Page 1

Technical Data Sheet No.: TD-TPU-TPV-11-12 Rev. B Date of Issue: April 2013

OPERATING MANUAL

Aalborg® TPU and TPV Peristaltic Pumps

1

Page 2

®

Aalborg

is a registered trademark of Aalborg Instruments & Controls.

®

Hypalon

Norprene

PharMed

is a registered trademark of DuPont Performance Elastomers, LLC.

®

is a registered trademark of Saint-Gobain Abrasives, Inc.

®

and Tygon® are registered trademarks of Saint-Gobain Performance

Plastics.

NOTE: Aalborg reserves the right to change designs and dimensions at its sole

discretion at any time without notice. For certified dimensions, please contact

®

Aalborg

.

2

Page 3

TABLE OF CONTENTS

1. GENERAL INFORMATION………………………………..4

1.1 General…………………………………………………...4

1.2 Principles of Operation…………………………………..4

1.2.1 TPU Models……………………………………………....5

1.2.2 TPV Models……………………………………………….6

1.2.3 TP1 & TP3 Pump Head Models……………………...…...6

2. UNPACKING THE PUMP………………………………….7

2.1 Inspect Package for Shipping Damage………………….7

2.2 Unpack Your Order……………………………………….7

3. PREPARATION & INSTALLATION……………..………....8

3.1 Installing Tubing in a TPU Pump………………………....8

3.2 Installing Tubing in a TPV Pump………………………....12

3.3 Installing the Pump……………………………………...17

4. SPECIFICATIONS………………………………………....18

5. OPERATING INSTRUCTIONS…………………………….19

5.1 Powering On……………………………………………..19

5.2 Priming the Pump………………………………………..19

5.3 Programming the TPUDP MUR3 Timer (if present)……. 20

5.4 Programming the TPURP MLR1 Timer (if present)….... .23

6. MAINTENANCE…………………………………………...25

7. TROUBLESHOOTING……………………………………..26

8. STORAGE………………………………………………....27

9. RETURN…………………………………………………..28

10. ABBREVIATIONS………………………………………....30

11. WARRANTY……………………………………………....31

3

Page 4

1. GENERAL INFORMATION

1.1 General

Aalborg’s TPU and TPV model peristaltic pumps are designed

for safety and long life. They are economical, easy to load,

sturdy, and compact for a small footprint. Designed for use

with liquids of widely diverse viscosity, they are suitable for

laboratory, processing and OEM applications, even fuel with

the appropriate tubing.

CAUTION: PERISTALTIC PUMPS, INCLUDING

MODELS TPU AND TPV, ARE NOT SUITABLE FOR USE

WITH BLOOD. THE ROLLER TECHNOLOGY CAN CAUSE

HEMOLYSIS.

1.2 Principles of Operation

Flexible tubing, which conveys fluid from source to

destination, is squeezed inside the pump head by rotating

rollers against a rigid, crescent-shaped occlusion wall. The

rollers induce suction in a pulsing rhythm. The occlusion is

adjustable on TPU models for increased pressure, or

decreased pressure to extend tubing life.

Each pump is comprised of a front panel with controls, a pump

head, a motor, a rigid case with four rubber feet and a handle.

4

Page 5

The handle is practical both to carry the pump and, when

rotated beneath the pump, to serve as a base that lifts and

angles the pump face, making the controls even more easily

accessible to the user.

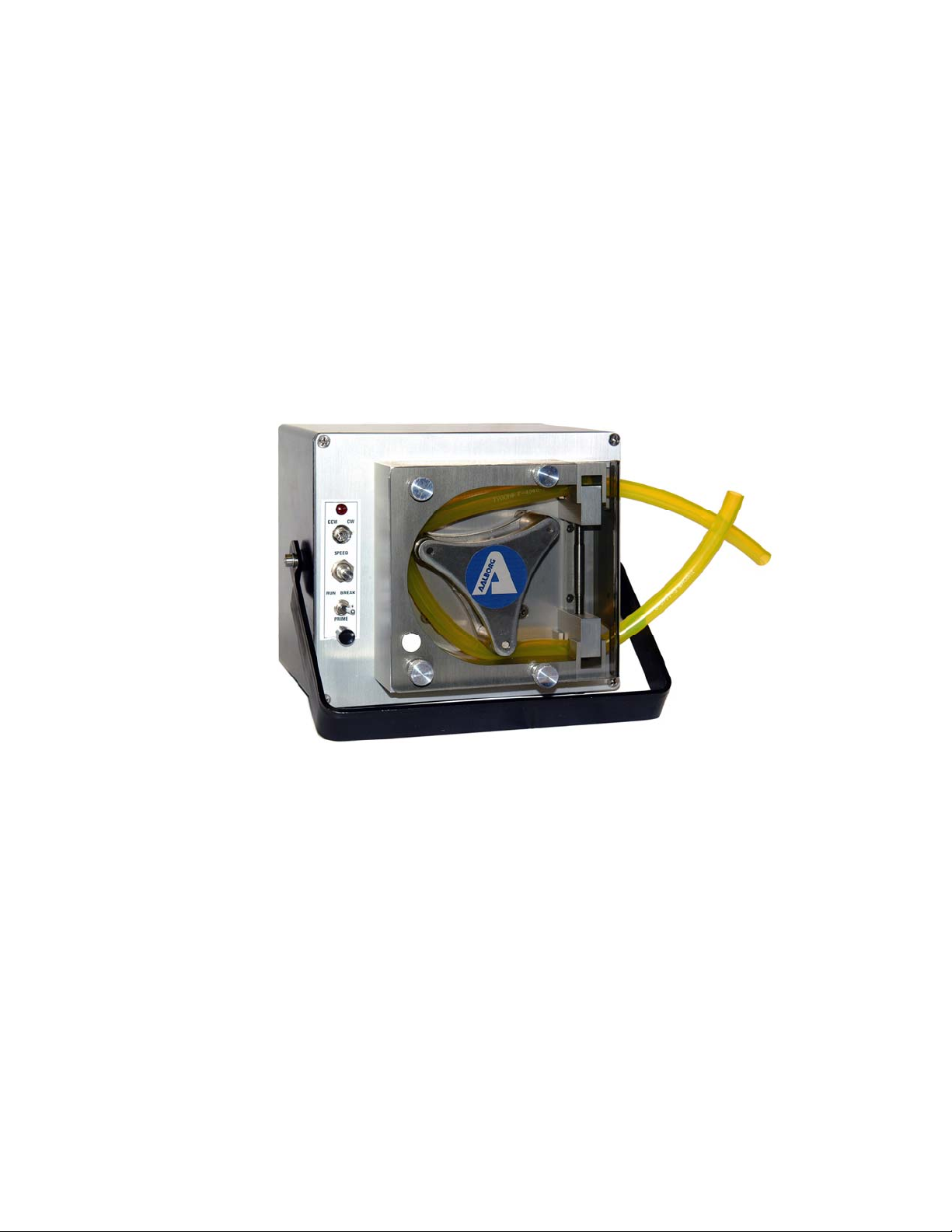

1.2.1 TPU Models

The TPU models are variable speed or fixed speed pumps. All

versions have 4 rollers standard, with an option of 10 rollers.

The fixed speed TPUFX, powered by an AC motor, is preset

at the factory between 3 and 50 rpm, according to the

customer’s order.

The variable speed TPUAD, TPUDP and TPURP models,

powered by a brushless 24 V DC motor, can be user-set from

0 to 60 rpm. Pumping direction is reversible.

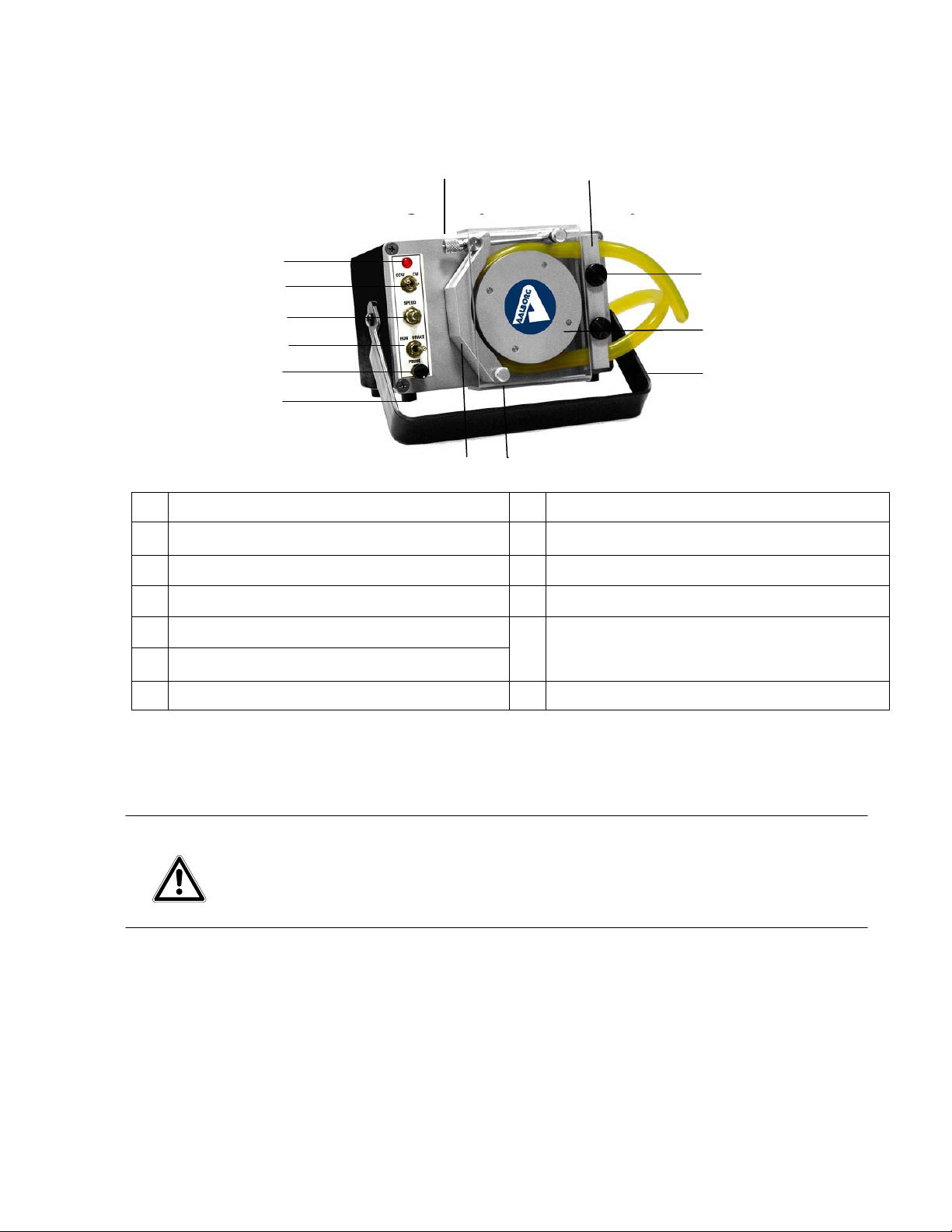

Figure 1: One Model TPU Pump: the TPUAD

5

Page 6

1.2.2 TPV Models

The TPV models, which have a pump head with 3 rollers, are

variable speed pumps, powered by a brushless 24 V DC motor,

can be user-set from 0 to 300 rpm. Pumping direction is

reversible.

Figure 2: One Model TPV Pump: the TPVAD

1.2.3 TP1 & TP2 Pump Head Models

The TP1 and TP2 models are stand alone pump heads with a

safety cover. They are not equipped with control panel, motor

or rigid case. The TP1 model has 4 rollers, while the TP2 model

has 10 rollers.

6

Page 7

2. UNPACKING THE PUMP

2.1 Inspect Package for Shipping Damage

Before you open the cardboard carton that contains your

order, carefully inspect the outside for any external damage

that may have occurred during shipping. If there is any

damage, report it immediately to the shipping company.

2.2 Unpack Your Order

Carefully open the carton from the top. Save all packing

materials for possible reuse for future storage or shipment.

If you find any shipping damage within the box, contact your

shipping company and report the damage to your Aalborg

®

distributor or to Aalborg directly.

Using the packing list, verify that you have received your entire

order. Promptly contact your Aalborg

®

distributor or Aalborg

directly if anything is missing.

7

Page 8

3. PREPARATION & INSTALLATION

3.1 Installing Tubing in a TPU Pump

If you have a TPV pump, skip to Section 3.2.

The pumps can take tubing of 1/8-, 3/16-, ¼- and 5/16-inch inner

diameter; all should have a wall thickness of 1/16 inch. Aalborg

recommends the use of the following flexible tubing: Tygon®

3603, peroxide-treated silicone, platinum-treated silicone,

PharMed®, Norprene®, and Hypalon®.

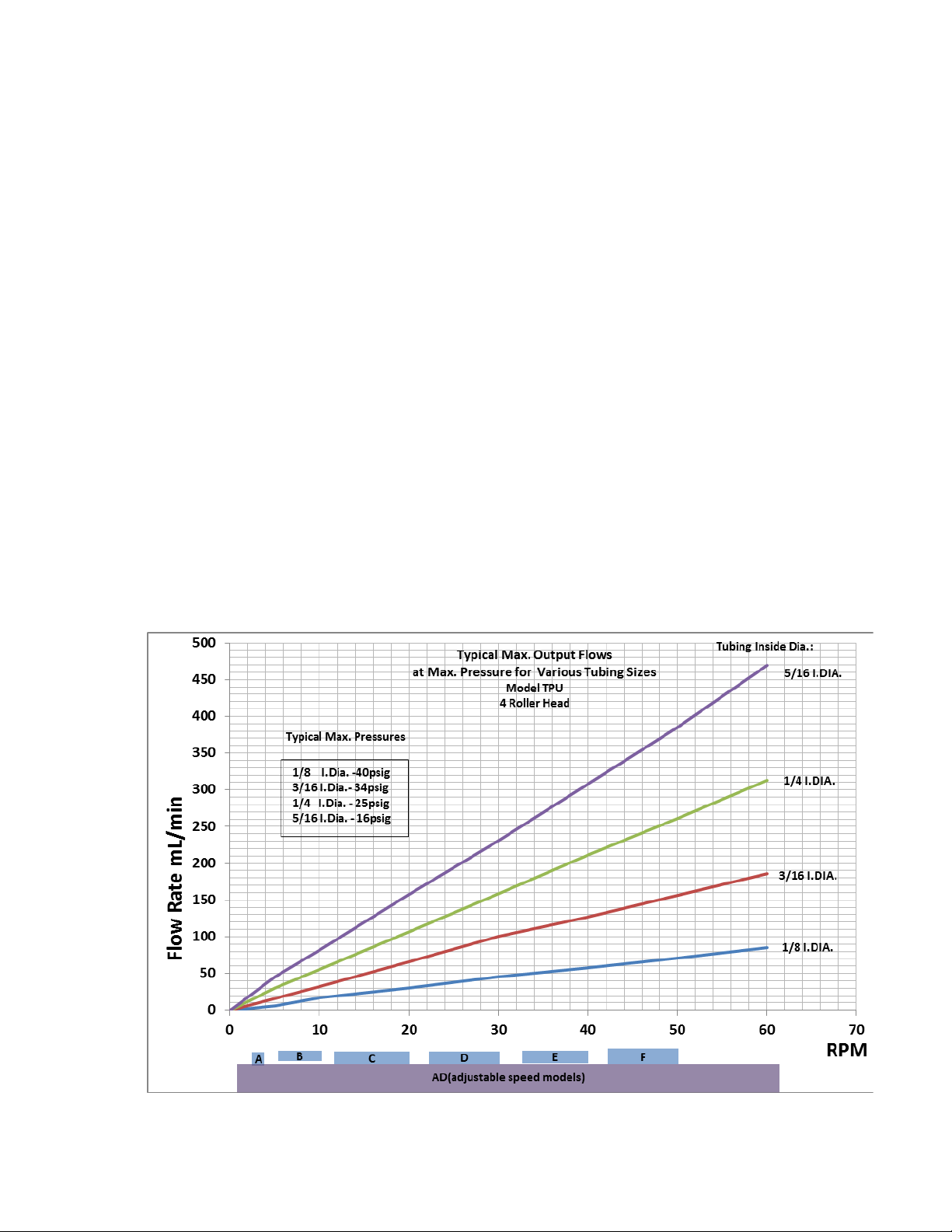

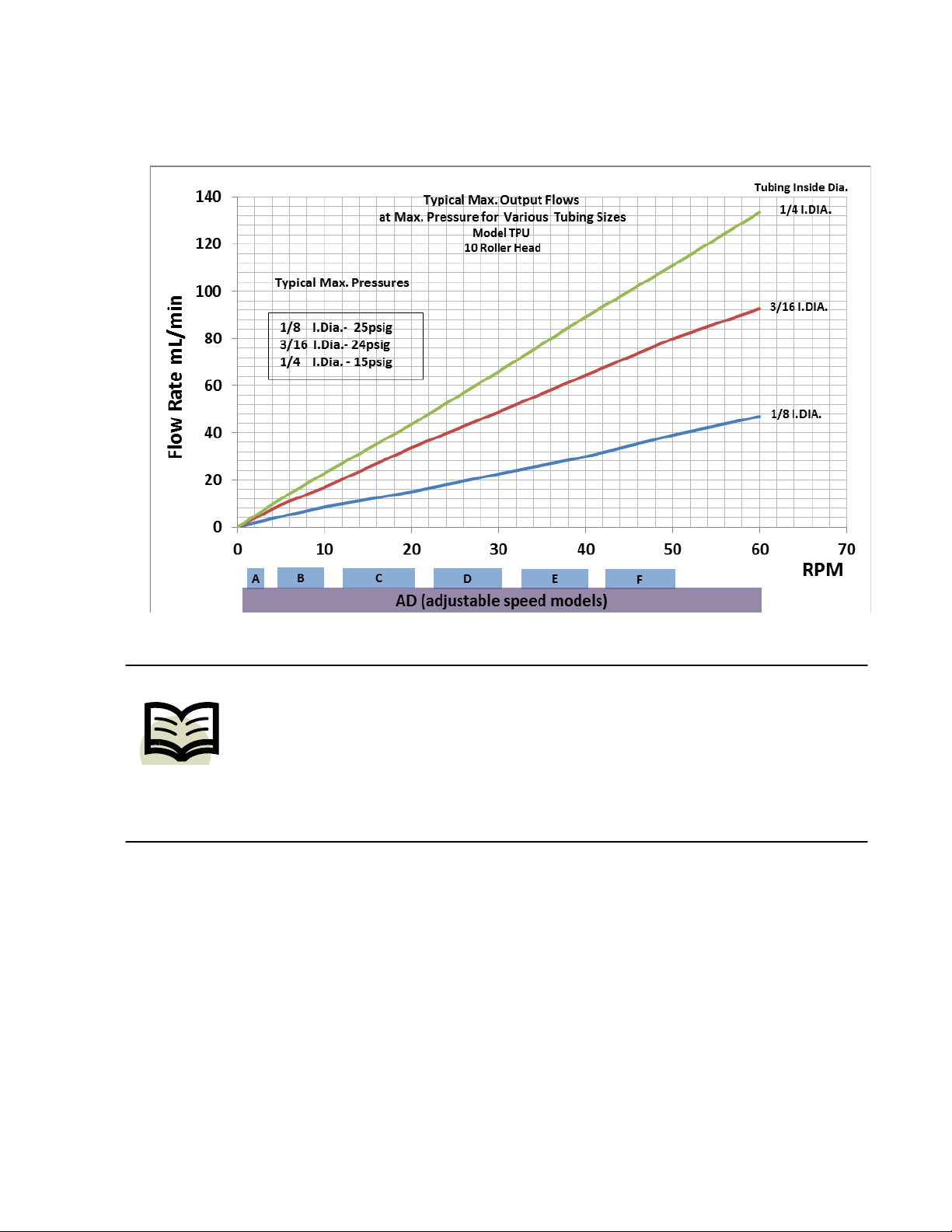

Graphs 1 & 2 provide typical flow rates for TPU pumps with 4

or 10 rollers, using Tygon® laboratory tubing of various inside

diameters:

®

GRAPH 1: TYPICAL TPU PUMP FLOW RATES (with 4 rollers)

8

Page 9

GRAPH 2: TYPICAL TPU PUMP FLOW RATES (with 10 rollers)

NOTE: Not all features are available on all TPU

models. In particular, the speed adjustment knob and

flow direction switch are not available on the fixed

speed models.

Figure 3 calls out the primary user-interface features of a TPU

pump.

9

Page 10

FIGURE 3: TPU PUMP FEATURES (model shown is a TPUAD)

1

2

13

12

11

10

9

8

7

6

3

4

5

1 Occlusion clamp lever 8 Foot (1 of 4)

2 Tubing separator 9 Prime button

3 Thumbscrews for separator 10 Run/Brake (on/off) switch

4 Transparent safety cover 11 Pumping speed adjustment knob

5 Handle/base 12 Flow direction switch (CCW,

6 Cover thumbscrew (1 of 2)

7 Occlusion clamp 13 Run indicator light

counterclockwise/CW, clockwise)

To install tubing, with reference to Figure 3:

CAUTION: MAKE SURE THE PUMP IS TURNED OFF.

BE CAREFUL NOT TO PINCH YOUR FINGERS.

1. Remove the 2 thumbscrews from the transparent safety

cover, then lift the cover away from the pump face and set

it aside.

10

Page 11

2. Unscrew the thumbscrew at the end of the occlusion

clamp lever until the lever is loose enough to move.

3. Move the occlusion clamp lever to release all pressure

from the occlusion clamp, opening the tubing channel.

4. Loosen the 2 black thumbscrews on the tubing separator,

until the separator is free.

5. Lift the separator straight away from the pump face and

set it aside.

6. To load the tubing, lay the tubing in the pump channel

around the pump head, turning the pump head by hand in

either direction, with both ends of the tubing on the

righthand side.

7. When the tubing is in place, reinstall the tubing separator,

with each end cupping the tubing.

8. Finger tighten the black thumbscrews on the tubing

separator until the separator fits snugly against the tubing .

Make sure the tubing is immobilized but not pinched.

9. Snap the occlusion clamp lever back into place and tighten

its thumbscrew until the occlusion clamp is appropriately

tight.

10. Hold the safety cover in place as you reinstall both

thumbscrews. Finger tighten the thumbscrews.

CAUTION: NEVER RUN THE PUMP WITHOUT THE

SAFETY COVER IN PLACE.

11

Page 12

3.2 Installing Tubing in a TPV Pump

The pumps can take tubing of ¼- , 5/16-, 3/8-, 7/16- and ½- inch

inner diameter; all should have a wall thickness of 1/16 inch.

Aalborg

®

recommends the use of the following flexible tubing:

Tygon® 3603, peroxide-treated silicone, platinum-treated

silicone, PharMed

®

, Norprene®, and Hypalon®.

Graphs 3a & 3b provide typical flow rates for TPV pumps with 3

rollers, using Tygon® laboratory tubing of various inside

diameters:

GRAPH 3a: TYPICAL TPV PUMP FLOW RATES

(1/4- , 5/16- & 3/8-inch inner diameter)

12

Page 13

GRAPH 3b: TYPICAL TPV PUMP FLOW RATES

(7/16- & 1/2-inch inner diameter)

13

Page 14

FIGURE 4: TPV PUMP FEATURES

12

11

10

9

8

7

1

2 4

3

5

6

1 Fixed occlusion wall 7 Prime button

2 Pump head (3 rollers) 8 Run/Brake (on/off) switch

3 Cover thumbscrew (1 of 4) 9 Pumping speed adjustment knob

4 Tubing 10 Flow direction switch

5 Adjustable tubing holder

subassembly (see Figure 5)

6 Handle/base 12 Rigid case

11 Run indicator light

One special feature of the TPV pumps is the adjustable tubing

holder subassembly, which functions like a turnbuckle to

loosen the subassembly for removal and to tighten it for

installation. The threading on both ends of its central rod

allows you to independently adjust the pressure of each end

block against the tubing.

14

Page 15

When the subassembly is removed from the pump, each end

block can be spun upward or downward independently on the

turnbuckle. As shown in Figure 5, the end blocks are grooved

on one side. These grooves fit onto the key ridge on the front

plate in order to set the subassembly securely in place.

FIGURE 5: ADJUSTABLE TUBING HOLDER SUBASSEMBLY

2

1

1 End block 2 Turnbuckle

NOTE: Each end block can be raised or lowered

independantly on the rod, to suit the need for the

pressure on the tubing at either ends.

To install tubing, with reference to Figures 4 & 5:

CAUTION: MAKE SURE THE PUMP IS TURNED OFF.

BE CAREFUL NOT TO PINCH YOUR FINGERS.

1

15

Page 16

1. Remove the 4 thumbscrews from the transparent safety

cover, then lift the cover away from the pump face and set

it aside.

2. Loosen the turnbuckle rod between the top and bottom

parts of the tubing holder subassembly, until the

subassembly is movable.

3. Lift the tubing holder straight away from the pump face.

4. To load the tubing, begin to lay the tubing in the pump

channel, with both ends on the righthand side.

5. Manually turn the tri-star shaped head to turn the rollers as

needed so you can insert the tubing against the occlusion

wall.

6. When the tubing is in place, reinstall the tubing holder, with

the cutout on each end cupping the tubing. Make sure to

align the groove in the tubing holder end blocks with the

key ridge on the pump face.

7. Finger tighten the turnbuckle rod between the ends of the

tubing holder until the tubing is securely help in place, top

and bottom.

8. Hold the safety cover in place as you reinstall all 4

thumbscrews. Finger tighten the thumbscrews.

CAUTION: NEVER RUN THE PUMP WITHOUT THE

SAFETY COVER IN PLACE.

16

Page 17

3.3 Installing the Pump

Place the pump on a stable, even surface, and position it so

the pump head and controls are easily accessible to the user.

CAUTION: AFTER THE TUBING IS LOADED BUT

BEFORE THE PUMP IS PRIMED OR RUN, REST THE

PUMP SQUARELY ON ITS 4 RUBBER FEET, TO

PREVENT LIQUID DRIPPING INTO THE PUMP HEAD OR ONTO

THE CONTROLS.

Once the pump has been primed, if desired, you can rotate the

handle underneath the pump to serve as a base. If needed,

tighten the screws that hold the handle to the pump body, so

the handle will not slip from the designated position.

17

Page 18

4. SPECIFICATIONS

TPU

Variable Speed

Rollers, quantity

Material

Maximum Lift,

Pump Head

Maximum

Suction,

Pump Head

Pumping Speeds 0 - 60 rpm Preset to 3, 10, 20,

Motor Brushless DC AC Shaded Pole Brushless DC

Power Supply* Power cord & plug Power cord & plug Power cord & plug

Electrical

Requirement

Fuses Two 2-Amp, 250 V, fast-acting, glass, 5 x 20 mm, UL-listed

4 Standard

10 Optional

316 Stainless steel

340 in H2O

(12.3 psig)

350 in H2O

(12.6 psig)

110-250 V 110-250 V 110-250 V

316 Stainless steel

30, 40 or 50 rpm

TPU

Fixed Speed

4 Standard

10 Optional

340 in H2O

(12.3 psig)

350 in H2O

(12.6 psig)

TPV

Variable Speed

3 Standard

316 Stainless steel

310 in H2O

(11.2 psig)

310 in H2O

(11.2 psig)

0 - 300 rpm

Reversible flow Yes No Yes

Priming function Yes No Yes

Timing function Optional No Optional

*Specific power cords & plugs available for North America, Europe, UK, and

Australia

DIMENSIONS

FX, AD, DP & RP

without handle 6.5 in W x 5.67 in D x 4.12 in H

(16.5 cm W x 14.4 cm D

pump head

alone

6.5 in W x 1.23 in D x 4.12 in H

(16.5 cm W x 3.1 cm D

TPU

x 10.5 cm H)

TPU1

x 10.5 cm H)

TPV

AD, DP & RP

7.7 in W x 7.45 in D x 6.56 in H

(19.6 cm W x 18.9 cm D

x 16.7 cm H)

TPU2

6.5 in W x 1.23 in D x 4.12 in H

(16.5 cm W x 3.1 cm D

x 10.5 cm H)

18

Page 19

5. OPERATING INSTRUCTIONS

5.1 Powering On

1. After you verify that your power cord plug is suitable for

your electrical supply, connect the cord to the back of the

pump case, then plug it into your power outlet.

2. On the back of the pump, turn the on/off power switch ON.

3. If your pump has a Run/Brake switch, turning the switch to

Run will turn the pump on.

5.2 Priming the Pump

With one end of the tubing in the liquid you need to pump, and

the other end in the target receptable or appropriately

clamped to the target site:

If your pump has a Prime button, press and hold the button

at Maximum Speed for a few seconds, until the liquid is

successfully suctioned into the tubing.

If your pump does not have a Prime button, turn the pump

On (main power switch on back). The amount of time it will

take for the pump to prime depends on the preset pump

speed.

19

Page 20

5.3 Programming the TPUDP MUR3 Timer (if present)

The timer relay on this pump model can be set to two modes

of operation, as explained with reference to Figures 6 & 7.

FIGURE 6: LOCATION OF MUR3 TIMER CONTROLS

1

1 See Figure 7 for a closer look

20

Page 21

FIGURE 7: MUR3 TIMER CONTROLS

1

2

3

4

5

1 Start Timer button 4 Multiplication knob

2 Timer ON/OFF switch 5 Relay timer Mode switch

3 Time Period knob

Single Shot Mode

1. Using an appropriate flathead screwdriver, dial the Time

Period (white) knob to the desired position, then dial the

Multiplication (blue) knob to the desired position.

2. To run once for the programmed time period, set the relay

timer MUR3 Mode switch to B.

3. Activate the timed program manually by pressing the

pump’s Start Timer button, or activate it remotely via the

9-pin connector on the pump’s rear panel.

21

Page 22

NOTE: For TPUDP pumps, a Remote Start option is

available using the 9-pin female D-connector located

on the rear panel, via pins 1 and 5.

Continuous Pulse Mode

1. Using an appropriate flathead screwdriver, dial the Time

Period (white) knob to the desired position, then dial the

Multiplication (blue) knob to the desired position.

2. To run a preset continuous program of a specified run time

(ON) followed by the same length of OFF time, set the relay

timer MUR3 Mode switch to Di.

Remember that you can also set the pumping speed, which

will control the amount dispensed during the ON period.

NOTE: Any time you change the TPUDP pump’s MUR3 timer

Mode, the new setting will be activated only after

cycling Timer’s On/Off switch. We recommend

therefore that you change timer Mode settings when

the timer switch set to the Off position. This way, when the

timer On/Off switch set back to the On position, the new

settings will be activated.

22

Page 23

5.4 Programming the TPURP MLR1 Timer (if present)

r

The TPURP timer relay can be set to dispense liquid over a

chosen time period, and to stop dispensing for another chosen

time period. With reference to Figure 8, use the top set of

knobs on the MLR1 timer relay for setting up the dispensing

ON mode, and use the bottom set for setting up the nondispensing OFF mode.

FIGURE 8: MLR1 TIMER CONTROLS

(shown uninstalled)

1

3

4

1 ON Time Period knob 3 OFF Time period knob

2 ON Multiplication knob 4 OFF Multiplication knob

2

The pump can be set to dispense ON and OFF for any of the

following 7 time periods:

1. 0.1 – 1 sec 5. 6 – 60 min

2. 1 – 10 sec 6. 1 – 10 h

3. 6 – 60 sec 7. 10 – 100 hr

4. 1 – 10 min

23

Page 24

Using an appropriate flathead screwdriver, dial the Time

Period (white) knob to the desired position, then dial the

Multiplication (blue) knob to the desired position. For

example, you want your pump to be ON (dispensing) for 24

minutes, and then to be OFF (not dispensing) for 3 hours:

1. Set the top (ON) Time Period knob to the 6 - 60 min range,

then dial the top Multiplication knob t0 the number 4. 6 x 4

= 24 minutes.

2. Set the bottom (OFF) Time Period knob to the 1 - 10 hr

range, then dial the bottom Multiplication knob t0 the

number 3. 1 x 3 = 3 hours .

NOTE: For TPURP pumps. the Start Timer button and

Remote Start option (using the 9-pin female

D-connector located on the rear panel) are not

supported.

24

Page 25

6. MAINTENANCE

Routinely check the tubing for wear and/or leaks. Replace

as needed.

Routinely clean the outside of the pump with a damp cloth,

then wipe it with a dry cloth.

25

Page 26

7. TROUBLESHOOTING

Symptom Possible Solution

Pump does not

power on.

Pump does not

produce the

expected flow.

Make sure the power cord is properly

connected between the back of pump

and the power outlet.

One or both of the fuses needs to be

replaced.

Liquid may have leaked into the pump

head: with the power OFF, clean the

pump head with a moist cloth, then dry

it. If it still does not run, call for service.

Tubing may be loose around the pump

head; remove, then reinstall it tightly.

26

Page 27

8. STORAGE

If you need to store your equipment, we advise you to pack it

for safety in the original shipping carton.

27

Page 28

9. RETURN

If you need to return your pump (or pump component) for

repair, please contact the customer service representative at

your Aalborg

®

distributor or, if you purchased the item

directly, contact the customer service representative at

Aalborg®. Be sure to request a Return Authorization Number

(RAN).

NOTE: Equipment returned without a RAN will not be

accepted.

We advise you to pack the equipment for safety in its original

shipping carton.

You are responsible for return shipping charges. Collect

shipments will be refused.

CAUTION: ANY EQUIPMENT RETURNED FOR

REPAIR MUST BE COMPLETELY CLEANED OF ANY

DANGEROUS MATERIAL, INCLUDING BUT NOT

LIMITED TO TOXIC, BACTERIALLY INFECTIOUS,

CORROSIVE OR RADIOACTIVE SUBSTANCES.

ALL EQUIPMENT RETURNED MUST INCLUDE A FULLY

EXECUTED, SIGNED AND DATED

AVAILABLE FROM YOUR AALBORG® SERVICE MANAGER.

SAFETY CERTIFICATE,

28

Page 29

Aalborg® reserves the right to charge you a fee for equipment

returned under warranty if the instrument is determined to be

free of defects covered by warranty.

29

Page 30

10. ABBREVIATIONS

r

r

The following abbreviations are used in this manual:

AC Alternating Current

cm Centimeters

D Deep

DC Direct Current

H High

Hg Mercury

H2O Water

hr Hours

in Inches

min Minutes

OEM Original Equipment Manufacture

RAN Return Authorization Numbe

rpm Revolutions per minute

sec Seconds

V Volts

W Wide

30

Page 31

11. WARRANTY

Aalborg® TPU and TPV Pumps, Pump Heads & Pump Motors

are warranted against defects in parts and workmanship for

a period of one year from the date of purchase.

If tubing used with is not recommended by Aalborg

®

, this

warranty may be void.

If the instrument is used to pump liquids specifically not

recommended by Aalborg

®

, this warranty may be void.

Defective products will be repaired or replaced solely at the

discretion of Aalborg® at no charge. Shipping charges are

the responsibility of the customer.

This warranty is void if the equipment is found to be

damaged by misuse, accident, or has been repaired or

modified by anyone other than Aalborg

®

or a factoryauthorized service facility.

This warranty defines the obligation of Aalborg® and no

other warranties expressed or implied will be recognized.

NOTE: See Section 9 for proper Return procedures.

31

Page 32

Aalborg

20 Corporate Drive

Orangeburg, New York 10962 USA

Phone: +1 845 770 3000

Fax: +1 845 770 3010

32

Loading...

Loading...