Page 1

ABB Power T&D Company Inc.

Relay Division

Coral Springs, FL 33065

Instruction Leaflet

I.L. 41-161J

Type COQ

Negative Sequence Generator Relay

Effective: May 1997

Supersedes I.L. 41-161H Dated July 1984

( | ) Denotes Change Since Previous Issue

CAUTION

!

Before putting protection relays into service,

remove all blocking which may have been

inserted for the purpose of securing the parts

during shipment. Make sure that all moving

parts operate freely. Inspect the contacts to

see that they are clean and can close properly. Operate the relay to check the settings

and electrical connections.

1. APPLICATION

The COQ is used to prevent a synchronous machine

from being damaged due to negative sequence fault

currents. Two varieties are available, as shown in

Figures 2 and 3, depending upon whether the neutral

can be formed at the COQ or whether the neutral

must be formed elsewhere. (See external schematic,

Figures 8 and 9.)

2. CONSTRUCTION AND OPERATION

The COQ consists of an induction disc overcurrent

unit, a negative sequence filter, and an indicating

contactor switch (ICS).

2.1. Overcurrent Unit

This is an induction-disc type unit operated by negative sequence quantities supplied to an electromagnet in the rear of the relay. A voltage is induced in the

secondary coil of this electromagnet by transformer

action of the main coil. Both coils are located on the

center leg of the electromagnet. Current flow is from

the secondary coil to coils on the outer legs of the

(50/60 Hertz)

electromagnet. The reaction between the outer leg

coil fluxes and the main coil flux creates an operating

torque on a spiral shaped aluminum disc mounted on

a vertical shaft.

2.2. Indicating Contactor Switch Unit (ICS)

The dc indicating contactor switch is a small clapper

type device. A magnetic armature, to which leafspring mounted contacts are attached, is attracted to

the magnetic core upon energization of the switch.

When the switch closes, the moving contacts bridge

two stationary contacts, completing the trip circuit.

Also during this operation two fingers on the armature deflect a spring located on the front of the

switch, which allows the operation indicator target to

drop. The target is reset from the outside of the case

by a push rod located at the bottom of the cover.

The front spring, in addition to holding the target, provides restraint for the armature and thus controls the

pickup value of the switch.

3. CHARACTERISTICS

3.1. Overcurrent Unit

The COQ negative sequence relay is available with

the following negative sequence current taps:

3 3.25 3.5 3.8 4.2 4.6 5.0

These tap values represent the current transformer

secondary amperes which correspond to one per unit

generator current. At these values of negative

sequence current, the moving contact will leave the

time dial stop and reach the stationary contacts in a

time as determined by the time dial setting and is as

shown by Figure 7. For example, with a time dial

All possible contingencies which may arise during installation, operation or maintenance, and all details and

variations of this equipment do not purport to be covered by these instructions. If further information is desired

by purchaser regarding this particular installation, operation or maintenance of this equipment, the local ABB

Power T&D Company Inc. representative should be contacted.

Printed in U.S.A.

Page 2

Page 3

I.L. 41-161J

TABLE 1

Typical Overcurrent Unit Burden And Thermal Rating

Input Continuous One Second Watts at Volt Amps Circuit Impedance

Condition Phase Rating Amps Rating Amps 5 Amps At 5 Amps Z ∠θ (R+jX)

Three A 5 100 8.3 8.3 0.33 ∠0° (0.33+j 0.00)

Phase B 5 100 1.3 3.8 0.15 ∠110° (-0.05+j 0.14)

C 5 100 2.9 4.7 0.19 ∠52° (0.11+j 0.15)

PHASE-TO-PHASE FAULT CONDITION

Phase A-B 5 100 6.1 6.5 0.26 ∠−161.7° (-0.24-j 0.08)

To B-C 5 100 3.4 8.0 0.32 ∠65° (0.13+j 0.29)

Phase C-A 5 100 10.2 11.5 0.46 ∠−152° (-0.41-j 0.22)

PHASE-TO-NEUTRAL FAULT CONDITION

Phase A-N 5 100 5.1 5.2 0.21 ∠8.70° (0.20+j 0.03)

To B-N 5 100 3.5 3.8 0.51 ∠24.3° (0.14+j 0.06)

Neutral C-N 5 100 4.8 5.5 0.22 ∠29.0° (0.19+j 0.11)

setting of “4” the relay will close its contacts in 30

seconds with the above tap currents applied to the

relay.

As shown by the curves of Figure 5, the relay’s characteristic is defined by a generator characteristic

I22T = K. The relay characteristic is such that it coincides with the generator characteristic at 1 per unit

negative sequence current but at higher values of

negative sequence current, the relay characteristic is

substantially parallel and slightly less than the generator characteristic. In this manner, a suitable margin

of safety is obtained between the two characteristics.

Figure 5 defines the relay characteristics for two generators – one with a permissible constant of “30” and

the other with a constant of “90”. The time dial settings for these constants are “4” and “11” respectively. Similar protection for other generators with

I22T constants between “30” and “90” is obtained by

settings of the time dial. Figure 4 shows the necessary time dial settings for various I22T constants. By

referring to this figure, the time dial can be set so the

relay protects different generators whose I22T constants range from “30” to “90”.

contact spacing. For this figure a tap setting of 3 is

used with a machine full load current of 4.

Typical time-current curves of the relay are shown in

Figure 7. Minimum pickup is approximately 0.6 of the

tap value current. See Table 1 for burdens and terminal ratings.

3.2. Trip Circuit

The main contacts will safely close 30 amperes at

250 volts dc and the seal-in contacts of the indicating

contactor switch will safely carry this current long

enough to trip a circuit breaker.

The indicating contactor switch has two taps that provide a pickup setting of 0.2 or 2 amperes. To change

taps requires connecting the lead located in front of

the tap block to the desired settings by means of a

screw connection.

3.3. Indicating Contactor Switch (ICS)

0.2 ampere tap 6.5 ohms dc resistance

2.0 ampere tap 0.15 ohms dc resistance

4. SETTING CALCULATIONS

Figure 6 demonstrates the use of a tap setting lower

than the full load current of the machine to accommodate I22Tlimits from 5 to 10 while still providing wide

Determine from the machine manufacturer the permissible I22T constant. From Figure 4, find the

required time dial setting.

3

Page 4

Page 5

I.L. 41-161J

5.1. Overcurrent Unit

Insert the tap screw in the appropriate tap determined under Section 4 “Setting Calculations”.

Adjust the time dial setting to the value determined

under Section 4 “Setting Calculations”.

5.2. Indicating Contactor Switch (ICS)

Select the 0.2 or the 2.0 ampere tap setting depending upon the type of device being operated by the

relay. This selection is made by connecting the lead

located in front of the tap block to the desired tap.

6. INSTALLATION

The relays should be mounted on switchboard panels or their equivalent in a location free from dirt,

moisture, excessive vibration, and heat. Mount the

relay vertically by means of the four mounting holes

on the flange for semi-flush mounting or by means of

the rear mounting stud or studs for projection mounting. Either a mounting stud or the mounting screws

may be utilized for grounding the relay. The electrical

connections may be made directly to the terminals by

means of screws for steel panel mounting or to the

terminal studs furnished with the relay for thick panel

mounting. The terminal studs may be easily removed

or inserted by locking two nuts on the stud and then

turning the proper nut with a wrench.

For detailed FT case information refer to I.L. 41-076.

7. ADJUSTMENTS AND MAINTENANCE

The proper adjustments to insure correct operation of

this relay have been made at the factory and should

not require readjustment after receipt by the customer. If the adjustments have been changed or the

relay taken apart for repairs, the instructions below

should be followed.

7.1. Acceptance Tests

The following tests are recommended when the relay

is received from the factory. If the relay does not perform as specified below, the relay either is not calibrated or it contains a defect.

Apply approximately 5 amperes, 3 phase positive

sequences current on 3 amp tap and see that relay

does not operate.

Set relay at #11 time dial and jumper terminals 2, 6

and 8. Set tap 3 and apply 26.0 amperes through ter-

minals 3 and 7. (See Figure 10.) (IA = 26 ∠0° and

IB = 26 ∠180° amperes. Therefore negative

sequence = 15 amps.)

Time of operation with relay in the case should be

3.2 seconds ±8%.

Repeat test with relay on 5.0 tap and 43.3 amperes

through terminals 7 and 9. Time of operation should

be 3.2 seconds ±8%. (Neg. Seq. = 25 amperes.)

7.2. Routine Maintenance

All relays should be inspected periodically and the

time of operation should be checked at such time

intervals as may be dictated by experience to be

suitable to the particular application. Phantom loads

should not be used in testing induction-type relays

because of the resulting distorted current wave

form which produces an error in timing.

All contacts should be cleaned periodically. A contact burnisher S#182A836H01 is recommended for

this purpose. The use of abrasive material for

cleaning contacts is not recommended, because of

the danger of embedding small particles in the face

of the soft silver and thus impairing the contact.

7.2.1. Overcurrent Unit

Apply a single phase current of 8.66 times tap value

(5 per unit negative sequence current) and check

that time of operation is in accordance with Figure

7.

7.2.2. Indicating Contactor Switch (ICS)

Close the main relay contacts and pass sufficient dc

current through the trip circuit to close the contacts

of the ICS. This value of current should not be

greater than the particular ICS tap setting being

used. The indicator target should drop freely.

7.3. Calibration

If the factory calibration has been disturbed, the following procedure should be followed to calibrate

the relay.

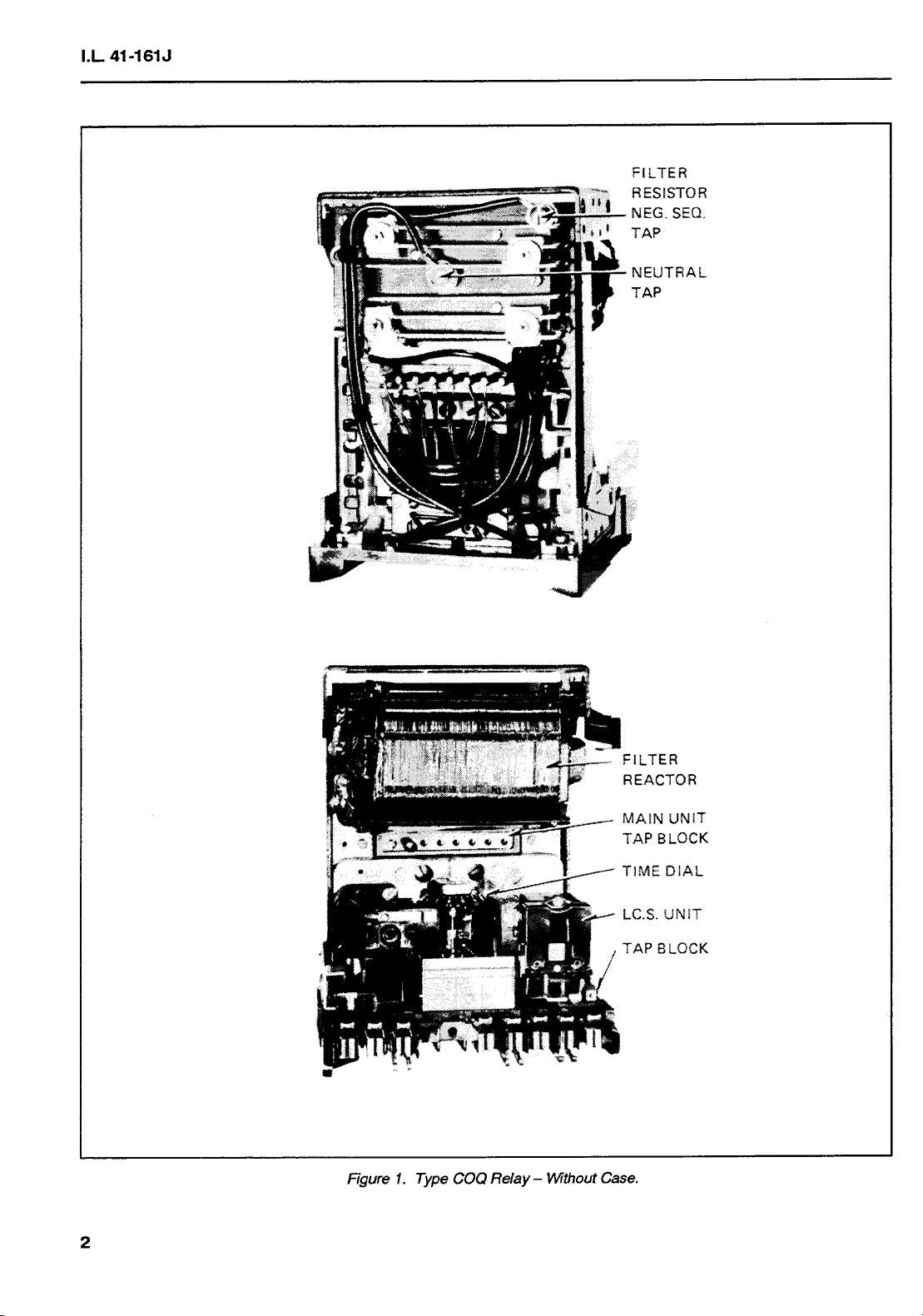

7.3.1. Filter

To adjust the filter resistor tap for no response to

positive-sequence current, remove relay from case

and proceed as follows:

a. Jumper switch jaws 2 and 6.

b. Remove overcurrent unit tap screw.

5

Page 6

I.L. 41-161J

c. Pass 10 amperes into switch jaw 3 and out

switch jaw 7.

d. With a 0-15 volt, Rectox type voltmeter, measure

and record voltage between switch jaw 3 and the

tap plate.

e. Now measure the voltage across the resistor.

Adjust top filter resistor position until this voltage

is 1.73 times the reading from (d) above. For

relays wired per Figure 2 connect the voltmeter

to switch jaw 3 and to the top filter resistor screw

connection (see Figure 1). For relays wired per

Figure 3 connect voltmeter across switch jaws 2

and 3.

To eliminate zero sequence response (relays wired

per Figure 2 only), remove tap screw, and connect

per Figure 10: Apply IX = 5 amperes; IY = 10

amperes. Measure voltage from terminal 3 to top

filter resistor screw connection (see Figure 1). Adjust

the neutral filter resistor tap until measured voltage is

zero.

7.3.2. Overcurrent Unit

Turn time dial until stationary contact is deflected

against the backstop. Adjust, if necessary, so that “0”

mark on time dial coincides with index. Then with

time dial at “0” wind up spring until about 5-1/2 convolutions show. From this preliminary setting, and

using 3 tap and time dial setting of “11”, adjust the

permanent magnet until the relay operates in 8.2

seconds with 15.6 amperes single phase or 3 per

unit through terminals 3 and 7 per Figure 10. This

adjustment is made by means of the damping magnet screw.

Next adjust the spring tension until the relay will

close contacts in 90 seconds with 5.2 amperes single

phase (which is tap value or one per unit negative

sequence current) applied through terminals 3 and 7.

This adjustment is made by means of the spiral

spring adjuster. All spring convolutions must be free.

8. RENEWAL PARTS

Repair work can be done most satisfactorily at the

factory. However, interchangeable parts can be furnished to the customers who are equipped for doing

repair work. When ordering parts, always give the

complete nameplate data.

6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Loading...

Loading...