Page 1

OPERATING MANUAL

SDPROC COMMAND

MODULES

Technical Data Sheet No. TD9704M Rev F

Date of Issue: August 2010

Page 2

Aalborg7is a registered trademark of Aalborg Instruments & Controls.

NOTE: Aalborg reserves the right to change designs and dimensions at its sole

discretion at any time without notice. For certified dimensions please contact Aalborg

7

.

Page 3

TABLE OF CONTENTS

(a) UNPACKING THE SDPROC COMMAND MODULE.......................................

a.1 Inspect Package for External Damage........................................................

a.2 Unpack the Command Module...................................................................

a.3 Returning Merchandise for Repair...............................................................

(b) INSTALLATION.............................................................................................

b.1 Location of Installation................................................................................

b.2 Electrical Connections.................................................................................

b.2.1 Connecting Flow Transducers.....................................................................

b.2.2 Power Input...............................................................................................

b.2.3 Applying Power to the SDPROC.................................................................

b.2.4 Remote Signal Interface.............................................................................

b.2.5 Relays Interface............................................................................................

(c) DESCRIPTION................................................................................................

(d) SPECIFICATIONS..........................................................................................

d.1 CE Compliance..............................................................................................

(e) OPERATING INSTRUCTIONS........................................................................

e.1 Preparation and Warm Up..........................................................................

e.2 Single Channel SDPROC.............................................................................

e.2.1 Start up Display..........................................................................................

e.2.2 Main Display...............................................................................................

e.2.3 Control Mode Status..................................................................................

e.2.4 Set Point Display..........................................................................................

e.2.5 Totalizer / Alarm Display..............................................................................

e.2.6 Setup Channel Display................................................................................

e.2.6.1 Internal/External/Program Reference..........................................................

e.2.6.2 Setup Gas Density Display.........................................................................

e.2.6.3 Setup Engineering Units Display................................................................

e.2.6.4 Setup Full Scale Flow Rate Display............................................................

e.2.6.5 Setup Relays Assignment Display..............................................................

e.2.7 Setup Alarm Display.....................................................................................

e.2.7.1 Setup Alarm Mode Display.........................................................................

e.2.7.2 Setup Alarm Low Display...........................................................................

e.2.7.3 Setup Alarm High Display...........................................................................

e.2.7.4 Setup Alarm Delay Display..........................................................................

e.2.7.5 Setup Alarm Action Display........................................................................

e.2.8 Setup Totalizer Display..................................................................................

e.2.8.1 Setup Totalizer Mode Display.....................................................................

e.2.8.2 Setup Totalizer Start Flow Display..............................................................

e.2.8.3 Setup Totalizer Stop Volume Display..........................................................

e.2.8.4 Setup Totalizer Action Display....................................................................

1

1

1

1

1

1

2

2

3

3

3

4

4

4

5

6

6

6

6

6

7

7

8

8

9

9

10

10

10

11

11

11

11

12

12

12

13

13

13

13

Page 4

e.2.9 Program Settings Display............................................................................

e.2.9.1 Batch Program Settings Display.................................................................

e.2.9.2 Timer Program Settings Display.................................................................

e.2.10 Status Check...............................................................................................

e.3 Multi Channel SDPROC...................................................................................

e.3.1 Start up Display............................................................................................

e.3.2 Main Display...................................................................................................

e.3.3 Channel Select...............................................................................................

e.3.4 Set Point Display............................................................................................

e.3.5 Control Mode Display.....................................................................................

e.3.6 Totalizer/Alarm Status Display.......................................................................

e.3.7 Setup Channel Display....................................................................................

e.3.7.1 Internal/External/Program Reference..........................................................

e.3.7.2 Setup Gas Density Display.........................................................................

e.3.7.3 Setup Engineering Units Display.................................................................

e.3.7.4 Setup Full Scale Flow Rate Display.............................................................

e.3.7.5 Setup Relays Assignment Display...............................................................

e.3.8 Setup Alarm Display.......................................................................................

e.3.8.1 Setup Alarm Mode Display..........................................................................

e.3.8.2 Setup Alarm Low Display............................................................................

e.3.8.3 Setup Alarm High Display...........................................................................

e.3.8.4 Setup Alarm Delay Display..........................................................................

e.3.8.5 Setup Alarm Action Display.........................................................................

e.3.9 Setup Totalizer Display...................................................................................

e.3.9.1 Setup Totalizer Mode Display......................................................................

e.3.9.2 Setup Totalizer Start Flow Display...............................................................

e.3.9.3 Setup Totalizer Stop Volume Display...........................................................

e.3.9.4 Setup Totalizer Action Display.....................................................................

e.3.10 Program Settings Display.............................................................................

e.3.10.1 Batch Program Settings Display.................................................................

e.3.10.2 Timer Program Settings Display.................................................................

e.3.10.3 Ratio Program Settings Display.................................................................

e.3.11 All Valves Control.........................................................................................

e.3.12 Real Time Clock Settings..............................................................................

e.3.13 Status Check.................................................................................................

(f) MAINTENANCE...........................................................................................

(g) ADC/DAC CALIBRATION PROCEDURES.....................................................

g.1 Digital to Analog (D/A) Slope Calibration..........................................................

g.2 Analog to Digital (A/D) Calibration..............................................................

(h) RS-232 SOFTWARE INTERFACE COMMANDS............................................h.1

h.1 General.........................................................................................................

h.2 Commands Structure..................................................................................

h.3 ASCII Commands........................................................................................

14

14

16

17

17

17

18

18

19

19

19

20

20

21

21

21

22

22

22

23

23

23

23

24

24

24

25

25

25

26

27

28

30

31

31

32

32

33

34

35

35

35

37

Page 5

(i) NETWORK COMMUNICATION INTERFACE (OPTIONAL)..............................

i.1 0Base-T RJ-45 Pinout................................................................................

i.2 Network Protocols......................................................................................

i.2.1 DHCP..........................................................................................................

i.2.2 DNS.............................................................................................................

i.2.3 IP Address..................................................................................................

i.3 Configuration....................................................................................................

i.4 Operation Using the SDPROC Web Page.........................................................

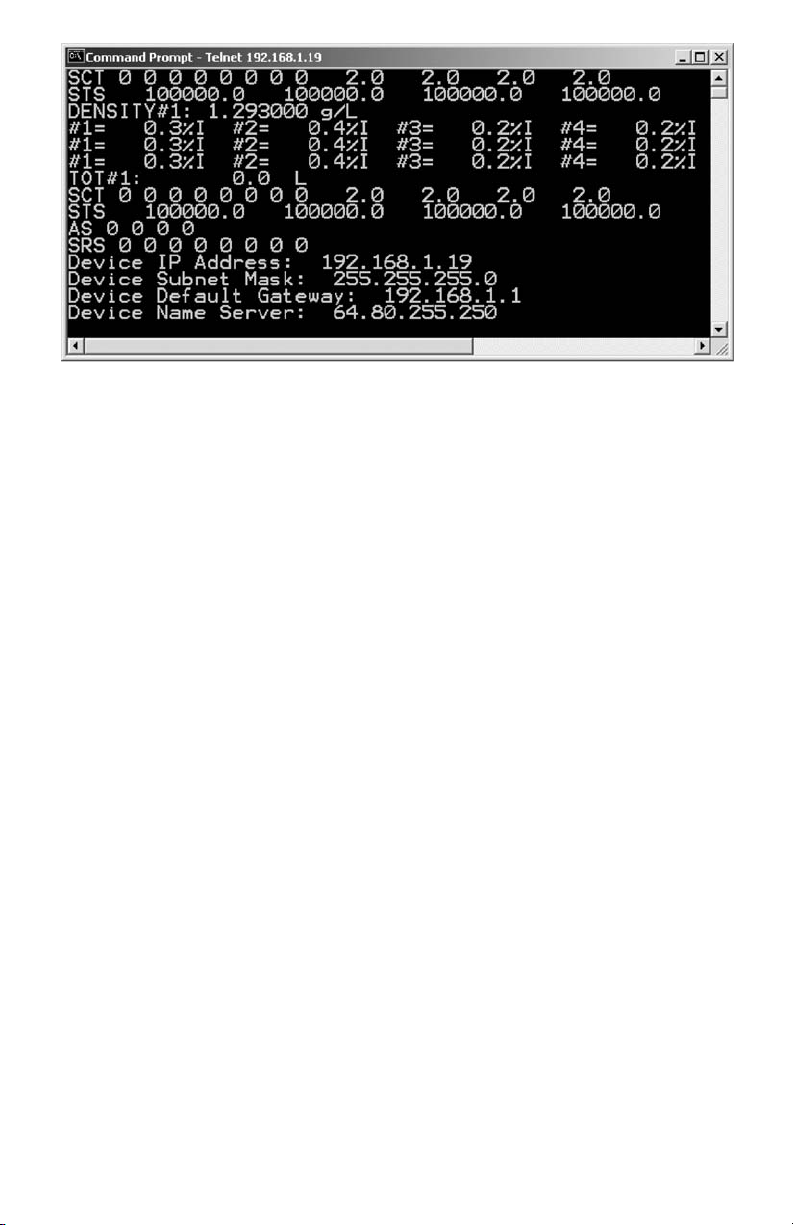

i.5 Operation Using the SDPROC Telnet Console..................................................

(j) TROUBLESHOOTING........................................................................................

j.1 Common Conditions........................................................................................

j.2 Troubleshooting Guide....................................................................................

j.3 Technical Assistance.......................................................................................

APPENDIX 1 COMPONENT DIAGRAM.................................................................

APPENDIX 2 DIMENSIONAL DRAWINGS............................................................

APPENDIX 3 WARRANTY....................................................................................

42

42

42

42

43

43

43

44

45

46

46

47

47

48

49

50

Page 6

Page 7

(a) UNPACKING THE SDPROC COMMAND MODULE

a.1 Inspect Package for External Damage

Your SDPROC Command Module was carefully packed in a sturdy cardboard carton,

with anti static cushioning materials to withstand shipping shock. Upon receipt,

inspect the package for possible external damage. In case of external damage to the

package contact the shipping company immediately.

a.2 Unpack the Command Module

Open the carton carefully from the top and inspect for any sign of concealed shipping

damage. In addition to contacting the shipping carrier please forward a copy of any

damage report to your distributor or Aalborg7 directly.

When unpacking the instrument please make sure that you have all the items indicated on the Packing List. Please report any shortages promptly.

a.3 Returning Merchandise for Repair

Please contact the customer service representative of your distributor or Aalborg7 if

you purchased the equipment directly, and request a Return Authorization Number

(RAN). Equipment returned without an RAN will not be accepted. Aalborg7 reserves

the right to charge a fee to the customer for equipment returned under warranty claims

if the instruments are tested to be free from warranted defects.

Shipping charges are borne by the customer. Equipment returned “collect” will not be

accepted!

It is mandatory that any equipment returned for servicing be purged and neutralized of

any dangerous contents including but not limited to toxic, bacterially contagious, corrosive or radioactive substances. No work shall be performed on a returned product

unless the customer submits a fully executed, signed SAFETY CERTIFICATE. Please

request form from the Service Manager.

(b) INSTALLATION

See AFM/AFC/GFM/GFC/DFC manual for specific instructions on the use and operation

of the mass flow meter or mass flow controller transducers.

b.1 Location of Installation

Set the SDPROC in a location where it will be used. This should be a stable surface.

Avoid exposing the SDPROC to damaging heat radiation from sunlight or heaters.

Avoid vibration and protect the product from moisture or aggressive chemical vapors.

1

Page 8

2

b.2 Electrical Connections

b.2.1 Connecting Flow Transducers

Attach the 15 pin “D” connector cable(s) between the interface panel on the rear of the

SDPROC and the Flow Meter/Controller transducer(s). (Number of channels will vary

from one to four in accordance with configuration and options purchased.)

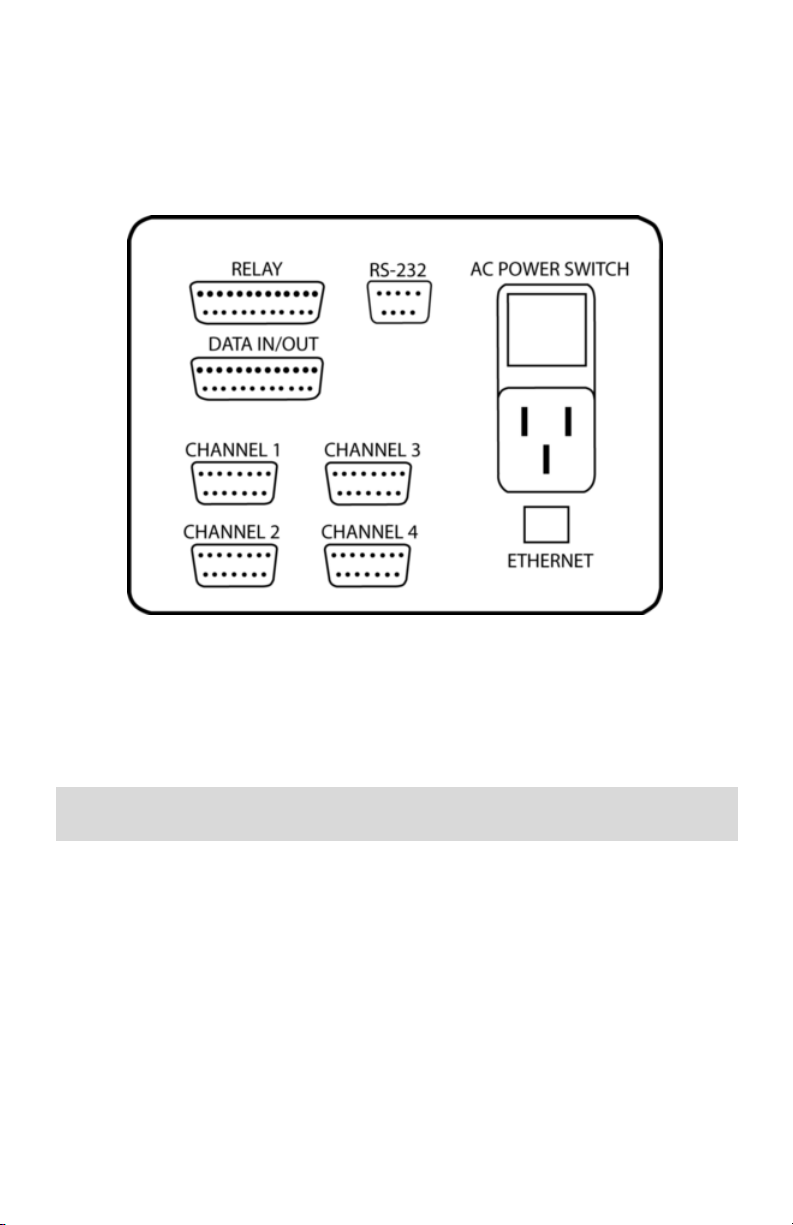

Figure b-1, Interface Panel for SDPROC.

No connection with the DATA IN/OUT, RELAYS or RS 232 connector is required for

operating the system. However, it may be desirable to perform remote monitoring or

control of the flow transducers. In this case, see the pin out chart for the “DATA

IN/OUT” connector in step b.2.4.

Important Notes:

Assure that the “Flow Transducer” cables are used in accordance with configuration

and options purchased.

In general, “D” Connector numbering patterns are standardized. There are, however,

some connectors with nonconforming patterns and the numbering sequence on your

mating connector may or may not coincide with the numbering sequence shown in our

pin configuration table above. It is imperative that the appropriate wires are matched in

accordance with the correct sequence regardless of the particular numbers displayed

on your mating connector, see the pin out chart for the “Flow Transducers” connector.

Power must be shut OFF when connecting or disconnecting any cables in the system.

Cable lengths for Flow Transducers and DATA IN/OUT may not exceed 9.5 feet (3 meters).

Page 9

3

Use of the SDPROC in a manner other than that specified in this manual or in writing

from Aalborg7, may impair the protection provided by the equipment.

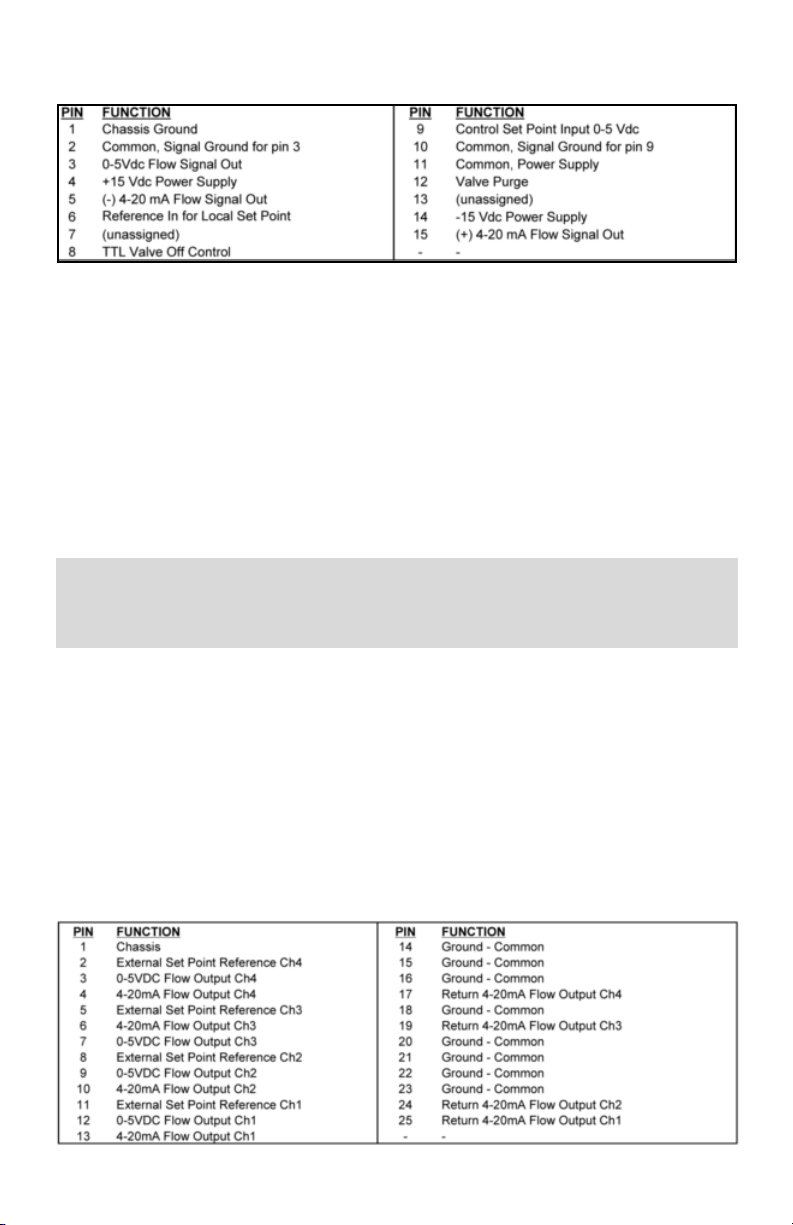

Figure b-2, Pin out chart for CHANNEL l/2/3/4 “Flow Transducers” connector.

b.2.2 Power Input

Make sure the POWER switch on the back of the SDPROC is OFF. On one end of the AC

line cord is a universal connector that will fit securely into the AC inlet receptacle at the

rear of the SDPROC. Make this connection. Per your specifications at the time of your

order, on the opposite end of the AC line cord is a plug compatible with the AC power

receptacle you intend to use for AC power supply. Make this connection to the AC

power supply receptacle. The SDPROC is capable of receiving 85VAC to 240VAC and

50/60Hz power without any need for jumpering or compensation.

Use only the AC power line cord supplied with the instrument. Do not attempt to

force or manipulate the plugs of the AC line cord in any way. If it does not fit

easily and securely, contact your distributor or Aalborg7.

b.2.3 Applying Power to the SDPROC

Turn the POWER switch to the ON position. A start up display will be briefly visible, and

will display the type of SDPROC configuration for the given unit. See the OPERATING

INSTRUCTIONS section of this manual for details on controls and displays.

b.2.4 Remote Signal Interface

At the rear of the SDPROC, there is a 25 pin Female Type “D” connector “DATA

IN/OUT”. The pin outs are as follows, (NOTE: “External Set Point Reference” is only

applicable to mass flow controllers).

Page 10

4

Turn the POWER OFF when not in use.

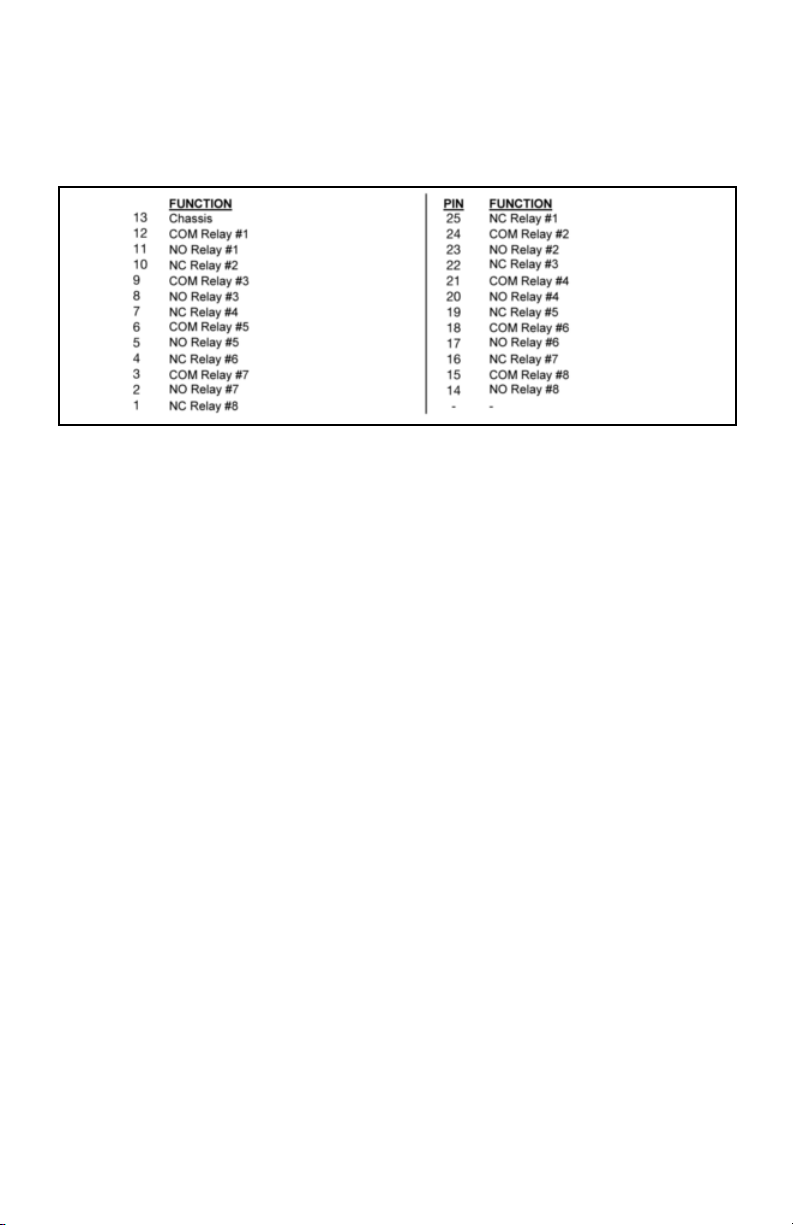

At the rear of the SDPROC, there is a 25 pin Male Type “D” connector “RELAYS”. The

pin outs are as follows:

b.2.5 Relays Interface

(c) DESCRIPTION

Microprocessor driven digital Command Modules are used in conjunction with any

analog or digital mass flow meters or controllers with 0-5 Vdc input /output signals.

One, two, three and four channel Command Module configurations are available.

Command Modules contain appropriate power supplies, 24x2 alpha-numeric dot

matrix display readout, and four panel buttons which provide complete control over all

the various functions necessary to measure and/or control flow. All channels may be

simultaneously monitored from output signals to a data aquistion or external monitoring device. RS-232 serial communication interface is standard for all models and supported via a 9 pin “D”-connector at the back panel of the Command Module. RS-232

Software interface commands set allows communications with the unit using either a

custom software program or a “dumb terminal” and provide complete control over all

modes and functions. Optional built-in Ethernet interface allows accessing any

Internet-connected SDPROC from a browser on your work station, PC, or laptop computer. Regardless of where you are, your Command Module is as close as the near-

est browser! There are two levels of Web-based Remote Controls: HTML web server

and TELNET. The flow set points, measured gas flow and associated totalizer data are

scaled directly in engineering units via front panel keypad, RS-232 or Ethernet interface. The following units of measure are supported: %F.S., SLPM, SLPH, SCCM, SCCH,

SCFM, SCFH, SCMM, SCMH, LBPM, LBPH, GRPM, GRPH (NOTE: In order to use mass

based engineering units proper value of the gas density has to be set for corresponding channel).

(d) SPECIFICATIONS

ENVIRONMENTAL (PER IEC 664): Installation Level II; Pollution Degree II

POWER SUPPLY: 85 to 264 VAC (47 to 63 Hz) 2A max.

Page 11

5

FUSE: 2A on input and output power line. When changing, unplug the device from

power source. Replace only with fuse 5mm 2A/250V FF.

DISPLAY: 24x2 LCD dot matrix with backlight; 24x2 Vacuum Florescent display

optional.

READINGS: 0 to 100% scale is standard; the following units of measure are supported: %F.S., SLPM, SLPH, SCCM, SCCH, SCFM, SCFH, SCMM, SCMH, LBPM,

LBPH, GRPM, GRPH.

ADC/DAC RESOLUTION: 12 bits (0.025%).

DIGITAL COMMUNICATION STANDARD: RS-232.

Optional: Ethernet TCP/IP (HTML Server or TELNET Console).

RS-232 COMMUNICATIONS PARAMETERS: 8 bits, two stop bits, no parity (8,2,N).

RS-232 DATA TRANSFER RATE: 9600 baud.

CONTACT CLOSURES: Two sets of dry contact relay outputs for each channel (0.5A at

125 Vac, 1A at 24 Vdc).

BUZZER: Piezo Audio Indicator at 3.0 KHz, 85 dB activated by Alarm or Totalizer.

DIMENSIONS: Length: 7.75 inch (19.5cm), width: 6.75 inch (17cm), height: 4.5 inch

(11cm).

WEIGHT: 6.00 lbs (1.8kg).

TRANSDUCER INTERFACE CABLE: Flat cable with 15 pin “D” connector on the ends

is standard for AFC series mass flow controllers. Optional round shielded cable is

available with male/female “D” connector ends for customer's mass flow meters or

controllers. [Cable length may not exceed 9.5 feet (3 meters)].

RELAYS PORT CABLE: Optional shielded cable with female 25 pin “D” connector to

connect to command module relays port.

DATA PORT CABLE: Optional shielded cable with male 25 pin “D” connector to connect to command module data port. [Cable length may not exceed 9.5 feet (3

meters)].

d.1 CE Compliance

Any SDPROC are in compliance with the below stated test standards currently accepted.

EMC Compliance with 89/336/EEC as amended;

CE COMPLIANCE: EN 50011:1998 Group 1, Class A August 1999 for emissions; EN 61000-6-1:2001 for immunity.

Page 12

6

(e) OPERATING INSTRUCTIONS

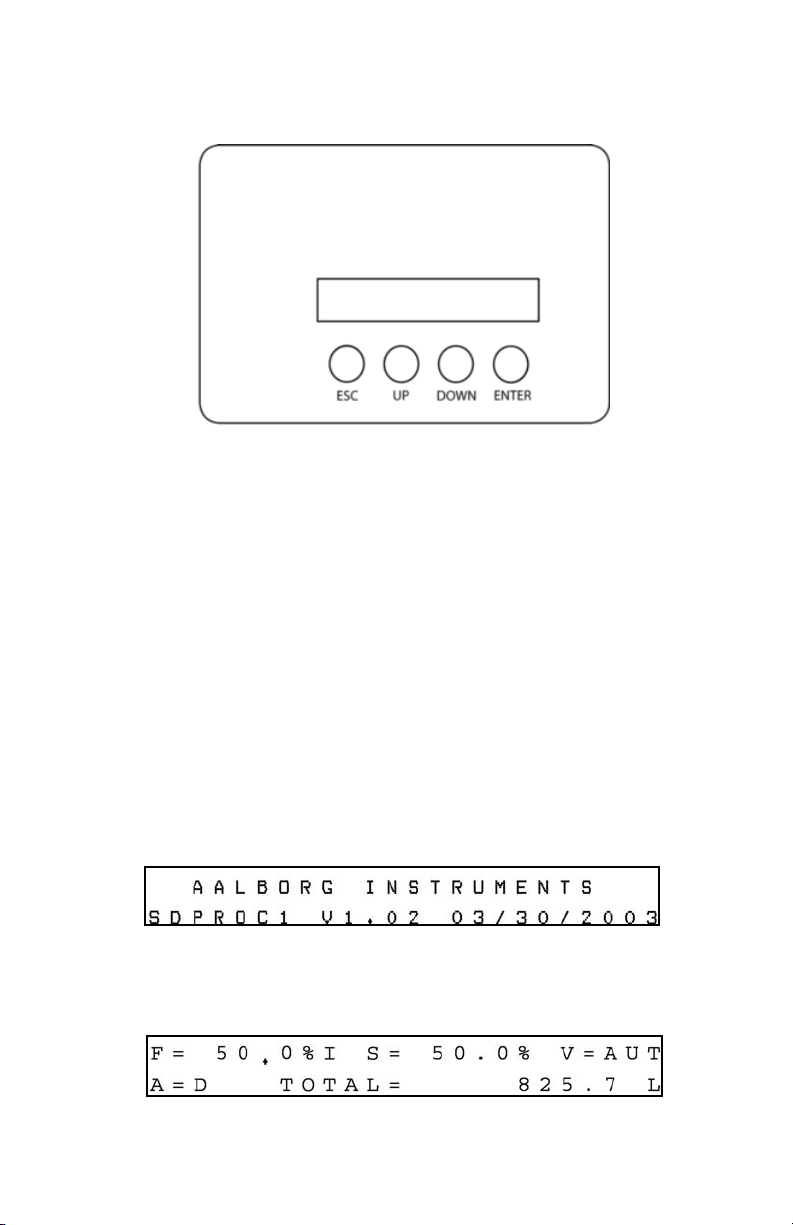

There are four buttons on the front panel of the SDPROC from which all functions can

be controlled or set. These are labeled “ESC”, “UP”, “DOWN”, and “ENTER”.

Figure e-1, Control Panel for SDPROC.

e.1 Preparation and Warm Up

It is assumed that the SDPROC and the Mass Flow Meter(s) and/or Controller(s) have

been correctly installed as described in this and the AFM/AFC/DFC/GFM/GFC manuals.

Turn the POWER switch to the ON position. A start up display will be briefly visible, and

will display the type SDPROC configuration for the given unit. Remember to allow for

proper warm up time by the mass flow transducer.

e.2 Single Channel SDPROC

e.2.1 Start up Display

Switching the power ON, the following will be shown on the display at the front of

the SDPROC.

e.2.2 Main Display

After a few seconds, the Start up display will clear and the Main Display will appear.

This display will remain active until the power is turned off or any button is pressed.

Page 13

7

The Main Display will indicate the following info:

= “F” current flow rate in % F.S. (NOTE: An “I” is indicated on the display

immediately following the displayed flow when the SDPROC is set for internal

reference and “E” for external reference.)

= “S” current set point in % F.S.

= “V” valve status by displaying a “CLS” for CLOSE, “OPN” for OPEN or

“AUT” for AUTO.

= “A” alarm status by displaying a “D” for disabled, “N” for no alarm events,

“L” for Low alarm and “H” for High alarm.

= “TOTAL” totalizer reading in current (volume/mass based) Engineering Units.

Readings are linear 0 to 100% of full scale. Direct engineering units are available on another screen. A proportionally linear 0 to 5 VDC or 4 to 20 mA output signal may be monitored simultaneously at the 25 pin “D” connector at the rear of the SDPROC (see section

b.2.4). Press the Down button under the Main Display screen, to set the GENERAL,

ALARM, TOTALIZER and PROGRAM settings (see section e.2.6).

e.2.3 Control Mode Status

There are three modes of operation that the mass flow controller can be set for. CLOSE

will shut off the power to the mass flow controller valve, allowing the valve to mechanically close. OPEN will provide maximum power to the valve to allow it to open fully.

This mode is used when there is a need to purge the gas flow system. AUTO mode will

allow the mass flow controller to maintain a given flow as set by the user. In order to

change mode of operation press the Esc button from the Main Screen. The following

display will appear.

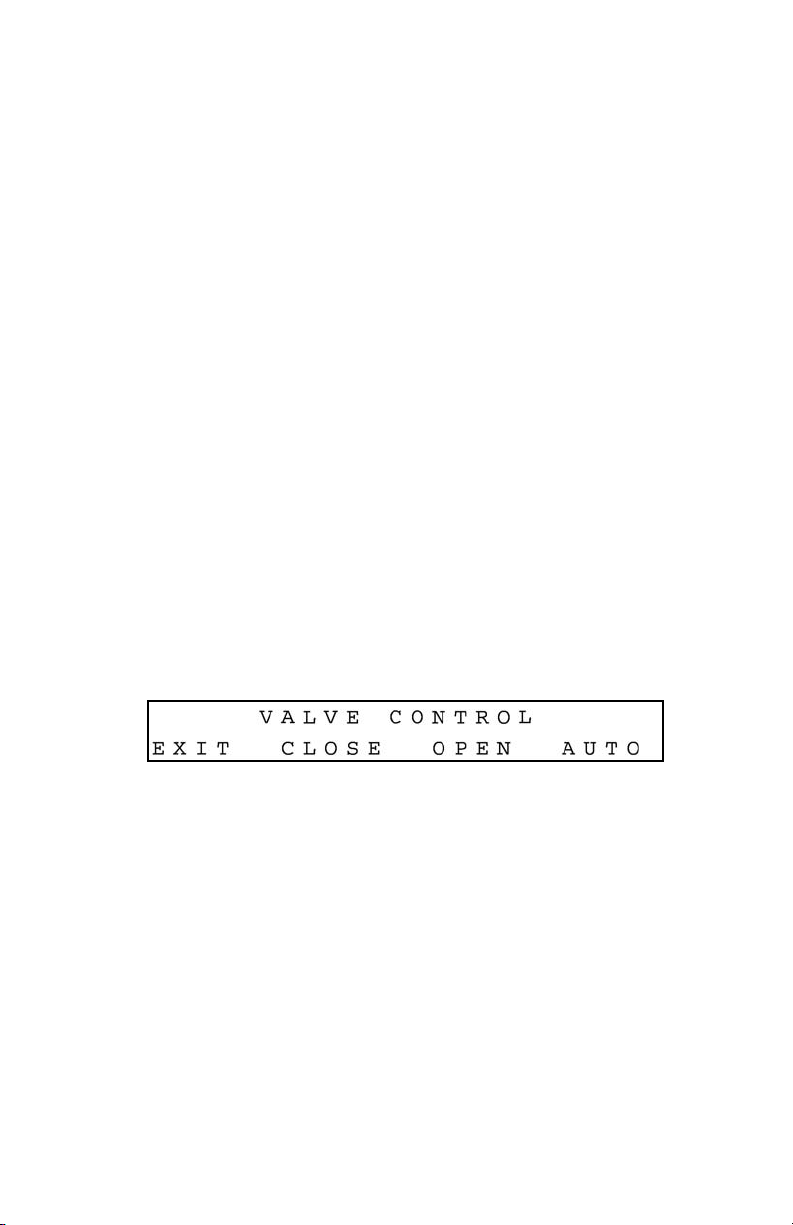

Valve Control Display for 1 channel SDPROC

To operate the mass flow controller in CLOSE, OPEN or AUTO modes, press the button

(UP, DOWN, ENTER respectively) directly below the mode shown on the display (see

section e.4.2). After pressing the button the Main Display will appear and indicate the

current valve status by displaying a “CLS” for CLOSE, “OPN” for OPEN, or “AUT” for

AUTO shown after the set point value.

Press the ENTER button under the Main Display screen, to set the desired flow for

AUTO control.

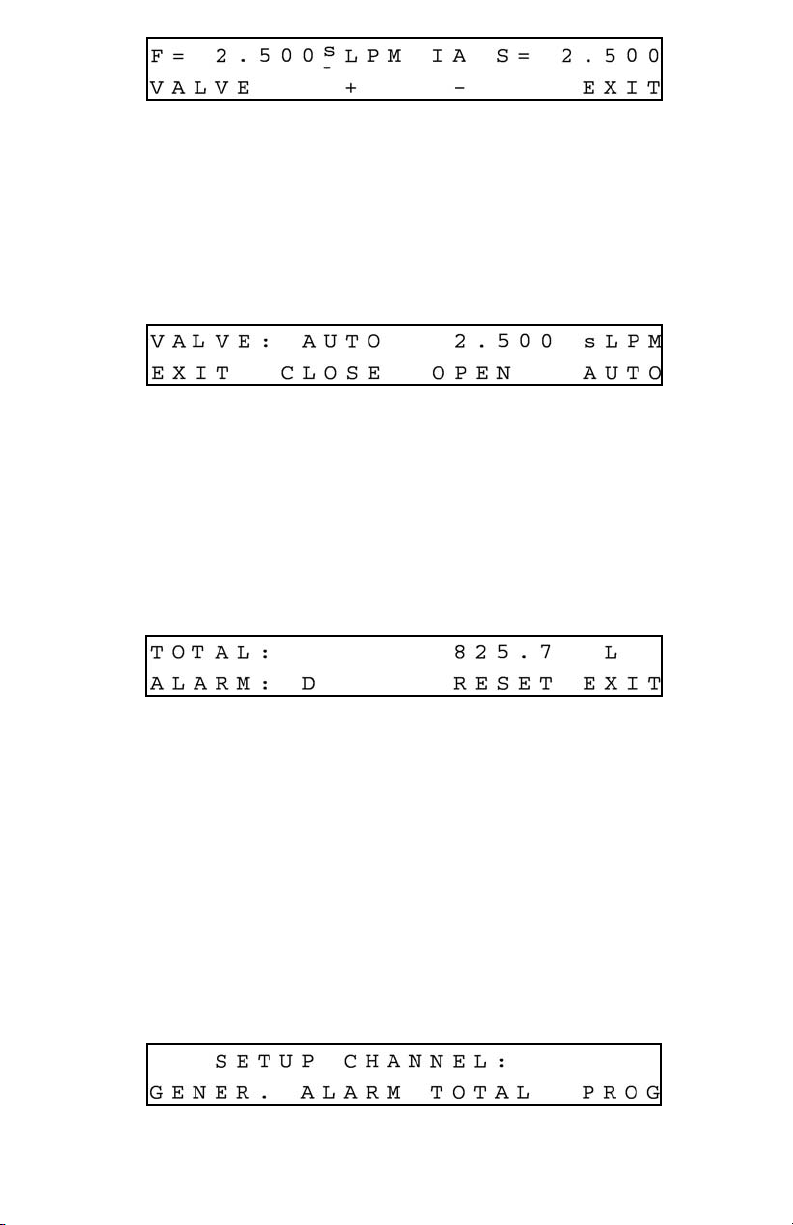

e.2.4 Setpoint Display

The following display is shown when adjustments to the set point reference signal

are desired.

Page 14

8

Set Point Display for 1 channel SDPROC

The UP button under the “+” and DOWN button under the “-” will increase and decrease

the set point respectively. Once set, press the ENTER button under EXIT on the display

to return to the Main Display. This set point is only applicable when the SDPROC is

used in INTERNAL REFERENCE mode. From the Set Point Screen in order to change

the mode of operation press the Esc button under VALVE on the display. The following

display will appear.

Valve Status/Flow Display for 1 channel SDPROC

To operate the mass flow controller in CLOSE, OPEN or AUTO modes, press the button

(UP, DOWN, ENTER respectively) directly below the mode shown on the display. First

line on the Display screen indicates the current valve status and flow rate in selected

engineering units. Pressing the Esc button from the Valve Status/Flow Display will display Totalizer/Alarm Screen.

e.2.5 Totalizer/Alarm Display

Totalizer/Alarm Display for 1 channel SDPROC

The first line of the Totalizer/Alarm screen indicates the totalizer reading in current (volume/mass based) Engineering Units. The second line shows alarm status by displaying a “D” for disabled, “N” for no alarm events, “L” for Low alarm and “H” for High

alarm. The totalizer can be reset to zero by pressing the Down button under RESET on

the display. Press the ENTER button under EXIT on the display in order to return in to

the Main Display screen.

e.2.6 Setup Channel Display

Pressing the Down button under the Main Display screen (see section e.2.2) will display SETUP CHANNEL screen shown below.

Page 15

9

Setup Channel screen allows to configure:

= General device settings: Int./Ext. Reference, Gas density, Engineering Units,

Full Scale Flow in L/Min and Relays assignment.

= Alarm Properties: Mode, High and Low settings in % F.S., Delay Time, Action.

= Totalizer Properties: Mode, Start Flow, Stop Volume, Action.

= Program Properties: Batch parameters and Timer Settings.

Press the Esc button under GENER. on the display in order to make General settings.

The following Internal/External/Program Reference display will appear.

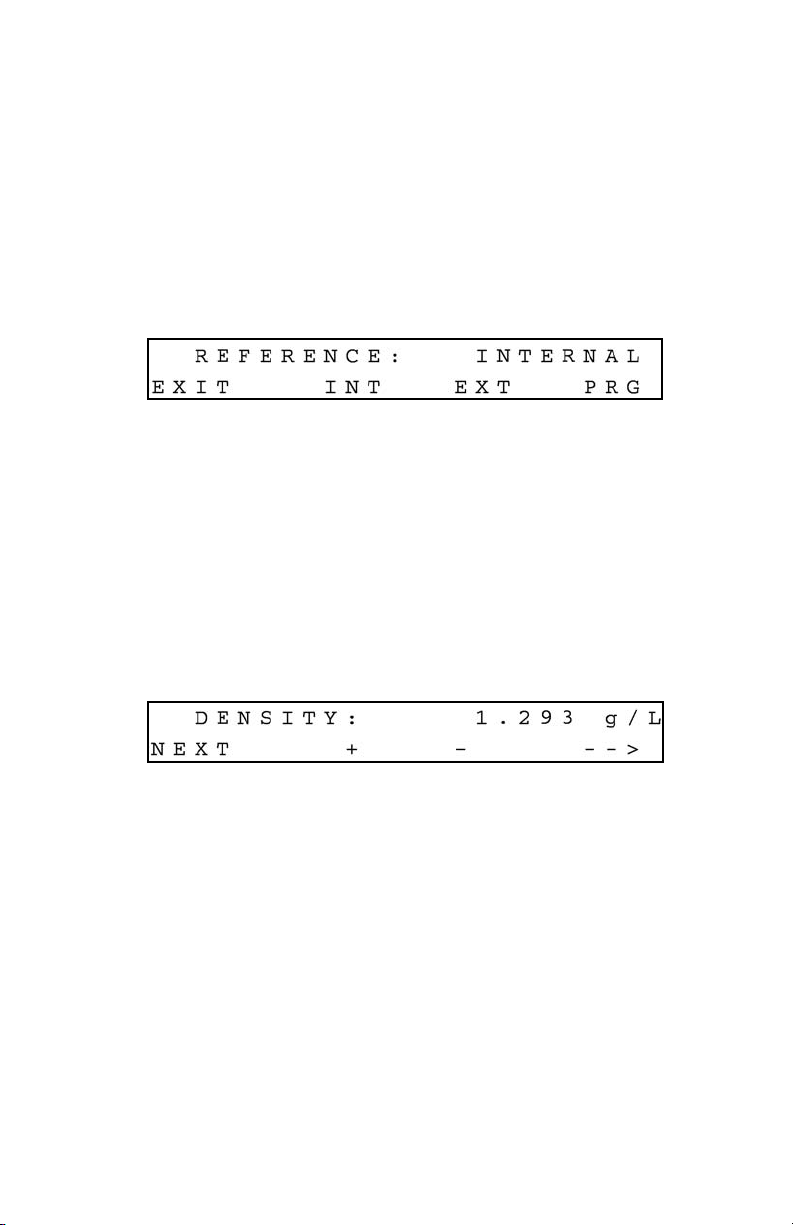

e.2.6.1 Internal/External/Program Reference

The INT/EXT/PRG refers to point of origin for the valve control reference signal. To

change this, press the button UP, DOWN, ENTER respectively. In the internal reference

mode, the control signal is set by the user with the SDPROC controls (see section

e.2.4).

Pressing the ENTER button on the front panel under PRG on the display of the SDPROC

will toggle the reference between PROGRAM BATCH and PROGRAM TIMER. When

complete with settings, press the ESC button under EXIT on the display, to go to the

Density screen. The following Setup Gas Density Display will appear.

e.2.6.2 Setup Gas Density Display

The proper settings of the gas density (in grams per liter) are required for mass based

engineering units (LBPH, LBPM, GrPH, GrPM). Press the ENTER button under (--->)

on the display, to move the flashing cursor to the desired position. Pressing (+) or (-)

will increment or decrement the particular digit respectively. The numbers will change

from 0 to 9 and next to decimal point (.). Pressing (+) button one more time will change

highlighted position of the cursor back to 0. The same is true in backward direction

when pressing the (-) button. Only one decimal point is allowed. If changing position

of the decimal point is required, change decimal point to any desired digit, next move

cursor to the required position and adjust it to the decimal point with (+) or (-) button.

When complete with gas density settings, press the ESC button under NEXT on the display, to go to the Engineering Units screen. The following Setup Engineering Units

Display will appear.

Page 16

10

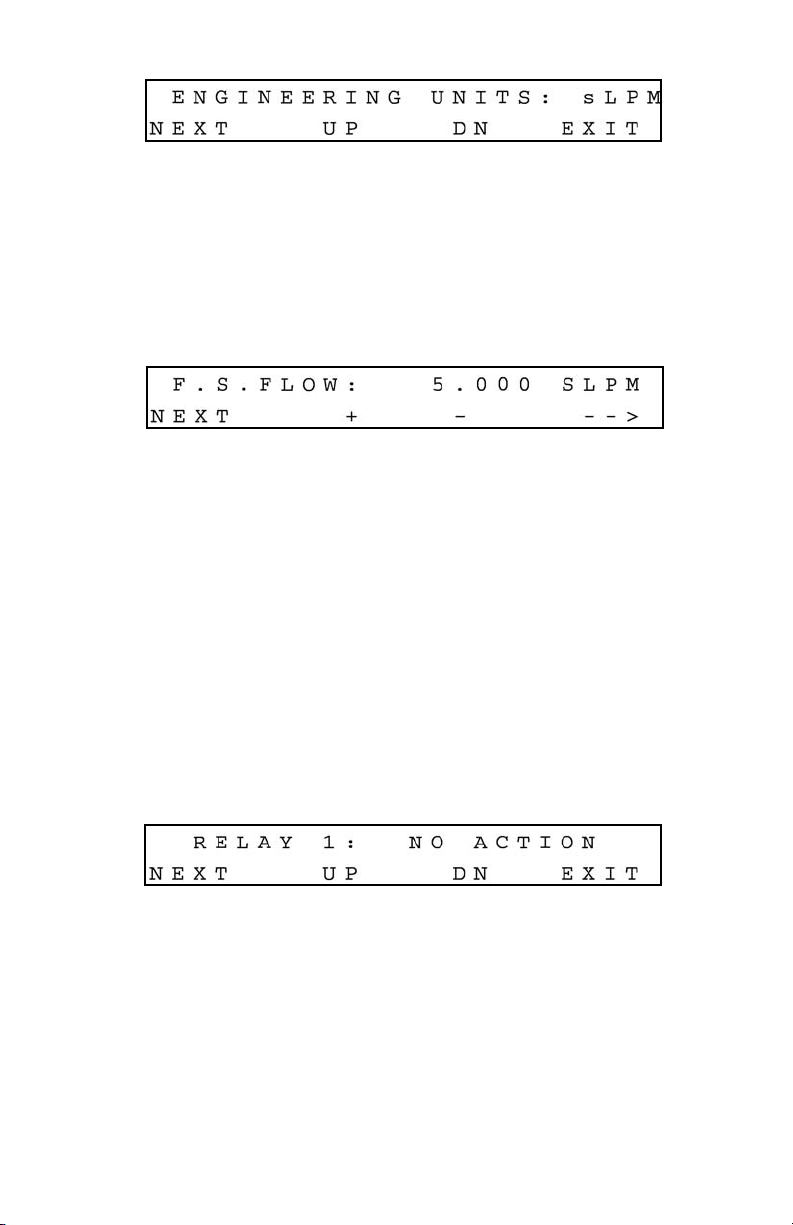

e.2.6.3 Setup Engineering Units Display

Press the UP or DN button, to change current engineering units. The following engineering units are supported: %F.S., SLPM, SLPH, SCCM, SCCH, SCFM, SCFH, SCMM,

SCMH, LBPM, LBPH, GRPM, GRPH. If no more settings are required, press the ENTER

button under EXIT on the display, to go back to the Main Display. Press the ENTER button under NEXT on the display in order to go to the Full Scale Flow Rate screen. The

following Setup Full Scale Flow Rate Display will appear.

e.2.6.4 Setup Full Scale Flow Rate Display

The proper settings of the Full Scale Flow Rate (in liters per minute) are required for any

engineering units except % F.S. If for example a mass flow controller used with

SDPROC is calibrated for 200 SCCM, the value of 0.2 has to be set. Press the ENTER

button under (--->) on the display, to move the flashing cursor to the digit, which has

to be adjusted. Pressing (+) or (-) will increment or decrement the particular digit

respectively. The numbers will change from 0 to 9 and next to decimal point (.).

Pressing (+) button one more time will change highlighted position of the cursor back

to 0. The same is true in backward direction when pressing the (-) button. Only one decimal point is allowed. If changing position of the decimal point is required, change the

decimal point to any desired digit, next move cursor to the required position and adjust

it to decimal point with the (+) or (-) button. When complete with Full Scale Flow Rate

settings, press the ESC button under NEXT on the display, to go to the Relays

Assignment screen. The following Setup Relays Assignment Display will appear.

e.2.6.5 Setup Relays Assignment Display

Two sets of dry contact relay are available for each channel. Each relay individually

can be assigned for:

= NO ACTION

= ALARM LOW

= ALARM HIGH

= TOTALIZER STOP

Press UP or DN button to change relay assignment. When complete with first relay

settings, press the ESC button under NEXT on the display, to go to the second relay.

Page 17

11

The following display will appear.

Press ESC button under NEXT on the display or the ENTER button under EXIT on the display, to go back to the Main Display.

e.2.7 Setup Alarm Display

Before enabling the Alarm make sure all alarm settings are configured properly. High

and Low alarm values have to be entered in %F.S. engineering units. ALARM conditions become valid when the difference between current readings and installed set

points is equal or more than corresponding values of high and low alarm levels. From

the Setup Channel Display (see section e.2.6) press the Up button under ALARM on

the display in order to make Alarm settings. The following display will appear.

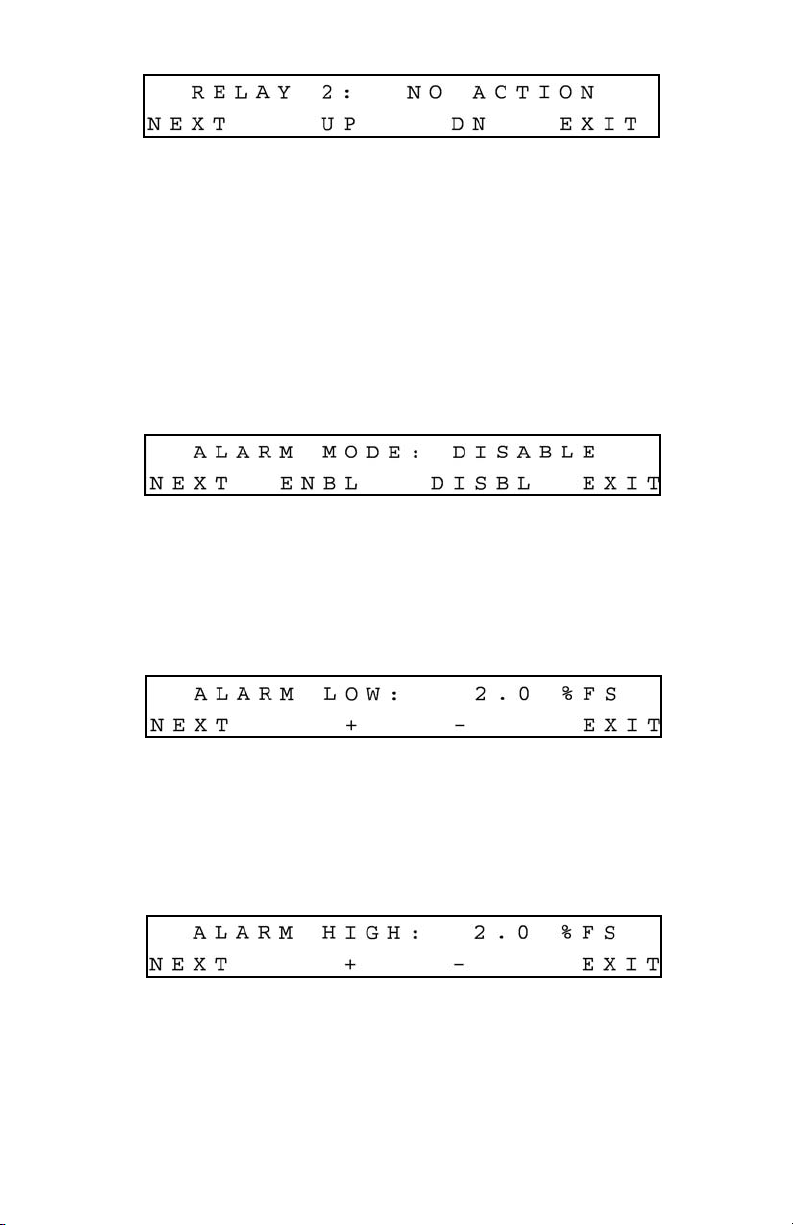

e.2.7.1 Setup Alarm Mode Display

To change Alarm Mode in ENABLED or DISABLED, press the button (UP, DOWN respectively) directly below the mode shown on the display. Press the ENTER button under EXIT

on the display, to go back to the Main Display. Press the ESC button under NEXT on the display to go to the Alarm Low settings. The following display will appear.

e.2.7.2 Setup Alarm Low Display

Pressing (+) or (-) will increment or decrement Low Alarm settings per 0.1% F.S. respectively. If no settings required for High Alarm press the ENTER button under EXIT on the display, to go back to the Main Display. Press the ESC button under NEXT on the display to

go to the Alarm High settings. The following display will appear.

e.2.7.3 Setup Alarm High Display

Pressing (+) or (-) will increment or decrement High Alarm settings per 0.1% F.S. respectively. If no settings are required for High Alarm press the ENTER button under EXIT on the

display, to go back to the Main Display. Press the ESC button under NEXT on the display to

go to the Alarm Delay settings. The following Setup Alarm Delay Display will appear.

Page 18

12

e.2.7.4 Setup Alarm Delay Display

Alarm Delay specifies the time interval in seconds the Alarm conditions have to be True

(without any interruption) before Alarm will be activated. If zero value is set, the Alarm

will be activated immediately after Alarm conditions are met. Pressing (+) or (-) will

increment or decrement Alarm Delay settings per 1 second respectively. If no settings

required for Alarm Action press the ENTER button under EXIT on the display, to go

back to the Main Display. Press ESC button under NEXT on the display go to the Alarm

Action settings. The following Setup Alarm Action Display will appear.

e.2.7.5 Setup Alarm Action Display

To change Alarm Action in NONE, BUZZER or VALVE, press the button (ESC, UP, DOWN

respectively) directly below the text shown on the display. If Buzzer action is chosen,

the audible signal will be activated when Alarm conditions become true.

In order to deactivate the audible signal during operation press any button on

the key pad.

(NOTE: The Alarm Conditions have to be removed or Alarm has to be disabled).

If Valve action is chosen the power to the mass flow controller valve will be shut off,

allowing the valve to mechanically close.

If the Valve was shut off as a result of the Alarm action, in order to go back to

normal operation the Valve mode has to be changed to AUTO (See section

e.2.3). NOTE: The Alarm Conditions have to be removed, or Alarm has to be

disabled prior to any attempts to change the Valve mode.

To go back to the Main Display, press the ENTER button under EXIT on the display.

e.2.8 Setup Totalizer Display

Before enabling the Totalizer make sure that all totalizer settings are configured properly. The totalizer Start value has to be entered in %F.S. engineering units. Totalizer will not

totalize until the flow rate become equal or more than Totalizer Start value. Totalizer Stop

value has to be entered in volume / mass based engineering units. Totalizer conditions

become valid when the totalized volume is equal or more than Totalizer Stop value. From

the Setup Channel Display (see section e.2.6) press Down button under TOTAL on the

display in order to make Totalizer settings. The following Setup Totalizer Mode Display

will appear.

Page 19

13

e.2.8.1 Setup Totalizer Mode Display

To change Totalizer Mode in ENABLED or DISABLED, press the button (UP, DOWN

respectively) directly below the mode shown on the display. To return to the Main

Display, press the ENTER button under EXIT on the display. Press the ESC button

under NEXT on the display to go to the Totalizer Start settings. The following Setup

Totalizer Start Flow Display will appear.

e.2.8.2 Setup Totalizer Start Flow Display

Pressing (+) or (-) will increment or decrement Totalizer Start settings per 0.1% F.S.

respectively. If no settings are required for Totalizer Stop value press the ENTER button under EXIT on the display, to go back to the Main Display. Press ESC button under

NEXT on the display to go to the Totalizer Stop settings. The following Setup Totalizer

Stop Volume Display will appear.

e.2.8.3 Setup Totalizer Stop Volume Display

The proper settings of the Totalizer Stop Volume (in volume/mass based engineering

units) is required if the Totalizer is set to Enabled. The engineering unit for Totalizer Stop

Volume has to be related to the current active engineering unit. If for example current

engineering unit is sLPM, the Totalizer Stop Volume has to be entered in liters. Press the

ENTER button under (--->) on the display, to move the flashing cursor to the digit, which

has to be adjusted. Pressing (+) or (-) will increment or decrement the particular digit

respectively. The numbers will change from 0 to 9 and next to the decimal point (.).

Pressing the (+) button one more time will change the highlighted position of the cursor

back to 0. The same is true in reverse direction when pressing the (-) button. Only one

decimal point is allowed. If changing the position of the decimal point is required, change

decimal point to any desired digit, then move the cursor to the required position, and

adjust it to the decimal point with (+) or (-) button. When complete with Totalizer Stop

Volume settings, press the ESC button under NEXT on the display, to go to the Totalizer

Action screen. The following Setup Totalizer Action Display will appear.

e.2.8.4 Setup Totalizer Action Display

Page 20

14

To change Totalizer Action in NONE, BUZZER or VALVE, press the button (ESC, UP,

DOWN respectively) directly below the text shown on the display. If Buzzer action is

chosen, the audible signal will be activated when Totalizer conditions become true.

In order to deactivate the audible signal during operation press any button on

the key pad (NOTE: The Totalizer has to be reset to zero or disabled).

If Valve action is chosen, the power to the mass flow controller valve will be shut off,

allowing the valve to mechanically close.

If the Valve was shut off as a result of the Totalizer action, in order to go back

to normal operation the Valve mode has to be changed to AUTO (See section

e.2.3). NOTE: The Totalizer reading has to be reset to zero or Totalizer has to be

disabled prior any attempts to change the Valve mode.

To return to the Main Display, press the ENTER button under EXIT on the display.

e.2.9 Program Settings Display

From the Setup Channel Display (see section e.2.6) press the Enter button under PROG

on the display in order to make Program settings. The following display will appear.

There are two program options: BATCH and TIMER flow control.

e.2.9.1 Batch Program Settings Display

The Batch Flow Control allows execution of custom, user preset programs of up to sixteen steps. During execution of the program the user can activate or deactivate the

LOOP mode. Various flow configurations may be preprogrammed: ramping, pulsing,

linearized increasing and/or decreasing of the flow. Before executing, the program

should be entered in the program table in the format: SETPOINT [% F.S.] - TIME [sec.].

TIME means: time it takes for the value of the output signal from mass flow controller

to linearly approach the SETPOINT value (ramping). Press the DOWN button under

BATCH on the display, to set up the BATCH table. The following display will appear.

Time Settings for first step of the BATCH table

Pressing (+) or (-) will increment or decrement the step time settings per 1, 10 or 100

seconds (depending on the value of the multiplier M) respectively. The maximum valid

value is 99999 seconds. Pressing the (+) button one more time will rollover time settings to zero.

Page 21

15

The same is true for 0 seconds, pressing the (-) button will rollover time settings to

99999 seconds. Press the ENTER button under MULT on the display, to change the

value of the multiplier to 10. Continuing to press the ENTER button under MULT on the

display, will change the value of the multiplier first to 100 and then back to 1. When

complete with TIME settings for the first step of the Batch program, press the ESC button under NEXT on the display, to go to the SETPOINT screen. The following display

will appear.

Set Point Settings for first step of the BATCH table

Pressing (+) or (-) will increment or decrement the step set point settings per 0.1%

F.S. respectively. When complete with SET POINT settings for the first step of the Batch

program, press the ENTER button under NEXT on the display, to go to the next step.

Continue with Time and Set point settings for as many steps as required for your application (16 is the maximum limit). When complete with all settings for the Batch program press the Esc button under EXIT on the display, to go to the BATCH control

screen. The following display will appear.

BATCH mode control screen with batch disabled

The two digit numbers after “SE:” indicate the number of the enabled steps for executions. Press the UP button under STEPS on the display, to change number of steps

from the batch program to be executed. With 16 steps enabled on the screen, pressing the Up button one more time will rollover the number of steps back to 1. Press the

ENTER button under LOOP on the display, to toggle the loop control ON and OFF. If

loop control is ON, after executing the last enabled step, the program will go back to

the first step and go on again until the loop mode will be disabled. NOTE: In order to

start batch program executions, press the Down button under START on the display.

NOTE: In order to execute a batch program, the valve control reference has to be set

to BATCH mode (See section e.2.6.1). The following display will appear.

BATCH mode control screen with batch enabled

Press the Down button under STOP on the display one more time, to toggle the batch

mode to OFF (disabled). Press the Esc button under EXIT on the display, to go to the

Main Display.

Page 22

e.2.9.2 Timer Program Settings Display

The Timer Flow Control allows execution of a custom, user preset program of up to 96

steps. Each step can be pre-programmed for a particular date, time, and set point value

in % F.S.. Every step has two fields: starting date, time and set point in % F.S. Before

executing, the program should be entered in the program table in the format:

TIME/DATE [XX.XX XX/XX/XXXX] - SETPOINT [% F.S.]. Time and date indicates exact

moments (+/- one minute accuracy) when the set point has to be executed by the mass

flow controller. From the Program Settings Display (See section e.2.9), press the Enter

button under TIMER on the display, to set up the TIMER table. The following display

will appear.

Time and date settings for first step of the TIMER table

Press ENTER button under (--->) on the display, to move flashing cursor to the hours

position. Pressing (+) or (-) will increment or decrement the time settings (hours).

When complete with hours settings press again ENTER button to move the flashing

cursor to the minutes position. When done with time settings press again ENTER button to move the flashing cursor to the date position (month, date and year) respectively.

Make sure date and time entered is not in the past (otherwise this step of the

program will not be executed).

When complete with TIME and DATE settings for first step of the Timer program, press

the ESC button under NEXT on the display, to go to the SETPOINT screen. The following display will appear

Set Point settings for first step of the TIMER table

Pressing (+) or (-) will increment or decrement the step set point settings per 0.1% F.S.

respectively. When complete with SET POINT settings for the first step of the Timer

program, press the ENTER button under NEXT on the display, to go to the next step.

Continue with Time/Date and Set point settings for as many steps as required for your

application (96 is maximum limit). When complete with all settings for the Timer program press the Esc button under EXIT on the display, to go to the Main Display screen.

Make sure the reference for set point is set to PROGRAM TIMER mode in

order for the Timer program to be executed (see section e.2.6.1).

16

Page 23

17

e.2.10 Status Check

While in the Main Display press the UP button on the front panel of the SDPROC. The

Relays Assignment Status will appear.

Relays Status Display One channel SDPROC

Pressing the UP button again will bring up the Totalizer Settings screen. Pressing the

DOWN button will return to the Main Display.

Totalizer Settings Display One channel SDPROC

Press UP one more time to return to the Main Display.

E.3 MULTI CHANNEL SDPROC

e.3.1 Start up Display

Switching the power ON, the following will be shown on the display at the front of the

SDPROC.

Start up Display for 2 channel SDPROC

Start up Display for 3 channel SDPROC

Start up Display for 4 channel SDPROC

Page 24

18

e.3.2 Main Display

After a few seconds, the Start up display will clear, and the Main Display will appear.

Main Display for 2 channel SDPROC

Main Display for 3 channel SDPROC

Main Display for 4 channel SDPROC

Readings are linear 0 to 100% of full scale. Direct engineering units are available on

another screen. A proportionally linear 0 to 5 VDC or 4 to 20 mA output signal may be

monitored simultaneously at the 25 pin “D” connector at the back of the SDPROC (see

section b.2.4). Press the Down button under the Main Display screen, to set the GENERAL, ALARM, TOTALIZER and PROGRAM settings (see section e.3.6).

e.3.3 Channel Select

There are three modes of operation that the mass flow controller can be set for. CLOSE

will shut off the power to the mass flow controller valve, allowing the valve to mechanically close. OPEN will provide maximum power to the valve to allow it to open fully.

This mode is used when there is a need to purge the gas flow system. AUTO mode will

allow the mass flow controller to maintain a given flow as set by the user or program.

Each channel is independent of the other, and therefore each will need to be set.

The basic display/menu elements for the two, three, and four channel SDPROC's are

essentially identical with the exception of the number of channels available.

To operate the mass flow controller in CLOSE, OPEN or AUTO modes, press the ENTER

button directly below the display screen.

Channel Select Display Multi channel SDPROC

Press the button on the SDPROC panel under the appropriate channel number displayed. This will select that channel for control configuration. (For this manual, chan-

Page 25

19

nel 3 has been selected.) The following Set Point Display will appear.

e.3.4 Set Point Display

Set point Display Multi channel SDPROC

The screen above assumes that the full scale flow rate for channel #3 is set to 5.0

SLPM and current units of measure is SLPM. The UP button under the “+” and DOWN

button under the “-” will increase and decrease the set point respectively. This set point

is only applicable when the SDPROC is used in INTERNAL REFERENCE mode (NOTE:

the character after “SP:” indicates current status for set point reference.)

When complete with the set point setting, press the ESC button under NEXT on the display, to proceed to the Control Mode Display or the ENTER button under EXIT on the

display, to go to the Main Display.

e.3.5 Control Mode Display

Control Mode Display Multi channel SDPROC

To operate the mass flow controller in CLOSE, OPEN or AUTO modes, press the button

(UP, DOWN, ENTER respectively) directly below the mode shown on the display. First

line on the Display screen indicates the current valve status and flow rate in selected

engineering units. Pressing the Esc button under NEXT on the display from the Control

Mode Display, will display the Totalizer /Alarm Screen for channel #3.

e.3.6 Totalizer/Alarm Status Display

Totalizer/Alarm Status Display for Multi channel SDPROC

The first line of the Totalizer/Alarm screen indicates the totalizer reading in current (volume/mass based) Engineering Units. The second line shows alarm status by displaying a “D” for disabled, “N” for no alarm events, “L” for Low alarm and “H” for High

alarm. The totalizer can be reset to zero by pressing the Down button under RESET on

the display. Press the ENTER button under EXIT on the display in order to return to the

Main Display screen. Press the Esc button under CH3 on the display in order to return

to the Set Point screen for channel #3.

Page 26

20

e.3.7 Setup Channel Display

Pressing the Down button under Main Display screen (see section e.3.2) will display

SETUP CHANNEL screen shown below.

Setup Channel Display for Multi channel SDPROC

Press the button on the SDPROC panel under the appropriate channel number displayed.

This will select that channel for device settings configuration. (For this manual, channel 3

has been selected.) The following display will appear.

Setup Channel screen allows to configure:

= GENERAL DEVICE SETTINGS: Int./Ext. Reference, Gas density, Engineering Units,

Full Scale Flow in L/Min and Relays assignment.

= ALARM PROPERTIES: Mode, High and Low settings in % F.S., Delay Time,

Action.

= TOTALIZER PROPERTIES: Mode, Start Flow, Stop Volume, Action.

= PROGRAM PROPERTIES: Batch parameters, Timer and Ratio Settings.

Press the Esc button under GENER on the display in order to make General settings.

The following Internal/External/Program Reference display will appear.

e.3.7.1 Internal/External/Program Reference

The INT/EXT/PRG refers to point of origin for the valve control reference signal. To

change this, press the button UP, DOWN, ENTER respectively. In the internal reference

mode, the control signal is set by the user with the SDPROC controls (see section e.3.4).

In external reference mode, the control signal is set by the user from a remote location.

This external reference signal is provided for via the DATA IN/OUT 25 pin “D” connector at the rear of the SDPROC (see section b.2.4).

Pressing the ENTER button on the front panel under PRG on the display of the SDPROC

will toggle the reference between PROGRAM BATCH, PROGRAM TIMER and

RATIO.When complete with settings, press the ESC button under EXIT on the display,

to go to the Density screen. The following Setup Gas Density Display will appear.

Page 27

21

e.3.7.2 Setup Gas Density Display

The proper settings of the gas density (in grams per liter) are required for mass based

engineering units (LBPH, LBPM, GrPH, GrPM). Press the ENTER button under (--->)

on the display, to move the flashing cursor to the desired position. Pressing (+) or (-)

will increment or decrement a particular digit respectively. The numbers will change

from 0 to 9 and next to the decimal point (.). Pressing the (+) button one more time

will change the highlighted position of the cursor back to 0. The same is true in reverse:

when pressing the (-) button. Only one decimal point is allowed. If changing the position of the decimal point is required, change the decimal point to any desired digit, then

move the cursor to the required position and adjust it to the decimal point with (+) or

(-) button.

When complete with gas density settings, press the ESC button under NEXT on the display, to go to the Engineering Units screen. The following Setup Engineering Units

Display will appear.

e.3.7.3 Setup Engineering Units Display

Press the UP or DN button, to change current engineering units. The following engineering units are supported: %F.S., SLPM, SLPH, SCCM, SCCH, SCFM, SCFH, SCMM,

SCMH, LBPM, LBPH, GRPM, GRPH. If no more settings are required, press the ENTER

button under EXIT on the display, to go back to the Main Display. Press the ENTER button under NEXT on the display in order to go to the Full Scale Flow Rate screen. The

following Setup Full Scale Flow Rate Display will appear.

e.3.7.4 Setup Full Scale Flow Rate Display

The proper settings of the Full Scale Flow Rate (in liters per minute) are required for

any engineering units except % F.S. If for example a mass flow controller used with

channel #3 of the SDPROC is calibrated for 200 SCCM, the value of 0.2 has to be set.

Press the ENTER button under (--->) on the display, to move the flashing cursor to the

digit, which has to be adjusted. Pressing (+) or (-) will increment or decrement a particular digit respectively. The numbers will change from 0 to 9 and next to the decimal

point (.). Pressing the (+) button one more time will change the highlighted position

of the cursor back to 0. The same is true in reverse, when pressing the (-) button. Only

one decimal point is allowed. If changing the position of the decimal point is required,

Page 28

22

change the decimal point to any desired digit, next move the cursor to the required

position, and adjust it to the decimal point with the (+) or (-) button. When complete

with Full Scale Flow Rate settings, press the ESC button under NEXT on the display, to

go to the Relays Assignment screen. The following Setup Relays Assignment Display

will appear.

e.3.7.5 Setup Relays Assignment Display

Two sets of dry contact relay are available for each channel. Each relay individually

can be assigned for:

= NO ACTION

= ALARM LOW

= ALARM HIGH

= TOTALIZER STOP

Press either the UP or DN button to change the relay assignment. When complete with

the first relay settings, press the ESC button under NEXT on the display, to go to the

second relay. The following display will appear.

Press the ESC button under NEXT on the display or the ENTER button under EXIT on

the display, to go back to the Main Display.

e.3.8 Setup Alarm Display

Before enabling the Alarm make sure all alarm settings are configured properly. High

and Low alarm values have to be entered in %F.S. engineering units. ALARM conditions become valid when the difference between current readings and installed set

points is equal or more than corresponding values of high and low alarm levels. From

the Setup Channel Display (see section e.3.7) press the Up button under ALARM on

the display in order to make Alarm settings. The following Setup Alarm Mode Display

will appear.

e.3.8.1 Setup Alarm Mode Display

To change the Alarm Mode in ENABLED or DISABLED, press the button (UP, DOWN

respectively) directly below the mode shown on the display. Press the ENTER button

under EXIT on the display, to go back to the Main Display. Press the ESC button under

Page 29

23

NEXT on the display to go to the Alarm Low settings. The following Setup Alarm Low

Display will appear.

e.3.8.2 Setup Alarm Low Display

Pressing (+) or (-) will increment or decrement Low Alarm settings per 0.1% F.S.

respectively. If no settings are required for High Alarm press the ENTER button under

EXIT on the display, to go back to the Main Display. Press the ESC button under NEXT

on the display to go to the Alarm High settings. The following Setup Alarm Low

Display will appear.

e.3.8.3 Setup Alarm High Display

Pressing (+) or (-) will increment or decrement High Alarm settings per 0.1% F.S.

respectively. If no settings are required for High Alarm press the ENTER button under

EXIT on the display, to go back to the Main Display. Press the ESC button under NEXT

on the display to go to the Alarm Delay settings. The following Setup Alarm Delay

Display will appear.

3.8.4 Setup Alarm Delay Display

Alarm Delay specifies the time interval in seconds the Alarm conditions have to be True

(without any interruption) before the Alarm will be activated. If zero value is set, the

Alarm will be activated immediately after Alarm conditions are met. Pressing (+) or (-)

will increment or decrement Alarm Delay settings per 1 second respectively. If no settings are required for Alarm Action press the ENTER button under EXIT on the display,

to go back to the Main Display. Press the ESC button under NEXT on the display to go

to the Alarm Action settings. The following Setup Alarm Action Display will appear.

e.3.8.5 Setup Alarm Action Display

To change Alarm Action in NONE, BUZZER or VALVE, press the button (ESC, UP, DOWN

respectively) directly below the text shown on the display. If Buzzer action is chosen

the audible signal will be activated when Alarm conditions become true.

Page 30

24

In order to deactivate the audible signal during operation, press any button on

the key pad (NOTE: Alarm Conditions have to be removed or Alarm for the

corresponding channel has to be disabled).

If Valve action is chosen the power to the mass flow controller valve will be shut off,

allowing the valve to mechanically close.

If the Valve was shut off as the result of the Alarm action, in order to go back to

normal operation the Valve mode has to be changed to AUTO (See section e.3.5).

NOTE: Alarm Conditions have to be removed or Alarm has to be disabled prior

any attempts to change the Valve mode.

Press the ENTER button under EXIT on the display, to go back to the Main Display.

e.3.9 Setup Totalizer Display

Before enabling the Totalizer ensure that all totalizer settings are configured properly.

Totalizer Start values have to be entered in %F.S. engineering units. Totalizer will not

totalize until the flow rate becomes equal or more than the Totalizer Start value.

Totalizer Stop values have to be entered in volume / mass based engineering units.

Totalizer condition becomes valid when the totalized volume is equal or more than the

Totalizer Stop value.

From the Setup Channel Display (see section e.3.7) press the Down button under

TOTAL on the display in order to make Totalizer settings. The following Setup Totalizer

Mode Display will appear.

e.3.9.1 Setup Totalizer Mode Display

To change the Totalizer Mode in ENABLED or DISABLED, press the button (UP, DOWN

respectively) directly below the mode shown on the display. Press the ENTER button

under EXIT on the display, to go back to the Main Display. Press the ESC button under

NEXT on the display to go to the Totalizer Start settings. The following Setup Totalizer

Start Flow Display will appear.

e.3.9.2 Setup Totalizer Start Flow Display

Pressing (+) or (-) will increment or decrement Totalizer Start settings per 0.1% F.S.

respectively. If no settings are required for Totalizer Stop value press the ENTER button under EXIT on the display, to go back to the Main Display. Press the ESC button

Page 31

25

under NEXT on the display to go to the Totalizer Stop settings. The following Setup

Totalizer Stop Volume Display will appear.

e.3.9.3 Setup Totalizer Stop Volume Display

The proper setting of the Totalizer Stop Volume (in volume/mass based engineering

units) is required if the Totalizer is set to Enabled. The engineering unit for Totalizer

Stop Volume has to be related to the current active engineering unit. If for example the

current engineering unit is sLPM, the Totalizer Stop Volume has to be entered in liters.

Press the ENTER button under (--->) on the display, to move the flashing cursor to the

digit, which has to be adjusted. Pressing (+) or (-) will increment or decrement a particular digit respectively. The numbers will change from 0 to 9 and next to the decimal

point (.). Pressing the (+) button one more time will change the highlighted position of

the cursor back to 0. The same is true in reverse, when pressing the (-) button. Only

one decimal point is allowed. If changing position of the decimal point is required,

change decimal point to any desired digit then move the cursor to the required position and adjust it to the decimal point with (+) or (-) button. When complete with

Totalizer Stop Volume settings, press the ESC button under NEXT on the display, to go

to the Totalizer Action screen. The following Setup Totalizer Action Display will appear.

e.3.9.4 Setup Totalizer Action Display

To change the Totalizer Action in NONE, BUZZER or VALVE, press the button (ESC, UP,

DOWN respectively) directly below the text shown on the display. If Buzzer action is

chosen the audible signal will be activated when the Totalizer condition becomes true.

In order to deactivate the audible signal during operation press any button on

the key pad (NOTE: The Totalizer has to be reset to zero or disabled).

If Valve action is chosen, the power to the mass flow controller valve will be shut off,

allowing the valve to mechanically close.

If the Valve was shut off as result of the Totalizer action, in order to go back to

normal operation the Valve mode has to be changed to AUTO (See section e.3.5).

NOTE: The Totalizer reading has to be reset to zero or the Totalizer has to be

disabled prior any attempts to change the Valve mode.

Press the ENTER button under EXIT on the display, to go back to the Main Display.

e.3.10 Program Settings Display

From the Setup Channel Display (see section e.3.7) press the Enter button under PROG

on the display in order to make Program settings. The following display will appear.

Page 32

26

There are three program options for multi channel SDPROC: BATCH, TIMER and RATIO

flow control.

e.3.10.1 Batch Program Settings Display

Batch Flow Control allows execution of a custom, user preset program of up to sixteen

steps. During execution of the program the user can activate or deactivate the LOOP

mode. Various flow configurations may be pre-programmed: ramping, pulsing, linearized increasing and/or decreasing of the flow. Before executing, the program should

be entered in the program table in the format: SETPOINT [% F.S.] - TIME [sec.]. TIME

means: time it takes for the value of the output signal from a mass flow controller to

linearly approach SETPOINT value (ramping). Press the UP button under BATCH on the

display, to set up the BATCH table. The following display will appear.

Time Settings for first step of the BATCH table

Pressing (+) or (-) will increment or decrement the step time settings per 1, 10 or 100

seconds (depending on the value of the multiplier M) respectively. The maximum valid

value is 99999 seconds. Pressing the (+) button one more time will rollover time settings

to zero. The same is true for 0 seconds, pressing the (-) button will rollover time settings

to 99999 seconds. Press the ENTER button under MULT on the display, to change the

value of the multiplier to 10. Continuing to press the ENTER button under MULT on the

display, will change the value of the multiplier first to 100 and then back to 1.

When complete with TIME settings for the first step of the Batch program, press the

ESC button under NEXT on the display, to go to the SETPOINT screen.

The following display will appear.

Set Point Settings for first step of the BATCH table

Pressing (+) or (-) will increment or decrement the step set point settings per 0.1% F.S.

respectively. When complete with SET POINT settings for the first step of the Batch

program, press the ENTER button under NEXT on the display, to go to the next step.

Continue with Time and Set point settings for as many steps as required for your application (16 is maximum limit). When complete with all settings for the Batch program

press the Esc button under EXIT on the display, to go to the BATCH control screen. The

following display will appear.

Page 33

27

BATCH mode control screen with batch disabled

The two digit number after “SE:” indicates the number of the enabled steps for executions. Press the UP button under STEPS on the display, to change the number of steps

from the batch program to be executed. With 16 steps enabled on the screen, pressing the Up button one more time will rollover the number of steps back to 1. Press the

ENTER button under LOOP on the display, to toggle the loop control ON and OFF. If

loop control is ON, after executing the last enabled step, the program will go back to

the first step and go on again until the loop mode will be disabled. In order to start the

batch program executions, press the Down button under START on the display. NOTE:

In order to execute the batch program, the valve control reference has to be set to

BATCH mode (See section e.2.6.1). The following display will appear.

BATCH mode control screen with batch enabled

Press the Down button under STOP on the display one more time, to toggle the batch

mode to OFF (disabled). Press the Esc button under EXIT on the display, to go to the

Main Display.

e.3.10.2 Timer Program Settings Display

The Timer Flow Control allows execution of a custom, user preset program of up to 96

steps. Each step can be pre-programmed for a particular date, time, and set point value

in % F.S.. Every step has two fields: starting date, time and set point in % F.S. Before

executing, the program should be entered in the program table in the format:

TIME/DATE [XX.XX XX/XX/XXXX] - SETPOINT [% F.S.]. Time and date indicates exact

moment (+/- one minute accuracy) when the set point has to be executed by the mass

flow controller. From the Program Settings Display (See section e.3.10), press the

Down button under TIMER on the display, to set up the TIMER table. The following display will appear.

Time and date settings for first step of the TIMER table

Press the ENTER button under (--->) on the display, to move the flashing cursor to the

hours position. Pressing (+) or (-) will increment or decrement the time settings

(hours). When complete with hours settings press again the ENTER button to move

the flashing cursor to the minutes position. When done with time settings press again

Page 34

the ENTER button to move the flashing cursor to the date position (month, date and

year) respectively.

Make sure date and time entered is not in the past (otherwise this step of the

program will not be executed).

When complete with TIME and DATE settings for first step of the Timer program, press

the ESC button under NEXT on the display, to go to the SETPOINT screen. The following display will appear.

Set Point settings for first step of the TIMER table

Pressing (+) or (-) will increment or decrement the step set point settings per 0.1% F.S.

respectively. When complete with SET POINT settings for the first step of the Timer

program, press the ENTER button under NEXT on the display, to go to the next step.

Continue with Time/Date and Set point settings for as many steps as required for your

application (96 is maximum limit). When complete with all settings for the Timer program press the Esc button under EXIT on the display, to go to the Main Display screen.

Make sure the reference for set point is set to the PROGRAM TIMER mode in

order for the Timer program to be executed (see section e.3.7.1).

e.3.10.3 Ratio Program Settings Display

Ratio Flow allows controlling flow of the mixture of up to four different gases (for 4

channel Command Module) with preset values of the ratio in % for each channel. The

flow rate of the mixture can be incremented or decremented by changing the set point

of the master channel #1. From the Program Settings Display (See section e.3.10),

press the Enter button under RATIO on the display, to set up the RATIO table. The following display will appear.

Ratio mode settings for third channel on the Multi-channel SDPROC

28

Page 35

29

By default, Ratio Mode is disabled for each channel. In order to be able to enable Ratio

Mode, the value of the ratio in % for a particular channel has to be more than 0%. It is

recommended to begin Ratio settings from the master channel #1 (master channel has

to be set to the highest value from the mixture). For example, if four gas mixtures are

desired with ratios: Gas#1=30%, Gas#2= 25%, Gas#3=25% and Gas#4=20% the

Gas#1 has to be set on channel#1 (master channel). In order to setup channel#1 from

the above screen, press the Esc button under NEXT on the display until the following

screen will appear.

Ratio mode settings for first channel on the Multi-channel SDPROC

Press one more time the Esc button under NEXT on the display, in order to go to the

Ratio value settings screen. The following display will appear.

Ratio value settings for first channel on the Multi-channel SDPROC

Pressing (+) or (-) will increment or decrement the Ratio Value settings per 0.1% F.S.

respectively. The number in the upper right corner of the screen, represents the total

value of the mixture (the sum of the ratio values for all available channels). It is important to have this number equal to 100% in the end of the ratio settings (otherwise the

Ratio mode will not operate properly). When complete with Ratio value settings fort the

first channel, press the Esc button under NEXT on the display, to go to the ratio settings

for the second channel. The following display will appear.

Ratio mode settings for second channel on the Multi-channel SDPROC

NOTE: The ratio mode for channel#2 is disabled because the ratio value is set to zero

by default. Press one more time the Esc button under NEXT on the display, to go to the

ratio settings for the second channel. The following display will appear.

Ratio value settings for second channel on the Multi-channel SDPROC

NOTE: This assumes that the ratio value for the master channel#1 was set to 35%.

Continue with ratio value settings for all required channels.

Page 36

30

Make sure that the total value of the mixture is equal to 100% in the end of the

ratio settings for all required channels.

When complete with ratio value settings for all required channels, go to the ratio mode

settings screen for each required channel and change the ratio mode from DISABLED

to ENABLED.

Make sure that the reference for set point is set to PROGRAM RATIO mode for

all required channels in order for the Ratio program to be executed

(see section e.3.7.1).

In order to change the flow rate for the mixture of gases use the Set Point screen for

the master channel#1 (See section e.3.4).While adjusting the set point for the master

channel in the Ratio mode, the SDPROC will automatically check the adjusted set point

for slave channels in order to keep them within the range between 2.0 and 100% F.S.

When complete with ratio settings, press the ENTER button under EXIT on the display,

to go to the Main Display screen.

e.3.11 All Valves Control

It may on occasion be desirable to set all the channels in the flow system to the same

mode of operation simultaneously. While in the Main Display press the ESC button on

the front panel of the SDPROC. The following screen will then appear.

All Valves Control Mode Display for Multi channel SDPROC

Choosing CLOSE, OPEN, or AUTO from this menu, will apply to all channels connected to the multi channel SDPROC. After making the selection, the Main Display returns.

Select EXIT if no changes are desired. The following Real-time Clock Settings display

will appear.

Page 37

31

e.3.12 Real-time Clock Settings

Real Time Clock Settings Display for SDPROC

Normally date and time for the Real-time Clock are set by the factory, unless the battery was replaced, or the CPU core was removed from the main board of the SDPROC.

In order to change date and time settings press the ENTER button under SET on the

display. This will activate the flashing cursor on the hours position. Pressing (+) or (-)

will increment or decrement the time settings (hours). When complete with hours settings press again the ENTER button to move the flashing cursor to the minutes position. When complete with minutes settings press again the ENTER button to move the

flashing cursor to the seconds position. When done with time settings press again the

ENTER button to move the flashing cursor to the date position (month, date and year)

respectively. When done with years settings press again the ENTER button to disable

Real-time settings and update new time and date.

Proper settings of the Real-time Clock is essential for the Timer program to be

executed correctly.

When complete with Real-time Clock settings, press the ENTER button under EXIT on

the display, to go to the Main Display screen.

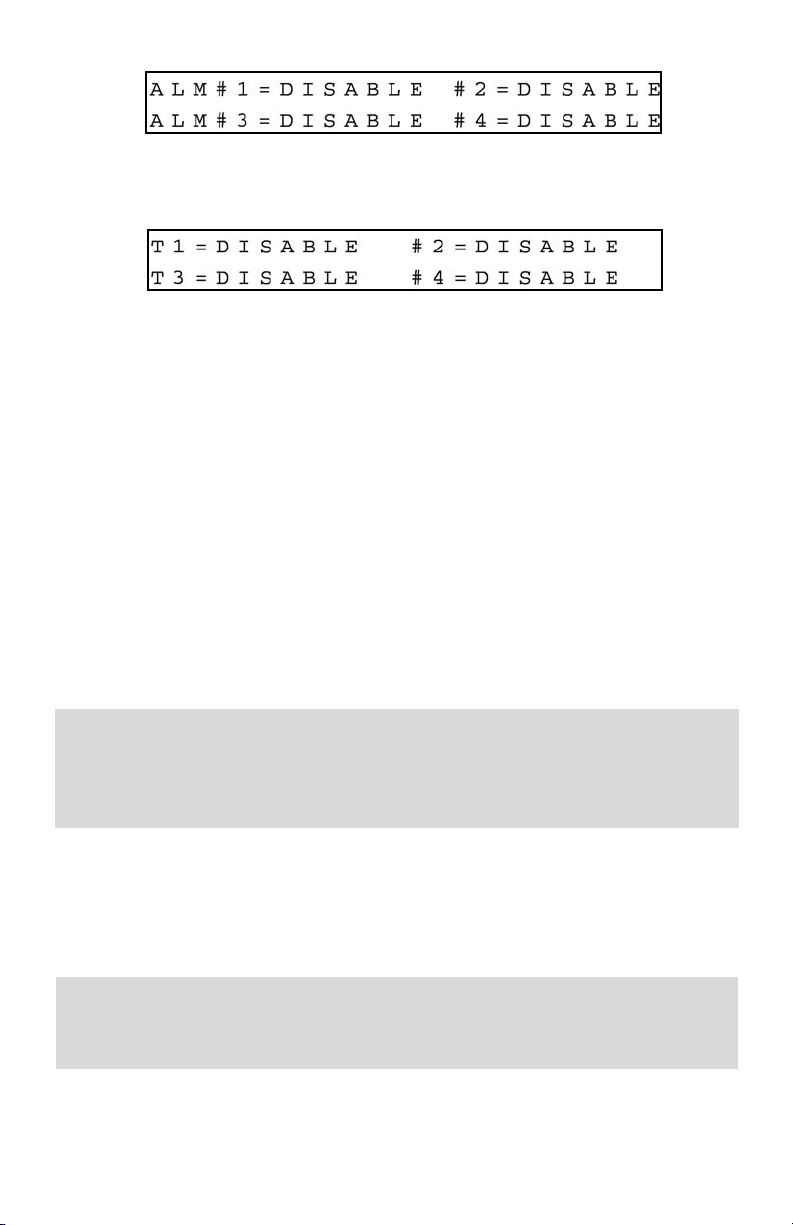

e.3.13 Status Check

While in the Main Display, press the UP button on the front panel of the SDPROC. The

Set point Status in % F.S. for all channels will appear.

Set point Status Display for Multi channel SDPROC

Pressing the UP button again will bring up the Set point Status in current engineering

units for all channels.

Pressing the UP button again will bring up the Valve Mode Status for all channels.

Valve Mode Status Display for Multi channel SDPROC

Page 38

Pressing the UP button again will bring up the Alarm Mode Status for all channels.

Alarm Mode Status Display for Multi channel SDPROC

Pressing the UP button again will bring up the Totalizer Mode Status for all channels.

Totalizer Mode Status Display for Multi channel SDPROC

Press UP one more time to return to the Main Display. NOTE: Pressing the Down

button from any of the status screens will switch status display to one step back.

(f) MAINTENANCE

The SDPROC does not require any regular maintenance. Any repair of defective components or parts of the SDPROC should be referred to your distributor or Aalborg7

(also see the TROUBLESHOOTING GUIDE section in this manual).

To replace AC inlet power fuses, turn the SDPROC power switch off. Remove the AC

power line cord from the inlet connector at the rear panel of the SDPROC. Slide the fuse

drawer open. Replace the defective fuse(s) with a 2A FF (very quick acting) fuse. Slide

the fuse drawer back in. Reconnect the AC the power line cord. Continue SDPROC

operation.

CAUTION: TO PROTECT SERVICING PERSONNEL IT IS MANDATORY THAT ANY

INSTRUMENT BEING SERVICED IS COMPLETELY PURGED AND NEUTRALIZED

OF TOXIC, BACTERIOLOGICALLY INFECTED, CORROSIVE OR RADIOACTIVE

CONTENTS.

(g) ADC/DAC CALIBRATION PROCEDURES

The ADC/DAC calibration for your SDPROC was performed at the factory. It is not

required to perform recalibration unless the firmware was reinitialized, or the main PC

board was replaced.

NOTE: Removal of the factory installed calibration seals and/or any adjustments

made to the instrument, as described in this section, will void any calibration

warranty applicable.

Turn the power off to the SDPROC. While the Esc and Enter buttons are pressed, turn

the SDPROC on. Continue to press Esc and the Enter buttons until the calibration

screen will appear (approximately 3-4 sec.).

32

,

Page 39

33

Calibration Mode Display

Proceed with instructions outlined in sections g.1 and g.2.

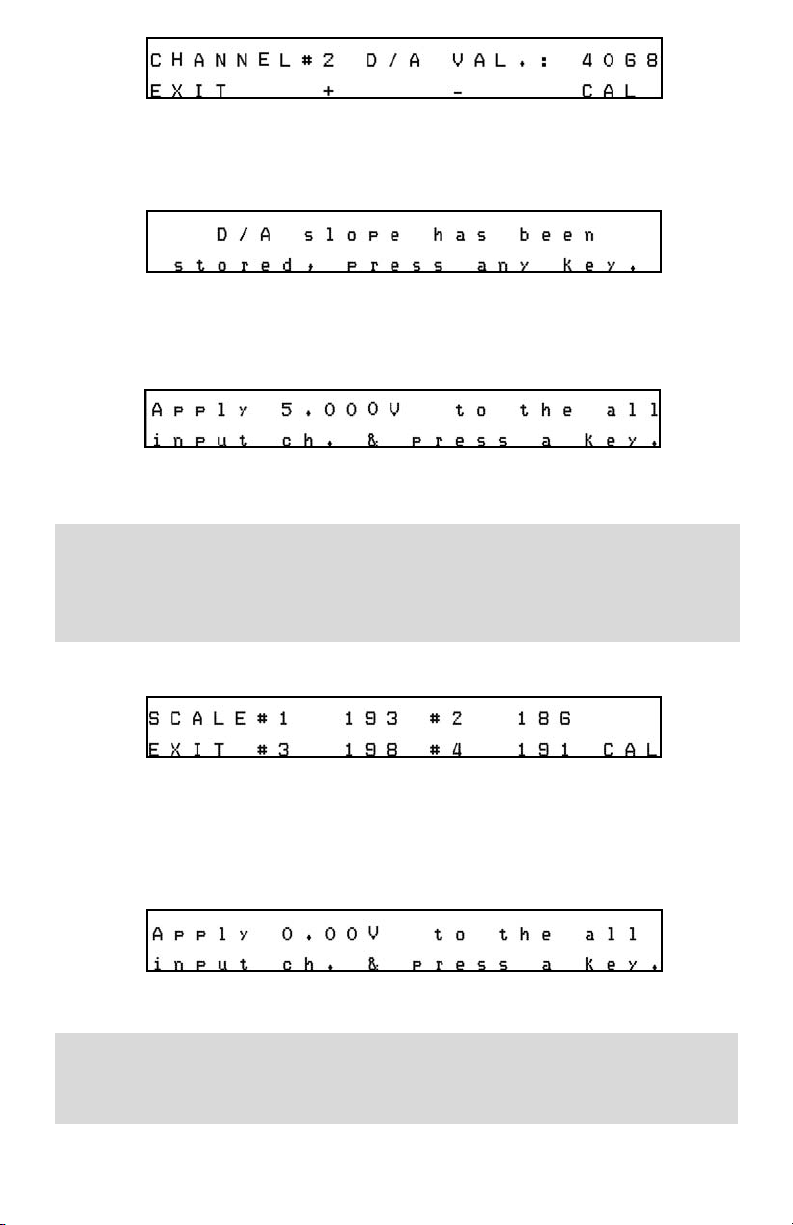

g.1 Digital to Analog (D/A) Slope Calibration

Select the D/A calibration mode from the Calibration Menu. The following display will

appear.

NOTE: The digital to analog (D/A) slope has to be calibrated for each channel

individually!

Using an accurate digital multimeter, measure the A/D output DC voltage between pins

9 (positive) and 10 (ground) of the Channel 1 15 pin “D” connector. Set the output DC

voltage for exactly 5.000 VDC using the “+” and “-” controls (UP and DOWN buttons

respectively, on the front panel of the SDPROC). When the “+” or “-” controls is

pressed at least once, the following display will appear.

The display should show the D/A value between 3900 and 4095. Save the D/A slope

parameter by pressing CAL (ENTER button). For the one channel SDPROC the following display will confirm your setting.

Press any key to return to the Calibration Mode Display.

For Multi channel SDPROC's, the calibration software will prompt for the second channel.

Using an accurate digital multimeter, measure the D/A output DC voltage between pins

9 (positive) and 10 (ground) of the Channel 2 15 pin “D” connector. Set the output DC

voltage for exactly 5.000 VDC using the “+” and “-” controls (UP and DOWN buttons

respectively, on front panel of SDPROC). When the “+” or “-” controls are pressed at

least once, the following display will appear.

,

Page 40

34

The display should show the D/A value between 3900 and 4095. Save the D/A slope

parameter by pressing the CAL (ENTER button).Proceed with D/A calibration for as