ABB CoriolisMaster FCB430, CoriolisMaster FCH430, CoriolisMaster FCH400, CoriolisMaster FCB450, CoriolisMaster FCB400 Operating Instructions Manual

...Page 1

—

ABB MEASUREMENT & ANALYTICS | OPERATING INSTRUCTION

CoriolisMaster FCB400, FCH400

Coriolis mass flowmeter

Device firmware version: 00.05.00

Measurement made easy

—

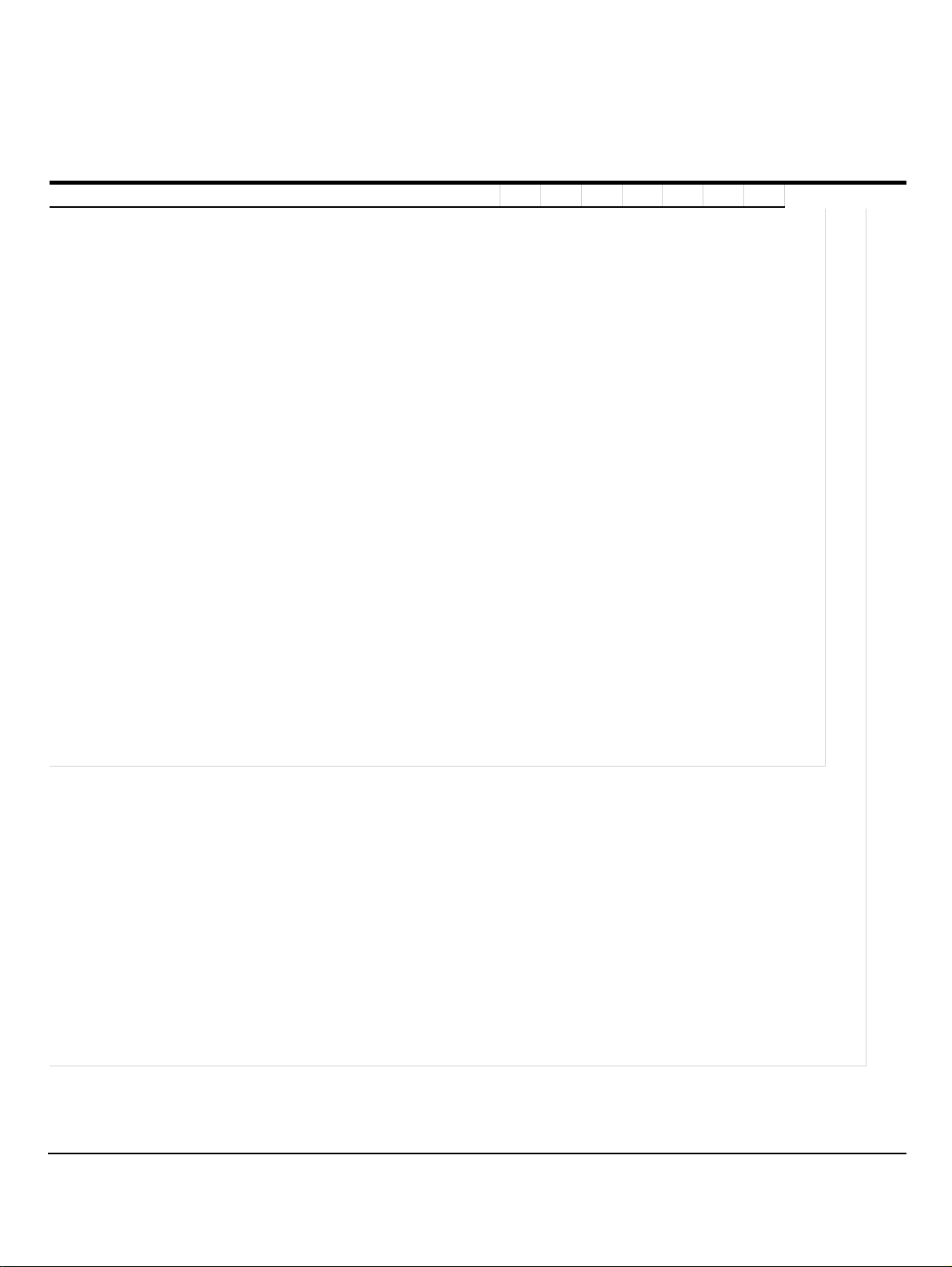

CoriolisMaster FCB430 / 450

CoriolisMaster FCH430 / 450

Introduction

With no up or downstream piping requirements

the compact Coriolis flowmeters can be installed

in the tightest spaces, enabling applications not

possible before.

CoriolisMaster FCB400

The compact Coriolis mass flowmeters from the

CoriolisMaster FCB400 series offer low pressure

drop, high capacity, an intuitive ABB display

featuring a standardized design and crossproduct compatibility, five modular inputs and

outputs as well as HART communication.

CoriolisMaster FCH400

The compact Coriolis mass flowmeters for

hygienic applications from the CoriolisMaster

FCH400 series additionally offer EHEDG certified

cleanability; all wetted materials are polished.

Additional Information

Additional documentation on CoriolisMaster

FCB400, FCH400 is available for download free of

charge at www.abb.com/flow.

Alternatively simply scan this code:

Page 2

2 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

Table of contents

Change from one to two columns

Name plate .............................................................................. 28

1 Safety .......................................................................... 4

General information and instructions .................................. 4

Warnings .................................................................................... 4

Intended use ............................................................................. 5

Improper use ............................................................................. 5

Notes on data safety ............................................................... 5

Warranty provisions ................................................................. 5

Manufacturer’s address .......................................................... 5

2 Use in potentially explosive atmospheres ............. 6

Device overview ........................................................................ 6

ATEX / IECEx ........................................................................ 6

cFMus .................................................................................... 7

Ex marking ................................................................................. 8

Description of model numbers ......................................... 8

ATEX / IECEx ...................................................................... 10

cFMus .................................................................................. 11

Temperature data .................................................................. 12

Temperature resistance for the connecting cable ...... 12

Environmental and process conditions for model

FCx4xx… ............................................................................. 12

Measuring medium temperature for sensors in

integral mount design with dual-compartment

housing ................................................................................ 13

Measuring medium temperature for sensors in

integral mount design with single-compartment

housing ................................................................................ 14

Measuring medium temperature for sensors in remote

mount design ..................................................................... 15

Electrical data ......................................................................... 16

Overview ............................................................................. 16

Zone 2, 21 and Division 2 – Model: FCx4xx-A2, FCx4xx-

F2 .......................................................................................... 17

Zone 1 ,21 und Division 1 – Model: FCx4xx-A1, FCx4xx-

F1 .......................................................................................... 18

Special connection conditions ........................................ 19

Installation instructions ........................................................ 20

ATEX / IECEx ...................................................................... 20

cFMus .................................................................................. 20

Use in areas exposed to combustible dust .................. 20

Opening and closing the housing .................................. 20

Cable entries in accordance with ATEX / IECEx ........... 21

Cable entries in accordance with cFMus ....................... 21

Electrical connections ...................................................... 22

Process sealing .................................................................. 22

Operating instructions .......................................................... 23

Protection against electrostatic discharges ................ 23

Repair................................................................................... 23

Changing the type of protection .................................... 24

3 Design and function ................................................ 25

General ..................................................................................... 25

Measuring principle ............................................................... 25

Device designs ........................................................................ 26

4 Product identification ............................................ 28

5 Transport and storage ........................................... 29

Inspection ............................................................................... 29

Transporting the device ....................................................... 29

Storing the device .................................................................. 30

Ambient conditions .......................................................... 30

Returning devices .................................................................. 30

6 Installation ................................................................ 31

General installation conditions ............................................ 31

Installation location and assembly ................................. 31

Liquid measuring media .................................................. 32

Gaseous measuring media .............................................. 33

Turn-off devices for the zero point adjustment .............. 33

Sensor insulation ................................................................... 34

Heat tracing of the sensor .............................................. 34

Devices for legal metrology in accordance with

MID / OIML R117 ..................................................................... 34

Process conditions ................................................................ 35

Temperature limits °C (°F) .............................................. 35

Pressure ratings ................................................................ 35

Housing as a protective device (optional) ................... 35

Material load for process connections .............................. 35

Material load curves for flange devices ........................ 36

Installing the sensor .............................................................. 37

Installing the transmitter in the remote mount design . 37

Opening and closing the housing ....................................... 38

Dual- compartment housing ........................................... 39

Single-compartment housing ......................................... 39

Adjusting the transmitter position .................................... 40

Transmitter housing ........................................................ 40

Rotate LCD indicator – dual-compartment housing .. 40

Installing the plug-in cards .................................................. 42

7 Electrical connections ............................................ 46

Safety instructions ................................................................ 46

Power supply .......................................................................... 46

Installing the connection cables ......................................... 47

Recommended cables ...................................................... 47

Pin assignment ....................................................................... 48

Electrical data for inputs and outputs .......................... 49

Connection examples ....................................................... 53

Connection to integral mount design ........................... 56

Connection to remote mount design............................ 58

Digital communication ......................................................... 61

HART® Communication .................................................... 61

Modbus® communication ............................................... 61

Cable specification ........................................................... 62

PROFIBUS DP® communication ...................................... 62

8 Commissioning ....................................................... 64

Hardware settings ................................................................. 64

Dual- compartment housing ........................................... 64

Single-compartment housing ......................................... 65

Configuration of digital outputs V1 / V2 or V3 / V4 ... 65

Checks prior to commissioning .......................................... 66

Page 3

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 3

Switching on the power supply .......................................... 66

Parameterization of the device .......................................... 66

Installation of ABB AssetVision Basic and ABB Field

Information Manager (FIM) ............................................ 66

Parameterization via the infrared service port adapter

............................................................................................. 69

Parameterization via HART® ........................................... 69

Basic Setup .............................................................................. 70

Menu: Easy Set-up ............................................................. 70

9 Operation ................................................................. 72

Safety instructions ................................................................. 72

Menu navigation ..................................................................... 72

Menu levels .............................................................................. 73

Process display ....................................................................... 74

Switching to the information level ...................................... 74

Error messages on the LCD display ............................... 75

Switching to the information level ...................................... 75

Resetting the customer password................................. 76

Selecting and changing parameters ................................... 77

Available units ......................................................................... 78

Available process variables ................................................. 80

Parameter overview ............................................................... 83

Parameter descriptions ........................................................ 95

Menu: Easy Set-up ............................................................. 95

Menu: Device Info .............................................................. 97

Menu: Device Setup .......................................................... 99

Menu: Display ................................................................... 106

Menu: Input / Output...................................................... 107

Menu: Process Alarm ...................................................... 112

Menu: Communication ................................................... 113

Menu: Diagnostics ........................................................... 115

Menu: Totalizer ................................................................ 119

Software history ................................................................... 121

Zero point balance under operating conditions ............ 121

Measurement of standard volumes .................................. 122

VeriMass erosion monitor .................................................. 124

Setup ................................................................................. 124

Concentration measurement DensiMass ........................ 125

Calculating standard volumes and standard densities

of liquids ........................................................................... 125

Accuracy of the concentration measurement ............ 126

Entering the concentration matrix .............................. 126

FillMass batch function ....................................................... 129

Setup ................................................................................. 130

Spare parts ........................................................................... 139

Replacing the fuse ............................................................... 139

Replacing the LCD indicator .............................................. 140

Replacing the frontend board ............................................ 141

Integral mount design .................................................... 141

Remote mount design ................................................... 143

Replacing the sensor ........................................................... 144

Returning devices ................................................................ 144

13 Dismounting and disposal ................................... 145

Dismounting ......................................................................... 145

Disposal ................................................................................. 145

14 Specification ......................................................... 146

15 Additional documents .......................................... 146

16 Appendix ................................................................. 147

Return form ........................................................................... 147

10 Diagnosis / error messages ................................. 131

Calling up the error description ........................................ 131

General ................................................................................... 131

Overview ................................................................................ 132

Error messages ..................................................................... 134

11 Maintenance ........................................................... 138

Safety instructions ............................................................... 138

Sensor .................................................................................... 138

Cleaning ................................................................................. 138

12 Repair ...................................................................... 138

Safety instructions ............................................................... 138

Page 4

4 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

‘

E

’

1 Safety

General information and instructions

These instructions are an important part of the product and

must be retained for future reference.

Installation, commissioning, and maintenance of the product

may only be performed by trained specialist personnel who have

been authorized by the plant operator accordingly. The specialist

personnel must have read and understood the manual and must

comply with its instructions.

For additional information or if specific problems occur that are

not discussed in these instructions, contact the manufacturer.

The content of these instructions is neither part of nor an

amendment to any previous or existing agreement, promise or

legal relationship.

Modifications and repairs to the product may only be performed

if expressly permitted by these instructions.

Information and symbols on the product must be observed.

These may not be removed and must be fully legible at all times.

The operating company must strictly observe the applicable

national regulations relating to the installation, function testing,

repair and maintenance of electrical products.

Warnings

The warnings in these instructions are structured as follows:

DANGER

The signal word ‘DANGER’ indicates an imminent danger.

Failure to observe this information will result in death or

severe injury.

WARNING

The signal word ‘WARNING’ indicates an imminent danger.

Failure to observe this information may result in death or

severe injury.

CAUTION

The signal word ‘CAUTION’ indicates an imminent danger.

Failure to observe this information may result in minor or

moderate injury.

NOTICE

The signal word

Note

‘Note’ indicates useful or important information about the

product.

NOTIC

indicates possible material damage.

Page 5

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 5

Intended use

This device is intended for the following uses:

• To convey liquids and gases (including unstable measuring

media).

• To meter mass flow directly.

• To meter volumetric flow (indirectly via mass flow and

density).

• To measure the density of the measuring medium.

• To measure the temperature of the measuring medium.

The device has been designed for use exclusively within the

technical limit values indicated on the identification plate and in

the data sheets.

When using measuring media, the following points must be

observed:

• Measuring media may only be used if, based on the state

of the art or the operating experience of the user, it can

be assured that the chemical and physical properties

necessary for operational security of the materials of the

wetted parts of the temperature sensor will not be

adversely affected during the operating time.

• Media containing chloride in particular can cause

corrosion damage to stainless steels which, although not

visible externally, can damage wetted parts beyond repair

and lead to the measuring medium escaping. It is the

operator's responsibility to check the suitability of these

materials for the respective application.

• Measuring media with unknown properties or abrasive

measuring media may only be used if the operator is able

to perform regular and suitable tests to ensure the safe

condition of the device

Improper use

The following are considered to be instances of especially

improper use of the device:

• Operation as a flexible compensating adapter in piping,

for example for compensating pipe offsets, pipe

vibrations, pipe expansions, etc.

• For use as a climbing aid, for example for mounting

purposes.

• For use as a bracket for external loads, for example as a

support for piping, etc.

• Material application, for example by painting over the

housing, name plate or welding/soldering on parts.

• Material removal, for example by spot drilling the

housing.

Change from two to one column

Notes on data safety

This product is designed to be connected to and to

communicate information and data via a network interface.

It is operator’s sole responsibility to provide and continuously

ensure a secure connection between the product and your

network or any other network (as the case may be).

Operator shall establish and maintain any appropriate measures

(such as but not limited to the installation of firewalls,

application of authentication measures, encryption of data,

installation of anti-virus programs, etc.) to protect the product,

the network, its system and the interface against any kind of

security breaches, unauthorized access, interference, intrusion,

leakage and / or theft of data or information.

ABB Automation Products GmbH and its affiliates are not liable

for damages and / or losses related to such security breaches,

any unauthorized access, interference, intrusion, leakage and /

or theft of data or information.

Warranty provisions

Using the device in a manner that does not fall within the scope

of its intended use, disregarding this manual, using

underqualified personnel, or making unauthorized alterations

releases the manufacturer from liability for any resulting

damage. This renders the manufacturer's warranty null and void.

Manufacturer’s address

ABB Automation Products GmbH

Measurement & Analytics

Dransfelder Str. 2

37079 Goettingen

Germany

Tel: +49 551 905-0

Fax: +49 551 905-777

Email: vertrieb.messtechnik-produkte@de.abb.com

Customer service center

Tel: +49 180 5 222 580

Email: automation.service@de.abb.com

Page 6

6 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

2 Use in potentially explosive atmospheres

Note

Further information on the Ex-Approval of devices can be found in the type examination certificates or the relevant certificates at

www.abb.com/flow .

Device overview

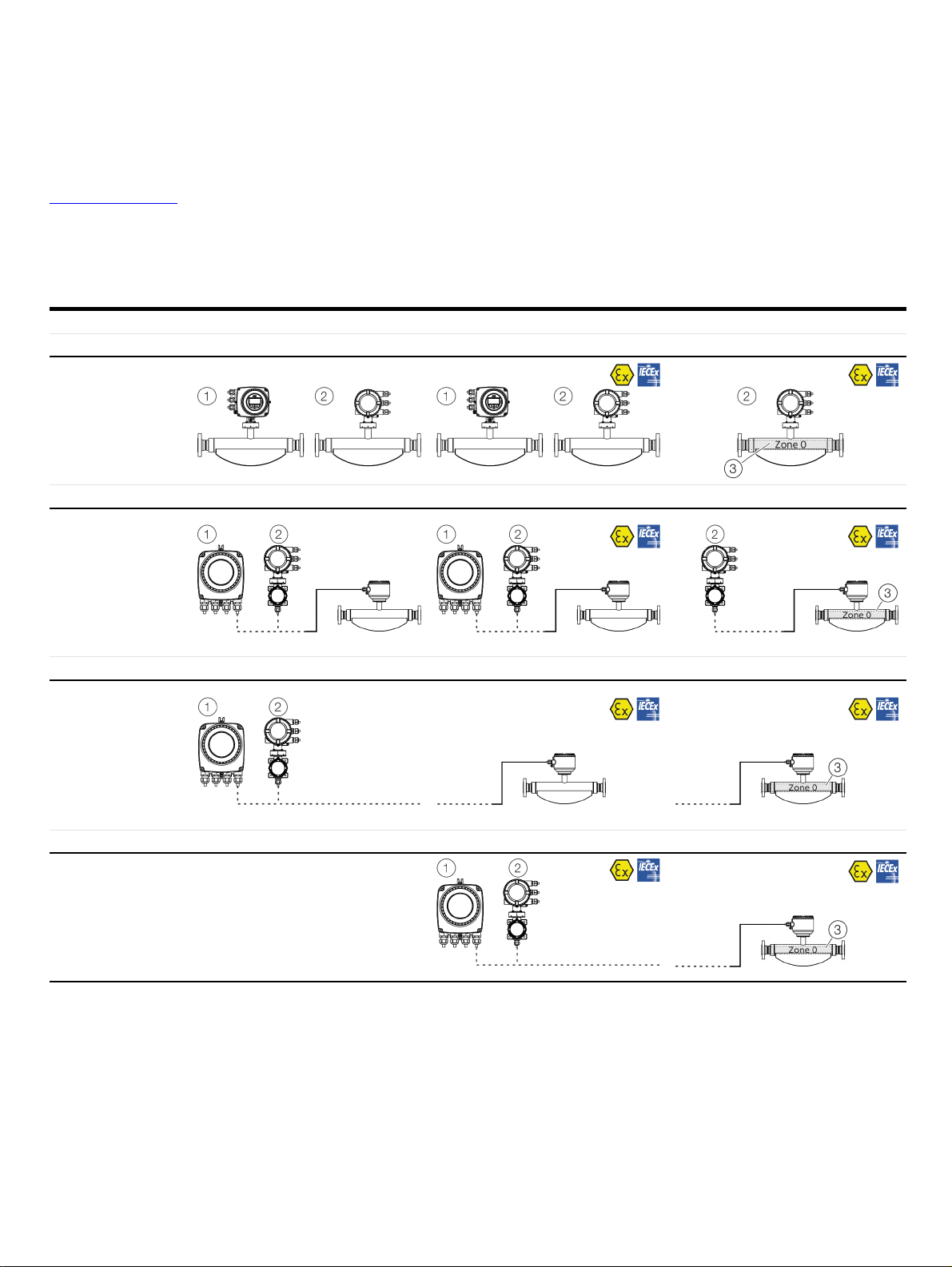

ATEX / IECEx

Standard / No explosion protection Zone 2, 21, 22 Zone 1, 21 (Zone 0)

Model number FCx4xx Y0 FCx4xx A2 FCx4xx A1

Integral mount design

• Standard

• Zone 2, 21, 22

• Zone 1, 21

• Zone 0

Model number FCT4xx Y0 FCx4xx Y0 FCT4xx A2 FCx4xx A2 FCT4xx A1 FCx4xx A1

Remote mount design

Transmitter and

flowmeter sensor

• Standard

• Zone 2, 21, 22

• Zone 1, 21

• Zone 0

Model number FCT4xx Y0 FCT4xx A2 FCx4xx A1

Remote mount design

Transmitter

• Standard

• Zone 2, 21, 22

Sensor

• Zone 1, 21

• Zone 0

Model number — FCT4xx A2 FCx4xx A1

Remote mount design

Transmitter

• Zone 2, 21, 22

Sensor

—

• Zone 1, 21

1 Single-compartment housing

2 Dual-compartment housing

3 Zone 0 within the meter tube

Page 7

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 7

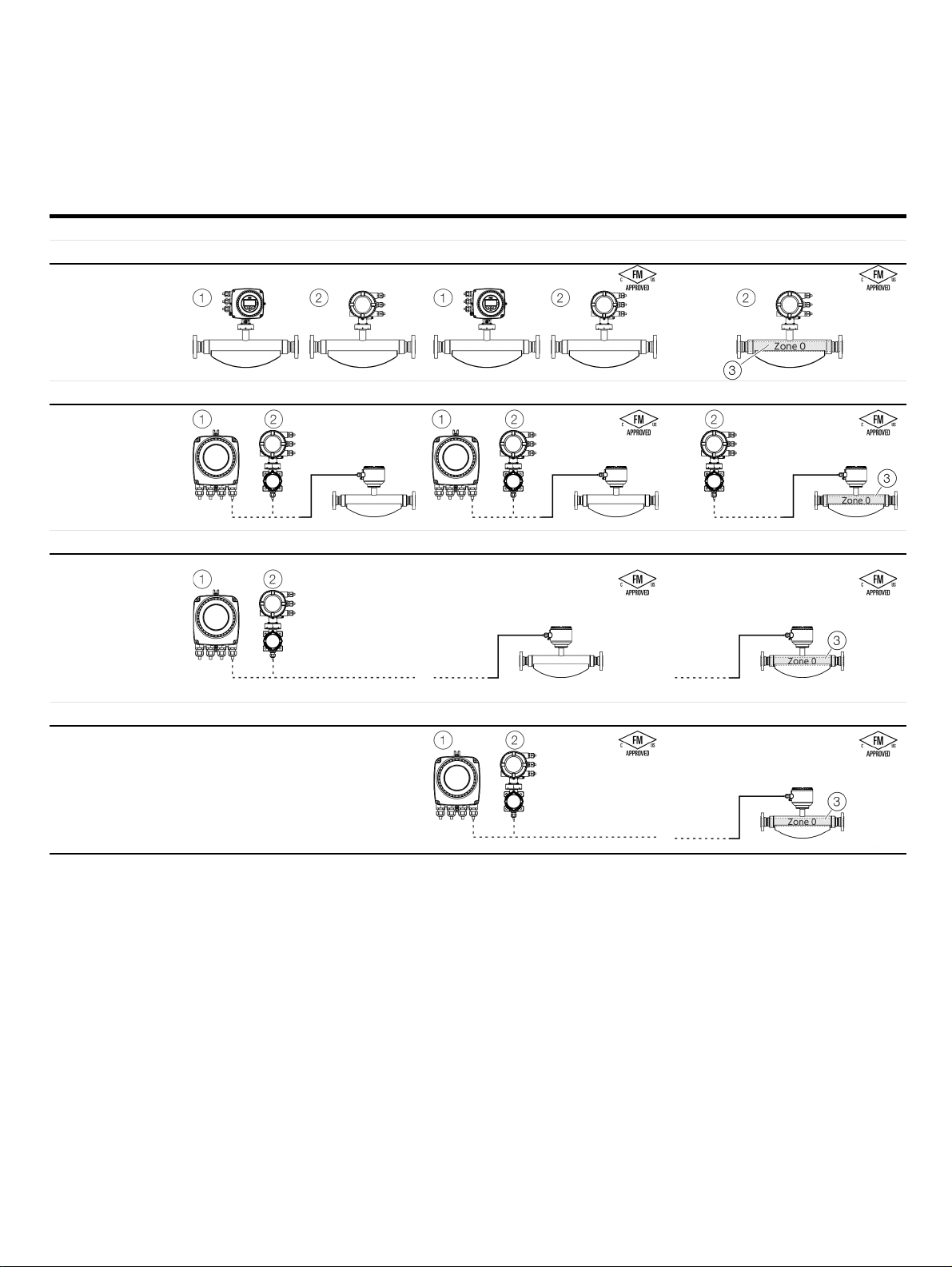

cFMus

Standard / No explosion protection Class I Div. 2 / Zone 2 Class I Div. 1 / Zone 1 (Zone 0)

Model number FCx4xx Y0 FCx4xx F2 FCx4xx F1

Integral mount design

• Standard

• Div. 2 / Zone 2

• Div. 1 / Zone 1

(Zone 0)

Model number FCT4xx Y0 FCx4xx Y0 FCT4xx F2 FCx4xx F2 FCT4xx F1 FCx4xx F1

Remote mount design

Transmitter and

flowmeter sensor

• Div. 2 / Zone 2

• Div. 1 / Zone 1

(Zone 0)

Model number FCT4xx Y0 FCT4xx F2 FCx4xx F1

Remote mount design

Transmitter

• Standard

Sensor

• Div. 2 / Zone 2

• Div. 1 / Zone 1

(Zone 0)

Model number — FCT4xx F2 FCx4xx F1

Remote mount design

Transmitter

• Div. 2 / Zone 2

Sensor

• Div. 1 / Zone 1

(Zone 0)

1 Single-compartment housing

2 Dual-compartment housing

3 Zone 0 within the meter tube

—

Page 8

8 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

… 2 Use in potentially explosive atmospheres

Ex marking

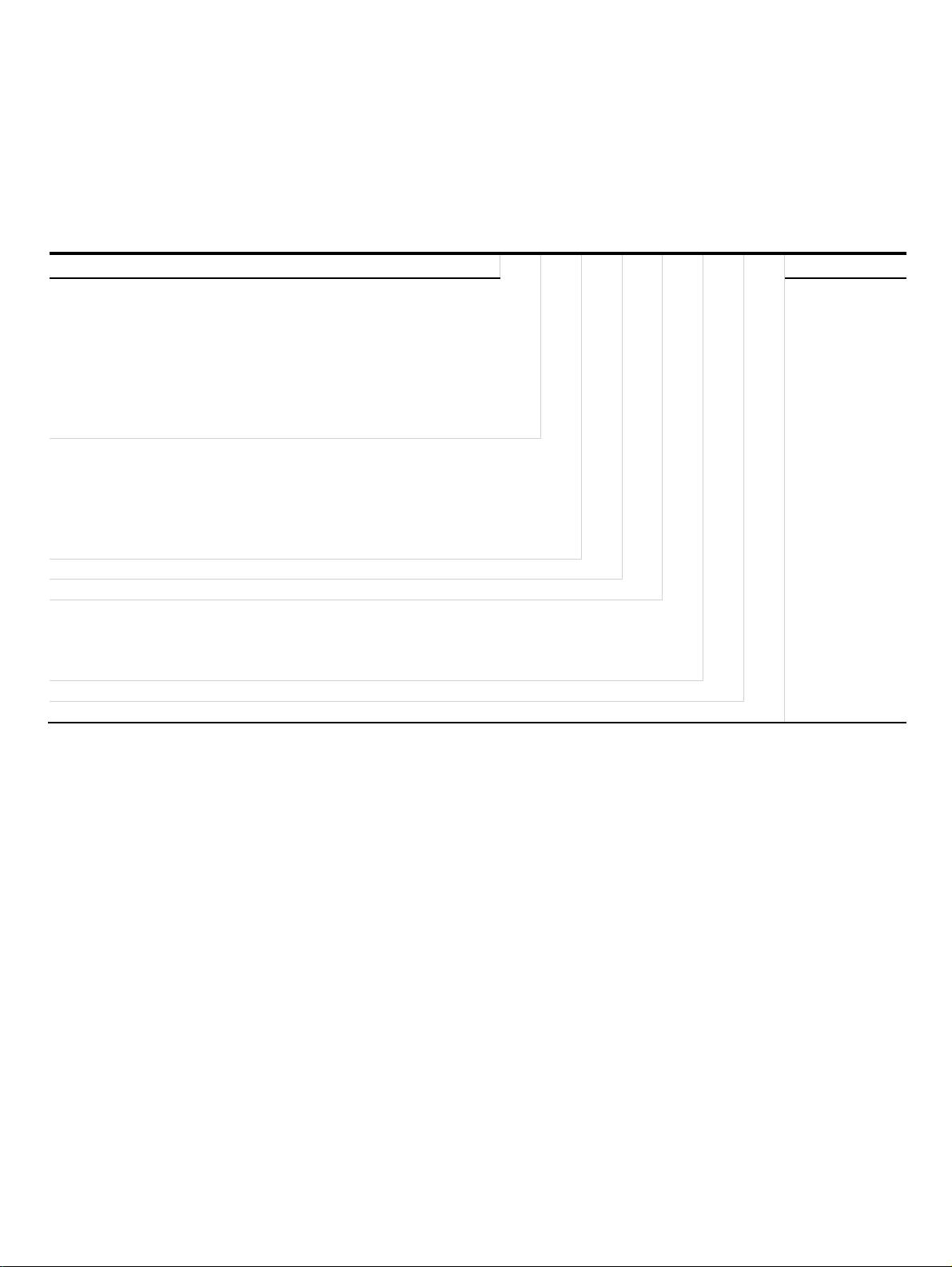

Description of model numbers

Each device design has a specific model number. The parts of the model number relating to explosion protection are listed in the

following table. The complete key to model numbers is described in the device data sheet.

Basic model

Explosion protection

Without

ATEX / IECEx (Zone 2 / 22)

ATEX / IECEx (Zone 1 / 21)

cFMus version, Class 1, Div. 2 (Zone 2 / 21)

cFMus version, Class 1, Div. 1 (Zone 1 / 21)

NEPSI (Zone 2 / 22)

NEPSI (Zone 1 / 21)

Design / terminal box material / cable glands

Integral mount - see transmitter housing

Remote mount / aluminum / 1 × M20 × 1.5

Remote mount / aluminum / 1 × NPT ½ in

Remote mount / stainless steel / 1 × M20 × 1.5

Remote mount / stainless steel / 1 × NPT ½ in

Nominal diameter / nominal connection diameter

Process connection

Material for wetted parts

Stainless steel

Polished stainless steel H1

Nickel alloy

Flow rate calibration

Density calibration

FCa4c d m f g h i j k l m

Y0

A2

A1

F2

F1

S2

S1

U1

A1

Y0

U2

A2

xxxxx

xx

A1

C1

x

x

Page 9

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 9

Basic model

Design / transmitter housing / transmitter housing material / cable gland

Integral mount / dual-compartment housing / aluminum / 3 × M20 × 1.5

Integral mount / dual-compartment housing / aluminum / 3 × NPT ½ in D2

Integral mount / dual-compartment housing / aluminum / 3 × M20 × 1.5 (Ex d / XP)

Integral mount / dual-compartment housing / aluminum / 3 × NPT ½ in (Ex d / XP) D6

Integral mount / dual-compartment housing / stainless steel / 3 × M20 × 1.5

Integral mount / dual-compartment housing / stainless steel / 3 × NPT ½ in D4

Integral mount / dual-compartment housing / stainless steel / 3 × M20 × 1.5 (Ex d /

XP)

Integral mount / dual-compartment housing / stainless steel / 3 × NPT ½ in (Ex d /

XP)

Integral mount / single-compartment housing / aluminum / 3 × M20 × 1.5 S1

Integral mount / single-compartment housing / aluminum / 3 × NPT ½ in

Remote mount / dual-compartment housing / aluminum / 3 × M20 × 1.5

Remote mount / dual-compartment housing / aluminum / 3 × NPT ½ in

Remote mount / dual-compartment housing / aluminum / 3 × M20 × 1.5 (Ex d / XP)

Remote mount / dual-compartment housing / aluminum / 3 × NPT ½ in (Ex d / XP)

Remote mount / dual-compartment housing / stainless steel / 3 × M20 × 1.5

Remote mount / dual-compartment housing / stainless steel / 3 × NPT ½ in

Remote mount / dual-compartment housing / stainless steel / 3 × M20 × 1.5 (Ex d /

XP)

Remote mount / dual-compartment housing / stainless steel / 3 × NPT ½ in (Ex d /

XP)

Remote mount / single-compartment housing, wall mounting / aluminum /

4 × M20 × 1.5

Remote mount / single-compartment housing, wall mounting / aluminum / 4 × NPT

½ in

Remote mount / not specified

Outputs

Current output 1 (active or passive), digital output 1 & 2 (passive),

HART®, PROFIBUS DP®

Current output 1 (active), digital output 1 & 2 (passive), HART®, Modbus® M1*

Current output 1 (active / passive), digital output 1 & 2 (passive), HART

Current output 1 (active / passive), digital output 1 & 2 (passive),

24 V DC transmitter loop power supply, HART®

Current output 1 (active / passive), digital output 1 & 2 (passive),

current output 2 (passive), HART®

Current output 1 (active / passive), digital output 1 & 2 (passive),

current output 2 (passive), current output 3 (passive), HART®

Current output 1 (active / passive), digital output 1 & 2 (passive),

current output 2 (passive), 24 V DC transmitter loop power supply, HART®

Without Y0

Power supply

100 to 230 V AC

11 to 30 V DC

Without

* The M1 design is identical in construction to the M5 design, as it can also be called in other locations

FCa4c d m f g h i j k l m

G3

D1

D5

D3

D7

D8

S2

R1

R2

R5

R6

R3

R4

R7

R8

W1

W2

Y0

D1

G0

G1

G2

G4

A

C

Y

Page 10

10 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

… 2 Use in potentially explosive atmospheres

… Ex marking

ATEX / IECEx

Note

• A specific marking applies, depending on the design.

• ABB reserves the right to modify the Ex-marking. Refer to the name plate for the exact marking.

Model number for use in Zone 2, 21 Ex marking Certificate

FCa4c – A2Y0fghijD

Integral mount design with dual-compartment

housing

FCa4c – A2efghijY

Sensor in remote mount design with dual-

compartment housing

FCT4c – A2R

Transmitter in remote mount design with dual-

compartment housing

Model number for use in Zone 1, 21 Ex marking Certificate

FCa4c – A1Y0fghijDx (x = 1 to 4)

Integral mount design with dual-compartment

housing

FCa4c – A1Y0fghijDx (x = 5 to 8)

Integral mount design with dual-compartment

housing (flameproof enclosure ‘Ex d’)

FCa4c – A1efghijY

Sensor in remote mount design with dual-

compartment housing

FCT4c – A1R (x = 1 to 4)

Transmitter in remote mount design with dual-

compartment housing

FCT4c – A1R (x = 5 to 8)

Transmitter in remote mount design with dual-

compartment housing

(flameproof enclosure ‘Ex d’)

II3G Ex ec IIC T6...T1 Gc

II2D Ex tc IIIC T80°C...Tmedium Dc

II3G Ex ec IIC T6 Gc

II2D Ex tc IIIC T80°C Dc

II 1/2 (1) G Ex db eb ia mb [ia Ga] IIC T6…T1 Gb

II 2 (1) D Ex ia tb [ia Da] IIIC T80°C Db

II 1/2 (1) G Ex db ia mb [ia Ga] IIB+H2 T6...T1 Gb

II 2 (1) D Ex ia tb [ia Da] IIIC T80°C Db

II 1/2 G Ex eb ia mb IIB+H2 T6…T1 Ga/Gb

II 2 D Ex ia tb IIIC T80°C Db

II 2 (1) G Ex db e ia mb [ia Ga] IIC T6…T1 Gb

II 2 (1) D Ex ia mb tb [ia Da] IIIC T80°C Db

II 2 (1) G Ex db ia mb [ia Ga] IIB+H2 T6…T1 Gb

II 2 (1) D Ex ia tb [ia Da] IIIC T80°C Db

ATEX:

FM15ATEX0014X, FM15ATEX0016X

IECEx:

IECEx FME 15.0005X

ATEX:

FM15ATEX0015X

IECEx:

IECEx FME 15.0005X

Page 11

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 11

cFMus

Note

• A specific marking applies, depending on the design.

• ABB reserves the right to modify the Ex-marking. Refer to the name plate for the exact marking.

Model number for use in Division 2 Ex marking Certificate

FCa4c – F2Y0fghijD

Integral mount design with dual-compartment housing

FCa4c – F2efghijY

Sensor in remote mount design with dual-compartment housing

Design in accordance with ANSI / ISA 12.27.01 as ‘Single Seal Device’

or as ‘Dual Seal Device’ (option TE2)

FCT4c – F2R

Transmitter in remote mount design with dual-compartment housing

Model number for use in Division 1 Ex marking Certificate

FCa4c – F1Y0fghijDx (x = 1 to 4)

Integral mount design with dual-compartment housing

FCa4c – F1Y0fghijDx (x = 5 to 8)

Integral mount design with dual-compartment housing

(Explosionproof ‘XP’).

Design in accordance with ANSI / ISA 12.27.01 as ‘Single Seal Device’

or as ‘Dual Seal Device’ (option TE2)

FCa4c – F1efghijY

Sensor in remote mount design with dual-compartment housing

Design in accordance with ANSI / ISA 12.27.01 as ‘Single Seal Device’

or as ‘Dual Seal Device’ (option TE2)

FCT4c – F1Rx (x = 1 to 4)

Transmitter in remote mount design with dual-compartment housing

FCT4c – F1Rx (x = 5 to 8)

Sensor in remote mount design with dual-compartment housing

(Explosionproof ‘XP’).

Change from one to two columns

NI: CL I,II,III Div 2, GPS ABCDEFG, T6…T1

DIP: CL II,III, Div 1, GPS EFG, T6

CL I, ZN 2, AEx ec IIC T6…T1 (USA)

ZN 21, AEx ia tb IIIC T80°C (USA)

CL I, ZN 2, Ex ec IIC T6...T1 (CAN)

ZN21,Ex ia tb IIIC T80°C (CAN)

See handbook for temperature class information

XP-IS: CL I, Div 1, GPS ABCD,T6…T1 (USA)

XP-IS: CL I, Div 1, GPS BCD,T6…T1 (CAN)

DIP: CL II,III, Div 1, GPS EFG,T6

CL I, ZN 1, AEx db ia IIB+H2 T6…T1 (USA)

ZN21, AEx ia tb IIIC T80°C (USA)

CL I, ZN 1, Ex db ia IIB+H2 T6…T1 (CAN)

ZN21, Ex ia tb IIIC T80°C (CAN)

See handbook for temperature class information and installation

drawing 3KXF000028G0009

XP-IS: CL I, Div 1, GPS BCD T6…T1 (USA)

DIP: CL II,III, Div 1, GPS EFG,T6

CL I, ZN 1, AEx db ia IIB+H2 T6…T1 (USA)

ZN 21, AEx ia tb IIIC T80°C (USA)

CL I, ZN 1, Ex db ia IIB+H2 T6…T1 (CAN)

ZN21, Ex ia tb IIIC T80°C (CAN)

See handbook for temperature class information and installation

drawing 3KXF000028G0009

XP-IS: CL I, Div 1, GPS BCD,T6…T1 (USA) XP-IS: CL I, Div 1, GPS

BCD,T6…T1 (CAN)

DIP: CL II,III, Div 1, GPS EFG, T6

CL I, ZN 1, AEx db ia IIB+H2 T6…T1 (USA)

ZN 21, AEx ia tb IIIC T80°C (USA)

CL I, ZN 1, Ex db ia IIB+H2 T6…T1 (CAN)

ZN21,Ex ia tb IIIC T80°C (CAN)

See handbook for temperature class information and installation

drawing 3KXF000028G0009

cFMus:

3050239

cFMus:

3050239

Page 12

12 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

… 2 Use in potentially explosive atmospheres

Temperature data

Temperature resistance for the connecting cable

Sensor in remote mount design

The temperature at the cable entries of the device depends on

the design, the measuring medium temperature T

ambient temperature T

amb.

.

medium

and the

For the electric connection of the device, use only cables with

sufficient temperature resistance in accordance with the

following table.

Devices in integral mount design with dual-compartment

housing

T

Temperature resistance

amb.

≤ 50 °C (≤ 122 °F) ≥ 105 °C (≥ 221 °F)

≤ 60 °C (≤ 140 °F) ≥ 110 °C (≥ 230 °F)

≤ 70 °C (≤ 158 °F) ≥ 120 °C (≥ 248 °F)

For sensors in remote mount design, the wires in the connection

T

Temperature resistance

amb.

≤ 50 °C (≤ 122 °F) ≥ 70 °C (≥ 158 °F)

≤ 60 °C (≤ 140 °F) ≥ 80 °C (≥ 176 °F)

≤ 70 °C (≤ 158 °F) ≥ 90 °C (≥ 194 °F)

Devices in integral mount design with single-compartment

housing

T

Temperature resistance

amb.

≤ 50 °C (≤ 122 °F) ≥ 75 °C (≥ 167 °F)

≤ 60 °C (≤ 140 °F) ≥ 85 °C (≥ 185 °F)

≤ 70 °C (≤ 158 °F) ≥ 95 °C (≥ 203 °F)

Change from two to one column

box must be additionally insulated with the enclosed silicone

hoses starting from ambient temperatures of T

amb.

≥ 60 °C

(≥ 140 °F).

Environmental and process conditions for model

FCx4xx…

Ambient temperature T

-40 to 70 °C*

Measuring medium temperature

T

medium

IP rating / NEMA rating IP 65, IP 67 /

* Optional, with order code ‘Ambient temperature range – TA9’

-20 to 70 °C

amb.

(-4 to 158 °F)

(-40 to 158 °F)*

-40 to 205 °C

(-40 to 400 °F)

NEMA 4X,Type 4X

Page 13

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 13

Measuring medium temperature for sensors in integral mount design with dual-compartment housing

Model FCx4xx-A1… and FCx4xx-F1… in Zone 1, Division 1

The table shows the maximum permissible measuring medium temperature as a function of ambient temperature and temperature

class.

Temperature class

Ambient temperature T

≤ 30 °C (≤ 86 °F) 205 °C (400 °F)*

≤ 40 °C (≤ 104 °F) 205 °C (400 °F)*

≤ 50 °C (≤ 122 °F) 205 °C (400 °F)*

≤ 60 °C (≤ 140 °F) 205 °C (400 °F)*

≤ 70 °C (≤ 158 °F) 205 °C (400 °F)*

* Only with the ‘Extended tower length – TE1, TE2 or TE3’ order option

T1 T2 T3 T4 T5 T6

amb.

130 °C (266 °F)

130 °C (266 °F)

130 °C (266 °F)

130 °C (266 °F)

130 °C (266 °F)

205 °C (400 °F)*

130 °C (266 °F)

205 °C (400 °F)*

130 °C (266 °F)

205 °C (400 °F)*

130 °C (266 °F)

205 °C (400 °F)*

130 °C (266 °F)

205 °C (400 °F)*

130 °C (266 °F)

195 °C (383 °F)*

130 °C (266 °F)

195 °C (383 °F)*

130 °C (266 °F)

195 °C (383 °F)*

130 °C (266 °F)

195 °C (383 °F)*

130 °C (266 °F)

195 °C (383 °F)*

130 °C (266 °F)

130 °C (266 °F) 95 °C (203 °F) 80 °C (176 °F)

130 °C (266 °F) 95 °C (203 °F) 80 °C (176 °F)

130 °C (266 °F) 95 °C (203 °F) 80 °C (176 °F)

130 °C (266 °F) 95 °C (203 °F) 80 °C (176 °F)

130 °C (266 °F) 95 °C (203 °F) 80 °C (176 °F)

Model FCx4xx-A2… and FCx4xx-F2… in Zone 2, Division 2

The table shows the maximum permissible measuring medium temperature as a function of ambient temperature and temperature

class.

Temperature class

Ambient temperature T

≤ 30 °C (≤ 86 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F)*

≤ 40 °C (≤ 104 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F)*

≤ 50 °C (≤ 122 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F)*

≤ 60 °C (≤ 140 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F)*

≤ 70 °C (≤ 158 °F) 205 °C (400 °F)*

* Only with the ‘Extended tower length – TE1, TE2 or TE3’ order option

T1 T2 T3 T4 T5 T6

amb.

130 °C (266 °F) 95 °C (203 °F) 80 °C (176 °F)*

60 °C (140 °F)

130 °C (266 °F)

205 °C (400 °F)*

130 °C (266 °F)

130 °C (266 °F)

130 °C (266 °F)

130 °C (266 °F)

130 °C (266 °F)

195 °C (383 °F)*

130 °C (266 °F)

130 °C (266 °F) 95 °C (203 °F) —

130 °C (266 °F) — —

130 °C (266 °F) — —

130 °C (266 °F) — —

Page 14

14 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

… 2 Use in potentially explosive atmospheres

… Temperature data

Measuring medium temperature for sensors in integral mount design with single-compartment housing

Model FCx4xx-A2… and FCx4xx-F2… in Zone 2, Division 2

The table shows the maximum permissible measuring medium temperature as a function of ambient temperature and temperature

class.

Temperature class

Ambient temperature T

≤ 30 °C (≤ 86 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F) 130 °C (266 °F) 95 °C (203 °F) 80 °C (176 °F)

≤ 40 °C (≤ 104 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F) 130 °C (266 °F) 95 °C (203 °F) —

≤ 50 °C (≤ 122 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F) 130 °C (266 °F) 95 °C (203 °F) —

≤ 60 °C (≤ 140 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F) 130 °C (266 °F) — —

≤ 70 °C (≤ 158 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F) 130 °C (266 °F) — —

* Only with the ‘Extended tower length – TE1, TE2 or TE3’ order option

T1 T2 T3 T4 T5 T6

amb.

Page 15

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 15

Measuring medium temperature for sensors in remote mount design

Model FCx4xx-A1…, FCx4xx-F1… in Zone 1

The table shows the maximum permissible measuring medium temperature as a function of ambient temperature and temperature

class.

Temperature class

Ambient temperature T

≤ 30 °C (≤ 86 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F) 130 °C (266 °F)

≤ 40 °C (≤ 104 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F) 130 °C (266 °F)

≤ 50 °C (≤ 122 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F) 130 °C (266 °F)

≤ 60 °C (≤ 140 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F) 130 °C (266 °F)

≤ 70 °C (≤ 158 °F) 205 °C (400 °F) 205 °C (400 °F) 195 °C (383 °F) 130 °C (266 °F)

T1 T2 T3 T4

amb.

T5 T6

95 °C (203 °F) 80 °C (176 °F)

95 °C (203 °F) 80 °C (176 °F)

95 °C (203 °F) 80 °C (176 °F)

95 °C (203 °F) 80 °C (176 °F)

95 °C (203 °F) 80 °C (176 °F)

Model FCx4xx-A2… and FCx4xx-F2… in Zone 2, Division 2

The table shows the maximum permissible measuring medium temperature as a function of ambient temperature and temperature

class.

Temperature class

Ambient temperature T

≤ 30 °C (≤ 86 °F) 205 °C (400 °F)*

≤ 40 °C (≤ 104 °F) 205 °C (400 °F)*

≤ 50 °C (≤ 122 °F) 205 °C (400 °F)*

≤ 60 °C (≤ 140 °F) 205 °C (400 °F)*

≤ 70 °C (≤ 158 °F) 180 °C (356 °F)*

* Only with the ‘Extended tower length – TE1, TE2 or TE3’ order option

T1 T2 T3 T4 T5 T6

amb.

195 °C (383 °F)

180 °C (356 °F)

140 °C (284 °F)

120 °C (248 °F)

80 °C (176 °F)

205 °C (400 °F)*

195 °C (383 °F)

205 °C (400 °F)*

180 °C (356 °F)

205 °C (400 °F)*

140 °C (284 °F)

205 °C (400 °F)*

120 °C (248 °F)

180 °C (356 °F)*

80 °C (176 °F)

195 °C (383 °F)*

130 °C (266 °F)

195 °C (383 °F)*

130 °C (266 °F)

130 °C (266 °F)*

130 °C (266 °F)

130 °C (266 °F)*

120 °C (248 °F)

130 °C (266 °F)*

80 °C (176 °F)

130 °C (266 °F)*

95 °C (203 °F)

130 °C (266 °F)*

95 °C (203 °F)

130 °C (266 °F)*

95 °C (203 °F)

130 °C (266 °F)*

95 °C (203 °F)

130 °C (266 °F)*

80 °C (176 °F)

95 °C (203 °F)*

80 °C (176 °F)

95 °C (203 °F)*

80 °C (176 °F)

80 °C (176 °F)*

60 °C (140 °F)

80 °C (176 °F)

——

——

—

—

Page 16

16 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

… 2 Use in potentially explosive atmospheres

Electrical data

Overview

Standard / No explosion protection Zone 2, 21 Zone 1, 21 (Zone 0)

Division 2 and Zone 2, 21 Division 2 and Zone 1, 21

ATEX:

–

IECEx:

–

USA:

–

Canada:

–

ATEX:

II 3 G & II 2 D

IECEx:

Gc & Db

USA:

NI & DIP

AEx ec & AEx tb

Canada:

Non-Incendive & Dust Ignition Proof

Ex ec & Ex tb

ATEX:

II 1/2 (1) G & II 2 (1) D

II 1/2 G & II 2 D

II 2 (1) G & II 2 (1) D

IECEx:

(Ga) Gb & (Da) Db

Ga/Gb & Db

(Ga) Gb & (Da) Db

USA:

XP-IS & DIP

AEx db ia & AEx ia tb

Canada:

XP-IS & DIP

Ex db ia & Ex ia tb

A

B

A

B

C

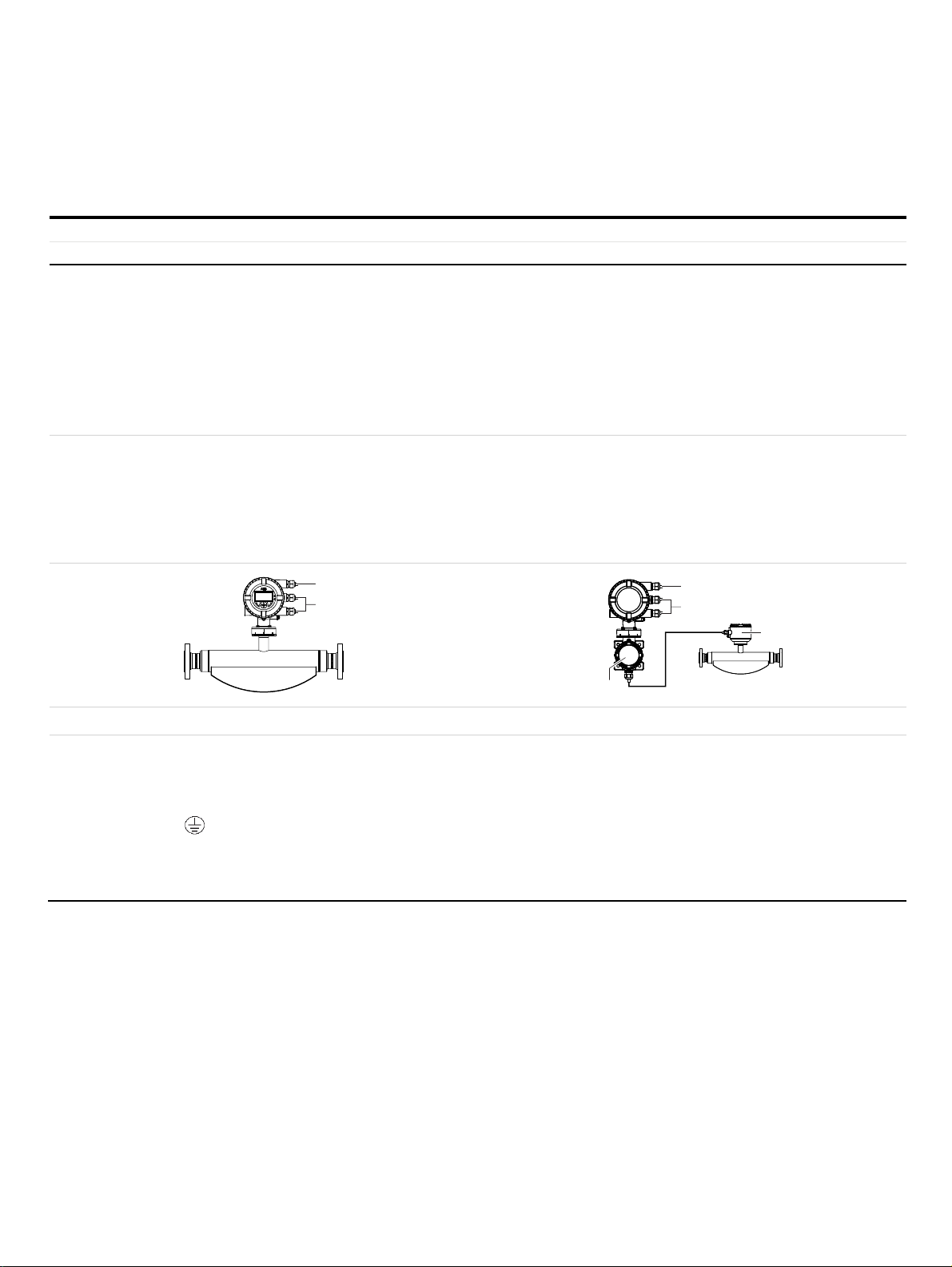

G11879b

C

G11879f

A Power supply B Inputs / outputs, communication C Signal cable (remote mount design only)

• Type of protection ATEX / IECEx: Increased safety

‘Ex e’

• Type of protection USA / Canada: ‘non IS’

• Maximum 250 Vrms

• Terminals: 1+, 2-, L, N,

• Type of protection ATEX / IECEx: Either increased

safety ‘Ex e’ or intrinsically safe ‘Ex ia’

• Type of protection USA / Canada: Either ‘non IS’ or

‘intrinsically safe IS’.

• When installing in ‘Ex ia’ or ‘IS’, suitable

• Terminals: A, B, UFE, GRN

• Type of protection ATEX / IECEx: Increased safety

‘Ex e’

• Type of protection USA / Canada: ‘non IS’

intrinsically safe isolation amplifiers must be used

for the connection.

• Terminals: 31, 32, Uco, V1, V2, V3, V4, 41, 42, 51, 52

Note

When installing in ‘Ex ia’ or ‘IS’ type of protection, the type of protection is determined by the type of electrical connection. The

information in Changing the type of protection on page 24 must be observed when changing the type of protection!

Page 17

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 17

Zone 2, 21 and Division 2 – Model: FCx4xx-A2, FCx4xx-F2

Outputs on basic device Operating values (general) Type of protection – ‘nA’ / ‘NI’

U

Current / HART output 31 / UCO, active

Terminals 31 / UCO

Current / HART output 31 / 32, passive

Terminals 31 / 32

Digital output 41 / 42, active*

Terminals 41 / 42 and V1 / V2*

Digital output 41 / 42, active**

Terminals 41 / 42 and UCO / 32**

Digital output 41 / 42, passive

Terminals 41 / 42

Digital output 51 / 52, active*

Terminals 51 / 52 and V1 / V2*

Digital output 51 / 52, passive

Terminals 51 / 52

All outputs are electrically isolated from each other and from the power supply.

Digital outputs 41 / 42 and 51 / 52 are not electrically isolated from each other. Terminals 42 / 52 have the same potential.

* Only in conjunction with additional ‘24 V DC loop power supply (blue)’ plug-in card in slot OC1.

** Only in conjunction with current output U

page 50.

/ 32 in ‘Powermode’, see Current output Uco / 32 as loop power supply for digital output 41 / 42 or 51 / 52 on

CO

N

30 V 30 mA 30 V

30 V 30 mA 30 V

30 V 30 mA 30 V

30 V 30 mA 30 V

30 V 25 mA 30 V

30 V 30 mA 30 V

30 V 30 mA 30 V

Inputs and outputs with optional plug-in cards Operating values (general) Type of protection – ‘nA’ / ‘NI’

U

N

Current output V3 / V4, active*

Terminals V3 / V4 and V1 / V2*

Current output V1 / V2, passive**

Current output V3 / V4, passive**

Terminals V1 / V2** or V3 / V4**

Digital output V3 / V4, active*

Terminals V3 / V4 and V1 / V2*

Digital output V1 / V2, passive**

Digital output V3 / V4, passive**

Terminals V1 / V2** or V3 / V4**

Digital input V3 / V4, active*

Terminals V3 / V4 and V1 / V2

Digital input V1 / V2, passive*

Digital input V3 / V4, passive*

Terminals V1 / V2** or V3 / V4**

Modbus® / PROFIBUS DP®

Terminals V1 / V2

* Only in conjunction with additional ‘24 V DC loop power supply (blue)’ plug-in card in slot OC1.

** The terminal assignment depends on the model number or the slot assignments. For connection examples, see Connection examples on page 53.

30 V 30 mA 30 V 30 mA

30 V 30 mA 30 V 30 mA

30 V 25 mA 30 V 25 mA

30 V 30 mA 30 V 30 mA

30 V 3.45 mA 30 V 3.45 mA

30 V 3.45 mA 30 V 3.45 mA

30 V 30 mA 30 V 30 mA

I

N

I

N

U

N

30 mA

30 mA

30 mA

30 mA

25 mA

30 mA

30 mA

U

N

I

N

I

N

Page 18

18 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

—30

—30

—30

—

—

—

—

—

—

… 2 Use in potentially explosive atmospheres

… Electrical data

Zone 1 ,21 und Division 1 – Model: FCx4xx-A1, FCx4xx-F1

Type of protection ‘e’ / ‘XP’ ‘ia’ / ‘IS’

Outputs on basic device U

Current / HART output 31 / UCO, active

M

[V]

30 0.2

[A]

I

M

U

[V]

U

I

I

P

P

C

C

C

C

O

I

O

I

O

I

O

I

OPA

[V]

[mA]

[mA]

[mW]

[mW]

[nF]

[nF]

[nF]

IPA

[nF]

L

[mH]

O

[mH]

30 30 115 115 815 815 10 10 5 5 0.08 0.08

Terminals 31 / UCO

Current / HART output 31 / 32, passive

30 0.2

— 115 — 815 — 27 — 5 0.08 0.08

Terminals 31 / 32

Digital output 41 / 42, active*

30 0.1

27.8 30 119 30 826 225 20 20 29 29 0.22 0.22

Terminals 41 / 42 and V1 / V2*

Digital output 41 / 42, active**

30 0.1

30 30 115 115 826 225 16 16 10 10 0.08 0.08

Terminals 41 / 42 and UCO / 32**

Digital output 41 / 42, passive

30 0.1

— 30 — 225 — 27 — 5 — 0.08

Terminals 41 / 42

Digital output 51 / 52, active*

30 0.1

27.8 30 119 30 826 225 20 20 29 29 0.22 0.22

Terminals 51 / 52 and V1 / V2*

Digital output 51 / 52, passive

30 0.1

— 30 — 225 — 27 — 5 — 0.08

Terminals 51 / 52

All outputs are electrically isolated from each other and from the power supply.

Digital outputs 41 / 42 and 51 / 52 are not electrically isolated from each other. Terminals 42 / 52 have the same potential.

* Only in conjunction with additional ‘24 V DC loop power supply (blue)’ plug-in card in slot OC1.

** Only in conjunction with current output U

/ 32 in ‘power mode’, see Current output Uco / 32 as loop power supply for digital output 41 / 42 or 51 / 52 on

CO

page 50.

Type of protection ‘e’ / ‘XP’ ‘ia’ / ‘IS’

Inputs and outputs with optional plug-in cards U

Current output V3 / V4, active*

I

M

M

[V]

[A]

30 0.1 27.8 30 119 30 826 225 29 29 117 117 0.4 0.4

Terminals V3 / V4 and V1 / V2*

Current output V1 / V2, passive**

30 0.1 — 30

Current output V3 / V4, passive**

Terminals V1 / V2** or V3 / V4**

Digital output V3 / V4, active*

30 0.1 27.8 30 119 68 826 225 17 17 31 31 0.4 0.4

Terminals V3 / V4 and V1 / V2*

Digital output V1 / V2, passive**

30 0.1 — 30

Digital output V3 / V4, passive**

Terminals V1 / V2** or V3 / V4**

Digital input V3 / V4, active*

30 0.1 27.8 30 119 3.45 826 25.8 17 17 31 31 0.4 0.4

Terminals V3 / V4 and V1 / V2

Digital input V1 / V2, passive*

30 0.1 — 30

Digital input V3 / V4, passive*

Terminals V1 / V2** or V3 / V4**

Modbus® / PROFIBUS DP®

30 0.1 4.2 4.2 150 150 150 150 1.5 1.5 6 6 0.14 0.14

Terminals V1 / V2

* Only in conjunction with additional ‘24 V DC loop power supply (blue)’ plug-in card in slot OC1.

** The terminal assignment depends on the model number or the slot assignments. For connection examples, see Connection examples on page 53.

Change from one to two columns

U

[V]

U

I

I

O

I

O

[V]

[mA]

[mA]

I

P

[mW]

O

[mW]

68 — 510 — 45 — 59

30 — 225 — 13 — 16

3.45 — 25.8 — 13 — 16

C

C

[nF]

C

C

I

OPA

[nF]

IPA

[nF]

L

[mH]

O

[mH]

P

I

O

[nF]

0.27

0.27

0.27

L

I

L

I

Page 19

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 19

… 2 Use in potentially explosive atmospheres

… Electrical data

Special connection conditions

Note

The AS plug-in card (24 V DC loop power supply) may only be

used to power the internal inputs and outputs on the device.

It must not be used to power external circuits!

Note

If the protective earth (PE) is connected in the flowmeter's

terminal box, you must ensure that no dangerous potential

difference can arise between the protective earth (PE) and the

potential equalization (PA) in areas with explosion risk.

Note

• For devices with a power supply of 11 to 30 V DC, on-site

external overvoltage protection must be provided.

• You must make sure that the overvoltage is limited to

140 % (= 42 V DC) of the maximum operating voltage.

The output circuits are designed so that they can be connected

to both intrinsically-safe and non-intrinsically-safe circuits.

• Combining intrinsically safe and non-intrinsically safe circuits

is not permitted.

• On intrinsically safe circuits, potential equalization should be

established along the entire length of the cable used for the

signal outputs.

• The rated voltage of the non-intrinsically safe circuits is

= 30 V.

U

M

• Intrinsic safety is preserved If the rated voltage U

= 30 V is

M

not up-scaled when connections are established to nonintrinsically safe external circuits.

• The information in Changing the type of protection on

page 24 must be observed when changing the type of

protection.

Devices connected to the relevant equipment must not be

operated at over 250 V

AC or 250 V DC to ground.

rms

Installation in accordance with ATEX or IECEx must comply with

the applicable national and international standards and

directives.

Installation in the USA or Canada must comply with ANSI / ISA

RP 12.6, ‘Installation of intrinsically safe systems for hazardous

(classified) locations’, the ‘National Electrical Code (ANSI / NFPA

70), sections 504, 505’ and the ‘Canadian electrical code (C22.1-

02)’.

Apparatus connected to the flowmeter must have appropriate

explosion protection approval in accordance with the Entity

concept.

The apparatus must have intrinsically safe circuits.

The apparatus must be installed and connected in accordance

with the relevant manufacturer documentation.

The electrical specifications in Electrical data on page 16 must

be observed.

Page 20

20 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

… 2 Use in potentially explosive atmospheres

Installation instructions

ATEX / IECEx

The installation, commissioning, maintenance and repair of

devices in potentially explosive atmospheres must only be

carried out by appropriately trained personnel. Works may be

carried out only by persons, whose training has included

instructions on different types of protection and installation

techniques, concerned rules and regulations as well as general

principles of zoning.

The person must possess the appropriate competences for the

type of work to be conducted.

The safety instructions for electrical apparatus in potentially

explosive areas must be in accordance with Directive

2014/34/EU (ATEX) and IEC 60079-14 (Installation of electrical

equipment in potentially explosive areas).

Comply with the applicable regulations for the protection of

employees to ensure safe operation.

cFMus

The installation, commissioning, maintenance and repair of

devices in areas with explosion hazard must only be carried out

by appropriately trained personnel.

The operator must strictly observe the applicable national

regulations with regard to installation, function tests, repairs,

and maintenance of electrical devices. (e. g. NEC, CEC).

Use in areas exposed to combustible dust

When using the device in areas exposed to combustible dusts

(dust ignition), the following points must be observed:

• The maximum surface temperature of the device may not

up-scale 85 °C (185 °F).

• The process temperature of the attached piping may up-

scale 85 °C (185 °F).

• Approved dust-proof cable glands must be used when

operating in Zone 21, 22 or in Class II, Class III.

Opening and closing the housing

DANGER

Danger of explosion if the device is operated with the

transmitter housing or terminal box open!

While using the device in potentially explosive atmospheres

before opening the transmitter housing or the terminal box,

note the following points:

• A valid fire permit must be present.

• Make sure that no flammable or hazardous atmospheres

are present.

WARNING

Risk of injury due to live parts!

When the housing is open, contact protection is not provided

and EMC protection is limited.

• Before opening the housing, switch off the power supply.

See also Opening and closing the housing on page 38.

Only original spare parts must be used to seal the housing.

Note

Spare parts can be ordered from ABB Service.

www.abb.com/contacts

Page 21

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 21

Cable entries in accordance with ATEX / IECEx

The devices are supplied with cable glands installed (certified in

accordance with ATEX or IECEx).

• The use of standard cable glands and closures is prohibited.

• The black plugs in the cable glands are intended to provide

protection during transport.

• The outside diameter of the connection cable must measure

between 6 mm (0.24 in) and 12 mm (0.47 in) to guarantee the

required tightness.

• Black cable glands are installed by default when the device is

supplied. If signal outputs are connected to intrinsically safe

circuits, replace the black cap on the corresponding cable

gland with the blue one supplied.

• Any unused cable entries must be sealed before

commissioning in accordance with the applicable standards.

Note

Low-temperature version devices (optional, up to −40 °C (−40 °F)

ambient temperature) are supplied with metal cable glands due

to the required temperature resistance.

Cable entries in accordance with cFMus

1 Transport protection plugs

Figure 1: Cable entry

The devices are delivered with ½ in NPT threads with transport

protection plugs.

• Unused cable entries must be sealed off prior to

commissioning using either approved pipe fittings or cable

glands in accordance with national regulations (NEC, CEC).

• Make sure that the pipe fittings, cable glands and, if

applicable, sealing plugs are installed properly and are leaktight.

• If the device is to be operated in areas with combustible

dusts, a threaded pipe connection or cable gland with

suitable approval must be used.

• The use of standard cable glands and closures is prohibited.

Note

Devices which are certified for use in North America are supplied

with a ½ in. NPT thread only and without cable glands.

Page 22

22 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

… 2 Use in potentially explosive atmospheres

… Installation instructions

Electrical connections

Note

The temperature at the cable entries of the device depends on

the design, the measuring medium temperature T

ambient temperature T

amb.

.

medium

and the

For the electric connection of the device, use only cables with

sufficient temperature resistance in accordance with the tables

at Temperature resistance for the connecting cable on page 12.

Grounding

The sensor must be grounded in accordance with the applicable

international standards.

Perform grounding of the device in accordance with Pin

assignment on page 48.

In accordance with NEC standards, an internal ground

connection is present in the device between the sensor and the

transmitter.

Perform grounding of the device in accordance with Pin

assignment on page 48.

Process sealing

In accordance with ‘North American Requirements for Process

Sealing between Electrical Systems and Flammable or

Combustible Process Fluids’.

Note

The device is suitable for use in Canada.

• For use in Class II, Groups E, F and G, a maximum surface

temperature of 165 °C (329 °F) may not be up-scaled.

• All cable (conduits) should be sealed from the device within a

distance of 18 in (457 mm).

ABB flowmeters are designed for the worldwide industrial

market and are suitable for functions such as the measurement

of flammable and combustible liquids and can be installed in

process pipes.

Connecting devices with cable (conduits) to the electric

installation makes it possible for measuring media to reach the

electric system.

To prevent measuring media from seeping into the electric

installation, the devices are equipped with process gaskets

which meet requirements in accordance with ANSI / ISA 12.27.01.

Coriolis mass flowmeters are designed as ‘Single Seal Devices’.

With the TE2 order option, ‘Extended tower length - insulation

capacity with dual gasket’, the devices can be used as a ‘Dual

Seal Devices’.

In accordance with the requirements of standard

ANSI / ISA 12.27.01, the existing operating limits of temperature,

pressure and pressure bearing parts must be reduced to the

following limit values:

Limit values

Flange or pipe material No limitations

Nominal sizes DN 15 to DN 150

(½ to 6 in)

Operating temperature -50 °C to 205 °C

(-58 °F to 400 °F)

Process pressure PN 100 / Class 600

Page 23

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 23

Operating instructions

Protection against electrostatic discharges

DANGER

Risk of explosion!

The painted surface of the device can store electrostatic

charges.

As a result, the housing can form an ignition source due to

electrostatic discharges in the following conditions:

• The device is operated in environments with a relative

humidity of ≤ 30 %.

• The painted surface of the device is thereby relatively free

from impurities such as dirt, dust or oil.

• Instructions on avoiding ignition in potentially explosive

environments due to electrostatic discharges in

accordance with PD CLC/TR 60079-32-1 and IEC TS 6007932-1 must be complied with!

Instructions on cleaning

The painted surface of the device must be cleaned only using a

moist cloth.

Devices which are approved for use in potentially explosive

atmospheres have an additional warning plate.

1 WARNING! – Danger due to electrostatic discharge.

Figure 2: Additional warning plate

Repair

Devices of type of protection ‘d’ are equipped with flameproof

joints in the housing. Contact ABB before commencing repair

work.

Change from two to one column

Page 24

24 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

… 2 Use in potentially explosive atmospheres

… Operating instructions

Changing the type of protection

If you are installing in Zone 1 / Div. 1, the current outputs and digital outputs of models FCB430/450 and FCH430/450 can be

operated with different types of protection:

• Current output and digital output in the ‘intrinsically safe ia / IS’ design

• Current output and digital output in non-intrinsically safe design

If a device that is already operational is operated with a different type of protection, the following measures must be

implemented/insulation checks performed in accordance with applicable standards.

Original installation New installation Necessary test steps

Zone 1 / Div. 1:

Current outputs and digital outputs in

non-intrinsically safe design

Zone 1 / Div. 1:

Current outputs and digital outputs in

intrinsically safe ia(ib) / IS design

Change from one to two columns

Zone 1 / Div. 1:

Current outputs and digital outputs in

intrinsically safe ia / IS design

Zone 1 / Div. 1:

Current outputs and digital outputs in

non-intrinsically safe design

• 500 V AC/1min or 500 × 1.414 = 710 V DC/1min

Test between terminals A / B, U

V1 / V2 and V3 / V4, and terminals A, B, U

, /GND, UCO / 32, 31 / 32, 41 / 42, 51 / 52,

FE

, GND, UCO, 31, 32, 41, 42, 51, 52,

FE

V1, V2, V3, V4 and the housing.

When this test is performed, no voltage flashover is permitted in or on the

device.

• Optical evaluation particularly of the electronic circuit boards, no visible

damage or evidence of explosion.

• Visual inspection, no damage visible on the threads (cover, ½ in NPT cable

glands).

Page 25

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 25

3 Design and function

General

The ABB CoriolisMaster operates according to the Coriolis

principle.

The construction features conventional parallel meter tubes and

is characterized in particular by its space-saving, sturdy design,

wide range of nominal diameters and minimal pressure loss.

Measuring principle

If mass flows through a vibrating pipe, Coriolis forces are

generated which bend or twist the pipe. These very small

measurement pipe deformations are picked up by optimally

mounted sensors and electronically evaluated. Because the

measured phase shift of the sensor signals is proportional to the

mass flow, the mass conveyed by the measuring device can be

recorded directly using the Coriolis mass flowmeter. The

metering principle is independent of the density, temperature,

viscosity, pressure and conductivity of the fluid.

The meter tubes always vibrate at resonance. This arising

resonant frequency is a function of the meter tube geometry, the

characteristics of the materials and the mass of the medium in

the resonating meter tube. It provides an accurate measure of

the density of the measuring medium.

An integrated temperature sensor records the measuring

medium temperature and is utilized for corrections to

temperature-dependent device parameters. In summary, it is

possible to simultaneously measure mass flow, density and

temperature with the Coriolis Mass Flowmeter. Other

measurement values can be derived from these values, e.g.

volume flow rate or concentration.

Change from two to one column

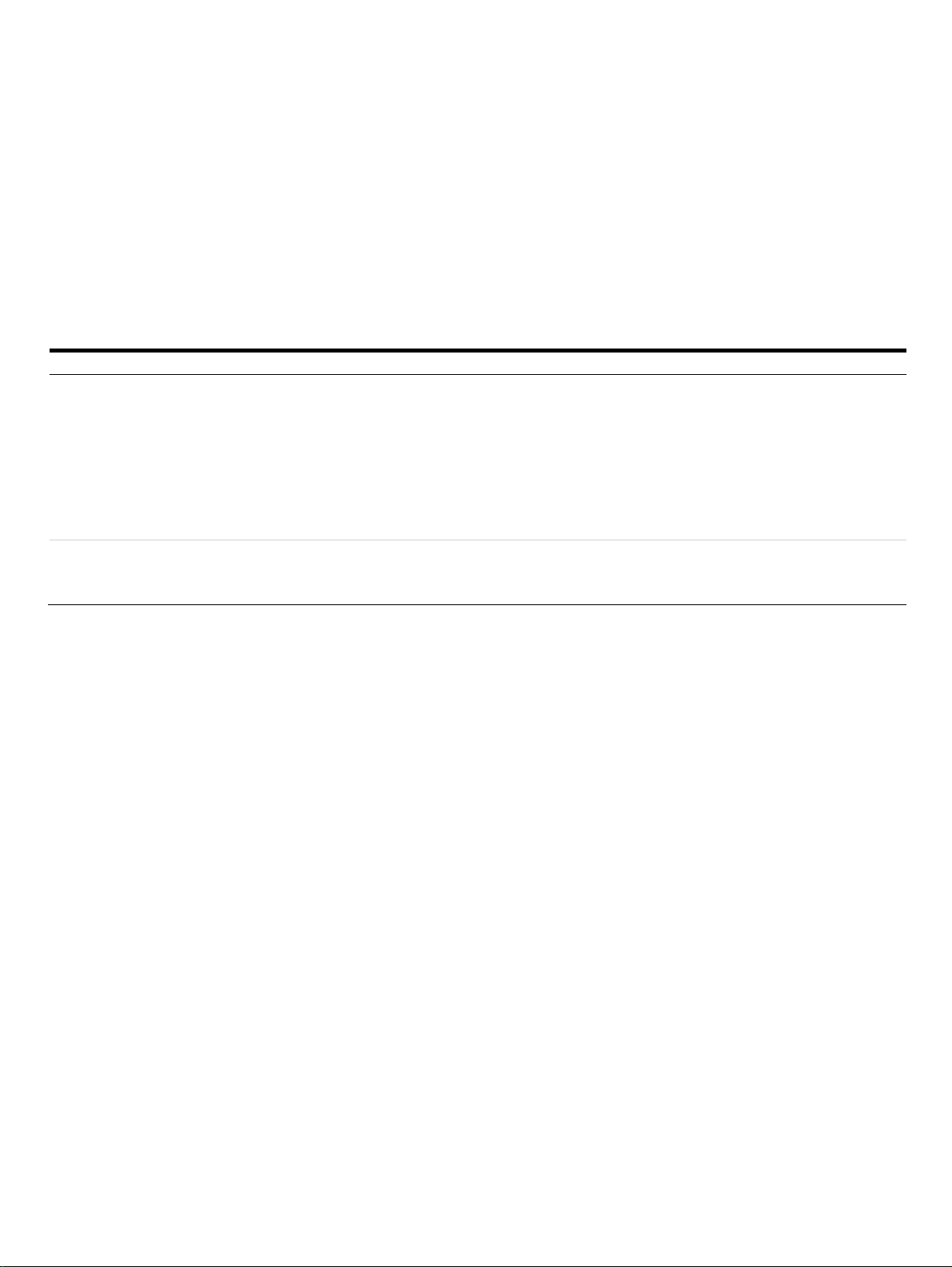

Function for calculating Coriolis force

2

cF

Coriolis force

Angular velocity

v

Velocity of the mass

m Mass

A Movement of the pipes inward, no flow

B Direction of the Coriolis force with flow and movement of the pipes

outward

C Movement of the pipes outward, no flow

D Direction of the Coriolis force with flow and movement of the pipes

inward

Figure 3: Simplified representation of Coriolis forces

vmcF

Page 26

26 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

… 3 Design and function

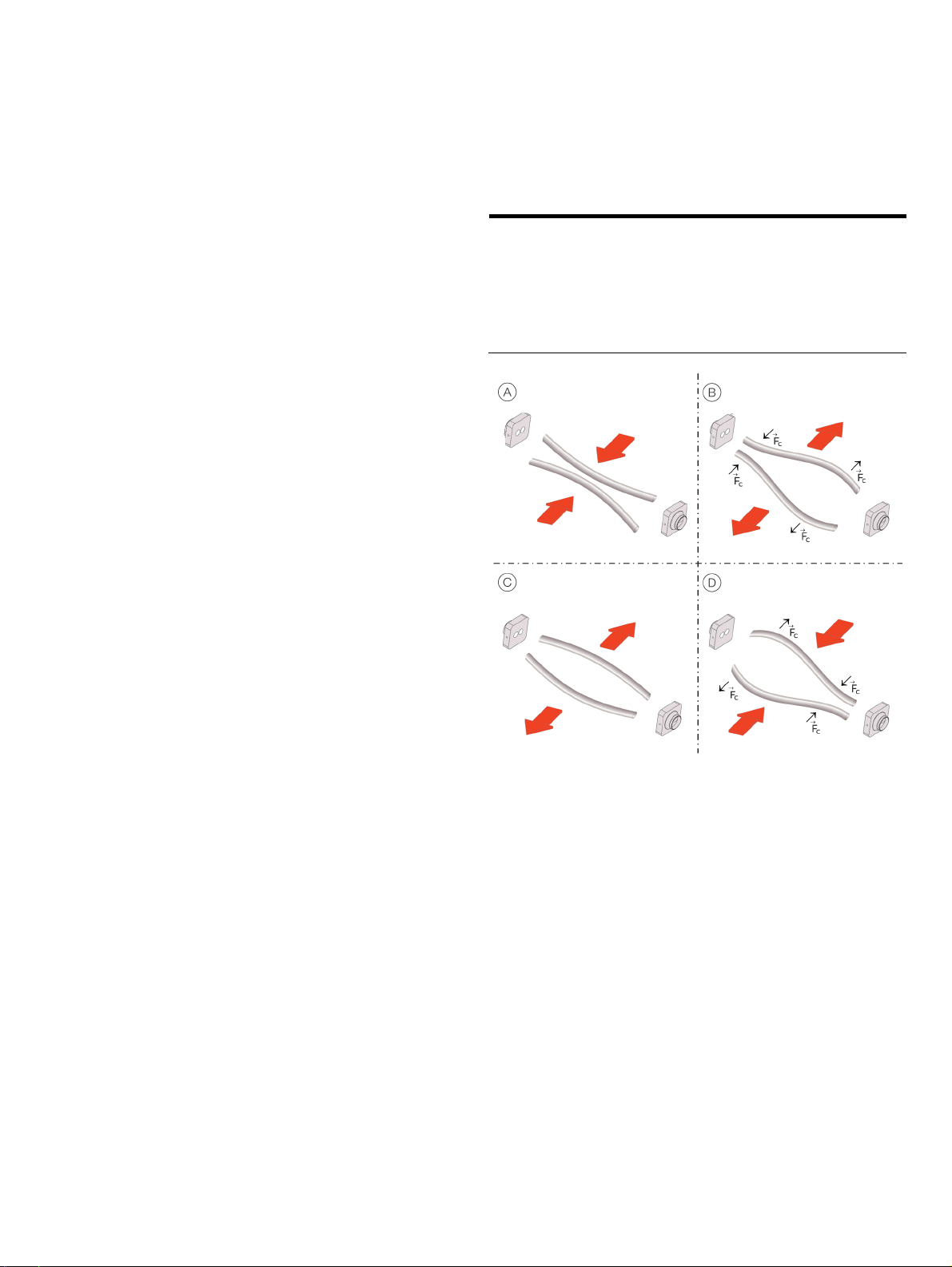

Device designs

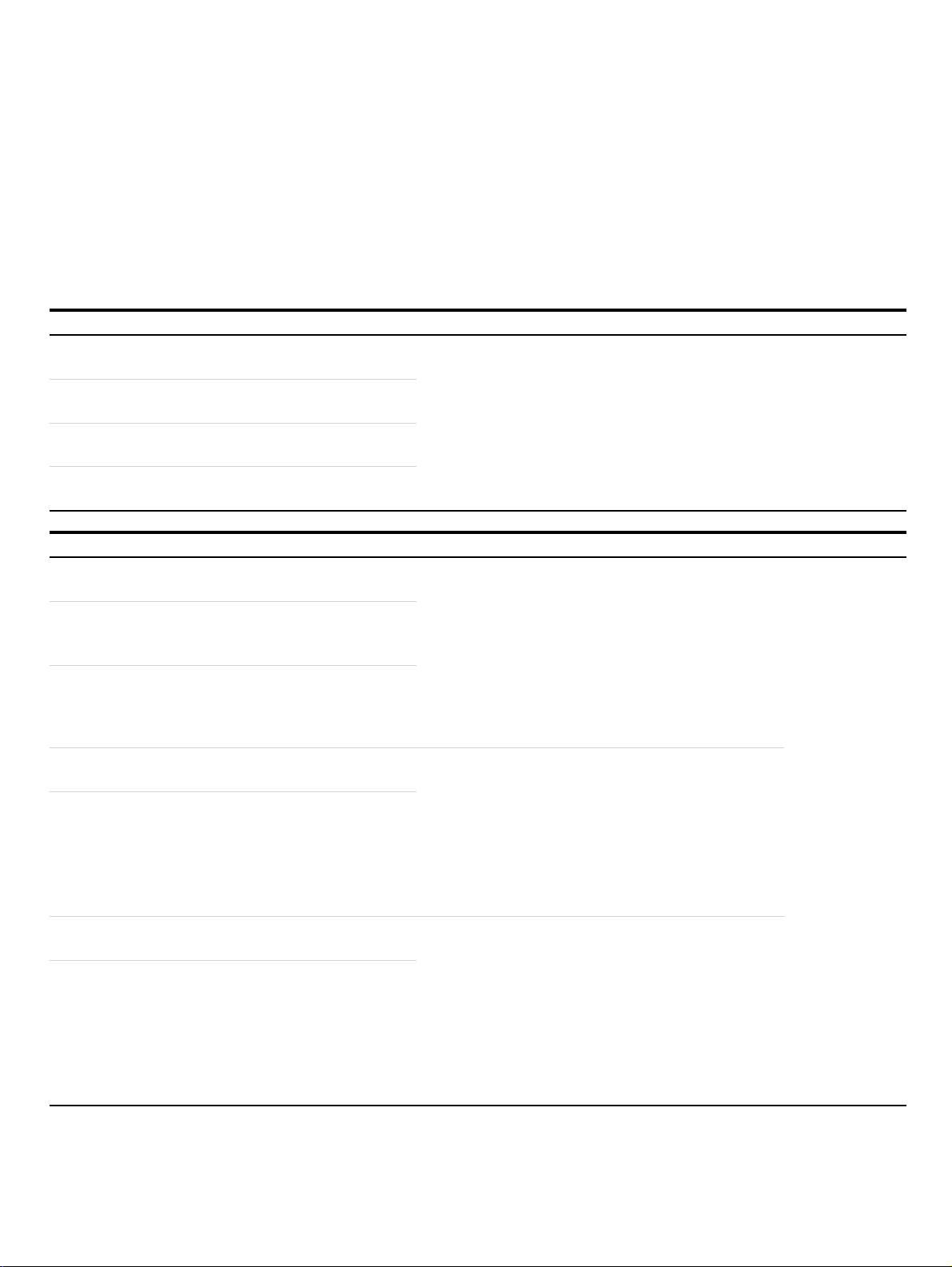

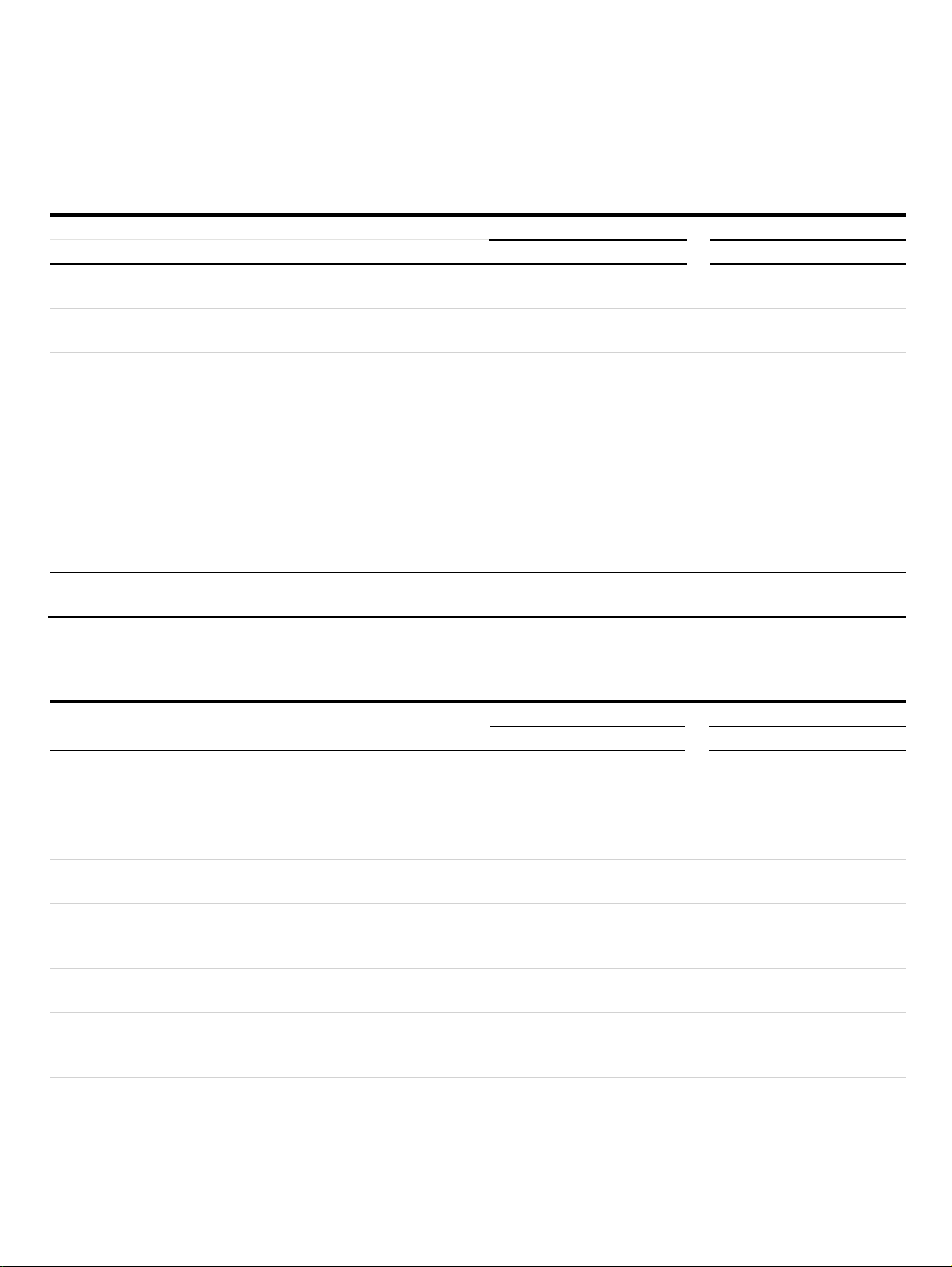

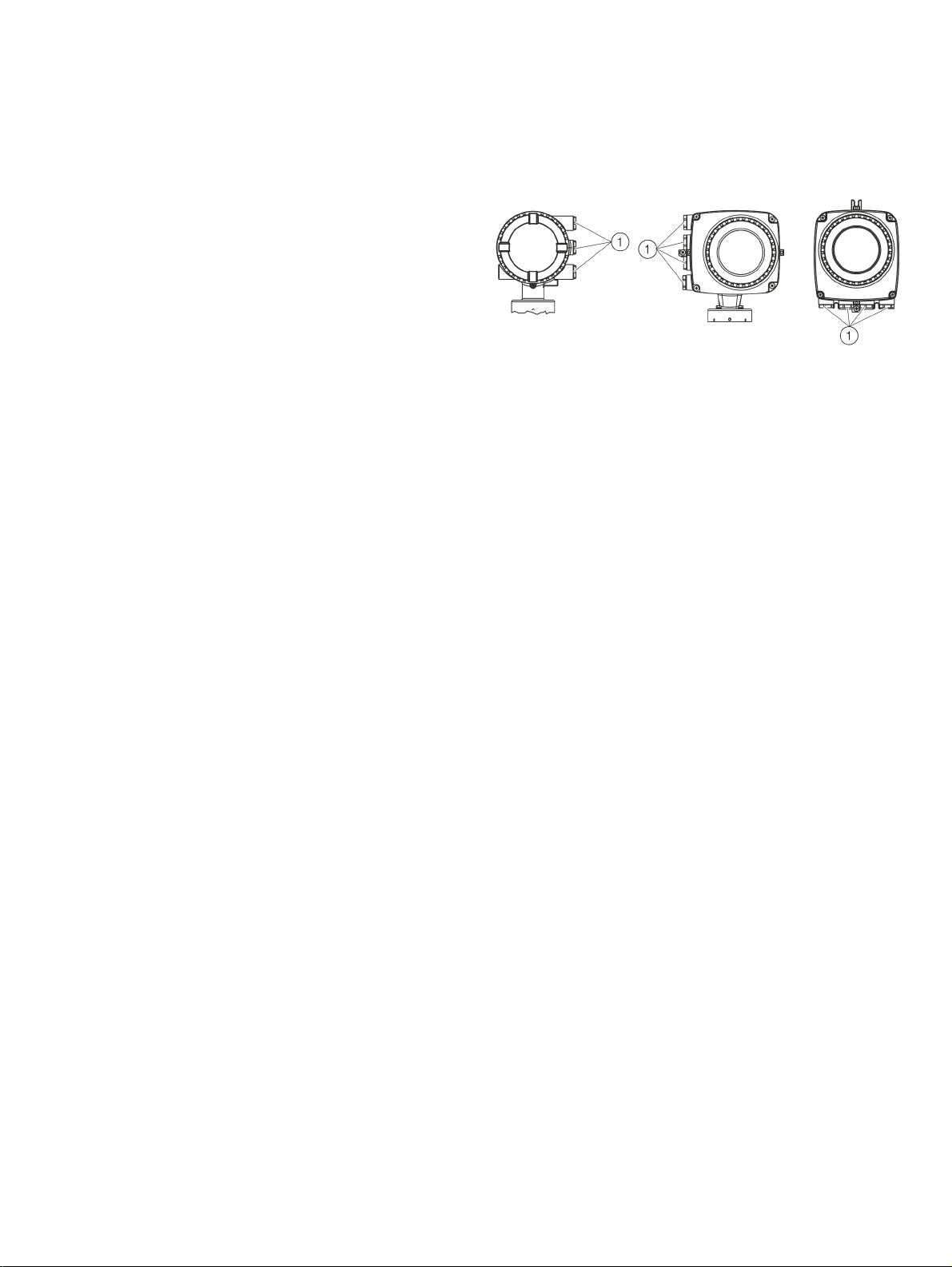

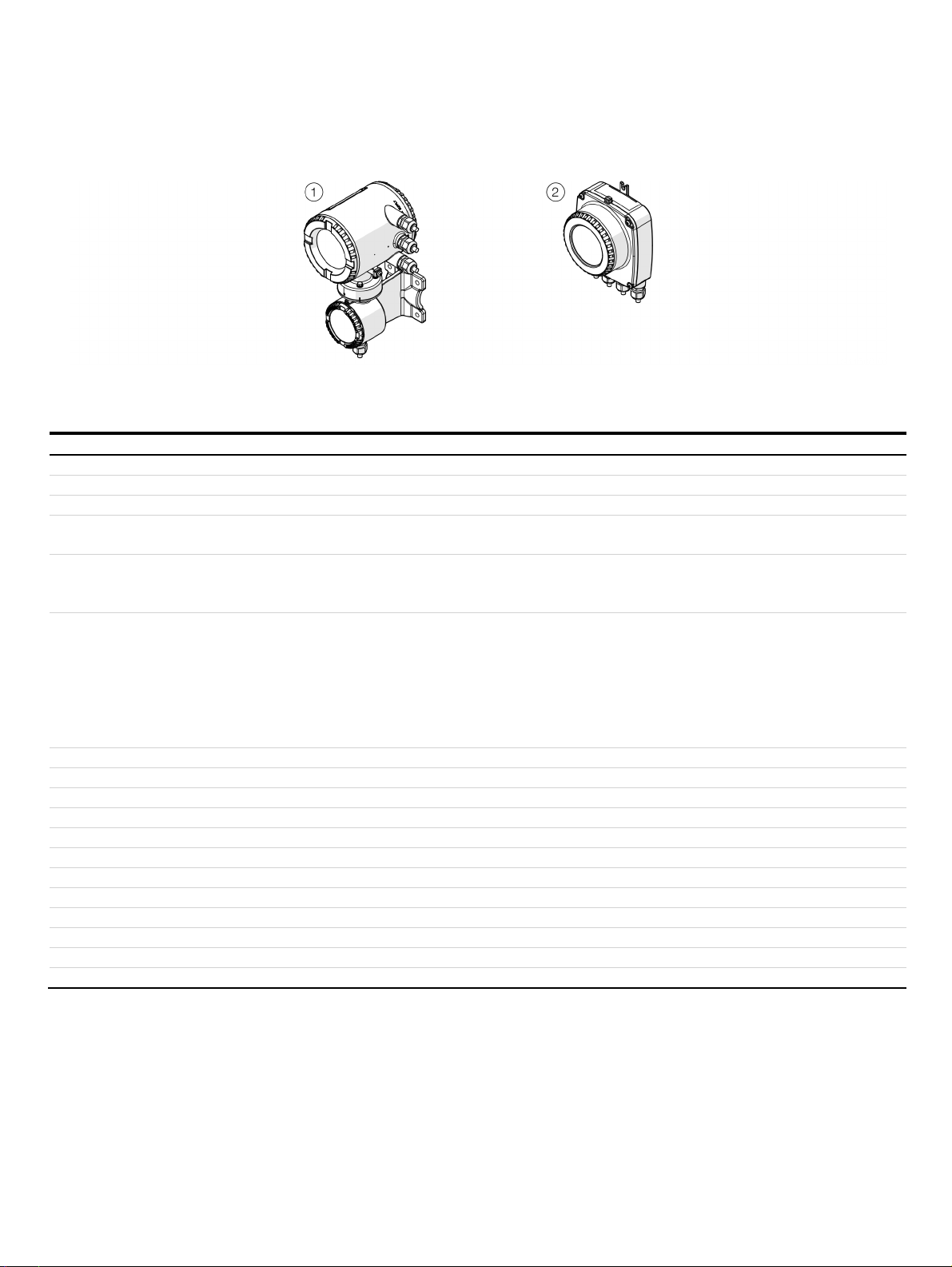

1 Sensor (integral mount design, dual-compartment housing)

2 Sensor (integral mount design, single-compartment housing)

Figure 4: Designs

3 Sensor (remote mount design)

Sensor

Model FCB400 standard design FCH400 hygienic design

Housing Integral mount design, remote mount design

Measuring accuracy for liquids FCB430 FCB450 FCH430 FCH450

Mass flow* 0.4 %, 0.25 % and 0.2 % 0.1 % and 0.15 % 0.4 %, 0.25 % and 0.2 % 0.1 % and 0.15 %

Volume flow* 0.4 %, 0.25 % and 0.2 % 0.15 % and 0.11 % 0.4 %, 0.25 % and 0.2 % 0.15 % and 0.11 %

Density 0.01 kg/l

Temperature 1 K 0.5 K 1 K 0.5 K

Measuring accuracy for gases* 1 % 0.5 % 1 % 0.5 %

Permissible measuring medium

temperature T

medium

−50 to 160 °C

(−58 to 320 °F)

Process connection

Flange DIN 2501 / EN 1092-1 DN 10 to 200; PN 40 to PN 160 —

Flange ASME B16.5 DN ½ to 8 in; CL150 to CL1500 —

JIS flange DN 10 to 200; JIS 10K to 20K —

Pipe fitting DIN 11851 DN 10 to 100 (⅜ to 4 in) DN 15 to 100 (½ to 4 in)

Pipe fitting SMS 1145 DN 25 to 80 (1 to 3 in) —

Tri-clamp DIN 32676 (ISO 2852)

Tri-clamp BPE

Female thread DIN ISO 228 and

DN 15 to 100 (¼ to 4 in)

DN ⅜ to 4 in

DN 15; PN 100 —

ASME B 1.20.1

Other connections On request On request

Wetted material Stainless steel 1.4435 or 1.4404 (AISI 316L), nickel-alloy

C4 / C22 (optional)

IP rating • Integral mount design: IP 65 / IP 67, NEMA 4X

• Remote mount design: IP 65 / IP 67 / IP 68 (sensor only, immersion depth: 5 m), NEMA 4X

Approvals

• Explosion protection ATEX / IECEx / cFMus ATEX / IECEx / cFMus

• Hygiene approvals — EHEDG, FDA compliant

• Legal metrology Type-tested for legal metrology in accordance with MID / OIML R117 or API / AGA

• Further approvals At www.abb.com/flow or upon request.

* Indication of accuracy in % of the measured value

• 0.002 kg/l

• 0.001 kg/l (optional)

• 0.0005 kg/l

−50 to 205 °C

(−58 to 400 °F)

0.01 kg/l

−50 to 160 °C

(−58 to 320 °F)

• 0.002 kg/l

• 0.001 kg/l (optional)

• 0.0005 kg/l

−50 to 205 °C

(−58 to 400 °F)

DN 20 to 100 (¼ to 4 in)

DN ⅜ to 4 in

Stainless steel, polished 1.4404 (AISI 316L) or 1.4435 (AISI

316L)

Page 27

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 27

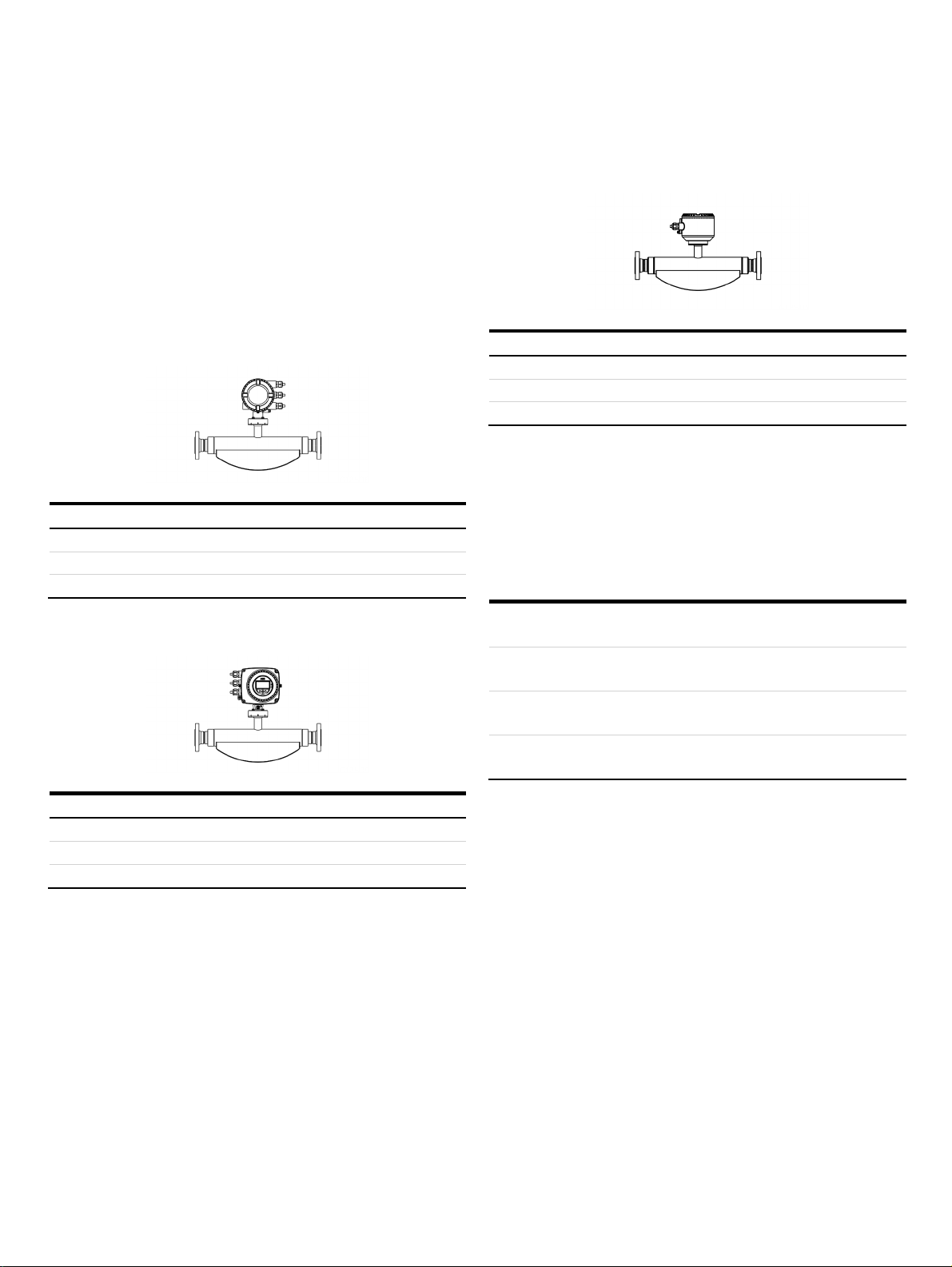

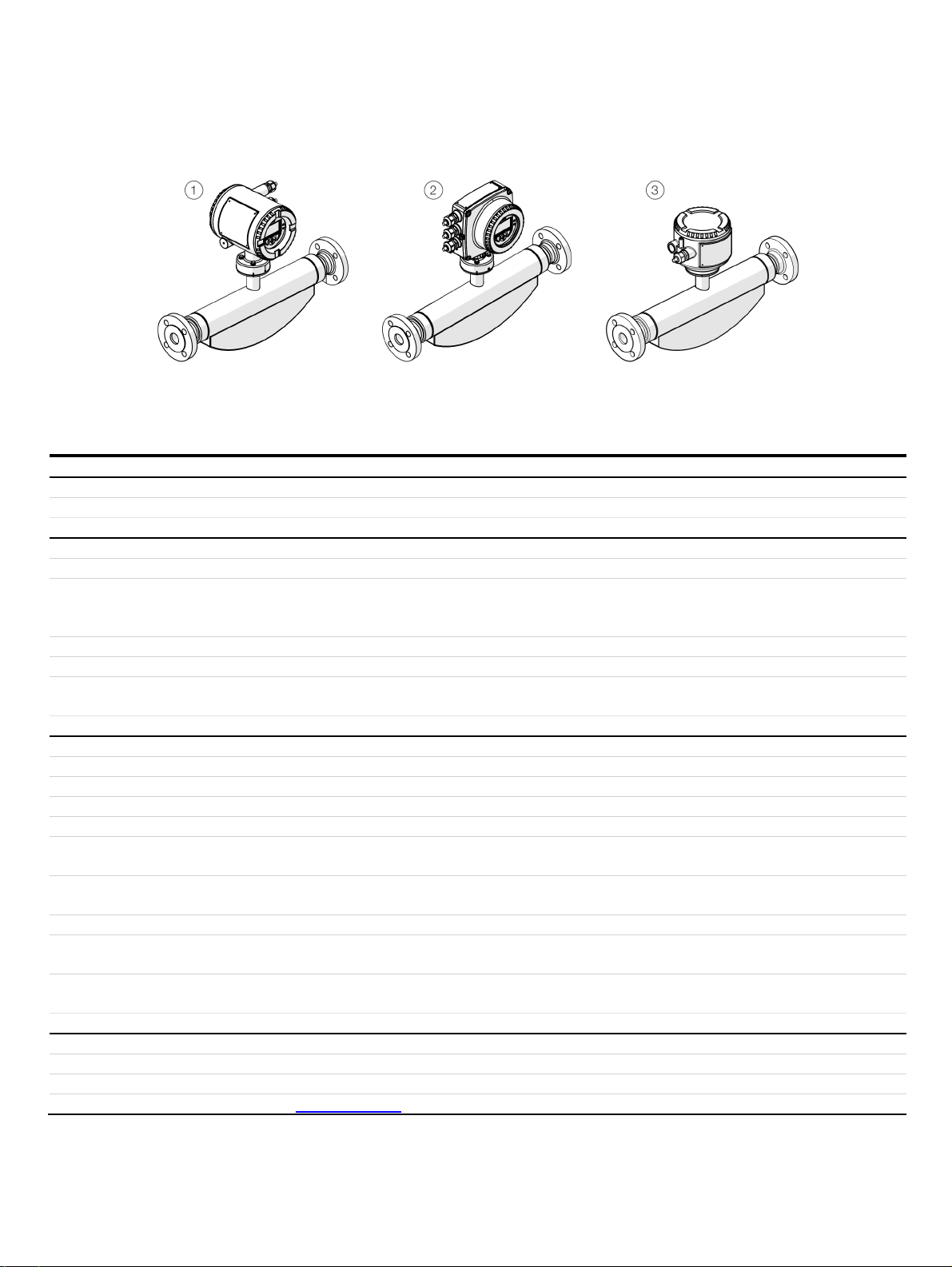

1 Dual-compartment housing

Figure 5: Transmitter with remote mount design

2 Single-compartment housing

Transmitter

Housing Integral mount design (see Figure 4, pos. 1 and 2), remote mount design.

IP rating IP 65 / IP 67, NEMA 4X

Cable length Maximum 200 m (656 ft), with remote mount design only

Power supply 100 to 240 V AC, 50 / 60 Hz

11 to 30 V DC, nominal voltage: 24 V DC

Outputs in basic version Current output: 4 to 20 mA active or passive

Digital output 1: passive, configurable as pulse, frequency or switch output

Digital output 2: passive, configurable as pulse or switch output

Additional optional outputs The transmitter has two slots in which plug-in cards can be inserted to provide additional inputs and

outputs. The following plug-in cards are available:

• Current output (maximum two plug-in cards simultaneously)

• Digital output (maximum one plug-in card)

• Digital input (maximum one plug-in card)

• Modbus or PROFIBUS DP interface (maximum of one plug-in card)

• 24 V DC loop power supply for active outputs (maximum one plug-in card)

External output zero return Yes

External totalizer reset Yes

Forward / reverse flow metering Yes

Counter Yes

Communication HART® protocol 7.1, Modbus® or Profibus DP® (using a plug-in card)

Empty pipe detection Yes, via configurable density alarm

Self-monitoring and diagnosis Yes

Local indicator Yes

Field optimization for flow and density Yes

Concentration measurement ‘DensiMass’ Yes, optional on models FCB450 and FCH450

‘FillMass’ filling function Yes, optional on models FCB450 and FCH450

‘VeriMass’ function Yes, optional

Change from one to two columns

Page 28

28 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

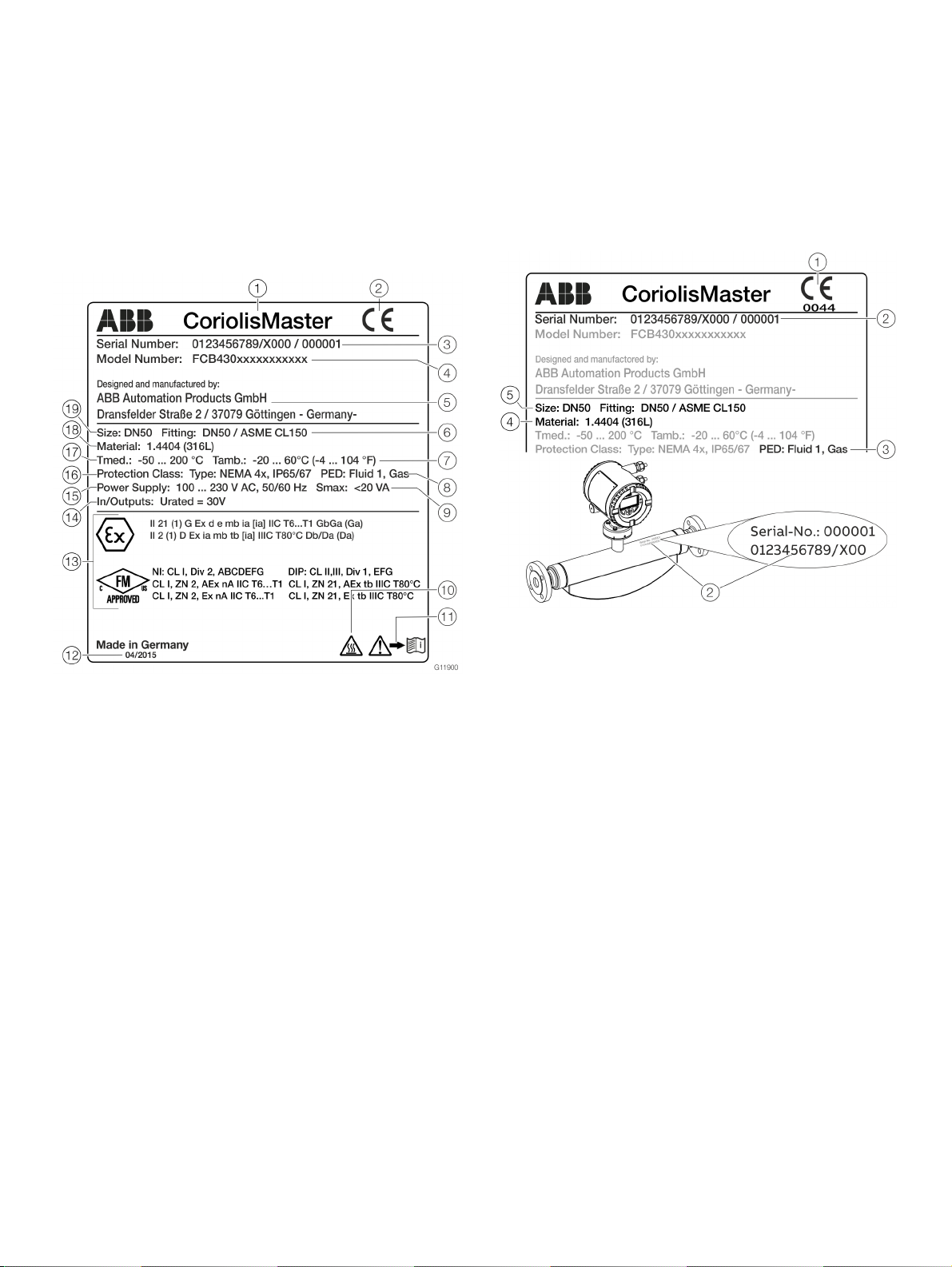

4 Product identification

Name plate

Note

The name plates displayed are examples. The device

identification plates affixed to the device can differ from this

representation.

The marking is provided on the name plate and on the sensor

itself in accordance with the Pressure Equipment Directive

(PED).

1 Type designation

2 CE mark

3 Serial number

4 Order code

5 Manufacturer

6 Process connection / pressure

rating

7 Ambient temperature range

8 PED marking

9 Maximum power consumption

j ‘Hot surface’ symbol

k ‘Observe operating instruction’

symbol

Figure 6: Name plate (example)

l Year of manufacture

(month / year)

m Ex marking, such as ATEX / IECEx

or FM / CSA

n Maximum voltage at inputs and

outputs

o Power supply

p IP rating

q Measuring medium temperature

range

r Meter tube material

s Nominal diameter

1 CE mark with notified body

2 Serial number of the sensor

3 Fluid group or reason for

exception

Figure 7: PED marking (example)

4 Material of the pressure-bearing

parts (wetted parts)

5 Nominal diameter / Nominal

pressure rating

The marking is dependent on the nominal diameter (> DN 25 or

≤ DN 25) of the sensor (also refer to Pressure Equipment

Directive 2014/68/EU).

Pressure equipment within the scope of the Pressure

Equipment Directive

The number of the notified body is specified underneath the CE

mark to confirm that the device meets the requirements of the

Pressure Equipment Directive.

The respective fluid group in accordance with the Pressure

Equipment Directive is indicated under PED.

Example: Fluid Group 1 = hazardous fluids, gaseous.

Pressure equipment beyond the scope of the Pressure

Equipment Directive

In PED the exception to Article 4 (3) of the Pressure Equipment

Directive is specified.

The pressure equipment is classified in the SEP (= Sound

Engineering Practice) ‘Good Engineering Practice’ category.

Page 29

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 29

5 Transport and storage

Observe the following instructions:

• Do not expose the device to humidity during transport.

Pack the device accordingly.

• Pack the device so that it is protected against vibrations

during transport, for example, by using air-cushioned

packing.

Inspection

Check the devices immediately after unpacking for possible

damage that may have occurred from improper transport.

Details of any damage that has occurred in transit must be

recorded on the transport documents.

All claims for damages must be submitted to the shipper

without delay and before installation.

Transporting the device

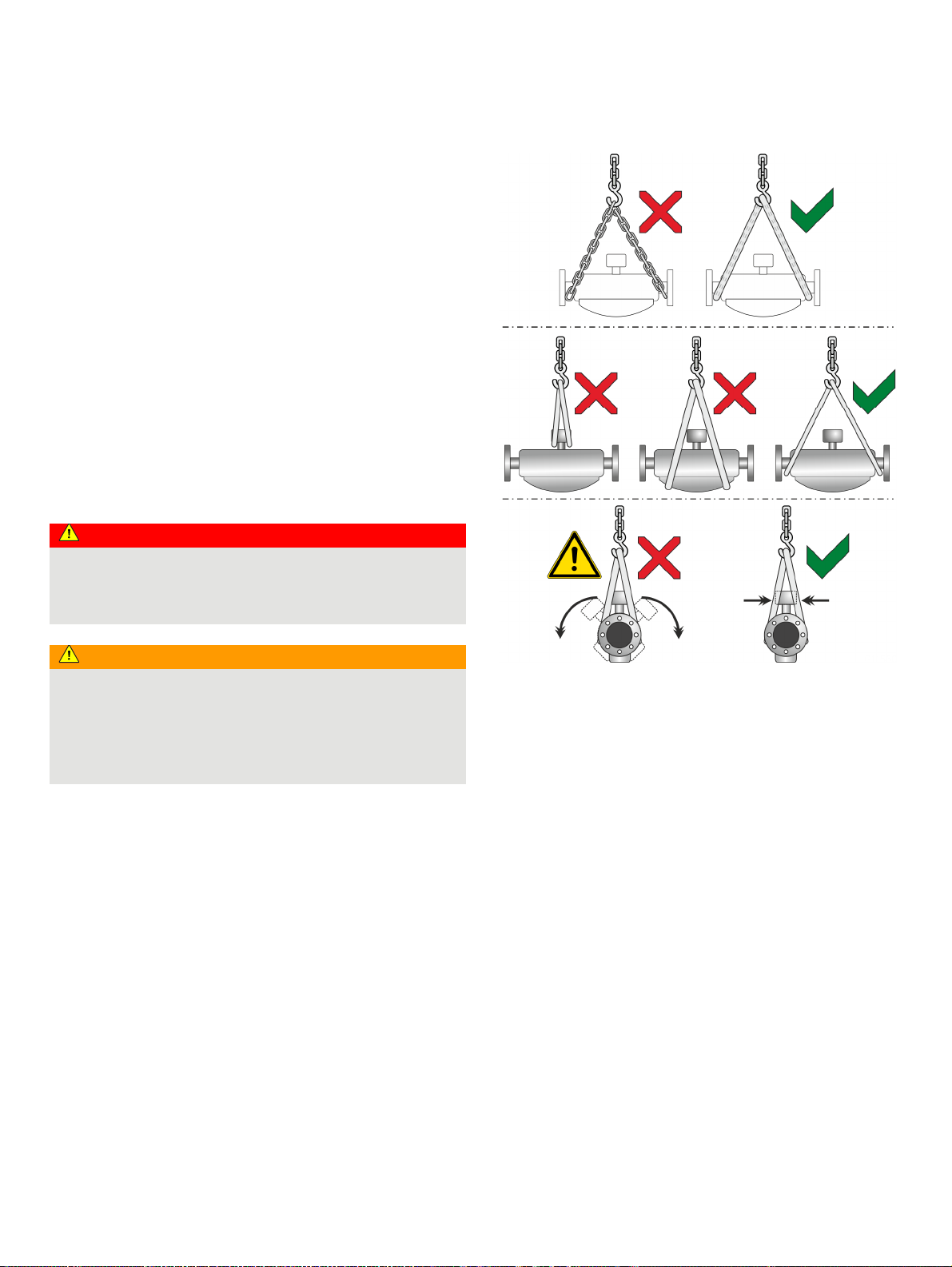

DANGER

Life-threatening danger due to suspended loads.

In the case of suspended loads, a danger of the load falling

exists.

• Standing under suspended loads is prohibited.

WARNING

Risk of injury due to device slipping.

The device's center of gravity may be higher than the harness

suspension points.

• Make sure that the device does not slip or turn during

transport.

• Support the device laterally during transport.

Figure 8: Transport instructions

Observe the following when transporting the device to the

measuring location:

• Observe the weight details of the device in the data

sheet.

• Use only approved hoisting slings for crane transport.

• Do not lift devices by the transmitter housing or terminal

box.

• The center of gravity of the device may be located above

the harness suspension points.

Page 30

30 CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E

… 5 Transport and storage

Storing the device

Bear the following points in mind when storing devices:

• Store the device in its original packaging in a dry and

dust-free location.

• Observe the permitted ambient conditions for transport

and storage.

• Avoid storing the device in direct sunlight.

• In principle, the devices may be stored for an unlimited

period. However, the warranty conditions stipulated in

the order confirmation of the supplier apply.

Ambient conditions

The ambient conditions for the transport and storage of the

device correspond to the ambient conditions for operation of

the device.

Adhere to the device data sheet!

Returning devices

For the return of devices, follow the instructions in Repair on

page 138.

Page 31

CoriolisMaster FCB400, FCH400 CORIOLIS MASS FLOWMETER | OI/FCB400/FCH400-EN REV. E 31

6 Installation

General installation conditions

Installation location and assembly

Note the following points when selecting the installation

location and when mounting the sensor:

• The ambient conditions (IP rating, ambient temperature

range T

installation location.

) of the device must be adhered to at the

ambient

• Sensors and transmitters must not be exposed to direct

sunlight. If necessary, provide a suitable means of sun

protection on site. The limit values for ambient

temperature T

must be adhered to.

ambient

• On flange devices, ensure that the counterflanges of the

piping are aligned plane parallel. Only install flange

devices with suitable gaskets.

• Prevent the sensor from coming into contact with other

objects.

• The device is designed for industrial applications.

No special EMC protective measures are required if the

electromagnetic fields and interference at the installation

location of the device comply with ‘Best Practice’ (in

accordance with the standards listed in the declaration of

conformity).