Page 1

PREPARATION and OPERATION

Prior to connecting gas/liquid flow lines inspect all parts of the

piping system including ferrules and fittings for dust or other

contaminants. Be sure to observe the direction of flow as indicated by the arrow on the front of the valve when connecting

the fluid flow system to be monitored.

Insert tubing into the compression fittings until the ends of the

properly sized tubing home flush against the shoulders of the

fittings. Compression fittings are to be tightened according to

the manufacturer's instructions to one and one quarter turns.

Avoid over tightening.

Once installed inline with the gas or liquid to be controlled,

apply a variable DC power source at the two solenoid wires to

proportionally open and close the solenoid valve (there is no

polarity). The valve is set to begin opening at approximately 5

VDC. They can also serve as "on off" valves (valves are not

guaranteed for absolute closure). Optional PSV-D DRIVER

MODULE is available when use of a 0 to 5 VDC or 4 to 20 mA

reference control signal is desired. Contact your distributor or

Aalborg7 for more information.

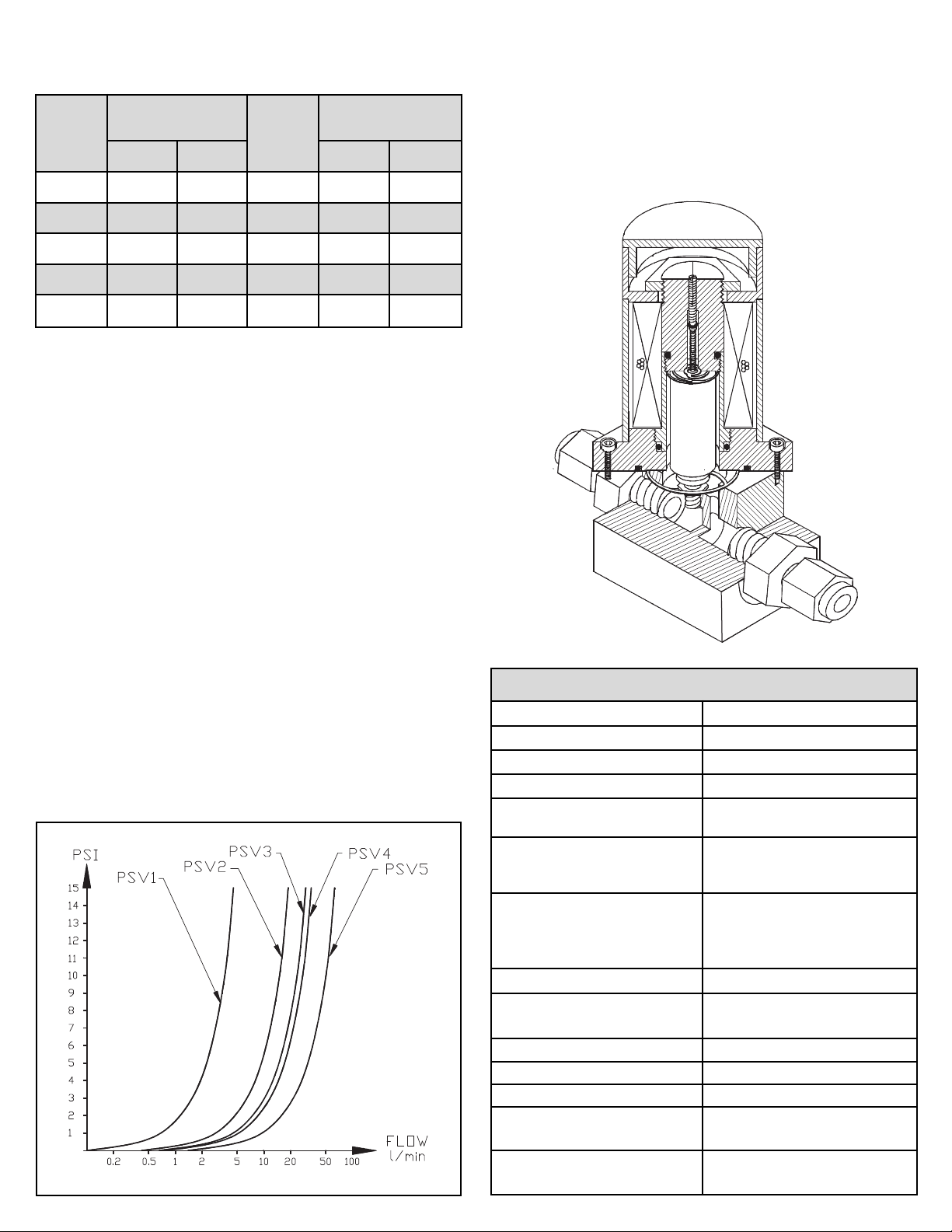

SPECIFICATIONS

POWER INPUT: 0 to 30 VDC.

MAXIMUM CURRENT REQUIRED: 400 mA.

ELECTRICAL CONNECTION: Male spade connectors.

TYPE OF OPERATION: Normally closed (nc).

CONNECTIONS:

1/4 inch compression fittings,

optional 1/8 inch and 3/8 inch.

DIMENSIONS:

3.55 inch (90.2mm) high x 3.25

inch (82.6mm) long (with fittings)

x 1.00 inch (25.4mm) deep.

WETTED MATERIALS:

Types: 316 and 416 stainless steel,

VITON7 O-rings; BUNA-N7,

EPR or KALREZ7 O-rings

are optional.

MAXIMUM PRESSURE: 500 psig (3448 kPa).

MAXIMUM DIFFERENTIAL

PRESSURE:

50 psid (345 kPa).

MAXIMUM INTERNAL LEAK: 0.5% FS.

LEAK INTEGRITY: 1 X 10-9scc / sec Helium.

FLUID TEMPERATURE: 14 FF to 122 FF (-10 FC to 50 FC).

MAXIMUM TEMPERATURE

(TYPICAL):

174 FF (79 FC) inside, 130 FF

(54

F

C) outside surface at 24 VDC.

ENVIRONMENTAL (PER IEC 664):

Installation level II; pollution

degree II.

MODEL

NUMBER

ORIFICE SIZE

Cv

*maximum flow

[ml / min]

[inch] [mm] Air Water

PSV-1 0.020 0.51 0.009 3500 125

PSV-2 0.040 1.02 0.033 13000 400

PSV-3 0.055 1.40 0.055 21500 700

PSV-4 0.063 1.60 0.068 25000 850

PSV-5 0.125 3.18 0.240 100000 2873

PROPORTIONATING SOLENOID VALVES

PSV Proportionating Solenoid Valves are uniquely designed

to respond to variable power inputs (0-30 VDC) to regulate

flow of liquids and/or gases proportionately. For added safety

PSV valves are normally closed (NC) when de-energized.

* based on 10 psig [690 mbar] differential pressure.

pressure drop

Page 2

TRADEMARKS

Aalborg

7 is a registered trademark of Aalborg Instruments Inc.

Buna

7 is a registered trademark of DuPont Dow Elastometers.

Kalrez

7 is a registered trademark of DuPont Dow Elastomers.

Viton

7 is a registered trademark of Dupont Dow Elastometers L.L.C.

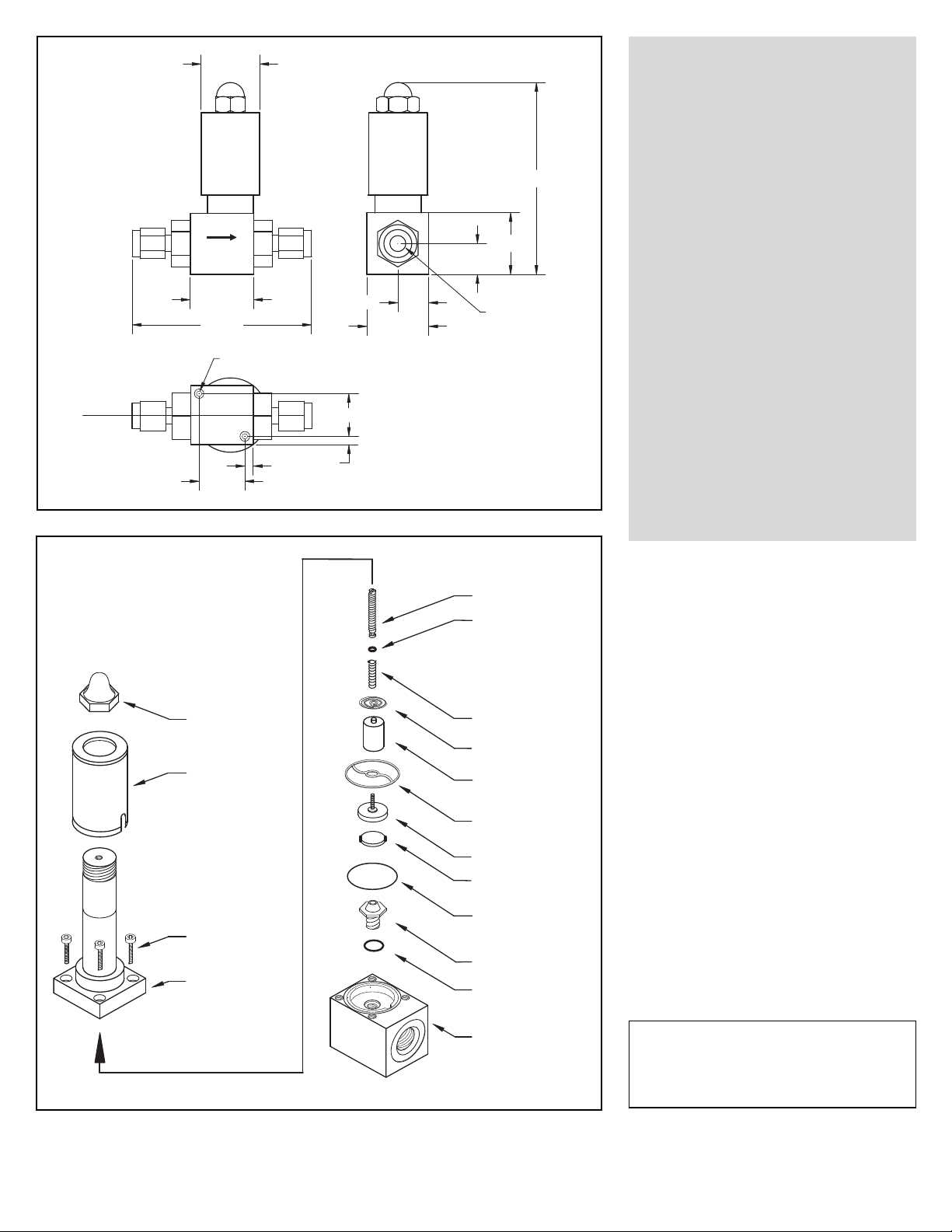

1.177

MAINTENANCE

The solenoid valve consists of 316 and

416 stainless steel, and VITON7 (or

optional BUNA-N7, EPR or KALREZ7) O-

rings and seals. No regular maintenance

is required except for periodic cleaning.

Various corrosive gases or liquids may

demand more frequent replacement of Orings and seals inside the valve. Be sure

to use an elastomer material, appropriate

for your specific application. Contact your

distributor or Aalborg7 for optional sealing

materials available.

Set the PSV for maximum flow, and

attempt to flush through in both directions

with a clean, filtered, and neutral gas such

as nitrogen. [Another option for fully opening the valve is to remove the plastic cap

on top of the valve, and turn the set screw

counterclockwise until it stops]. If blockage is not alleviated, return the unit to

your distributor or Aalborg7 for servicing.

It is the users responsibility to determine

if the instrument is appropriate for their

OXYGEN application, and for specifying

O2 cleaning service if required. Aalborg7

is not liable for any damage or personal

injury, whatsoever, resulting from the use

of this instrument for oxygen.

If the valve is left in the active mode for

an extended period of time, it may

become warm or even hot to the touch.

Use care in avoiding direct contact with

the valve during operation.

To protect servicing personnel it is

mandatory that any instrument being

serviced is completely purged and

neutralized of toxic, bacteriologically

infected, corrosive or radioactive

contents.

Use of the PSV valve in a manner other

than that specified in this instruction

sheet, may impair the protection

provided by the equipment.

AALBORG INSTRUMENTS w 20 CORPORATE DRIVE w ORANGEBURG, NY 10962 w PHONE: 845.770.3000 w FAX: 845.770.3010

E-MAIL: info@aalborg.com w TOLL FREE IN USA or CANADA: 1.800.866.3837w WEB SITE: www.aalborg.com

PSV

SOLENOID VALVE

Aalborg7 reserves the right to change designs and dimensions at its sole discretion at any time without notice.

For certified dimensions please contact Aalborg7

.

TD 1293 Revision H

FLOW

1.250

3.250

6-32 UNC (2)HOLES

0.938

0.156

0.156

0.500

0.688

0.500

Ø 0.250

COMPRESSION

1.000

FITTING

1.000

3.851

NUT

GUARD ASSEMBLY

4-40 SOCKET SCREW

VALVE BODY

ADJUST. SCREW

O-RING

COMPRESSION SPRING

SPIRAL SPRING

CORE

SPIDER SPRING

STEM

SEAT-VITON INSERT

O-RING

ORIFICE

O-RING

BLOCK

05-19-2006

Loading...

Loading...