Page 1

Technical Data Sheet No.: VTX180002 Rev. D

Date of Issue: September 2010

US Patent No. 4,862,750

OPERATING MANUAL

Vortex Meter

Page 2

Aalborg7is a registered trademark of Aalborg Instruments & Controls.

NOTE: Aalborg7 reserves the right to change designs and dimensions at its sole

discretion at any time without notice. For certified dimensions please contact Aalborg7.

Page 3

TABLE OF CONTENTS

1. GENERAL INFORMATION...................................................

1.1 General................................................................................................

1.2 Principles of Operation........................................................................

1.3 Sensor Operation.................................................................................

1.4 Calibration Factor.................................................................................

2. HANDLING AND STORAGE.................................................

2.1 Handling Precautions..........................................................................

2.2 Storage................................................................................................

3. INSTALLATION................................................................

3.1 Installation...........................................................................................

3.2 Selecting the Installation Site...............................................................

3.3 Piping Guidelines.................................................................................

3.4 Temperature and Pressure Taps..........................................................

3.5 Orientation...........................................................................................

3.6 Alignment Rings and Gaskets..............................................................

3.7 Identification Check..............................................................................

3.8 Installation Procedure..........................................................................

4. ELECTRONICS.....................................................................

4.1 Description................................................................................................

4.2 Specifications............................................................................................

4.3 Handling and Storage................................................................................

4.4 Mounting....................................................................................................

4.5. Wiring Connections..................................................................................

4.5.1 Power Supply Connections.......................................................................

4.5.2 Analog 4-20 mA Output Signals Connections............................................

4.5.3 Programmable optically isolated Output Signals Connections....................

4.5.4 Programmable optically isolated Flow Pulse Output

Signal Connections................................................................................

4.5.5 Communication Parameters and Connections..........................................

5. LCD KEYPAD OPERATION: DATA ENTRY AND CONFIGURATION...........

5.1 Display Indications......................................................................................

5.2 Menu Sequence.......................................................................................

5.3 Parameter Entry.........................................................................................

5.3.1 Submenu Program protection....................................................................

5.3.2 Submenu Flow Meter Info..........................................................................

5.3.3 Submenu Measuring Units........................................................................

5.3.4 Submenu L1 Alarm Menu...........................................................................

5.3.4.1 Submenu L2 Flow Alarm..........................................................................

5.3.4.2 Submenu L2 Temperature Alarm (*optional).......................................

1

1

1

1

2

2

2

3

3

3

3

5

5

6

6

7

7

8

8

9

10

11

11

12

13

13

14

15

15

15

19

22

22

23

24

26

26

29

Page 4

5.3.4.3 Submenu L2 Pressure Alarm (*optional).............................................

5.3.5 Submenu L1 Totalizer Menu................................................................

5.3.5.1 Submenu L2 Totalizer#1 and Totalizer#2 Menus..................................

5.3.5.2 Submenu L2 Pulse Output Menu................................................................

5.3.6 Submenu L1 Output Menu...................................................................

5.3.6.1 Submenu L2 Analog 4-20mA Menus....................................................

5.3.6.2 Submenu L2 Digital Optical Outputs Menus.........................................

5.3.6.3 Submenu L2 RS-485 Address Menus..................................................

5.3.7 Submenu L1 Calibration Menu................................................................

5.3.7.1 Submenu L2 PWM DSP Menu................................................................

5.3.7.2 Submenu L2 FFT DSP Menu................................................................

5.3.7.3 Submenu Meter Size.............................................................................

5.3.7.4 Submenu Meter Full Scale Range........................................................

5.3.7.6 Submenu Meter Low Flow Cut Off.......................................................

5.3.7.7 Submenu Meter Low Frequency Cut Off..............................................

5.3.7.8 Submenu Meter High Frequency Cut Off.............................................

5.3.7.9 Submenu Meter Vortex DSP Filter Coefficient..........................................

5.3.7.10 Submenu Meter Calibration Pilot Timer...............................................

5.3.8 Submenu L1 Date/Time Adjust Menu..................................................

5.3.9 Submenu L1 Fluid Menu........................................................................

5.3.9.1 Submenu L2 Flowing Fluid Menu........................................................

5.3.9.2 Submenu L2 Goyal-Doraiswamy Menu................................................

5.3.9.3 Submenu L2 API 2540 Menu..............................................................

5.3.9.4 Submenu Nat Gas AGA8 Menu............................................................

5.3.9.5 Submenu Other Gases Menu...............................................................

5.3.9.6 Submenu Cust Flow. Cond Menu........................................................

5.3.9.7 Submenu STD Temp. (F)......................................................................

5.3.9.8 Submenu STD Pres. (PSIA).................................................................

5.3.9.9 Submenu NORM Temp. (C).................................................................

5.3.9.10 Submenu NORM Pres. (KPA)..............................................................

5.3.10 Submenu L1 Diagnostic Menu.............................................................

5.3.10.1 Submenu L2 System Events Reg. Menu.............................................

5.3.10.2 Submenu L2 System Events Log Menu...............................................

5.3.10.3 Submenu Raw Pulse Counts................................................................

5.3.10.4 Submenu Pulse Frequency..................................................................

5.3.10.5 Submenu PWM Frequency...................................................................

5.3.10.6 Submenu AWD Frequency....................................................................

5.3.10.7 Submenu DSP FFT Output...................................................................

5.3.10.8 Submenu DSP FFT Output...................................................................

5.3.10.9 Submenu DSP FFT Average..................................................................

5.3.10.10 Submenu Piezo Sensors RMS.............................................................

5.3.10.11 Submenu Sensor Attenuation...............................................................

5.3.10.12 Submenu T/P ADC Output...................................................................

5.3.10.13 Submenu DAC Outputs Value..............................................................

5.3.10.14 Submenu CPU Temperature.................................................................

30

32

32

34

36

37

37

38

38

39

42

44

44

45

45

45

45

45

46

46

46

48

49

50

50

50

52

52

52

52

52

53

57

60

60

60

60

60

60

60

60

61

61

61

61

Page 5

5.3.11 Submenu L1 Display Menu......................................................................

5.3.11.1 Submenu Display Mode...........................................................................

5.3.11.2 Submenu Screen Cycle Time...................................................................

5.3.11.3 Submenu Screen Mask............................................................................

5.3.12 Submenu L1 Data Log Menu....................................................................

5.3.12.1 Submenu Data Logger Mode...................................................................

5.3.12.2 Submenu Data Log Configuration...........................................................

5.3.12.3 Submenu Log # of Samples.....................................................................

5.3.12.4 Submenu Process Variable.......................................................................

5.3.12.5 Submenu Samples Interval......................................................................

5.3.12.6 Submenu DL Start Condition...................................................................

5.3.12.7 Submenu DL Stop Condition...................................................................

5.3.12.8 Submenu Data Log Status.......................................................................

6. ANALOG CIRCUITRY CALIBRATION.............................................

6.1 Analog 4-20 mA output Circuitry calibration...........................................

6.1.1 Initial setup..............................................................................................

6.1.2 Analog 4-20 mA channel#1 output calibration.........................................

6.1.3 Analog 4-20 mA channel#2 output calibration.........................................

6.2 Temperature and Pressure Sensors Calibration*......................................

7. START UP...........................................................................

7.1 Cautions Prior to Start Up........................................................................

8. TROUBLESHOOTING.............................................................

8.1 Common Conditions................................................................................

8.2 Troubleshooting Guide.............................................................................

APPENDIX

APPENDIX A EEPROM VARIABLES........................................................

APPENDIX B VORTEX METER ASCII SOFTWARE INTERFACE COMMANDS........

APPENDIX C MECHANICAL DRAWINGS...................................................

APPENDIX D ELECTRICAL INTERCONNECT OPTIONS..................................

APPENDIX E CIRCUIT DIAGRAMS........................................................

WARRANTY..................................................................................

61

61

62

62

62

62

63

63

63

63

63

64

64

65

65

66

66

67

68

68

68

69

69

70

73

80

102

104

108

112

Page 6

1

1. GENERAL INFORMATION

1.1 General

Vortex Shedding is not new. Da Vinci observed vortex shedding in 1513. Von

Karman provided an empirically determined formula for it in 1911-1912. One

observes it as eddies downstream of a rock or a piling in a fast moving stream.

Yet, it wasn’t until it was successfully developed and installed in the late 1960’s

that this significant development in the science of flow measurement was given

considerable attention by industry.

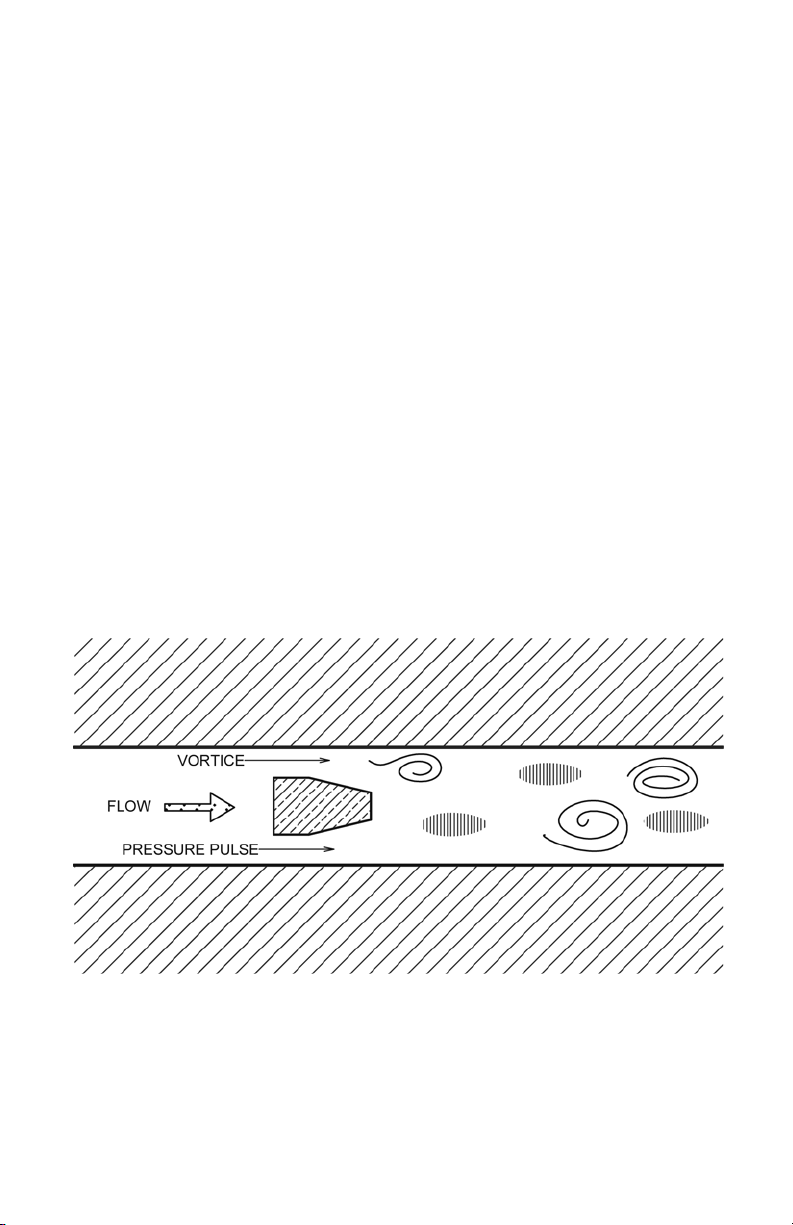

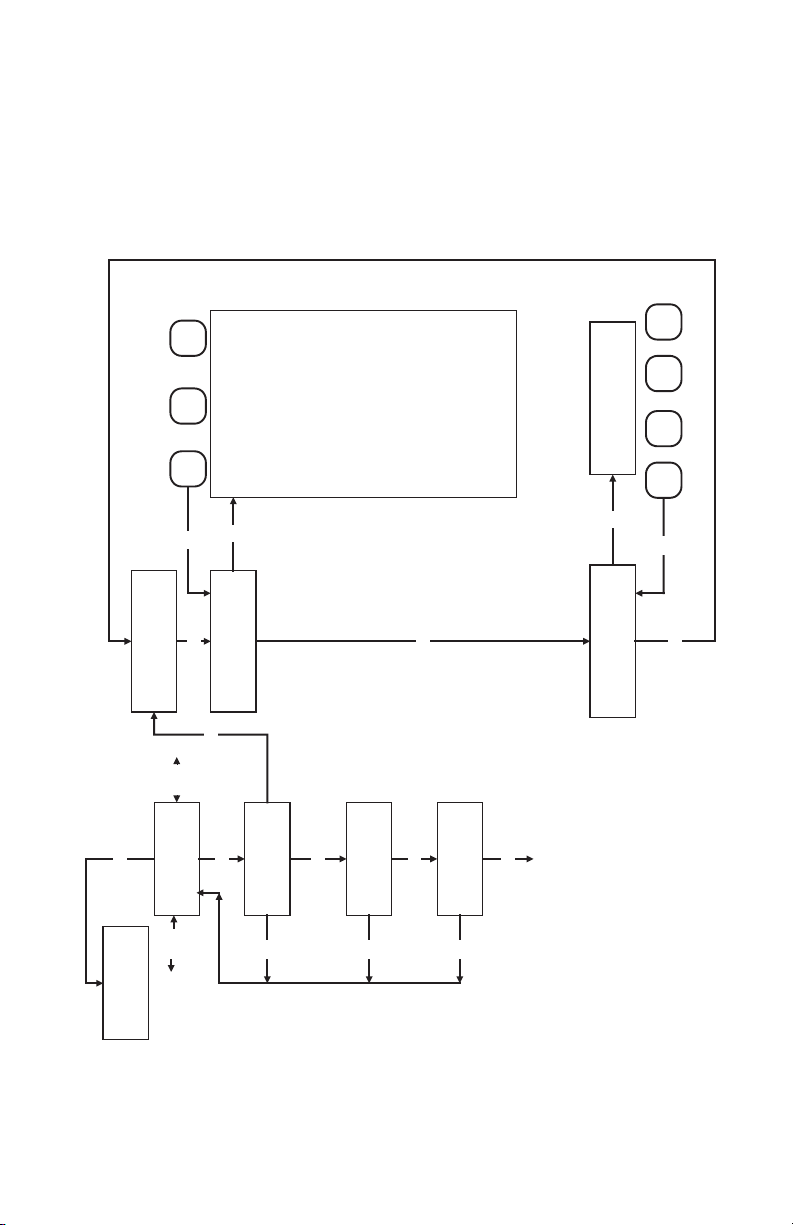

1.2 Principles of Operation

With the controlled use of an obstruction installed in a given pipeline, vortices

are generated downstream of the obstruction when fluid or gas flows through

a pipe. A vortex is a swirling low pressure eddy which forms alternately from

side to side of the bluff body. With each eddy, there is formed a corresponding

high pressure pulse opposite the bluff body. (See Figure 1.) These pulses are

directly proportional to the velocity of a given fluid. Each pulse represents given

volumetric units of fluid for a given line size. Since each pulse represents a unit

volume, the output is therefore linear with respect to flow rate.

FIGURE 1

Page 7

2

1.3 Sensor Operation

Two pressure sensing devices are mounted in the pipe wall of the flow meter.

Inserted in its center is a stainless steel bluff body, on either side

of which alternating stresses are induced in response to the forming and

shedding of vortices. The piezo electric sensors detect the pressure pulses, and

their energy content is amplified in the preamplifier and processed to furnish an

output proportional to the rate of flow.

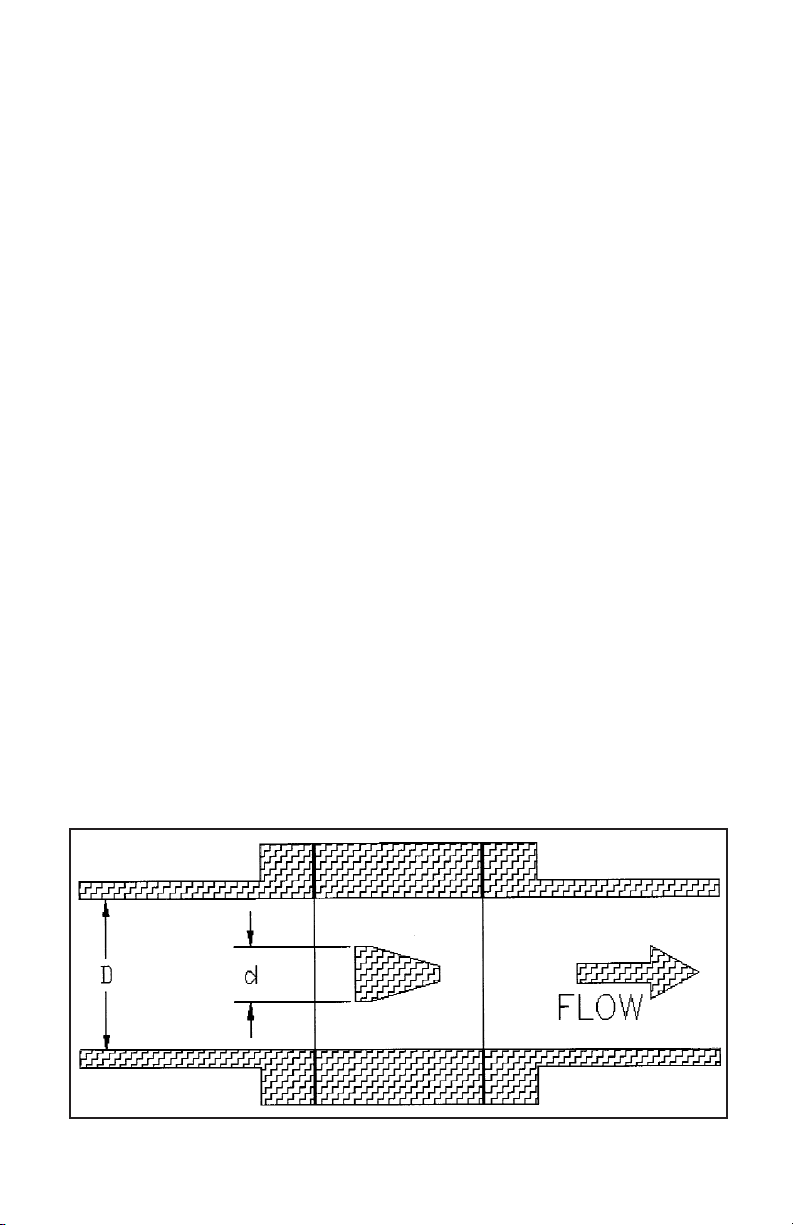

1.4 Calibration Factor

The frequency at which vortices are shed is a linear function of fluid velocity,

and therefore, a measure of flow. Vortex frequency is insensitive to density (temperature, pressure), the total volumetric flow of compressible fluids should however be adjusted to flow conditions other then calibration conditions. In the range

covered by the particular flowmeter, vortex frequency is insensitive to specific

gravity, viscosity, and temperature of the fluid and depends only upon the width

(d) in inches and shape of the flow element, and the inside diameter (D) of the

pipeline in inches.

The frequency is: F = SV/d

where : F = Karman vortex frequency

S = constant (Strouhal Number)

V = fluid velocity at the flow element

d = face width of the element

The frequency relationship is accurately linear and reproducible, eliminating the

need for “wet calibration.” (See Figure 2.)

2. HANDLING AND STORAGE

FIGURE 2

Page 8

3

2.1 Handling Precautions

The vortex flow meter has been tested at the factory. When the instrument is

received, it should be inspected for damage due to mishandling during

shipment. If damage is evident, report it to the carrier immediately and have

them present when the case is opened. They are responsible for any damage

during shipment. If you have any problems or questions, consult the factory or

your local representative.

2.2 Storage

After receiving the Flow Meter, care should be taken to avoid unnecessary

damage. If the meter is not scheduled to be installed soon after delivery, the

following steps should be observed:

A) After inspection, the meter should be repacked into its original packing.

B) If the meter being stored has been previously installed, care should be

taken to remove all process fluids and corrosives.

C) Select a clean, dry site free of mechanical vibration, shock and chemical

corrosives.

3. INSTALLATION

3.1 Installation

The Aalborg7 vortex flow meter is designed to operate under a wide variety of conditions. To ensure its longevity of operation, precautions should be taken before

and during its installation.

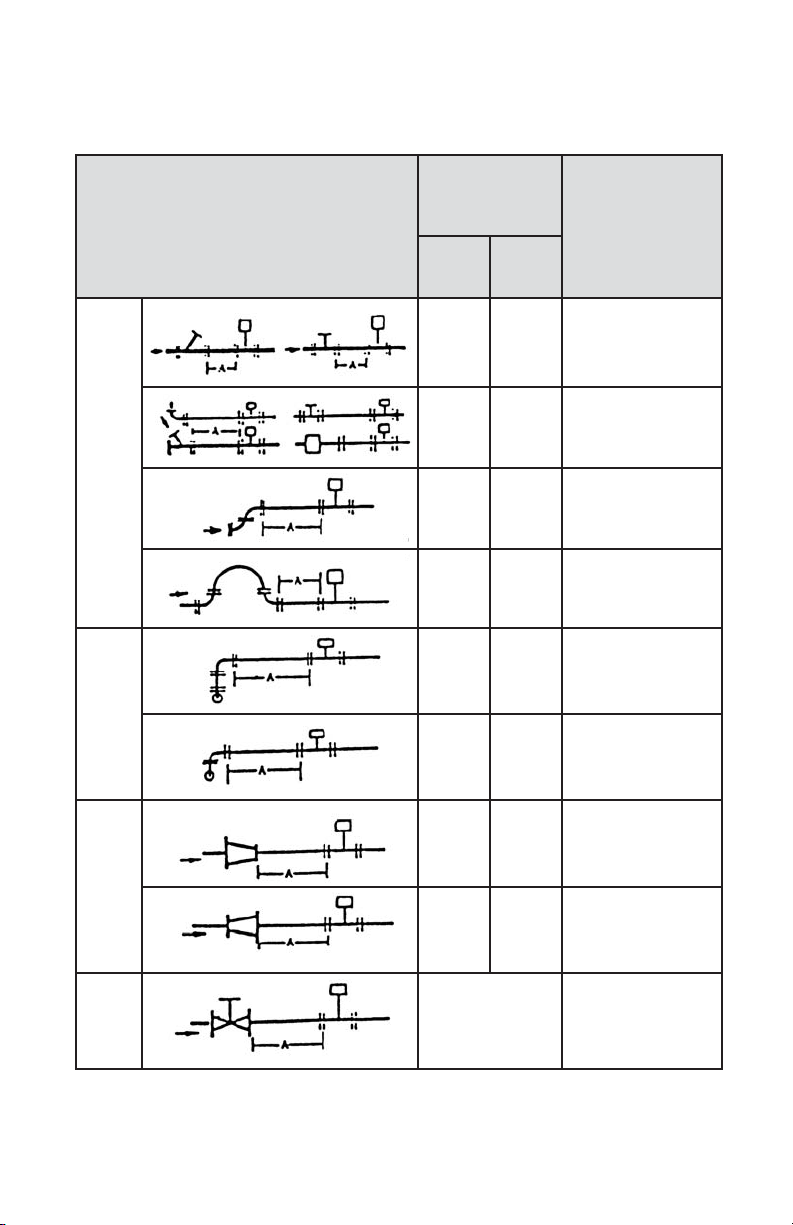

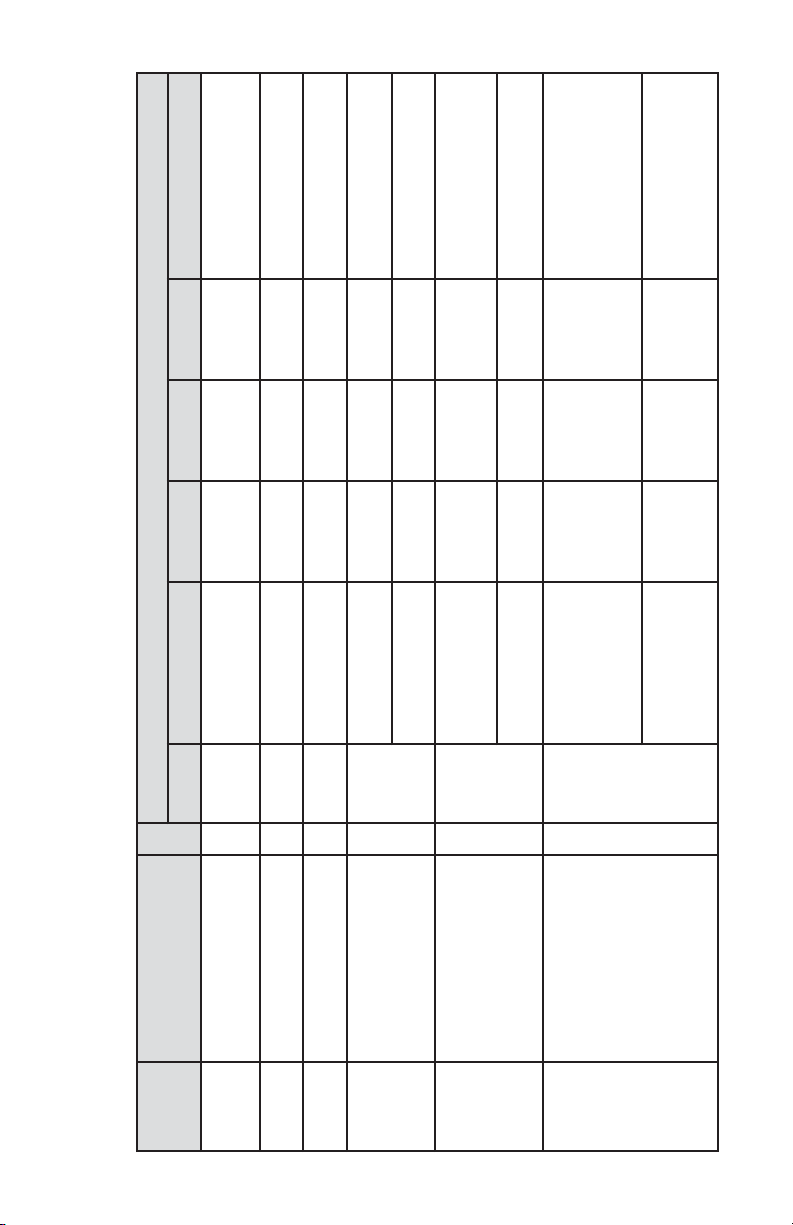

3.2 Selecting the Installation Site

A) The vortex meter requires a minimum of 20 straight diameters upstream

and 5 straight unobstructed diameters of downstream piping. One

diameter is equal to the internal pipe diameter. This is necessary to ensure

regulated formation of vortices. (See Figure 3 for the piping requirements

chart for various piping recommendations.)

B) Choose a site with minimal mechanical vibrations.

C) Avoid areas of high humidity or corrosive atmosphere where possible.

D) When installing the meter, choose a site which is accessible and allows

ease of wiring and maintenance.

Page 9

4

Piping Table

3.3 Piping Guidelines

FIGURE 3

TYPICAL PIPING

Recommended

Straight Pipe

Length “A”

REMARKS

Without

Vanes

With

Vanes

15D* 15D Closed branch

20D 15D

Elbow, Tee,

Branch pipe

25D 15D Elbow, 2 places

25D 15D Long-radius bends

30D

25D

15D

15D

Elbow

Long-radius bend

40D

35D

20D

20D

Elbow

Long-radius bend

20D 15D

Contracting pipe

40D 20D

Expanding pipe

Recommend Meter

Be Installed

Upstream

Regulating,

reducing valves Ball,

check valves

Shut-off valve

ALL FITTINGS IN SAME PLANE

FITTINGS IN

TWO PLANES

VARIED SECTION

VALVES

Page 10

5

Note : Straight pipe length on the downstream side to be 5 pipe

diameters minimum. *D = Pipe internal diameter.

To ensure the high accuracy of flow measurement specified on the identification

sheet, piping and installation instructions must be followed carefully.

A) The pipe immediately up and down stream of the flow meter must be of

sufficient length, straight and free of obstructions. Refer to the piping

requirements chart for exact dimensions (Figure 3).

B) It is recommended that straightening vanes be used on all vortex meters,

but it is not necessary.

C) The schedule of the pipe being used must match the schedule of the

meter for at least 20 diameters upstream and 5 diameters downstream of

the flow meter.

D) When the vortex meter is being used as a controller, it is recommended

that any regulating valve be located downstream of the flow meter.

E) Weld beads on the internal wall of the pipe before or after the flow meter

should be ground flush with the pipe wall before the meter is installed.

F) Proper style and proper size gaskets should always be used when

installing the flow meter.

G) The meter body and signal processor may be rotated into any position

permitted by the pipe flanges. The flow meter has no moving

parts and is not position sensitive.

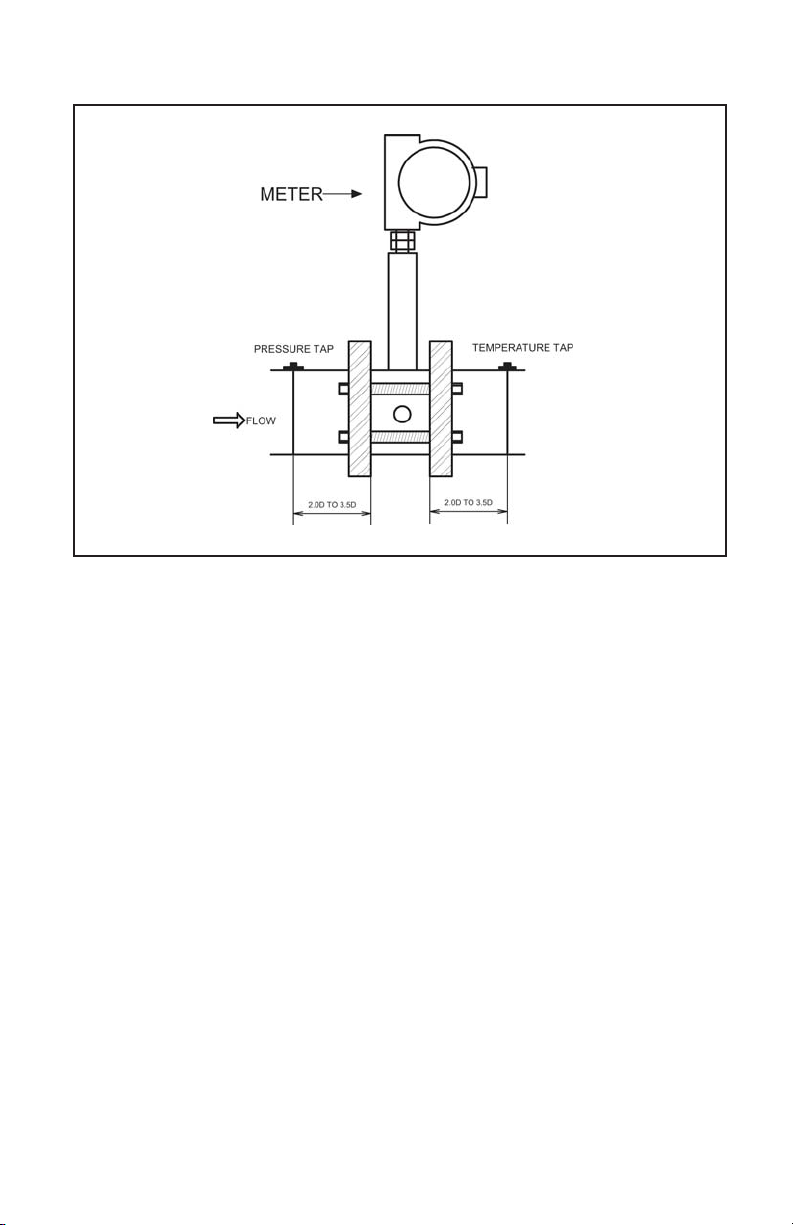

3.4 Temperature and Pressure Taps (Optional)

Installation of temperature and pressure transducers (if used) should be in

accordance with the manufacturer’s specifications.

A) The temperature transducer should be installed between 2.5 and 3.5

diameters from the downstream side of the wafer body. Consult the

factory for the exact dimensions, or refer to additional information at the

end of this manual.

B) The pressure transducer should be installed between 2.0 and 3.5

diameters from the upstream side of the wafer body. Consult the factory

for the exact dimensions, or refer to additional information at the end of

this manual (See Figure 4).

Page 11

6

3.5 Orientation

FIGURE 4

The flow meter uses piezo-electric sensing elements with no moving parts. This

eliminates wear and allows for vertical or horizontal installation.

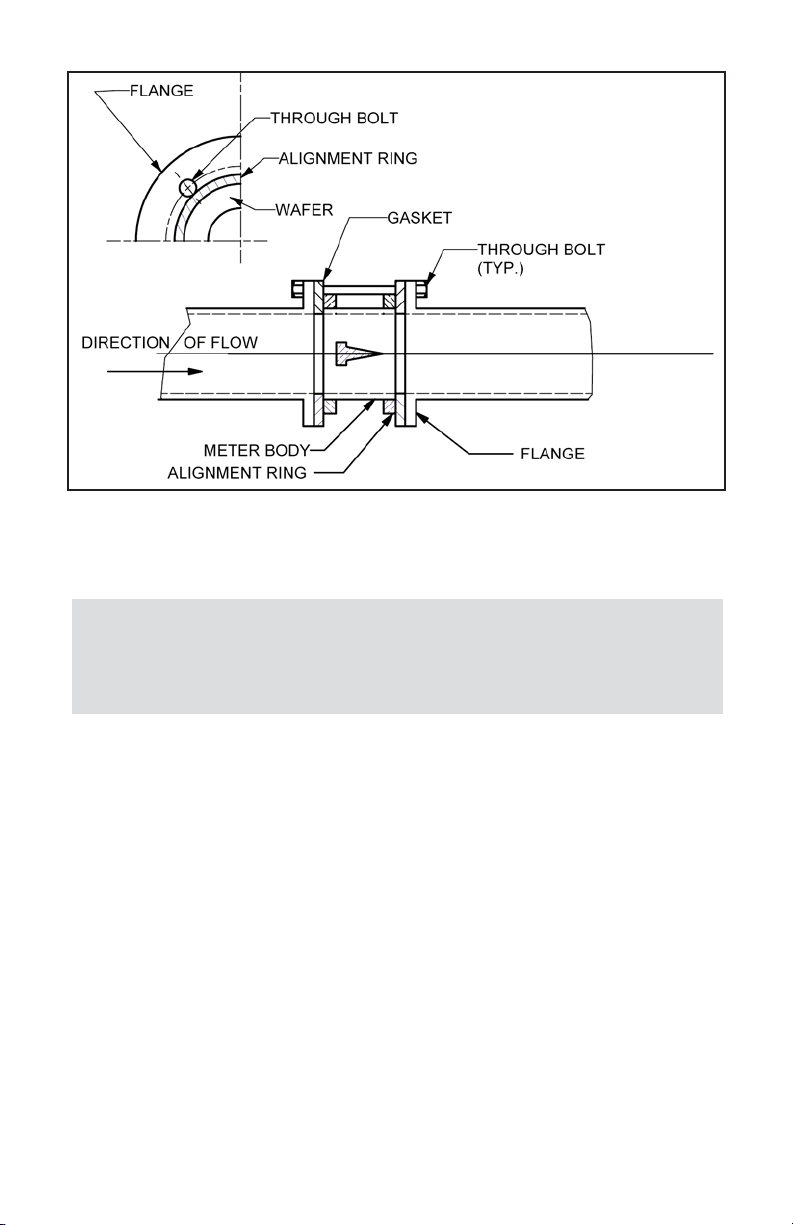

3.6 Alignment Rings and Gaskets

Alignment rings may be provided with the meter and should be used to ensure

proper alignment of the flow meter to the pipe flanges. Misalignment can result

in percentage errors and can even result in a non-functional meter.

Gasket size and correct installation are essential to accurate measurement.

Care should be taken when installing the flow meter to prevent the slightest

protrusion of the gasket into the flow line. The I.D. of the gasket should be 1/8

inch larger than the I.D. of the meter. This will prevent the gasket from slipping

into the line during installation.

3.7 Identification Check

Before continuing on to the installation of the flow meter, be sure that all of the

parameters of the application match or fall within the limits specified by the identification sheet. If more than one meter has been purchased, check the I.D.

sheet versus the meter tag to ensure that the correct meter is being installed.

Page 12

7

3.8 Installation Procedure

The Vortex Wafer flow meter is a flangeless style meter. It is installed between

pipe flanges using alignment rings through bolts and gaskets. The inside

diameter of the surrounding pipe should be identical to the I.D. of the meter.

The following installation procedures should be used to insure proper alignment

of the flow meter which in turn will insure accuracy:

A) Check the weldmount mating flanges for internal weld bead. If weld bead

exists in the pipeline, it must be ground flush with the pipe wall. Failure to

do this will result in high percentage errors and erratic outputs.

B) Check the pipe for proper alignment on both sides of the installation

location.

C) Check the overall piping. Be sure it meets or exceeds minimum straight

upstream and downstream requirements, approximately 20 diameter

upstream and 5 diameters downstream.

D) Check for adequate clearance on both sides of the signal processor

housing. A minimum distance of 24 inches is required for ease of wiring

and maintenance.

E) For meters over 150 lb. flange ratings, place the two purchased alignment

rings over the ends of the meter body.

F) Place the flange gaskets between the meter body and the opposing

flanges of the pipeline. Be sure that the arrow on the meter body is

indicating the correct direction of flow.

G) Insert the bolts through the bolt holes in the flanges and run the nuts

onto the bolts. Snug the nuts tight enough to hold the alignment.

H) Check the alignment of the meter body to the pipeline. Check the

concentricity of the gaskets, being sure that they are not protruding into

the flow line. The bolts should bear against the outside of the flange bolt

holes. (See Figure 5, end view of flange, alignment ring and gasket.)

Page 13

8

4. ELECTRONICS

WARNING!

WIRING THE TRANSMITTER WITH THE POWER ON MAY RESULT IN

INTERNAL DAMAGE OR LOSS OF MEMORY! PLEASE MAKE ALL

WIRING CONNECTIONS BEFORE SWITCHING ON THE POWER.

4.1 Description

The Smart Transmitter is supplied with all vortex flow meter. It is designed to

be locally mounted or wall mounted, remote from the meter, for easy user access.

The local keypad/display can be programmed to display various process variables:

instantaneous volumetric and mass flow rate, total flow, temperature*, pressure*

and density* in engineering units.

The flow rate can be displayed in 30 different volumetric and 25 mass flow engineering units. Flow meter parameters and functions can be programmed remotely via the RS-232/RS-485 interface or locally via LCD/KeyPad using multi level

menus. Vortex flow meters support various functions including: two programmable flow Totalizers, low, high or range flow, temperature* and pressure* Alarms,

two digital programmable optically isolated outputs, two programmable (for different process variables: volumetric flow, mass flow, temperature*, pressure*) 420 mA analog outputs, programmable optically isolated flow rate Pulse output,

battery backed Real Time Clock [RTC], programmable process Variable Data Log

FIGURE 5

Page 14

9

(total 15872 records) with date and time stamp, extensive Diagnostic events log

and register, and feature a password protected access to the process parameters

to ensure against tampering or resetting.

(* - optional feature)

4.2 Specifications

Fluid Types:

Steam, Gas, Liquid.

Flow Accuracy (Including Linearity):

±1% of AR.

Repeatability:

±0.25% of full scale.

Ambient Temperature:

-12 °C to 65 °C (-15 °F to 149 °F).

Fluid Temperature:

-20 °C to 232 °C std./to 260 °C opt.

(-3 °F to 450 °F std./to 500 °F opt).

Fluid Temperature Measurement Range*:

-20 to 260C (-4 to 500 °F).

Temperature Accuracy (Including Linearity)*:

+/- 0.5C

Fluid Pressure Measurement Range*:

can be ordered for following options: 0 - 100 PSIA

0 - 200 PSIA

0 - 300 PSIA

0 - 500 PSIA

0 - 750 PSIA

0 - 1000 PSIA

Pressure Accuracy (Including linearity)*

: +/- 0.5% of full scale.

Fluid Proof Pressure*:

3 X F.S.

Fluid Burst Pressure*:

10 X F.S.

Flow Response Time:

Adjustable based on Noise Redaction Filter (NRF) and

Damping settings (minimum 1000 ms).

Analog Output Signals:

Linear 4-20 mA, self-powered (sourcing type,

non-isolated), 600 ohms maximum loop resistance.

Optically Isolated Outputs:

UCE @ 40Vdc, ICE @ 150 mA (Voltage –

Isolation: 5000 Vrms).

Page 15

10

Optically Isolated Flow Pulse Output:

UCE @ 60Vdc, ICE @ 50 mA (Voltage –

Isolation: 5000 Vrms).

Flow Meter Input Power:

15 to 30 Vdc, 100 mV maximum peak to peak

output noise. Power consumption: +15Vdc (150 mA maximum); +24Vdc (100

mA maximum); Circuit board have built-in polarity reversal protection, 300mA

resettable fuse provide power input protection. 115 or 230 Vac transformer

(optional).

Communication Interface:

RS-232 standard (RS-485 optional).

Communications Parameters (RS-232/RS-485):

Baud rate: ...................... 9600 baud

Stop bit: ...................... 1

Data bits: ...................... 8

Parity: ...................... None

Flow Control: ...................... None

Display:

Local 2x16 characters LCD. In the process mode can be set to display

statically or dynamically (with preset interval time) up to 13 different combinations of the process and diagnostic parameters.

Key Pad:

4 push button key pad.

CE Compliance: EMC Compliance with 89/336/EEC as amended.

Emission Standard: EN 55011:1991, Group 1, Class A

Immunity Standard: EN 55082-1:1992

(* - optional feature)

4.3 Handling and Storage

The smart transmitter has been tested and programmed at the factory. When

the transmitter is received, it should be inspected for damage due to mishandling

during shipment. If damage is evident, report it to the carrier immediately

and have them present when the carton is opened. The carrier is responsible for

any damage during shipment. If you have any problems or questions, consult

the factory or your local representative.

After receiving the unit, handle with care to avoid any unnecessary damage. If

the unit is not scheduled to be installed immediately after delivery, the following

steps should be observed:

Page 16

A) After inspection, the transmitter should be repacked into its original

packing.

B) Select a clean, dry place to store the meter.

C) Avoid areas of extreme temperatures. The unit should be stored in an area

that falls between -15 °F and +149 °F.

4.4 Mounting

The transmitter enclosure for remote option has two mounting feet for easy wall

mounting. The enclosure should be located within 100 feet from the pipeline

sensor, and ideally should be at eye level for easy viewing and access to the keypad for programming.

High-Temperature Installations:

Install the meter body so the electronics are positioned to the side of or below

the pipe. Insulation may be required around the pipe to maintain a temperature

below 149 °F (65 °C).

4.5. Wiring Connections

The transmitter module fits snugly within the enclosure, but will slide out by

hand without the necessity of a tool for removal.

11

CAUTION: Make proper grounding connections before switching on

power. Grounding the flow meter and transmitter modules is one of

the most important procedures of Vortex installation. Proper

grounding ensures correct and accurate flow measurement.

Use dedicated Grounding Clamp on the meter and transmitter body

(see pages 105-107) to make the proper connection to building

protective earth.

WARNING:

Some of the IC devices used in the transmitter are static sensitive and

may be damaged by improper handling. When adjusting or servicing

the transmitter, use of a grounded wrist strap is recommended to

prevent inadvertent damage to the integral solid state circuitry.

Page 17

12

CAUTION: Do not apply power voltage above 30Vdc. Doing so will

cause Vortex meter damage or faulty operation.

Make sure power is OFF when connecting or disconnecting any cables

in the system.

The TB1 – TB4 terminals accept 14 to 24 gauge wires, but 18 gauge shielded

wire (Belden 8760) or 20 gauge shielded wire (Belden 9154) is recommended.

When making wiring connections, cable glands should be fitted and sealed to

prevent moisture entering the enclosure.

4.5.1 Power Supply Connections

The power supply requirements for Vortex flow meter are: 15 to 30 Vdc 100 mV

maximum peak to peak output noise, (unipolar power supply)

Terminal TB1, Pin 1 --------------- DC Power (+)

Terminal TB1, Pin 2 --------------- DC Power (-)

Terminal TB1, Pin 3 --------------- GND, building protective earth

(connect to dedicated GND clamp

inside of the enclosure).

The (+) and (-) power inputs are each protected by a 300mA M (medium timelag) resettable fuse. If a shorting condition or polarity reversal occurs, the fuse

will cut power to the flow transducer circuit. Disconnect the power to the unit,

remove the faulty condition, and reconnect the power. The fuse will reset once

the faulty condition has been removed.

NOTE: For remote transmitter option use shielded twisted pair cable in

order to reduce EMI on sensors signals. Use 24 AWG or larger wire and

do not exceed 100 feet (30 meters). Use supplied cable termination kit

to properly terminate the transmitter end of the signal cable.

The termination kit includes:

1. Molex 3 position Connector Housing (P/N: 50-57-9403) 1 ea.

2. Molex Female Connector Terminals (P/N: 16-02-1114) 3 ea.

Make sure to connect terminal #4 on the meter side to pin #2

(central pin) on the Molex connector (see APPENDIX D on page 104

for more details)

Page 18

13

This linear output signal by default represents 0-100% of the selected process

variable full scale range. User may adjust 4mA and 20 mA settings individually

for each output if different range of the process variable is required (see

Paragraph 5.3.12.4)

Terminal TB3, Pin 1 --------------- (+) Plus 4-20mA Analog Output#1

Terminal TB3, Pin 2 --------------- (-) Minus 4-20mA Analog Output#1

Terminal TB3, Pin 3 --------------- (+) Plus 4-20mA Analog Output#2

Terminal TB3, Pin 4 --------------- (-) Minus 4-20mA Analog Output#2

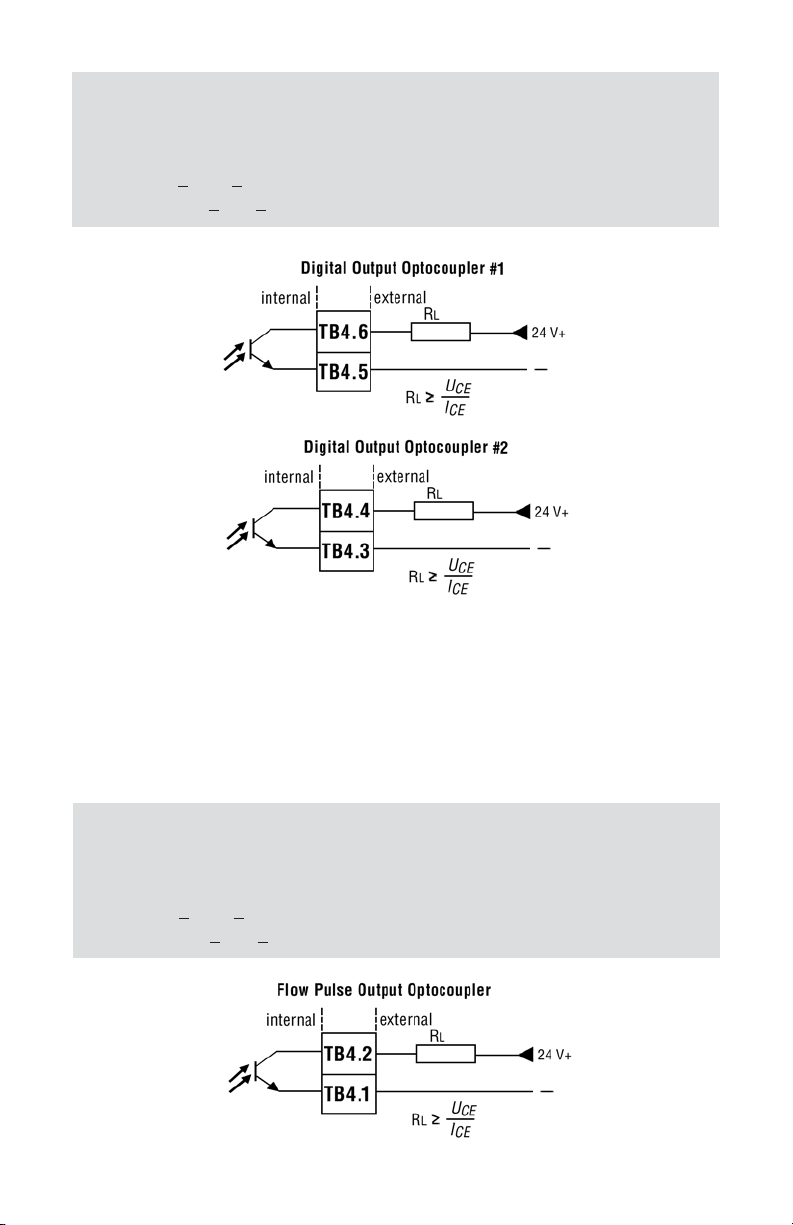

4.5.3 Programmable optically isolated Output

Signals Connections

Optocoupler #1 - Terminal TB4 (pins 6 and 5):

Terminal TB4 Pin 6 --------------- Plus (+) (passive)

Terminal TB4 Pin 5 --------------- Minus (-) (passive)

Optocoupler #2 - Terminal TB4 (pins 4 and 3):

Terminal TB4 Pin 4 --------------- Plus (+) (passive)

Terminal TB4 Pin 3 --------------- Minus (-) (passive)

WARNING: The 4-20 mA current loop output is self-powered (sourcing

type, non-isolated). Do NOT connect an external voltage source to the

output signals.

4.5.2 Analog 4-20 mA Output Signals Connections

Vortex Flow Meters are equipped with two calibrated 4-20 mA output signals

(which can be assigned to any of four process variables: Volumetric Flow, Mass

Flow, Temperature*, Pressure*).

CAUTION: When connecting the load to the output terminals, do not

exceed the rated values shown in the specifications. Failure to do so

might cause damage to this device. Be sure to check if the wiring and

the polarity of the power supply is correct before turning the power ON.

Wiring error may cause damage or faulty operation.

Use of the Vortex flow meter in a manner other than that specified in this manual

or in writing from Aalborg, may impair the protection provided by the equipment.

Page 19

14

4.5.4 Programmable optically isolated Flow Pulse

Output Signal Connections

Terminal TB4 (pins 2 and 1):

Terminal TB4 Pin 2 --------------- Plus (+) (passive)

Terminal TB4 Pin 1 --------------- Plus (-) (passive)

WARNING: Optically isolated Flow Pulse output require application of

external DC voltage across terminals. Do not exceed maximum allowed

limits for voltage and current provided below:

2 V <

UCE < 60 V

0.2 mA < ICE < 50 mA

WARNING: Optically isolated outputs require application of external DC

voltage across terminals. Do not exceed maximum allowed limits for

voltage and current provided below:

2 V <

UCE < 40 V

0.2 mA <

ICE < 150 mA

Page 20

15

4.5.5 Communication Parameters and Connections

The digital interface operates via RS-232 (optional RS-485) and provides access

to applicable internal data including: flow, temperature*, pressure*, totalizers

and alarm settings, flow calibration settings, process fluid parameters and engineering units selection.

Communication Settings for RS-232/RS-485 communication interface:

Baud rate: ………………… 9600 baud

Stop bit: ……………………1

Data bits: …………………. 8

Parity: ………………… None

Flow Control: ………………… None

RS-232 communication interface connection:

Crossover connection has to be established:

Terminal TB2 Pin 1 (Tx-) ------------ RS-232 RX (pin 2 on the DB9 connector)

Terminal TB2 Pin 2 (Rx+) ------------ RS-232 TX (pin 3 on the DB9 connector)

Terminal TB2 Pin 3 ------------- RS-232 SIGNAL GND (pin 5 on the DB9

connector)

RS-485 communication interface connection:

The RS485 converter/adapter must be configured for: multidrop, 2 wire, half

duplex mode. The transmitter circuit must be enabled by TD or RTS (depending on

which is available on the converter/adapter). Settings for the receiver circuit

should follow the selection made for the transmitter circuit in order to eliminate

echo.

Terminal TB2 Pin 1 (Tx-) --------------- RS-485 T(-) or R(-)

Terminal TB2 Pin 2 (Rx+) --------------- RS-485 T(+) or R(+)

Terminal TB2 Pin 3 --------------- RS-485 GND (if available)

5. LCD KEYPAD OPERATION:

DATA ENTRY AND CONFIGURATION

5.1 Display Indications

Initially, after the power is first turned on, the Banner Screen is shown for 1 second, then flow meter model number is shown in the first line of the display and

the revisions for EEPROM table and firmware in the second line. Subsequently

the actual process information is displayed.

Page 21

16

Figure 5.1: Vortex meter first Banner Screen

Figure 5.2: Vortex meter second Banner Screen

Figure 5.3: Vortex meter initial PI Screen

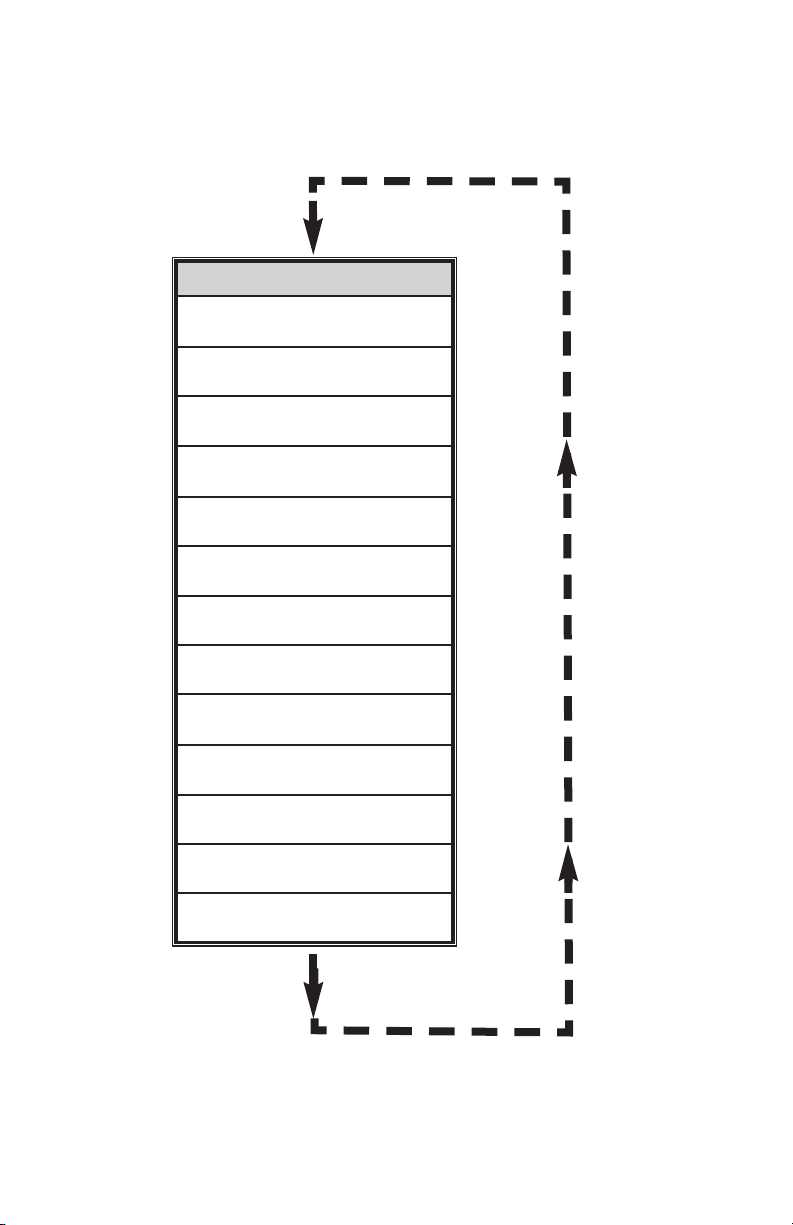

Based on flow meter configuration (with or without Temperature/Pressure

option), different parameters may be displayed in the Process Information (PI)

screen by pressing the Up or Dn pushbuttons.

Process Information screens can be configured to be static or dynamic (see

Paragraph 5.3.11 “Display Menu”). Using Screen Mask settings user can enable

(unmask) or disable (mask) up to 13 different process variable combinations (see

Figure 5.4). In the static mode pressing Up button, pages through the PI screens

in the forward direction, pressing Dn button, pages through the PI screens in the

reverse direction. When the last PI screen is reached, the firmware “wraps

around” and scrolls to the initial PI screen once again.

In the dynamic mode firmware initiates automatic screen sequencing with user

adjustable screen Cycle Time (see Paragraph 5.3.11.2 “Display Menu”). When the

last PI screen is reached, the firmware “wraps around” and scrolls to the initial PI

screen once again.

AALBORG VORTEX

SMART FLOW METER

VXW10L-44AB-L2D4

Fw: A001 Tbl: A001

325.3 litr/min

T1: 60639.3 litr

NOTE: Actual content of the LCD screen may vary depending on the

model.

Page 22

17

NOTE: Actual content of the LCD screen may vary depending on the

model.

NOTE: For devices without Temperature and Pressure measurement

hardware, the screens with T/P process info will display static data

entered during meter configuration procedure via Process Fluid menu

(see Paragraph 5.3.9).

Process Information Mode Screens

Page 23

18

Figure 5.4: Vortex meter Process Information Screens

Vol Flow

Total#1

Vol Flow

Total#2

Mass Flow

Total#1

Mass Flow

Total#2

Total #1

Total #2

Vol Flow

Temp Press

Mass Flow

Temp Press

Vol Flow

Mass Flow

Fa Stat.

Ta Stat. Pa Stat.

Vol Flow

RMS1 RMS2

Mass Flow

Density

Flow Velocity

Date/Time

F:PC F:PWM

F: WD F:FFT

Page 24

19

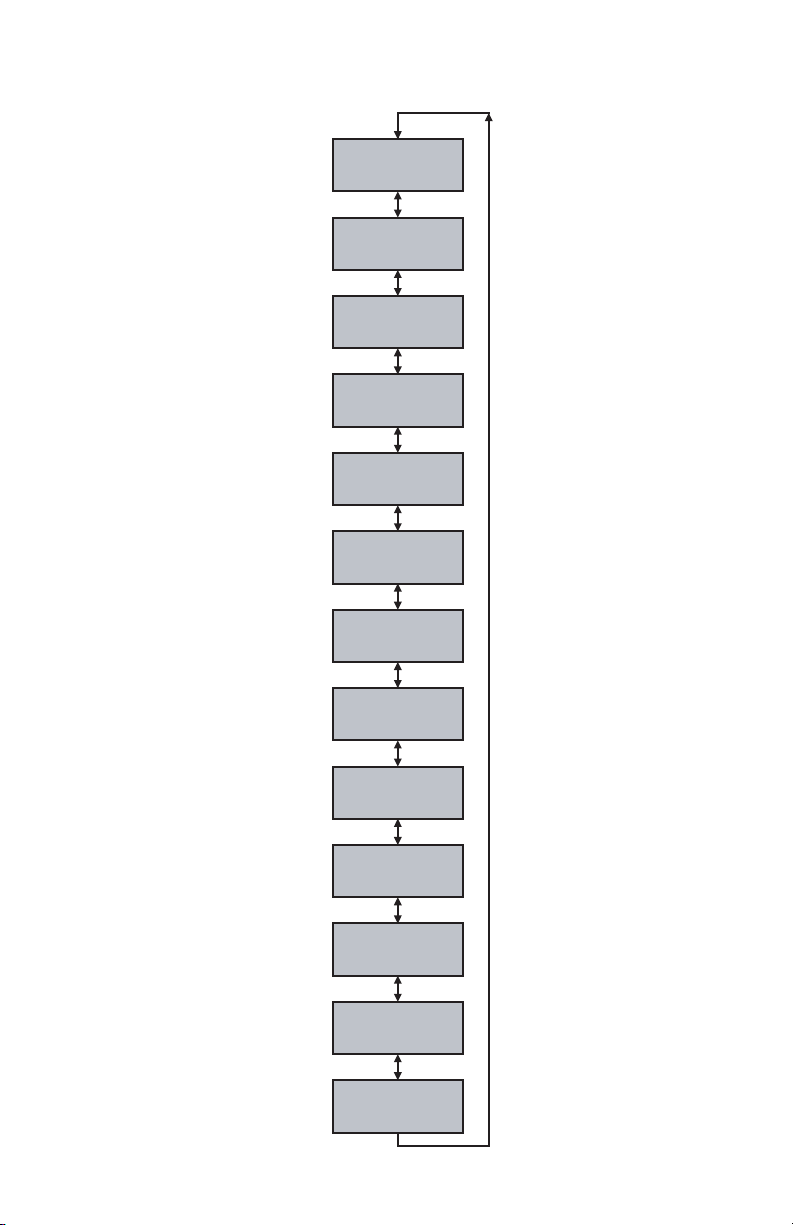

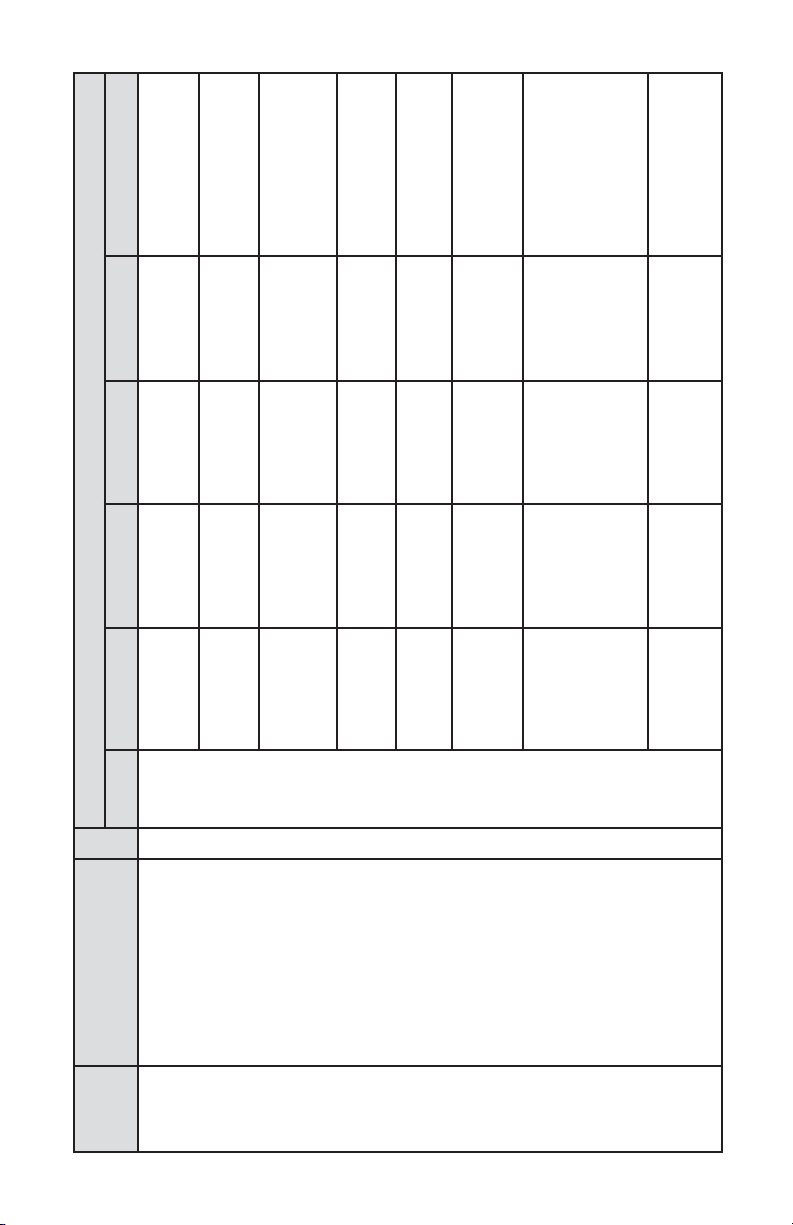

5.2 Menu Sequence

The listing below gives a general overview of the standard top-level display menu

sequence when running firmware version A001. The ESC pushbutton is used to

toggle between the process mode (PI screens) and the Setup menus.

The listing in Section 5.2 shows the standard display menu sequence and submenus using the UP button to move through the menu items. The first message

displayed the first time the ESC button is pressed after the meter is powered up is

“Prog. Protection ON”. Thereafter, pressing the ESC button while the flow meter

is in monitoring mode (PI screens) will display the parameter that was last exited.

Program Protection may be turned “off” by pressing the ENT pushbutton when

the Program Protection menu is displayed. The firmware will prompt with

“Change Prog Prot”. Pressing UP or DN button will toggle current protection status. If password is set to any value more than zero, the firmware will prompt with

“Enter Prot Code”. User has to enter up to 3 digits program protection code, in

order to be able to access password protected menus. Once correct password is

entered, program protection is turned off until unit is powered up again.

When the last menu item is reached, the firmware “wraps around” and scrolls to

the first item on the menu once again (see Figure 5.5). The menu items in the first

column are upper-level configuration mode functions. Submenu selections are

shown on the Figure 5.6). The allowable selections of sub-menu items which are

selected by tabular means are shown in detail in Section 5.3.

Page 25

20

Top Level 1 Setup Menus

Prog. Protection

on/off

Prog. Prot. Code

old/new

Submenu L1

Flow Meter Info

Submenu

Measuring Units

Submenu L1

Alarm Menu

Submenu L1

Totalizer Menu

Submenu L1

Output Menu

Submenu L1

Calibration Menu

Submenu L1

Date/Time Adjust

Submenu L1

Fluid Menu

Submenu L1

Diagnostic Menu

Submenu L1

Display Menu

Submenu L1

Data Log Menu

Figure 5.5 Upper level 1 Setup Menu structure.

Page 26

21

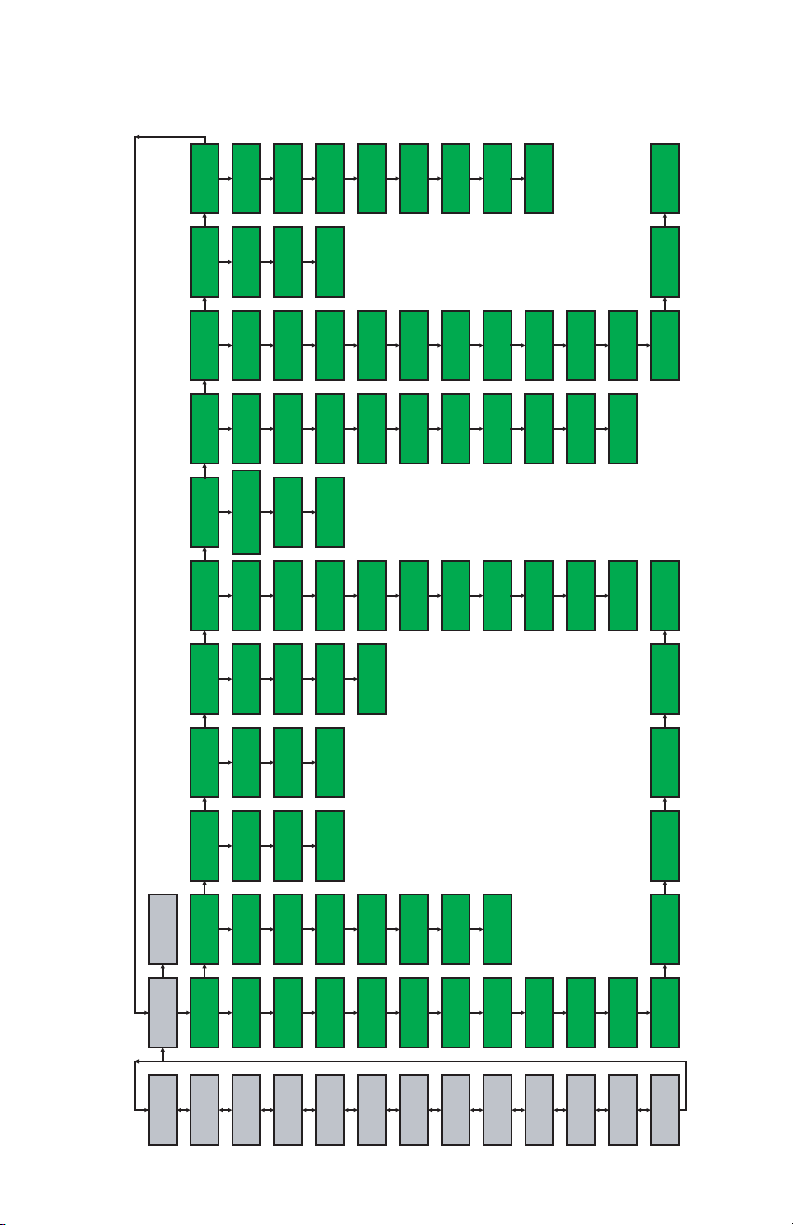

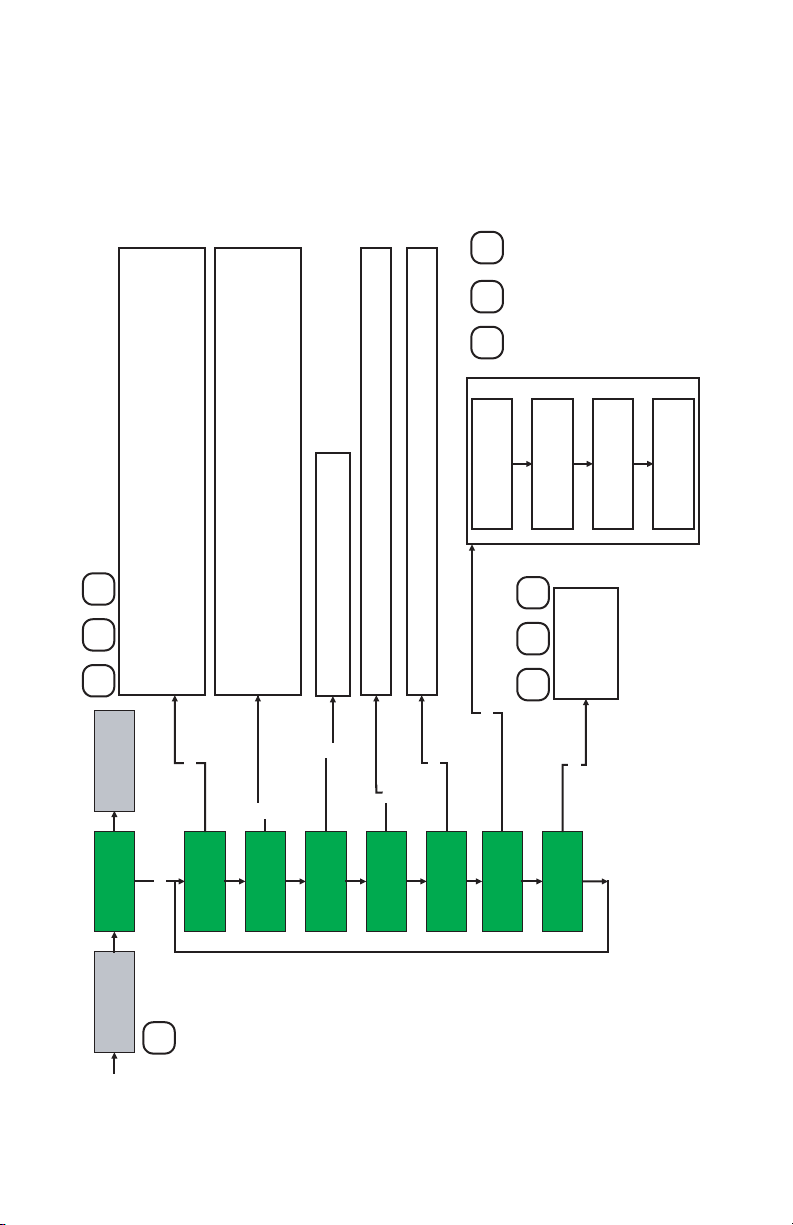

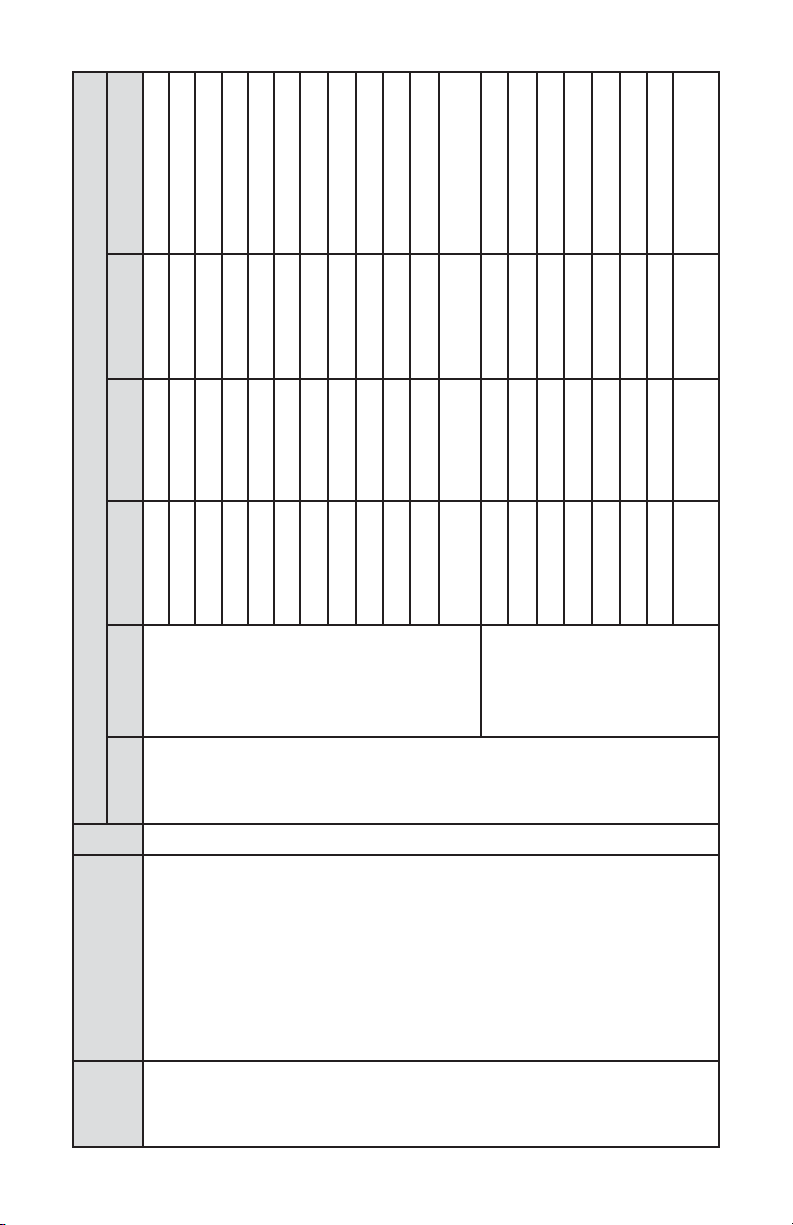

Figure 5.6 Setup Menu structure

SETUP MENUS

Loop

Disabled

Sub menu L1

Data Log Menu

Data Log Mode:

Static

Sub menu L1

Display Menu

Display Mode:

3600

DataLog Config:

Log #of Sampls:

2 sec.

Sub menu

Screen Mask

Screen Time:

60 sec.

Vol Flo w

Log Interval:

Proces Vari able:

Unconditional

Flow Alarm Hi

Start Conditions:

DLI:2503 Ov:0

Stop Conditions:

Data Log Status

37.5 C

CPU Temp:

DAC Output:

#1:538 #2:1521

Sub menu L1

Sub menu L2

Sub menu L2

Diagnostic Menu

Fluid Menu

Flowing Fluid

Sub menu L1

Sub menu L2

Sub menu L1

Date/TimeAdjust

05/25/2010 09:40

Current Date/Time

Sub menu L1

Sub menu L2

CalibrationMenu

PWM DSPMenu

Setup Mode Screens

Output Menu

Sub menu L1

Sub menu L2

4-20mA Output1

Totalizer #1

Sub menu L1

Sub menu L2

Totalizer Menu

Flow Alarm

Alarm Menu

Sub menu L1

Sub menu L2

Menu

Password

litr/min

Sub menu L1

Vol Flo w Units

Measuring Units

Raw Pulses Cnt

API 2540.

Sub menu L2

Sub menu L2

Goyal-Dorais.

16:24:11

Set Date:

Set Time:

05/25/2010

0.750 inch

Meter Size

Sub menu L2

FFT DSPMenu

Sub menu L2

Sub menu L2

Optical Outputs

4-20mA Output2

Totalizer #2

Pulse Output

Sub menu L2

Sub menu L2

Sub menu L2

Sub menu L2

Temper. Alarm

Pressure Alarm

deg C

kg/min

Temper. Units

Mass Flow Units

560 T:2000 ms

Events Log File

Sys. Events Reg

280.2 280.0 Hz

280.2 280.0 Hz

PulseFrequency

PWMFrequency:

Other Gases.

Sub menu L2

Sub menu L2

Nat Gas AGA8

1001.170

Meter Factor

2800 Litr/min

Meter FS Range

11

RS-485 Address

PSI

g/cm^3

Density Units

Pressure Units

FFT Output:

FFT Aver age:

Sensors RMS:

280.6 280.1 Hz

280.5Hz A: 325

AWDFrequency:

21.0 C

STD Temp:

Sub menu L2

Cust Flow. Cond

5.0 %FS

50.00 Hz

Low Freq Cutoff

Low Flow Cutoff

Actual

Sub menu L2

UD Flow Units

Flow Units Cond

S1:425 S2:412

280.2Hz D:2223

21.0 C

14.70 PSIA

Normal Temp:

STD Pressure:

2.158

1009.00 Hz

Vortex Coeff.

Hi Freq Cutoff

T/P ADC Out:

T:1245 P:0547

S1:127 S2: 120

Sensor Attenuat

14.70 PSIA

Normal P ress:

25.6 Hours

Not Assigned

User Tag Name:

Calib. Pilot Time

08/21/2011

Calib. Date Due

08/21/2010

Calibration Date

Model Number:

VXW-10L-4S4A

248561-1

Serial Number:

A002

Status

Password

Scr eens

Proc ess M ode

Total#1

Vol Flo w

1000.0 L/min

Sub menu L1

Full Scal e Flow

Flow Meter Info

Total#2

Total#1

Vol Flo w

Mass Flow

Water

0.750 inch

Meter Size

Floing Fluid:

Total#2

Total #1

Total #2

Mass Flow

Inst alled

Comm. Interface

RS-485 ADD:11

Vol Flo w

Temp Press

4-20mA Output1

Vol Flo w

Mass Flow

Mass Flow

Temp Press

Vol Flo w

T/P Sensors

Disabled

Temperature

Optical Out #1

4-20mA Output2

Fa Stat.

Vol Flo w

RMS1 RMS2

Ta Stat. Pa Stat.

A001

Disabled

Optical Out #2

Density

Mass Flow

Firmware Ver:

EEPROM Ver:

Date/Time

F: WD F:FFT

Flow Velocity

F:PC F:PWM

Page 27

22

5.3 Parameter Entry

There are two methods of data entry: • Direct numerical number entry.

• Tabular Input from a table menu.

If menu with direct numerical entry is selected use Up button to increment digit

value from 0-9. Use Dn button to move cursor to another digit position. When

desired value is entered use ENT button to accept (save in the EEPROM) new

value.

If menu with tabular entry is selected, the available menu options can be set with

the Up and Dn buttons and are accepted by pressing ENT button.

5.3.1 Submenu Program protection

After power has been turned on, programming parameters may only be changed

by turning program protection “OFF”. There are two ways to turn off the program protection:

1. If program protection code (PP-code) is set to “0” (factory default), the

program protection is turned off by pressing ENTER key.

2. If a PP-code (1 to 255) other than “0” has been entered, this code must be

entered in order to turn the program protection “OFF”.

The PP-code can be changed after the program protection has been turned off.

In order to protect device configuration parameters when changing the PP-code

the old PP-code must be entered after ENTER has been pressed.

NOTE: During data entry the input values are checked for

acceptability. If data is not acceptable, it is rejected and a message

is generated indicating that the new data has not been accepted.

Prog. Protection code

Old PP-code ?

0

Page 28

23

Press ENTER key after entry of old PP-code.

Now enter the new PP-code (0-255) and press ENTER key. The new PP-code is

now valid to turn off the program protection. If the PP-code is forgotten, it can

be restored only via digital communication interface.

5.3.2 Submenu Flow Meter Info

This submenu contains information about the meter main configuration parameters. These items are informational only, not password protected and may not be

changed (read only).

New PP-code ?

0

Page 29

24

Figure 5.7 Submenu L1 Measuring Units structure.

5.3.3 Submenu Measuring Units

Ent

Dn Up

Cursor

1.000

Numerical Entry

UD Vol U. Factor

Tabular Entry

Ent

Dn Up

Alarm Menu

Sub menu L1

Sub menu L1

Measuring Units

bbl/sec, bbl/min, bbl/hr, bbl/day, Vol User

f^3/sec, f^3/min, f^3/hr, f^3/day, gal/sec, gal/min, gal/hr, gal/day,

Igal/sec, Igal/min, Igal/hr, Igal/day, MilL/sec, MilL/min, MilL/hr, MilL/day,

%FS, litr/sec, litr/min, litr/hr, litr/day, m^3/sec, m^3/min, m^3/hr, m^3/day,

Ent

Ent

litr/min

Vol Flow Units

Lton/day, Mass User

g/cm^3, kg/m^3, g/litr, kg/litr, lb/ft^3, lb/gal, lb/in^3

psi, bar, mbar, inHg, mmHg, kPa, MPa, atm, gcm2, kgc2, torr

Ston/sec, Ston/min, Ston/hr, Ston/day, Lton/sec, Lton/min, Lton/hr,

lb/sec, lb/min, lb/hr, lb/day, Mton/sec, Mton/min, Mton/hr, Mton/day,

gram/sec, gram/min, gram/hr, gram/day, kg/sec, kg/min, kg/hr, kg/day,

Ent

Mass Flow Units

deg F, deg C, Kelvin, Rankine

Ent

kg/min

deg C

Temper. Units

Ent

Ent

PSI

Pressure Units

g/cm^3

Density Units

UD VU Time Base

Ent

Tabular Entry

Dn Up

Ent

Sub menu L2

UD Flow Units

Numerical Entry

Tabular Entry

60 Sec

UD Mass U Factor

Actual

Normal

Standard

Ent

Actual

Flow Units Cond

Tabular Entry

1.000

60 Sec

UD MU Time Base

Sub menu L1

Flow Meter Info

Esc

to L1 Menu

Press Esc to return

Page 30

NOTE: Program the Measuring Units first because later menus may be

based on the units selected.

25

Use the Measuring Units Menu to configure the flow meter with the desired units

of measurement. These are global settings and determine what appears on all

process information screens and data log records. Units should be selected to

meet your particular metering needs.

The instantaneous flow rate may be simultaneously displayed in Volumetric and

Mass engineering units. In addition to conventional flow units user defined flow

engineering units may be configured for Volumetric and Mass flow units. Before

using Volumetric User defined flow unit make sure proper conversion factor of the

new unit with respect to one liter is set (the default entry is 1.00 Liter). Before

using Mass User defined flow unit make sure proper conversion factor of the new

unit with respect to one gram is set (the default entry is 1.00 gram) Also proper

time base values for both User Defined Units have to be set. The following selections are available: 1 second, 60 seconds (1 minute), 3600 seconds (1 Hour),

86400 seconds (1 Day). The default entry is 60 seconds.

The Volumetric flow rate for Gases may be shown with following units conditions:

Standard, Normal, and Actual. The temperature and pressure for Standard and

Normal conditions can be programmed in the Flowing Fluid menu (see Paragraph

5.3.9). By default Standard conditions are: 70 °F and 14.7 PSIA, Normal conditions are 0 °C and 101.3 KPa.

For flow meters with T/P hardware installed the actual process temperature and

pressure derived from corresponding sensors. For flow meters without T/P hardware the actual process temperature and pressure should be preset in the Flowing

Fluid menu (see Paragraph 5.3.9).

NOTE: Your flow meter is pre-programmed at the factory for your

application’s process fluid and T/P conditions and does not require any

reprogramming unless your process fluid or T/P conditions are

changed.

NOTE: If Gas is selected as flowing fluid, when Standard Volumetric

units are selected the prefix S will precede engineering units name on

the PI screens (for example: Slitr/min). When Normal Volumetric units

are selected the prefix N will precede engineering units name on the PI

screens (for example: Nlitr/min). For Actual Volumetric units there will

be no prefix in front of engineering unit name (for example: litr/min).

Flow Units Conditions settings only applicable for Volumetric Flow

units. For Liquids the Flow Units conditions are always Actual.

Page 31

5.3.4 Submenu L1 Alarm Menu

5.3.4.1 Submenu L2 Flow Alarm

Vortex flow meter provides the user with a flexible alarm/warning system that

monitors the Fluid Flow for conditions that fall outside configurable limits as well

as visual feedback for the user via the LCD or via an optically isolated outputs.

The flow alarm has several attributes which may be configured by the user via

LCD/Keypad or digital communication interface. These attributes control the conditions which cause the alarm to occur and to specify actions to be taken when the

flow rate is outside the specified conditions. Flow Alarm can be assigned to

Volumetric or Mass Flow reading.

Flow Alarm conditions become true when the current flow reading is equal or higher/lower than corresponding values of high and low flow alarm levels. Alarm action

can be assigned with preset delay interval (0-3600 seconds) to activate the optically isolated output (separate for High and Low alarm). Latch Mode control feature allows each optical output to be latched on or follow the corresponding alarm

status.

Following settings are available for Flow Alarm (see Figure 5.8):

a) Flow Alarm Mode Tabular entry

This function determines whether Flow Alarm is Enabled or Disabled.

The following selections are available: Enabled or Disabled. The default

entry is Disabled. Alarm Mode selections can be set with the Up and Dn

buttons and are accepted by pressing ENT button.

26

Page 32

27

Figure 5.8 Submenu L1 Alarm Menu structure.

Numerical

Tabular

Numerical

Tabular

Numerical

Tabular

Flow Alarm Mode

Esc

Disabled

Mass Flow

2.03 gram/sec

18.06 gram/sec

High Flow Alarm

Flow Alarm Delay

Ent

Ent

Sub Menu

Flow Alarm Cond.

Low Flow Alarm

Top Level 1 Setup

Ent

Up/Dn

Flow Alarm

Sub menu L2

Temper. Alarm

Up/Dn

Sub menu L1

Ent

Enter

Alarm Menu

Up/Dn Up/Dn

Sub menu L2

Disabled

1 second

Flow Alarm Latch

Numerical

Numerical

199.5 deg. C

90.0 PSI

Numerical

Tabular

Disabled

1 second

Temp Alarm Latch

Temp Alarm Delay

Disabled

1 second

Pres. Alarm Latch

Pres. Alarm Delay

Tabular

Disabled

10.0 deg. C

Low Temp Alarm

10.0 PSI

Low Pres. Alarm

High Temp Alarm

High Pres. Alarm

Temp Alarm Mode

Disabled

Pres Alarm Mode

Enter

Ent

Up/Dn

Sub menu L2

Pressure Alarm

Esc

Esc

Screen

Process

Sub Menu

Top Level 1 Setup

Page 33

28

b) Flow Alarm Conditions Tabular entry

Flow Alarm can be assigned to Volumetric or Mass Flow reading.

c) Low Flow Alarm Numerical entry

The limit of required Low Flow Alarm value can be entered in increments

of 0.1% from 0 - 100%F.S.

If a Low Alarm occurs, and one of the two optical outputs is assigned to the Low

Flow Alarm Event (see paragraph 5.3.5.2) the optically isolated output will be

activated when the flow is less than the Low Flow Alarm value.

The Low Flow Alarm condition is also indicated on the corresponding Process

Information Screen by displaying L character.

d) High Flow Alarm Numerical entry

The limit of required High Flow Alarm value can be entered in currently

active Volumetric or Mass Flow units.

If a High Alarm occurs, and one of the two optical outputs is assigned to the High

Flow Alarm Event (see Section 5.3.6.2) the optically isolated output will be activated when the flow is more than the High Flow Alarm value. The High Flow Alarm

condition is also indicated on the corresponding Process Information Screen by

displaying H character.

e) Flow Alarm Action Delay Numerical entry

The Flow Alarm Action Delay is a time in seconds that the Flow rate value

must remain above the high limit or below the low limit before an alarm

condition is indicated. Valid settings are in the range of 0 to 3600 seconds.

f) Flow Alarm Action Latch Tabular entry

The Flow Alarm Action Latch settings controls Latch feature when optically

isolated outputs are assigned to Flow Alarm event. Following settings are

available: Disable or Enabled.

By default, flow alarm is non-latching. That means the alarm is indicated

only while the monitored flow value exceeds the specified set conditions. If

NOTE: If Flow Alarm Conditions were changed, make sure to adjust

Low and High Flow Alarm settings in corresponding flow Engineering

Units.

NOTE: Note: The value of the Low Flow Alarm must be less than the

value of the High Flow Alarm.

NOTE: The value of the High Flow Alarm must be more than the value

of the Low Flow Alarm.

Page 34

29

optically isolated output is assigned to the Flow Alarm event, in some cases,

the Flow Alarm Latch feature may be desirable.

5.3.4.2 Submenu L2 Temperature Alarm (*optional)

Vortex flow meter with T/P option provides the user with a flexible alarm/warning

system that monitors the Fluid Temperature for conditions that fall outside configurable limits as well as visual feedback for the user via the LCD or via an optically

isolated outputs.

The temperature alarm has several attributes which may be configured by the user

via LCD/Keypad or digital communication interface. These attributes control the

conditions which cause the alarm to occur and to specify actions to be taken when

the temperature value is outside the specified conditions.

Temperature Alarm conditions become true when the current temperature reading

is equal or higher/lower than corresponding values of high and low temperature

alarm levels. Alarm action can be assigned with preset delay interval (0-3600 seconds) to activate the optically isolated output (separate for High and Low alarm).

Latch Mode control feature allows each optical output to be latched on or follow

the corresponding alarm status.

Following settings are available for Temperature Alarm (see Figure 5.8):

a) Temperature Alarm Mode Tabular entry

This function determines whether Temperature Alarm is Enabled or

Disabled. The following selections are available: Enabled or Disabled. The

default entry is Disabled. Alarm Mode selections can be set with the Up

and Dn buttons and are accepted by pressing ENT button.

b) Low Temperature Alarm Numerical entry

The limit of required Low Temperature Alarm value can be entered in

currently active Temperature Engineering units.

If a Low Temperature Alarm occurs, and one of the two optical outputs is assigned

to the Low Alarm Event (see Section 5.3.6.2) the optically isolated output

will be activated when the process temperature is less than the Low Temperature

Alarm value. The Low Temperature Alarm condition is also indicated on the corresponding Process Information Screen by displaying L character.

NOTE: The value of the Low Temperature Alarm must be less than

the value of the High Temperature Alarm.

Page 35

c) High Temperature Alarm Numerical entry

The limit of required High Temperature Alarm value can be entered in currently

active Temperature Engineering units.

If a High Alarm occurs, and one of the two optical outputs is assigned to the High

Alarm Event (see Section 5.3.6.2) the optically isolated output will be activated

when the process Temperature is more than the High Temperature Alarm value.

The Temperature Alarm condition is also indicated on the corresponding Process

Information Screen by displaying H character.

d) Temperature Alarm Action Delay Numerical entry

The Temperature Alarm Action Delay is a time in seconds that the Temperature

reading value must remain above the high limit or below the low limit before an

alarm condition is indicated. Valid settings are in the range of 0 to 3600 seconds.

e) Temperature Alarm Action Latch Tabular entry

The Temperature Alarm Action Latch settings controls Latch feature when

optically isolated outputs are assigned to Temperature Alarm event. Following

settings are available: Disable or Enabled.

By default, Temperature alarm is non-latching. That means the alarm is indicated

only while the monitored Temperature value exceeds the specified set conditions.

If optically isolated output is assigned to the Temperature Alarm event, in some

cases, the Temperature Alarm Latch feature may be desirable.

5.3.4.3 Submenu L2 Pressure Alarm (*optional)

Vortex flow meter with T/P option provides the user with a flexible alarm/warning

system that monitors the Fluid Pressure for conditions that fall outside configurable limits as well as visual feedback for the user via the LCD or via an optically

isolated outputs.

The Pressure alarm has several attributes which may be configured by the user via

LCD/Keypad or digital communication interface. These attributes control the conditions which cause the alarm to occur and to specify actions to be taken when the

pressure value is outside the specified conditions. Pressure Alarm conditions

become true when the current pressure reading is equal or higher/lower than

30

NOTE: The value of the High Temperature Alarm must be more than the

value of the Low Temperature Alarm.

Page 36

31

corresponding values of high and low pressure alarm levels. Alarm action can be

assigned with preset delay interval (0-3600seconds) to activate the optically isolated output (separate for High and Low alarm). Latch Mode control feature allows

each optical output to be latched on or follow the corresponding alarm status.

Following settings are available for Pressure Alarm (see Figure 5.8):

a) Pressure Alarm Mode Tabular entry

This function determines whether Pressure Alarm is Enabled or Disabled.

The following selections are available: Enabled or Disabled. The default

entry is Disabled. Alarm Mode selections can be set with the Up and Dn

buttons and are accepted by pressing ENT button.

b) Low Pressure Alarm Numerical entry

The limit of required Low Pressure Alarm value can be entered in

currently active Pressure Engineering units.

If a Low Pressure Alarm occurs, and one of the two optical outputs is

assigned to the Low Alarm Event (see paragraph 5.3.5.2) the optically

isolated output will be activated when the process pressure is less than

the Low Pressure Alarm value. The Low Pressure Alarm condition is also

indicated on the corresponding Process Information Screen by displaying

L character.

c) High Pressure Alarm Numerical entry

The limit of required High Pressure Alarm value can be entered in

currently active Pressure Engineering units.

If a High Alarm occurs, and one of the two optical outputs is assigned to

the High Alarm Event (see paragraph 5.3.5.2) the optically isolated output

will be activated when the process Pressure is more than the High

Pressure Alarm value. The Pressure Alarm condition is also indicated on

the corresponding Process Information Screen by displaying H character.

d) Pressure Alarm Action Delay Numerical entry

The Pressure Alarm Action Delay is a time in seconds that the Pressure

reading value must remain above the high limit or below the low limit

NOTE: The value of the Low Pressure Alarm must be less than the

value of the High Pressure Alarm.

NOTE: The value of the High Pressure Alarm must be more than the

value of the Low Pressure Alarm.

Page 37

32

5.3.5 Submenu L1 Totalizer Menu

5.3.5.1 Submenu L2 Totalizer#1 and Totalizer#2

Menus

Vortex flow meter provides the user with two independent Programmable Flow

Totalizers. Each Totalizer can be configured for Volumetric or Mass flow.

The total volume of the flowing fluid is calculated by integrating the actual instantaneous fluid flow rate with respect to time. The Totalizers value are stored in the

Battery Backed RAM and saved every 1 second. In case of power interruption the

last saved Totalizers values will be loaded on the next power on cycle, so Totalizers

reading will not be lost. The LCD/keypad and digital communication interface commands are provided to:

- Enable/Disable totalizing the flow

- configure totalizer to Volumetric or Mass flow process variable

- start the totalizer at a preset flow rate (in current Vol. or Mass flow units)

- assign action at a preset total volume (Event Volume)

- reset the totalizer to ZERO

NOTE: Before enabling the Totalizer, ensure that all totalizer settings are

configured properly. Totalizer Start values have to be entered in

currently active Volumetric or Mass flow engineering unit. The Totalizer

will not totalize until the process flow rate becomes equal to or more

than the Totalizer Start value. Totalizer Event values must be entered in

currently active volume or mass based engineering units. If the

Totalizer Event at preset total volume feature is not required, then set

Totalizer Event value to zero (default settings).

before an alarm condition is indicated. Valid settings are in the range of

0 to 3600 seconds.

e) Pressure Alarm Action Latch Tabular entry

The Pressure Alarm Action Latch settings controls Latch feature when

optically isolated outputs are assigned to Pressure Alarm event. Following

settings are available: Disable or Enabled.

By default, Pressure alarm is non-latching. That means the alarm is

indicated only while the monitored Pressure value exceeds the specified

set conditions. If optically isolated output is assigned to the Pressure

Alarm event, in some cases, the Pressure Alarm Latch feature may be

desirable.

Page 38

33

Figure 5.9 Submenu L1 Totalizer Menu structure.

Numerical

Tabular

Tabular

Numerical

Tabular

Disabled

Volumetric Flow

Totalizer#1 Mode

Tot#1 Flow Cond.

Disabled

Totalizer#2 Mode

Tot#2 Flow Cond.

Setup

Sub Menu

Top Lev el 1

Esc

Enter

Sub menu L1

Totalizer Menu

Up/Dn Up/Dn

Tot#1 Flow Start

Mass Flow

Tot#2 Flow Start

Ent

Totalizer #1

Sub menu L2

0 litr

100. 0 litr/m in

Tot#1 Event Vol.

0.0 gram

2.15 gram/sec

Tot#2 Event Vol.

Ent

Up/Dn

Totalizer #2

Sub menu L2

Up/Dn

Value?

Reset Total #1

Esc

Enabled

Disabled

Value?

Tabular Entry

Volum. Flow

Tabular Entry

Numerical Entry

Numerical Entry

Ent

Ent

Mass. Flow

Dn Up

Dn Up

Reset Total #2

Enter

Pulse Mode:

Ent

Enter

Esc

Up/Dn

Pulse Output

Sub menu L2

Esc

Esc

Enter EscEsc

Up/Dn

Disabled

Pulse Flow Cond.

Enter

Enter

Up/Dn

Up/Dn

Up/Dn

[Unit]/Pulse

Volumetric Flow

Esc

100 mS

60.00 Ltr

Pulse On Time

Esc

Screen

Process

Sub Menu

Top Level 1 Setup

Page 39

The Totalizers reading can be reset by pressing ENTER button. A typical display

with flow meter Totalizer#1 Reset screen is shown below.

The next conformation screen will appear only for 2 seconds.

If during these two seconds user will press ENTER button again, the Totalizer#1

volume will be reset to zero. Following screen will appear for two seconds

5.3.5.2 Submenu L2 Pulse Output Menu

The flow Pulse Output is operating independently from totalizers and based on

configuration settings (see Figure 5.9) can provide pulse frequency proportional

to instantaneous fluid flow rate.

The LCD/keypad and digital communication interface commands are provided to:

- Enable/Disable Pulse Output

- configure Pulse Output for Volumetric or Mass flow process variable

- configure the Unit/Pulse value (in current Vol. or Mass flow units)

- configure Pulse Active On Time (50 - 13000 ms)

34

NOTE: The Pulse Output minimum Active On time is a 50 millisecond

(.05 second). The Optical Pulse Output cannot operate faster than one

pulse every 100 millisecond (.1 second). A good rule to follow is to set

the Unit/Pulse value equal to the maximum flow in the same units per

second. This will limit the pulse rate to no faster than one pulse every

second.

Reset Total #1

Value?

Press Ent key to

reset Totalizer!

Press Ent key to

The Totalizer has been reset!

Page 40

35

For example: Maximum flow rate = 1200 kg/min

(1200 kg/min = 20 kg/sec)

If unit per pulse is set to 1200 kg per pulse, the Optical Pulse

Output will pulse once every minute.

If unit per pulse is set to 20 kg per pulse, the Optical Pulse

Output will pulse once every second.

The Optically isolated Pulse Output incorporate Pulse output queue, which accumulate pulses if the Pulse Output is accumulating process flow faster than the

pulse output hardware can function. The queue will allow the pulses to “catch up”

later if the flow rate decreases. A better practice is to slow down the Pulse Output

by increasing the value in the Unit/Pulse setting in the Pulse Output menu (see

Figure 5.9).

Page 41

36

5.3.6 Submenu L1 Output Menu

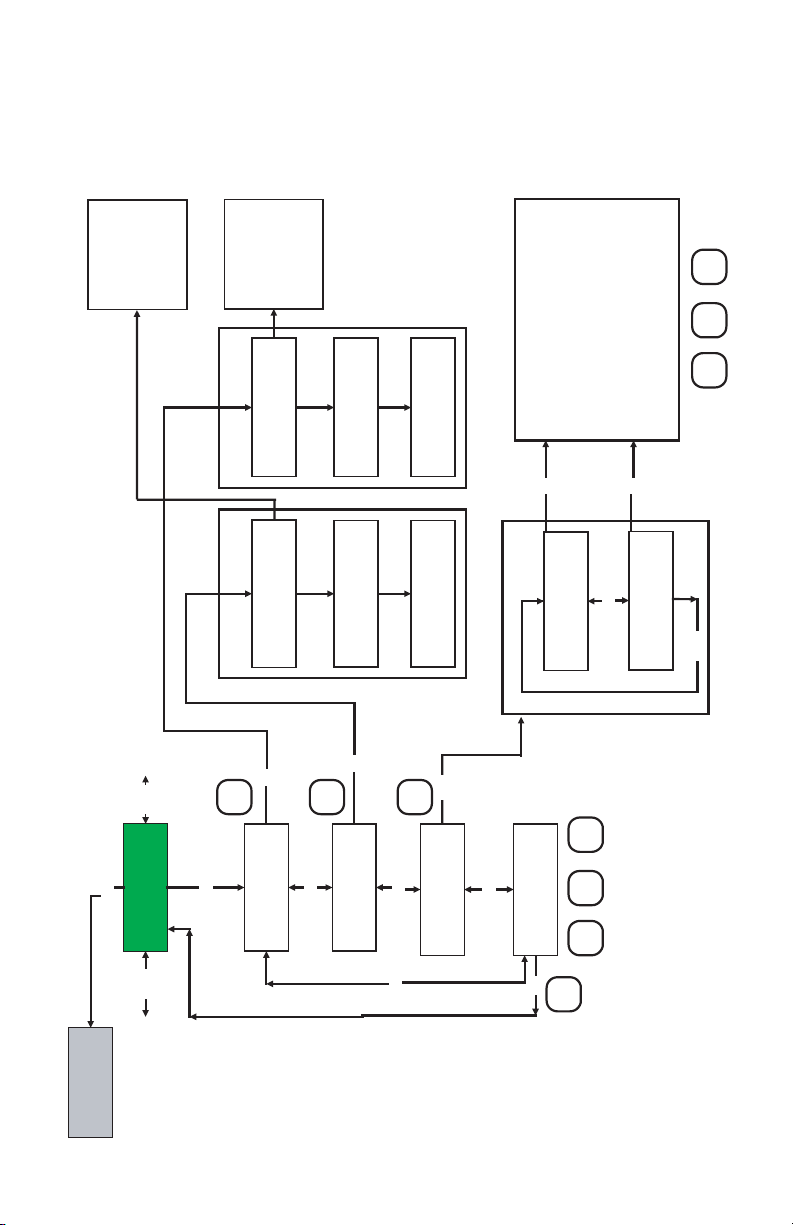

Figure 5.10 Submenu L1 Output Menu structure

Disabled

Tabular

Disabled

Mass Flow

Volum. Flow

Tabular

Pressure

Temperature

Volum. Flow

Pressure

Mass Flow

Temperature

T. Range H-L

Diagnostic

Manual On

P. Range H-L

High P. Alarm

Low P. Alarm

Ent

Disabled

Dn Up

Numerical

Volum. Flow

4-20mAOut#1 Mode

Tabular Tabular

Numerical

Mass Flow

4-20mAOut#2 Mode

Ent

Ent

Ent

Setup

Sub Menu

Top Level 1

Numerical

0.0 litr/min

Out#1 4 mA Value

Numerical

0.0 gram/sec

Out#2 4 mA Value

Ent

Ent

Tabular

High T. Alarm

Low T. Alarm

F. Range H-L

High F. Alarm

Low F. Alarm

Total#1 Event

Total#2 Event

2150.0 litr/min

Out#1 20 mA Value

Ent

Tabular

21.56 gram/sec

Out#2 20 mA Value

Enter

Opt #1 Function

Numerical

Hexadecimal

Ent

Tabular

Up/Dn

Low F. Alarm

Opt #2 Function

High F. Alarm

Up/Dn

Entry

Ent

11

Up/Dn

RS-485 Address

Dn Up

Esc

Esc

Process

Screen

Esc

Sub menu L1

Up/Dn Up/Dn

Top Level 1

Enter

Output Menu

Up/Dn

Sub menu L2

4-20mA Output#1

Up/Dn

Sub menu L2

4-20mA Output#2

Up/Dn

Sub menu L2

Optical Outputs

Setup

Sub Menu

Page 42

37

5.3.6.1 Submenu L2 Analog 4-20mA Menus

Vortex Flow Meters are equipped with two channels programmable analog 4-20

mA outputs. Each channel can be individually assigned to one of the following

process variables: Volumetric Flow, Mass Flow, Temperature*, Pressure*. By

default channel #1 is set to Volumetric Flow and channel #2 is set for Mass flow.

For each channel 4 mA and 20 mA points, which define the flow meter output

range, can be preset to maximize resolution of analog output. The meter is most

accurate when operated within the expected flow ranges for your application.

Setting the range to the limits of expected readings will maximize flow meter performance.

When adjusting 4-20mA limits, the value of the limits have to be entered in currently selected (global) for particular process variable engineering units.

5.3.6.2 Submenu L2 Digital Optical Outputs Menus

Two sets of optically isolated digital outputs are provided to actuate user supplied

equipment. These are programmable via digital interface or LCD/Keypad such

that the outputs can be made to switch when a specified event occurs (e.g. when

a low or high flow alarm limit is exceeded or when the totalizer reaches a specified value) or may be directly controlled by user.

The user can configure each optical output action from 14 different options:

- Disabled: No Action (output is not assigned to any events and not energized)

- Low Flow Alarm

- High Flow Alarm

- Range between H&L Flow alarm settings

- Totalizer #1 reading exceed set limit

- Totalizer #2 reading exceed set limit

- Low Temperature alarm (*T/P option only)

- High Temperature alarm (*T/P option only)

- Range between High and Low Temperature alarm (*T/P option only)

- Low Pressure alarm (*T/P option only)

- High Pressure alarm (*T/P option only)

- Range between High and Low Pressure alarm (*T/P option only)

NOTE: Your Vortex Flow Meter was calibrated at the factory for the

specified fluid and full scale flow range: 4mA – 0%F.S. and 20mA –

100%F.S. (see device’s label or calibration data sheet). There is no need

to adjust the Flow Meter 4-20 mA range limits settings, unless

adjustment for specific range is needed.

Page 43

38

- Diagnostic: Output will be energized when any of the Diagnostic or System

events are active

- Manual On Control: Output will be energized until Disabled option will be

selected.

By default both optically isolated outputs are disabled.

5.3.6.3 Submenu L2 RS-485 Address Menus

The standard Vortex flow meter comes with an RS-232 interface. For the optional

RS-485 interface, two hexadecimal characters of the address must be assigned.

By default each flow meter is shipped with RS-485 address 11. When more than

one device is present on RS-485 bus each device should have unique address. The

two characters of address in the hexadecimal representation can be changed from

00 to FF.

RS-485 address setting is not used for Vortex flow meter with RS-232 interface.

5.3.7 Submenu L1 Calibration Menu

The Calibration Menu contains the calibration coefficients for the flow meter, DSP

algorithm settings and Noise Reduction Filters parameters. These values should be

changed only by properly trained personnel. The Pipe ID, Vortex Meter Calibration

Factor, Full Scale Range and Low Flow Cutoff are set at the factory. Consult the factory for help with these settings if the meter is showing erratic flow rate.

NOTE: Address 00 is reserved for global addressing. Do not assign, the

global address for any device. When command with global address is

sent, all devices on the RS-485 bus execute the command but do not

reply with an acknowledge message.

NOTE: Do not assign the RS-485 address for two or more devices on

the same RS-485 bus. If two or more devices with the same address

are connected to the one RS-485 network, a communication collision

will take place on the bus and communication errors will occur.

NOTE: Your Vortex Flow Meter was calibrated configured at the factory

for the specified fluid, flowing conditions, and full scale flow range

(see device’s label or calibration data sheet). There is no need to adjust

the Flow Meter calibration factor, unless adjustment for specific

installation or flowing conditions high or low frequency off is needed.

Any alteration of the flow meter calibration factor will VOID calibration

warranty supplied with instrument.

Page 44

39

5.3.7.1 Submenu L2 PWM DSP Menu

Digital Signal Processing software algorithm can be set to calculate flow rate

based on five different methods:

a) Auto

b) number of pulses over preset measure interval

c) PWM (pulse width measurement)

d) FFT

e) AWD (Analog Watchdog circuitry, for troubleshooting only)

By default Vortex Frequency source is set to Auto. In this mode flow meter automatically switching source to best suited algorithm.

All methods calculates frequency of the pulses from the flow meter sensor. The

number of pulses over preset measure interval method convenient when pulsating

flow or especially noisy signals are encountered. This method allows to get stable

average flow rate if pulse measure interval is set to values equal or more than 2000

ms. This parameters effects the flow update rate. With higher value of the pulse

measure interval, the and stability of the flow measurement improves, but

response time become longer. A suggested pulse measure interval value of 2000

seconds is a good starting point for most applicable process fluids. With lower

settings the response time of the meter will be shorter, but and stability will

degrade. The pulse measure interval settings are only related to the number of

pulses over preset measure interval method. Pulse measure interval can be selected between 500 and 60000 ms.

Page 45

40

Figure 5.11 Submenu L2 PWM DSP Menu structure.

Tabular Entry

Ent

Dn Up

Numerical Entry

Esc

PWM

AUTO

Pulse Counts

FFT

Ent

AWD PWM

Dn Up

Numerical Entry

Ent

Dn Up

Numerical Entry

Ent

Dn Up

Numerical Entry

Ent

Dn Up

Numerical Entry

Ent

Dn Up

Numerical Entry

Ent

Dn Up

Tabular Entry

Ent

Dn Up

Enabled

Esc

Disabled

Enter

Pulse Counts

VorFreq. Source

Esc