Page 1

OPERATING MANUAL

SMV

Stepping Motor Valve

Technical Data Sheet No. TD0305M Rev. C

Date of Issue: May 2012

Page 2

Aalborg®reserves the right to make changes to information and

specifications in this manual without notice.

Page 3

TABLE OF CONTENTS

1. UNPACKING THE SMV Motorized Valve........................

1.1 Inspect Package for External Damage..................................................

1.2 Unpack the Motorized Valve..................................................................

1.3 Returning Merchandise for Repair........................................................

2. INSTALLATION...............................................................................

2.1 Primary Gas Connections.....................................................................

2.2 Electrical Connections...........................................................................

3. SPECIFICATIONS..........................................................................

3.1 CE Compliance......................................................................................

4. OPERATING INSTRUCTIONS....................................................

4.1 Preparation and Warm Up.....................................................................

4.2 Valve OFF Control (Open Collector NPN Compatible).........................

4.3 Valve Purge/Open.................................................................................

5. TROUBLESHOOTING...................................................................

5.1 Common Conditions..............................................................................

5.2 Troubleshooting Guide...........................................................................

5.3 Technical Assistance.............................................................................

APPENDIX 1 DIMENSIONAL DRAWINGS

APPENDIX 2 WARRANTY

1

1

1

1

2

2

2

4

5

6

6

7

7

8

8

9

9

Page 4

TRADEMARKS

Aalborg®is a registered trademark of Aalborg Instruments.

Buna

®

is a registered trademark of DuPont Dow Elastometers.

Kalrez®is a registered trademark of DuPont Dow Elastomers.

Viton

®

is a registered trademark of Dupont Dow Elastometers L.L.C.

Page 5

1. UNPACKING THE SMV MOTORIZED VALVE

1.1 Inspect Package for External Damage

Your SMV Motorized Valve was carefully packed in a sturdy cardboard car-

ton, with anti-static cushioning materials to withstand shipping shock. Upon

receipt, inspect the package for possible external damage. In case of external

damage to the package contact the shipping company immediately.

1.2 Unpack the Motorized Valve

Open the carton carefully from the top and inspect for any sign of concealed

shipping damage. In addition to contacting the shipping carrier please forward

a copy of any damage report to your distributor or Aalborg

®

directly.

When unpacking the instrument please make sure that you have all the items

indicated on the Packing List. Please report any shortages promptly.

1.3 Returning Merchandise for Repair

Please contact the customer service representative of your distributor or

Aalborg

®

if you purchased your Motorized Valve directly, and request a Return

Authorization Number (RAN). Equipment returned without an RAN will

not be accepted. Aalborg

®

reserves the right to charge a fee to the customer

for equipment returned under warranty claims if the instruments are tested to

be free from warrantied defects.

Shipping charges are borne by the customer. Items returned "collect" will not

be accepted!

It is mandatory that any equipment returned for servicing be purged and neutralized of any dangerous contents including but not limited to toxic, bacterially infectious, corrosive or radioactive substances. No work shall be performed

on a returned product unless the customer submits a fully executed, signed

SAFETY CERTIFICATE. Please request form from the Service Manager.

1

Page 6

2. INSTALLATION

2.1 Primary Gas Connections

Prior to connecting gas lines inspect all parts of the piping system including

ferrules and fittings for dust or other contaminants. Be sure to observe the

direction of gas flow as indicated by the arrow on the front of the meter when

connecting the gas system to be monitored.

Insert tubing into the compression fittings until the ends of the properly sized

tubing home flush against the shoulders of the fittings. Compression fittings

are to be tightened according to the manufacturer's instructions to one and

one quarter turns. Avoid over tightening which will seriously damage fittings.

SMV Motorized Valves are supplied with standard 3/8 inch (SMV-20), 1/2

inch (SMV-30), or 3/4 inch (SMV-40) inlet and outlet compression fittings.

Using a Helium Leak Detector or other equivalent method perform a thorough

leak test of the entire system. (All SMV's are checked prior to shipment for

leakage within stated limits. See specifications in this manual.)

2.2 Electrical Connections

The motorized valve requires a +12VDC power supply with a minimum current rating of 800 mA. Operating power and valve control signals are supplied

via the 9-pin "D" connector located at the side of the valve. For normal operating the motorized valve requires at least two control signals:

l Direction (12V CMOS logic level, pin 8 on the 9-pin "D" connector)

l Speed (0-2.5 VDC analog signal, pin 4 on the 9-pin "D" connector)

When direction is LOW (GND) valve goes down (closes), when direction is

HIGH valve goes up (opens). The "speed" voltage on pin 4 determines how

quickly the valve will operate. The signal amplitude for "speed" control signal

must remain within the limits of 0 to +2.5 VDC.

It may be necessary to override "direction" and "speed" signals with a preset

(2.75 VDC) speed control signal. This can be accomplished with valve CLOSE

and PURGE control signals (open collector NPN compatible). In order to

CLOSE valve pin 3 on the 9-pin "D" connector has to be connected to GND

(pin 2). A GREEN light on the top of the valve will indicate a CLOSE valve

condition. In order to PURGE valve pin 7 on the 9-pin "D" connector has to be

connected to GND (pin 2). A RED light on the top of the valve will indicate a

fully OPEN valve condition.

2

Page 7

During normal operation the valve remains in the last position as it is de-energized. After powering up, the valve will be automatically closed within the first

10 seconds and after that resumes control operation.

FIG.b-1 SMV 9-PIN “D” CONNECTOR CONFIGURATION

WARNING: DO NOT CONNECT 24 Vdc POWER SUPPLY UNLESS YOUR

SMV VALVE WAS ORDERED AND CONFIGURED FOR 24Vdc VOLTAGE

(SEE POWER REQUIREMENTS LABEL). DO NOT APPLY TO THE

DIRECTION CONTROL SIGNAL (PIN 8) VOLTAGE MORE THAN 12 Vdc

Important Notes:

In general, "D" Connector numbering patterns are standardized. There are,

however, some connectors with nonconforming patterns and the numbering

sequence on your mating connector may or may not coincide with the numbering sequence shown in our pin configuration table above. It is imperative

that you match the appropriate wires in accordance with the correct sequence

regardless of the particular numbers displayed on your mating connector.

Make sure power is OFF when connecting or disconnecting any cables in

the system.

The power input is protected by a 1600mA M (medium time-lag) resettable

fuse. If a shorting condition or polarity reversal occurs, the fuse will cut power

to the valve circuit. Disconnect the power to the unit, remove the faulty condition, and reconnect the power. The fuse will reset once the faulty condition

has been removed.

Use of the SMV Motorized Valve in a manner other than that specified in

this manual or in writing from Aalborg

®

, may impair the protection

provided by the equipment.

3

,

PIN FUNCTION

1 (unassigned).

2 Common, Power Supply Minus.

3 Valve Off Control (12V CMOS Low active).

4 Speed control signal (analog 0-2.5 Vdc).

5 (unassigned).

6 Common for Speed control.

7 Valve PURGE control (12V CMOS Low Active).

8 Direction control signal (digital 12Vdc CMOS logic).

9 +12 Vdc (+24Vdc optional) Power Supply Plus.

Page 8

3. SPECIFICATIONS

MATERIALS OF CONSTRUCTION:

ALUMINUM MODELS: Aluminum housings and valve blocks, Viton

®

O-Rings, PFA

closing pins.

STAINLESS/PTFE MODELS: 316 stainless steel valve blocks, PTFE-lined Aluminum

Housing blocks, Viton

®

O-Rings, and PFA closing pins.

MAXIMUM FLOW RATES: 1000 sL/min (air), 28 L/min (water).

CONNECTIONS: 3/8", 1/2", compression and 3/4" FNPT.

ELECTRICAL CONNECTIONS: 9-pin "D" connector, located at the side of the valve.

POWER INPUT: +12Vdc @ 800mA standard or optional +24Vdc @ 600mA. Power

input is protected by 1600mA resetable fuse.

DIRECTIONAL CONTROL SIGNAL: 12Vdc CMOS compatible logic signal (10K input

impedance). UP: Logic High (>7.5Vdc <= 12Vdc). Do not apply more than 12 Vdc.

DOWN: Logic Low (<2.3Vdc).

SPEED CONTROL SIGNAL: Analog 0 to 2.5Vdc (100K input impedance).

TTL ON/OFF OVERRIDE: TTL low level to pins 7 and 3 (10K input impendence).

RESPONSE TIME: 100ms time constant.

DIFFERENTIAL PRESSURES: 700 to 1000 mbars (10 to 15 psid).

MAXIMUM OPERATING PRESSURE: 500 psig (35 bars).

MAXIMUM DIFFERENTIAL PRESSURE: 50 psig (3.45 bars).

ENVIRONMENTAL (PER IEC 664): Installation Level II; Pollution Degree II.

GAS AND AMBIENT TEMPERATURE: 32

F

F to 122 FF (0 FC to 50 FC).

LEAK INTEGRITY: 1 x 10

-7

sccs He max to the outside environment.

WETTED MATERIALS:

SMV20/SMV30/SMV40: Anodized aluminum, brass, and 316 stainless steel with

VITON

®

O-rings seals; BUNA-N®, EPR or KALREZ®O-rings are optional.

4

Page 9

SMV20-S/SMV30-S/SMV40-S: 316 stainless steel with VITON®O-rings seals;

BUNA-N®, EPR or KALREZ®O-rings are optional.

Aalborg

®

makes no expressed or implied guarantees of corrosion resistance

of Motorized Valves as pertains to different flow media reacting with components of valves. It is the customers' sole responsibility to select the model

suitable for a particular gas based on the fluid contacting (wetted) materials

offered in the different models.

3.1 CE Compliance

Any model SMV bearing a CE marking on it, is in compliance with the below

stated test standards currently accepted.

EMC Compliance with 89/336/EEC as amended;

Emission Standard: EN 55011:1991, Group 1, Class B

Immunity Standard: EN 55082 1:1992

5

Page 10

TABLE I FLOW CONFIGURATIONS

4. OPERATING INSTRUCTIONS

The SMV motorized valve requires a +12VDC power supply with a minimum

current rating of 800 mA. The operating power and valve control signals are

supplied via the 9-pin "D" connector located at the side of the valve.

The SMV motorized valve has three modes of operation: Valve Active

(Auto), Valve OFF Control and Valve Purge (Open).

4.1 Valve Active (Auto)

For normal operating in Auto mode the motorized valve requires at least two

control signals:

l Direction (12Vdc CMOS compatible logic level, pin 8 on the 9-pin "D" connector)

l Speed (0-2.5 VDC analog signal, pin 4 on the 9-pin "D" connector)

When direction is LOW (GND) valve goes down (closes), when direction is

HIGH valve goes up (opens). The "speed" voltage on pin 4 determines how

quickly the valve will operate. The signal amplitude for "speed" control signal

must remain within the limits of 0 to +2.5 VDC. The 2.5 Vdc input signal corresponds to approximately 250 steps per second. With resolution of the stepping motor of 0.00025"/step it results in a maximum speed about 0.0625"/sec.

6

MODEL

NUMBERS

CONSTRUCTION

MAXIMUM FLOW RATE

(at 20 psi diff. pressure, 70

F

F)

Cv CONNECTIONS

AIR WATER

sL/min scfh L/min GPM

SMV20-A Aluminum 200 424 5.6 1.48 0.336 3/8”

SMV20-S

316 stainless

steel/PTFE

200

424 5.6 1.48

0.336 3/8”

SMV30-A Aluminum 500 1060 14.2 3.75 0.855 1/2”

SMV30-S

316 stainless

steel/PTFE

500 1060 14.2 3.75

0.855

1/2”

SMV40-A Aluminum 1000 2119 28 7.4 1.735 3/4” FNPT

SMV40-S

316 stainless

steel/PTFE

1000 2119

28 7.4

1.735

3/4” FNPT

Page 11

4.2 Valve OFF Control

(Open Collector NPN Compatible)

It may be necessary or desirable to set the flow and maintain that setting while

being able to turn the flow control valve off and on again. Closing of the valve

(without changing the "speed"and "direction" control signals) can be accomplished by connecting pin 3 of the 9-pin "D" connector to COMMON ( power

ground). The Motorized valve will be given the command to close indicated by

a green light on top of the unit).

Conversely, when the connection is left open or pin 3 remains unconnected

the valve remains active (executes "speed"and "direction" control signals).

The valve will remain active when the VALVE OFF pin remains "floating".

This feature is compatible with open collector NPN transistor switches, as

found in DC output ports of programmable controllers and similar devices.

The simplest means for utilizing the VALVE OFF control feature, is to connect

a toggle switch between the COMMON and VALVE OFF pins of the SMV

valve.

4.3 Valve Purge

At times, it may be necessary to purge the flow system with a neutralizing gas

such as pure dry nitrogen. The SMV valve is capable of a full open condition

for the valve, regardless of setpoint conditions. Connecting the PURGE pin

(pin 7 on 9 pin "D" connector) to ground will fully open the valve.

A red light on top of the valve will indicate an OPEN valve condition, normal

for flow conditions.

Please note that the valve stays OPEN even if power is no longer applied.

To CLOSE the Motorized Control Valve, connect pins 3 and 2.

7

Page 12

5. TROUBLESHOOTING

5.1 Common Conditions

Your SMV motorized valve was thoroughly checked at numerous quality control points during and after manufacturing and assembly operations.

It was carefully packed to prevent damage during shipment. Should you feel

that the instrument is not functioning properly please check for the following

common conditions first:

Are all cables connected correctly?

Are there any leaks in the installation?

Is the power supply correctly selected according to requirements? When several meters are used a power supply with appropriate current rating should be

selected.

Were the connector pinouts matched properly? When interchanging with

other manufacturers' equipment, cables and connectors must be carefully

wired for correct pin configurations.

8

Page 13

5.2 Troubleshooting Guide

For best results it is recommended that instruments are returned to the factory for servicing. See section 1.3 for return procedures.

5.3 Technical Assistance

Aalborg®Instruments will provide technical assistance over the phone to qualified repair personnel. Please call our Technical Assistance at 800-866-3837.

Please have your Serial Number and Model Number ready when you call.

9

INDICATION LIKELY REASON REMEDY

no response to

"speed" and "direction"

control signals

inadequate gas

pressure

apply appropriate gas

pressure

cable or connector

malfunction

check cables and all

connections or replace

valve out of adjustment return to factory for

repair / replacement

valve does not work in

OPEN position

incorrect valve

adjustment

return to factory for

repair / replacement

pc board defect return to factory for

repair / replacement

cable or connectors

malfunction

check cable and

connectors or replace

valve does not work in

CLOSE position

incorrect valve

adjustment

return to factory for

repair / replacement

pc board defect return to factory for

repair / replacement

cable or connectors

malfunction

check cable and

connectors or replace

Page 14

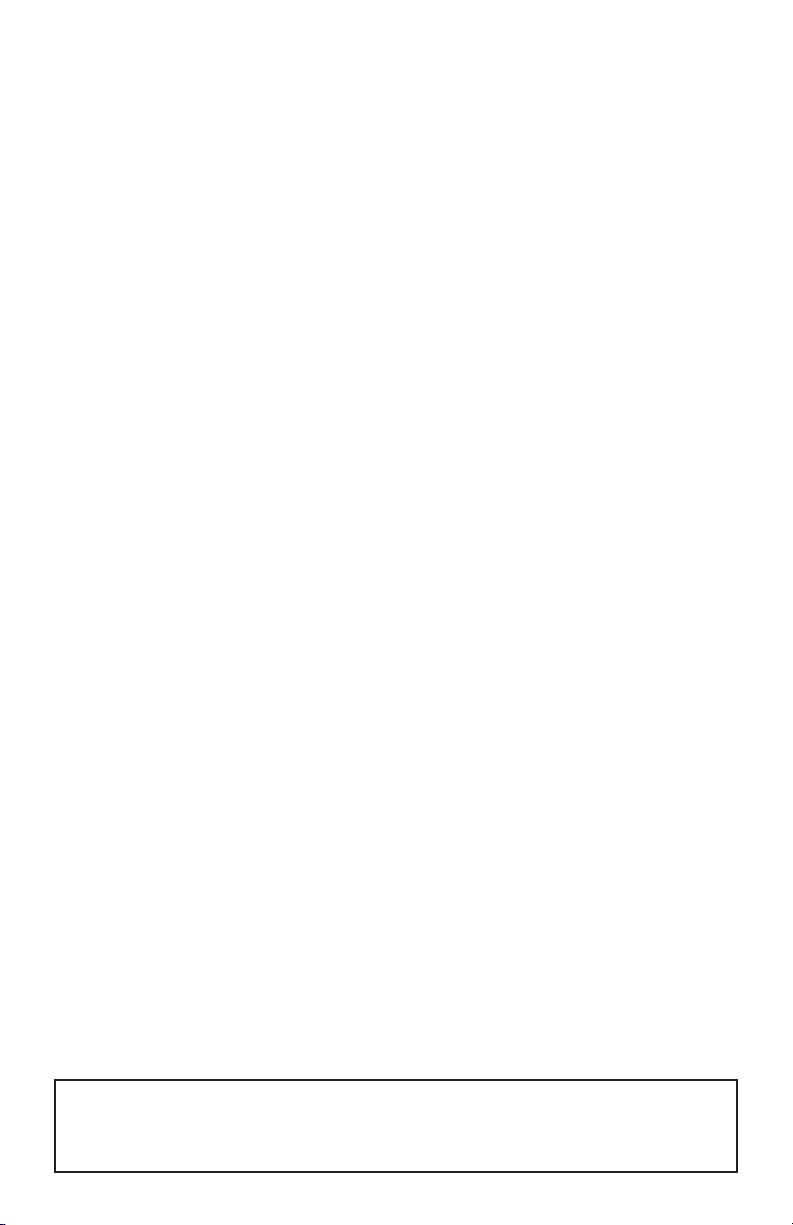

APPENDIX 1

SMV MOTORIZED VALVE

10

6.425"

163 mm

1.125"

29 mm

control valve

3/8"

compression

fitting

depth 2.000

50.8mm

SMV20

3.000

76.2 mm

5.16"

131 mm

Page 15

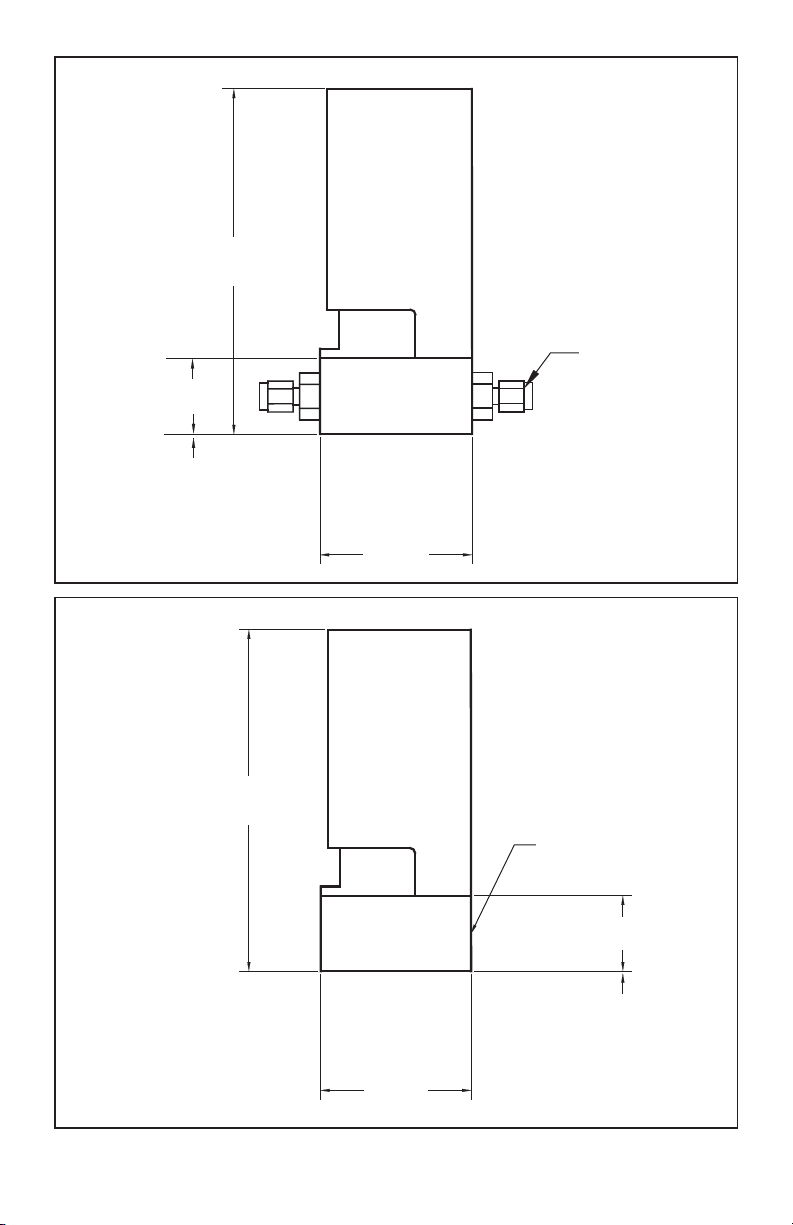

11

6.800"

224 mm

1.500"

38.1 mm

depth 2.00

50.8 mm

control valve

1/2"

compression

fittings

6.800"

224 mm

SMV40

3.000

76.2 mm

control valve

3.000

76.2 mm

SMV30

3/4" FNPT

1.500"

38.1 mm

depth 2.000

50.8 mm

Page 16

APPENDIX 2

WARRANTY

NOTE: Follow Return Procedures In Section 1.3.

12

Aalborg®SMV motorized valves are warranted against parts and

workmanship for a period of one year from the date of purchase. It

is assumed that equipment selected by the customer is constructed of materials compatible with gases or liquids used. Proper

selection is the responsibility of the customer. It is understood that

gases under pressure present inherent hazards to the user and to

equipment, and it is deemed the responsibility of the customer that

only operators with basic knowledge of the equipment and its limitations are permitted to control and operate the equipment covered

by this warranty. Anything to the contrary will automatically void the

liability of Aalborg

®

and the provisions of this warranty. Defective

products will be repaired or replaced solely at the discretion of

Aalborg

®

at no charge. Shipping charges are to be borne by the

customer. This warranty is void if the equipment is damaged by

accident or misuse, or has been repaired or modified by anyone

other than Aalborg

®

or factory authorized service facility. This warranty defines the obligation of Aalborg®and no other warranties

expressed or implied are recognized.

CAUTION:

This product is not intended to be used in life support applications!

Loading...

Loading...