Page 1

OPERATING MANUAL

PWE

Digital Paddle Wheel

Flow Meter

Technical Data Sheet No.: TD-10-09-118M

Date of Issue: October 2009

Page 2

Aalborg7is a registered trademark of Aalborg Instruments & Controls.

NOTE: Aalborg reserves the right to change designs and dimensions at its sole

discretion at any time without notice. For certified dimensions please contact Aalborg7.

Page 3

TABLE OF CONTENTS

1. UNPACKING THE PWE FLOW METER..........................................

1.1 Inspect Package for External Damage........................................................

1.2 Unpack the PWE meter..............................................................................

1.3 Returning Merchandise for Repair..............................................................

2. PWE FLOW METERS TECHNICAL DATA..........................................

2.1 Principles of Operation...............................................................................

2.2 Electrical Connections................................................................................

2.2.1 Power Supply Connections........................................................................

2.2.2 Analog Output Signals Connections.............................................................

2.2.3 Flow Sensor Pulse Output Signals Connections........................................

2.2.4 Programmable optically isolated Output Signals Connections....................

2.2.5 Communication Parameters and Connections.............................................

2.3 PWE Flow Meter Specification....................................................................

2.4 PWE Maintenance.........................................................................................

2.4.1 Sensors.......................................................................................................

2.4.2 PWE Paddle Wheel Disassembly................................................................

3. LCD KEYPAD OPERATION: DATA ENTRY AND CONFIGURATION...........

3.1 Display Indications (applicable for LCD options only)................................

3.1.1 PWE with RTD option Process Information Screens..................................

3.1.2 PWE without RTD option Process Information Screens.............................

3.2 Menu Sequence............................................................................................

3.3 Parameter Summary and Data Entry.............................................................

4. PARAMETER ENTRY...............................................................

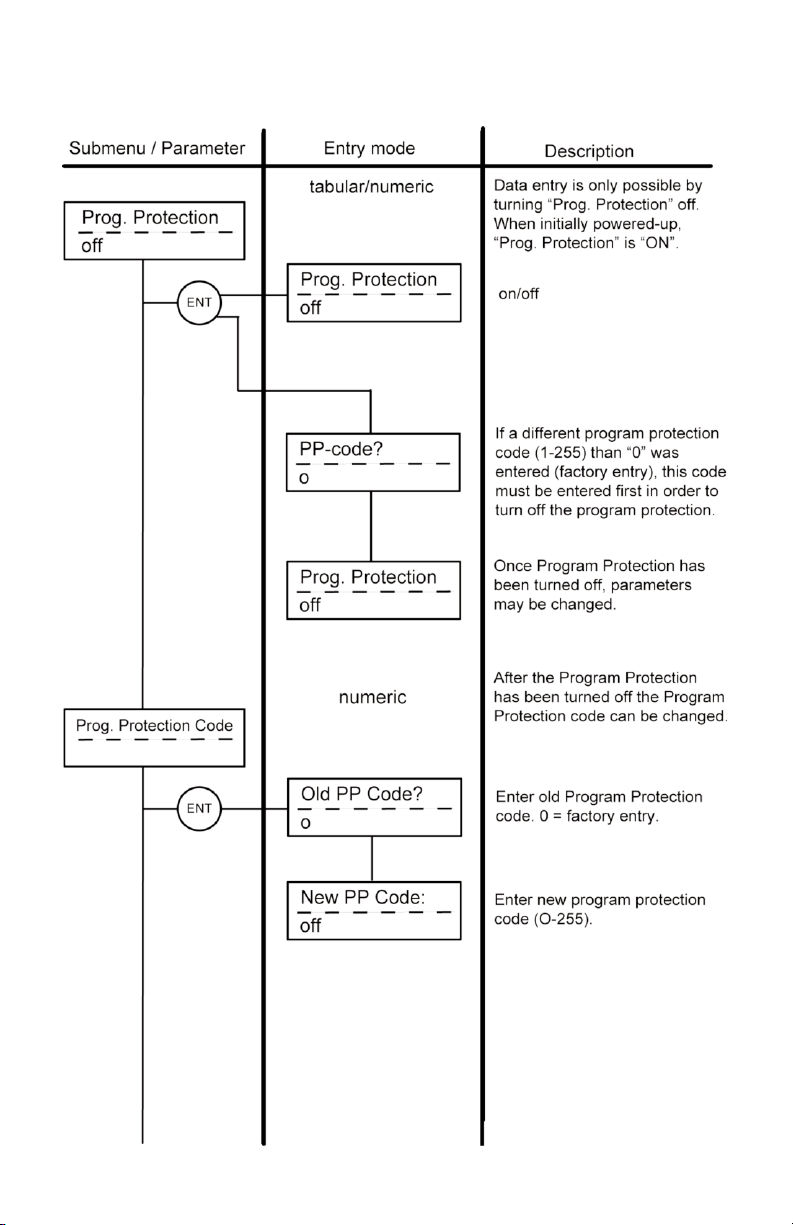

4.1 Submenu Program protection...................................................................

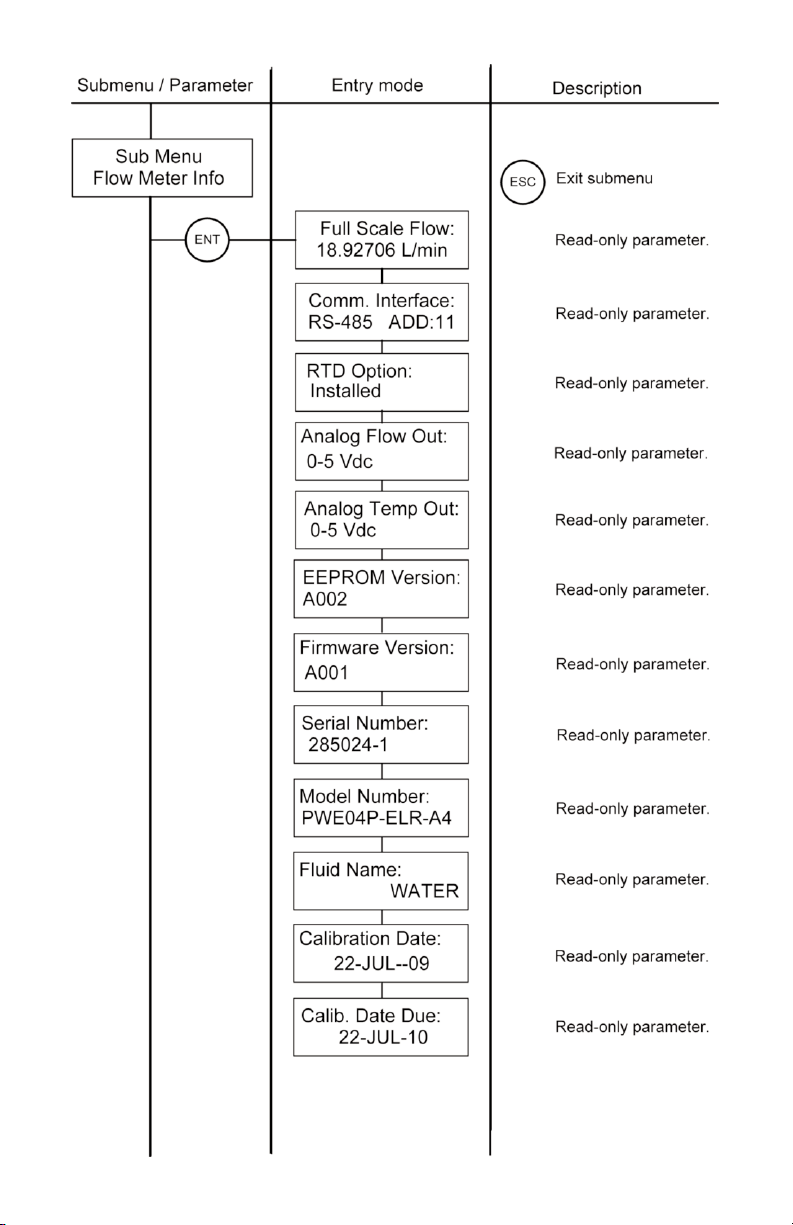

4.2 Submenu Flow Meter Info...........................................................................

4.2.1 Full Scale Flow..............................................................................................

4.2.2 Communication Interface............................................................................

4.2.3 RTD hardware option..................................................................................

4.2.4 Analog Flow Output settings.......................................................................

4.2.5 Analog Temperature Output settings...........................................................

4.2.6 Flow Meter EEPROM data base version.....................................................

4.2.7 Flow Meter Firmware version.......................................................................

4.2.8 Flow Meter Serial number.............................................................................

4.2.9 Flow Meter Model number..........................................................................

4.2.10 Fluid Name.................................................................................................

4.2.11 Flow Meter Calibration Date........................................................................

4.2.12 Flow Meter Calibration Date Due..................................................................

4.2.13 Flow Meter User Tag Name.........................................................................

1

1

1

1

1

1

2

3

3

4

5

6

7

9

9

9

11

11

12

14

15

17

25

25

26

26

26

27

27

27

28

28

28

28

29

29

29

29

Page 4

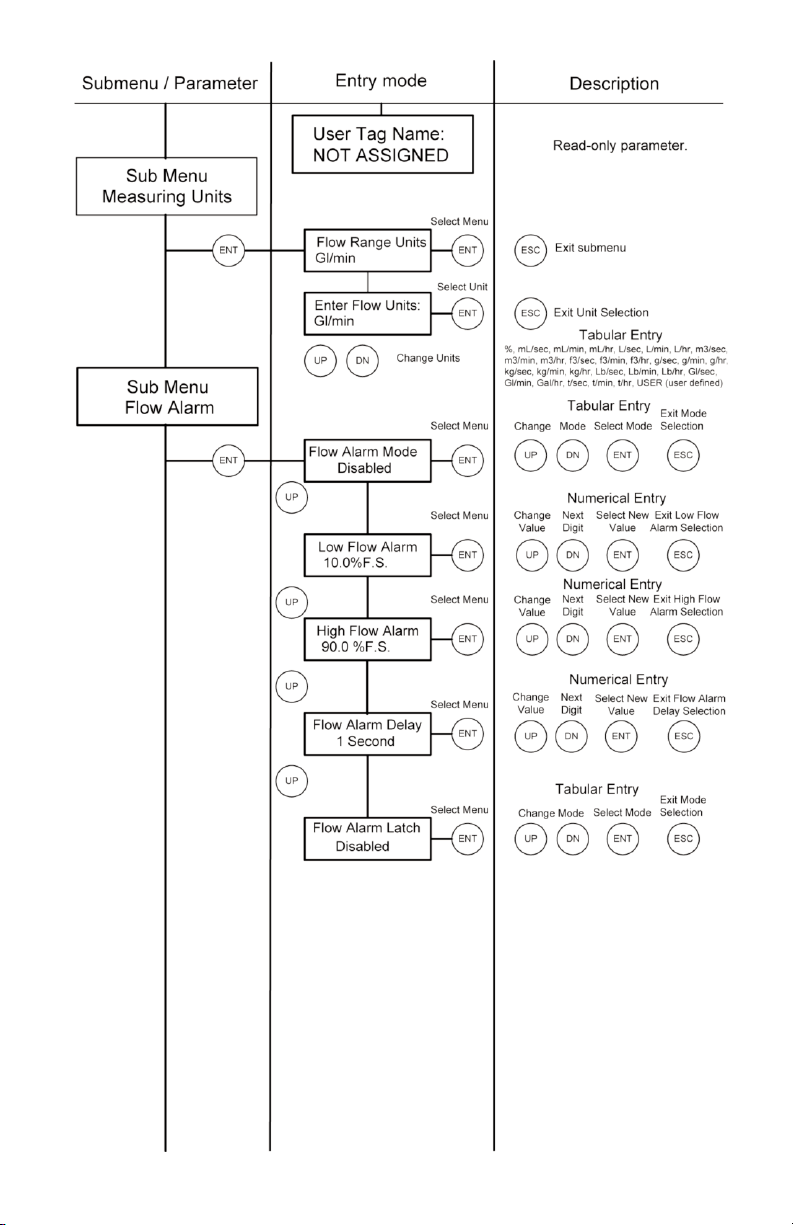

4.3 Submenu Measuring Units........................................................................

4.3.1 User Defined Measuring Unit......................................................................

4.3.1.a User Defined Unit Factor Numeric entry......................................................

4.3.1.b User Defined Unit Time Base Tabular entry................................................

4.3.1.c User Defined Unit Density support Tabular entry.....................................

4.4 Submenu Flow Alarm.................................................................................

4.4.1 Flow Alarm Mode Tabular entry................................................................

4.4.2 Low Flow Alarm Numerical entry..............................................................

4.4.3 High Flow Alarm Numerical entry..............................................................

4.4.4 Flow Alarm Action Delay Numerical entry...................................................

4.4.5 Flow Alarm Action Latch Tabular entry.....................................................

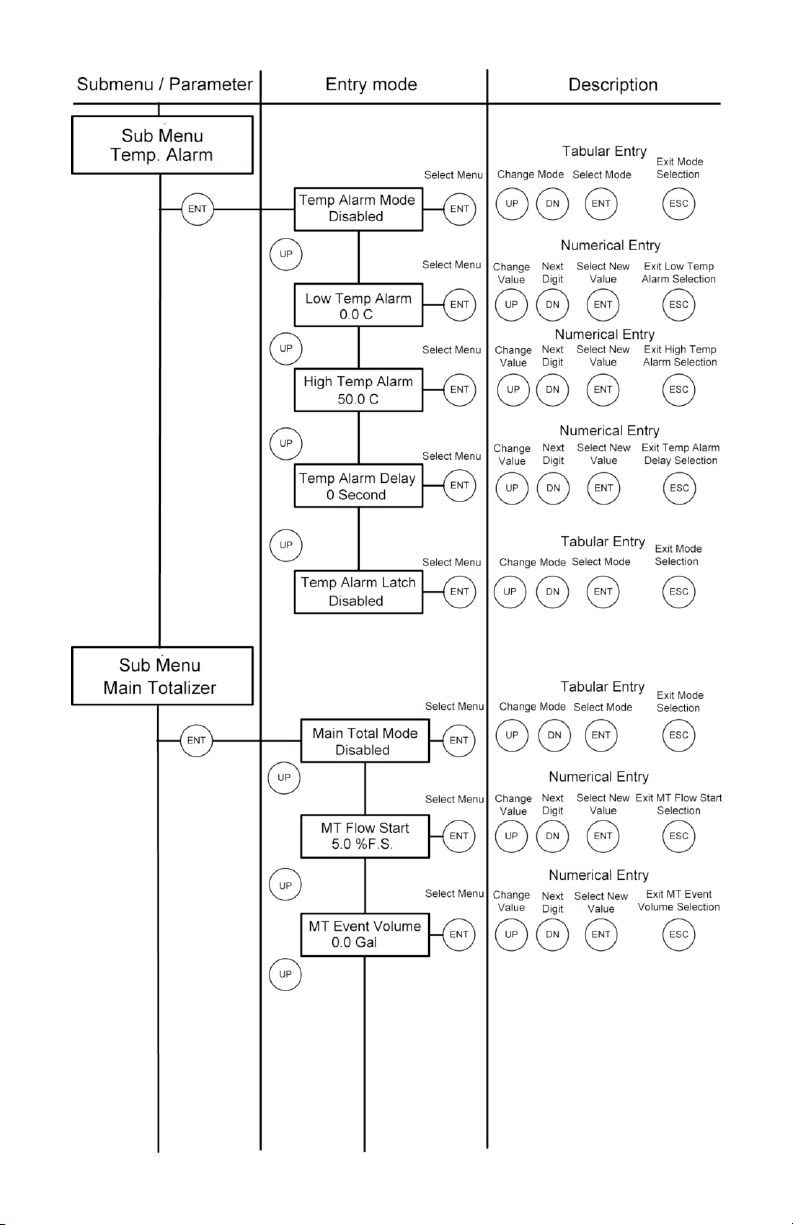

4.5 Submenu Temperature Alarm (*optional)...................................................

4.5.1 Temperature Alarm Mode Tabular entry...................................................

4.5.2 Low Temperature Alarm Numerical entry...................................................

4.5.3 High Temperature Alarm Numerical entry...................................................

4.5.4 Temperature Alarm Action Delay Numerical entry.....................................

4.5.5 Temperature Alarm Action Latch Tabular entry.........................................

4.6 Submenu Main Totalizer..............................................................................

4.6.1 Main Totalizer Mode Tabular entry............................................................

4.6.2 Main Totalizer Flow Start Numerical entry................................................

4.6.3 Main Totalizer Event Volume Numerical entry..........................................

4.6.4 Main Totalizer Reset Tabular entry............................................................

4.7 Submenu Pilot Totalizer............................................................................

4.7.1 Pilot Totalizer Mode Tabular entry..............................................................

4.7.2 Pilot Totalizer Flow Start Numerical entry..................................................

4.7.3 Pilot Totalizer Event Volume Numerical entry.............................................

4.7.4 Pilot Totalizer Reset Tabular entry.............................................................

4.8 Submenu Optical Outputs Numerical entry..................................................

4.9 Submenu Flow Meter Configuration.........................................................

4.9.1 Submenu Flow Meter Low Flow Cut–off Numerical entry........................

4.9.2 Submenu Pulse Number Measure Interval Numerical entry........................

4.9.3 Submenu Flow Meter Calibration Factor Numerical entry........................

4.9.4 Submenu Flow Meter Measure Mode Tabular entry.................................

4.9.5 Submenu Noise Reduction Filter Damping Time Numerical entry............

4.9.6 Submenu Noise Reduction Filter Sample Number Numerical entry............

4.9.7 Submenu Flow Linearizer Tabular entry....................................................

4.9.8 Submenu Fluid Density Numerical entry...................................................

4.9.9 Submenu Pilot Calibration timer Tabular entry...........................................

4.10 Submenu LCD Back Light Numerical Entry...............................................

4.11 Submenu Alarm Events Log....................................................................

4.11.1 Submenu Alarm Events Log Status...........................................................

4.11.2 Submenu Alarm Events List......................................................................

4.11.3 Submenu Alarm Events Log Mask...........................................................

4.12 Submenu Diagnostic...................................................................................

30

32

32

32

33

33

33

34

34

35

35

36

36

36

37

38

38

39

39

40

40

40

41

41

42

42

42

43

44

44

44

45

45

46

46

47

47

47

48

48

50

51

51

51

Page 5

4.12.1 Submenu Raw Pulses Count.....................................................................

4.12.2 Submenu Pulse Frequency.........................................................................

4.12.3 Submenu Raw RTD reading (RTD option only)........................................

4.12.4 Submenu DAC_A Flow Output..................................................................

4.12.5 Submenu DAC_B Temperature Output....................................................

4.12.6 Submenu CPU Temperature........................................................................

4.12.7 Submenu Raw VCC Reading....................................................................

5. ANALOG OUTPUT SIGNALS.....................................................

5.1 Analog Output Signals configuration........................................................

5.2 Analog Output Signals calibration............................................................

5.2.1 Initial Setup...............................................................................................

5.2.2 Flow 0-5 Vdc analog output calibration....................................................

5.2.3 Flow 4-20 mA analog output calibration....................................................

5.2.4 Temperature 0-5 Vdc analog output calibration*......................................

5.2.5 Temperature 4-20 mA analog output calibration*....................................

6. PWE FLOW CALIBRATION PROCEDURES.....................................

6.1 Connections and Initial Warm Up.............................................................

6.2 Flow Meter Span Calibration....................................................................

6.3 Flow Meter Linearization Table Calibration..................................................

7. RS-485/RS-232 SOFTWARE INTERFACE COMMANDS.....................

7.1 General.......................................................................................................

7.2 Commands Structure................................................................................

7.3 ASCII Commands Set..............................................................................

8. TROUBLESHOOTING...............................................................

8.1 Common Conditions.................................................................................

APPENDIX I

PWE EEPROM Variables.................................................

APPENDIX II Component Diagram Top Side......................................

Component Diagram Bottom Side..................................

APPENDIX III Dimensional Drawing................................................

APPENDIX IV Warranty................................................................

52

52

52

52

53

53

53

53

53

54

55

56

56

57

57

58

58

59

59

61

61

61

63

71

71

73

76

76

77

78

Page 6

1. UNPACKING THE PWE

1.1 Inspect Package for External Damage

Your PWE Paddle Wheel Meter was carefully packed in a sturdy cardboard carton,

with antistatic cushioning materials to withstand shipping shock. Upon receipt,

inspect the package for possible external damage. In case of external damage to

the package contact the shipping company immediately.

1.2 Unpack the PWE meter

Open the carton carefully from the top and inspect for any sign of concealed shipping damage. In addition to contacting the shipping carrier please forward a copy

of any damage report to your distributor or Aalborg

®

directly. When unpacking the

instrument please make sure that you have all the items indicated on the Packing

List. Please report any shortages promptly.

1.3 Returning Merchandise for Repair

Please contact the customer service representative of your distributor or Aalborg

®

if you purchased your PWE Meter directly, and request a Return Authorization

Number (RAN). Equipment returned without an RAN will not be accepted.

Aalborg

®

reserves the right to charge a fee to the customer for equipment returned

under warranty claims if the instruments are tested to be free from warranted

defects. Shipping charges are borne by the customer. Items returned "collect" will

not be accepted! It is mandatory that any equipment returned for servicing be

purged and neutralized of any dangerous contents including but not limited to

toxic, bacterially infectious, corrosive or radioactive substances. No work shall be

performed on a returned product unless the customer submits a fully executed,

signed SAFETY CERTIFICATE. Please request form from the Service Manager.

2. PWE FLOW METERS TECHNICAL DATA

2.1 Principles of Operation

PWE liquid flow meters consist of a meter body that is installed in-line in a conduit system. Inside, between the inlet and the outlet connections is a rotary wheel

with permanent magnets embedded at 180 degrees in paddles.

Fluid flowing through the meter causes the paddle to spin. A magnetic sensor

picks up the frequency of pulses, and the readings are proportional to the liquid

flow taking place. The number of pulses per unit time interval and a K-factor (pulses/unit of flow) facilitate determining the volumetric rate of flow through the

meter.

1

Page 7

Additionally, the PWE Flow Meter incorporates a Microcontroller driven circuitry

and non-volatile memory that stores all hardware specific variables. The flow rate

can be displayed in 29 different volumetric or mass flow engineering units. Flow

meter parameters and functions can be programmed remotely via the RS-232/RS485 interface or locally via optional LCD/KeyPad. PWE flow meters support various functions including: two programmable flow totalizers, low, high or range flow

and temperature* alarms, 2 programmable optically isolated outputs, 0-5 Vdc / 420 mA analog outputs (jumper selectable) for each process (flow and temperature*) variable, self diagnostic alarm. Optional local 2x16 LCD* readout with

adjustable back light provides flow rate, temperature*, total volume reading in currently selected engineering units, diagnostic events indication and feature a password protected access to the process parameters to ensure against tampering or

resetting.

2.2 Electrical Connections

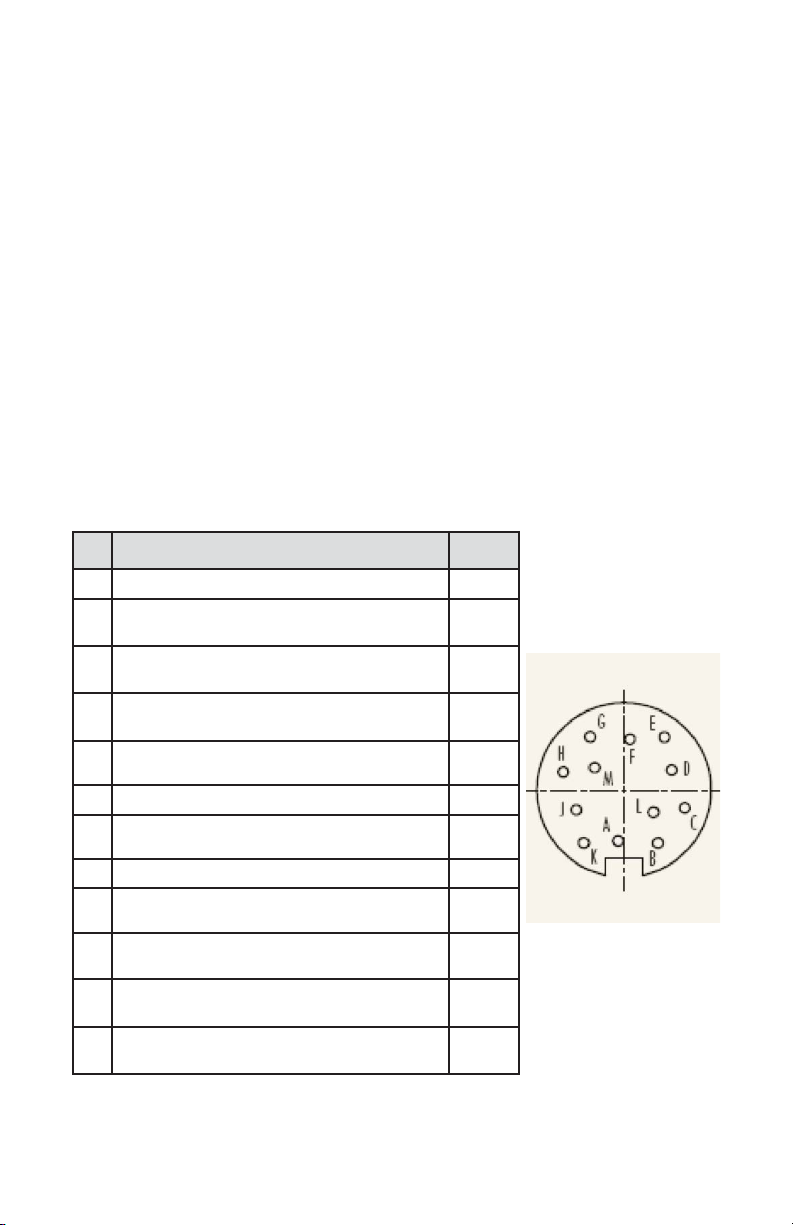

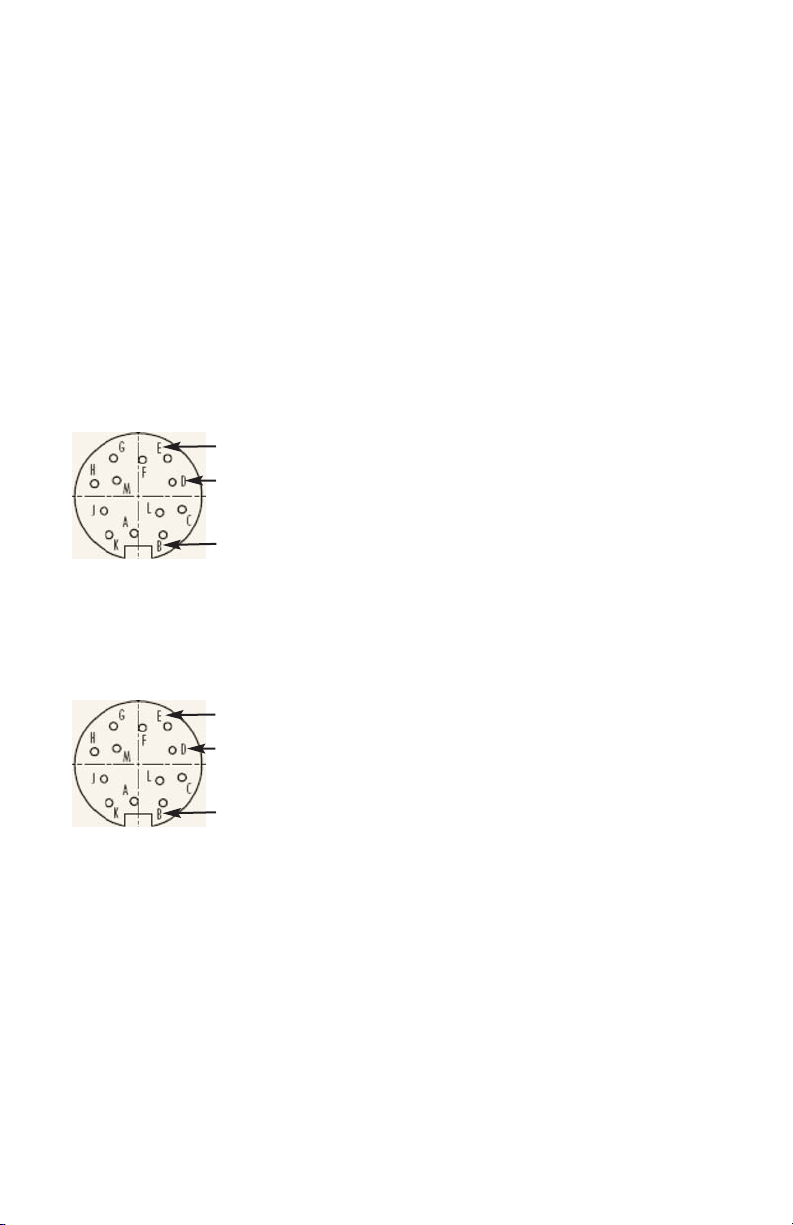

PWE flow meter is supplied with “M16” cylindrical 12 pin connector. Pin diagram

is presented in figure b-1.

Figure b-1, PWE 12 Pin "M16" Connector Configuration

PIN PWE FUNCTION TYPE

A Plus Power Supply (+ DC power 11 to 26 Vdc) +Power

B

Common Power Supply, (DC power 11 to 26 Vdc),

Digital Common

-Power,

Common

C

Flow Sensor Pulse Output (active), 3.3Vdc 3K min.

load impedance

Output

Only

D

Digital Communication interface, RS485 (-)

(Optional RS232 TX)

Input

/Output

E

Digital Communication interface, RS485 (+)

(Optional RS232 RX)

Input

/Output

F Optical Output No.1 Plus (+) (passive) Input

G

Optical Output No.1 Minus (-) (passive)

Return

for Pin F

H Optical Output No.2 Plus (+) (passive) Input

J Optical Output No.2 Minus (-) (passive)

Return

for Pin H

K

Common, Analog Signal Ground For Pins L & M,

(4-20 mA return)

Signal

Common

L

Temp. Analog Output Plus (+) 0-5 Vdc or 4-20 mA,

jmp. selectable

Output

Only

M

Flow Analog Output Plus (+), 0-5 Vdc or 4-20 mA,

jmp. selectable

Output

Only

2

Page 8

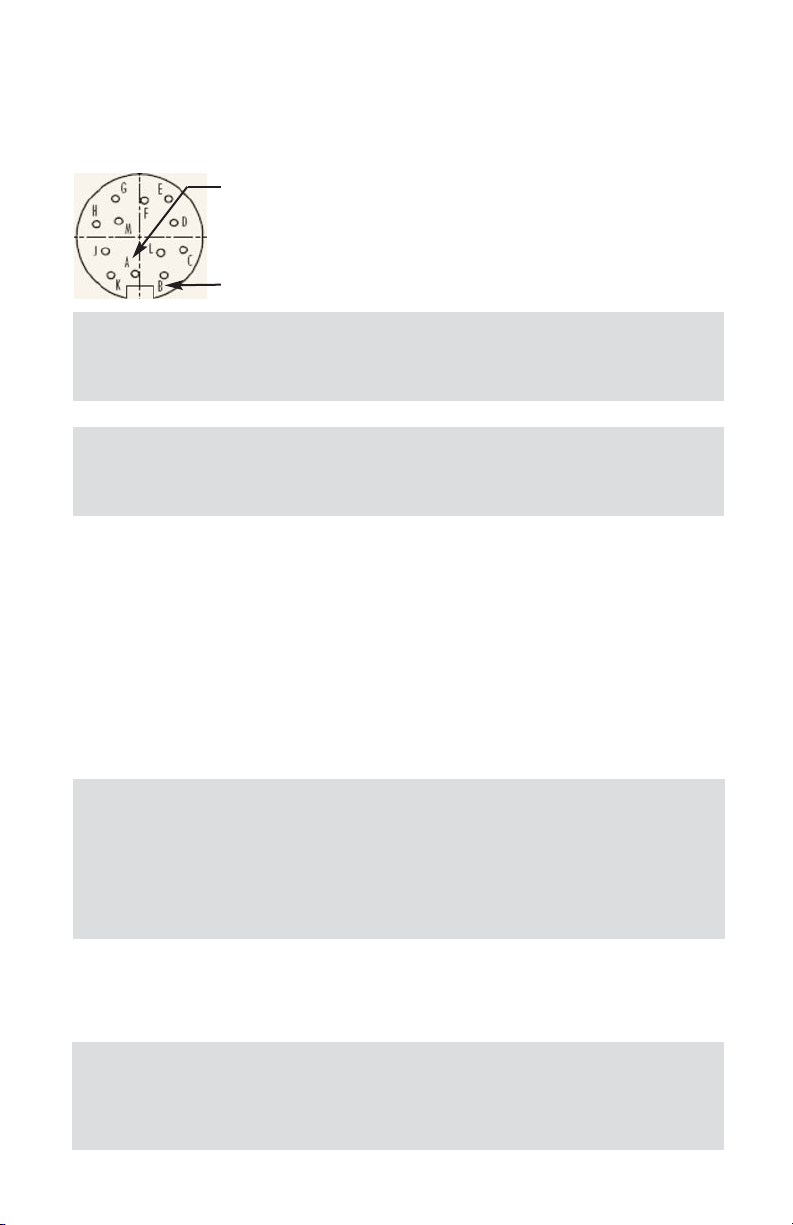

2.2.1 Power Supply Connections

The power supply requirements for PWE flow meter are: 11 to 26 Vdc 100 mV

maximum peak to peak output noise, (unipolar power supply).

Pin A ------------- DC Power (+)

Pin B ------------- DC Power (-)

The (+) and (-) power inputs are each protected by a 300mA M (medium time-lag)

resettable fuse. If a shorting condition or polarity reversal occurs, the fuse will cut

power to the flow transducer circuit. Disconnect the power to the unit, remove

the faulty condition, and reconnect the power. The fuse will reset once the faulty

condition has been removed.

Use of the PWE flow meter in a manner other than that specified in this manual or

in writing from Aalborg

®

, may impair the protection provided by the equipment.

2.2.2 Analog Output Signals Connections

PWE series Flow Meters are equipped with either calibrated 0-5 or calibrated 4-20

mA output signals (jumper selectable). This linear output signal represents

0-100% of the flow meter’s full scale range.

CAUTION: Do not apply power voltage above 26Vdc.

Doing so will cause PWE damage or faulty operation.

3

Make sure power is OFF when connecting or disconnecting any cables

in the system.

CAUTION: When connecting the load to the output terminals, do not

exceed the rated values shown in the specifications. Failure to do so

might cause damage to this device. Be sure to check if the wiring and

the polarity of the power supply is correct before turning the power

ON. Wiring error may cause damage or faulty operation.

WARNING: The 4-20 mA current loop output is self-powered (sourcing

type, non-isolated). Do NOT connect an external voltage source to the

output signals.

Page 9

Flow 0-5 VDC or 4-20 mA output signal connection:

Pin M ------------ (+) Plus Flow Analog Output

Pin K ------------ (-) Minus Flow Analog Output

Temperature 0-5 VDC or 4-20 mA output signal connection (optional):

Pin L ------------ (+) Plus Temperature Analog Output

Pin K ------------ (-) Minus Temperature Analog Output

To eliminate the possibility of noise interference, use a separate cable entry for

the DC power and analog signal lines (pins L, M, K on “M16” connector).

2.2.3 Flow Sensor Pulse Output Signals

Connections

Pin C ------------ (+) Flow Sensor Pulse Output (active), 3.3Vdc

Pin B ------------ DC Power (-), Digital Common

4

WARNING: Observe jumper configuration before connecting 4-20 mA

current loop load. Failure to make proper jumper configuration (see

Figure 5-1) may cause damage for output circuitry.

Do NOT connect an external voltage source to the output signals.

WARNING: The flow sensor pulse output is self-powered (open drain,

pulled up with 10K resistor to internal 3.3Vdc rail).

Do NOT connect an external voltage source to the pulse output signals.

Use load with input impedance more than 30K is recommended.

Page 10

5

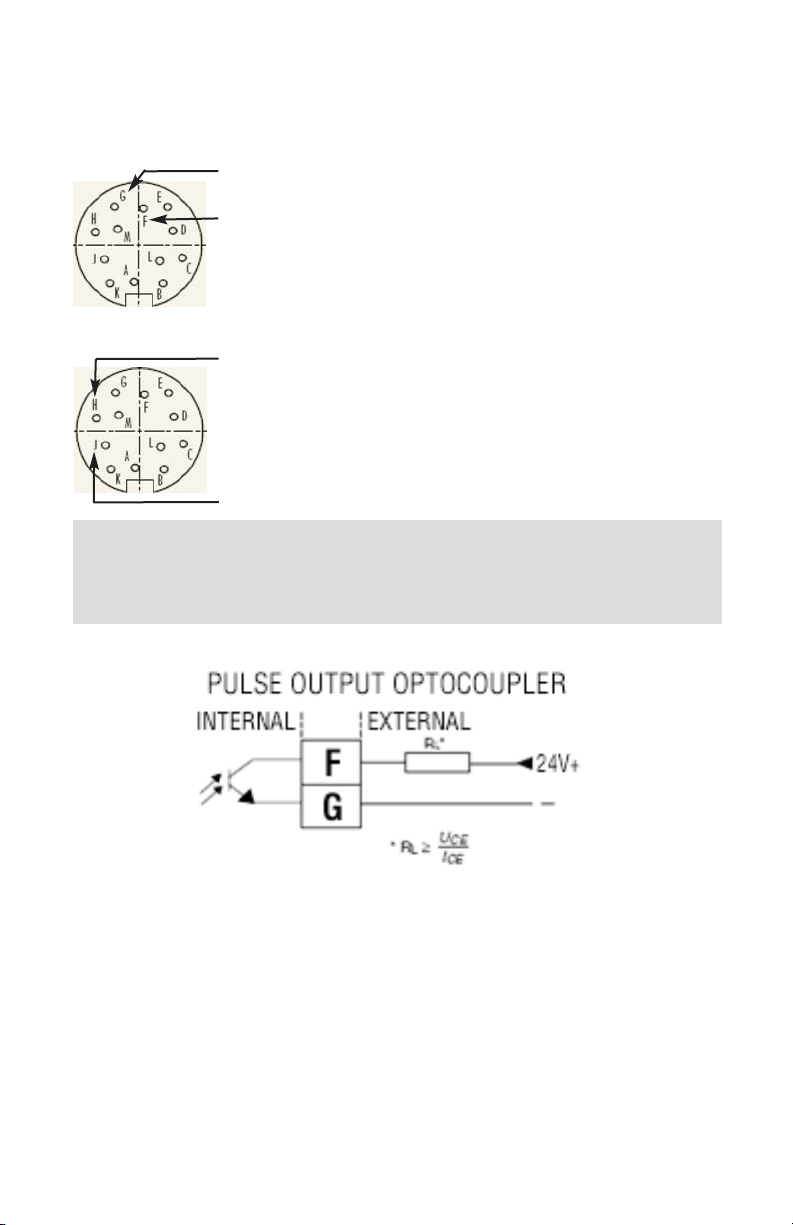

2.2.4 Programmable optically isolated Output

Signals Connections

Optocoupler #1 (pins F and G):

Pin F ------------ Plus (+) (passive)

Pin G ------------ Plus (-) (passive)

Optocoupler #2 (pins H and J):

Pin H ------------ Plus (+) (passive)

Pin J ------------ Plus (-) (passive)

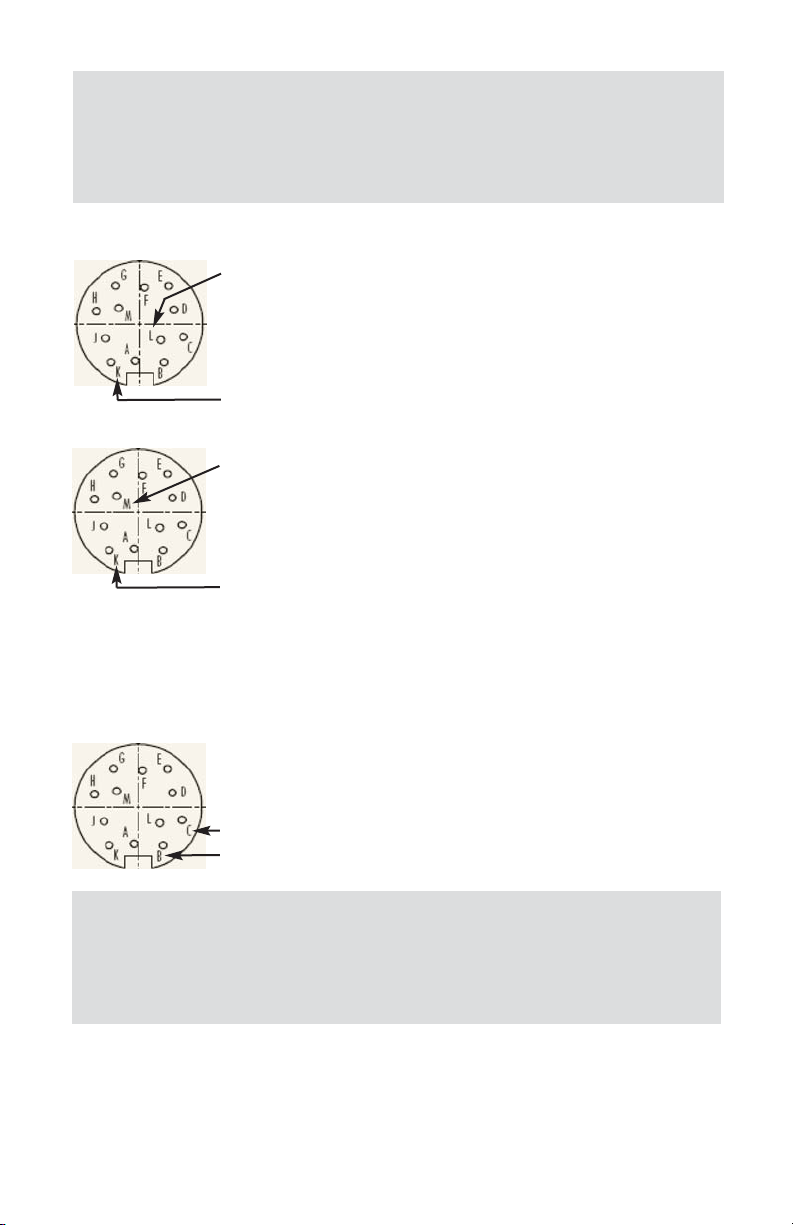

2.2.5 Communication Parameters and Connections

The digital interface operates via RS485 (optional RS-232) and provides access to

applicable internal data including: flow, temperature, totalizers and alarm settings,

flow linearizer table, fluid density and engineering units selection.

WARNING: Optically isolated outputs require application of DC voltage

across terminals. Do not exceed maximum allowed limits for voltage

and current provided below:

Page 11

6

Communication Settings for RS-485/RS-232 communication interface:

Baud rate: ------------ 9600 baud

Stop bit: ------------ 1

Data bits: ------------ 8

Parity: ------------ None

Flow Control: ------------ None

RS-485 communication interface connection:

The RS485 converter/adapter must be configured for: multidrop, 2 wire, half duplex

mode. The transmitter circuit must be enabled by TD or RTS (depending on which

is available on the converter/adapter). Settings for the receiver circuit should follow

the selection made for the transmitter circuit in order to eliminate echo.

Pin D ------------ RS-485 T(-) or R(-)

Pin E ------------ RS-485 T(+) or R(+)

Pin B ------------ RS-485 GND (if available)

RS-232 communication interface connection:

Crossover connection has to be established:

Pin D ------------ RS-232 RX (pin 2 on the DB9 connector)

Pin E ------------ RS-232 TX (pin 3 on the DB9 connector)

Pin B ------------ RS-232 SIGNAL GND

(pin 5 on the DB9 connector)

Page 12

7

2.3 PWE Flow Meter Specification

FLOW MEDIUM: Please note that PWE Flow Meters are designed to work only

with liquids. Never try to measure flow rates of dry gas.

CALIBRATIONS: Performed at standard conditions [14.7 psia (101.4 kPa) and

70 °F (21.1 °C)] unless otherwise requested or stated.

VISCOSITY: Calibrated to 1 cPoise (water). Meters can be used for fluids up to

50 cPoise with field calibration (maximum flow range may be affected).

ENVIRONMENTAL (PER IEC 664): Installation Level II; Pollution Degree II.

FLOW ACCURACY (INCLUDING LINEARITY): ±1% of FS.

REPEATABILITY: ±0.25% of full scale.

TEMPERATURE ACCURACY (INCLUDING LINEARITY)*: ±0.5 °C.

FLOW RESPONSE TIME: Approximately 1 seconds (above 10% of full scale

flow), approximately 2 seconds (below 10% of full scale flow).

MAXIMUM PRESSURE: 10 bar (150 psi).

MAXIMUM PRESSURE DROP: See Table 2.3.1 for pressure drops associated

with various models and flow rates.

FLUID AND AMBIENT TEMPERATURE: 14 °F to 140 °F (-10 °C to 60 °C).

OUTPUT SIGNALS: Linear 0-5 Vdc (3000 ohms min load impedance);

Linear 4-20 mA (500 ohms maximum loop resistance).

Maximum noise 20mV peak to peak (for 0-5 Vdc output).

Flow Pulse Output: 3.3 Vdc amplitude (3000 ohms min load impedance).

OPTICALLY ISOLATED OUTPUTS: UCE 40Vdc, ICE 150 mA.

FLOW METER INPUT POWER: 11 to 26 Vdc, 100 mV maximum peak to peak

output noise. Power consumption: +12Vdc (150 mA maximum);

+24Vdc (100 mA maximum); Circuit board have built-in polarity reversal

protection, 300mA resettable fuse provide power input protection.

Page 13

COMMUNICATIONS PARAMETERS (RS-232/RS-485):

Baud rate: ...................... 9600 baud

Stop bit: ...................... 1

Data bits: ...................... 8

Parity: ...................... None

Flow Control: ...................... None

DISPLAY*: Optional local 2x16 characters LCD with adjustable backlight (2 lines of text).

KEY PAD*: Optional 4 push button key pad.

CE COMPLIANCE: EMC Compliance with 89/336/EEC as amended.

Emission Standard: EN 55011:1991, Group 1, Class A

Immunity Standard: EN 55082-1:1992

(* - optional feature)

Table 2.3.1 PWE Flow Meter Flow Ranges and Pressure Drop

Table 2.3.2 PWE Flow Meter wetted materials

8

FLOW RATE FOR PWE

METER

SIZES

FLOW RATE H20

INLET/OUTLET

PORTS FEMALE

NPT

MAXIMUM PRESSURE DROP

[L/min] Gal/min Bar PSI

PWE4 0.15-18.9 0.04-5 3/8" 1 15

PWE6 0.3-37.6 0.08-10 1/2" 1.4 20

PWE8 0.6-64.4 0.15-17 3/4" 1.4 20

PWE10 1.3-132.5 0.35-35 1" 1.4 20

WETTED MATERIALS

POLYPROPYLENE MODELS PVDF MODELS

BODY Polypropylene PVDF

LID Acrylic PVDF

PADDLE WHEEL

PVDF

Nickel Tungsten Carbide

PVDF

Zirconia Ceramic

BEARINGS Sapphire Jewels Sapphire Jewels

O-RINGS EPDM PTFE

PLATINUM RTD 316 stainless steel casing 316 stainless steel casing

Page 14

9

2.4 PWE MAINTENANCE

CAUTION: Some of the IC devices used in the flow meter signal

conditioning circuitry are static sensitive and may be damaged by

improper handling. When adjusting or servicing the signal converter,

use of a grounded wrist strap is recommended to prevent inadvertent

damage to the integral solid state circuitry. The flow meter signal

conditioning circuitry uses complex electronic circuit components.

Generally, due to the complexity of troubleshooting integrated circuit

devices, maintenance beyond the PCB assembly level is not

recommended. Also, caution must be used when connecting test

probes, as even a momentary accidental short circuit may damage or

destroy an integrated circuit device.

CAUTION: Never use compressed air or gases to test the meter,

as this would damage the Bearings.

2.4.1 Sensors

In rare instances, due to electrical damage, the pulse sensor or RTD need to be

replaced by disconnecting the signal cable connector from the PCB and unscrewing it and installing a replacement. This procedure can be done only by factory

authorized personel.

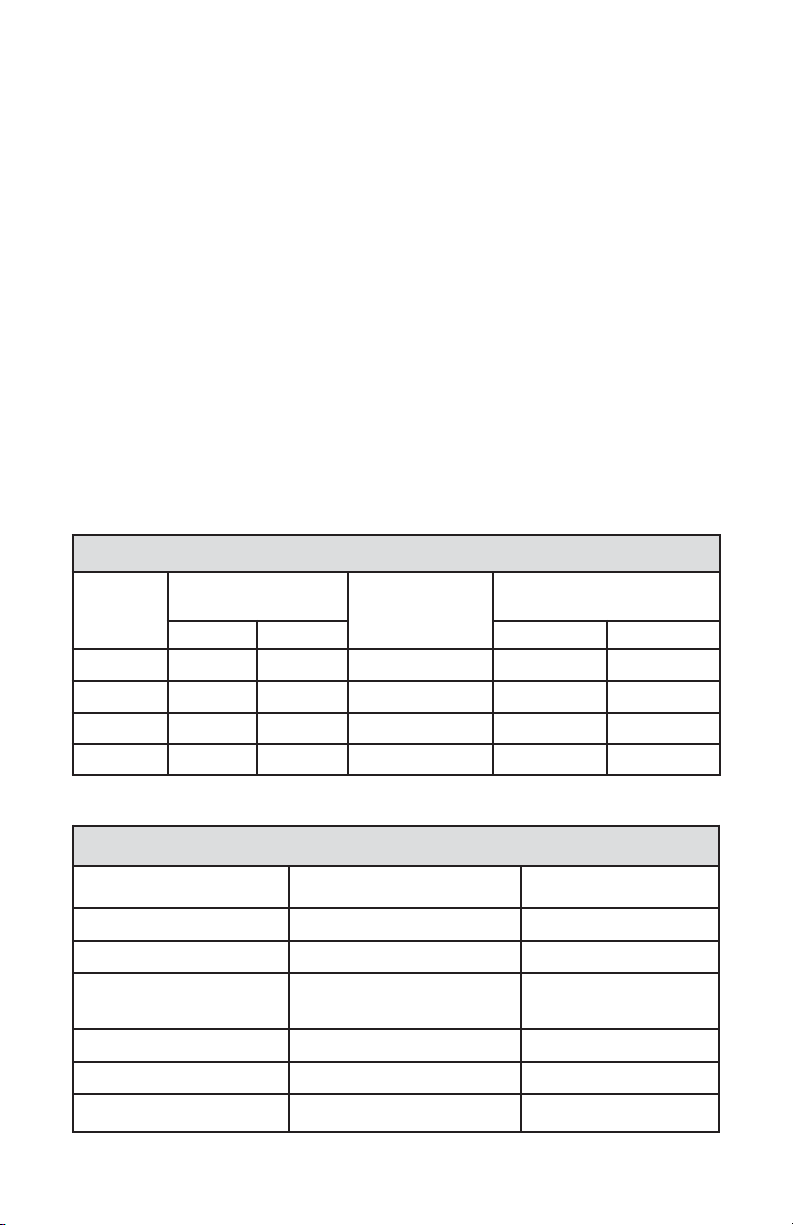

2.4.2 PWE Paddle Wheel and Bearings Replacement

To replace the paddle wheel, disconnect the meter from electrical and liquid lines.

Unscrew 4 screws that hold the lid in place. Remove the lid by lifting it up and

move the wheel out. The Wheel’s embedded shaft is supported at each end by sapphire bearings to minimize friction and facilitate very low flow rate measurements

(see Figure 2-1). Reassembly is made ensuring that the shaft end is inserted gently into the bottom bearing. Check to see if the wheel is free to spin before the lid

is installed. Gently put the lid over the opening and gently spin it by hand until the

upper bearing, installed in the lid, drops into the place. Hold the lid down and

check for free spinning by lightly blowing into the port; or lightly shake and listen

if both shaft ends got into the bearings. Make sure the O-ring is in its seat, insert

four cap screws and gradually tighten them. Bearings are made of sapphire, which

rarely needs replacement, unless they were physically shattered. Bearings highly

susceptible to careless disassembly and reassembly practices. While the unit is

disassembled for paddle wheel replacement, bearing could be replaced with bearing removal tool.

Page 15

10

1

4

2

3

2

7

6

5

8

NOTE: Platinum RTD is not shown.

PARTS LIST

PARTS PWEP MATERIALS PWET MATERIALS

1 LOWER BLOCK POLYPROPYLENE PVDF

2 JEWEL BEARING (2 required) PVDF SAPPHIRE

3 PADDLE WHEEL

PVDF & NICKEL

TUNGSTEN CARBIDE

PVDF &

ZIRCONIA CERAMIC

4 LID ACRYLIC PVDF

5 JUMPER COMPARTMENT PLUG POLYPROPYLENE

6 SCREW 8-32 (4 required) STAINLESS STEEL

7 O-RING EPDM PTFE

8 SCREW 6-32 STAINLESS STEEL

Figure 2-1 PWE assembly presentation drawing

Page 16

11

3. LCD KEYPAD OPERATION: DATA ENTRY AND

CONFIGURATION

(applicable for LCD options only)

3.1 Display Indications

Initially, after the power is first turned on, the flow meter model number is shown

in the first line of the display and the revisions for EPROM table and firmware in

the second line. Subsequently the actual process information is displayed. The

instantaneous flow rate is displayed on the first line in percent or in direct

reading units with flow alarm status indication. For flow meters without RTD

option, the main totalizer value, up to 9 digits (including decimal), is displayed in

the second line with its corresponding units.

For flow meters with RTD option, the temperature reading value in deg C, is displayed in the second line with temperature alarm status indication. This display is

designated as process information (PI) screen throughout the remainder of this

manual.

The temperature value (applicable for RTD option only) in deg F can be displayed

in the PI screen by pressing the ENT pushbutton. The temperature indication can

be switched from deg C to deg F and back by pressing ENT pushbutton.

Figure 3.1: PWE first Banner Screen

Figure 3.2: PWE with RTD option initial Process Information Screen

AALBORG PW METER

Fw: A001 Tbl: A001

5.001 Gl/min AD

20.1 C TA: D

Note: Actual content of the LCD screen may vary depending on the

model and device configuration.

,

Page 17

12

Figure 3.3: PWE without RTD option initial Process Information Screen

Based on flow meter configuration (with or without RTD option), different parameters may be displayed in the PI screen by pressing the UP or DN pushbuttons.

3.1.1 PWE with RTD option Process Information

Screens

Pressing UP and DN buttons from initial PI screen will switch display as following:

[Initial PI screen]

Action: Keypad UP

i

Figure 3.4: PWE with RTD option Process Information Screen with Main Totalizer

Action: Keypad UP

i

Figure 3.5: PWE with RTD option Process Information Screen with Pilot Totalizer

5.001 Gl/min AD

MT: 60639.38 Gal

5.001 Gl/min AD

MT: 60639.38 Gal

5.001 Gl/min AD

PT: 65.81 Gal

Page 18

13

Action: Keypad UP

i

Figure 3.6: PWE with RTD option PI Screen with flow range, temperature and

Main Totalizer

Action: Keypad UP

i

Action: Keypad UP

i

Figure 3.7: PWE with RTD option PI Screen with Main Totalizer, temperature and

Pilot Totalizer

Action: Keypad UP

i

Figure 3.8: PWE with RTD option PI Screen with Main and Pilot Totalizers

5.001 Gl/min AD

20.1 C *******Gal

MT: 60639.38 Gal

20.1 C 65.81 Gal

MT: 60639.38 Gal

PT: 65.81 Gal

Page 19

14

Action: Keypad UP

i

Figure 3.9: PWE with RTD option initial Process Information Screen

Pressing UP button, pages through the PI screens in the forward direction.

Pressing DN button, pages through the PI screens in the reverse direction. When

the last PI screen is reached, the firmware "wraps around" and scrolls to the initial

PI screen once again.

3.1.2 PWE without RTD option Process

Information Screens

Pressing UP and DN buttons from initial PI screen will switch display as following:

[Initial PI screen]

Action: Keypad UP

i

Figure 3.10: PWE without RTD option PI Screen with Main and Pilot Totalizer

Action: Keypad UP

i

Figure 3.11: PWE without RTD option initial PI Screen with Main and Pilot

Totalizer

MT: 60639.38 Gal

PT: 65.81 Gal

5.001 Gl/min AD

20.1 C TA: D

5.001 Gl/min AD

PT: 65.81 Gal

Page 20

15

Action: Keypad UP

i

Figure 3.12: PWE without RTD option initial PI Screen with Flow rate and Main

Totalizer

3.2 Menu Sequence

The listing below gives a general overview of the standard top-level display menu

sequence when running firmware version A002. The ESC pushbutton is used to

toggle between the process mode (PI screens) and the menu.

The listing in Section 3.2 shows the standard display menu sequence and submenus using the UP button to move through the menu items. The first message

displayed the first time the ESC button is pressed after the converter is powered

up is "Prog. Protection ON". Thereafter, pressing the ESC button while the

flow meter is in monitoring mode (PI screens) will display the parameter that was

last exited.

Program Protection may be turned "off" by pressing the ENT button when the Prog.

Protection menu is displayed. The firmware will prompt with "Change Prog Prot”.

Pressing UP or DN button will toggle current protection status. If password is set

to any value more than zero, the firmware will prompt with "Enter Prot Code". User

has to enter up to 3 digits program protection code, in order to be able to access

password protected menus. Once correct password is entered, program protection id turned off until unit is powered up again.

When the last menu item is reached, the firmware "wraps around" and scrolls to

the first item on the menu once again (see Figure 3.12). The menu items in the first

column are upper-level configuration mode functions. Submenu selections

(shown indented in the second column) only appear if the associated upper level

is selected by pressing the ENT push button. The allowable selections of submenu items which are selected by tabular means are shown in detail in Section 3.3

5.001 Gl/min AD

MT: 60639.38 Gal

Page 21

16

Figure 3.12 Upper level menu structure.

CONFIGURATION DATA

Prog. Protection

on/off

Prog. Prot. Code

old/new

Submenu

Flow Meter Info

Submenu

Measuring Units

Submenu

Flow Alarm

Submenu

Temp. Alarm

Submenu

Main Totalizer

Submenu

Pilot Totalizer

Submenu

Optical Outputs

Submenu

FlowMeter Config

LCD Back Light

50 %F.S.

Submenu

Alarm Events Log

Submenu

Diagnostic

Page 22

17

3.3 Parameter Summary and Data Entry

Page 23

18192021222324

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

4. PARAMETER ENTRY

There are two methods of data entry: • Direct numerical number entry

• Tabular Input from a table menu.

If menu with direct numerical entry is selected use Up button to increment digit

value from 0-9. Use Dn button to move cursor to another digit position. When

desired value is entered use ENT button to accept (save in the EEPROM) new

value.

If menu with tabular entry is selected, the available menu options can be set

with the Up and Dn buttons and are accepted by pressing ENT button.

Note: During data entry the input values are checked for acceptability.

If data is not acceptable, it is rejected and a message is generated

indicating that the new data has not been accepted.

4.1 Submenu Program protection

After power has been turned on, programming parameters may only be changed

by turning program protection "OFF". There are two ways to turn off the

program protection:

1. If program protection code (PP-code) is on "0" (factory default), the

program protection is turned off by pressing ENTER key.

2. If a PP-code (1 to 255) other than "0" has been entered, this code must be

entered in order to turn the program protection "OFF".

The PP-code can be changed after the program protection has been turned off.

In order to protect device configuration parameters when changing the PP-code

the old PP-code must be entered after ENTER has been pressed.

Press ENTER key after entry of old PP-code.

25

,

Prog. Protection code

-----------------------------

Old PP-code?

----------------------------0

Page 31

26

Now enter the new PP-code (0-255) and press ENTER key. The new PP-code is

now valid to turn off the program protection. If the PP-code is forgotten, it can

be restored only via digital communication interface.

4.2 Submenu Flow Meter Info

This submenu contains information about the meter main configuration parameters. These items are informational only and may not be changed (read only).

4.2.1 Full Scale Flow

This display indicates the full scale range of the meter in L/min. The full scale

range of the flow meter is related to the lower block inside diameter. It is set on

the factory during calibration procedure. The full scale range of the meter is not

user changeable. A typical display is shown below.

4.2.2 Communication Interface

This display indicates type of the digital communication interface (RS-232 or

RS-485) and device address (two hexadecimal characters of the address will be

displayed only for RS-485 interface option). All flow meters are shipped from the

factory with default address 11. A typical display for device with RS-485 option

is shown below.

New PP-code

----------------------------0

Full Scale Flow:

18.92706 L/min

Comm. Interface:

RS-485 ADD: 11

Page 32

27

4.2.3 RTD hardware option

This display indicates presence of the RTD hardware. If second line of the screen

indicates “Installed”, then flow meter is equipped with RTD with signal processing circuitry and ready for temperature measurement. A typical display for device

with RTD option is shown below.

4.2.4 Analog Flow Output settings

This display indicates which type of the jumper selectable Flow analog output is

currently active. The device can be set for 0-5 Vdc or 4-20 mA output. A typical

display for device with jumper configuration for 0-5 Vdc Flow output is shown

below.

4.2.5 Analog Temperature Output settings

This display indicates which type of the jumper selectable Temperature analog output is currently active. The device can be set for 0-5 Vdc or 4-20 mA output. A typical display for device with jumper configuration for 0-5 Vdc Temperature output

is shown below.

Note: Analog Temperature Output settings screen will be available

on the devices which are not equipped with RTD option as well. In

this case user should not be under impression that unit supports

temperature measurement.

RTD Option:

Installed

Analog Flow Out:

0-5 Vdc

Analog Temp Out:

0-5 Vdc

,

Page 33

28

4.2.6 Flow Meter EEPROM data base version

This display indicates current version of the EEPROM data base. The EEPROM

stores all flow meter configuration parameters. The Flow Meter EEPROM data base

version is not user changeable. A typical display with EEPROM version is shown

below.

4.2.7 Flow Meter Firmware version

This display indicates current version of the flow meter firmware. The Flow Meter

Firmware version is not user changeable. A typical display with firmware version

is shown below.

4.2.8 Flow Meter Serial number

This display indicates the serial number of the flow meter. This number is generated by the factory and is unique to the instrument. The flow meter serial number

is not user-changeable. A typical display with flow meter serial number is shown

below.

4.2.9 Flow Meter Model number

This display indicates the model number of the flow meter. The flow meter model

number is not user-changeable. A typical display with flow meter model number

is shown below.

EEPROM Version:

A001

Firmware Version

A002

Serial Number:

245893-1

Model Number:

PWE04P-ELN-A2

Page 34

29

4.2.10 Fluid Name

This display indicates the name of the fluid the flow meter was calibrated for. The

fluid name may be changed by user via digital communication interface. A typical

display with fluid name is shown below.

4.2.11 Flow Meter Calibration Date

This display indicates the date when most recent calibration of the flow meter was

performed. The calibration date may be changed by user via digital communication interface. A typical display with flow meter calibration date is shown below.

4.2.12 Flow Meter Calibration Date Due

This display indicates the date when next calibration of the flow meter has to be

performed. The calibration date due may be changed by user via digital communication interface. A typical display with flow meter calibration date due is shown

below.

4.2.13 Flow Meter User Tag Name

Flow meter Tag is the quickest and shortest way of identifying and distinguishing

between multiple flow meters. Flow meters can be tagged according to the

requirements of your application. The tag may be up to 16 characters long and is

user-defined. A typical display with flow meter Tag Name is shown below.

Fluid Name:

WATER

Calibration Date:

08/01/2009

Calib. Date Due:

08/01/2010

Page 35

4.3 Submenu Measuring Units

This submenu allows selection of units for flow rate and Totalizer reading. Units

should be selected to meet your particular metering needs.

30

User Tag Name:

NOT ASSIGNED

Note: Once Flow Unit of Measure is changed the Totalizer’s Volume

based Unit of Measure will be changed automatically.

,

Page 36

31

UNITS OF MEASURE

NUMBER INDEX

FLOW RATE

ENGINEERING

UNITS

TOTALIZER

ENGINEERING

UNITS

DESCRIPTION

1 0 % %s Percent of full scale

2 1 mL/sec mL Milliliter per second

3 2 mL/min mL Milliliter per minute

4 3 mL/hr mL Milliliter per hour

5 4 L/sec Ltr Liter per second

6 5 L/ min Ltr Liter per minute

7 6 L/hr Ltr Liter per hour

87

m

3

/sec m

3

Cubic meter per second

98

m

3

/ min m

3

Cubic meter per minute

10 9

m

3

/hr m

3

Cubic meter per hour

11 10

ft

3

/sec ft

3

Cubic feet per second

12 11

ft

3

/min ft

3

Cubic feet per minute

13 12

ft

3

/hr ft

3

Cubic feet per hour

14 13 Gl/sec Gal Gal per sec

15 14 Gl/min Gal Gal per minute

16 15 Gal/hr Gal Gal per hour

17 16 g/sec g Grams per second

18 17 g/min g Grams per minute

19 18 g/hr g Grams per hour

20 19 kg/sec kg Kilograms per second

21 20 kg/min kg Kilograms per minute

22 21 kg/hr kg Kilograms per hour

23 22 Lb/sec Lb Pounds per second

24 23 Lb/min Lb Pounds per minute

25 24 Lb/hr Lb Pounds per hour

26 25 t/sec Ton Ton (metric) per sec

27 26 t/min Ton Ton (metric) per minute

28 27 t/hr Ton Ton (metric) per hour

29 28 User UD User defined

Page 37

32

The listed units in the table above can be set with the Up and Dn buttons and are

accepted by pressing ENT button.

4.3.1 User Defined Measuring Unit

This function enables user defined configuration of any engineering unit in the

converter. The following three parameters are available for this function:

a) Unit volume factor (defined in Liters)

b) Unit time base (defined in Seconds)

c) Unit with or without density support.

4.3.1.a User Defined Unit Factor Numeric entry

This parameter indicates the factor of the new unit with respect to one liter. The

default entry is 1.00 Liter.

4.3.1.b User Defined Unit Time Base Tabular entry

This parameter indicates the time base for User Defined Unit. The following selections are available: 1 second, 60 seconds (1 minute), 3600 seconds (1 Hour). The

default entry is 60 seconds.

The listed time based selections above can be set with the Up and Dn buttons and

are accepted by pressing ENT button.

Note: The entry of the listed parameters a), b) and c) is only

necessary in case the required engineering unit is not available in the

table above, (see Section 4.3).

,

UD Unit Factor

1.00 Liter

UDU Time Base

60 Seconds

Page 38

33

4.3.1.c User Defined Unit Density support

Tabular entry

This function determines whether the newly entered user defined engineering unit

is a mass unit (with density) or a volumetric unit (without density). The following

selections are available: Enabled or Disabled. The default entry is Disabled.

The listed above density support selections can be set with the Up and Dn buttons

and are accepted by pressing ENT button. If density was selected, also refer to

section 4.9.8.

4.4 Submenu Flow Alarm

PWE provides the user with a flexible alarm/warning system that monitors the

Fluid Flow for conditions that fall outside configurable limits as well as visual feedback for the user via the LCD (only for devices with LCD option) or via an optically isolated outputs.

The flow alarm has several attributes which may be configured by the user via

optional LCD/Keypad or digital communication interface. These attributes control

the conditions which cause the alarm to occur and to specify actions to be taken

when the flow rate is outside the specified conditions.

Flow Alarm conditions become true when the current flow reading is equal or

higher/lower than corresponding values of high and low flow alarm levels. Alarm

action can be assigned with preset delay interval (0-3600seconds) to activate the

optically isolated output (separate for High and Low alarm). Latch Mode control

feature allows each optical output to be latched on or follow the corresponding

alarm status.

4.4.1 Flow Alarm Mode Tabular entry

This function determines whether Flow Alarm is Enabled or Disabled. The following selections are available: Enabled or Disabled. The default entry is Disabled.

UDU Use Density

Disabled

Flow Alarm Mode

Disabled

Page 39

34

The listed above Alarm Mode selections can be set with the Up and Dn buttons

and are accepted by pressing ENT button.

4.4.2 Low Flow Alarm Numerical entry

The limit of required Low Flow Alarm value can be entered in increments of

0.1% from 0 - 100%F.S.

A typical display with flow meter Low Flow Alarm is shown below.

If a Low Alarm occurs, and one of the two optical outputs is assigned to the Low

Alarm Event (see Section 4.8) the optically isolated output will be activated when

the flow is less than the Low Flow Alarm value. The Flow Alarm condition is also

indicated on the display Process Information Screen by displaying L character. A

typical display with flow meter Process Information Screen and activated Low

Flow Alarm is shown below.

4.4.3 High Flow Alarm Numerical entry

The limit of required High Flow Alarm value can be entered in increments of 0.1%

from 0 - 100%F.S.

A typical display with flow meter High Flow Alarm settings is shown below.

Note: The value of the Low Flow Alarm must be less than the

value of the High Flow Alarm.

,

Note: The value of the High Flow Alarm must be more than the

value of the Low Flow Alarm.

,

Low Flow Alarm

10.0 %F.S.

0.401 Gl/min AL

MT: 65.81 Gal

Page 40

If a High Alarm occurs, and one of the two optical outputs is assigned to the High

Alarm Event (see Section 4.8) the optically isolated output will be activated when

the flow is more than the High Flow Alarm value. The Flow Alarm condition is also

indicated on the display Process Information Screen by displaying H character. A

typical display with flow meter Process Information Screen and activated High

Flow Alarm settings is shown below.

4.4.4 Flow Alarm Action Delay Numerical entry

The Flow Alarm Action Delay is a time in seconds that the Flow rate value must

remain above the high limit or below the low limit before an alarm condition is

indicated. Valid settings are in the range of 0 to 3600 seconds. A typical display

with flow meter Flow Alarm Delay settings is shown below.

4.4.5 Flow Alarm Action Latch Tabular entry

The Flow Alarm Action Latch settings controls Latch feature when optically isolated outputs are assigned to Flow Alarm event. Following settings are available:

Disable or Enabled.

By default, flow alarm is non-latching. That means the alarm is indicated only

while the monitored flow value exceeds the specified set conditions. If optically

isolated output is assigned to the Flow Alarm event, in some cases, the Flow Alarm

Latch feature may be desirable.

35

High Flow Alarm

90.0 %F.S.

4.641 Gl/min AH

MT: 67.81 Gal

Flow Alarm Delay

1 Second

Page 41

36

The listed above Flow Alarm Action Latch selections can be set with the Up and

Dn buttons and are accepted by pressing ENT button.

4.5 Submenu Temperature Alarm (*optional)

PWE with RTD option provides the user with a flexible alarm/warning system that

monitors the Fluid Temperature for conditions that fall outside configurable limits

as well as visual feedback for the user via the LCD (only for devices with LCD

option) or via an optically isolated outputs.

The temperature alarm has several attributes which may be configured by the user

via optional LCD/Keypad or digital communication interface. These attributes control the conditions which cause the alarm to occur and to specify actions to be

taken when the temperature value is outside the specified conditions. Temperature

Alarm conditions become true when the current temperature reading is equal or

higher/lower than corresponding values of high and low temperature alarm levels.

Alarm action can be assigned with preset delay interval (0-3600seconds) to activate the optically isolated output (separate for High and Low alarm). Latch Mode

control feature allows each optical output to be latched on or follow the corresponding alarm status.

4.5.1 Temperature Alarm Mode Tabular entry

This function determines whether Temperature Alarm is Enabled or Disabled. The

following selections are available: Enabled or Disabled. The default entry is

Disabled.

The listed above Temperature Alarm Mode selections can be set with the Up and

Dn buttons and are accepted by pressing ENT button.

4.5.2 Low Temperature Alarm Numerical entry

The limit of required Low Temperature Alarm value can be entered in increments

of 0.1 °C from -9.9 °C to 99.9 °C.

Flow Alarm Latch

Disabled

Temp Alarm Mode

Disabled

Page 42

37

A typical display with flow meter Low Temperature Alarm is shown below.

A typical display with flow meter Low Temperature Alarm is shown below.

If a Low Temperature Alarm occurs, and one of the two optical outputs is assigned

to the Low Alarm Event (see Section 4.8) the optically isolated output will be activated when the temperature is less than the Low Temperature Alarm value.

The Temperature Alarm condition is also indicated on the display Process

Information Screen by displaying L character. A typical display with flow meter

Process Information Screen and activated Low Temperature Alarm is shown

below.

4.5.3 High Temperature Alarm Numerical entry

The limit of required High Temperature Alarm value can be entered in increments

of 0.1°C from -9.9 °C to 99.9 °C.

A typical display with flow meter High Temperature Alarm settings is shown below

Note: The value of the Low Temperature Alarm must be less than the

value of the High Temperature Alarm. The value of the Temperature

can be entered only in °C units.

,

Note: The value of the Low Temperature Alarm must be less than the

value of the High Temperature Alarm. The value of the Temperature

can be entered only in °C units.

Note: The value of the High Temperature Alarm must be more than the

value of the Low Temperature Alarm.

,

,

Low Temp Alarm

0.0 C

5.001 Gl/min AD

-0.5 C TA: L

Page 43

If a High Temperature Alarm occurs, and one of the two optical outputs is assigned

to the High Alarm Event (see Section 4.8) the optically isolated output will be activated when the flow is more than the High Temperature Alarm value.

The Temperature Alarm condition is also indicated on the display Process

Information Screen by displaying H character. A typical display with flow meter

Process Information Screen and activated High Temperature Alarm settings is

shown below.

4.5.4 Temperature Alarm Action Delay

Numerical entry

The Temperature Alarm Action Delay is a time in seconds that the Temperature

value must remain above the high limit or below the low limit before an alarm condition is indicated. Valid settings are in the range of 0 to 3600 seconds. A typical

display with flow meter Temperature Alarm Delay settings is shown below.

4.5.5 Temperature Alarm Action Latch Tabular entry

The Temperature Alarm Action Latch settings controls Latch feature when optically isolated outputs are assigned to Temperature Alarm event. Following settings

are available: Disable or Enabled.

By default, flow alarm is non-latching. That means the alarm is indicated only while

the monitored Temperature value exceeds the specified set conditions. If optically

isolated output is assigned to the Temperature Alarm event, in some cases, the

Temperature Alarm Latch feature may be desirable.

38

High Temp Alarm

50.0 C

5.001 Gl/min AD

51.4 C TA: H

Temp Alarm Delay

1 Second

Page 44

The listed above Temperature Alarm Action Latch selections can be set with the

Up and Dn buttons and are accepted by pressing ENT button.

4.6 Submenu Main Totalizer

The total volume of the liquid is calculated by integrating the actual liquid flow rate

with respect to time. The Main Totalizer value is stored in the EEPROM and saved

every 1 second. In case of power interruption the last saved Totalizer value will be

loaded on the next power on cycle, so Main Totalizer reading will not be lost. The

optional LCD/keypad and digital communication interface commands are provided to:

- reset the totalizer to ZERO

- start the totalizer at a preset flow rate

- assign action at a preset total volume

- start/stop totalizing the flow

4.6.1 Main Totalizer Mode Tabular entry

This function determines whether Main Totalizer is Enabled or Disabled. The following selections are available: Enabled or Disabled. The default entry is

Disabled.

The listed above Main totalizer Mode selections can be set with the Up and Dn

buttons and are accepted by pressing ENT button.

39

Temp Alarm Latch

Disabled

Main Total Mode

Disabled

Note: Before enabling the Main Totalizer, ensure that all totalizer settings

are configured properly. Totalizer Start values have to be entered in

%F.S. engineering unit. The Totalizer will not totalize until the flow rate

becomes equal to or more than the Totalizer Start value. Totalizer Stop

values must be entered in currently active volume / mass based

engineering units. If the Totalizer Stop at preset total volume feature is

not required, then set Totalizer Stop value to zero (default settings).

,

Page 45

40

4.6.2 Main Totalizer Flow Start Numerical entry

The Main Totalizer Start Flow value can be entered in increments of 0.1% from 0.0

– 100.0%F.S. A typical display with flow meter Main totalizer Start Flow settings is

shown below.

4.6.3 Main Totalizer Event Volume Numerical entry

Main Totalizer Event Volume value must be entered in currently active volume /

mass based engineering units. Totalizer action event become true when the totalizer reading and preset "Event Volume" values are equal.

If the Totalizer Event at preset total volume feature is not required, then set

Totalizer Event Volume value to zero (default settings).

A typical display with flow meter Main Totalizer Event Volume settings is shown

below.

4.6.4 Main Totalizer Reset Tabular entry

The Main Totalizers reading can be reset by pressing ENTER button. A typical display with flow meter Main Totalizer Reset screen is shown below.

The next conformation screen will appear only for 2 seconds.

MT Flow Start

5.0 %F.S.

MT Event Volume

0.0 Gal

Reset Main Total

Value?

Press Ent key to

reset Totalizer!

Page 46

41

If during these two seconds user will press ENTER button again, the Main Totalizer

volume will be reset to zero. Following screen will appear for two seconds.

4.7 Submenu Pilot Totalizer

The total volume of the liquid is calculated by integrating the actual liquid flow rate

with respect to time. The Pilot Totalizer value is stored in the flow meter volatile

memory (SRAM) and saved every 100 ms. In case of power interruption the Pilot

Totalizer volume will be lost (reset to zero). The optional LCD/keypad and digital

communication interface commands are provided to:

- reset the totalizer to ZERO

- start the totalizer at a preset flow rate

- assign action at a preset total volume

- start/stop totalizing the flow

4.7.1 Pilot Totalizer Mode Tabular entry

This function determines whether Pilot Totalizer is Enabled or Disabled. The following selections are available: Enabled or Disabled. The default entry is Disabled.

The listed above Pilot totalizer Mode selections can be set with the Up and Dn buttons and are accepted by pressing ENT button.

The Totalizer has

been reset!

Pilot Total Mode

Disabled

Note: Before enabling the Pilot Totalizer, ensure that all totalizer settings

are configured properly. Totalizer Start values have to be entered in

%F.S. engineering unit. The Totalizer will not totalize until the flow rate

becomes equal to or more than the Totalizer Start value. Totalizer Stop

values must be entered in currently active volume / mass based

engineering units. If the Totalizer Stop at preset total volume feature is

not required, then set Totalizer Stop value to zero (default settings).

,

Page 47

42

4.7.2 Pilot Totalizer Flow Start Numerical entry

The Pilot Totalizer Start Flow value can be entered in increments of 0.1% from

0.0 – 100.0%F.S. A typical display with flow meter Pilot totalizer Start Flow set-

tings is shown below.

4.7.3 Pilot Totalizer Event Volume Numerical entry

Pilot Totalizer Event Volume value must be entered in currently active volume /

mass based engineering units. Totalizer action event become true when the totalizer reading and preset "Event Volume" values are equal.

If the Totalizer Event at preset total volume feature is not required, then set

Totalizer Event Volume value to zero (default settings). A typical display with flow

meter Pilot Totalizer Event Volume settings is shown below.

4.7.4 Pilot Totalizer Reset Tabular entry

The Pilot Totalizers reading can be reset by pressing ENTER button. A typical display with flow meter Pilot Totalizer Reset screen is shown below.

The next conformation screen will appear only for 2 seconds.

PT Flow Start

10.0 %F.S.

PT Event Volume

0.0 Gal

Reset Pilot Total

Value?

Press Ent key to

reset Totalizer!

Page 48

43

If during these two seconds user will press ENTER button again, the Pilot Totalizer

volume will be reset to zero. Following screen will appear for two seconds.

4.8 Submenu Optical Outputs Numerical entry

Two sets of optically isolated outputs are provided to actuate user supplied equipment. These are programmable via digital interface or optional LCD/Keypad such

that the outputs can be made to switch when a specified event occurs (e.g. when

a low or high flow alarm limit is exceeded or when the totalizer reaches a specified value) or may be directly controlled by user.

The user can configure each optical output action from 11 different options:

- Disabled: No Action (output is not assigned to any events and not energized)

- Low Flow Alarm

- High Flow Alarm

- Range between H&L Flow alarm settings

- Main Totalizer reading exceed set limit

- Pilot Totalizer reading exceed set limit

- Low Temperature alarm (*RTD option only)

- High Temperature alarm (*RTD option only)

- Range between High and Low Temperature alarm (*RTD option only)

- Diagnostic: Output will be energized when any of the Diagnostic events are active

- Manual On Control: Output will be energized until Disabled option will be

selected.

A typical display with Optical Output Function selection is shown below.

The listed above Optical Output selections can be set with the Up and Dn buttons

and are accepted by pressing ENT button.

The Totalizer has

been reset!

Opt #1 function

Disabled

Page 49

44

4.9 Submenu Flow Meter Configuration

4.9.1 Submenu Flow Meter Low Flow Cut–off

Numerical entry

The low flow cut-off can be selected between 0.0 and 10.0 % of the full scale

range. Flows less than the cut-off value are internally driven to zero and not totalized. The analog 0-5 vdc or 4-20mA current outputs are set to 0.0 Vdc and 4.00

mA correspondently. The switching threshold for the low flow cut-off has 1.0

%F.S. hysteresis. A typical display with Low Flow Cut–off selection is shown

below.

4.9.2 Submenu Pulse Number Measure Interval

Numerical entry

Signal Processing software algorithm can be set to calculate flow rate based on

two different methods (see Section 4.9.4):

a) number of pulses over preset measure interval

b) pulse width measurement

Both methods calculates frequency of the pulses from the flow meter sensor. The

number of pulses over preset measure interval method convenient when pulsating flow or especially noisy signals are encountered.

This method allows to get stable average flow rate if pulse measure interval is set

to values more than 4000 ms. This parameters effects the flow update rate. With

higher value of the pulse measure interval, the resolution and stability of the flow

measurement improves, but response time become longer. A suggested pulse

measure interval value of 4000 seconds is a good starting point for most applicable process fluids. With lower settings the response time of the meter will be

shorter, but resolution and stability will degrade.

The pulse measure interval settings are only related to the number of pulses over

preset measure interval method. Pulse measure interval can be selected between

500 and 60000 ms. A typical display with pulse measure interval selection is

shown below.

Low Flow Cut–off

1.000 %F.S.

Page 50

4.9.3 Submenu Flow Meter Calibration Factor

Numerical entry

Calibration Factor is defined as the number of pulses from flow sensor per one

gallon of fluid passing through the meter. This is the parameter by which the factory calibrates the flow meter. Change of this parameter is rarely needed by customers. It is only necessary if you believe the PWE flow meter is no longer accurate.

A typical display with Calibration Factor selection is shown below.

4.9.4 Submenu Flow Meter Measure Mode

Tabular entry

Signal Processing software algorithm can be set to calculate flow rate based on

two different methods:

a) number of pulses over preset measure interval

b) pulse width measurement

First method (a) was explained earlier (see Section 4.9.2). Second method (b)

allows get quick response time and best resolution of the flow rate, but with pulsating or especially noisy flow environment the stability of the flow rate reading

may be compromised. A digital filter (noise reduction algorithm) is available in

the flow meter when pulsating flow or especially noisy signals are encountered

(see Sections 4.9.5 and 4.9.6). The digital filter improves the displayed instantaneous flow values.

45

Measure Interval

4000 ms

Calibration-Fact

1366 Pulse/Gal

Note: Your PWE Flow Meter was calibrated at the factory for the

specified fluid and full scale flow range (see device’s label or calibration

data sheet). There is no need to adjust the Flow Meter calibration

factor, unless adjustment for specific installation or fluid is needed.

Any alteration of the flow meter calibration factor will VOID calibration

warranty supplied with instrument.

,

Page 51

46

The digital filter only works with pulse width measurement method and is not

applicable for flow measurement mode (a) – “number of pulses over measure

interval”. A typical display with Measure Mode selection is shown below. By

default unit shipped from the factory with Measure Mode set to “Pulse Width”.

4.9.5 Submenu Noise Reduction Filter Damping

Time Numerical entry

A noise reduction filter algorithm (running average of the individual flow inputs) is

available in the flow meter when pulsating flow or especially noisy signals are

encountered. There are two parameters that make up Signal Processing Control:

Damping Time and Number of Samples. They are described individually below.

Damping Time: The damping value can be selected between 0 and 99 seconds.

The value represents the response time of the running average flow rate change.

The higher the damping value the longer the response time of the filter. If noise

reduction filter is not desired it may be disabled by setting Damping Time parameter to zero. By default unit shipped from the factory with Damping Time value set

to 5. A typical display with Damping Time selection is shown below.

4.9.6 Submenu Noise Reduction Filter Sample

Number Numerical entry

This is the second parameter that makes up noise reduction filter algorithm. The

sample number value can be selected between 1 and 32. The number of samples

value represents the number of previous individual inputs used to calculate the

average value. Eventually the number of samples in the running average also

affects the response time. The more samples is used, the more inertial flow output reading will be to the actual flow change. A suggested nominal number of 5

samples is a good starting point for most applicable process fluids. A typical display with Sample Number selection is shown below.

Measure Mode

Pulse Width

NRF Damping Time

05 Seconds

Page 52

4.9.7 Submenu Flow Linearizer Tabular entry

The Flow Linearization algorithm may be used to improve linearity of the flow

measurement. The Flow Linearization table is built during factory calibration procedure and stored in the device EEPROM. The Flow Linearizer can be used with

both flow measurement algorithms. By default unit shipped from the factory with

enabled Flow Linearizer. A typical display with Flow Linearizer selection is shown

below.

The listed above Flow Linearizer selections can be set with the Up and Dn buttons

and are accepted by pressing ENT button.

4.9.8 Submenu Fluid Density Numerical entry

When the flow is displayed in gravimetric (mass based) units (e.g: g, kg, t, pound)

a density value of the actual fluid must be entered for the flow rate and total calculation. The translation conversion to mass flow is settable between 0.01 and

5.00000 g/cm3. A typical display with Fluid Density selection is shown below.

4.9.9 Submenu Pilot Calibration timer Tabular entry

The Pilot Calibration timer accumulates operational hours since last time unit was

calibrated. The value of the timer may be reset by the user by pressing Ent button.

A typical display with Calibration timer selection is shown below.

47

NRF Sample Numb.

05

Flow Linearizer

Enabled

Fluid Density

1.12500 g/cm3

Pilot Cal. Timer

70.0 Hours

Page 53

48

Once Ent button is pressed the next conformation screen will appear only for 2

seconds.

If during these two seconds user will press ENTER button again, the Calibration

Timer value will be reset to zero.

4.10 Submenu LCD Back Light Numerical Entry

This parameter indicates the level (intensity) of the LCD back light. The value of

the LCD back light level can be entered in increments of 1% from 0 - 80%F.S. If

LCD back light is not desired, it can be turn off by setting back light level to zero.

A typical display with LCD Back Light selection is shown below.

4.11 Submenu Alarm Events Log

PWE series Flow Meters are equipped with a self-diagnostic alarm event log which

is available via digital interface and on screen LCD indication (for devices with

optional LCD). A typical display with Alarm Events Log selection is shown below.

Press Ent key to

reset Cal. Timer

LCD Back Light

50 %F.S.

Sub Menu

Alarm Events Log

Page 54

49

The following diagnostic events are supported:

Event

Number

Diagnostic Alarm Event Description

LCD bit

Code

1 CPU Temperature too High 0

2 Flow rate more than 125% F.S. 1

3 High Flow Alarm 2

4 Low Flow Alarm 3

5 High Fluid Temperature Alarm 4

6 Low Fluid Temperature Alarm 5

7 Fluid Temperature Above measurement Limit 6

8 Fluid Temperature Below measurement Limit 7

9 Main Totalizer exceed set event volume limit 8

10 Pilot Totalizer exceed set event volume limit 9

11 EEPROM Failure 10

12 DC/DC converter Voltage too High 11

13 DC/DC converter Voltage too Low 12

14 Communication Error 13

15 Reserved 14

16

FATAL ERROR (reset or maintenance service is

required for return in to the normal operation)

15

Any Alarm events that may have occurred (Event 0 to Event F) are

stored in the internal register. All detected events remain stored until the

register is manually reset (by pressing ENTER key or by means of the

digital communication interface). The Alarm Event Log register is

mapped to the SRAM (volatile memory). In case of power interruption

the Alarm Event Log register will be automatically reset.

,

Page 55

50

4.11.1 Submenu Alarm Events Log Status

Each alarm event has fixed designated position on the LCD screen. Most significant event code (F) is set on the right side of the LCD and least significant event

code (0) is set on the left side of the LCD. If event is not present (not active) it is

represented on the LCD as dot (.) character. If event is present (or was detected

in the past) it is represented on the LCD with corresponding character. A typical

display with Alarm Events Log Status without any detected events is shown below.

In the example shown below, event 1 (Flow rate more than 125% F.S.) and event

2 (High Flow Alarm) have occurred since the last reset.

In order to reset (clear) Event Log press Ent button. Following screen will appear

just for two seconds.

If during these two seconds user will press Ent button again, the Alarm Event Log

will be cleared.

Event Log Status

. . . . . . . . . . . . . . . .

Event Log Status

. . 23 . . . . . . . . . . . .

Press Ent key to

Clear events Log

Note: Each Alarm Event can be individually masked (disabled) using

Event Log Mask menu selection (see Section 4.11.3) If alarm event is

masked (disabled) it will not be registered in the Event Status Log even

actual event has occurred.

,

Page 56

51

4.11.2 Submenu Alarm Events List

This menu selection provides list of the descriptions and corresponding code for

all supported events.

If ENTER is pressed again, the description for each error is displayed:

The shown above Event List selections can be scrolled with the Up and Dn buttons. By pressing ENT or Esc buttons user may exit from scrolling mode.

4.11.3 Submenu Alarm Events Log Mask

With this menu selection user may individually mask (disable) any Alarm Event. A

typical display with Alarm Events Mask selection is shown below.

In the example shown above, event 1 (Flow rate more than 125% F.S.) is masked

with asterisk. In order to change event mask settings user should press Ent button. The flashing cursor will appear on the left of the LCD screen (on the 0 event

position). Use Dn button to move to desired event code. Use Up button to change

mask status (asterisk represent masked event). Use Ent button to accept and save

new mask settings.

4.12 Submenu Diagnostic

This submenu provides troubleshooting information about the meter internal variables. These items are informational only and may not be changed (read only).

Events List

Press Enter Key

Events List

0-CPU Temp. High

Event Log Mask

0*23456789ABCDEF

Page 57

52

4.12.1 Submenu Raw Pulses Count

This menu selection provides number of pulses from the flow sensor within specific measurement interval.

In the example shown above the raw pulses count is 400 within 4000 ms measuring interval, which represents pulse frequency of 100 Hz.

4.12.2 Submenu Pulse Frequency

This menu selection provides raw value of the frequency from the pulse width

measurement circuitry.

4.12.3 Submenu Raw RTD reading (RTD option only)

This menu selection provides raw value of the ADC counts for RTD circuitry. The

reading only applicable for PWE meters with optional RTD functionality.

4.12.4 Submenu DAC_A Flow Output

This menu selection provides current value of the DAC register for analog flow

output circuitry.

Raw Pulses Count

400 T= 4000mS

Pulse Frequency

100.00 Hz

Raw RTD Reading

1250 Counts

DAC_A Output (F)

3125 Counts

Page 58

53

4.12.5 Submenu DAC_B Temperature Output

This menu selection provides current value of the DAC register for analog temperature output circuitry.

4.12.6 Submenu CPU Temperature

This menu selection provides current value of the PCB and CPU temperature in °C.

4.12.7 Submenu Raw VCC Reading

This menu selection provides current normalized value of the DC/DC converter

output in counts. The typical values are in the range between 2800 and 3200

counts.

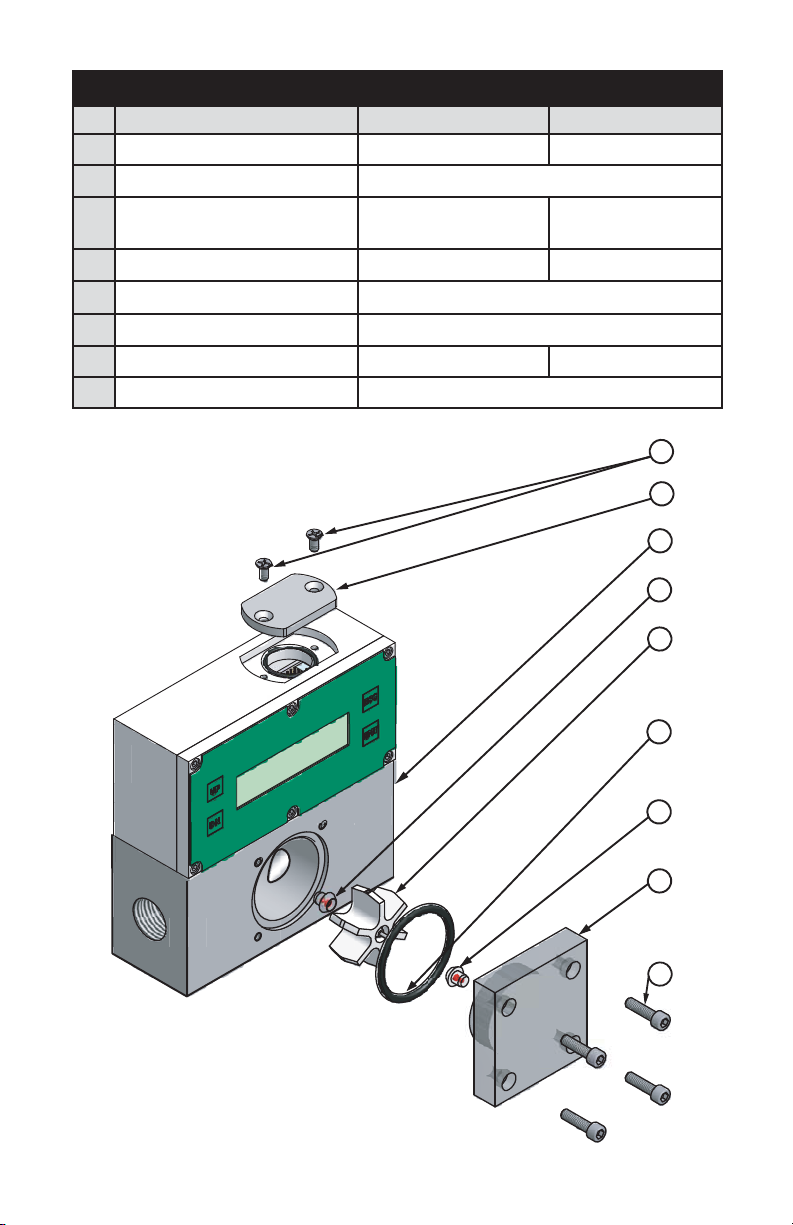

5. Analog Output Signals

5.1 Analog Output Signals configuration

PWE series Flow Meters are equipped with calibrated 0-5 Vdc and/or 4-20 mA output signals for flow and temperature* process variables. The set of the jumpers

(J3A, J3B, J3C, J3D, J3E, J3F) located on the top of the flow meter, inside of the

maintenance access window (see Figure 5-1 “PWE configuration jumpers”) are

used to switch between 0-5 Vdc or 4-20 mA output signals. Jumpers J3A, J3B,

J3C are used to set flow analog output type and jumpers J3D, J3E, J3F are used

to set temperature* analog output type (see Table 5-1). Jumper J3G is used to

configure RS-485 termination resistor (by default is off).

DAC_B Output (T)

1358 Counts

CPU Temperature

35.8 C

Raw VCC Reading

3065 Counts

Page 59

54

Figure 5-1 PWE configuration jumpers

Table 5-1

Function

Analog Flow Output Analog Temp. Output* RS-485

J3A J3B J3C J3D J3E J3F J3G

Analog

Output

0-5 Vdc 2-3 5-6 8-9 11-12 14-15 17-18

4-20 mA 1-2 4-5 7-8 10-11 13-14 16-17

RS-485

220 Ohm

Termination

Resistor

OFF 20-21

ON 19-20

5.2 Analog Output Signals calibration

Note: The analog output available on the PWE Flow Meter was calibrated

at the factory for the specified fluid and full scale flow range (see the

device’s front label). There is no need to perform analog output

calibration unless the EEPROM IC was replaced or offset/span

adjustment is needed. Any alteration of the analog output scaling

variables in the EEPROM table will VOID calibration warranty supplied

with instrument.

,

Page 60

55

Note: It is recommended to use the Aalborg®supplied calibration and