm

Maximum surface roughness where the gasket is applied: 120 µm

Applying the Gasket

Apply the gasket on the rear of the frame.

If the mounting surface is not plane and robust enough, the degree IP69K is not guaranteed.

A special mounting flange is included to provide the necessary support.

NOTE

CP620, CP630, CP635 CP650, CP661, CP665, CP676

including –x(-WEB) versions including –x(-WEB) versions

Gasket

A

16

Installation cut-out

B

CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 17

Installation Procedure

Place the fixing brackets.

Screw each fixing screw until the bezel corner gets in contact with the panel.

CAUTION!

17 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 18

Communication Cables

The communication cable must be chosen for the type of device being connected.

Connection to an AC-500 with the TK681 CP600-AC500 RS232 communication cable

Connection to an AC-500(-eCo) with the TK682 CP600-AC500-eCo RS485 communication cable

*) all resistors: 0.25 W

Shield

1

18 CP620, CP630, CP635, CP651, CP661, CP665, CP676

SubD9 male

2

Page 19

Connections

Serial port

1

2x Ethernet port

2

Serial port

1

USB port

3

Power supply connector

4

2x USB port

3

Expansion slot for plugin module

5

SD card slot

6

2x Expansion slot for plugin modules

5

2x Ethernet port

2

19

Power supply connector

4

SD card slot

6

CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 20

Serial Port

The serial port is used to communicate with the PLC or with another type of controller.

Different electrical standards are available for the signals in the PLC port connector: RS-232, RS-422,

RS-485.

It is always necessary to use the correct cable type to connect on the PLC.

If the proper cable is not used, communication with the PLC will not be possible.

NOTE

The serial port is software programmable. Make sure you select the appropriate interface in the programming software.

Serial port.

RS-232 RS-422, RS-485

Pin Description Pin Description

1 GND 1 GND

2 2

3 TX 3 CHA-

4 RX 4 CHB-

5 5

6 +5 V output 6 +5 V output

7 CTS 7 CHB+

8 RTS 8 CHA+

9 9

The communication cable must be chosen for the type of device being connected.

Ethernet Port

The Ethernet port has two status indicators.

Ethernet Port

A OFF: Valid link has not been detected

ON: Valid link has been detected

20 CP620, CP630, CP635, CP651, CP661, CP665, CP676

B ON: No activity

OFF: Activity

Page 21

Power Supply, Grounding and Shielding

DC Power Connector, Female - R/C Terminal Blocks (XCFR2), manufactu red by Weidmüller Inc.,

Cat. No. BLZ 5.08, torque 4.5 lb-in

Ensure that the power supply has enough power capacity for the operation of the equipment.

NOTE

The unit must always be grounded to earth. Grounding helps limit the effects of noise due to electromagnetic interference on the control system.

1. Do the earth connection using either the screw or the fasten terminal located near the power supply

terminal block. A label helps identify the ground connection.

2. Connect to ground the terminal 3 on the power supply terminal block.

3. The power supply circuit may be floating or grounded. In the latter case, connect to ground the power

source common as shown in the figure below with a dashed line.

When using the floating power scheme, note that the panes internally connects the power common to

ground with a 1 MΩ resistor in parallel with a 4,7 nF capacitor.

The power supply must have double or reinforced insulation.

Suggested wiring for the power supply.

All the electronic devices in the control system must be properly grounded. Grounding must be performed

according to applicable regulations.

21 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 22

Battery

The Control Panels are equipped with a rechargeable lithium battery, not user-replaceable.

The battery maintains the hardware real-time clock (date and time).

Charging the Battery

At first installation recharge the battery for 48 h.

When the battery is charged, it assures a period of 3 month of data back-up at 25 °C.

CP620-x(-WEB)

CP630, CP635, CP651, CP661, CP665, CP676 including –x(-WEB) versions

The battery must not be disposed as unsorted domestic waste.

NOTE

22

Dispose the battery according to the local regulations.

CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 23

Cleaning Faceplates

The equipment must be cleaned only with a soft cloth and neutral soap product. Do not use solvents.

23 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 24

Getting Started

The Control Panels (CP6xx-x, not CP6xx-x-WEB versions) must be programmed with the programming

package PB610 Panel Builder 600.

The Control Panels are programmed via the Ethernet interface.

The Control Panel must be in configuration mode to be programmed.

To program a Control Panel connect the Control Panel to a PC running PB610 Panel Builder 600

software package.

The software package PB610 Panel Builder 600 is a Windows

stalled. The Windows

and must already be installed on the PC.

PB610 Panel Builder 600 uses the PC Ethernet interface to communicate with the target device.

Make sure that the proper firewall policy is configured in order to allow PB610 Panel Builder 600 to

access the network.

The version of the Panel Builder used must be compatible with the PB610 Panel Builder 600 Runtime

version installed on the Control Panel to be programmed. An update of the panel´s runtime can be done

by means of the programming software.

Check with technical support for more information on compatibility between firmware and programming

software.

TM

environment is not included in the software package PB610 Panel Builder 600

TM

application and must be properly in-

24 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 25

System Settings

The Control Panels have a system settings tool to allow basic and preliminary settings to the unit.

System settings tool

The system settings tool is a rotating menu.

Use the navigation buttons Next and Back to scroll between the available options.

On the left side the selected component and function are highlighted.

On the right side, on the “Info” pane, the information about the selected option is shown.

For example the version of the Main OS component.

The system settings tool has two operating modes: User Mode and System Mode. The difference between them is the number of available options.

System settings in User Mode is activated from the contextual menu, accessible by clicking and holding

any unused area on the touchscreen for a few seconds. Default holding time is 2 sec. This is a runtime

parameter that could have been changed.

System settings in System Mode can be activated with the so-called emergency system access procedure. This procedure consists in tapping in the middle of the touchscreen with a finger at a high frequency

while the system is powering up. The emergency procedure can only be accessed at power up.

User Mode

User Mode is the simplest possible interface where a generic user can get access to the basic settings of

the panel:

Calibrate Touch: allows to calibrate the touchscreen interface

Network: allows to change the options of the panel on-board network card

Time: allows to change the panel RTC (real time clock) options, including time zone and DST (day-

light saving time)

Display settings: automatic backlight turnoff and brightness adjustment

BSP settings: allows to check the BSP (Board Support Package) version (example 2.37), check the

operating hours timers for the unit and separately for the backlight, enable/disable the buzzer, enable/disable the use of the “low battery” front LED indicator

25 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 26

System Mode

System Mode is the complete interface of the system settings tool where all options are available.

Additionally to the options of the User Mode the following options are available:

Format Flash: allows to format the internal panel flash disk

Resize Image Area: allows to resize the flash portion reserved to store the splash screen image dis-

played by the unit at power up.

Download Configuration OS: allows to check current version and upgrade the back-up operating sys-

tem.

Download Main OS: allows to check current version and upgrade the main operating system.

Download Splash Image: allows changing the splash screen image displayed by the unit at power

up; the image should be provide in a specific format. We suggest to update Splash Screen Image directly from Panel Builder software which supports this feature starting from V 1. 50

Download Bootloader: allows to check current version of the system boot loader and to upgrade it.

Only for CP651-x, CP661-x, CP665-x, CP676-x:

Download Main FPGA: allows to check current version and upgrade the main FPGA firmware.

Download Safe FPGA: allows to check current version and upgrade the back-up (safe) copy of the

FPGA Firmware.

Download System Supervisor: allows to check current version and upgrade the system supervisor

firmware responsible for RTC and power supply handling.

26 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 27

Dedicated LED Indicators

There is one LED in the upper left part of the front below the red stripe. The meaning of the LED indicator

is explained in the following table:

LED color Status Meaning

Green On Normal Operation

Blinking

Red On

Communication error or alarm requires acknowledgement

Hardware fault or battery low

27 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 28

Unpacking and Packing Instructions

To repack the unit follow the instructions backwards.

28 CP620, CP630, CP635, CP651, CP661, CP665, CP676

Page 29

JOKAB SAFETY DK A/S

Rugmarken 15

3520 Farum

Denmark

Phone: +45 44341454

Mail: info@jokabsafety.dk

Web: www.jokabsafety.dk

Contact us

ABB Automation Products GmbH

Eppelheimer Straße 82

69123 Heidelberg, Germany

Phone: +49 62 21 701 1444

Fax: +49 62 21 701 1382

E-Mail: plc.sales@de.abb.com

www.abb.com/plc

Note:

We reserve the right to make technical changes or modify the

contents of this document without prior notice. With regard to

purchase orders, the agreed particulars shall prevail. ABB AG

does not accept any responsibility whatsoever for potential

errors or possible lack of information in this document.

We reserve all rights in this document and in the subject

matter and illustrations contained therein. Any reproduction,

disclosure to third parties or utilization of its contents – in

whole or in parts – is forbidden without prior written consent

of ABB AG.

© Copyright 2011-2014 ABB.

All rights reserved.

Subject to alterations.

3ADR059030M0204

Loading...

Loading...