Page 1

—

ABB MEASUREMENT & ANALYTICS | OPERATING INSTRUCTION

266CRx, 266CSx, 266JRx, 266JSx

Multivariable pressure transmitters

Engineered solutions for all

applications

Measurement made easy

—

266 multivariable

Introduction

The 2600T family provides comprehensive range of

top quality pressure measurement products,

specifically designed to meet the widest range of

applications ranging from arduous conditions in

offshore oil and gas to the laboratory environment

of the pharmaceutical industry.

For more information

Further publications for 2600T series pressure

products are available for free download from:

www.abb.com/pressure

or by scanning this code:

Download the Brochure or search for

RB/2600T-EN on https://library.abb.com/en.

Page 2

Contents

1 ABB .............................................................................. 4

2 Introduction ................................................................... 4

2.1 About the manual ............................................. 4

2.2 Structure of the operating manual ...................... 4

2.3 Customer Service Centers worldwide ................ 4

3 Safety ........................................................................... 5

3.1 General information and notes for the reader ..... 5

3.2 Intended use .................................................... 5

3.3 Improper use .................................................... 5

3.4 Target groups and qualifications ........................ 5

3.5 Warranty provisions .......................................... 5

3.6 Plates and symbols ........................................... 6

3.6.1 Safety / warning symbols, note symbols ............ 6

3.7 Compliance with Pressure Equipment Directive

(2014/68/EU) .................................................... 6

3.8 Transport .......................................................... 6

3.9 Transport safety instructions ............................. 6

3.10 Obligations of the owner ................................... 6

3.11 Storage conditions ............................................ 7

3.12 Safety instructions for electrical installation ........ 7

3.13 Safety instructions for operation ........................ 7

3.14 Safety information for inspection and maintenance

........................................................................ 7

3.15 Returning devices ............................................. 7

3.16 Integrated management sys tem ........................ 7

3.17 Disposal ........................................................... 8

3.17.1 Information on WEEE Directive 2012/19/EU

(Waste Electrical and Electronic Eq uipment) ...... 8

3.17.2 ROHS Directive 2011/65/EU ............................. 8

3.18 Cyber security .................................................. 8

4 Unpacking the device .................................................... 8

4.1 Scope of delivery .............................................. 8

4.2 Identification ..................................................... 8

4.3 Storage ............................................................ 8

4.4 Handling ........................................................... 8

5 Product identification ..................................................... 9

6 Use in potentially explosive atmospheres ..................... 10

6.1 Hazardous atmospheres ................................. 10

7 Function and system design......................................... 11

7.1 Components of the pressure transmitter .......... 11

7.2 Product description ......................................... 11

7.3 Measuring range limits and span limits ............ 11

8 Mounting ..................................................................... 12

8.1 IP rating ......................................................... 12

8.2 Factory settings .............................................. 12

8.3 Venting / draining transmitters without diaphragm

seals .............................................................. 13

8.4 Mounting position ........................................... 13

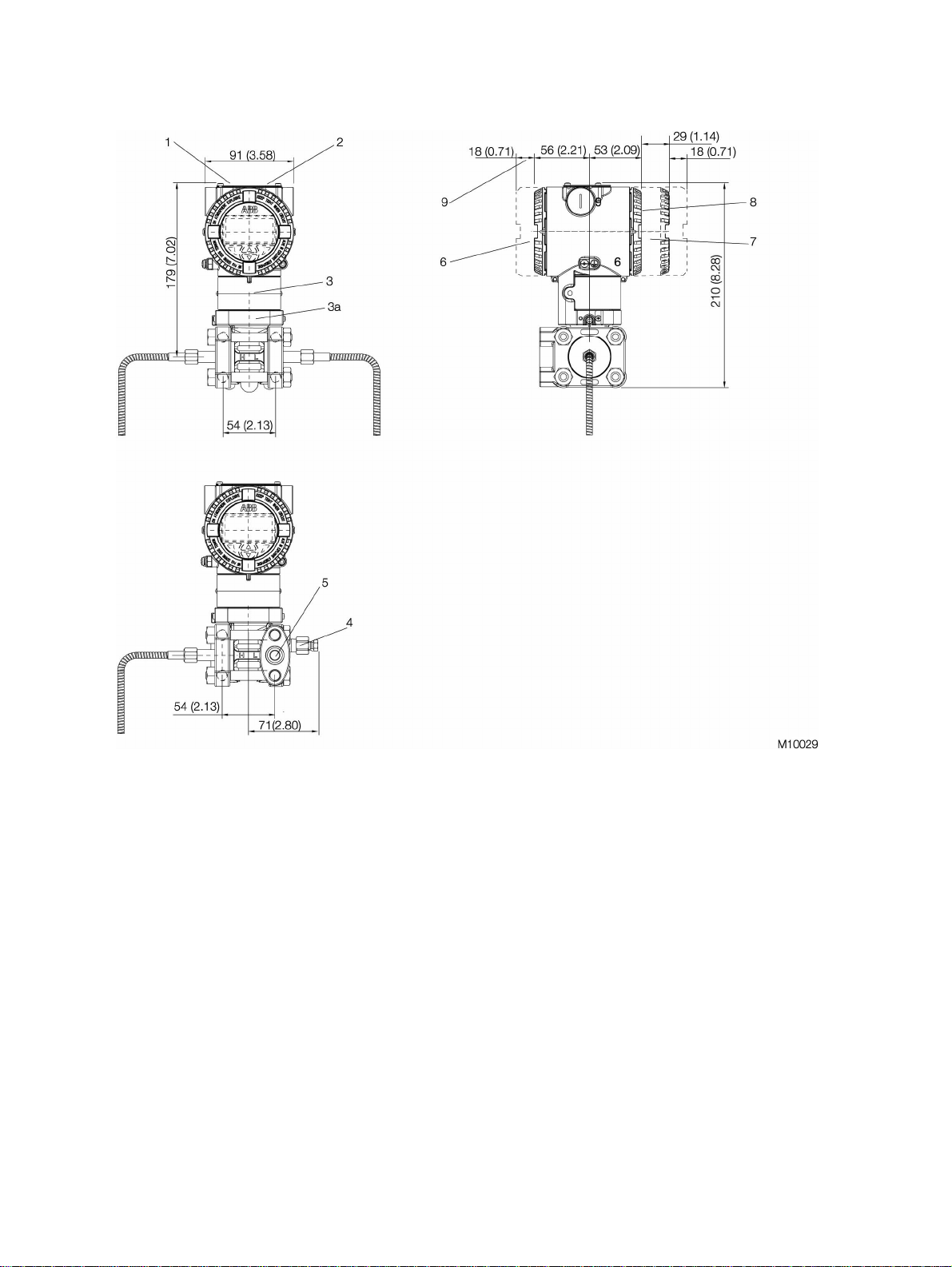

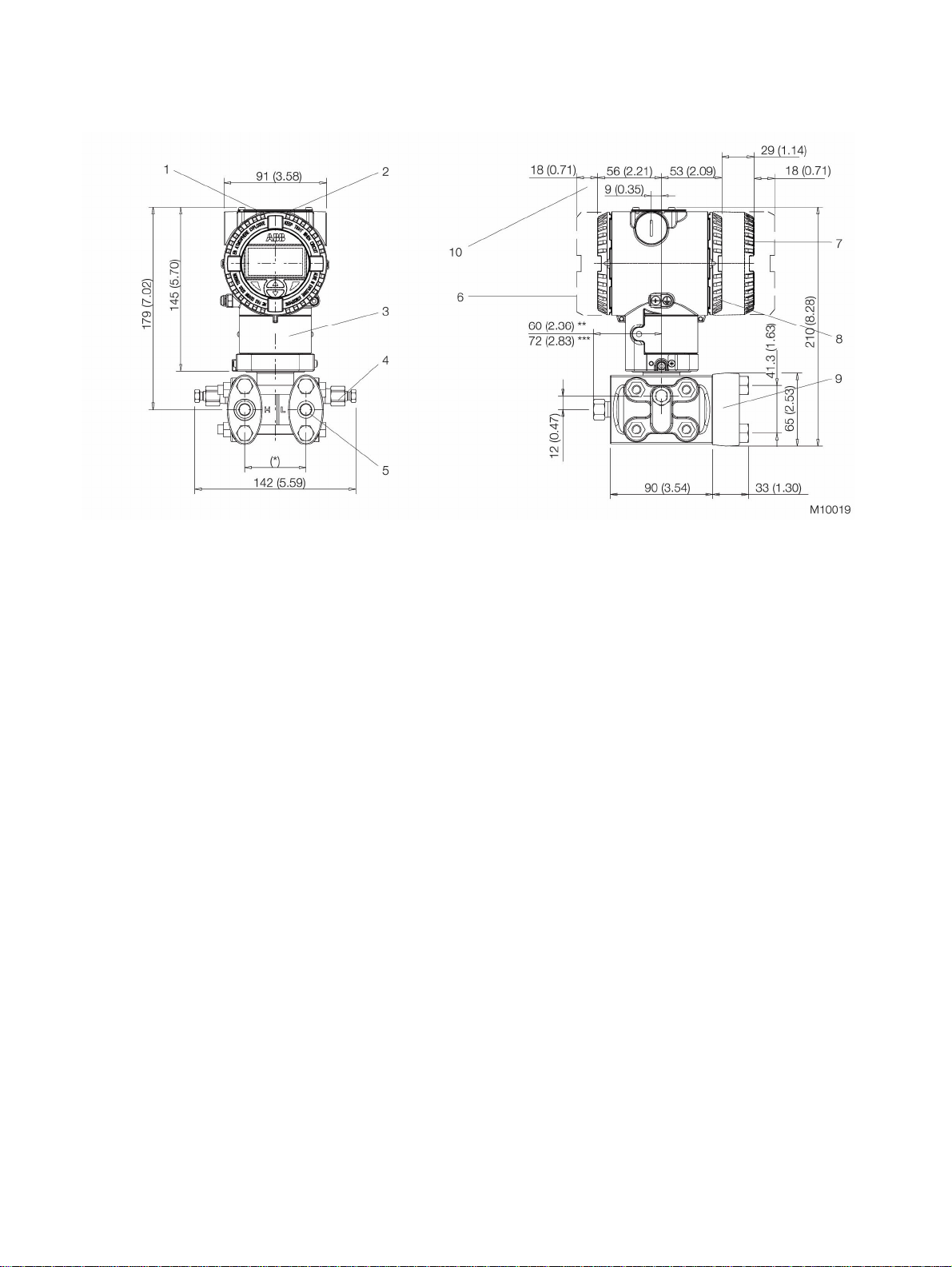

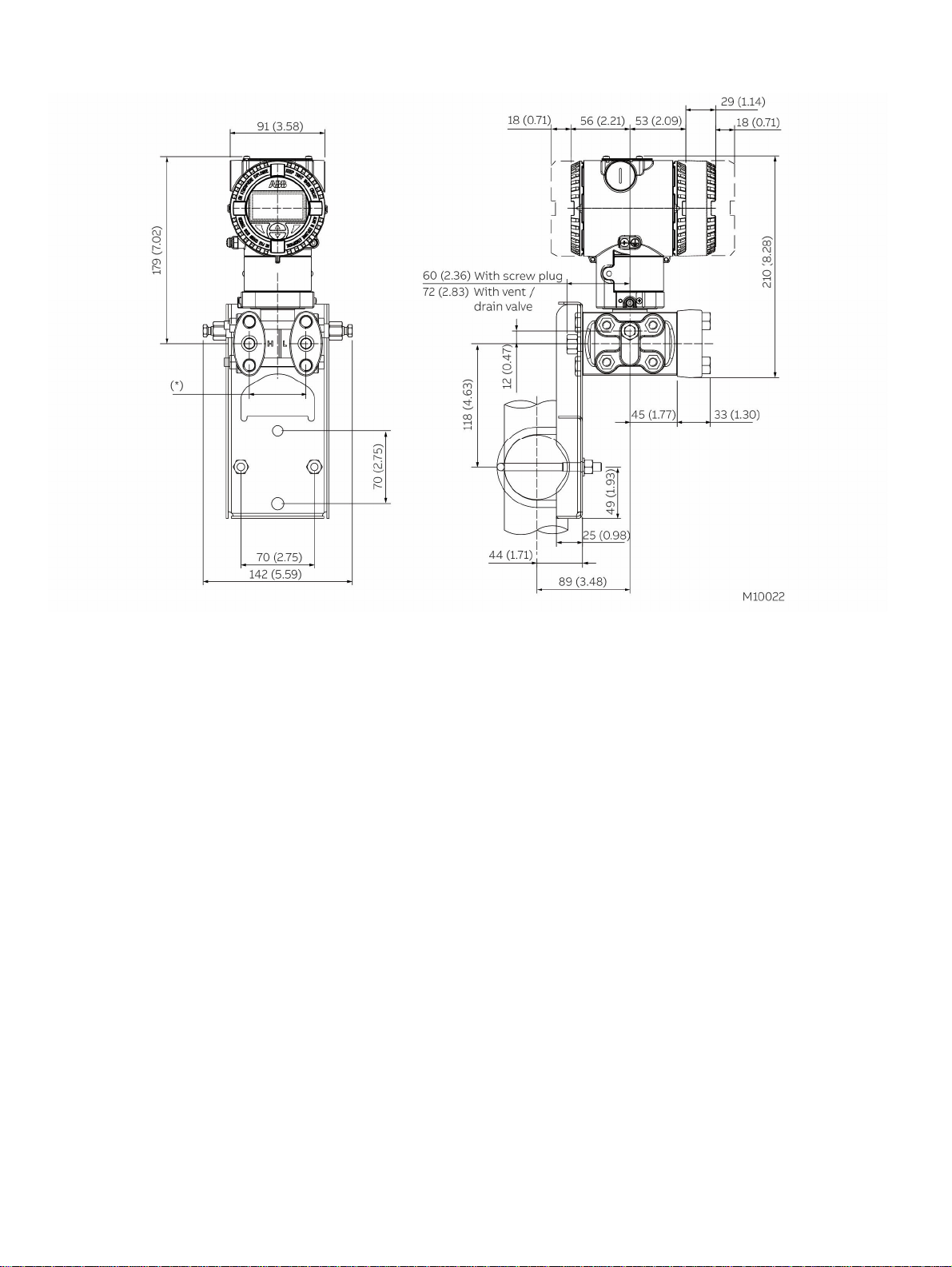

8.5 Mounting dimensions 266CRx/JRx .................. 14

8.5.1 Transmitter with barrel housing ....................... 14

8.5.2 Transmitter with barrel housing and mounting

bracket, for vertical or horizontal mounting on

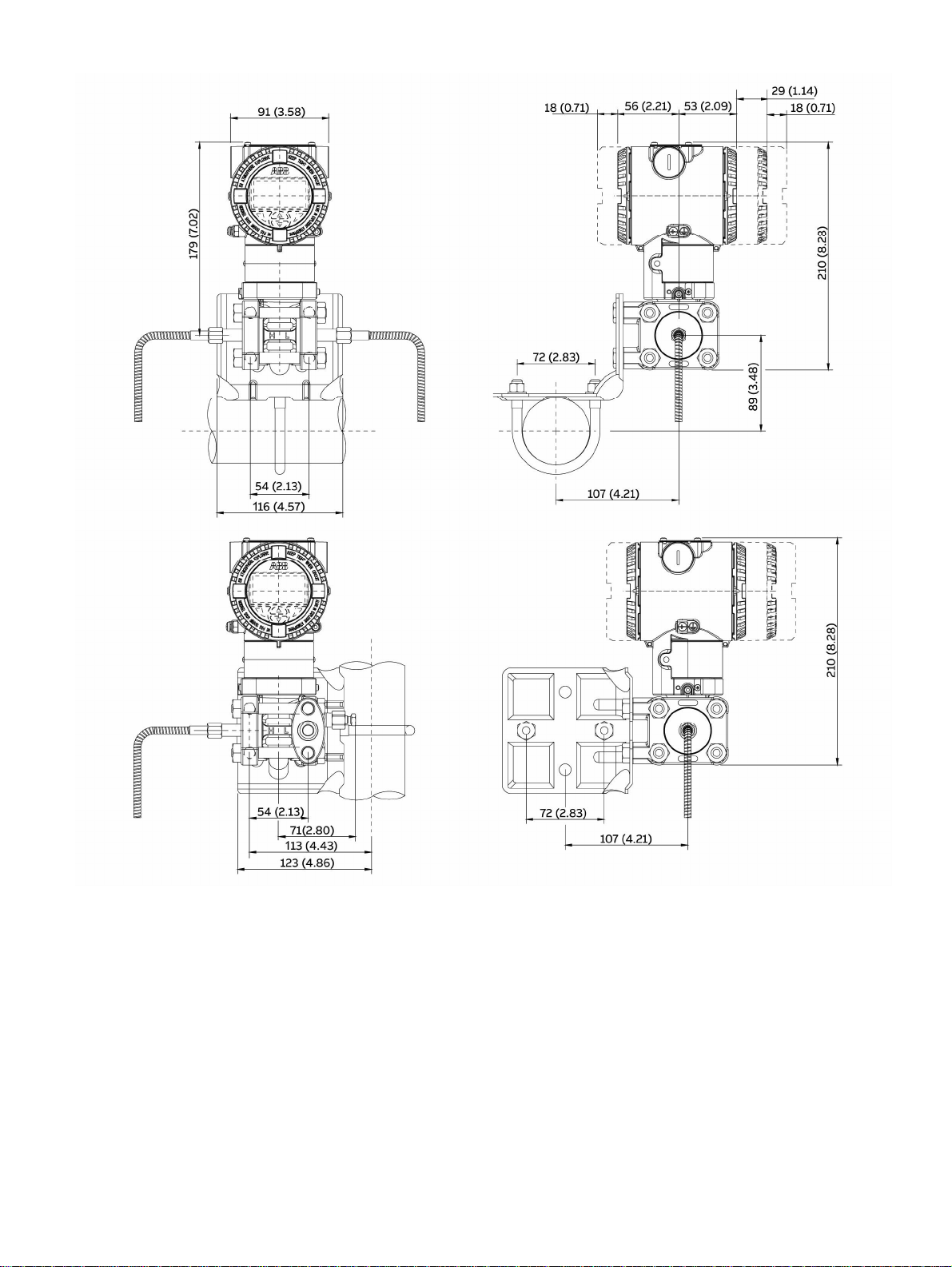

60 mm (2 in.) pipe ........................................... 15

8.5.3 Transmitter with DIN housing and mounting

bracket, for vertical or horizontal mounting on

60 mm (2 in.) pipe ........................................... 16

8.5.4 Transmitter with barrel housing and flat bracket,

for vertical or horizontal mounting on

60 mm (2 in.) pipe ........................................... 17

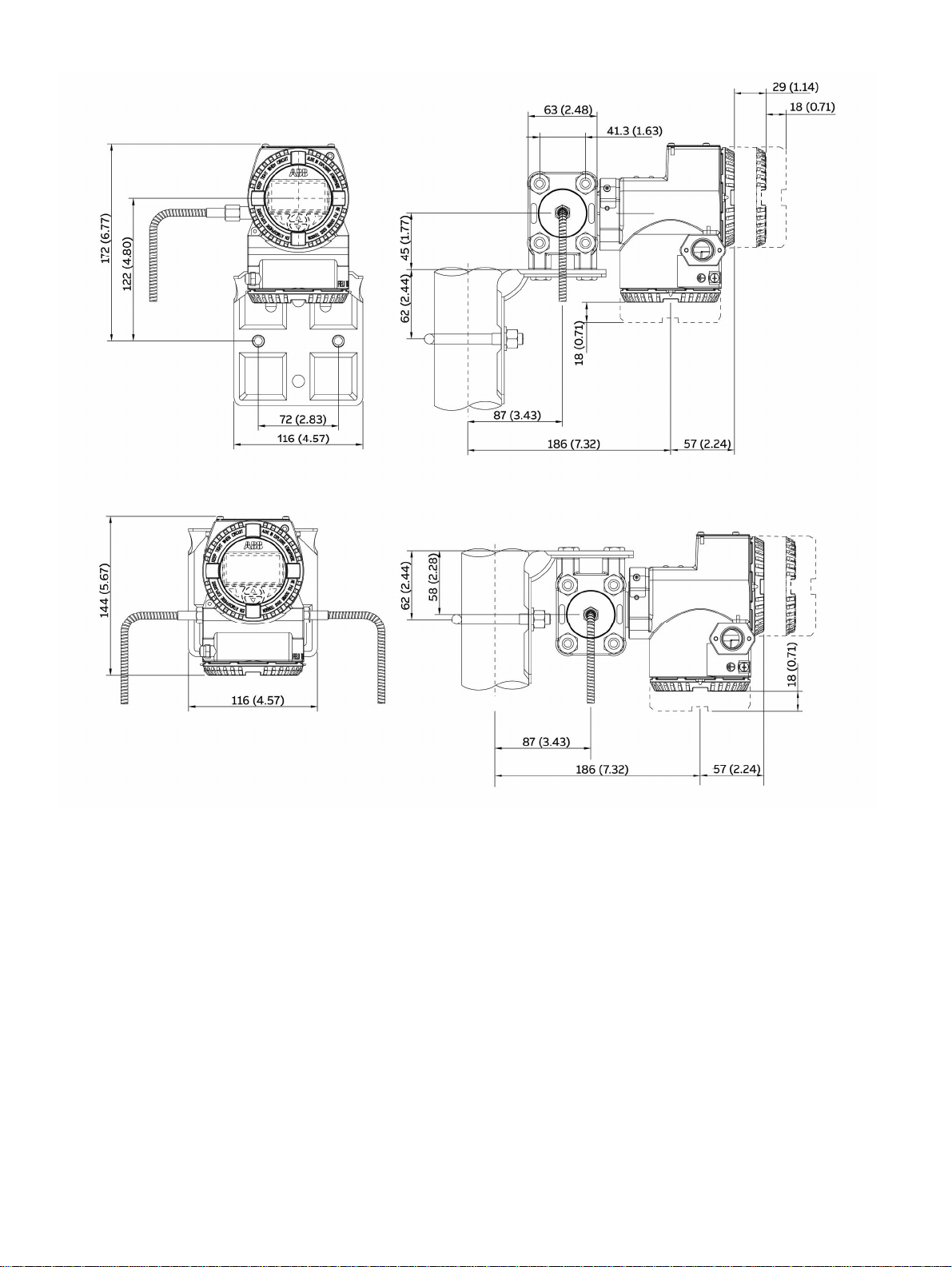

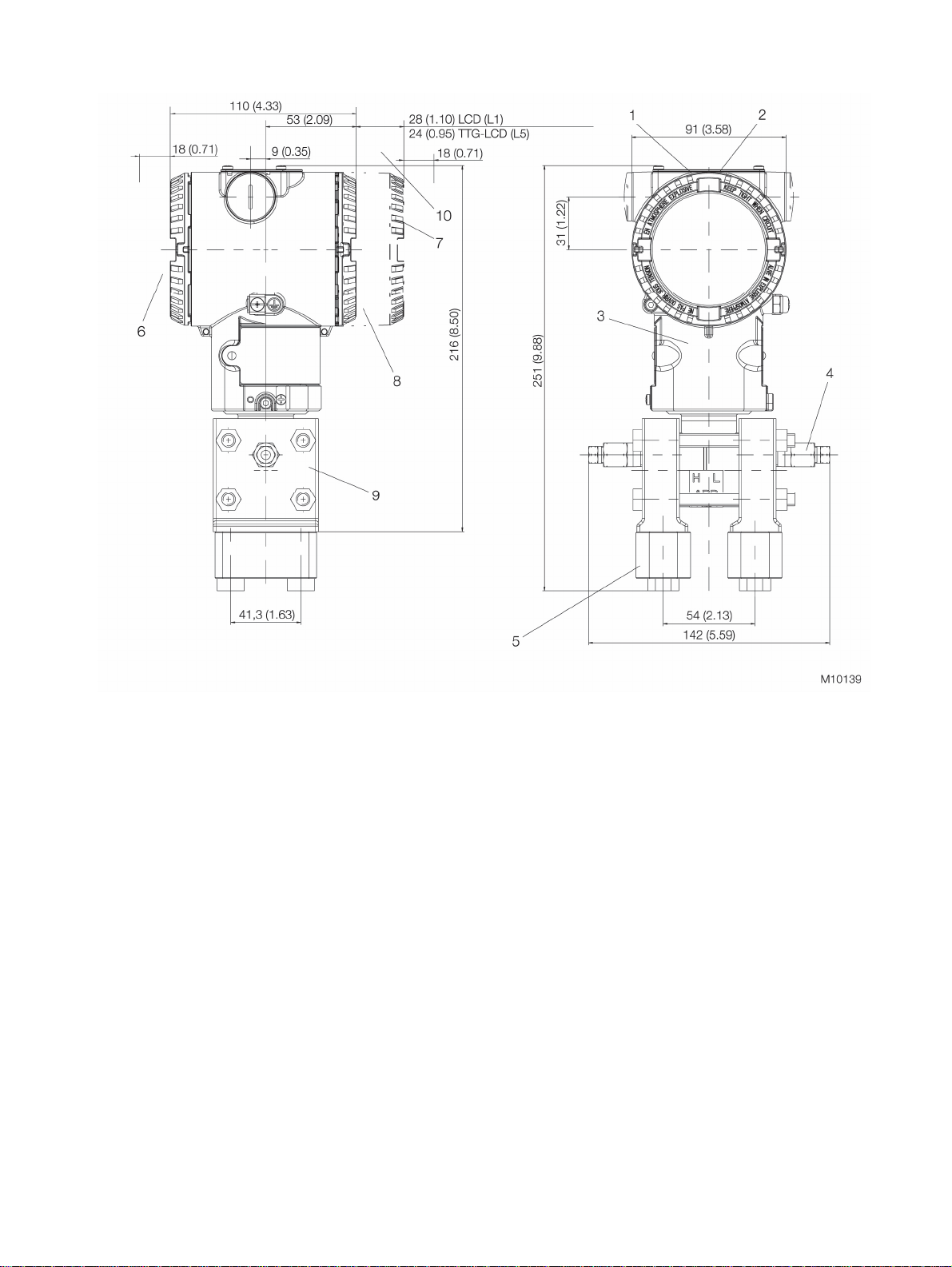

8.6 Mounting dimensions 266CSx/JSx .................. 18

8.6.1 Transmitter with barrel housing - Horizontal

flanges ........................................................... 18

8.6.2 Transmitter with barrel housing - Vertical flanges

...................................................................... 19

8.6.3 Transmitter with mounting bracket, for vertical or

horizontal mounting on 60 mm (2 in.) pipe pipe 20

8.6.4 Transmitter with DIN aluminum housing horizontal flanges with mounting bracket for

vertical or horizontal mounting on 60 mm (2 in.)

pipe ................................................................ 21

8.6.5 Transmitter with flat bracket, for vertical or

horizontal mounting on 60 mm (2 in.) pipe ....... 22

8.6.6 Installation via (optional) mounting brackets..... 23

8.7 Rotating the transmitter housing ...................... 23

8.8 Rotating the integral LCD display .................... 24

8.9 Connecting impulse lines ................................ 24

8.10 Process connections ....................................... 25

8.11 Temperature measurement ............................. 25

8.12 Mounting recommendations ............................ 25

8.12.1 Flow measurement of steam (condensible vapor)

or clean liquids ............................................... 26

8.12.2 Flow measurement of gas or liquid with solids in

suspension ..................................................... 26

8.12.3 Fill level measurement on closed tanks ........... 27

8.12.4 Fill level measurement on open tanks with fluids28

8.12.5 Fill level measurement on the s team boiler (drum

water level) ..................................................... 28

9 Electrical connections .................................................. 29

9.1 Cable connections .......................................... 29

9.2 Connection of the analog output (HART) ......... 30

9.3 Digital output (pulse / limit output).................... 31

9.4 Wiring ............................................................ 31

9.5 Protective conductor connection / grounding.... 31

2 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 3

10 Commissioning ............................................................ 32

10.1 General remarks ............................................. 32

10.2 Output signal .................................................. 32

10.3 Zero point correction following installation ........ 32

10.3.1 Setting precalibrated devices ........................... 33

10.3.2 Zero-point increase/suppression on precalibrated

devices ........................................................... 33

11 Configuration ............................................................... 34

11.1 Write protection .............................................. 34

11.2 Hardware settings ........................................... 34

11.3 Factory settings .............................................. 35

11.4 Configuration of the transmitter without integrated

LCD display .................................................... 36

11.4.1 Configuration of LRV and URV (4 … 20 mA

range)............................................................. 36

11.5 Configuration of the pressure transmitter menu-

controlled without integrated LCD display ........ 37

11.5.1 Menu navigation ............................................. 37

11.5.2 Menu levels .................................................... 37

11.5.3 Activation of the operating menu ..................... 38

11.5.4 Selecting and changing parameters ................. 40

11.5.5 Easy Set-Up ................................................... 42

11.5.6 Overview of parameters on the configuration level

..................................................................... 44

11.6 Configuration with the PC / laptop or handheld

terminal .......................................................... 56

11.7 Damping and transmission function ................. 57

11.7.1 Damping ......................................................... 57

11.7.2 Transmission function ..................................... 57

14 Maintenance / Repair ................................................... 73

14.1 Dismounting ................................................... 73

14.2 Safeguard the housing cove r for devices with “Ex

d” type of protection ........................................ 73

14.3 Mounting / dismounting the button unit ............ 74

14.4 Mounting / dismounting the LCD display .......... 74

14.5 Measuring cell of the multivariable transmitter .. 74

14.6 Removing / installing the process flange .......... 75

14.6.1 Replacing the measuring cell........................... 75

12 Error messages ........................................................... 61

12.1 Error states and alarms ................................... 61

13 Ex relevant specifications ............................................. 67

13.1 Specific Conditions of Use (X) ......................... 67

13.2 Explosion protection requirements and IP rating

(ATEX) ........................................................... 67

13.3 Applications for "Ex ia" transmitters categories 1 G

and 1 D .......................................................... 67

13.3.1 Example applications ...................................... 68

13.4 Applications for Ex ia transmitters categories

1/2 G and 1/2 D .............................................. 69

13.4.1 Example applications ...................................... 69

13.5 Application for Ex d transmitters categories 1/2 G

and 1/2 D........................................................ 70

13.5.1 Example applications ...................................... 70

13.6 Applications for Ex nL transmitters Categories 3 G

and 3 D .......................................................... 71

13.6.1 Example applications ...................................... 71

13.7 Electrical data for the LCD display ................... 72

13.8 Explosion protection requiremen ts (North

America) ......................................................... 72

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 3

Page 4

1 ABB

ABB is an established multinational company which

develops and manufactures products for measurement

technology.

We offer our customers application know-how, service, and

support all over the world.

The quality, accuracy, and performance of our products are

the result of more than 100 years of experience and ongoing

innovative developments featuring the very latest

technologies.

2.3 Customer Service Centers worldwide

For support of ABB instrumentation products local

subsidiaries are available worldwide. If it is not possible for

you to contact the ABB subsidiary in your country, you can

also contact one of the following competence centers for

pressure measurement technology.

ABB S.p.A.

Industrial Automation

Via Vaccani, 4 Loc. Ossuccio

22016 Tremezzina (Co)

Italy

Tel: +39 0344 58111

Fax: +39 0344 56278

2 Introduction

2.1 About the manual

This manual is an operating and maintenance manual for the

series 2600T pressure transmitter models. It contains

information on initial installation, configuration, calibration

and fault correction.

Read this manual before working with the product.

2.2 Structure of the operating manual

This manual describes the installation, operation, and fault

correction of model 266Jxx and 266Cxx pressure

transmitters. The sections of this manual describe the

individual phases of the product life cycle, starting with

delivery and identification of the transmitter, the installation

and electrical connection, configuration, extending to fault

correction and maintenance.

For special applications that are not considered in the

examples, we recommend that you first familiarize yourself

with the mode of operation of the pressure transmitter based

on this manual.

Helps for calibration or fault correction are provided directly

in the respective chapters.

If there are additional questions the user can contact ABB

directly. All addresses in this regard are on the last page of

this manual. Additional information is on the website at

www.abb.com/measurement.

ABB Inc.

Industrial Automation

125 E. County Line Road

Warminster, PA 18974

USA

Tel.: +1 215 674 6000

Fax: +1 (0)215 674 7183

measurement@us.abb.com

ABB Inc.

Industrial Automation

3450 Harvester Road

Burlington

Ontario L7N 3W5

Canada

Tel.: +1 905 639 8840

Fax: +1 (0)905 639 8639

ABB India Limited

Industrial Automation

Peenya Industrial Area, Peenya

Bangalore, Karnataka 560058

India

Tel.: +91 80 4206 9950

Fax: +91 (0)80 2294 9389

ABB Engineering (Shanghai) Ltd.

Industrial Automation

No. 4528, Kangxin Highway, Pudong New District,

Shanghai 201319

P.R. China

Tel.: +86 21 6105 6666

Fax: +86 (0)21 6105 6677

4 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 5

3 Safety

3.1 General information and notes for the reader

These instructions are an important part of the product and

must be retained for future reference.

Installation, commissioning, and maintenance of the product

may only be performed by trained specialist personnel who

have been authorized by the plant operator accordingly. The

specialist personnel must have read and understood the

manual and must comply with its instructions.

For additional information or if specific problems occur that

are not discussed in these instructions, contact the

manufacturer.

The content of these instructions is neither part of nor an

amendment to any previous or existing agreement, promise

or legal relationship.

Modifications and repairs to the product may only be

performed if expressly permitted by these instructions.

Information and symbols on the product must be observed.

These may not be removed and must be fully legible at all

times.

The operating company must strictly observe the applicable

national regulations relating to the installation, function

testing, repair and maintenance of electrical products.

3.2 Intended use

The 266Jxx / 266Cxx multivariable pressure transmitters

measure the mass flow of gases, vapors, and liquids in the

process industry.

For information on measuring ranges and permissible

overload, refer to the section "Specifications".

3.3 Improper use

The following are considered to be instances of improper

use of the device:

— For use as a climbing aid, e.g. for mounting purposes

— For use as a support for external loads, e.g. as a support

for piping, etc.

— Material application, e.g. by painting over the housing,

name plate or welding/soldering on parts.

— Material removal, e.g. by spot drilling the housing.

3.4 Target groups and qualifications

Installation, commissioning and maintenance of the product

may only be performed by trained specialist personnel who

have been authorized by the plant operator to do so. The

specialist personnel must have read and understood the

manual and comply with its instructions.

The operators must strictly observe the applicable national

regulations with regards to installation, function tests,

repairs, and maintenance of electrical products.

3.5 Warranty provisions

Using the device in a manner that does not fall within the

scope of its intended use, disregarding this manual, using

underqualified personnel, or making unauthorized alterations

releases the manufacturer from liability for any resulting

damage. This renders the manufacturer's warranty null and

void.

Using these products as intended includes compliance with

the following points:

— Read and follow the instructions in this manual

— The technical limit values must be complied with (refer to

the section “Technical data").

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 5

Page 6

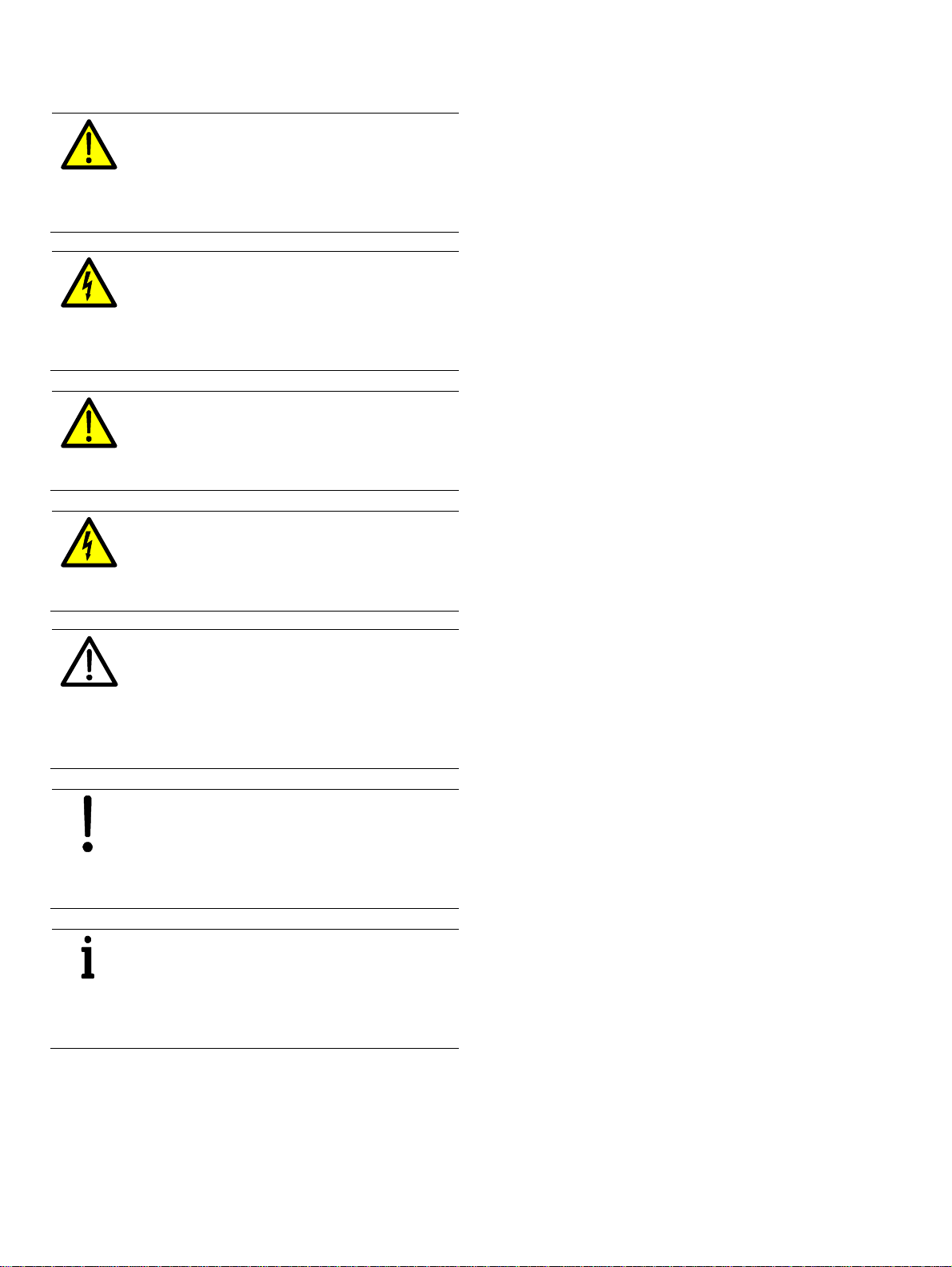

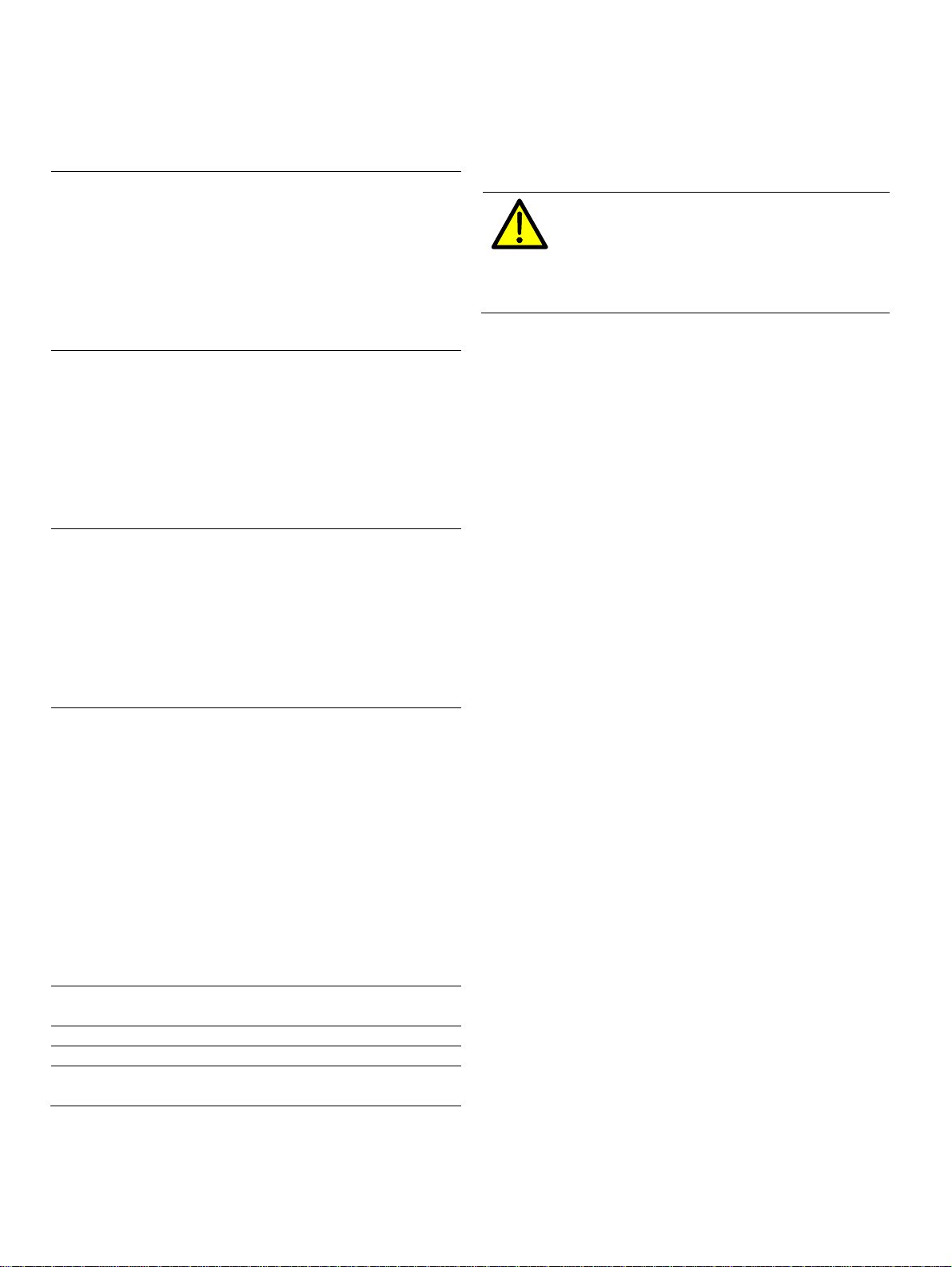

3.6 Plates and symbols

3.6.1 Safety / warning symbols, note symbols

DANGER – Serious damage to health / risk to

life

This symbol in conjunction with the signal word

"DANGER" indicates an imminent danger.

Failure to observe this safety information will

result in death or severe injury.

3.7 Compliance with Pressure Equipment Directive

(2014/68/EU)

Devices with PS > 200

Devices with a permissible pressure of PS > 200 bar (20

MPa) have been tested for compliance by the notified body

(0474) according to module H and can be used for liquids of

group 1 (PED: 1G).

The rating plate contains the following designations: PED:

1G.

DANGER – Serious damage to health / risk to

life

This symbol in conjunction with the signal word

"DANGER" indicates an imminent electrical

hazard. Failure to observe this safety

information will result in death or severe injury.

WARNING – Bod ily injury

This symbol in conjunction with the signal word

"WARNING" indicates a potentially dangerous

situation. Failure to observe this safety

information may result in death or severe injury.

WARNING – Bod ily injury

This symbol in conjunction with the signal word

"WARNING" indicates a potential electrical

hazard. Failure to observe this safety

information may result in death or severe injury.

CAUTION – Minor injuries

This symbol in conjunction with the signal word

"CAUTION" indicates a potentially dangerous

situation. Failure to observe this safety

information may result in minor or moderate

injury. The symbol may also be used for

property damage warnings.

NOTICE – Property damage

This symbol indicates a potentially damaging

situation.

Failure to observe this safety information may

result in damage to or destruction of the product

and / or other system components.

Devices with PS ≤ 200

Devices with a permissible pressure PS ≤200 bar correspond

to article 4 paragraph 3. They have not been subject to a

conformity validation. These instruments were designed and

manufactured according to SEP Sound Engineering

Practices.

3.8 Transport

After final calibration, the device is packed in a carton to

provide protection against physical damage.

3.9 Transport safety instructions

Observe the following instructions:

— Do not expose the device to humidity during transport.

Pack the device accordingly.

— Pack the device so that it is protected against vibrations

during transport, e.g., by using air-cushioned packaging.

Prior to installation, check the devices for possible damage

that may have occurred as a result of improper transport.

Details of any damage that has occurred in transit must be

recorded on the transport documents. All claims for damages

must be submitted to the shipper without delay and before

installation.

3.10 O bligations of the owner

Prior to using the devices with corrosive or abrasive media,

the owner must check the level of resistance of all parts that

come into contact with the process liquid.

ABB would be pleased to provide support in the selection of

suitable materials, however we can assume no liability

whatsoever.

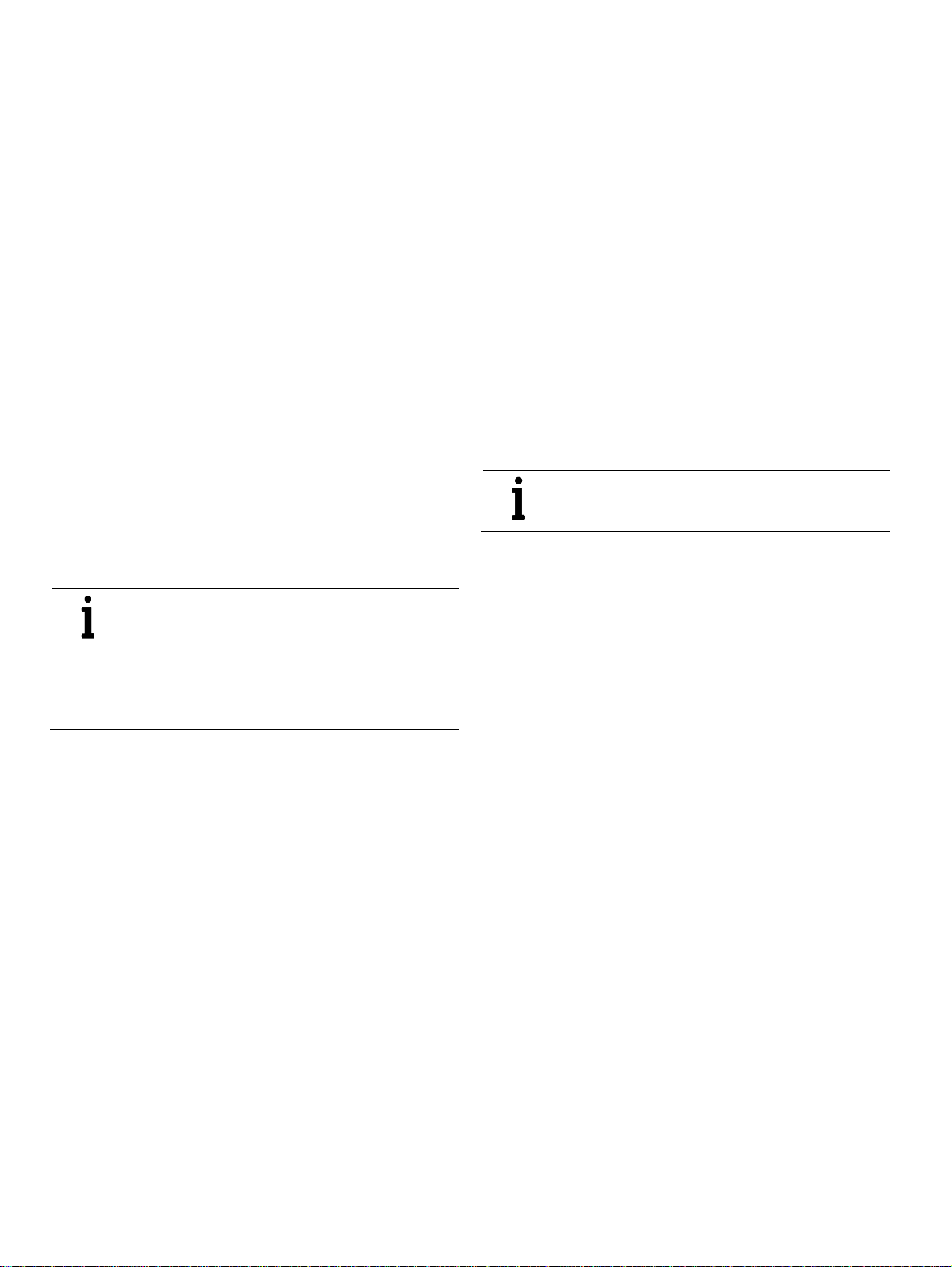

IMPORTANT (NOTE)

This symbol indicates operator tips, particularly

useful information, or important information

about the product or its further uses. The signal

word "IMPORTANT (NOTE)" does not indicate

a dangerous or harmful situation.

6 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 7

3.11 Stor age conditions

— The device must be stored in dry and dust-free

conditions. Always keep the device in its original

package during storage / transport.

— Observe the permissible ambient conditions for transport

and storage according to the chapter “Technical Data”.

— In principle, the devices may be stored for an unlimited

period. However, the warranty conditions stipulated in

the order confirmation of the supplier apply.

3.12 Safet y instructions for electrical installation

The electrical connection may only be established by

authorized specialist personnel and in accordance with the

connection diagrams.

The electrical connection information in this manual must be

observed; otherwise, the IP rating may be adversely

affected.

Ground the measurement system according to requirements.

3.13 Safet y instructions for operation

Before switching on the device, make sure that your

installation complies with the environmental conditions listed

in the chapter “Technical Data” or on the data sheet.

If there is a chance that safe operation is no longer possible,

take the device out of operation and secure it against

unintended startup.

3.15 Retur ning devices

Use the original packaging or a secure transport container of

an appropriate type if you need to return the device for repair

or recalibration purposes. Fill out the return form (see the

Appendix) and include this with the device.

According to the EU Directive governing hazardous

materials, the owner of hazardous waste is responsible for

its disposal or must observe the following regulations for

shipping purposes:

All devices delivered to ABB must be free from any

hazardous materials (acids, alkalis, solvents, etc.).

3.16 I ntegrated management system

ABB actively promotes environmental awareness and has an

operational management system that meets the

requirements of ISO 9001:2015, ISO 14001:2015, and

OHSAS 18001:2007.

Our products and solutions are intended to have minimum

impact on the environment and persons during

manufacturing, storage, transport, use and disposal.

This includes the environmentally friendly use of natural

resources. ABB conducts an open dialog with the public

through its publications.

3.14 Safet y information for inspection and maintenance

WARNING – Electrical dangers!

When the housing is open, EMC protection is

impaired and there is no longer any protection

against accidental contact.

Switch off the power supply before opening the

housing.

Corrective maintenance work may only be performed by

trained personnel.

— Before removing the device, depressurize it and any

adjacent lines or containers.

— Check whether hazardous materials have been used as

materials to be measured before opening the device.

Residual amounts of hazardous material may still be

present in the device and could escape when it is

opened.

Within the scope of operator responsibility, check the

following as part of a regular inspection:

— the pressure-carrying walls / lining of the pressure

device

— the measurement-related function

— the leak tightness

— the wear (corrosion)

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 7

Page 8

3.17 Disposal

This product is manufactured from materials that can be

recycled by specialist recycling companies.

3.17.1 Information on WEEE Directive 2012/19/EU (Waste

Electrical and Electronic Equipment)

This product or solution is subject to the WEEE Directive

2012/19/EU or corresponding national laws. Starting from

August 15th 2018, electrical and electronic equipment

marked with the crossed-out wheeled bin symbol may not be

disposed as unsorted municipal waste. Waste of electrical

and electronic equipment (WEEE) shall be treated

separately using the national collection framework available

to customers for the return, recycling and treatment of

WEEE.

Proper disposal prevents negative effects on people and the

environment, and supports the reuse of valuable raw

materials.

ABB can accept and dispose of returns for a fee.

3.17.2 ROHS II Directive 2011/65/EU

European Directives 2012/19/EU (WEEE) and 2011/65/EU

(RoHS II) define the products that are subject to regulated

collection and disposal or reuse in the event of disposal or at

the end of their service life. RoHS also prohibits the

marketing of electrical and electronic equipment that

contains certain amounts of lead, cadmium, mercury,

hexavalent chromium, polybrominated biphenyls (PBB), and

polybrominated diphenyl ethers (PBDE) (also known as

hazardous substances with restricted uses).

Standards/Specifications applied: EN 50581:2012.

The product provided by ABB complies with the

requirements of the substances restrictions at the time of

delivery. Contamination traces for which the manufacturer is

not responsible, cannot be ruled out according to generally

recognized rules of technology.

Change from tw o to one col umn

3.18 Cyber security

Disclaimer

This product is designed to be connected to and to

communicate information and data via a network interface. It

is operator’s sole responsibility to provide and continuously

ensure a secure connection between the product and your

network or any other network (as the case may be). Operator

shall establish and maintain any appropriate measures (such

as but not limited to the installation of firewalls, application of

authentication measures, encryption of data, installation of

anti-virus programs, etc) to protect the product, the network,

its system and the interface against any kind of security

breaches, unauthorized access, interference, intrusion,

leakage and/or theft of data or information.

ABB and its affiliates are not liable for damages and/or

losses related to such security breaches, any unauthorized

access, interference, intrusion, leakage and/or theft of data

or information.

Communication protocol specific

The HART protocol is an unsecured protocol, such as the

intended application should be assessed to ensure that

these protocols are suitable before implementation.

Change from one to two col umns

4 Unpacking the device

4.1 Scope of delivery

— Multivariable transmitter model 266Cxx or 266Jxx

— Multilingual Quick Reference Manual, calibration

protocol, and possibly optionally requested certificates in

an envelope.

— Hexagon socket wrench for unscrewing the fastening

screws of the housing

— Additional parts as specified in the purchase order:

— 1/2”-NPT-f adapter with appropriate seals

— Fastening accessories

— Accessories for the electrical connection

Change from tw o to one col umn

8 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

4.2 Identification

Identify the device in accordance with the instructions in

chapter “Product identification” to ensure it is the right

device.

4.3 Storage

Special measures are not required for storing the device in

shipping status and in accordance with the specified storage

conditions. The storage period is unlimited.

The guarantee conditions agreed with the company and

specified in the order confirmation remain unaffected.

4.4 Handling

Special precautionary measures are not required for

handling of the device. However, standard procedures must

be complied with.

Page 9

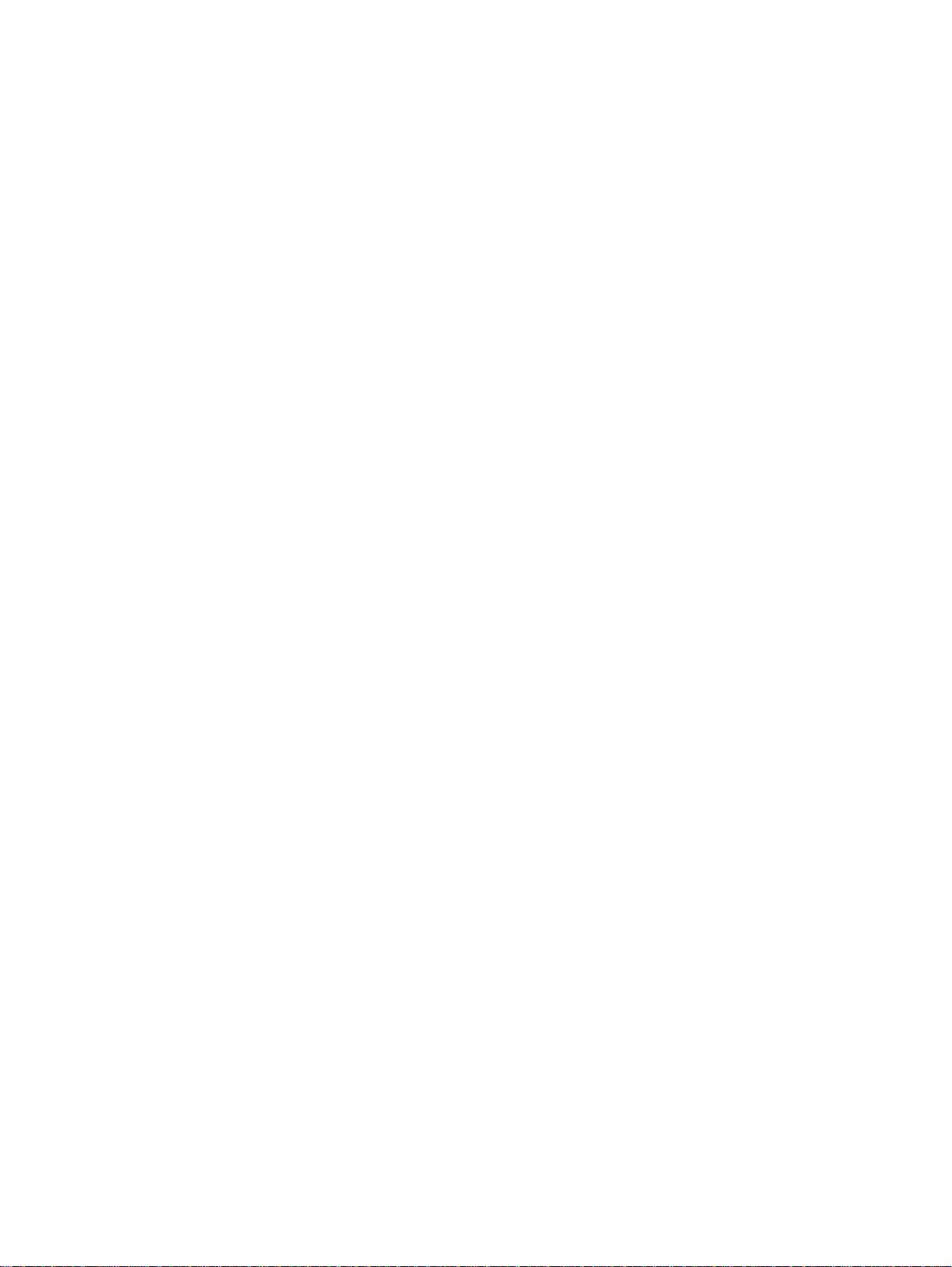

5 Product identification

ABB S.p .A.

Made in Italy

The device is identified via the signs (plates) presented in

Fig. 1.

The certification plate (A) is on the transmitter and indicates

whether the device is designed for general use or for use in

hazardous areas.

The name plate (B) provides information including the model

number, maximum operating pressure, measuring range

limits and span limits, power supply, output signal,

membrane material, filling fluid, serial number, maximum

permissible operating pressure (PS), and maximum

permissible temperature (TS).

Please specify the serial number when submitting inquiries

to the ABB customer service department.

Change from tw o to one col umn

An additional plate (C) provides the measuring point no. of

the client and the calibration range. The device can be used

as a pressure transfer accessory (category III) as defined by

the Pressure Equipment Directive 2014/68/EU. In this case,

you will find the number of the notified body that has verified

compliance next to the CE mark.

The certification plate shown (A) has been issued for ABB

S.p.A., 22016 Tremezzina (CO), Italy and bears the following

numbers:

— FM09ATEX0023X

— FM09ATEX0024X

— FM09ATEX0025X

CE-Identification number of the notified bodies to Pressure

Equipment Directive: 0474, to ATEX certification: 0722.

B

C

A

Fig. 1: Product identification

The figure shows the transmitter with barrel housing. The 266 series also includes transmitters with DIN housing. A"

Change from one to two col umns

Optional stainless steel attachment plate with customer data,

fastened with wire (option code I1)

The model 266 multivariable transmitter is delivered with an

optional stainless steel attachment plate with customer data

that is fastened with wire. Customer specific text that has

been specified in the purchase order is laser printed on the

attachment plate. For this, 4 lines of 32 characters each are

provided.

Fig. 2: Optional s t ainl es s s t eel at t ac hment plate with c us t omer data,

fastened with wire

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 9

Page 10

6 Use i n poten tially explosive

atmospheres

6.1 Hazardous atmospheres

With or without integral LCD display

INTRINSIC SAFETY Ex ia:

ATEX Europe (c ode E 1) approv al

II 1 G Ex ia IIC T6...T4 Ga, II 1/2 G Ex ia IIC T6...T4 Ga/Gb,

II 1 D Ex ia IIIC T85 °C Da, II 1/2 D Ex ia IIIC T85 °C Da; IP66, IP67.

IECEx (code E 8) approval

Ex ia IIC T6...T4 Ga/Gb, Ex ia IIIC T85 °C Da; IP66, IP67.

NEPSI China (c ode E Y)

Ex ia IIC T4/T5/T6 Ga, Ex ia IIC T4/T5/T6 Ga/Gb,

Ex iaD 20 T85/ T100/ T135, Ex iaD 20/21 T85/ T100/ T135.

EXPLOSION PROOF:

ATEX Europe (c ode E 2) approv al

II 1/2 G Ex db IIC T6 Ga/Gb Ta=–50 °C to +75 °C,

II 1/2 D Ex tb IIIC T85 °C Db Ta = –50 °C to +75 °C; IP66, IP67.

IECEx (code E 9) approval

Ex db IIC T6 Ga/ Gb Ta=–50 °C to +75 °C,

Ex tb IIIC T85 °C Db Ta = –50 °C to +75 °C; IP66, IP67.

NEPSI China (c ode E Z)

Ex d IIC T6 Gb, Ex tD A21 IP67 T85 °C.

INTRINSIC SAFETY Ex ic:

ATEX Europe (c ode E 3 ) ty pe examinat ion

II 3 G Ex ic IIC T6...T4 Gc, II 3 D Ex tc IIIC T85 °C Dc;

IP66, IP67.

IECEx (code E R) ty pe examinat ion

Ex ic IIC T6...T4 Gc, Ex tc IIIC T85 °C Dc;

IP66, IP67.

NEPSI China (c ode E S) t y pe exami nat ion

Ex ic IIC T4~T6 Gc, Ex nA IIC T4~T6 Gc, Ex tD A22 IP67 T85 °C.

FM Approvals US (c ode E6) and

FM Approvals Canada (c ode E 4):

— Ex plosion proof (US): Class I, Zone 1 AEx d IIC T4 Gb

— Ex plosion proof (Canada): Class I, Zone 1 Ex d II C T4 Gb

— Noninc endiv e: Class I, Division 2,

Groups A, B, C, D T6...T4

— Energy li mited (US): Class I, Zone 2 AEx nC IIC T6...T4

— Energy li mited (Canada): Class I, Zone 2 Ex nC II C T6.. .T4

— Int rins ically saf e: Class I, II, III, Division 1,

Groups A, B, C, D, E, F, G T6...T4

Class I, Zone 0 AEx ia IIC T6...T4 (US)

Class I, Zone 0 Ex ia IIC T6...T4

(Canada)

Type 4X, IP66, IP 67 for all abov e mark ings.

COMBINED FM A pprovals US and Canada

— Int rins ically saf e (code EA )

COMBINED A TE X, FM and IE CEx A pprov als (c ode EN)

NEPSI combined (code EP = EY + EZ), (code EQ = EY + EZ + ES)

Technical Regulat ions Cus t oms Union EA C (Russia, K az akhst an,

Belarus), I nmetro (B razil )

For ambient temperatures -40 … 85°C (-40 … 185°F) the

information based on the temperature classes in the

associated certificates, must be complied with.

The temperature sensor circuit (Pt100) and the digital output

(pulse / limit value output) must be connected in accordance

with the requirements of the Ex certificate.

WARNING - General danger for Model 266

used in Zone 0!

The housing contains aluminum, which can lead

to a potential danger of ignition through impact

or friction. For this reason, impact or friction

must be avoided during installation and use.

10 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 11

7 Function and system design

Change from tw o to one col umn

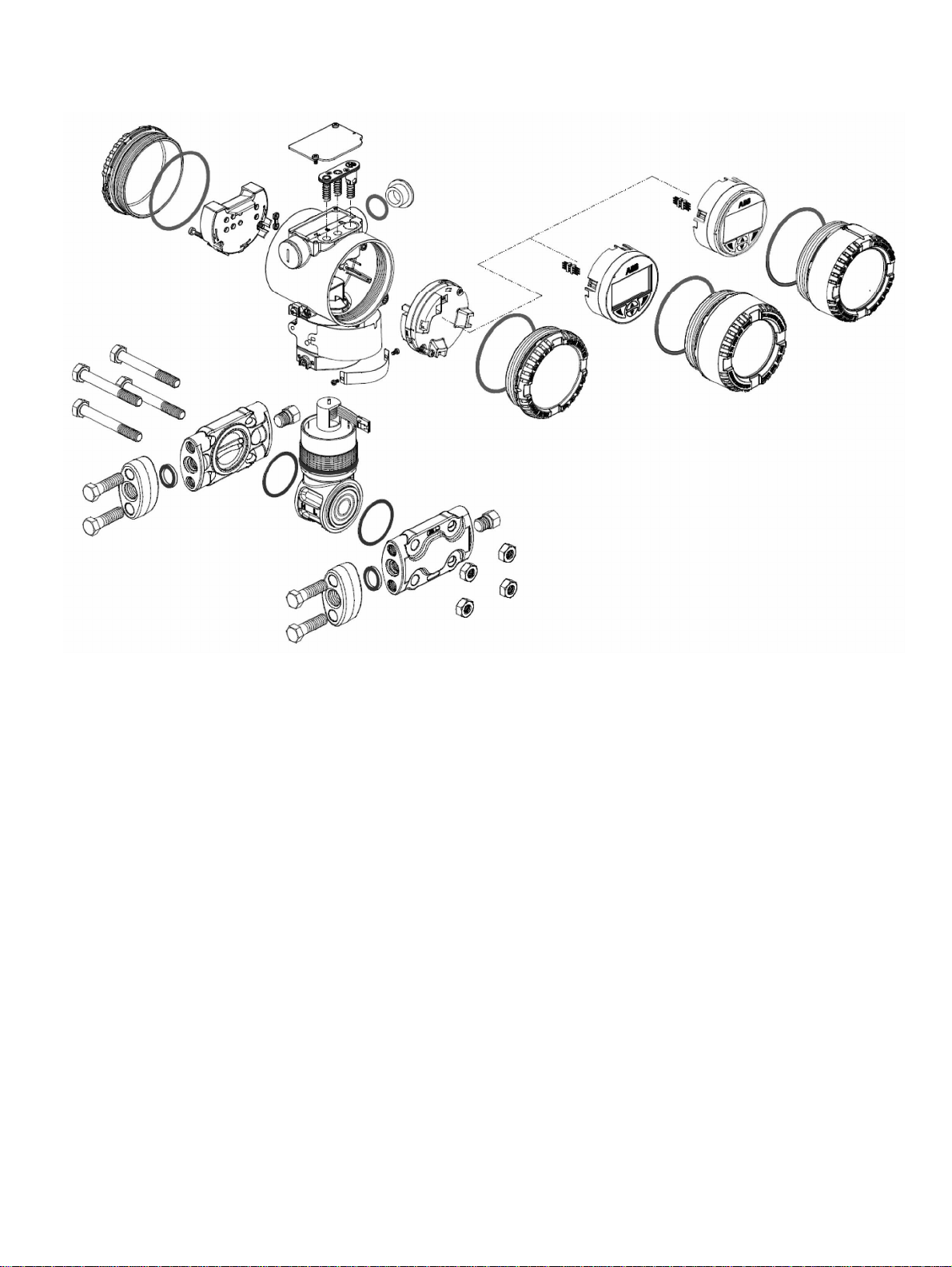

7.1 Components of the pressure transmitter

Fig. 3: Device ov erv iew

Change from one to two col umns

7.2 Product description

The 266Jxx/266Cxx multivariable pressure transmitters

measure the mass flow of gases, vapors, and liquids in

accordance with the differential pressure procedure and the

level of the liquids in the process industry. These

transmitters supply an analog or digital output signal.

Simultaneously and with high accuracy they measure

differential pressure, static pressure and with a Pt100 in 4conductor technology, they also measure the process

temperature. The differential pressure measuring ranges are

scaled from 1 to 2000 kPa. The measuring ranges for static

pressure are 0.6 to 2, 10 and 41 MPa. The transmitters can

be overloaded on one side to the respective upper

measuring range value of the static pressure.

7.3 Measuring range limits and span limits

The data sheets for the Series 2600T multivariable

transmitters contain all the information concerning the

measuring range and measuring span of the individual

models, as well as the sensor code.

The following terminology is used for the different

parameters:

URL: Upper Range Limit of a specific sensor. The highest

measured value t hat c an be measured by the transmitt er.

LRL: Lower Range Limit of a specific sensor. The lowest

measured value t hat c an be measured by the transmitt er.

URV: Upper Range Value The highest meas ured v alue to

which the transmitt er is cal ibrat ed.

LRV: Lower Range Value. The lowest measured value t o whic h

the transmitt er is c ali brated.

SPAN: Measuring span. The algebrai c diff erenc e bet ween t he

start of the meas uring range and t he end of the

measuring range. The s mal lest span is the s malles t v alue

that can be s elected wit hout i mpai ring t he s pec ified

measuring acc urac y.

TURN DOWN

RATIO:

Span ratio The ration between t he maxim um s pan and

the calibrat ed span.

The measuring transmitter can be calibrated to any

measuring range between LRL and URL with the following

restrictions.

— LRL ≤ LRV ≤ (URL - CAL SPAN)

— CAL SPAN ≥ MIN SPAN

— URV ≤ URL

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 11

Page 12

8 Mounting

Before installing the transmitter, check whether the device

design meets the requirements of the measuring point from a

measurement technology and safety specifications point of

view. This applies in respect of the:

— Measuring range

— Overload resistance

— Temperature

— Explosion protection

— Operating voltage

The suitability of the materials must be checked as regards

their resistance to the media. This applies in respect of the:

— Gasket

— Process connection, separating diaphragm, etc.

8.1 IP rating

The housing of pressure transmitters of the R266 series

satisfies the requirements of IP degree of protection

IP 66 / IP 67 (NEMA 4X) in accordance with IEC 60529.

The first digit indicates the protection of the integrated

electronics against penetration of foreign objects, including

dust.

The digit “6” means that the housing is dust tight (i.e. dust

cannot penetrate). The second digit indicates the protection

of the integrated electronics against the penetration of water.

The digit “6” means that the housing is watertight and can

even withstand a strong water jet under the specified

conditions.

The digit “7” means that the housing is watertight and can be

temporarily immersed at a specified pressure and for a

specific time, without water penetrating.

In addition, the relevant directives, regulations, standards,

and accident prevention regulations must be observed (e. g.,

VDE/VDI 3512, DIN 19210, VBG, Elex V, etc.).

Measurement accuracy is largely dependent on correct

installation of the transmitter and, if applicable, the

associated impulse line(s).

As far as possible, the measuring setup should be free from

critical ambient conditions such as large variations in

temperature, vibrations, or shocks.

IMPORTANT (NOTICE)

If unfavorable ambient conditions cannot be

avoided for reasons relating to building

structure, measurement technology, or other

issues, the measurement quality may be

affected.

(See "Specifications" chapter).

If a remote seal with capillary tube is installed on the

transmitter, the additional operating instructions for remote

seals and the related data sheets must be observed.

8.2 Factory settings

The transmitter is factory configured according to the

customer’s order specifications.

IMPORTANT (NOTICE)

Under normal conditions no additional settings

are required.

The typical configuration includes:

— Number of the measuring point tag

— Calibrated span

— Configuration of the flow or liquid level calculation

— Configuration of the LCD display

12 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 13

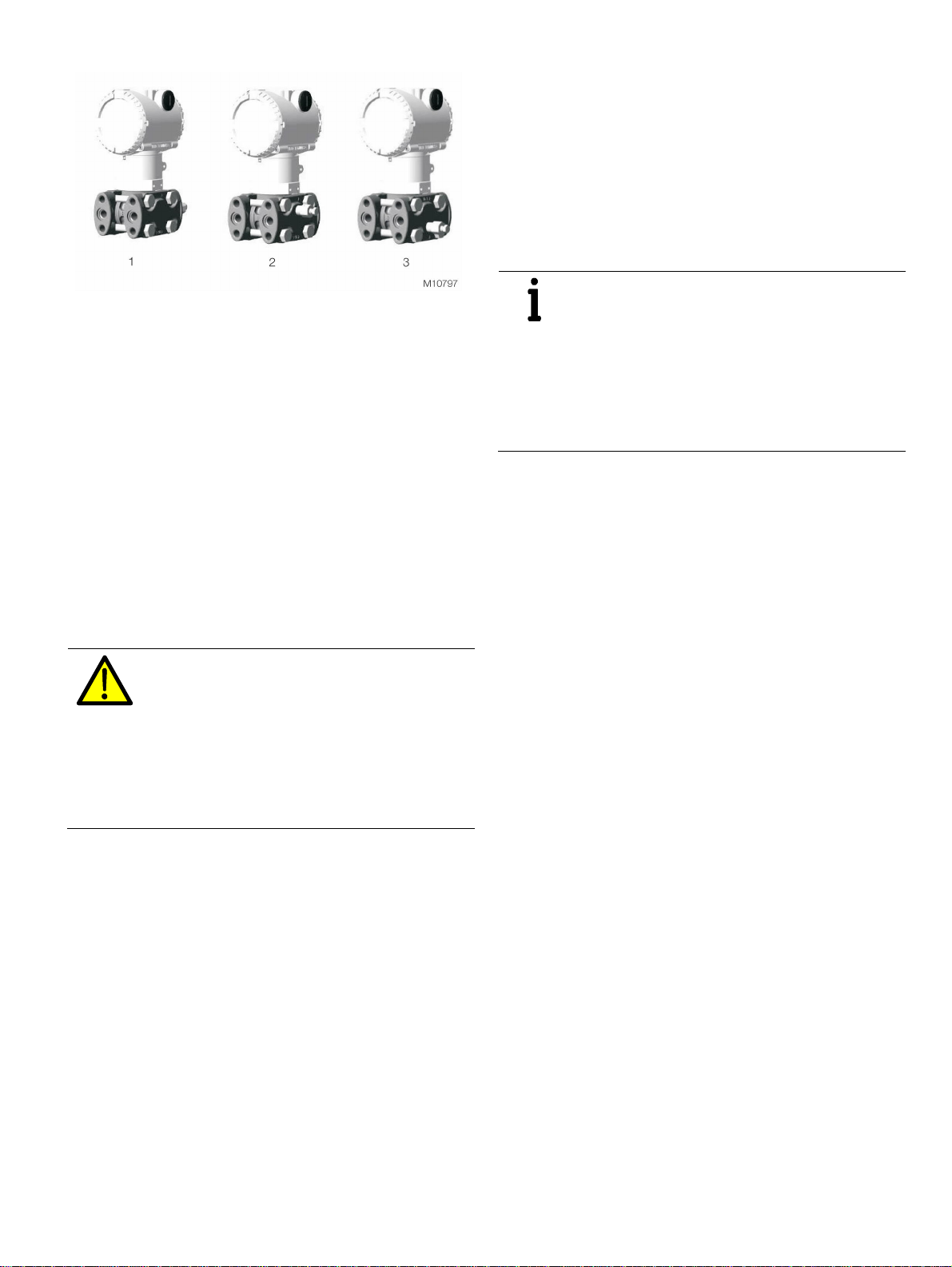

8.3 Venting / draining transmitters without diaphragm seals

Fig. 4

1 Valve on t he proces s axis | 2 Flange side v alve on t op |

3 Flange s ide v alve on t he bott om

For transmitters without diaphragm sealers the following

instructions on venting and draining must be complied with.

It is important to attach the transmitter in such a manner and

to layout the process line in such a manner that gas bubbles

in liquid measurements can be routed back into the process

and not get in to the measuring chambers.

The optional vent / drain valves on the transmitter are

attached on the measuring cell flanges. Align the transmitter

so that these vent / drain valves are arranged above the tap

points for liquid measurement, so that gas can escape

upward. For gas measurements align the transmitter so that

the vent / drain valves are arranged below the tap points, so

that air or condensate can drain.

8.4 Mounting position

The transmitter can be attached directly on a valve manifold

provided for flange installation.

Optionally a fastening bracket for wall or pipe installation

(2” pipe) is available as an accessory.

For models 266CRx and 266JRx fastening brackets must

always be used.

Ideally the transmitter must be mounted in such a manner

that the separating diaphragms are standing vertical, to

avoid later zero point offsets.

IMPORTANT (NOTICE)

If the transmitters are mounted with an

inclination that is not vertical, the filling fluid

exerts hydrostatic pressure on the measuring

diaphragm, which causes a zero point offset. In

this case the zero point can be adjusted via the

zero point button or with the command “Install

position correction”. See chapter

“Configuration”.

Change from tw o to one col umn

DANGER - severe health impairments / lifethreatening danger due to escaping

measurement medium!

During the venting or draining process medium

that is being discharged can escape and

endanger personnel who are not working in the

vicinity.

Consequently when venting or draining, any

escaping process medium must be collected.

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 13

Page 14

8.5 Mounting dimensions 266CRx/JRx

(No design information) - dimensions in mm (inch)

8.5.1 Transmitter with barrel housing

Fig. 5: B arrel ho us ing

1 Settings | 2 Rating plate | 3 Certification plate | 3a Optional plate (c ode I 2) | 4 V ent / drain v alve |

5 Process c onnec tion | 6 T ermi nal s ide | 7 LCD di s play hous ing cover | 8 Elect ronics si de | 9 Space for removing t he c over

Note

In the case of models with just one remote seal, the threaded connection (1/4 – 18 NPT directly or 1/2 – 14 NPT using

adapter) of the standard process flange, the gasket groove, and the gasket comply with IEC 61518.

The screw-on thread for attaching the adapter flange to the process flange is 7/16 -20 UNF.

14 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 15

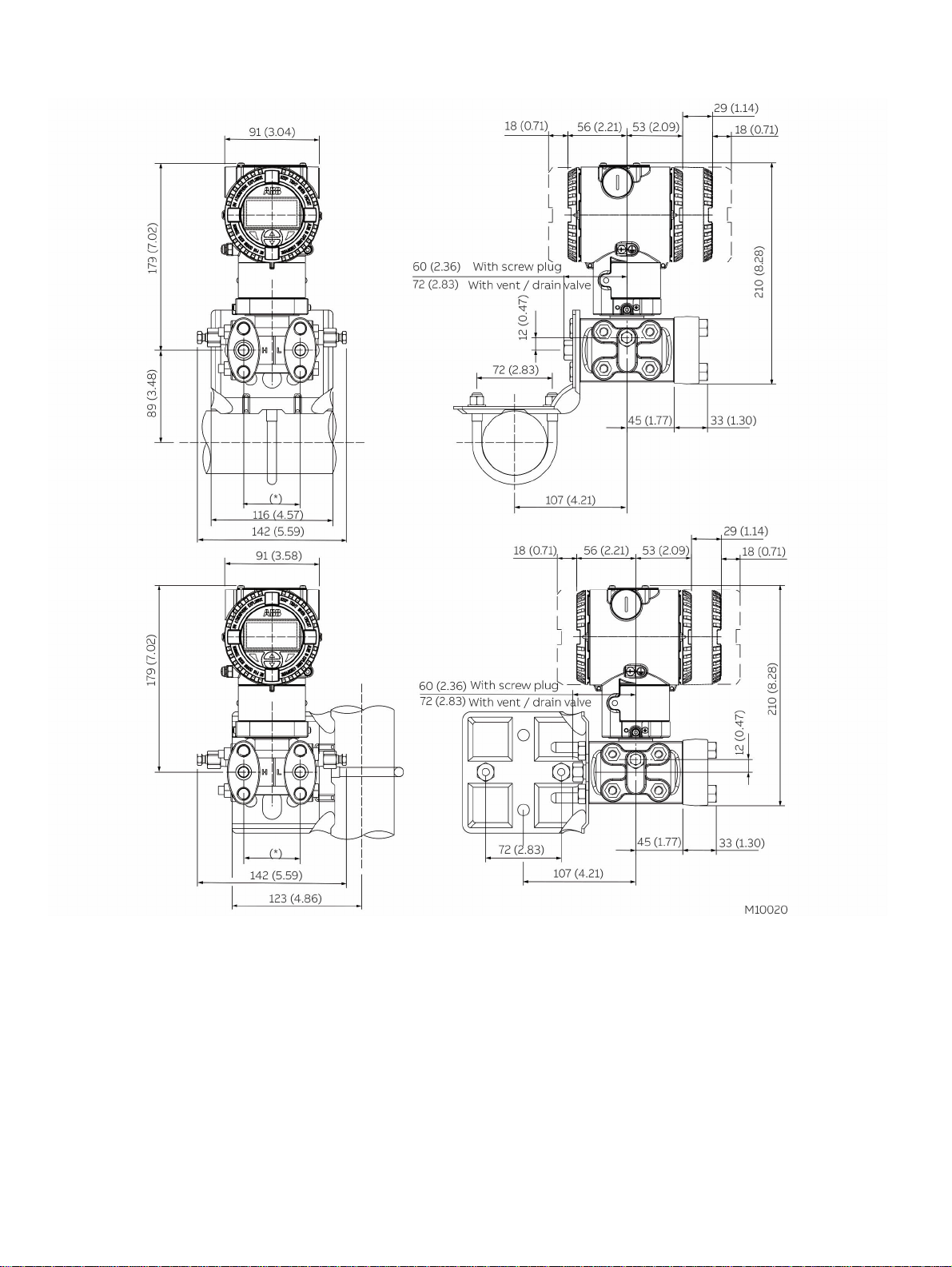

8.5.2 Transmitter with barrel housing and mounting bracket, for vertical or horizontal mounting on 60 mm (2 in.) pipe

Fig. 6: P ipe mount ing - barrel housing

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 15

Page 16

8.5.3 Transmitter with DIN housing and mounting bracket, for vertical or horizontal mounting on 60 mm (2 in.) pipe

Fig. 7: P ipe mount ing - DIN h ous ing

16 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 17

8.5.4 Transmitter with barrel housing and flat bracket, for vertical or horizontal mounting on 60 mm (2 in.) pipe

Fig. 8: Fl at brac k et f or pipe mounting - barrel hous ing

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 17

Page 18

8.6 Mounting dimensions 266CSx/JSx

(not design data) - dimensions in mm (inch)

8.6.1 Transmitter with barrel housing - Horizontal flanges

Fig. 9: B arrel ho us ing - horizontal flanges

1 Settings | 2 Rat ing plat e | 3 Cert ific ation plat e | 4 Vent / drain v alve | 5 Process connec t ion |

6 Terminal si de | 7 LCD di s play hous ing c ov er | 8 El ectronic s side | 9 P roc ess fl ange adapt er | 10 Space for removing t he c ov er

* 54 (2.13) mm (in.) via 1/4 - 18 NPT process flanges

51 (2.01), 54 (2.13), or 57 (2.24) mm (in) via 1/2 - 14 NPT adapter flanges.

Note: Process connect io n and sea l gro ove sat is fy I EC 161518. Thread for attaching adapt e r f lang es or ot he r c ompon ent s (e.g. , manif ol d) on t he p roc ess f lange:

7/16 -20 UNF.

** With screw plug

*** With vent / drain valve

18 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 19

8.6.2 Transmitter with barrel housing - Vertical flanges

Fig. 10 : B arrel ho us ing - v e rt ical flanges

1 Settings | 2 Rat ing plat e | 3 Cert ific ation plat e | 4 Vent / drain v alve | 5 Process connec t ion |

6 Terminal si de | 7 LCD di s play hous ing c ov er | 8 El ectronic s side | 9 P roc ess fl ange adapt er | 10 Space for removing t he c ov er

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 19

Page 20

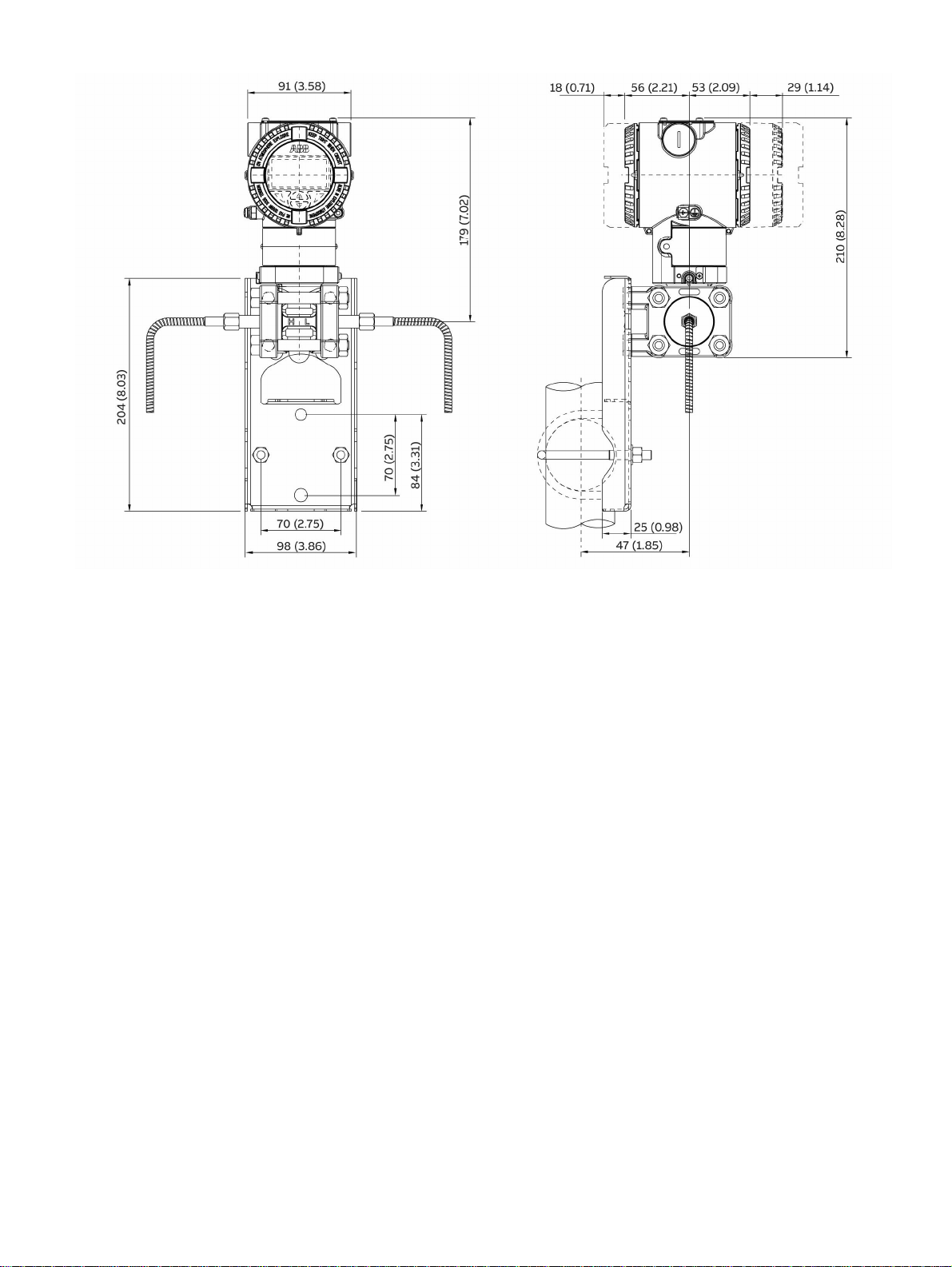

8.6.3 Transmitter with mounting bracket, for vertical or horizontal mounting on 60 mm (2 in.) pipe pipe

Fig. 11 : P ipe mount ing - barrel housing

* 54 (2.13) mm (in.) via 1/4 - 18 NPT process flanges

51 (2.01), 54 (2.13), or 57 (2.24) mm (in) via 1/2 - 14 NPT adapter flanges.

Note: Process connect io n and sea l gro ove sat is fy I EC 161518. Thread for attaching adapt e r f lang es or ot he r c ompon ent s (e.g. , manif ol d) on t he p roc ess f lange:

7/16 -20 UNF.

** With screw plug

*** With vent / drain valve

20 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 21

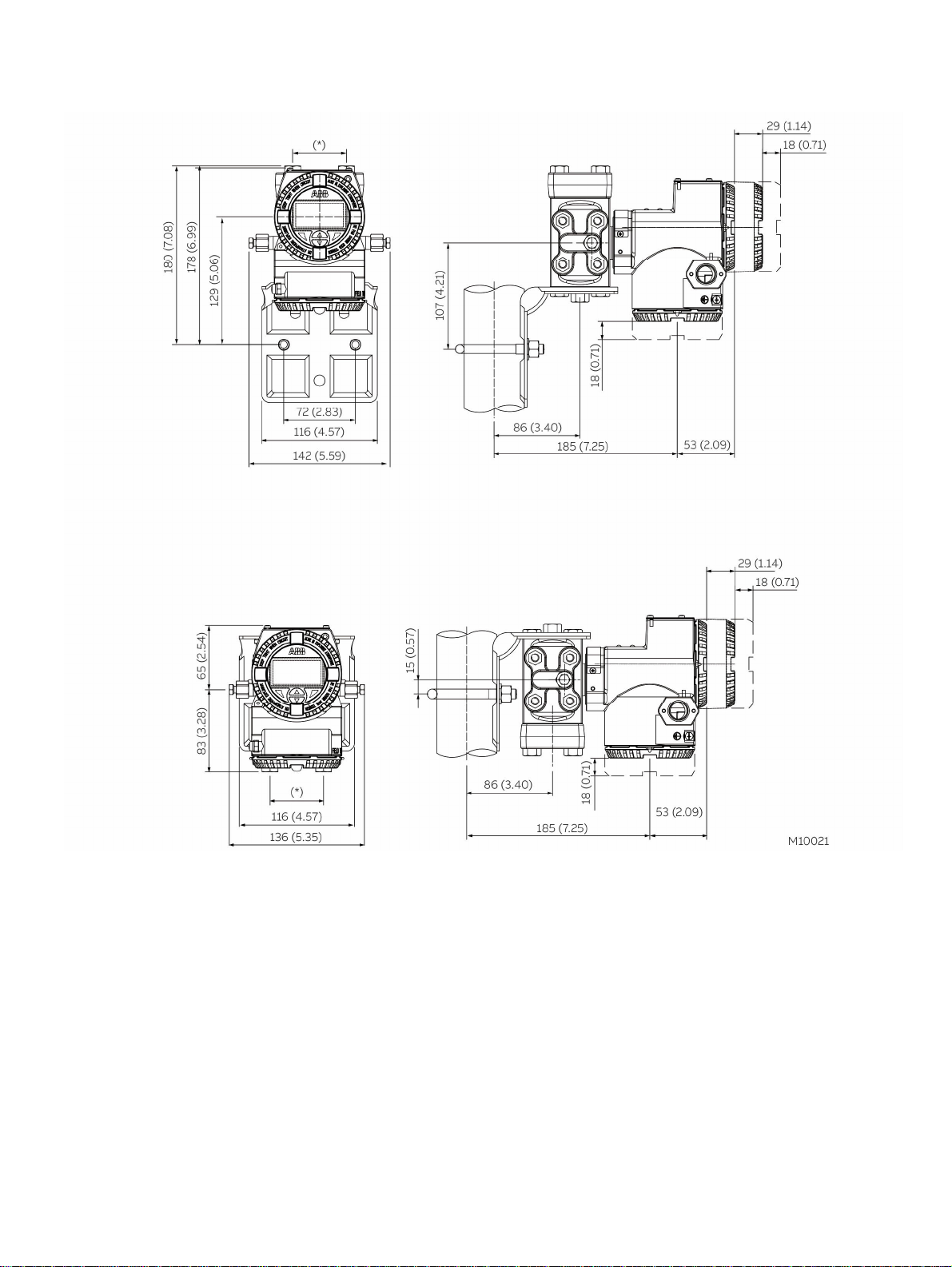

8.6.4 Transmitter with DIN aluminum housing - horizontal flanges with mounting bracket for vertical or horizontal mounting

on 60 mm (2 in.) pipe

Fig. 12 : P ipe mount ing - DIN h ous ing

* 54 (2.13) mm (in.) via 1/4 - 18 NPT process flanges

51 (2.01), 54 (2.13), or 57 (2.24) mm (in) via 1/2 - 14 NPT adapter flanges.

Note: Process connect io n and sea l gro ove sat is fy I EC 161518. Thread for attaching adapt e r f lang es or ot he r c ompon ent s (e.g. , manif ol d) on t he p roc ess f lange:

7/16 -20 UNF.

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 21

Page 22

8.6.5 Transmitter with flat bracket, for vertical or horizontal mounting on 60 mm (2 in.) pipe

Fig. 13 : Fl at brack et f or pipe mounting - ba rr el housing

* With screw plug

** With vent / drain valve

Change from one to two col umns

22 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 23

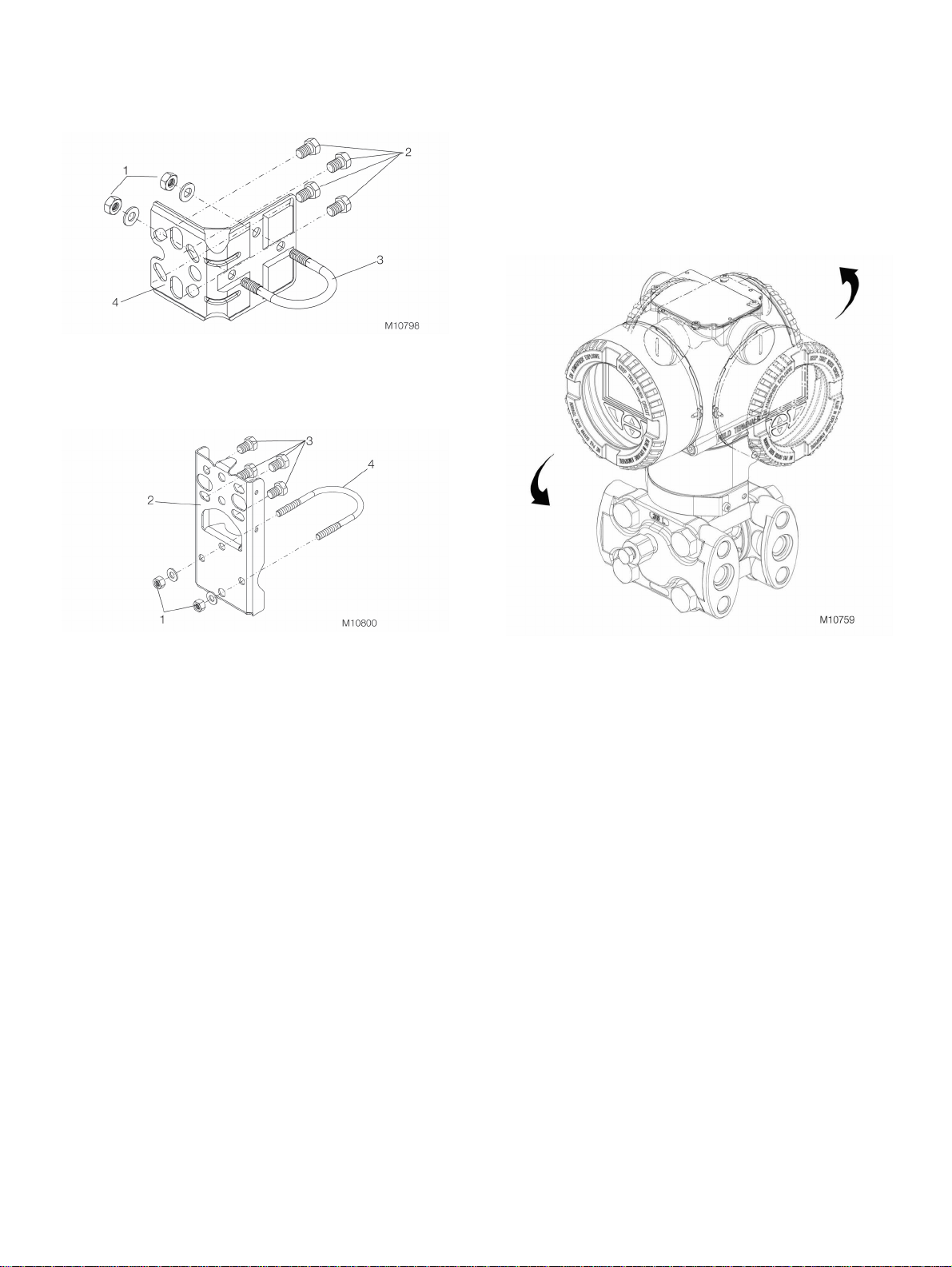

8.6.6 Installation via (optional) mounting brackets

With the mounting brackets available the transmitter can be

mounted in different positions.

Fig. 14 : Detail v ie w of the mounting brac k et , B2, f or pipe and wall

installat ion.

1 Washers and nuts f or f asteni ng t he U-bolt |

2 Mounting s c rews for t he trans mitter |

3 U-bolt | 4 Mounting bracket

8.7 Rotating the transmitter housing

To improve access to electrical connections and for better

visibility of the optional LCD display in the field, the

transmitter housing can be rotated through 360°. A stop

prevents the housing from being turned too far.

In order to rotate the housing, the fixing screw must be

loosened and unscrewed approx. one revolution (do not

remove it). As soon as the desired position is reached, the

fixing screw will be retightened.

Fig. 15: Detail view of the mounting bracket, B5

1 Washers and nuts f or f asteni ng t he U-bolt |

2 Mounting brac k et in f lange des ign, B 5 |

3 Mounting s c rews for t he trans mitter |

4 U-bolt

Fig. 16 : Rotat ing housing

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 23

Page 24

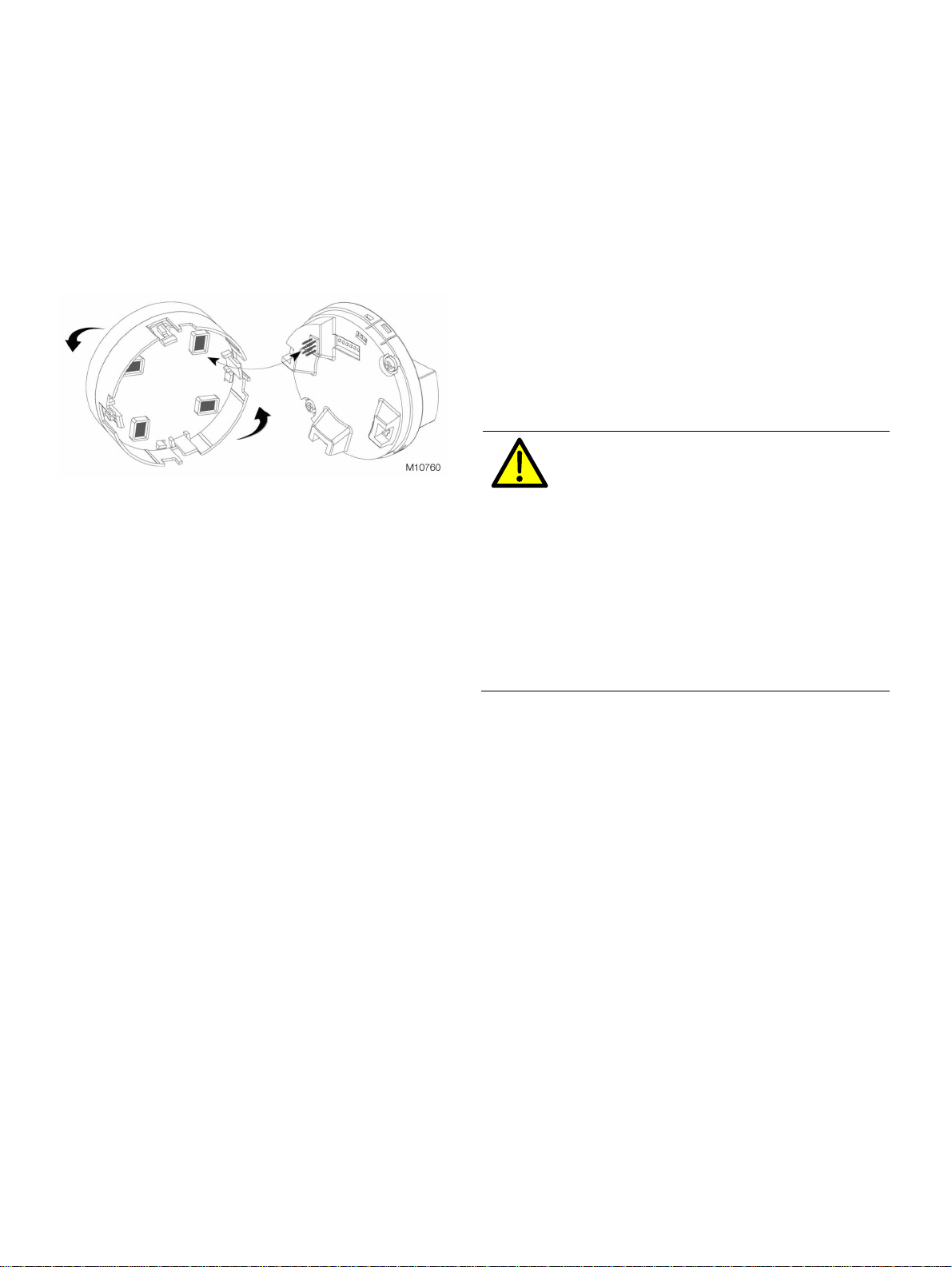

8.8 Rotating the integral LCD display

If the device has an integral LCD display, this can be

mounted in four different positions, each of which can be

rotated through 90°.

To rotate the LCD display, open the windowed cover

(ensuring compliance with special requirements for

hazardous areas) and pull the LCD display out of the

electronics module. Reposition the LCD display connector

accordingly. Plug the LCD display back into the electronics

module, checking that the 4 plastic fixing locks are securely

in place.

Fig. 17 : Rotat ing the LCD di splay

8.9 Connecting impulse lines

In order for the impulse lines to be laid correctly, the

following points must be observed:

— The impulse lines must be as short as possible and have

no sharp bends

— Lay the impulse lines so that no deposits can

accumulate in them. Gradients should not be less than

approx. 8 % (ascending or descending)

— The impulse lines should be blown through with

compressed air or, better still, flushed through with the

medium prior to connection

— With wet legs, the liquid in both lines must be at the

same level

— With vaporous measuring media, measures must be

taken to prevent steam entering the measuring

chambers of the measuring cell and causing overheating

— It may be necessary to use condensate vessels or

similar with small measuring spans and vaporous media

— If you are using condensate vessels (steam

measurement), you should ensure that the vessels are at

the same elevation in the differential pressure piping

— As far as possible, keep both impulse lines at the same

temperature

— Completely depressurize the impulse lines if the medium

is a liqu id

— Lay the impulse lines so that gas bubbles (when

measuring liquids) or condensate (when measuring

gases) can flow back into the process line

— Ensure that the impulse lines are connected correctly

(connection of high-pressure and low-pressure sides to

the measuring cell, seals, etc.)

— All connections must be secure and tight

— Lay the impulse lines so that the medium cannot be

blown out over the measuring cell

WARNING – bo dily injury!

Leaks in the process lines can result in death or

severe injuries.

Install and seal process connections and all

accessory elements (including valve blocks)

before the charging the device with pressure.

For applications with toxic or hazardous

substances prior to venting or draining, take all

precautionary measures that are recommended

in the respective safety data sheet. Only tighten

the screws of the fastening accessories with a

size 12 mm (15/32”) inch hexagon socket

wrench.

24 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 25

8.10 Process connections

Fig. 18

On the flange of the 266 multivariable transmitter there are

1/4 – 18 NPT process connections with middle point

spacings of 54 mm (2.13 in.). The process connections on

the flange enable direct attachment of 3 element or 5

element valve manifolds.

Optionally flange adapters with 1/2 – 14 NPT connections

are available. By turning one or both adapters, middle point

spacing of 51 mm (2.01 in.), 54 mm (2.13 in.) or 57 mm

(2.24 in.) is possible.

Mount the adapters as follows:

1. Correctly position the adapters with inserted O-ring.

2. Screw the adapters on the transmitter connection flange

with the provided screws.

Tighten the scr ews as follows: Preliminary tightening

hand tight, preliminary tightening with 10 Nm, final

tightening with 50 Nm.

8.11 Temperature measurement

— Mount the temperature sensor in the downstream pipe of

the primary element.

— Consider the downstream straight pipe requirements .

— If there is a significant difference between the

temperature of the measuring medium and the ambient

temperature, the measuring error caused by heat

conduction must be minimized by insulating the

installation location accordingly.

— Use class "A" sensors to maximize accuracy.

— The lengths of the protective tubes should be

15 ... 20 times the diameter of the protective tube for gas

measurements and 3 ... 5 times the diameter of the

protective tube for liquid measurements.

8.12 Mounting recommendations

The arrangement of the impulse lines depends on the

respective measurement application.

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 25

Page 26

8.12.1 Flow measurement of steam (condensible vapor) or

clean liquids

8.12.2 Flow measurement of gas or liquid with solids in

suspension

Fig. 19 : St eam f low measurement

A High-press ure v alve | B Low press ure v alve |

C Equaliz ing v alve | H High pres s ure s ide | L Low pres s ure side

Place taps to the side of the process line.

For liquid measurements, mount the transmitter next to or

underneath the taps, for steam measurements underneath

the taps.

Mount the vent / drain valve pointing upward.

For steam applications, fill the vertical section of the impulse

lines with a compatible fluid through the appropriate filling

connections.

The height of the liquid column between process line and

transmitter must be the same on the high pressure side and

the low pressure side, so that an accurate measurement is

ensured. For implementation of this requirement it can be

practical for steam measurements, to use the impulse lines

condensate tanks.

To commission the transmitter, operate the valves in the

following sequence:

1. Open the equalizing valve (C)

2. Close the low pressure valve (B) and high pressure

valve (A).

3. Open the primary shutoff valves

4. Slowly open the high pressure valve (A) so that the

measuring medium can flow into the measuring cell on

both sides.

5. Vent or drain the measuring cell and close the valves.

6. Open the low pressure valve (B) and close the

equalizing valve (C).

Fig. 20 : Flow measureme nt of gas es or li q uids

A High-press ure v alve | B Low press ure v alve |

C Equaliz ing v alve | H High pres s ure s ide | L Low pres s ure side

Place taps above or to the side of the line.

Mount the transmitter above the taps.

To commission the transmitter, operate the valves in the

following sequence:

1. Open the equalizing valve (C)

2. Close the low pressure valve (B) and high pressure

valve (A).

3. Open the primary shutoff valves

4. Slowly open the high pressure valve (A) so that the

measuring medium can flow into the measuring cell on

both sides.

5. Vent or drain the measuring cell and close the valves.

6. Open the low pressure valve (B) and close the

equalizing valve (C).

26 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 27

8.12.3 Fill level measurement on closed tanks

Non-condensing measuring medium (dry leg)

Condensing measuring medium (wet leg)

Fig. 22 : Level measurement on c los ed t ank s (w et leg)

Fig. 21 : Level measurement on c los ed t ank s (dry leg)

Mount the transmitter at the same height or below the lowest

level to be measured.

Connect the high pressure side "+" (H) of the transmitter to

the bottom of the tank.

Connect the low pressure side "-" (L) of the transmitter to the

top of the tank, above the maximum level.

Mount the transmitter at the same height or below the lowest

level to be measured.

Connect the high pressure side "+" (H) of the transmitter to

the bottom of the tank.

Connect the low pressure side "-" (L) of the transmitter to the

top of the tank, above the maximum level.

Fill the vertical part of the impulse line of the low pressure

side with a compatible filling liquid via the appropriate filling

connections.

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 27

Page 28

8.12.4 Fill level measurement on open tanks with fluids

Fig. 23 : Level measurement on op en t ank s

Mount the transmitter at the same height or below the lowest

level to be measured.

Connect the high pressure side "+" (H) of the transmitter to

the bottom of the tank.

Leave the low pressure side “–” (L) of the transmitter open to

the atmosphere.

8.12.5 Fill level measurement on the steam boiler (drum

water level)

Fig. 24 : Level measurement on the s t eam boiler

Mount the transmitter at the same height or below the lowest

level to be measured.

Connect the high pressure side "+" (H) of the transmitter to

the bottom of the tank.

The low pressure side “–” (L) of the transmitter up at the

tank. Above the maximum level, connect using a condensate

vessel.

Use the condensate tank to ensure that the impulse line of

the low pressure side is always filled with liquid (condensate)

at a constant height.

28 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 29

9 Electrical connections

The relevant directives must be complied with for the

electrical installation!

Because the transmitter cannot be switched off, surge

protection devices, lightning protection, or grid disconnect

possibilities must be provided at the plant.

NOTICE - material damage due to electrostatic

discharge!

An open cover does not provide contact

protection. Touching conductive parts can

damage electronic components (in some cases

beyond repair) due to electrostatic discharge.

Therefore, do not touch conductive

components.

Check that the existing supply voltage corresponds to that

indicated on the rating plate. The same lines are used for

both the power supply and the output signal.

If an optional surge protector is provided and if the

transmitter is used in a hazardous area, energy must only be

supplied via a voltage source with galvanic isolation from the

grid. Because the inherently safe power circuits of the

transmitter are grounded, a sufficient equipotential bonding

must be ensured for the entire supply line.

DANGER – explosion hazard!

If the type of protection specified on the

certification plate does not agree with the

requirements imposed on the implementation

site, explosions or fires can be triggered. In this

case the transmitter must NOT be connected

electrically.

DANGER - severe health impairments / lifethreatening danger!

The lines can carry dangerous touch voltages

and cause electric shocks. An electric shock

can be fatal or can cause serious injuries.

Consequently do not touch the conductors and

connection terminals.

Change from tw o to one col umn

9.1 Cable connections

The electric connection is made using a 1/2-14 NPT or

M20 x 1.5 cable entry. Basically, a metal cable gland should

be provided for th Pt100 cable, since a shielded cable will be

used. Connect the shielding within the metal cable gland!

To ensure an 4X and IP 66-67 IP rating for the transmitter,

the cable gland must be screwed into the housing (1/2" NPT

female thread) using a suitable sealing compound.

IMPORTANT (NOTICE)

If cable glands are not used, the red transport

screw plugs must be replaced with suitable

screw plugs when the transmitter is installed.

This is because the transport screw plugs are

not certified as protected against explosion.

This requirement is particularly relevant in

hazardous areas.

IMPORTANT (NOTICE)

For the purpose of simulation, a 178 Ω resistor

(206°C / 402.8°F) with 2 jumpers has been

installed between the terminals for the Pt100

connection. This resistor (including the jumpers

in the case of 4-wire connections) must be

removed before connecting the Pt100. If a

Pt100 is not connected, the resistor must not be

moved.

IMPORTANT (NOTICE)

For category 3 transmitters for use in “Zone 2” a

type of protection approved for this cable gland

must be provided by the customer (see chapter

“Ex-relevant technical data”). An appropriate

thread M20 x 1.5 must be provided in the

electronics housing for this purpose.

for transmitters with “Ex d”, Flameproof

Enclosure” the housing cover must be arrested

with the securing screw.

The screw plug possible provided with the

transmitter must be inserted on site with the

sealant, Molykote DX. If a different sealant is

used, the responsibility rests with the executing

installer.

At this point we expressly state that after

several weeks the housing cover can only be

unscrewed with an increased expenditure of

force. This is not caused by the threads, but

instead is due solely to the type of seal.

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 29

Page 30

9.2 Connection of the analog output (HART)

Fig. 25 : Elec t rical connect ions

1 Digital out put | 2 Connec tion for Pt100 res ist anc e thermom et er | 3 Int ernal ground c onnec tion | 4 External ground connec t ion |

5 Remote display | 6 Handheld termi nal | 7 P ower s upply

Change from one to two col umns

For connection of signal voltage / supply voltage twisted

cable with a conductor cross section of 18 … 22 AWG /

0.8 … 0.35 mm2 to2 to max. 1500 m length must be used.

Avoid cable installation, together with other power lines (with

inductive load, etc.), as well as the vicinity to large electrical

installations.

For longer leads a greater cable cross section is required.

For shielded cables the cable shielding must only be placed

on one side (not on both sides). For the grounding on the

transmitter the inner terminal marked with can also be

used. The output signal (4 ... 20 mA) and the power supply

are conducted via the same conductor pair. The transmitter

always works with a supply voltage between 10.5 and 42 V

DC.

The HART handheld terminal can be connected to any

connection point in the circuit if a resistance of at least

250 Ω is present in the circuit. If there is resistance less than

250 Ohm an additional resistor must be provided to enable

communication. The handheld terminal is connected

between the resistor and transmitter, not between the

resistor and the power supply.

For devices with “Ex ia” type of protection, “Intrinsic Safety”

(FM, CSA, and SAA approval) the supply voltage must not

exceed 30 V DC. In some countries the maximum supply

voltage is limited to lower values. The permissible supply

voltage is specified on the name plate on the top of the

transmitter.

The possible line length depends on the total capacity and

the total resistance and can be estimated based on the

following formula.

65 x 10

L =

6

C

+ 10000

f

-

R x C C

L = Line length in meters

R = Total resistance in Ohm

C = Line capacity

Cf = Maximum internal capacity in pF of the HART field

devices in the circuit

30 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Page 31

9.3 Digital output (pulse / limit output)

This digital output can be set as a pulse or limit output

(transistor output) by making parameter changes using the

software.

NPN transistor with open-collector output

Contact swit c hing c apac ity 10 … 30 V, m axim um 120 mA DC

Low-level output v oltage 0 … 2 V

High-level out put v oltage Maximum 30 V

Quiescent current 500 µA

9.4 Wiring

Proceed as follows to wire the transmitter:

— Unscrew the transport screw plug from one of the two

cable entries located on both sides in the upper part of

the transmitter housing

— These cable entries have a 1/2 inch NPT or M20x1.5

female thread. Various adapters and bushings can be

fitted to these threads to comply with plant wiring

(conduit) standards

DANGER - Risk to life due to explosion!

In an explosion-proof / flameproof installation in

a hazardous area, the housing cover of the

terminal compartment must not be removed

when the voltage is connected, as an explosion

may be caused by spark formation. Before

removing the housing cover of the terminal

compartment, disconnect the equipment from

the supply voltage and take suitable measures

to prevent reconnection.

— Remove the housing cover from the terminal

compartment.

— Run the connection cable through the opening and

connect the + wire to the + terminal and the - wire to the

– terminal.

— Run the temperature sensor cable (if there is one)

through the second cable entry and connect it to the

designated terminals

IMPORTANT (NOTICE)

Do not connect the supply voltage across the

test terminals. It could damage the test diode in

the test connection.

— Replace the housing cover on the terminal compartment

and tighten it by hand until the cover contacts the

housing metal-to-metal. To prevent the housing cover

from turning, in "Ex-d” type of protection (flameproof

enclosure) installations, lock it by turning the locking

screw / hex-head screw anti-clockwise with the

2 mm Allen key supplied with the device.

1 Cover safety screw

Fig. 26

WARNING – bo dily injury!

If the cables, cable glands and stopper plugs

used for the electrical connection do not satisfy

the requirements for the type of protection (e.g.

intrinsic safety, flameproof enclosure, etc.) and

the necessary degree of protection for the

housing (e.g. IP 6x in accordance with IEC EN

60529 or NEMA 4x), explosions or fires can be

triggered.

For this reason, the red plastic transport caps

must be replaced with cable glands or stopper

plugs, that are approved for the required type of

protection and the required degree of protection

for the housing. See section “Ex-relevant

technical data”.

9.5 Protective conductor connection / grounding

For the ground (PE) of the transmitter or the connection of a

protective conductor, a connection is available on the

exterior of the housing, and also in the terminal

compartment. Both connections must be galvanically

connected to one another. These connection points can be

used if grounding or the connection of a protective conductor

is prescribed by national regulations for the selected type of

supply or the type of protection used.

— Plug and seal the cable entries. Make sure that when the

installation has been completed, these openings are

properly sealed to prevent the entry of rain and corrosive

vapors and gases. In particular, for "Ex-d" (flameproof

enclosure) installations, plug unused openings with a

suited sealing plug that has been certified for explosion

protection.

— If applicable, install the connection cable with a drip

loop. Arrange the drip loop so the lower part is located

below the cable entry and the transmitter housing

Fig. 27

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 31

Page 32

10 Commissioning

10.1 G eneral remarks

Once the pressure transmitter has been installed, it is put

into operation by switching on the operating voltage.

Prior to switching on the operating voltage check:

— Process connections

— Electrical connection

— Complete filling of the impulse line and measuring

chamber of the measuring cell with the measuring

medium.

The transmitter can then be put into operation.

To do this, the valves must be actuated in the following order

(in home position, all valves are closed):

1. Open the shut-off valves on the pressure tap connection

(if present).

2. Open the pressure equalization valve of the valve block.

3. Open the shut-off valve of the high pressure side (H) on

the valve block.

4. Open the shut-off valve on the low pressure side (L) on

the valve manifold.

5. Close the pressure equalization valve.

Decommissioning is executed in the reverse sequence.

If, when using transmitters with type of protection "intrinsic

safety", an ammeter is connected to the output circuit or a

modem is connected in parallel while there is a risk of

explosion, the sums of the capacitances and inductances of

all circuits, including the transmitter (see EC-typeexamination certificate) must be equal to or less than the

permissible capacitances and inductances of the intrinsically

safe signal circuit (see EC-type-examination certificate for

the power supply unit).

Only passive or explosion-proof test devices or display

instruments may be connected.

10.2 O utput signal

If the applied pressure is within the values indicated on the

rating plate, the output current ranges between 4 and 20 mA.

If the pressure applied falls outside the set range, the output

current will be between 3.5 mA and 4 mA if the range is

underranged or between 20 mA and 22 mA if the range is

overrranged (depending on the respective configuration).

Standard setting for normal operation

3.8 mA / 20.5 mA

A current that is < 4 mA or > 20 mA may also indicate that

the microprocessor has detected an internal error.

Standard setting for error detection

21.8 mA

In this case diagnosis of the error can be executed with the

aid of different configuration tools.

IMPORTANT (NOTICE)

A brief interruption in the power supply results

in initialization of the electronics (program

restarts).

10.3 Zero point correction following installation

Once the transmitter has been installed, it is advisable to

check the zero point and correct it if necessary.

If the output signal stabilizes only slowly, it is likely that a

large damping time constant has been set on the transmitter.

32 OI/266CXX/266JXX/HART-EN Rev. C | 266CRx, 266JRx, 266CSx, 266JSx

Fig. 28: Operating buttons, write protection turn switch

1 Zero | 2 Span | 3 Write protection switch

Page 33

10.3.1 Setting precalibrated devices

(The lower range value has already been set to 0.)

266Cxx transmitters do not support this function if the "Level

measurement" calculation function has been activated. In

this case, the correction must be made using the optional

LCD indicator, the handheld terminal, or the DTM.

IMPORTANT (NOTICE)

For this purpose, the DIP switch on the

electronics board must be set to position 1.

A PV Bias / Offset correction can be performed via the local

push buttons as follows:

— Separate the transmitter from the process and equalize

the pressure in the two measuring chambers by

adjusting the bypass valve in the manifold.

— Check the transmitter output signal

If it is at 4 mA (or PV = 0), zero point correction is not

required.

I f t he output is not at zero, proceed as follows:

— Unscrew the screws attaching the name plate to the top

of the transmitter housing

— Rotate the name plate so that the push buttons can be

accessed

— Check that the write protection rotary switch is set to

write enable

— Press and hold down the zero button (Z) on the top of

the transmitter for at least 3 seconds

The output signal switches to 4 mA and the message

“OPER DONE” appears on the LCD display (if there is

one).

— If nothing happens, check the write protection rotary

switch.

It is probably set to write protection.

— For all other diagnosis notices, refer to the instructions

— As soon as zero point correction is complete, reconnect

the transmitter to the process

— Open the pressure equalization valve on the manifold.

— Open the shut-off valve of high-pressure side

— Open the pressure equalization valve on the manifold.

— Open the shut-off valve on the low-pressure side

10.3.2 Zero-point increase/suppression on precalibrated

devices

(e.g., 4 ... 20 mA = -100 ... 100 mbar)

This function is only supported by 266Jxx and 266Cxx

transmitters if the calculation function has been disabled.

IMPORTANT (NOTICE)

For this purpose, the DIP switch on the

electronics board must be set to position 0.

— Isolate the transmitter from the process and vent the

transmitter measuring chamber(s) to atmosphere

— Apply the lower range value pressure (4 mA).

The pr essure must be stable and applied with a high

level of accuracy (< 0.05 %, observing the set damping

value)

— Check the transmitter output signal

If it is at 4 mA (or PV = 0), zero point correction of the

transmitter is not required.

I f t he output is not at zero, proceed as follows:

— Unscrew the screws attaching the name plate to the top

of the transmitter housing

— Rotate the name plate so that the push buttons can be

accessed

— Check that the write protection rotary switch is set to

write enable.

— Press and hold down the zero button (Z) on the top of

the transmitter for at least 3 seconds

The output signal switches to 4 mA and the message

“OPER DONE” appears on the LCD display (if there is

one)

— If nothing happens, check the write protection rotary

switch.

It is probably set to write protection.

— For all other diagnosis notices, refer to the instructions

— As soon as zero point correction is complete, reconnect

the transmitter to the process

— Open the pressure equalization valve on the manifold.

— Open the shut-off valve of high-pressure side

— Open the pressure equalization valve on the manifold.

— Open the shut-off valve on the low-pressure side

IMPORTANT (NOTICE)

After the transmitter has been adjusted as

described above, the zero bias / offset value is

activated and stored in the memory of the

transmitter. In this case calibration of the

transmitter is can no longer be executed. Only if

the PV bias / offset value is reset, will a sensor

calibration be possible again.

266CRx, 266JRx, 266CSx, 266JSx | OI/266CXX/266JXX/HART-EN Rev. C 33

Page 34

11 Configuration

The transmitter is delivered preconfigured according to the

information provided when placing the order. However,

should a change to the configuration be necessary (because

measuring point data has changed since the original plans

were drawn up, for example), the following options are

available:

— Local keypad for the LRV / URV setting (266Jxx only)

and zero point correction following installation

— Menu-led configuration of the transmitter with the

integrated LCD indicator

— Configuration using a handheld terminal

— Configuration using a PC / laptop with graphical user

interface (DTM)

How to use these tools to make the configuration settings is

described in the corresponding related documentation.

11.1 Wr ite protection

The write protection prevents unauthorized users from

overwriting the configuration data. With activated write

protection the operating buttons "0% (Z)" and "100 % (S)"

have no function.

A change of parameters with the integral LCD indicator, via a

handheld terminal, or the user interface (DTM) are not

possible either.

However the configuration data can be read out via the

graphic user interface (DTM) or a comparable

communication tool. If needed the operating device can also

be sealed with a lead seal.

Write protection can be activated as follows (see also the

symbols on the plate).

1. Use a suitable screwdriver to press the switch all the

way down.

2. Turn the switch 90° clockwise.

11.2 Hardware settings

Fig. 30: DIP switches (example, HART version)

There are six DIP switches on the secondary electronics.

They are used to make settings if an LCD display is not

present.

DIP switches 1 and 2 activate REPLACE MODE for the

sensor and the secondary electronics (NEW SENSOR / NEW

ELECTRONIC).

DIP switch 3 specifies the functions of the external

pushbuttons (Z/S) PUSHBUTTON MODE). Zero corrections /

span corrections or PV offset (bias) / PV offset (bias) reset.

DIP switches 4 and 5 are use to select the alarm current

(high / low).

IMPORTANT (NOTICE)