Page 1

—

ABB MEASUREMENT & ANALYTICS | OPERATING INSTRUCTION

CL3020

CLD NOx analyzer

Measurement made easy

Page 2

2

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Table of Contents

Important precautions .............................................................................................. 5

Use dry, oil-free instrument air only ................................................................. 5

Safety notice......................................................................................................... 5

Model CL3020 specifications ................................................................................... 6

Performance specifications ............................................................................... 6

Features ................................................................................................................ 6

Mechanical specifications .................................................................................. 7

Overview ...................................................................................................................... 8

Measurement configurations ............................................................................ 8

Theory of operation ................................................................................................... 9

Chemiluminescence measurement of NO

Zirconium oxide measurement of O

Pneumatic design .............................................................................................. 10

Analyzer setup and quick start procedure........................................................... 13

Connect the analyzer ......................................................................................... 13

...................................................... 9

x

............................................................... 9

2

Apply power to the analyzer and check diagnostics ................................... 14

Set analog outputs of the analyzer ................................................................ 15

Calibrate the analyzer ....................................................................................... 16

Display screens and details of operation ............................................................ 17

Home screen, warnings, and alarms .............................................................. 17

Calibration menu ............................................................................................... 18

Diagnostic screen .............................................................................................. 19

Trend screen ....................................................................................................... 20

Config screen ..................................................................................................... 20

Analog output scaling screen .......................................................................... 21

Analog output trim screen ............................................................................... 22

IP address screen ............................................................................................... 23

QR code ............................................................................................................... 23

About screen ...................................................................................................... 24

Alarm screen ....................................................................................................... 24

Config alarms screen ........................................................................................ 25

Troubleshooting ...................................................................................................... 26

Diagnostics and operating parameters ........................................................ 26

Warnings and alarms .................................................................................. 26

Sample and ozone flow .............................................................................. 26

Converter temperature .............................................................................. 27

Page 3

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

3

Gas concentration readings ...................................................................... 27

System checks .................................................................................................... 27

Electrical connections and fuse ................................................................ 27

Leak checking ............................................................................................... 28

Component information .................................................................................. 28

Oxygen sensor module ............................................................................... 28

Ozonator ....................................................................................................... 28

reaction cell .......................................................................................... 28

NO

x

Converter ...................................................................................................... 29

Main board .................................................................................................... 29

Digital communications ......................................................................................... 30

Setting the IP address ...................................................................................... 30

Modbus over TCP/IP ......................................................................................... 30

Analyzer fault register ................................................................................ 30

Remote operation via VNC ............................................................................... 32

Spare parts ................................................................................................................ 33

List of Figures

Figure 1 Functional pneumatics diagram ........................................................... 12

Figure 2 Home screen............................................................................................. 17

Figure 3 Home screen showing active alarm ..................................................... 17

Figure 4 Home screen showing furnace and ozonator warnings ................... 18

Figure 5 Home screen showing main menu choices ......................................... 18

Figure 6 Calibration menu, for NOx1 gas ............................................................ 19

Figure 7 Numeric entry of calibration bottle value using pop-up keypad ..... 19

Figure 8 Diagnostic screen .................................................................................... 20

Figure 9 Trend screen ............................................................................................. 20

Figure 10 Config screen: Sub-screens for further configuration .................... 21

Figure 11 Analog output scaling screen .............................................................. 22

Figure 12 Analog output trim screen ................................................................... 22

Figure 13 IP address screen ................................................................................... 23

Figure 14 QR code snapshot screen .................................................................... 23

Figure 15 About screen .......................................................................................... 24

Figure 16 Alarm screen, with one alarm cleared and two others active ........ 24

Figure 17 Config alarm screen .............................................................................. 25

Page 4

4

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

List of Tables

Table 1 I/O Analog output pin assignments (typical) ....................................... 14

Table 2 Expected flows and temperatures during normal analyzer

Table 3 Analyzer fault register bit assignments ................................................ 31

Table 4 Modbus register map ............................................................................... 31

Table 5 Analyzer spare parts list........................................................................... 33

operation .................................................................................................... 15

Page 5

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

5

Important precautions

Use dry, oil-free instrument air only

Caution: This instrument will be damaged if used with in-

strument air that is not completely dry and oilfree. Ensure instrument air has −40 °C dew point

and has been filtered to remove all oil and particulates.

Safety notice

This instrument operates from potentially lethal line voltage. In addition,

some internal components operate at high temperature and can cause serious burns. Observe all precautions when using this device, and particularly

be sure that all devices connected to the instrument are safely wired and

properly grounded. Always disconnect power to the instrument before

opening the enclosure or servicing.

Caution: The analyzer should not be operated without the

cover in place and the cooling fan fully operational.

The exterior surface of the converter furnace and

tubes will rise to nearly 80 °C if operated without

the cover in place. Serious burns can result if the

proper precautions are not taken.

Page 6

6

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

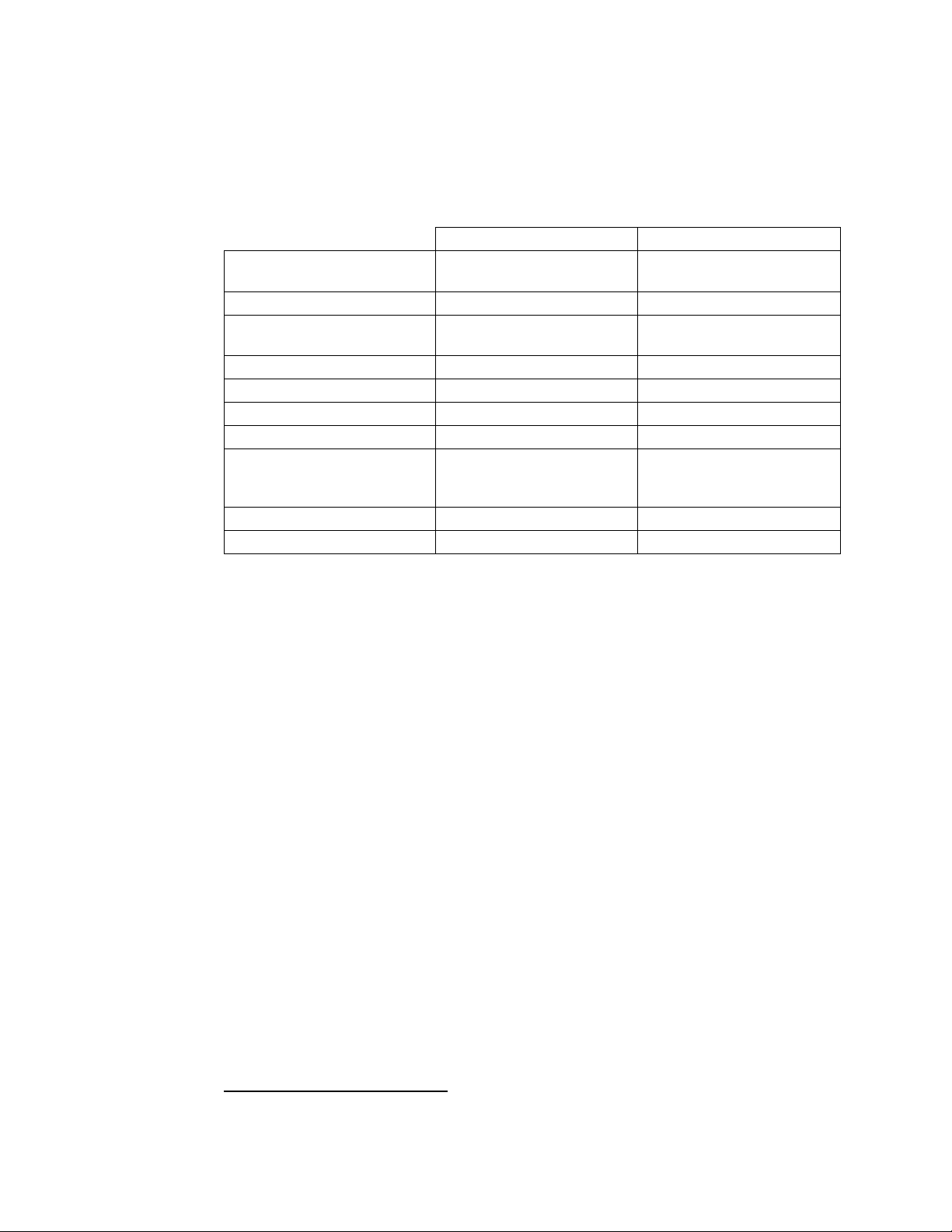

Model CL3020 specifications

Performance specifications

NOx O2

Measurement technology Chemiluminescence using

all solid-state detection

Measurement range 0 to 1000 ppm 0 to 25 % O2

Full scale range Continuously adjustable

from 5 to 1000 ppm

Zero noise < 0.04 PPM < 0.02 % O2

Zero calibration drift Better than ± 0.1 PPM Better than ± 0.1 % O2

Span noise < 0.25% of reading < 0.02 %O2

Span calibration drift Better than ± 1% of reading Better than ± 0.1 % O2

Linearity error < 2% of high calibration

value across range from

zero to full scale

Response time T95 < 10 seconds T95 < 10 seconds

NO2 converter efficiency > 95%

Amperometric Zirconium

oxide cell

Continuously adjustable

from 5 to 25 % O

< 1% of high calibration gas

1

value across range from

zero to full scale1

2

Features

• Touch-screen interface: All diagnostics and controls are accessible

through an advanced, full-color 5” touch screen interface.

• One-touch calibration: Once target gas values (e.g. bottle concentra-

tions) have been entered, span and zero responses may be captured,

and hence the analyzer calibrated, at the touch of the screen.

• Trend-screen: Gas concentrations are plotted in a chart-recorder style

trend with user settable scales for in-depth data analysis at a glance.

• Diagnostics and alarms: Critical component temperatures and gas flows

are measured within the analyzer and reported on the diagnostic screen.

Target values and alarmable deviations are user-settable. These alarms

are displayed on the home screen, as well as warning messages for internal communication errors or if the converter or ozonator has been disabled.

• Analog outputs: Each measurement, including dual ranges for NO

output as either 4-20mA or 0-10V (user selectable). Analog outputs can

be forced to low (4mA/0V) or high (20mA/10V) for troubleshooting. Further, the gain and offset of these analog outputs may be trimmed within

, is

x

1

Provided the calibration value is 80 to 100% of the full scale.

Page 7

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

7

approximately +/-5% of full scale to compensate for offsets or other issues with an external the data acquisition system, independent of analyzer calibration.

• QR code (2D barcode): Analyzer configuration and operating parame-

ters, including calibration settings, can be sent via any mobile device

that has a QR code / barcode scanning app for ease in remote troubleshooting and support.

• Digital communications: MODBUS over TCP/IP included, allowing access

to gas concentrations, diagnostics, alarms, and other instrument parameters. The analyzer is also equipped with a VNC server that allows full remote operation from any device with a VNC viewer connected to the network. Using a locally connected PC or mobile device, factory personnel

may remotely inspect and diagnose analyzer problems as if they were

standing in front of the analyzer.

Mechanical specifications

• EIA 19-inch rack mount enclosure, 11 in. deep, 3 rack units tall

(5.25 inches).

• Weight: 24 lbs.

• Power: 120VAC, 4 Amps max.

• Sample flow rate: Requires approximately 0.1 SLPM at atmospheric pres-

sure (e.g. from a vented sample manifold) per NO

measurement channel

x

• Instrument air: Requires approximately 0.2 SLPM dry, instrument-quality,

oil-free air at atmospheric pressure (e.g. from a vented manifold), per

NOx measurement channel

Page 8

8

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Overview

The Model CL3020 CLD NOx analyzer is designed specifically for use in low-

CEMS applications. NOx and NO (if dual-channel) are measured using

NO

x

chemiluminescence and a molybdenum-based NO

converter for total NOx.

2

The Model CL3020 meets or exceeds 40CFR60 and 40CFR75 demands for

relative accuracy, linearity, and calibration drift in low and ultra-low NO

x

gas-fired turbine applications.

Caution: The CL3020 is designed to analyze a clean, dry

sample, as is typical of a conventional extractive

CEMS. The sample dew point should be less than 5

C, and without any appreciable particulates or

other condensable or reactive gases. As with all

NOx analyzers, care should be taken in SCR applications to scrub any residual ammonia from the

sample to avoid contamination of internal components.

Measurement configurations

The Model CL3020 has several different configurations:

1. Dual-ranging NO

measured using a molybdenum-based converter to convert any NO

the gas stream to NO

able, e.g full scales of. 100 PPM and 25 PPM, in addition to a single range

output for O

2. Dual NO

(speciating), with or without O2. In this configuration, two inde-

x

pendent chemiluminescence cells are used to simultaneously measure

one converted stream (total NO

difference of these two is reported as NO

be used with an external NH

one channel, total NO

. A variety of analog output options are available in this configura-

NH

3

tion.

3. Enhanced performance for low range NO

scales less than 200 PPM, greater sensitivity may be achieved with modified flows. Flows given in this manual are for standard configuration;

consult factory for more information about flows in this configuration.

, with or without O2. In this configuration, total NOx is

x

. Two separately calibratable NOx ranges are avail-

x

.

2

) and one unconverted stream (NO). The

x

. This configuration may also

2

converter to measure total NOx plus NH3 on

3

on the other channel, with the difference being

x

, with or without O2. For full

x

2

in

Page 9

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

9

Theory of operation

The Model CL3020 CLD NOx analyzer uses chemiluminescence as the fundamental detection mechanism for NO

metric) zirconium oxide cell for the O

these mechanisms and their implementation in the analyzer are given below.

Chemiluminescence measurement of NOx

Chemiluminescence is defined as a chemical reaction that gives off light. Nitric oxide (NO) emits infrared light when it reacts with ozone (O

. By introducing a sample containing NO into a reaction cell and mixing

NO

2

it with ozone, one can measure the amount of light emitted by the ensuing

reaction and can infer the amount of nitric oxide present in the original

sample.

It is important to note that only NO is the only species directly measured.

, defined as the sum of NO and NO2 in a sample, is measured by first

NO

x

converting any NO

lybdenum-based converter. If so equipped, NO only is measured in a second

chemiluminescence cell from a sample that does not visit the converter.

measurement and a pumped (ampero-

x

measurement. A brief description of

2

) to form

3

to NO before it enters the measurement cell using a mo-

2

Zirconium oxide measurement of O2

The oxygen measurement makes use of the fact that zirconium oxide conducts oxygen ions when heated above approximately 600 °C. Platinum electrodes on the interior and exterior of a zirconium oxide tube provide a catalytic surface for the exchange of oxygen molecules and oxygen ions. As molecules encounter the platinum electrodes, they become ionized and are

transported through the body of the zirconium oxide. This charge transport

ultimately establishes an electric potential across the electrodes that is proportional to the log of the ratio of oxygen concentrations on each side of

the oxide (The Nernst Equation). Thus, if a reference gas (usually instrument

air at 20.9 % O

ple gas flowing across the outer electrode can be determined. In a conventional zirconium-oxide oxygen analyzer, this voltage is exponentiated to determine the concentration.

In the Model CL3020, a second zirconium-oxide cell is ganged together to

pump oxygen into the first cell, which is maintained at a constant voltage.

The amount of oxygen needed to maintain the primary cell at the operating

point is a more sensitive measurement of sample concentration, and allows

for measurement at zero oxygen. This pump signal is carefully measured

and related back to the sample concentration.

) flows across the inner electrode, the concentration of sam-

2

Page 10

10

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Pneumatic design

Although the chemiluminescence technique is extraordinarily sensitive, specific to NO

pressures, flows, cell geometry, etc. that must be carefully engineered to

produce a properly functioning analyzer. The pneumatic design of the Model

CL3020 is shown in figure 1; the flow scheme is substantially different than

other gas analyzers. To properly operate and service the analyzer, it is important that the flow scheme be well-understood.

Starting on the upper left side of the diagram, instrument air is drawn into

the analyzer from a manifold vented to atmospheric pressure. Excess air

flow should be available at this manifold to ensure integrity of instrument

air to the analyzer. It is important that the air be free of oil and particulates.

Ozone for the chemiluminescence reaction is produced in the ozonator, and

is drawn into the cell where it mixes with the sample stream as described

earlier. A flow-control orifice is embedded in the fitting on the ozone inlet(s)

of the reaction cell(s), and the instrument vacuum pulls the proper flow

through the ozonator.

Two sample channels, if so equipped, may be present on the analyzer. Excess sample flow should be available to each to ensure good sample integrity to the analyzer. A sample pump configured to deliver 1 SLPM under

slight positive pressure to a 1/4" Swagelok

with a vent tube at least three feet long on each branch is an ideal connection.

, and inherently linear, there are many subtle effects involving

x

TM

tee connected to the analyzer,

Note: Under no circumstances should the sample inputs or ozone

feed air be pressurized.

For the total NO

where any NO

channel, the sample first flows through the converter

x

is converted to NO, while any NO present is unaltered. The

2

furnace temperature is displayed on the front panel of the analyzer. Next,

this sample flows though the oxygen sensor (if so equipped), and then

through the sample flow meter. This flow rate should approximately

70 SCCM. The sample then flows on to the reaction cell where it mixes with

the ozone stream and the NO

measurement is performed. The reaction cell

x

is kept at 40 °C.

The exhaust port of the reaction cell contains a critical flow orifice, which

when backed by a sufficiently strong vacuum, controls the

total flow

drawn

through the analyzer. Exhaust from the cell is routed through the high temperature furnace to destroy all the ozone in the exhaust stream to preserve

the integrity of downstream components. Unlike carbon filters or other de-

Page 11

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

11

signs, this ozone destruction technique is very safe and effective. No measurable ozone is left in the exhaust. The analyzer is normally configured for an

external pump to provide critical vacuum to pull the exhaust from the reaction cell. The flow through the analyzer is independent of this vacuum, provided it is low enough to meet the conditions for critical flow. The pressure

on the downstream side of the critical flow orifice (measured under conditions of full analyzer flow) should be no more than 30% of atmospheric

pressure.

If equipped, a second sample channel is present which does not flow

through the converter, therefore measuring only NO. The difference between these two channels represents the NO

sample, or any such other speciation (e.g. NH

concentration in the original

2

) depending upon external

3

system configuration.

Page 12

12

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

N

O2

Conv

ert

er

F

urnace

Air Inlet

1/4“ Swage

lo

k

1 slpm, max

dry, oi

l-

f

re

e

V

ac

uu

m

must be less

than 300 Torr

at 1.2 slpm

NOx/NO2

I

nl

et

Oz

one

F

low

Meter

Sam

ple orif

ice

f

itt

ing

Vent to atmosphere

(vent tube should be

at least 3 feet lon

g t

o

preven

t d

if

f

us

i

on

)

An

alyzer Enclosure

Samp

le 1

Flow

Meter

O

xyg

en

S

ensor

Ex

aus

t orifice

f

itti

ng

Ozone orifice

fitting

Ozone

Generat

or

Sample 2

Flow

Meter

NOx

cell

(sam

ple

2)

Sample or

ifi

ce

fitting

E

xau

st or

ifice

fi

ttin

g

Ozon

e or

ifi

ce

f

itt

ing

Vent to

at

mo

s

ph

er

e

(v

en

t

tu

b

e s

ho

u

ld

be

a

t l

ea

s

t 3

fe

e

t l

on

g

to

p

r

ev

e

nt

di

f

fu

si

o

n)

P

r

ep

ar

e

d s

a

mp

le from

s

am

pl

e conditioning

system; .25 to 1 slpm,

slightly above atm

p

re

s

su

r

e,

dr

y to less

than 1% water content

P

re

p

ar

ed

s

am

p

le

fr

o

m

s

am

p

le

co

n

di

ti

o

ni

ng

s

ys

te

m

; .

2

5 to 1 slpm,

slightly above atm

p

r

es

s

ur

e,

d

ry

to

l

es

s

t

h

an

1%

w

at

er

c

ontent

Vent to

atmosphere

Exhaust

Outlet

NO

I

nl

et

Instrument

Ai

r I

n

le

t

NOx c

ell

(sample 1)

O

p

ti

on

a

l 2

nd

N

O c

h

an

ne

l

Figure 1 Functional pneumatics diagram

Page 13

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

13

Analyzer setup and quick start procedure

For experienced users already acquainted with gas monitoring techniques

and equipment, the following is a summary of installation and startup steps

for a typical CEMS installation; consult factory for other applications. Analyzer menus and operation are described in more detail in the next section

of the manual. To ensure the quickest and most reliable startup, please fol-

low the five steps below in the order shown.

Connect the analyzer

1. Connect instrument air and sample to inlets via 1/4” SwagelokTM fittings.

a. Instrument air: 1 SLPM of dry, oil-free air, vented to ambient condi-

tions. The instrument draws approximately 0.2 SLPM of air per

NO

channel, and a sufficient excess should be supplied to the an-

x

alyzer to ensure the analyzer only pulls instrument air, not ambient

air, from the vented connection (see figure 1).

b. Sample #1 (NO

): 0.2 SLPM of sample from a sample manifold

x

vented to atmospheric pressure. The instrument draws approximately 60 SCCM of sample per NO

channel, and a sufficient ex-

x

cess should be supplied to the analyzer to ensure the analyzer only

pulls sample gas, not ambient air from the vented connection (see

figure 1).

c. Sample #2 (NO), if equipped: 0.2 SLPM of sample from a sample

manifold vented to atmospheric pressure. The instrument draws

approximately 70 SCCM of sample per NO

channel, and a suffi-

x

cient excess should be supplied to the analyzer to ensure the analyzer only pulls sample gas, not ambient air from the vented connection (see figure 1)

2. Connect 1/4” diameter exhaust line (to pump or eductor) to 1/4”

Swagelok™ exhaust port. The vacuum source should be able of maintain an absolute pressure of less than 200 Torr at 1 SLPM flow. For example, a Thomas/Gardner model 2688VE44 mechanical pump or AirVac Engineering AVR-038H air driven eductor.

3. Connect analog output signals via 8-pin Phoenix Contact connector

(provided) per the pin assignments listed in Table 1, and/or Ethernet

connection if using digital communications.

Warning: This instrument is designed for use with 120V AC

input power only. Serious equipment damage

and/or injury will occur if it is connected to improper power.

Page 14

14

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Analog Outputs: The CL3020 analyzer has four analog outputs, assignable

to various measurements, depending upon configuration. Below are analog

output assignments typical of a dual-range non-speciating NO

analyzer.

x-O2

Refer to analog output section of this manual for more information.

NOx output (primary range):

4-20 mA or 0-10V 0 to full-scale ppm

NOx output (secondary range):

4-20 mA or 0-10V 0 to full-scale ppm

O2 output:

4-20 mA or 0-10V 0 to full-scale % O2

Reserved Pin 7: low

Pin 1: low

Pin 2: high

Pin 3: low

Pin 4: high

Pin 5: low

Pin 6: high

Pin 8: high

Table 1 I/O Analog output pin assignments (typical)

Apply power to the analyzer and check diagnostics

Caution: The analyzer should not be operated without the

cover in place. The exterior surface of the converter furnace and tubes will rise to nearly 80°C if

operated without the cover in place. Serious burns

can result if the proper precautions are not taken.

1. Apply power by connecting the instrument power cord (provided).

Verify that the fan is operating by feeling for air flow at the back of

the instrument. If inadequate flow is suspected, shut down power.

Caution: The analyzer should not be operated without the

cover in place and the cooling fan fully functional.

Care should be taken to avoid blocking the air

vents in the side panel. Standard EIA rack mounting should provide enough space for adequate

cooling.

2. After approximately one minute the touchscreen will complete its

startup cycle and be at the home screen. Navigate to the diagnostic

screen and verify the following as summarized in Table 2:

Page 15

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

15

a. Verify that the sample-flow (on the diagnostic screen) indicates

approximately 70 SCCM per channel and the ozone-flow (diagnostic screen) indicates approximately 230 SCCM for single channel

or 460 SCCM for dual channel configuration. If flows are not

NO

x

correct, check pneumatic connections and external system components (e.g. pump).

b. Verify the furnace temperature is rising. The furnace temperature

should reach 400°C in about 30 minutes.

c. Verify the ozonator temperature is rising. The ozonator tempera-

ture should reach 40°C in about 15 minutes. It may be necessary to

adjust the ozonator setpoint temperature for operation in unusually cool or warm environments. The operating temperature is not

important, it is only necessary that the ozonator temperature remains constant.

d. Verify the NO

reaction cell(s) temperatures is rising. The NOx cell

x

temperature(s) should reach 40°C in about 15 minutes.

Parameter Value

Sample flow 70 SCCM

Ozone flow 230 SCCM single NOx, 460 SCCM dual NOx

Converter temperature 400 oC

Ozonator temperature 50 °C (user settable)

NOx cell #1 temperature 40 °C

NOx cell #2 temperature (if equipped) 40 °C

Table 2 Expected flows and temperatures during normal analyzer operation

Set analog outputs of the analyzer

From the analog output screen located within the Config menu, set full

scale to desired values for each output channel, per configuration. Refer to

analog output section of this manual for more information.

Page 16

16

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Calibrate the analyzer

After installation and temperatures have reached their setpoints above, the

and O2 channels can each be calibrated via the following procedure:

NO

x

1. Low calibration:

a. Flow low calibration gas through the sample handling system and

analyzer. Dry nitrogen, EPA protocol zero gas, or well-scrubbed instrument air is recommended as a low calibration gas for NO

may be zeroed on NO span gas.

O

2

b. Wait approximately two minutes or until reading settles. It may be

helpful to monitor the trend screen to evaluate when the reading

has reached final value.

c. Enter the value of the low calibration gas, typically 0.

d. Press “Low Capture” soft button on the calibration screen.

2. High calibration:

a. Flow high calibration gas through the sample handling system and

analyzer.

.

x

b. Wait approximately two minutes or until reading settles. It may be

helpful to monitor the trend screen to evaluate when the reading

has reached final value.

c. Enter the value of the high calibration gas, typically from the re-

ported bottle value from the calibration gas supplier.

d. Press “High Capture” soft button on the calibration screen.

Page 17

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

17

Display screens and details of operation

Home screen, warnings, and alarms

The analyzer home screen analyzer is shown in Figure 2 below. In this view,

only gas concentrations are displayed. Gas concentrations displayed will

vary by configuration.

Figure 2 Home screen

If active alarms are present (any diagnostic variable out of range, see section on Alarm screen), a red triangle with an exclamation point will appear in

the lower right-hand corner of the display as shown in Figure 3. Touching

this icon will bring up the Alarm screen as described later.

Figure 3 Home screen showing active alarm

If there are active warnings, these descriptors will be annunciated in a banner at the bottom of the screen as shown in Figure 4. Possible warnings include:

• Communications error between display and main analyzer board,

warning the display may not be updating thus readings or statuses

may be invalid.

• Ozonator and/or furnace disabled (see Configuration screen)

• Analog outputs forced high or low (see Analog Output Trim screen)

Page 18

18

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Figure 4 Home screen showing furnace and ozonator warnings

Analyzer menus may be accessed by touching the screen anywhere, causing

the menu bar to become available at the bottom of the screen for about five

seconds as shown in Figure 5. When the menu is visible, any of the main

screens (Calibrate, Diagnostics, Trend, Config, of Alarm) may be selected.

Note: The menu bar will appear from any of the main screens by touching

the screen anywhere there is not an active input box or button, enabling to

return to the Home screen from any other main screen.

Figure 5 Home screen showing main menu choices

Calibration menu

Figure 6 shows an example calibration screen, in this case NOx1. Each gas

has its own calibration screen selectable by touching the corresponding rectangle from the column of choices on the right of the screen.

In this screen the raw value displayed corresponds to the percentage of analog input from the sensor. When troubleshooting, the raw value is often

more important to examine than the calculated concentration. This is because the calculated value may be corrupted by erroneous calibration, but

the raw value represents the underlying sensor response. The gain is the calculated correspondence between gas concentration and raw value captured

during calibration, as described below.

Page 19

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

19

The analyzer is calibrated by assigning sensor responses to gas concentrations. Any two points may be used for calibration, but typically zero and

span are chosen. Bottle values for calibration may be entered by selecting

the appropriate field and entering numeric values form the pop-up touch

keypad, as shown in Figure 7. This same keypad is available for all numeric

entries throughout the interface.

Stored raw values corresponding to gas bottle values (or known process values) may be “captured” by pressing the high or low capture buttons when

high or low concentration gas, respectively, is flowed to the analyzer. These

response values may be entered manually by entering raw values in these

fields using a numeric pop-up touch keypad.

Figure 6 Calibration menu, for NOx1 gas

Figure 7 Numeric entry of calibration bottle value using pop-up keypad

Diagnostic screen

Table 2 shows typical values for expected flows and temperatures during

normal operation. These diagnostics are displayed in the main diagnostic

screen, and shown in Figure 8. Refer to the Alarms screen for setting limits

on these parameters, and the troubleshooting section of this manual of if

these values are out of range.

Page 20

20

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

The 32-bit Fault Register is defined in more detail in the digital communications section. Bit 0 is on the far right, bit 15 is on the far left. Bits are one

(TRUE) if in alarm condition, zero if not alarmed.

Figure 8 Diagnostic screen

Trend screen

The trend screen is shown in Figure 9. Note that the scale for Oxygen (on

the left) and NO

and bottom numbers and rescaling with the pop-up keypad. The trend

screen displays ten minutes of data, refreshing once a second.

reading(s) on the right is adjustable by selecting the top

x

Figure 9 Trend screen

Config screen

The configuration screen is shown in Figure 10.

Furnace power and ozonator output may be toggled by tapping the appropriate buttons. Ozonator temperature will be maintained if disabled, only

the ozonator discharge itself is disabled. Warnings messages will be displayed on other screens when either of these components is disabled.

Page 21

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

21

The furnace temperature setpoint may be adjusted from this screen. During

steady state operation at room temperature, the power duty cycle should

be approximately 35%.

Averaging time for signals may be set to any value between 3 and 60 seconds. 15 seconds is the default,

Sub-screens for Analog outputs, IP address, QRC, and About may be accessed from this screen and are described below.

Figure 10 Config screen: Sub-screens for further configuration

Analog output scaling screen

The analog output screen is shown in Figure 11, in the case of dual-ranging

with O2. Other gas configurations are similar and self-explanatory. Con-

NO

x

centrations corresponding to low and high analog outputs may be set using

the numeric pop-up keypad as shown in Figure 7.

Current (4-20 mA) or voltage (0-10V) output is selectable from the Type

menu box in the upper right-hand corner. Note the voltage output is intended for use only with high impedance (>1000 kOhm) devices.

Actual live outputs are shown for reference

Note the “gear” icon to the left of each channel. Selecting this icon brings up

the Analog output trim screen for each channel, as described below.

Page 22

22

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Figure 11 Analog output scaling screen

Analog output trim screen

Each analog output channel may be trimmed independently from its own

screen, as shown in Figure 12. Under normal operation, the output is in “live”

mode, but it may be forced to either the high or low limits by selecting the

corresponding box. When the output is so forced, the corresponding trim

field is active and may be used to adjust the actual output up or down to

make up for any system discrepancies. In this manner, the analog loops and

any external data acquisition system may be calibrated independent of gas

concentration readings. This may also be used for troubleshooting external

connections.

Note that when any outputs are forced high or low, a warning is displayed

to the user in the warning banner in the lower portion of any main screen.

The “Next” and “Return” buttons allow the user to cycle through other analog channels and/or return to the main analog output screen.

Figure 12 Analog output trim screen

Page 23

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

23

IP address screen

The IP address screen is available from the Config screen. Either a static or

dynamic IP address screen may be specified.

Figure 13 IP address screen

QR code

A standard QR code (2D barcode) image, as shown in Figure 14, may be displayed for capture and analysis by any mobile device with barcode scanning

capability. Scanning with a mobile device will provide a text description of

the analyzer configuration, status, and current readings that can be sent to

support personnel for troubleshooting assistance.

Figure 14 QR code snapshot screen

Page 24

24

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

About screen

The About screen, as shown in Figure 15, shows the current software versions for the system.

Figure 15 About screen

Alarm screen

The alarm screen is shown in Figure 16, accessible from the home screen by

touching the red triangle. An active, or historical but uncleared, alarm sets

the corresponding bit in the fault register, and causes the red alarm icon to

flash on any main screen. If an alarm condition is still being met (causing the

alarm), the alarm listing will be highlighted red. If the alarm condition is no

longer being met (not alarmed), the text will no longer be highlighted in red,

but still visible in the alarm history. The history can be cleared by tapping

the “Clear” button. Only alarms that are no longer active may be cleared; if

an alarm condition is still occurring it will reactivate and not remain cleared.

To access the sub-menus allowing configuration of each alarm, touch the

Config Alarms button on this screen.

Figure 16 Alarm screen, with one alarm cleared and two others active

Page 25

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

25

.

Config alarms screen

Each alarmable temperature and flow is configurable, as shown in Figure 17,

in this case for the furnace temperature. While factory defaults settings

should normally not require modification, allowing these to be configurable

enables the user to operate the analyzer in custom configurations for

unique applications or for testing purposes, while still having meaningful

alarm conditions. A target value and deviation from the target may be set in

the corresponding boxes. Note in the case of a control loop, like furnace

temperature, this is only the target for the alarm, not the control setpoint

temperature

Figure 17 Config alarm screen

Page 26

26

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Troubleshooting

Below is troubleshooting information on the analyzer, as well as information

on many of the sub-assemblies within the unit. Before troubleshooting the

analyzer, read through the diagnostic and operating parameters explanations to help narrow down any problems.

Warning: Potentially lethal line voltage, lethal high voltage

(within the ozone generator), and dangerously hot

tubing and subassemblies are present within the

analyzer. Service within the analyzer should be

performed only by qualified, trained personnel,

and only after the unit has been unplugged and allowed to cool for at least one hour with the cover

off.

Diagnostics and operating parameters

The diagnostics on the analyzer display much instrument status information (see diagnostics screen). From these readings, it is usually possible

to narrow down the source of any problems:

Warnings and alarms

The Home screen of the display will display the presence of any warnings or

alarms. Carefully check this information to troubleshoot any problems, for

example if NO

been left disabled.

Sample and ozone flow

Because these two flow rates are intimately related, it is important to consider them together. Sample flow is the amount of flow drawn through the

sample inlet through the analyzer. Ozone flow is the amount of feed air

pulled through the ozonator.

A critical flow orifice located in the exhaust fitting of the NO

mines the total flow (sample and ozone flow combined). This total flow rate

should be approximately 230 SCCM per channel.

One may determine several things by inspecting the NO

flow meters:

is not responding it may be the case that the ozonator has

x

cell deter-

x

sample and ozone

x

• If the both flows are correct, it is very unlikely that there are pneumatic

problems within the analyzer.

Page 27

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

27

• If the both flow are low, there may leaks in the analyzer, the critical flow

exhaust orifice may blocked, the sample inlet may be blocked, the exhaust may be blocked or not vented properly, or the vacuum at the rear of

the analyzer may be inadequate.

• If the ozone flow is too low, the ozone air feed orifice may be blocked,

there may be a leak in the ozone supply tubing, or the compressed air

supply to the instrument may be faulty.

• If the sample flow is too low, the sample orifice may be blocked, there

may be a leak in the sample tubing, or the sample supply to to the instrument may be blocked

• If either or both flows are too high, check for pressurization of sample or

instrument air (inadequate or blocked vents), or other blockages. For example, if the ozone flow is restricted, one indication may be higher than

normal sample flow, and vice versa.

Converter temperature

The converter furnace temperature is maintained at 400 °C. The temperature should not vary by more than two degrees. If it is not at the proper

value, the furnace heater, thermocouple, or relay could be at fault.

Gas concentration readings

The O2 value should be stable to approximately 0.02% (absolute). Instability

or inaccurate readings could be caused by leaks or a faulty O

ule. The NO

reading should be stable to better than 0.25% or reading, or

x

sensor mod-

2

0.02 PPM, whichever is greater. Instability or inaccurate readings could be

caused be leaks, a faulty ozonator, or a faulty NO

sensor or sensor board.

x

System checks

Component failures within the analyzer are relatively uncommon. Most performance or reliability problems are due to improper system connections,

leaks, faulty electrical connections, or improper configuration, in that order.

Before opening the analyzer enclosure, double-check that the external connections and supply of conditioned sample gas, compressed air, and line

voltage are correct. The following may aid in troubleshooting if the analyzer

is not functioning properly and no faults are apparent form the diagnostic

information.

Electrical connections and fuse

Be sure all connectors on the main board are firmly seated and that all wires

within these connectors are firmly attached. There is a fuse holder on the

main power inlet of the analyzer, serviceable from the analyzer back panel.

Page 28

28

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Leak checking

Leaks may cause many non-obvious problems, a leak check is highly recommended when servicing or troubleshooting gas analyzers for any reason.

Leak checking should be done under vacuum, never pressure with the following procedure:

1. Seal the sample and instrument air inlet(s) on the back of the analyzer.

2. Connect a vacuum pump to the exhaust port, with an isolation valve in

between the pump and the analyzer, and a vacuum gauge on the analyzer side of the isolation valve.

3. Open the isolation valve, pump the analyzer down, and record the vac-

uum reading.

4. Close the isolation valve. The isolated analyzer pressure should not in-

crease more than 2 Torr/second.

If leaks are found, check all fittings for tightness, and locate the leak by progressively isolating parts of the analyzer. In general, if a leak is present it will

be very noticeable, not subtle. A slight apparent leak within the ozonator is

acceptable; a metered sweep of the ozonator assembly is designed to minimize stray ozone within the analyzer enclosure.

Component information

Information on service replacement of many of the analyzer components is

given below. Only proceed to investigation of components after thoroughly

checking pneumatic and electrical connections both inside and external to

the analyzer as noted above. “Part-swapping” without clear indication of

component failure is not a recommended troubleshooting or repair technique.

Oxygen sensor module

This is serviced as a unit. If approximately 9VDC is present on pins 1 and 2 of

the five-pin connector, and oxygen readings are unstable, nonlinear, or inaccurate, replace this module. If 9VDC is not present, examine connections.

Ozonator

Lethal voltage is present with the ozonator: Do not attempt to service the

ozone generator, and never open its enclosure or allow tools to come near it

when the analyzer is energized. The ozonator hums audibly when operating,

if power is being supplied to this unit (24VDC) and there is no hum, the

ozonator should be replaced.

NOx reaction cell

The NOx reaction cell has several fittings and the NOx sensor mounted on it.

Page 29

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

29

The exhaust fitting on the back of the cell houses the critical flow orifice. It

may be changed by disconnecting the tube leading into the furnace and unscrewing the fitting. The orifice and fitting are replaced as an assembly.

If the readings have dropped, or if the analyzer has been subjected to ammonia, it may be necessary to clean the window on the sensor:

1. Turn off power to the analyzer and remove vacuum from the exhaust port.

2. Remove the two screws holding the detector assembly to the reaction

cell and remove the detector assembly.

3. Wipe off the optical window of the sensor through this port with deion-

ized water or rubbing alcohol to remove any film or deposits. Do not use

harsh solvents or abrasive materials.

4. Reinstall the detector assembly.

5. Energize analyzer, and apply vacuum. Leak check if readings unstable.

Converter

The converter has a cartridge heater and a thermocouple. The heater element and thermocouple connect to the main board near the back of the analyzer. The converter is typically replaced as an assembly, although the thermocouple and heater may be field replaced by experienced service personnel. The heater assembly should be replaced if either side of the heater

shows less than 1 MΩ resistance to the shell or if the heater resistance is not

approximately 70 Ω.

The power control relay for the heater is socketed near the rear of the board

and may require replacement if the converter power supply has been shortcircuited. The molybdenum charge may be replaced, consult factory for details.

Main board

If the main board must be replaced, the analyzer should be de-energized

and all connections removed before attempting to remove the board.

Page 30

30

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Digital communications

The model CL3020 analyzer can act as a MODBUS server (slave) and may

also be operated remotely via any standard PC or mobile VNC viewer. Additionally, a QR-code, i.e. 2D barcode, may be scanned by a mobile device to

capture a complete snapshot of instrument status that can easily be sent to

remote troubleshooting personnel.

Setting the IP address

The IP address for the analyzer is normally set to a static value of 192.168.1.50,

and can be changed by tapping the IP Address button on the Config Screen.

Either a static or dynamically assigned (DHCP) address can be specified.

Modbus over TCP/IP

The CL3020 can serve as a MODBUS slave over TCP/IP. The MODBUS register map is shown in Table 4.

Analyzer fault register

The 32-bit analyzer fault register reflects the alarm status of the analyzer,

whereas any non-zero value represents an alarm condition. The fault register bit assignments are listed in Table 3. The lowest bit (0) is set to true if

any alarm is present allowing for quick reading of a single bit for overall

alarm status. The fault register is also available in float data-type representation of the 32-bit value to allow it to be read along with many other input

registers using a single read command.

Bit Parameter True (1) if

0 Instrument Fault Any alarm

1…5 Reserved

6 O2 Heater Alarm

7 Sample Flow 1 Alarm

8 Sample Flow 2 Alarm

9 Ozonator Flow Alarm

10 NO x 1 Te m p Alarm

11 NOx2 Temp Alarm

12 Ozonator Temp Alarm

13 Furnace Temp Alarm

14 Analyzer Temp Alarm

15 Comms Error Alarm

16…31 Reserved

Modbus server version 1.00100

Page 31

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

31

Table 3 Analyzer fault register bit assignments

Parameter Register

Num*

Data

Type

Notes

Modbus Slave Version 30001 Int32

System Board Firmware Version 30003 Int32

Display Software Version 30005 Int32

Status (integer) 30007 Int32

Status (float) 30021 Float Float of (Int32 Status) to allow all float reads

Concentration Gas NOx 1 30023 Float Live concentration in gas-units

Concentration Gas NOx 2 30025 Float Live concentration in gas-units

Concentration Gas O2 30027 Float Live concentration in gas-units

Reserved 30029

Raw Response Gas NOx 1 30031 Float Live signal response in % of available input

Raw Response Gas NOx 2 30033 Float Live signal response in % of available input

Raw Response Gas O2 30035 Float Live signal response in % of available input

Reserved 30037

Temperature Analyzer 30039 Float degrees C

Temperature NOx 1 Cell 30041 Float degrees C

Temperature NOx2 Cell 30043 Float degrees C

Temperature Ozonator 30045 Float degrees C

Temperature Furnace 30047 Float degrees C

Heater Power Furnace 30049 Float Live furnace power in %

Flow Sample 1 30051 Float Live sample 1 flow in cm3

Flow Sample 2 30053 Float Live sample 2 flow in cm3

Flow Ozone 30055 Float Live ozone flow in cm3

Stored Span Response NOx 1 40101 Float Stored response in % of available input

Stored Zero Response NOx 1 40103 Float Stored response in % of available input

Stored Span Response NOx 2 40105 Float Stored response in % of available input

Stored Zero Response NOx 2 40107 Float Stored response in % of available input

Stored Span Response O2 40109 Float Stored response in % of available input

Stored Zero Response O2 40111 Float Stored response in % of available input

Span Bottle Concentration Gas 1 40113 Float Bottle concentration in gas-units

Zero Bottle Concentration Gas 1 40115 Float Bottle concentration in gas-units

Span Bottle Concentration Gas 2 40117 Float Bottle concentration in gas-units

Zero Bottle Concentration Gas 2 40119 Float Bottle concentration in gas-units

Span Bottle Concentration Gas 3 40121 Float Bottle concentration in gas-units

Zero Bottle Concentration Gas 3 40123 Float Bottle concentration in gas-units

Converter Furnace Enabled 1 Bool True (1) enables furnace power

Ozonator Enabled 2 Bool True (1) enables ozonator power

* Register numbers 30xxx are input registers, 40xxx are holding registers,

x are output coils. Modbus server version 1.00100

Table 4 Modbus register map

Page 32

32

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

Remote operation via VNC

It is possible to operate the CL3020 remotely by any VNC viewer connected

via TCP/IP. Every display and every action that is available from the analyzer

display is duplicated on the remote device, with a mouse click or screen

touch on the remote device serving as the same input as front screen touch

commands.

Any VNC viewer may be used, once the IP address of the analyzer is known.

The VNC connection password is CL3020 (case sensitive) and cannot be

changed. TCP port 5900 is used for the VNC connection and must not be

blocked by any routers or firewalls between the analyzer and the remote device.

Page 33

CL3020 OPERATING INSTRUCTION | OI/CL3020-EN REV. A

33

Spare parts

Part description Part number Recommended on-site quantity

Exhaust orifice fitting 1000-1020 2

Sample orifice fitting 1000-1030 2

Ozone orifice fitting 1000-1031 2

NOx detector O-ring 1000-1032 2

Fuse 1000-1033 2

Oxygen sensor 1000-1034 1 (if configured)

Ozone generator 1000-1035 Optional

NO2 furnace assembly 1000-1036 None

Furnace media recharge 1000-1037 None

NOx Detector 1000-1038 None

Flowmeter 1000-1039 None

Furnace relay 1000-1040 None

Furnace heater 1000-1041 None

Furnace thermocouple 1000-1042 None

Furnace sample fittings 1000-1043 None

Display 1000-1044 None

Electronics board 1000-1045 None

Fan 1000-1046 None

Sample tubing, 5 ft 1000-1047 None

Exhaust tubing, 2 ft 1000-1048 None

Tubing tee 1000-1049 None

Table 5 Analyzer spare parts list

Page 34

—

ABB Automation GmbH

Measurement & Analytics

Stierstädter Str. 5

60488 Frankfurt am Main

Germany

Fax: +49 69 7930-4566

Mail: cga@de.abb.com

abb.com/analytical

—

We reserve the right to make technical changes or modify the contents of this document

without prior notice. With regard to purchase orders, the agreed particulars shall prevail.

ABB does not accept any responsibility whatsoever for potential errors or possible lack of

information in this document.

We reserve all rights in this document and in the subject matter and illustrations contained

therein. Any reproducti on, disclosure to third parties or utilization of its contents – in w hole

or in parts – is forbidden without prior written consent of ABB.

© ABB 2018

OI/CL3020-EN Rev. A 04.2018

Loading...

Loading...