Page 1

Technical Data SheetNo.

TD-DPM-

Date of Issue:

6HSWHPEHU

OPERATING MANUAL

Aalborg

Intelligent Digital Mass Flow Meters

£

DPM

Page 2

Aalborg® is a registered trademark of Aalborg Instruments & Controls.

NOTE: Aalborg reserves the right to change designsand dimensions at its sole

discretion at any time without notice. For certified dimensions, please contact Aalborg.

Page 3

TABLE OF CONTENTS

1. Unpacking the DPM Mass Flow Meter.......................................

1.1 Inspect Package for External Damage..................................

1.2 Unpack the Mass Flow Meter................................................

1.3 Returning Material for Repair................................................

2. Installation.................................................................................

2.1 Safety Instructions..................................................................

2.2 Primary Gas Connections......................................................

3. Electrical Connections...............................................................

3.1 Power Supply Connections....................................................

3.2 Output Signals Connections..................................................

3.3 Digital Communication Interface Connections.....................

4. Principle of Operation..............................................................1

5. Specifications............................................................................1

5.1 CE Compliance....................................................................1

5.2 DPM Accessories.................................................................1

6. Operating Instructions...............................................................1

6.1 Preparation and Power Up..................................................1

6.2 Swamping Condition............................................................1

6.3 Meter Process Information (PI) Screens..............................1

6.4 Local User Interface Menu Structure...................................

6.4.1 Parameter Entry..............................................................2

6.4.2 Submenu “Change PP Password”..................................2

6.4.3 Submenu “Device Information”.......................................2

6.4.4 Submenu “Units of Measure”..........................................2

6.4.5 Submenu “User-Defined Units”.......................................2

6.4.6 Submenu “Select Gas”...................................................2

6.4.7 Submenu “User-Defined Mixture”...................................3

6.4.8 Submenu “Gas Flow Alarm”...........................................3

6.4.9 Submenu “Gas Pressure Alarm”....................................3

6.4.10 Submenu “Gas Temperature Alarm”............................4

6.4.11 Totalizers Settings........................................................

6.4.12 Submenu “Pulse Output”..............................................4

6.4.13 General Settings...........................................................4

6.4.13.1 STP/NTP Conditions................................................4

6.4.13.2 Display and Process Information (PI) Screens........4

6.4.13.3 Submenu “Communication Port Settings”...............

4

1

Page 4

6.4.13.4 Submenu “Modbus Interface” (optional)..................5

6.4.13.5 Relay Assignment....................................................5

6.4.13.6 Analog Output Configuration...................................5

6.4.13.7 Status LED Settings................................................5

6.4.13.8 Signal Conditioner Settings.....................................5

6.4.14 Sensor Zero Calibration................................................5

6.4.14.1 DP Sensor Zero Calibration.....................................5

6.4.14.2 Start AP Auto Tare...................................................5

6.4.15 Submenu “Alarms and Diagnostic”...............................

6.4.15.1 Alarm Event Register...............................................6

6.4.15.2 Diagnostic Events Register......................................6

6.4.15.3 Sensors ADC Reading (read only)..........................6

6.4.15.4 Temperature Sensors Diagnostic (read only)..........6

6.4.15.5 Analog Output & PO Queue Diagnostic (read only)

6.4.15.6 Reference Voltage & DSP Calculation Diagnostic

6.5 Multi-Functional Push-Button Operation.............................

7 Maintenance.............................................................................7

7.1 General................................................................................7

7.2 Cleaning................................................................................7

8 Recalibration.............................................................................7

9 RS-235/RS-485 Software Interface Commands.......................7

9.1 General................................................................................7

9.2 Commands Structure...........................................................7

10 Troubleshooting......................................................................9

10.1 Common Conditions..........................................................9

10.2 Troubleshooting Guide......................................................

10.3 Technical Assistance.......................................................

Appendix I: Component Diagram..............................................

Appendix II: Dimensional Drawings...........................................

Appendix III: Warranty................................................................

Appendix IV: Index of Figures....................................................

Appendix V: Index of Tables......................................................10

.....

9

2

Page 5

1.

UNPACKING THE DPM MASS FLOW METER

1.1

Your DPM Mass Flow Meterwas carefully packed in a sturdy cardboard carton, with

anti-static cushioning materials to withstand shipping shock. Upon receipt, inspect the

package for possible external damage. If the unopened package is damaged, contact the

shipping companyimmediately to make a report.

1.2

Open the carto n carefully from th e top and inspect for any sig n of concealed shippi ng

damage. If there is any damage, in addition to contacting the shipping company, forward

a copy of any damage reportto yourdistributoror to Aalborgdirectly.

When unpackin g the instrument, make sur e that you have all the items indi cated on

Packing List. Promptly report any discrepancy.

1.3

Contact the customer service representative at your distributor, or at Aalborgif you

purchased your Mass Flow Meter directly, to request a

(RAN). Equipment returned without a RAN will not be accepted.

right to charge a fee to the customer for equipment returned under warranty claims if the

instruments are found, when examined and tested, to be free of warrantied defects.

Shipping charges are borne by the customer. Meters returned collect will

It is mandatory that any equipment returned for service be purged of any

hazardous contents including, but not limited to, toxic, infectious,

corrosive or radioactive material. No work shall be performed on a returned

product unless the customer submits a fully executed and signed SAFETY

CERTIFICATE. Contact the Service Manager at your distributor or at

Aalborg to obtain this form prior to returning the product.

Inspect Package for External Damage

Unpack the Mass Flow Meter

Returning Material for Repair

Return Authorization Number

the

Aalborg reserves the

not

be accepted.

2.

2.1

INSTALLATION

Safety Instructions

CAUTION

responsibilities of the manufacturer shall be voided if usersfail to follow

CAUTION:

use in life

cause personal injury. Customers employing this device for use insuch

applications do so at their own risk andagree tobe fully responsible for

damages resulting from improper use or sale.

: Aalborg warranties and all

LIFE SUPPORT APPLICATIONS: TheDPM is not designed for

support applications where any malfunction of the device may

other direct or implied

any

3

Page 6

CAUTION:

may be damaged by improper handling. When adjusting or servicing the

device, always wear a grounded wrist strap to prevent inadvertent damage to

the integral solid-state circuitry.

Some of the IC devices used in the DPM are static-sensitive and

2.2

The DFM Mass Flow Meter will

may be introduced into the instrument. If gases are contaminated,

prevent theintroduction of impediments to thesensor.

For more information, contact your distributor or Aalborg.

The DPMMassFlowMetercanbemountedinanyposition.Itisnotrequiredtomaintain

straight runs of pip e upstream or downstream of the meter. It is preferable to install the

meter in a stable

moisture, and drafts.

Prior to connecting gas lines, inspect all parts of the piping system, including

ferrules and other fittings, for dust or other contaminants. Do not use pipe grease or

sealant on process connections as they can contaminate narrow laminar flow

elements that may cause permanent damage to the meter.

When connecting the gas system to be monitored, be sure to observe the direction of gas flow

asindicated byt he arrow onthefr ont of themeter.

Insert tubing into the compression fittings until the ends of the properly sized tubing sit

flush against the shoulders of the fittings. Compression fittings are to be tightened 1¼

turns according to the manufacturer's instructions. Avoid overtightening

seriously damage the compression fitting.

Primary Gas Connections

not

operate with liquids. Only clean, non

theymustbe filteredto

CAUTION:

specifically cleaned and prepared for such an application.

DPM meters should not be used for monitoring oxygen gas unless

environment, free of frequent and sudden temperature changes, high

corrosive gases

which may

Pressure Requirements

Maximum operating line(common mode)pressure for "BREEZE" Low Differential Pressure

DPM04/14/24/34/44/54 series flow meters is 50PSIG (3.44 Bar). If the installation

line pressure is more than 50 PSIG(3.44 Bar), a pressure regulator must be installed

upstream of the flow meter to bring pressure down to 50PSIG (3.44 Bar).

Maximum operating line (common mode)pressure for DPM07/17/37/47/57/67/77 series flow

meters is 120PSIG (8.3 Bar). If the installation line pressure is more than 120 PSIG (8.3

Bar), a pressure regulator must be installed upstream of the flow meter to bring pressure

down to 120 PSIG (8.3 Bar)

4

Page 7

CAUTION:

maximum pressure in the gas line must not exceed 120PSIG (8.3bar).

Applying pressure above 120 PSIG (8.3 bar) will cause permanent damage

to the differential pressure sensor.

For DPM07/17/37/47/57/67/77 series flow meters, the

CAUTION:

ser ies flow meters, the maximum pressure in the gas line must not exceed

50PSIG (3.44bar). Applying pressure above 50 PSIG (3.44 bar) will cause

permanent damage to the differential pressure sensor.

CAUTION: Do not apply upstream – downstream differential pressure

exceeding 9.75 PSID to "BREEZE" Low Differ

DPM04/14/24/34/44/54

differential pressures may cause permanent damage to the product.

Normally high common mode pressure (within 50 PSIG) will not damage

the differential pressure sensor, but pressure transients (momentary

pressure variations) on upstream or downstream ports can result in

permanent sensor damage to the product.

Avoid instantaneous application of high pressure from quick on/off

solenoid valves upstream or downstream of the meter.

CAUTION: Do not apply upstream – downstream differential pressure

exceeding 12 PSID to DPM07/17/37/47/57 series flow meters. Exposure

to higher differential pressures may cause permanent damage to the

product. Normally high common mode pressure (within 120 PSIG) will

not damage the differential pressure sensor, but pressure transients

(momentary pressure variations) on upstream or downstream ports can

result in permanent sensor damage to the product.

Avoid instantaneous application of high pressure from quick on/off

solenoid valves upstream or downstream of the meter.

CAUTION:

meet the DPM meter’s pressure and temperature ratings. A margin of safety

should be provided if spikes and surges existin the process. Proper

pressurerelief valvesandburstplatesshouldbeinstalledin high

applications.

For DPM04/14/24/34/44/54 "BREEZE"Low Differential Pressure

ential Pressure

series flow meters. Exposure to higher

The usershall install the instrument onlyin processlines that

pressure

CAUTION:

tube and the narrow flow channels in the laminar flow element, the

user should install the instrument in process lines that have clean

gases. Upstream particulate filters with maximum particulate size

20P are recommended for all applications.

DPM transducer ports are equipped with 10-32 female thread (DPM04/07), 1/8" NPT

female thread (DPM14/17/37), 1/4" NPT female thread DPM24/34/47, 1/2" NPT female

thread (DPM44/57) and 3/4" NPT female thread (DPM54/67/77). DPM24/34/47, 1/2"

NPT female thread (DPM44/57) and 3/4" NPT female thread (DPM54/67/77).

To avoid obstructions and contamination in the sensor

5

Page 8

3.

ELECTRICAL CONNECTIONS

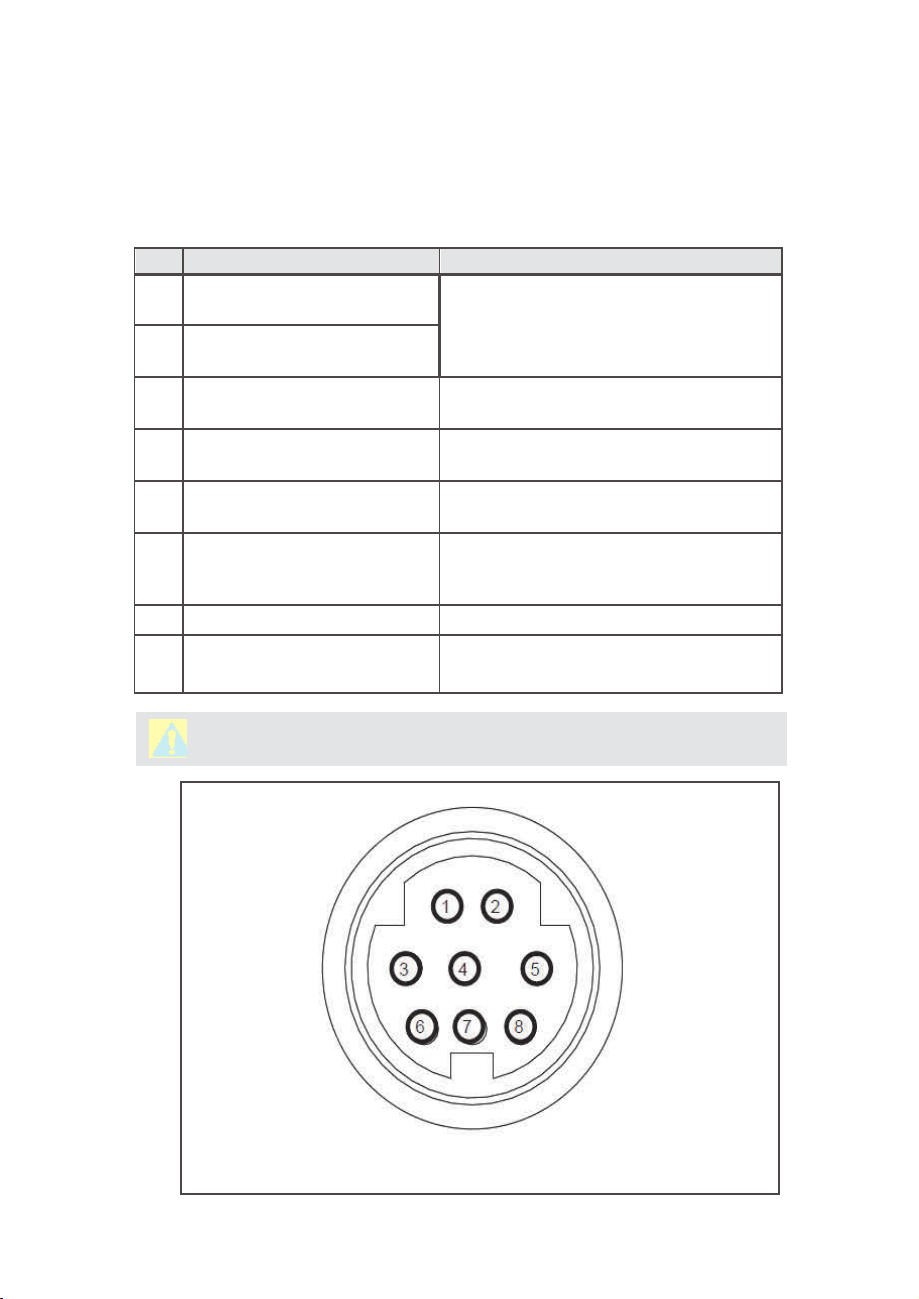

DPM is equipp ed with an 8 pin -Min iDIN power,anal og/relay out put,

communication

Figure 1

TABLE I: 8-PIN DESIGNATIONS AND NOTES

PIN FUNCTION

interface connector.

for a Pin Diagram

.

1 Solid State SPST Relay NO

(normally open) contact #1

2 Solid State SPST Relay NO

(normally open) contact #2

3

RS-232 RX / RS-485 (–)

Communication Interface input

4 Analog (0-5Vdc,0-10Vdc,4-20

mA) Output reference (-)

5 RS-232 TX / RS-485(+)

Communication Interface input

6 Analog (0-5Vdc, 0-10Vdc or

4-20 mA) Output (+)

7 Power supply, positive (+)

8

Powersupply, common (-)

RS-232 Signal Ground

Table I

explains the pin designations. See

NOTE

Do not exceed SSR maximum voltage 48

AC peak/DC and maximum load current 400

mA.

Also accessible via Audio jack connector

(

see Figures 2 & 25)

Common (return) for pin 6 (0-5Vdc or

0-10 Vdc or 4-20 mA)

Also accessible via Audio jack connector

see Figures 2 & 25).

(

Output. Do not apply external voltage

current source. Be sure to observe

or any

recommended load

impedance.

Power input 9 – 26 Vdc.

Power input and RS-232 communication

common.

CAUTION:

FIGURE 1: DPM 8-PIN Mini-DIN CONNECTOR CONFIGURATION

4-20 mA analogoutput requires at least 12 Vdcpower.

6

Page 9

CAUTION: Generally, "Mini-DIN" Connector numbering patterns are

standardized. There are, however, some connectors with

nonconforming patterns, so the numbering sequence on your mating

connector may or may not coincide with that shown in our pin

configuration above. It is imperative that you match the appropriate

wires in accordance with the correct sequence regardless of the

particular numbers displayed on the mating connector.

3.1

The AC to DC power supply requirements for DPM transducers are 9 to 26 Vdc, with

maximum load current at least 100 mA (unipolar power supply), and maximum ripple

below 150 mV P-P.

Power can be applied to the DPM meter either through the power jack (see Figure

) or the 8-pin Mini-DIN connector (see Figure 1).

Power Supply Connections

CAUTION:

as this may damage the instrument.

DC Power (+) --------------- pin 7 of the 8-pin Mini-DIN connector

DC Power (-) --------------- pin 8 of the 8-pin Mini-DIN connector

CAUTION:

damage the DPM and/or cause faulty operation.

CAUTION:

any cables or wires to or from the system.

NOTE:

time-lag) r eset fuse. If a shorti ng condition or pol arity reversal occ urs, the

fusewill cut power to the flow transducercircuit: disconnectthe power to the

unit, correct the faulty condition, and reconnect the power. The fuse will

reset once the faulty condition has been corrected.

Never apply power simultaneously from both connectors,

Never apply power voltage above 26Vdc. Doing so may

Make sure power is OFF when connecting or disconnecting

The (+)and (-) power inputs are each protected by a 300mA M(medium

3.2

Output Signals Connections

CAUTION:

exceed the rated values shown in the specifications (see Section 5).

Failure to do so might cause damage to this device. Be sure to check

if the wiring and the polarity of the power supply are correct before

turning the power ON. Wiring error may cause damage or faulty

operation.

When connecting the load to the output terminals, do not

7

Page 10

DPM series Mass Flow Meters are equipped with calibrated 0-5Vdc, 0-10Vdc or

4-20 mA output signals. This linear output signal represents 0-100% of the flow

meter’s full scale range. The user may select the desired analog interface type

using a local OLED/Joystick interface or via digital communication interface.

CAUTION:

isolated, sourcing type). Do not connect an external voltage source

(for example, current loop powered systems) to the output signals.

For 0-5 VDC, 0-10 VDC or 4-20 mA output signal connection:

External load Plus (+) --------------------------- pin 6 of the 8-pin Mini-DIN connector

External load Minus (-)--------------------------- pin 4 of the 8-pin Mini-DIN connector

CAUTION:

check actual analog output interface configuration. Connecting low

impedance (< 5K

damage to or faulty operation of the electronics circuitry.

NOTE:

CAUTION:

always check actual analog output interface configuration.

Connecting high impedance (> 500

may cause non linear or faulty operation of the electronics circuitry.

Toeliminate the possibility of noise interference, it is recommended that you use a separate cable

entry for the DC power, digital communication interface, and analog output interface signal

lines.

The 4-20 mA current loop output is self-powered (non-

When connecting the load to the output terminals, always

ȍ

) loads to the 0-5Vdc or 0-10 Vdc output may cause

4-20 mA analog output requires at least 12 Vdc power input.

When connecting the load to the output terminals,

ȍ

) loads to the 4-20 mA output

3.3

The digital interface operates via RS-232 or RS-485 (user-selected) and provides access to

all applicable internal configuration parameters and data.

Digital Communication Interface Connections

CAUTION: Before proceeding with communication interface

connection, verify the meter’s actual communication interface type. For

devices with OLED display, the interface type will be briefly (for about

2 seconds) displayed on the banner screen when power is applied. If

your meter does not have a display, the communication interface type

can be identified by briefly pressing the multi-function button and

(

see

monitoring status LED response

Section 6.5).

8

Page 11

Communication Settings for RS-232/RS-485 communication interface

The default baud rate is 9600 baud (user-selected; see Section 5, Specifications).

Stop bit:

Data bits:

Parity:

Flow Control:

RS-232 Communication Interface Connection

Crossover connection must be established:

HOST PC RS-232 RX Meter (RS-232 TX)

(pin 2 on the host PC DB9 connector)------pin 3 (Ring) of the 3-pin stereo jack

connector (TX+)

HOST PC RS-232 TX Meter (RS-232 RX)

(pin 3 on the host PC DB9 connector)------ pin 2 (Tip) of the 3-pin stereo jack

connector (RX-)

HOST PC RS-232 SIGNAL GND Meter (Digital GND)

(pin 5 on the host PC DB9 connector)------pin 1 (Sleeve) of the 3-pin stereo jack

connector

Each DPM ordered with RS-232 interface option is supplied with default crossover -

foot long communication cable (AALBORG P/N: CBL-A232) DB9 female to stereo 3.5 mm

Plug.

If custom length cable is required, it can be assembled using the connection

diagram shown in Figure 2.

....................

....................

....................

....................

1

8

None

None

9

Page 12

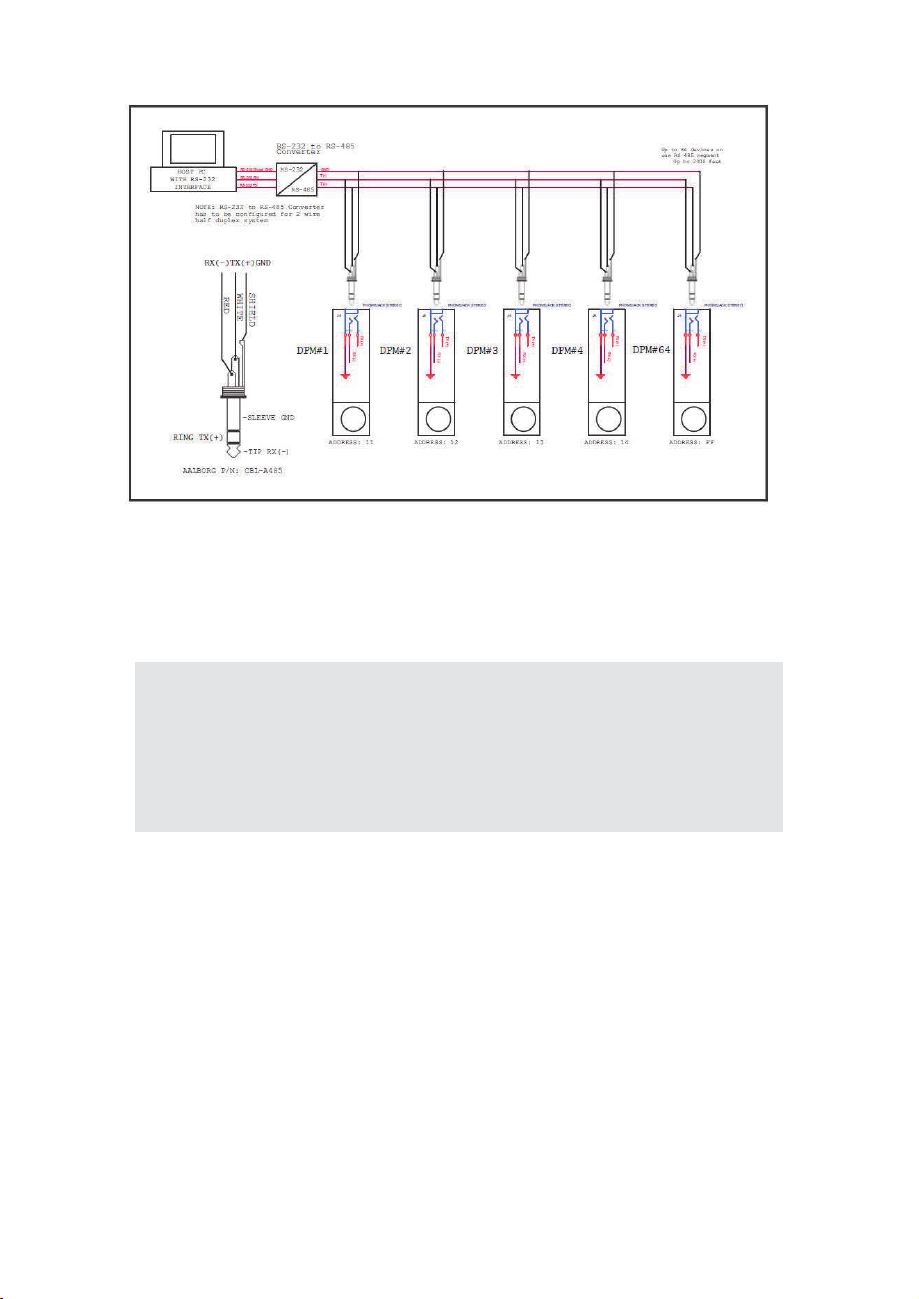

RS-485 Communication Interface Connection

The RS-485 converter/adapter must be configured for: multidrop, 2-wire, half

duplex mode (see Figure 3). The transmitter circuit must be enabled by TD or

RTS (depending on which is available on the converter/adapter). Settings for

the receiver circuit should follow the selection made for the transmitter circuit

in order to eliminate echo.

RS-485 A line T(-) or R(-) ............. pin 2 on 3-pin Audio-connector, middle

section or "tip" DPM (RX-), (WHITE

wire)

RS-485 B line T(+) or R(+) ........... pin 3 on 3-pins Audio-connector, the

"ring" section DPM (TX+), (RED wire)

RS-485 GND (if available) ............ pin 1 on 3-pin Audio-connector, the

“sleeve” section DPM (GND), (Shield

wire)

Each DPM ordered with RS-485 interface option is supplied with a default

3-foot length of communication cable (AALBORG P/N: CBL-A485) Stereo

3.5 mm plug to stripped wires.

If custom length cable is required, it can be assembled using the connection

diagram shown in Figure 3:

10

Page 13

F

IIGGUURRE3:DDPPMRR

When the DPM device is set as the last device on the long RS-485 bus segment,

ȍ

the 120

and (-) terminals close (< 6 feet) to this device.

bus termination resistor must be connected between the RS-485 (+)

SS-

44885CCOO

MMMM

UUNNIICC

ATTIIOONN IINNTTEERRFFAACCECCOO

NNNNEECCTTIIOONN

S

NOTE:

Wermination resistor between the RS-485 (+) and (-) pins. On

instruments with a local display and joystick interface, the 120ȍ

termination resistor can be activated (enabled) using General

Settings / Communication Port / RS-485 Termination menu selection.

By default, the instrument is shipped from the factory with the RS-485

Termination mode set to Disabled.

The DPM instrument offers an integrated switchable 120ȍ

11

Page 14

4.

PP

RRIINNCCIIPPLLEOOFFOOPPEERRATTIIOONN

The DPM series flow meters integrate precision a differential pressure sensor

which accurately measures pressure drop across the special restriction flow

element (RFE). The geometry of the RFE is designed to ensure laminar flow in

each branch within the entire range of operation of the DPM instrument.

According to principles of fluid dynamics, the volumetric flow rates of a gas in the

laminar flow conduits are proportional to differential pressure across the

restriction flow element. In addition, precision absolute pressure and temperature

sensor readings are used to calculate mass flow rate using ideal gas laws.

The DPM flow meter supports multi-gas functionality which allows users on site to

select the desired measured gas using local Display/Joystick interface or digital

communication interface. See Tables X - XVIII which provide lists of supported

gases.

The DPM flow meter can display flow rate in 43 different mass flow or 15 different

volumetric flow engineering units. Flow meter parameters and functions can be

programmed locally via optional OLED/Joystick interface or remotely via the RS232/RS-485 interface or optional Modbus RTU interface. DPM flow meters

support various functions including two programmable flow totalizers; low, high or

range flow; temperature and pressure alarms; automatic zero adjustment

(activated via local or digital communication interface); programmable solid state

relay (SSR); programmable 0-5 Vdc, 0-10 Vdc or 4-20 mA analog outputs; userprogrammable pulse output (via SSR); and self-diagnostic alarms. Optional local

OLED readout with adjustaEOH brightness level provides mass and volumetric

flow rate, total volume reading in currently selected engineering units, and

GLDJQRVWLFHYHQWVDQGLQGLFDWLRQ

5.

FLOW MEDIUM:

clean gases,

CALIBRATIONS:

°C]) unless otherwise requested orstated.

ENVIRONMENTAL (PER IEC 664):

FLOW ACCURACY (INCLUDING LINEARITY):

temperature and pressure.

REPEATABILITY:

FLOW TEMPERATURE COEFFICIENT:

FLOW PRESSURE COEFFICIENT:

FLOW RESPONSE TIME:

SSPPEECCIIFFIICCA

Please note that DPM Mass Flow Meters are designed to work only with

never

TTIIOONN

S

any corrosive gas and

Performed at standard conditions (14.7 psia [101.4 kPa] and 70 °F [21.1

+0.15% of full scale.

default 10 ms (user-adjusted).

never

Installation Level II; Pollution Degree II.

0.05% of full scale/ °C or less.

0.01% of full scale/psi (6.895 kPa) or less.

12

any liquid.

±(0.5% RD + 0.2% FS) at calibration

Page 15

INSTRUMENT WARM-UP TIME:

< 5 seconds.

MAXIMUM MEASURABLE FLOW RANGE:

OPERATION RANGE/TURNDOWN RATIO:

MASS REFERENCE CONDITIONS (STP): 70°f & 14.696 PSIA(other references

available on request).

MAXIMUM INTERNAL GAS PRESSURE (STATIC):

'3036,*

%5((=(/RZ'LIIHUHQWLDO3UHVVXUHPRGHOV'3036,*

0$;,080,167$17$1(286',))(5(17,$/35(6685($&5266,1/(7$1'287/(7

PROOF PRESSURE:

%5((=(/RZ'LIIHUHQWLDO3UHVVXUHPRGHOV'3036,*

TEMPERATURE:

MOUNTING ATTITUDE SENSITIVITY:

RELATIVE GAS HUMIDITY RANGE:

INGRESS PROTECTION:

2873876,*1$/6

'30 36,'

%5((=(/RZ'LIIHUHQWLDO3UHVVXUHPRGHOV'3036,'

'3036,*

-WRÛ&WRÛ)

IP40.

Linear 0-5 (3000 min. load impedance);

/LQHDU PLQORDGLPSHGDQFH

/LQHDUP$ PD[LPXPORRSUHVLVWDQFH

0D[LPXPQRLVHP9SHDNWRSHDNIRURXWSXW

TRANSDUCERINPUTPOWER:

noise. Power consumption: 100 mAmaximum.

133% Full Scale.

0.5% to 100% Full Scale / 200:1.

OPERATING

None.

0 to 100% (Non-Condensing).

9 to26Vdc,150mVmaximumpeaktopeakoutput

Circuit boards have built-in polarity reversal protection, and a 300mA resettablefuse

provides power input protection.

DIGITAL OUTPUT SIGNALS:Standard RS-232 or RS-485 (user-selected).

Optional Modbus over isolated RS-485 transceiver

:(77('0$7(5,$/66WDLQOHVVVWHHO9LWRQ2ULQJVKLJKWHPSHUDWXUH

SRO\DPLGHDOXPLQDFHUDPLFHSR[\VLOLFRQHJODVVJROG

CAUTION:

corrosion resistance of mass flow meters as pertains to different

flow media reacting with any components of the meters. It is solely

the customer’s responsibility to select the model best suited for a

particular gas, based on the fluid contacting (wetted) materials

offered in the different models.

Aalborg® makes no expressed or implied guarantees of

.

13

Page 16

INNLL

E E

T T

1/8"

AANND OOUUTTLL

NPT

E E

TT

CCOO

NNNNEECCTTIIOONNSS

:: DPM04/07

10-32

female

thread, DPM14/17/37

female thread, DPM24/34/47 1/4" NPT female thread , DPM44/57 1/2" NPT

female thread, DPM54/67/77 3/4" NPT female thread for user-supplied fittings.

DISPLAY: Optional 128 x 64 pixels graphic yellow OLED with Esc button and

Joystick interface. Simultaneously displays: Mass Flow, Totalizer Volume,

Pressure and Temperature or Mass Flow, Volumetric Flow, Pressure and

Temperature (user-selectable screens).

5..11

CCEECommpp

lliiaannccee

EMCCompliancewith2004/108/ECas amended. CISPR11

Emission Standard: EN61000-6-3, Group 1, Class A

Immunity Standard: EN61000-6-1, IEC EN 61000-4-2, IEC EN 61000-4-3

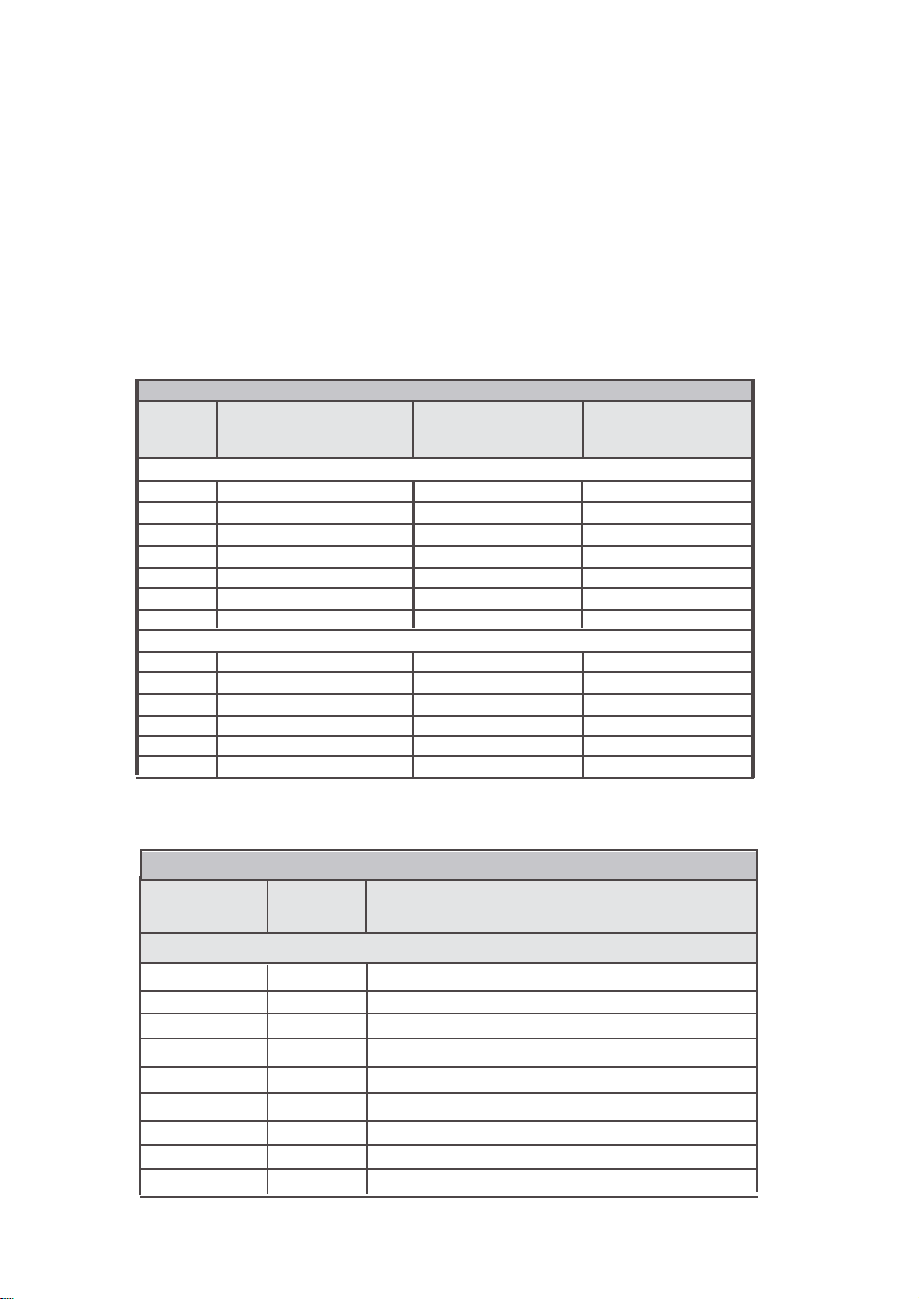

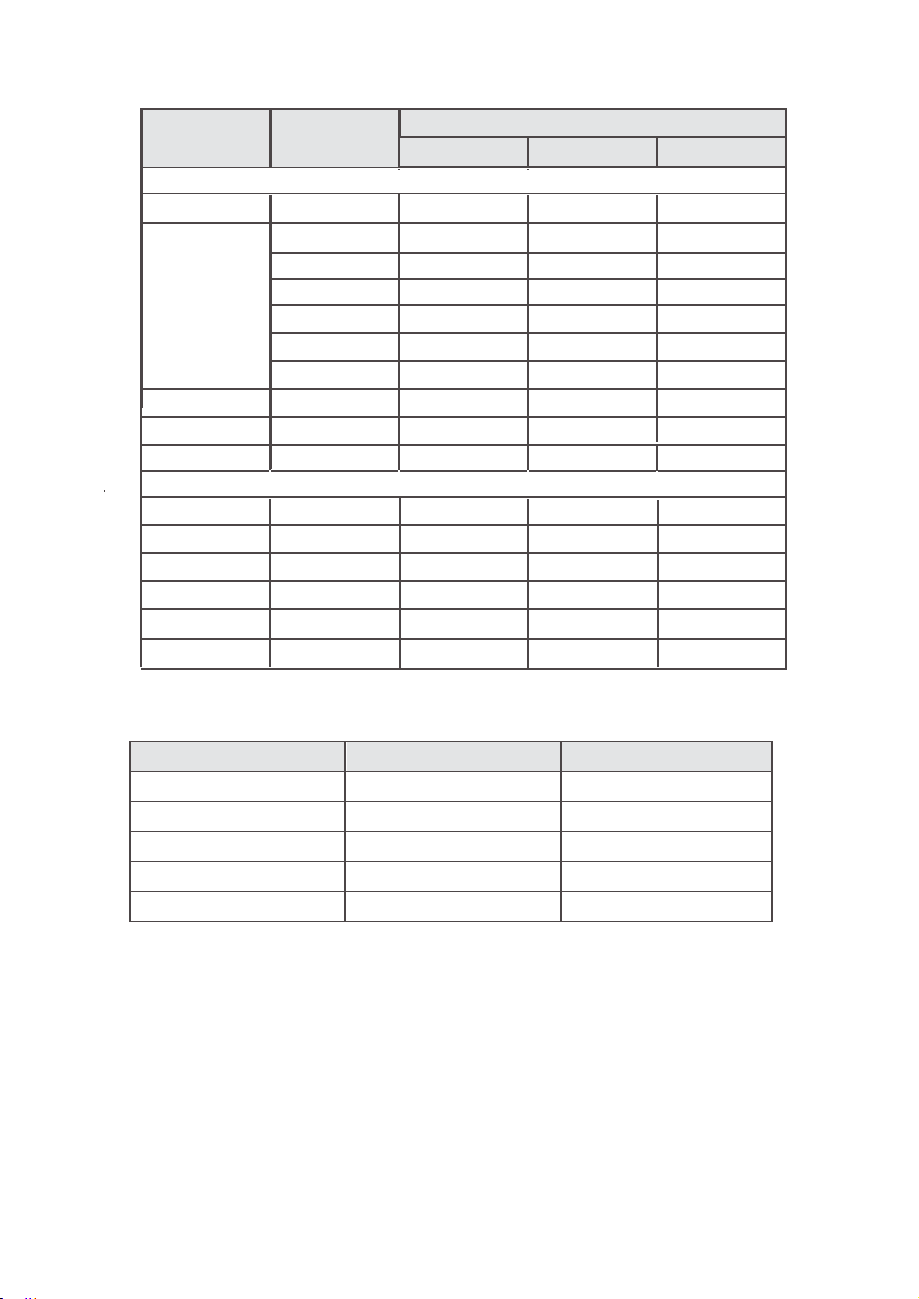

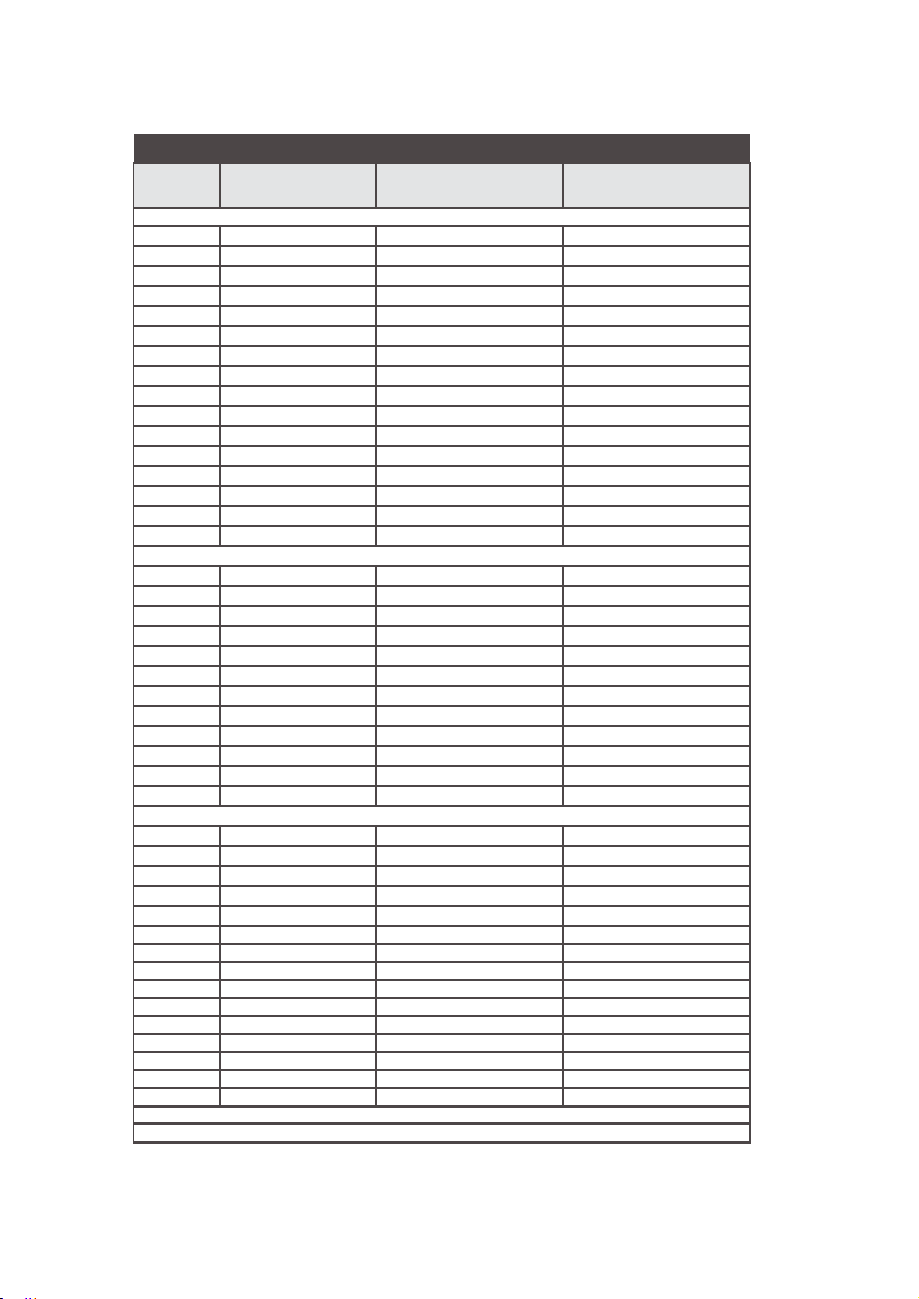

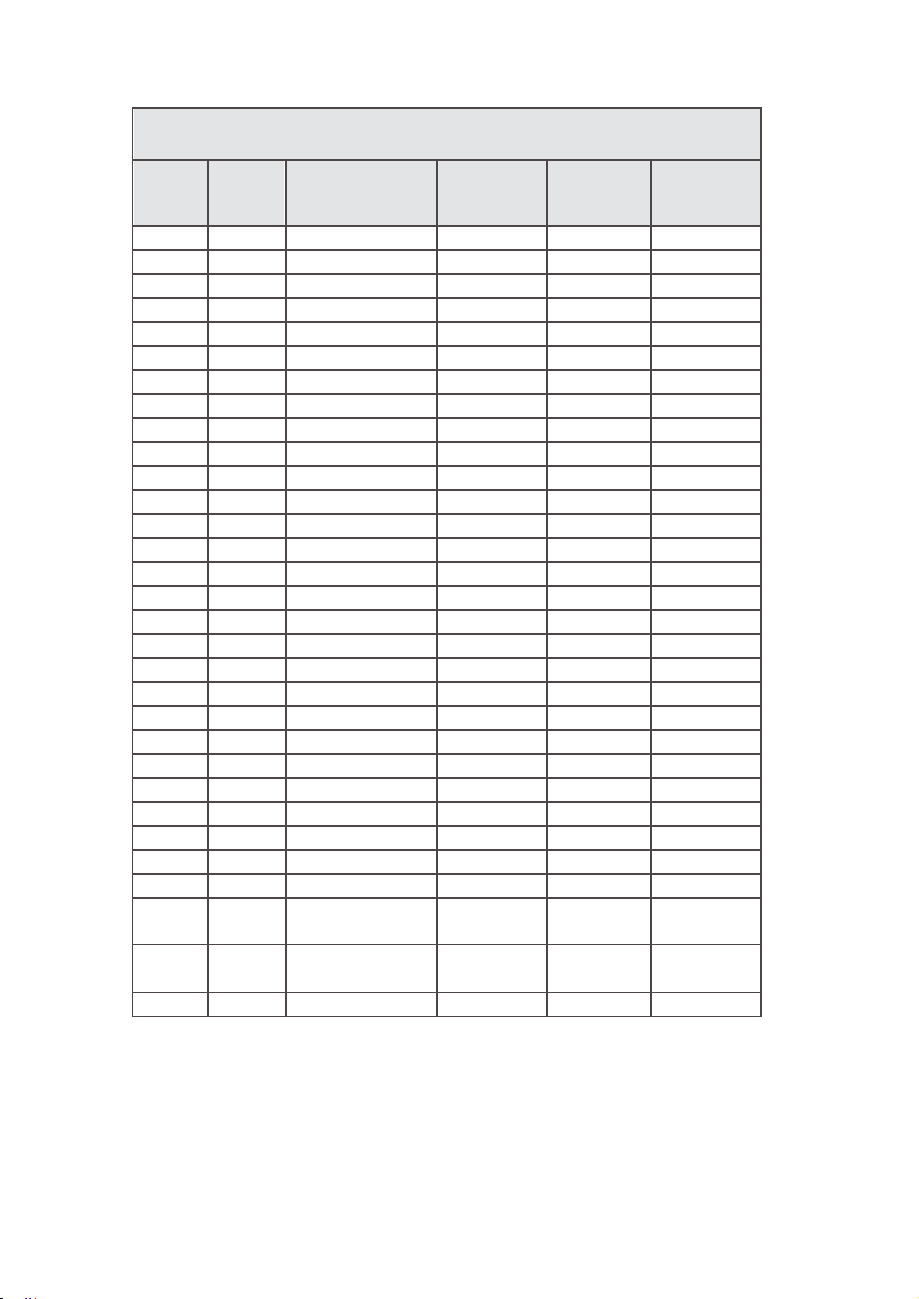

TABLE II: DPM FLOW RANGES

MODEL

NO.

DPM07

DPM17

DPM37

DPM47

DPM57

DPM67

DPM77

DPM04

DPM14

DPM24

DPM34

DPM44

DPM54

FULL SCALE MASS

FLOW RATE

STANDARD PRESSURE DROP [AIR]

0.5 to 50 sml/min

51 sml/min to 20 sl/min

21 sl/min to 50 sl/min

51 sl/min to 100 sl/min

101 sl/min to 250 sl/min

251 sl/min 500 sl/min

501 sL/min to 1000 sL/min

DPM (BREEZETM) LOW PRESSURE DROP [AIR]

0.5 smL/min to 20 smL/min

21 smL/min to 2 sL/min

2.1 sL/min to 10 sL/min

10.1 sL/min to 20 sL/min

20.1 sL/min to 40 sL/min

40.1 sL/min to 100 sL/min

PRESSURE DROP

AT FULL SCALE

FLOW (PSID)

1.0

1.0

2.0

2.5

5.5

5.5

7.0

0.06

0.07

0.085

0.3

0.15

0.25

PROCESS

CONNECTION

10-32 Female Thread

1/8" NPT Female

1/8" NPT Female

1/4" NPT Female

1/2" NPT Female

3/4" NPT Female

3/4" NPT Female

10-32 Female Thread

1/8" NPT Female

1/4" NPT Female

1/4" NPT Female

1/2" NPT Female

3/4" NPT Female

5..11

DPM Accessories

MODEL

NO.

DPM07 / 04

DPM07 / 04

DPM17 / 14

DPM17 / 14

D PM37 / 34

DPM24 / 34 / 47

DPM44 / 57

DPM54 / 67

DPM54 / 77

FITTING

CODE

F1C5

F2C5

F2C2

F2C4

F4C4

F4C6

F8C6

1210-1-12-316

1210-1-12-316

TABLE III: DPM ACCESSORY'S

DESCRIPTION

FITTINGS

10-32 Thread, 1/8" Tubing, Compression, 316 ss.

10-32 Thread, 1/8" Tubing, Compression, 316 ss.Nickel Plated Brass

1/8" NPT Thread, 1/8" tubing, Compression, 316 ss.

1/8" NPT Thread, 1/4" tubing, Compression, 316 ss.

1/4" NPT Thread, 1/4" tubing, Compression, 316 ss.

1/4" NPT Thread, 3/8" tubing, Compression, 316 ss.

1/2" NPT Thread, 3/8" tubing, Compression, 316 ss.

3/4" NPT Thread 3/4" tubing, Compression, 300 series ss.

3/4" NPT Thread 3/4" tubing, Compression, 300 series ss.

14

Page 17

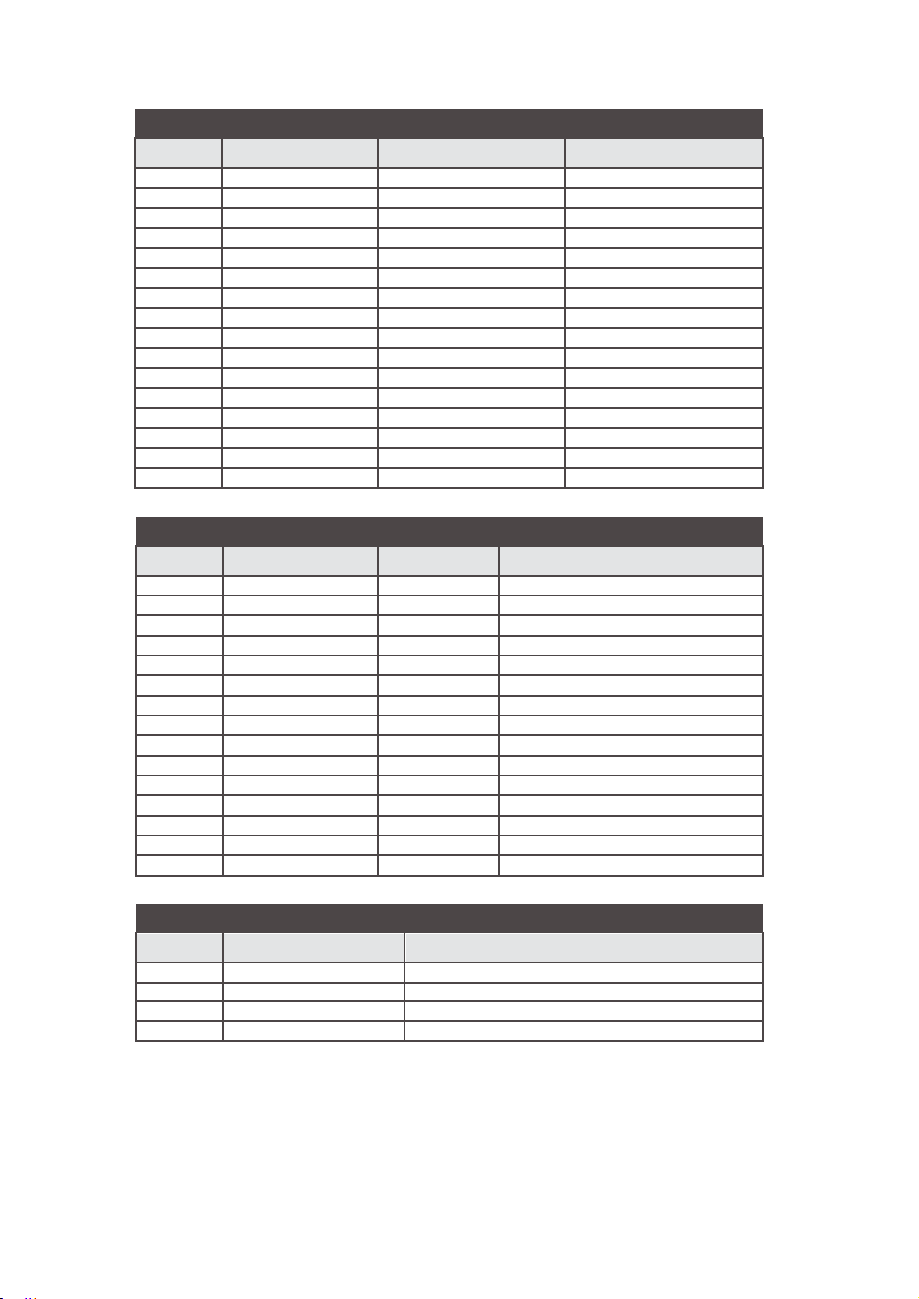

MODEL NO.

PS-GFM-110NA-2

PS-GFM-110NA-4

PS-GFM-230EU-2

PS-GFM-230EU-4

PS-GFM-240UK-2

POWER SUPPLIES

DESCRIPTI ON

Power Supply, 110 V / 12 Vdc / North America.

Power Supply, 110 V / 24 Vdc / North America.

Power Supply, 220 V / 12 Vdc / Europe.

Power Supply, 220 V / 24Vdc / Europe.

Power Supply 240 V / 12 Vdc / United Kingdom.

5..22

DDPPMAAcccce

CBL-A232

CBL-A485

CBL-8MINIDIN-3

CBL-8MINIDIN-12

USB-RS-232

USB-RS-485

ECS803-1

TDG1026-8C

MOD27T

JMOD4S-1

TRD815BL-2

TRD815BL-10

TRD815BL-25

TRD815BL-10

TRD815BL-25

ssssoorriiees

CABLES

Communication Cable for DPM with RS-232 Interface FT

3.5mm

stereo audio connector with 3-wire to 9-pin female

D-connector

Communication Cable for DPM with RS-485 Interface 3 FT

3.5m m

Shielded cable 8-pin Min-DIN with stripped ends 3 feet long

Shielded cable 8-pin Min-DIN with stripped ends 12 feet long

COMMUNICATION PORT ACCESSORIES

USB to RS-232 converter

USB to RS-485 converter

MODBUS INTERFACE ACCESSORIES

RJ45 shielded Y-adapter (Passive TAP).

RJ45 Modular Coupler.

RJ45 Line Terminator (100 ȍ0.25 W).

RJ45 Splitter fully shielded (5xRJ45, 1 input 4 outputs).

Category 5E Patch Twisted Pair Cable, RJ45 / RJ45, Blue 2.0 feet.

Category 5E Patch Twisted Pair Cable, RJ45 / RJ45, Blue 10.0 feet.

Category 5E Patch Twisted Pair Cable, RJ45 / RJ45, Blue 25.0 feet.

Category 5E Patch Twisted Pair Cable, RJ45 / RJ45, Blue 10.0 feet.

Category 5E Patch Twisted Pair Cable, RJ45 / RJ45, Blue 25.0 feet

(included with each DPM).

stereo audio connector with 3-wire to stripped ends.

15

Page 18

MOODDEELL

DPM 07/17

DPM 47

DPM 57

DPM 67

DPM 77

DPM04

DPM14

DPM24

DPM34

DPM44

DPM54

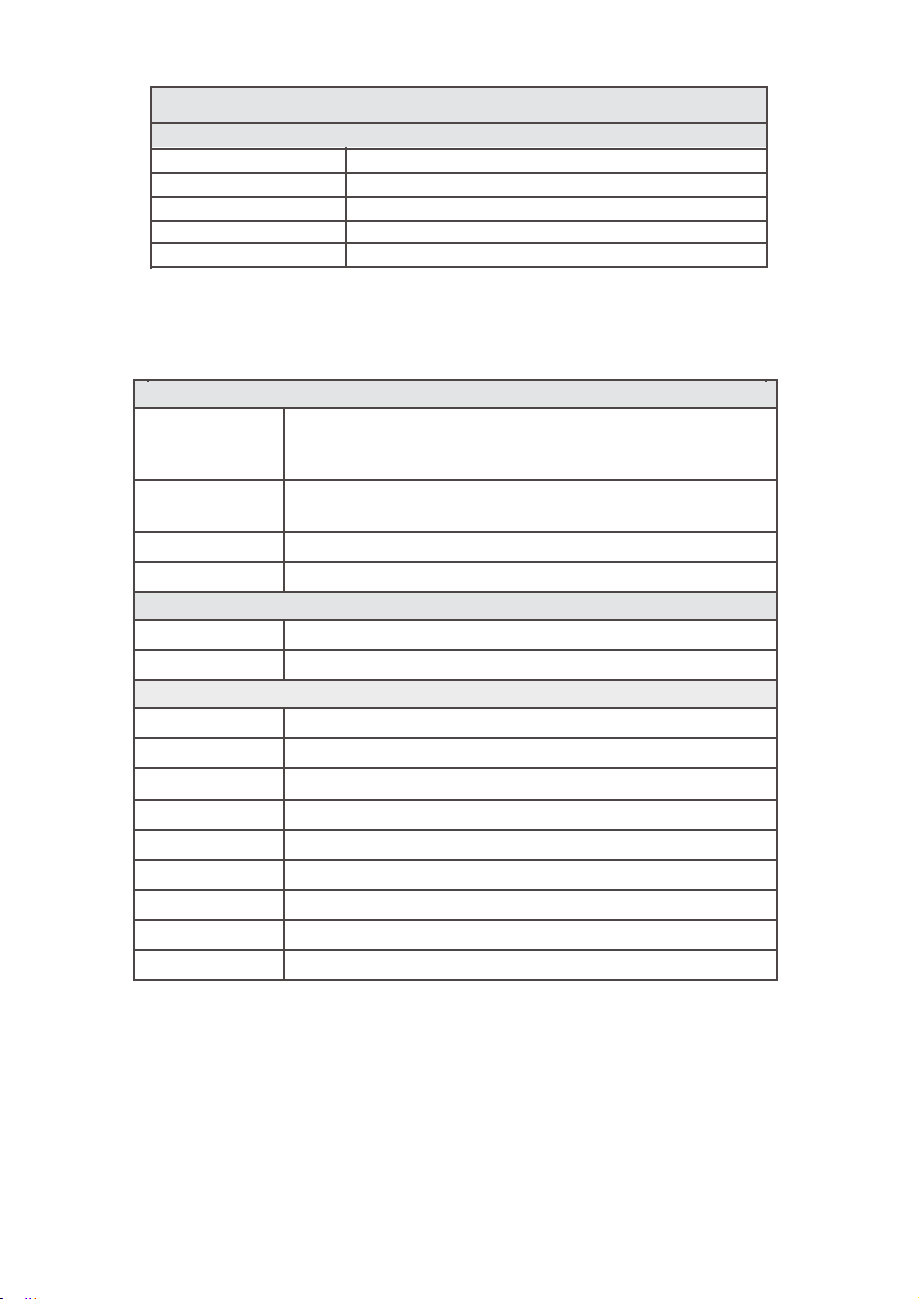

TABLE IV: PRESSURE DROPS

M

FLLOOWRRAATTEE

[ssttdll iitteerrss//mmiinn

STANDARD PRESSURE DROP [ AIR]

up to 10 703

100 1757 2.5 17.236

200

500

1000

DPM (BR EEZE) LOW PRESSURE DROP [AIR]

0.02

10

2 0

4 0

100

]

[

mmmm

20

30

40 1406 2.0 13.789

50 1406

60 1757

2

105.5

AAXXIIMMUUMM

H2O

] [

703 1.0 6.894

1406 2.0 13.789

TBD

TBD TBD TBD

TBD TBD TBD

42.2

49.2

59.8

210.9

175.8

PPRREESSSSUURREEDDRROOPP

ppssiidd

] [kkPPaa]]

1.0

2.0 13.789

2.5

TBD TBD

0.06

0.07

0.085

0.3

0.15

0.25

6.894

17.236

0.413

0.483

0.586

2.068

1.034

1.724

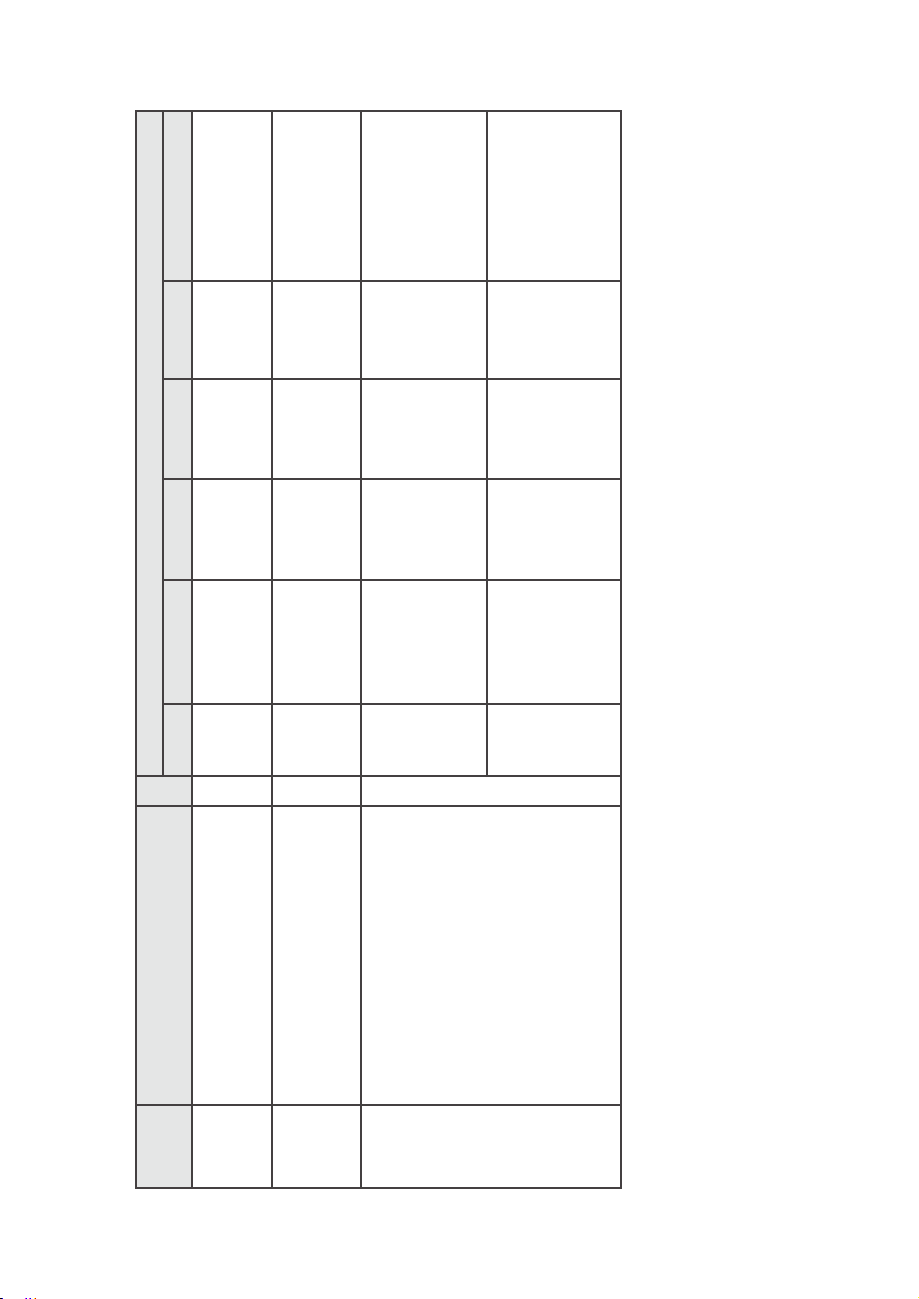

TABLE V: APPROXIMATE WEIGHTS

MOODDEELL WEEIIGGHH

DPM04/07/14/17 flow meter

DPM34/37/44/47 flow meter

DPM54/57 flow meter

DPM67 flow meter

DPM77 flow meter

6.

6..11

Now that the Mass Flow Meter has been correctly installed and thoroughly testedas

describedin

turnedon,theBannerScreenisshownfor 2 seconds (see Figure 4), then device

firmware and

communication interface type and hexadecimal address value on the second line,

Communication Port baud rate on the third line, andModbushardwarestatusand decimal

addressvalueonthefourthline (see

Subsequently, the actual process information (PI) is displayed.

OOPPEERRA

PPrreeppaarraattiioonaanndPPoo

TTIINNGGIINNSSTTRRUUCC

Section 2

, makesuretheflowsourceisOFF.Initially, afterthepower

EEPROM database revisions will be displayed on the first line,

0.85 lbs. (0.4 kg) 2.55 lbs. (1.2 kg)

1.15 lbs (0.52 kg) 3.0 lbs (1.36 kg)

3.5lbs (1.6kg) 5.1lbs (2.32kg)

4.5lbs (2.04kg)

5.2lbs (2.35kg)

wweerUU

Figure 5

T

TTIIOONN

SS

pp

). These areshownforanother

SHHIIPPPPIINNGWWEEIIGGHH

6.7lbs (3.04kg)

8.75lbs (3.97kg)

TT

is first

2 seconds.

16

Page 19

Fiigguurre

44::

DPPMMfirrsst BBaa

FFww:AA000011TTbbll::AA000011

CCOOMM::RRSS

BBaauuddRRaattee

MM

ooddBBuuss:

22332AAdddd::1111

:99660000

YAA

dddd::1111

nnnneerr SSccrreeee

nn

Fiigguurre55::

The main DPM flow meter screen shows current instrument Pressure, Temperature,

Mass Flow, and Totalizer Volume readings in previously selected units of measure.

DPPMMFF

ii rr

mmwwaarr

eeaa

nndCCoo

mmmm

uunniiccaattiioon

Absolute Pressing

Reading

PSIA

0.00

Current Mass Flow

Rate Reading

22.67

T1: 14726.0 Sml

Totalizer #1 Reading

Figure 6: DPM Initial Process Information

NOTE:

the model and device configuration.

NOTE:

the status LED will emit a constant GREEN light (normal operation,

ready to measure).

Actual content of the OLED screen may vary depending on

5 seconds after the initial powering of the DPM flow meter,

IInntteerffaaccee

27.7

Sml

min

IInnff

oormationSSccrreeee

Temperature

Reading

Current Unit of

C

Measure for

Mass Flo w

Totalizer#1

Units of

Measure

nn

6..22

If a flow of more than 133% the nominal maximum flow rate of the Mass Flow

Meter is taking place (displayed mass flow reading is flashing), a condition

known as "swamping" may occur. Readings of a "swamped" meter cannot be

assumed to be either accurate or linear. Flow must be restored to below 133%

of maximum meter range. Once flow rates are lowered to within calibrated

range, the swamping condition will end.

SSwwaa

mmppiinn

ggCCoonnddiittiioo

n

17

Page 20

6..33

MMeetteerPPrrooccee

sssIInn

ffoorrmm

aattiioon((PPII))ss

ccrr

eeenns

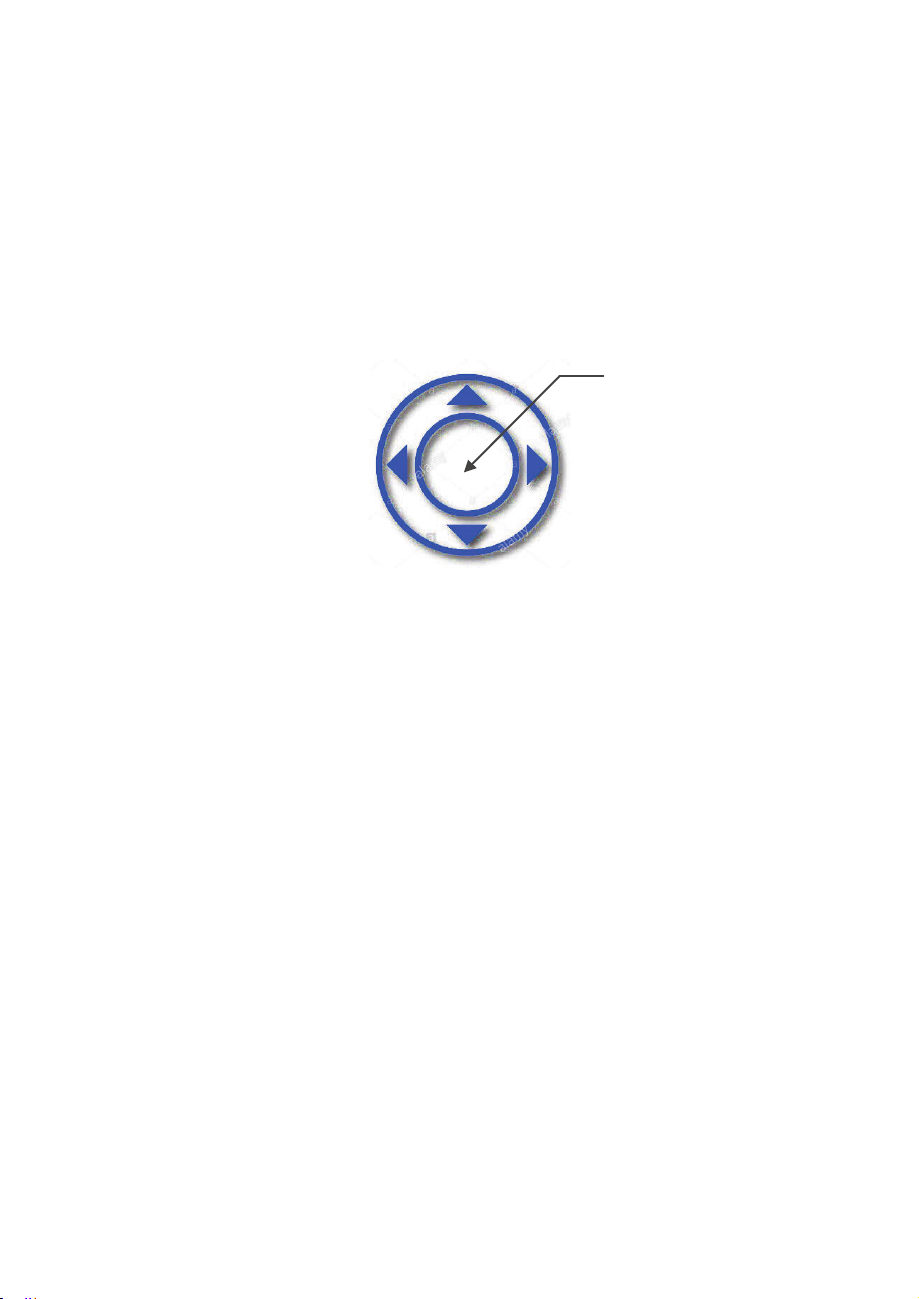

Based on meter configuration, different parameters may be displayed in the

Process Information (PI) screen by moving the control joystick (see Figure

7) Up or Down (DN). Process Information screens can be configured to be

static or dynamic (see Section 6.4.13.2 “Display and Process Information

(PI) Screens”). Using PI Screen Mask settings, the user can enable

(unmask) or disable (mask) up to 6 different process information

combinations.

UP

LEFT

Press here for

Enter command

RIGHT

DOWN

FIGURE 7: JOYSTICK

In the Static Mode, moving the joystick Up pages through the PI screens in

the forward direction, while moving the joystick DN pages through the PI

screens in the reverse direction. When the last PI screen is reached, the

firmware “wraps around” and scrolls to the initial PI screen once again.

In the Dynamic Display Mode, the firmware initiates automatic screen

sequencing with user-adjusted screen Cycle Time (see Section 6.4.13.2

“Display and Process Information (PI) Screens”). When the last PI screen is

reached, the firmware “wraps around” and scrolls to the initial PI screen

once again.

18

Page 21

PSIA

222..7777

0..000

T

11::144772266..00Sm

255..7

PI Screen #1 (Pressure, Temperature,

C

Mass Flow Rate, Totalizer #1)

Smmll

miinn

l

Com. Interface type

and device address

Analog Interface Type

Flow, Pressure,

Temperature

Alarms Status

Totalizers Status

Alarm Events Status

Register

PSIA

222..7777

255..5

Smmll

0..000

T

22::0..00Sm

222..7777

PSIA

miinn

244..5

Smmll

0..000

V

::0..00mll//mmiin

miinn

AAIIR

FFSS:00..22000000LL//mmiin

RRSS

22332

00

--55VV

ddccMMooddbbuuss::

PPOOWWEERR

::1199..66HHrr

AAllmm::DDDDD RReell::D

TT

11::DD TT22::EE PPOO::DD

A

EE

::00000000DDEE

::0000000

PI Screen #2 (Pressure, Temperature,

C

Mass Flow Rate, Totalizer #2)

l

PI Screen #3 (Pressure, Temperature,

C

Mass Flow Rate, Volumetric Flow Rate)

PI Screen #4 (Selected Gas, Instrument

Full Scale Range, Interface Information)

Currently Selected Gas Name

Instrument Full Scale Range

YY

Modbus interface H/W status (Y, N)

PI Screen #5 (Events Notification screen)

Time elapsed from the power up event

Relay assignment

Pulse Output Status

Diagnostic Events Status Register

PI Screen #6 (Instrument Diagnostic)

DP Sensor Raw Counts

AP Sensor Raw Counts

DP Sensor reading mBar

Temperature Sensor

Raw Counts

FIGURE 8: DPM PROCESS INFORMATION SCREENS

DD

::11664433553399001

AA::--

44110066337

DDPP

:00..00005

T:226688335

00..00000011

2244..8833

88998

19

DP Sensor Temperature Raw Counts

AP Sensor Temperatur e Raw Counts

DP sensor reading in PSID

CC

Temperature Sensor Reading (deg.C)

Page 22

6..44

LLooccaalUUsseerrIInntteerrffaacc

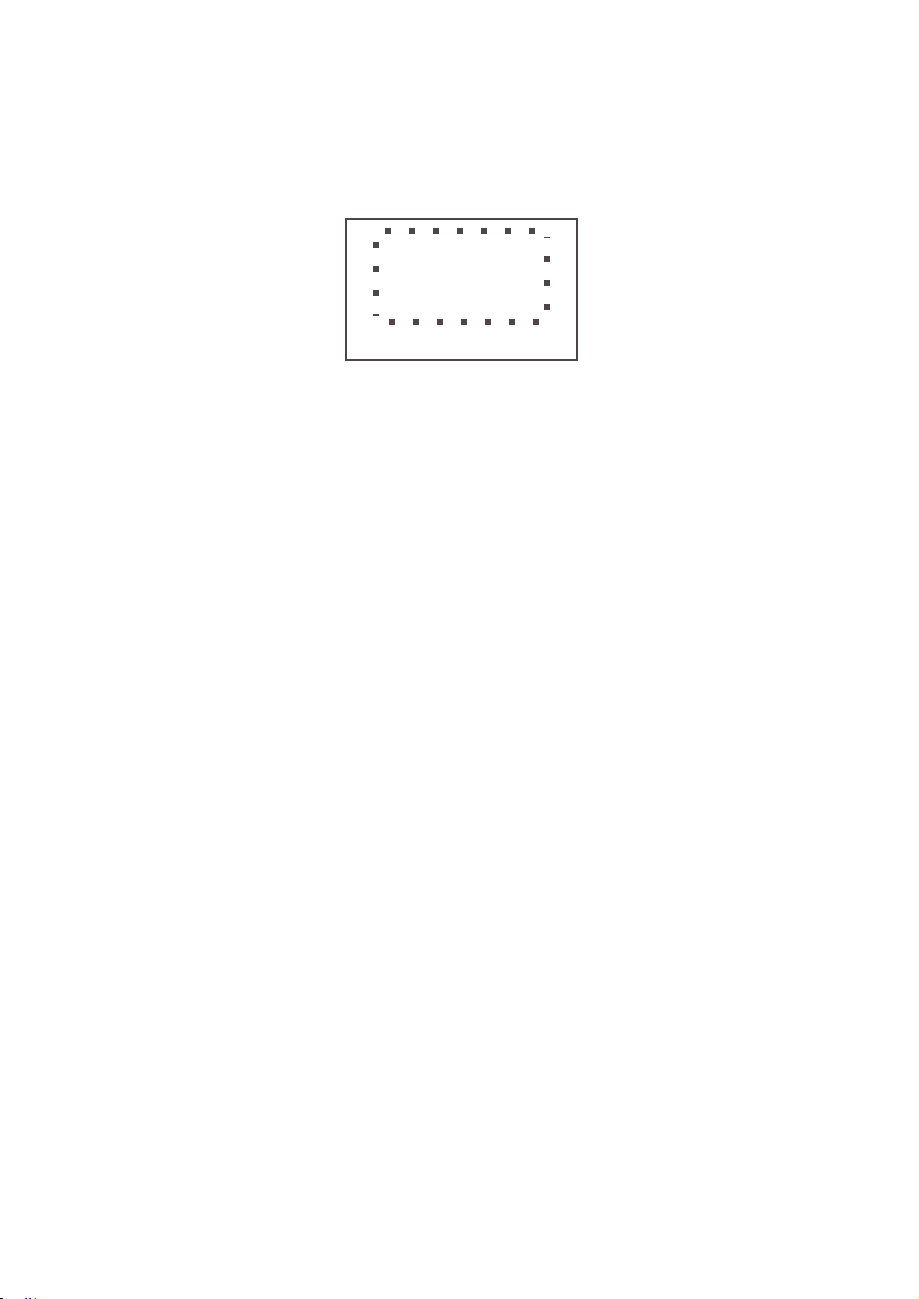

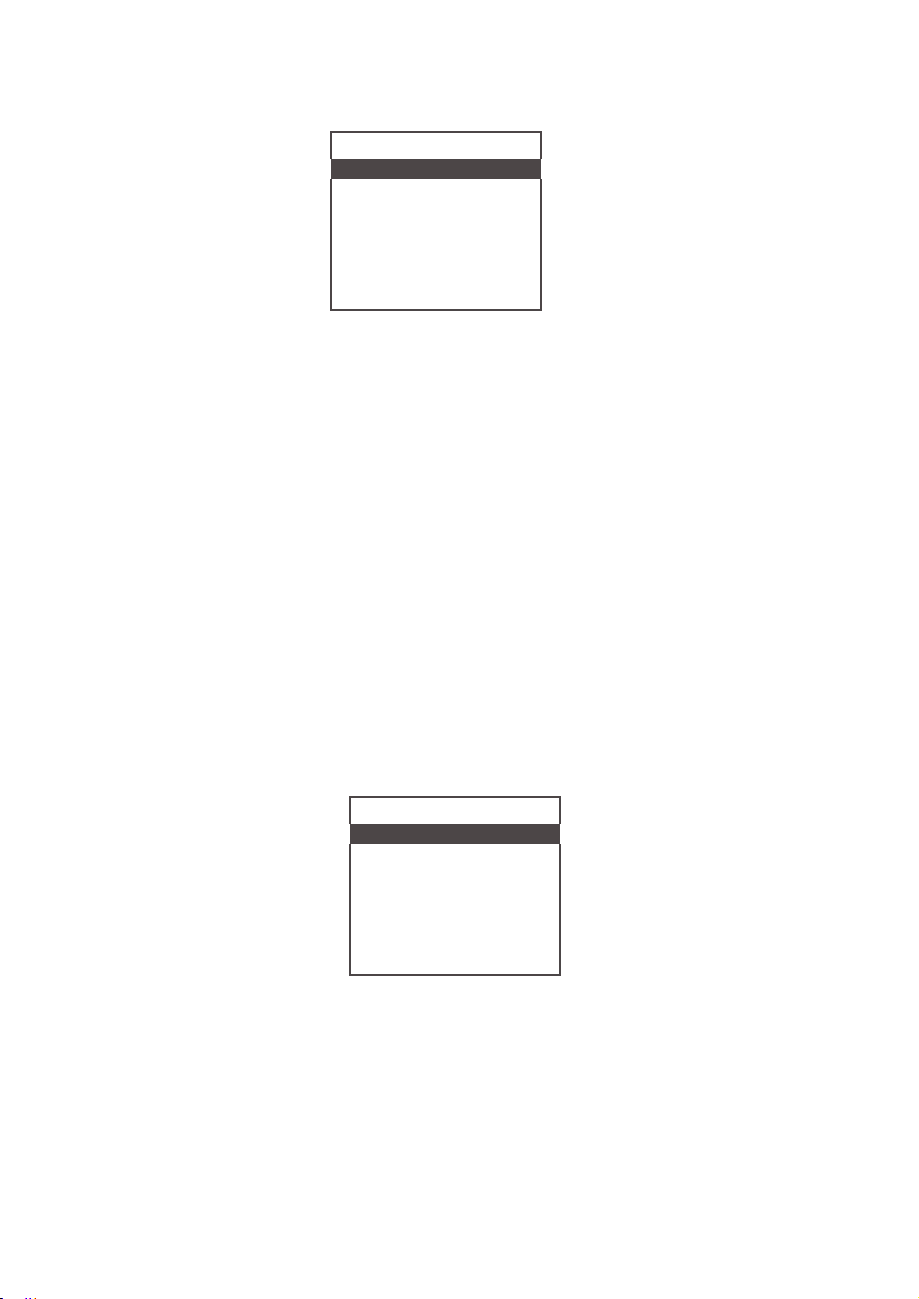

The diagram in Figure 13 gives a general overview of the standard top-level

display menu structure (when running firmware version A001). The Esc

push-button is used to toggle between the Process Mode (PI screens) and

the Setup menus, and to return to upper menu level.

In order to move through the menu items, the user must move the joystick

UP and DN. When the last item in the menu is reached, the menu “wraps

around” and scrolls back to the beginning of the menu items list. Similarly,

when the first menu item is highlighted and the joystick is moved UP, the

menu “wraps around” and scrolls down to the end of the menu item’s list. In

order to select the desired menu item, the user must press the joystick

down (this action is equivalent to the Enter button). To go back to upper

menu level, the user must press the Esc button.

All process configuration parameter settings are password-protected. In

order to access or change them, Program Protection (PP) should be

disabled. Each time the device is powered up, the Program Protection is

enabled automatically. By default, the device is shipped from the factory

with the Program Protection (PP) password set to Zero (PP Disabled). If the

PP password is set to Zero (Disabled), entering a PP password is not

required. A subsequent screen will appear and the Program Protection

menu item will be selected:

Fiigguurre

eMMee

nnuuSS

ttrruuccttuurr

PRR

OOGG

RRAAMMPPRROOTTEECCTTIIOONN

E

NNAABBLLEE

DIISSAABBLLEE

uusshUUpp,,DDn

P

settttiinngg,,EEnn

seettttiinngg,EEssc

9: Program Protection Screen

tt

oocchhaanngg

t ttooSSaavv

ttooEExxii

:

DD

D

ee

ee

tt

e

Moving the joystick DN to select the Disabled option and then pushing the

joystick (ENT) to save settings will disable program protection.

If the PP password is set to any value more than Zero, the firmware will

prompt with “Enter Program Protection Password” (see Figure 10).

Enntteerr PPrr

ooggrraamPPrrootteeccttiioonn

Paasssswwoorrdd::

P

uusshUUpp,,DDn

seettttiinngg,EEnn

seettttiinngg,EEssc

Figure 10: Program Protection Password Screen

The user must enter up to 3 digits for the program protection code, in order

to be able to access password protected menus.

tt

oocchhaanngg

t ttooSSaavv

ttooEExxii

ee

ee

tt

20

Page 23

NOTE:

Program Protection (PP) password set to Zero (PP Disabled).

Once the correct password is entered, the Program Protection is turned off

until the unit is powered up again.

By default, the device is shipped from the factory with the

6..44..11PPaarraammeetteerEEnnttrr

There are two methods of data entry:

x Direct numerical entry.

x Tabular Input from a menu.

If the menu with direct numerical entry is selected, move the joystick UP or DN

to increase or decrease digit value between 0-9. Move the joystick RIGHT or

LEFT to move the cursor to another digit position. When the desired value is

entered, use joystick equivalent of an ENT button to accept (to be saved in the

EEPROM) the new value

NOTE:

acceptability. If data is not acceptable, it is rejected and a message

is generated to indicate that the new data has not been accepted.

If the menu with tabular entry is selected, the available menu options can be

set using the joystick UP and DN positions and are accepted by pressing the

joystick equivalent of an ENT button.

6..44..22

In order to get access to “Change Program Protection (PP) Password”

menu, Program Protection must be disabled. If PP password is set to Zero

(Disabled), entering PP Password is not required and PP can be disabled

from “Program Protection” menu (see Figure 9). If PP Password is set to

any value more than Zero, the firmware will prompt with “Enter Program

Protection Password” (see Figure 10). The user must enter a program

protection code (up to 3 digits). If the PP password is lost or forgotten,

contact the factory or your distributor.

During data entry, the input values are checked for

SSuu

bbmmeennu““CChhaannggePPPPPPaasssswwoorrdd

y

.

”

Once the “Change PP Password” menu is selected, the following screen will appear:

OOlld

PPPPPPaasssswwoorrdd:

NNeew

PPPPPPaasssswwoorrdd:

EEnntteer OOlldPPPPPPaasssswwoorrdd

Figure 11: Change PP Password Screen

21

Page 24

In order to protect device configuration parameters when changing the PP

password, the old PP password must first be entered.

Once old and ne w passwords are ent ered, the firmwa re will prompt wit h a

confirmation

message (see

Figure 12: PP Password Change Confirmation Screen

Figure 12

) that thenew password hasbeen saved:

Neeww

PPPPPPaasssswwoorrdd

h

aa

ssbb

eeee

nnssaavveed

PP PPaasssswwoorrddiissCChhaannggeed

..44..33SSuu

6

This submenu contains information about the device’s main configuration parameters.

These items are informational only, not password-protected, and cannot be changed

(read only).

6..44..44

Use the “Units of Measure" Menu to navigate to Measuring Units settings for

Mass Flow, Volumetric Flow, Pressure, and Temperature readings. This option

allows configuration of the flow meter with the desired units of measurement.

These are global settings and determine what appears on all Process

Information screens and in all data log records. Units should be selected to

meet your particular metering needs. A total of 44 different mass-based

engineering units (Standard, Normal and True Mass) are supported (see Table

VI). A total of 15 different volumetric flow rate units are supported (see Table

VII).

Supported Pressure units of measure are listed in Table VIII, and Supported

Temperature units of measure are listed in Table IX.

bbmmeennu““DDeevviicceIInnffoorrmm

SSuu

bbmmeennu““UUnniitt

ssooff

aattiioonn””

MMeeaassuurree””

22

Page 25

TABLE VI: LIST OF SUPPORTED MASS FLOW UNITS OF MEASURE

USER DEFINED

44 USER U

U

d

Number

1

2

3

4

5

6

7

8

9

10 Sm3/min Sm3

11 Sm3/hr Sm3

12 Sm3/day Sm3

13 Sf3/sec Sf3

14 Sf3/min Sf3

15 Sf3/hr Sf3

16 Sf3/day Sf3

17 gr/sec gr

18 gr/min gr

19 gr/hr gr

20 gr/day gr

21 kg/min kg

22 kg/hr kg

23 kg/day kg

24 lb/min lb

25 lb/hr lb

26 lb/day lb

27

28 oz/min

29 NuL/min NuL

30 NmL/sec NmL

31 NmL/min NmL

32 NmL/hr NmL

33

34 NL/min

35 NL/hr

36 NL/day

37 Nm3/min Nm3

38 Nm3/hr Nm3

39 Nm3/day Nm3

40 Nf3/sec Nf3

41 Nf3/min Nf3

42 Nf3/hr Nf3

43 Nf3/day Nf3

Mass Flow Rate

Units

%FS

SuL/min

SmL/sec SmL

SmL/min SmL

SmL/hr SmL

SL/sec SL

SL/min

SL/hr

SL/day SL Liter per day

oz/sec oz

NL/sec NL

Totalizer Volume Units

STANDARD

TRUE MASS

NORMAL

Description

%s

SuL

SL Liter per minute

SL Liter per hour

oz

NL Liter per minute

NL Liter per hour

NL Liter per day

Percent of Full Scale

Microliters per minute

Milliliter per second

Milliliters per minute

Milliliter per hour

Liter per second

Cubic meter per minute

Cubic meter per hour

Cubic meter per day

Cubic feet per second

Cubic feet per minute

Cubic feet per hour

Cubic feet per day

Grams per second

Grams per minute

Grams per hour

Grams per day

Kilograms per minute

Kilograms per hour

Kilograms per day

Pounds per minute

Pounds per hour

Pounds per day

Ounce per second

Ounce per minute

Microliters per minute

Milliliter per second

Milliliters per minute

Milliliter per hour

Liter per second

Cubic meter per minute

Cubic meter per hour

Cubic meter per day

Cubic feet per second

Cubic feet per minute

Cubic feet per hour

Cubic feet per day

23

serDefine

Page 26

TABLE VII: LIST OF SUPPORTED VOLUMETRIC FLOW UNITS OF MEASURE

Number

1

2

3

4

5

6

7

8

9

10 m3/min m3

11 m3/hr m3

12 m3/day m3

13 f3/sec f3

14 f3/min f3

15 f3/hr f3

16 f3/day f3

Number

1

2

3

4

5

6

7

8

9

10 inHgA inHg

11 mmHgA mmHg

12

13

14 TorrA torr Torr

15

Flow Rate Units

%FS

uL/min uL

mL/sec mL

mL/min mL

mL/hr mL

L/sec

L/min

L/hr

L/day

TABLE VIII: LIST OF SUPPORTED ABSOLUTE PRESSURE UNITS OF MEASURE

Pressure Units Name Short Name

PSIA

barA barA

mbarA mbar Millibar

hPaA hPaA

kPaA kPaA

MPaA MPaA

atm atm Atmosphere

g/cm2A gcm2

kg/cmA kgc2

cmH2OA

inH2OA

%FS %FS

Totalizer Volume Units

%s

L

L

L

L

psiA

Gram-force per square centimeter

Kilogram-force per square centimeter

cmH2

inH2

Pound per square inch

,QFKRIPHUFXU\>Û&@

Millimeter RIPHUFXU\>Û&@

&HQWLPHWHURIZDWHU>Û&@

,QFKRIZDWHU>Û&@

Percent of Full Scale

Description

Percent of Full Scale

Microliters per minute

Milliliter per second

Milliliters per minute

Milliliter per hour

Liter per second

Liter per minute

Liter per hour

Liter per day

Cubic meter per minute

Cubic meter per hour

Cubic meter per day

Cubic feet per second

Cubic feet per minute

Cubic feet per hour

Cubic feet per day

Description

bar

Hecto Pascal

Kilo Pascal

Mega Pascal

Number

1

2

3

4

TABLE IX: LIST OF SUPPORTED TEMPERATURE UNITS OF MEASURE

Temperature Units Label

Û) degree Fahrenheit

Û& degree Celsius

K

Û5

Description

Kelvin

degree Rankine

24

Page 27

NOTE:

may be based on the units selected. Once Flow Unit of Measure is

changed, the Totalizer’s Unit of Measure will be automatically updated.

Program the Measuring Units first because subsequent menus

6..44..55““SSuu

In addition to conventional flow units, user-defined flow engineering units

may be selected. Use the “Engineering Units and K-Factor” menu to

navigate to the “User-Defined Units” menu option. This option enables userdefined configuration of any engineering unit required for process

measurement.

The following three parameters are available for this function:

x UD Unit volume K-Factor (defined in Liters)UD Unit time base

x UD Unit use density (units with or without density support)

Before using the User-Defined Unit, be sure the proper conversion factor of

the new unit, with respect to one liter, is set. The default entry is 1.00 Liter.

Also, proper time-based values for User-Defined Units must be set.

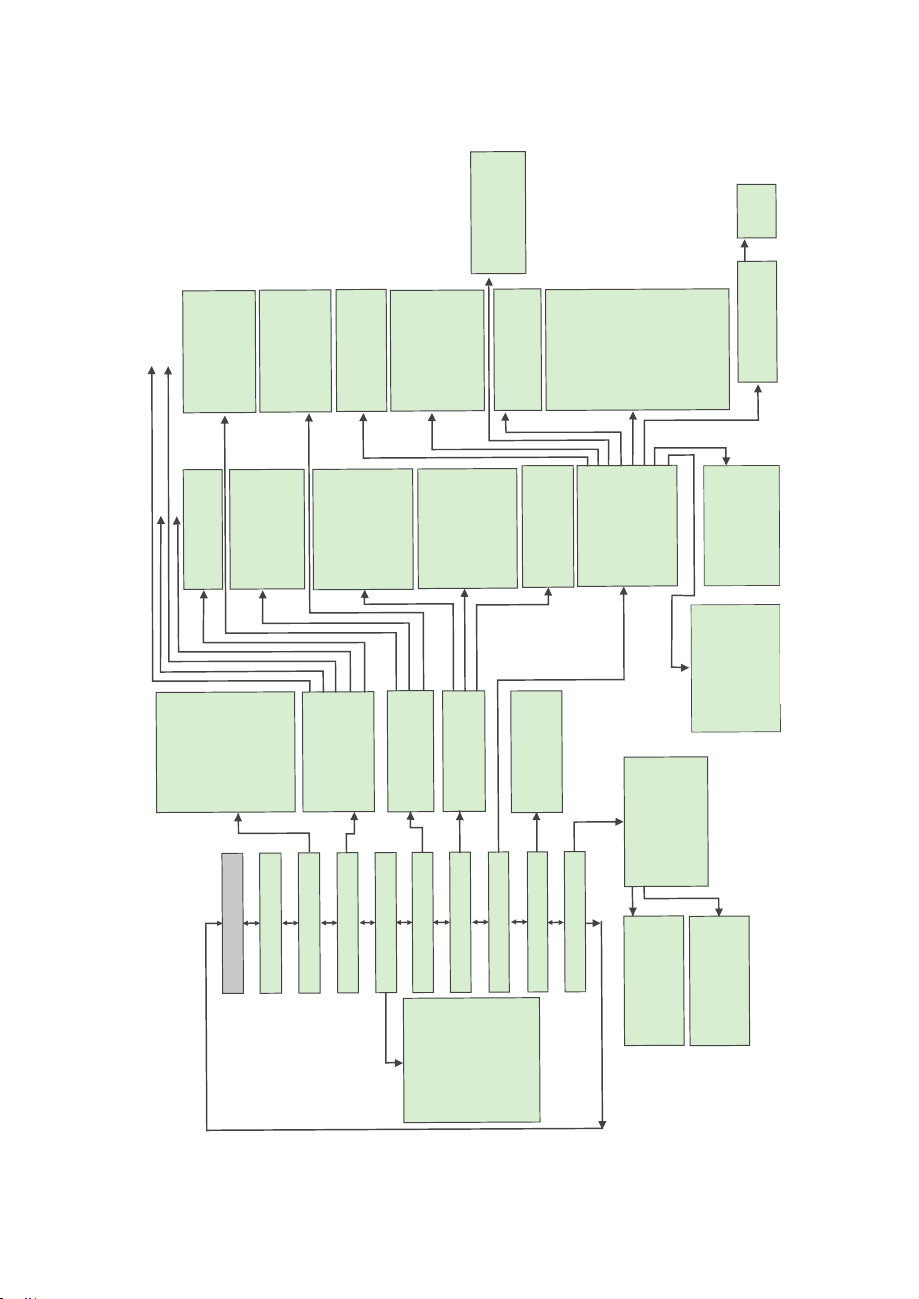

Figure 13 explains by diagram the various upper level display menus.

bbmmeennuuUUsseerr--DDee

(defined in Seconds)

fifinneedUUnniittss”

25

Page 28

Program Protaction (PP)

Change PP Password

Device Information

Units of Measure

Alarm Settings

Totalizers Settings

General

Settings

Select Gas

***** Main Menu *****

Alarm Event Menu

Diagnostic Events

Sensors ADC Reading

Temperature Sensors

AnalogOut & POQueue

Miscellaneous Param

Sensor Zero Calibr.

Tot

al

izer #1

Tot

al

izer #2

Pul

se Output

Gas Flow Alarm

Gas Pressure Alarm

Gas Temperature Alarm

Mass Flow

Volumetric Flow

Pressure

Temperature

User Defined Unit

Device ID & FS Flow

Analog/Com Interface

Firmware/EE Version

Flow Alarm Settings

Pressure Alarm Set.

Temp Alarm Settings

Totalizer#1 Settings

Totalizer#2 Settings

Pulse Outputs & LEDs

General Settings

Standard Temperature

Standard Pressure

Normal Temperature

Normal Pressure

Display Oper. Mode

Screen Cy

cle Ti

me

PI Screens Config.

OLED

Bright

nes

s

Screen Saver

Mode

OLED SS Time Out

OLED SS Brightness

Flow Rate Prec

ision

Baud Rate Settings

Dev

. ModBus Address

ModBus Com. Parity

ModBus Com. StopBit

Disabled

Low F. Alarm

High F. Alarm

F. Range H - L

Low P. Alarm

High P.

Alarm

P. Range H - L

Low T. Alarm

High T. Alarm

T. Range H - L

Tot

alizer #1 Event

Totali

zer #2 Event

Puls

e Output

Alarm Events

Diagnostic Events

Manual On

Totalizer #1 Mode

Tot#1 Flow Start

Tot#1 Action Vol.

Tot#1 PowerOn Delay

Tot#1 Auto Reset

Tot#1 AutoRes Delay

Reset Totalizer #1

Tot#1 DP Precision

Totalizer #2 Mode

Tot#2 Flow Start

Tot#2 Action Vol.

Tot#2 PowerOn Delay

Tot#2 Auto Reset

Tot#2 AutoRels Delay

Reset Totalizer #2

Tot#2 DP Precision

PulseOutput Mode

Pulse Flow Start

[Unit]/Pulse

Pulse Active Time

STP/NTP Units Cond

Display & PI Screens

Communication P

ort

ModBus Interface

Relay Assignment

Analog Output

Status LED Settings

Signal Conditioner

UD Unit K-Factor

UD Unit Time Base

UD Unit Use Density

Pressure Alarm Mode

Low Pressure Alarm

High Pressure Alarm

Pressure Alarm Delay

Pressure Alarm Latch

PA Power Up Delay

F

low Damping

Flow NLEF Mode

Pressure Damping

Pressure NLEF Mode

LCD Flow Average

Gas Temp. Damping

LCD Flow Dead Band

Recent Gases

Standard Gases

Bioreactor Gases

Breathing Gases

Chromatography Gases

Fuel Gases

Laser Gases

O2

Concen

trat

or

S

tack Gases

Welding Gases

Use Defined Mixture

Alarm & Diagnostic

A

larm Events Status

A

larm Events Mask Reg.

A

larm Events

Latch Reg.

Reset Alarm Events Reg.

Diag.

Events Status

Diag.

Events Mask

Reg.

Diag.

Events Latch Reg.

Reset Diag. Events Reg.

Start Auto Zero Now

Start AP Auto Tare

Vi

ewZeroParameters

Default Events

F. Alarm & Tot Events

Alarm Ev

ent

s

Diagnostic Events

Main Com. Interface

Modbus Interface

Analog Output Mode

Analog Output Cal.

Analog Output Test

0-5 Vdc

0-10 Vdc

4-20 mA

Temp. Alarm Mode

Low Temp. Alarm

High Temp. Alarm

Temp. Alarm Delay

TA Power Up Delay

Temp. Alarm Latch

Flow Alarm Mode

Low Flow Alarm

High Flow Alarm

Flow Alarm Delay

Flow Alarm Latch

FA Power Up Delay

UART Tranceiv Mode

Baud Rate Settings

RS-485 Bus Address

RS-485 Termination

See Table V,,I

See Table V,

See Table I;

See Table V,,

Figure 13 DPM Upper Levels Menu Structure

Page 29

6..44..66

The currently active gas can be selected by the user via OLED/joystick or digital communication

interface. The gas data are allocated in different gas groups (see

“Recent Gases” group keeps up to 16 recently selected gases. The detailed list of the gases for

each group is provided in Tables X through XVIII, beginning on the following page.

For example, to select Nitrogen, the user should navigate to “Select Gas”

then highlight “Nitrogen” and press the joystick equivalent of an

SSuu

bbmmeennu""SSeelleecctGGaass""

Recent Gases

Standard Gases

Bioreactor Gases

Breathing Gases

Chromatograpy Gases

Fuel Gases

Laser Gases

O2 Concentrator

Stack Gases

Welding Gases

User Defined Mixture

Figure 14: Selecting Gas Group

Figure 14

Ent

button.

below). The

Ö

“Standard Gases”,

27

Page 30

TABLE X: Standard Pure Non-Corrosive Gases

AA

ll lDDaattaa

ffoor SStaannddaarrddCC

Gaa

ss

S

Nuummbbee

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 Kr Krypton 24.839148

18

19

20

21

22

23

24

25

26

27

28 A1025

29 Star29

30

hhoorrtt

r

Naamm

e

Air Air 18.259686

Ar Argon 22.377244

CO2

N2

O2 Oxygen

He

CO Carbon Monoxide

C2H4 Ethylene

C2H6 Ethane

n-C4H10

i-C4H10

C3H8 Propane

D2

H2

N2O

CH4 Methane

Ne Neon

SF6 Sulfur Hexafluoride

Xe

C2H2 Acetylene

C25 25% CO2 / 75% Ar

C10 10% CO2 / 90% Ar

C8 8% CO2 / 92% Ar

C2 2% CO2 / 98% Ar

C75 75% CO2 / 25% Ar

He75 75% He / 25% Ar

He25 25% He / 75% Ar

P5 95% Ar / 5% CH4

LoonngNNaammee

Carbon Dioxide

Nitrogen 17.624584

Helium 19.668342

n-Butane 7.3072193

i-Butane 7.4018705

Deuterium 12.473107

Hydrogen 8.8198202

Nitrous Oxide

Xenon

90% He / 7.5%

Ar / 2.5% CO2

Stargon CS 90%

Ar/8%CO2/2%O2

oonnddiittiioonnss

A

bbssoolluutte

Viissccoossiitt

(μμPPaa--ss))

14.743078

20.3345

17.475804

10.187017 1.168818 0.99401503

9.2398038 1.255226 0.99208387

8.0415054 1.857567 0.98310908

14.654788

10.949931

30.847242

15.042726 6.121213 0.98816832

22.710043

10.334757

20.455223

21.609367 1.672811 0.99905731

21.762981

22.223694

16.611552

23.052769

23.043143

21.314678

21.730903

22.146573

((

770

°°FFaa

nnd 1144..669966

yy

0.16568373

0.16672796

0.083436355

0.66562262

0.83530908

0.53762966

0.31866435

PPSSIIAA

Deennssiittyyg/l

1.2000185

1.6555318

1.8322844

1.1604245

1.3261455

1.1604842

2.4852646

2.4755419

1.8332083

3.4779701

5.4674713

3.4606011

1.6988495

1.6693503

1.6589828

1.7870162

1.2822075

1.6627585

1.6060633

)

Coommpprreessssiibb

0.99963453

0.99932392

0.99473012

0.99976728

0.99930979

1.0004913

0.99959984

0.96854578

0.97234976

1.0005847

1.0005991

0.99430109

0.99816159

1.0004838

0.9978346

0.99450233

0.99244221

0.99859725

0.9991131

0.99927304

0.99639528

1.0005554

1.0000347

1.0005383

0.99911456

0.99928305

ii ll iittyy

28

Page 31

Gaa

ss

Nuummbbee

r

36 Bio-5M

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

S

hhoorrtt

Naamm

e

Bio-10M

Bio-15M

Bio-20M

Bio-25M

Bio-30M

Bio-35M

Bio-40M

Bio-45M

Bio-50M

Bio-55M

Bio-60M

Bio-65M

Bio-70M

Bio-75M

Bio-80M

Bio-85M

Bio-90M

Bio-95M

AA

ll lDDaattaa

ffoor SSttaannddaarrddCC

LoonngNNaammee

5%CH4 / 95%CO2

10%CH4 / 90%CO2

15%CH4 / 85%CO2

20%CH4 / 80%CO2

25%CH4 / 75%CO2

30%CH4 / 70%CO2

35%CH4 / 65%CO2

40%CH4 / 60%CO2

45%CH4 / 55%CO2

50%CH4 / 50%CO2

55%CH4 / 45%CO2

60%CH4 / 40%CO2

65%CH4 / 35%CO2

70%CH4 / 30%CO2

75%CH4 / 25%CO2

80%CH4 / 20%CO2

85%CH4 / 15%CO2

90%CH4 / 10%CO2

95%CH4 / 5%CO2

TABLE XI: Bioreactor Gases

oonnddiittiioonnss

((

770

°°FFaa

nnd 1144..669966

A

bbssoolluutte

Viissccoossiitt

yy

(μμPPaa--ss))

14.653659 1.7701352

14.559299 1.7147013

14.459421 1.6564349

14.353426 1.5978991

14.24079

14.120874 1.4809418

13.992953 1.4225176

13.856199 1.3641278

13.709659 1.3057712

13.55223

13.382616 1.1891512

13.1993

13.000513 1.0726464

12.784241 1.0144337

12.548154 0.95624539

12.289467 0.89808023

12.004793 0.83993679

11.690063 0.78181364

11.340435 0.72370939

PPSSIIAA

Deennssiittyyg/l

1.5394019

1.2474461

1.1308852

)

Coommpprreessssiibb

0.99498978

0.99523243

0.99544756

0.99567147

0.99588751

0.9960956

0.99629569

0.99648773

0.99667173

0.99684765

0.99701551

0.99717531

0.99732702

0.99747066

0.9976062

0.99773363

0.99785292

0.99796403

0.99806694

ii ll iittyy

29

Page 32

Gaa

ss

Nuummbbee

r

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

Gaa

ss

Nuummbbee

r

71 P-5

72 P-10

TABLE XII: Breathing Gases

AA

ll lDDaattaa

ffoor SStaannddaarrddCC

S

hhoorrtt

Naamm

e

EAN-32

EAN-36

EAN-40

HeOx-20 20%O2 / 80%He

HeOx-21 21%O2 / 79%He

HeOx-30 30%O2 / 70%He

HeOx-40 40%O2 / 60%He

HeOx-50 50%O2 / 50%He

HeOx-60 60%O2 / 40%He

HeOx-80 80%O2 / 20%He

HeOx-99 99%O2 / 1%He

EA-40

EA-60

EA-80

Metabol

S

hhoorrtt

Naamm

e

32%O2 / 68%N2

36%O2 / 64%N2

40%O2 / 60%N2

Enri Air-40%O2

Enri Air-60%O2

Enri Air-80%O2

Metabolic Exhalant

(16%O2 / 78.04%N2 /

5%CO2 / 0.96%Ar)

TABLE XIII: Chromatography Gases

AA

ll lDDaattaa

ffoor SStaannddaarrddCC

Loonng Nammee

5%CH4 / 95%Ar 22.146573 1.6060633

10%CH4 / 90%Ar 21.899835 1.5565932

Loonng

Naamm

oonnddiittiioonnss

e

((

770

°°FFaa

nnd 1144..669966

A

bbssoolluutte

Viissccoossiitt

yy

(μμPPaa--ss))

18.553594 1.2134468

18.665372 1.2200749

18.77622

21.160783

21.164401

21.120337

20.99441

20.851246 0.7451824

20.714981

20.499515 1.0934087

20.338992 1.3144914

19.15564

19.56039

19.953017 1.3009447

18.04915

oonnddiittiioonnss

((

770

A

bbssoolluutte

Viissccoossiitt

(μμPPaa--ss))

°°FFaa

y

PSSIIAA)

PPSSIIAA

Deennssiittyyg / l

1.2267031

0.39742666

0.40901481

0.51331687

0.62923199

0.86118182

1.2505528

1.2757473

1.2250145

nnd 1144..669966

Deennssiitt

)

yy

g / l

Compressibility

0.99961365

0.99959516

0.9995768

1.000575

1.0005744

1.0005531

1.0005002

1.0004169

1.0002995

0.99993193

0.99934879

0.99951725

0.9994476

0.99937862

0.99952679

Compressibility

0.99928305

0.99924058

30

Page 33

Gaa

Nuummbbee

74

75

76

77

78

79

80

81

82

83

84

T

TABLE XIV: Fuel Gases

AA

ll lDDaattaa

ffoor SStaannddaarrddCC

S

hhoorrtt

ss

rr

Naamm

e

SynG-1

SynG-2

SynG-3

SynG-4

NatG-1

NatG-2

NatG-3

Coal

Gas

Endo

HHO

HD-5

LoonngNNaammee

40%H2 / 29%CO /

20%CO2 / 11%CH4

64%H2 / 28%CO /

1%CO2 / 7%CH4

70%H2 / 4%CO /

25%CO2 / 1%CH4

83%H2 / 14%CO /

3%CH4

93%CH4 / 3%C2H6 /

1%C3H8 / 2%N2 /

1%CO2

95%CH4 / 3%C2H6 /

1%N2 / 1%CO2

95.2CH4 / 2.5%C2H6 /

0.2%C3H8 /

0.1%n-C4H10 /

1.3%N2 / 0.7%CO2

50%H2 / 35%CH4 /

10%CO / 5%C2H4

75%H2 / 25%N2

66.67%H2 / 33.33%O2

LPG 96.2%C3H8 /

1.5%C2H6 /

0.4%C3H6 /

1.9%n-C4H10

oonnddiittiioonnss

((

770

°°FFaa

nnd 1144..669966

A

bbssoolluutte

Viissccoossiitt

yy

(μμPPaa--ss))

15.253299 0.80779626

14.781416 0.44282577

14.725047

13.737274 0.25149803

11.020257 0.71638178

11.006305 0.69973554

10.99793

12.23411

13.712892 0.35247105

16.838285 0.49714469

8.0566953

PPSSIIAA

Deennssiittyyg / l

0.5672004

0.69890329

0.47642496

1.8596915

)

Coommpprreessssiibb

0.99952272

1.0003283

0.99990018

1.0005186

0.9979886

0.99804196

0.99804914

0.9988977

1.0005199

1.0004234

0.98305588

ii ll iitty

85

HD-10

LPG 85%C3H8 /

10%C3H6

/ 5%n-C4H10

8.060707 1.8793052

31

0.98275016

Page 34

Gaa

Nuummbbee

89

90

91

92

93

94

Gaa

Nuummbbee

99

100

101

AA

ll lDDaattaaffoorSSttaa

ss

S

hhoorrtt

r

Naamm

e

LG-4.5

LG-6

LG-7

LG-9

HeNe-9 9%Ne / 91%He 22.266969 0.22372402

LG-9.4

6%CO2 / 14%N2 / 80%He 19.810188

7%CO2 / 14%N2 / 79%He

9%CO2 / 15%N2 / 76%He 19.644085 0.46382218

9.4%CO2 / 19.25%N2 /

nnddaarrddCC

oonnddiittiioonnss((770°°FFaannd 1144..669966

Loonng

Naamm

e

4.5%CO2 / 13.5%N2 /

82%He

71.35%He

A

bbssoolluutte

Viissccoossiitt

yy

(μμPPaa--ss))

19.875867 0.37436617

19.76977

19.488366 0.51269615

TABLE XVI: O2Concentrator Gases

AA

TABLE XV: Laser Gases

ll lDDaattaaffoorSStaa

ss

S

hhoorrtt

r

Naamm

e

OCG-89

OCG-93

OCG-95

89%O2 / 7%N2 / 4%Ar

93%O2 / 3%N2 / 4%Ar

95%O2 / 1%N2 / 4%Ar

nnddaarrddCC

oonnddiittiioonnss((770°°FFaannd 1144..669966

Loonng

Naamm

e

A

bssoolluuttee

Viissccoossiitt

(μμPPaa--ss))

20.276364

20.373369

20.421571

yy

PPSSIIAA

)

Deennssiittyyg / l

0.4041824

0.42074815

PPSSIIAA

Deennssiittyyg / l

1.3277141

1.334345 0.99932581

1.3376605

Compressibility

1.0005373

1.0005193

1.0005058

1.0004745

1.0004795

1.0004588

)

Compressibility

0.99934333

0.99931705

Gaa

Nuummbbee

104

105

106

107

108

109

AA

ll lDDaattaa

ffoor SStaannddaarrddCC

ss

S

hhoorrtt

r

Namm

ee

FG-1

FG-2

FG-3

FG-4

FG-5

FG-6

7%O2 / 12%CO2 / 80%N2

13%O2 / 7%CO2 / 79%N2

Loonng

Naamm

2.5%O2 / 10.8%CO2 /

85%N2 / 1%Ar

2.9%O2 / 14%CO2 /

82.1%N2 / 1%Ar

3.7%O2 / 15%CO2 /

80.3%N2 / 1%Ar

/ 1%Ar

10%O2 / 9.5%CO2 /

79.5%N2 / 1%Ar

/ 1%Ar

oonnddiittiioonnss

((

770

°°FFaa

A

bbssoolluutte

Viissccoossiitt

(μμPPaa--ss))

nnd 1144..669966

Deennssiittyyg / l

yy

1.2415291

1.2635492

1.2715509

1.2569936

1.2452832

1.2335784

Compressibility

0.99938947

0.99927301

0.99923323

0.99932823

0.99940281

0.99947428

PPSSIIAA

)

e

17.553974

17.489167

17.484521

17.642257

17.781725

17.922258

32

TABLE XVII: Stack Gases

Page 35

AA

Gaa

Nuummbbee

114

115

116

117

118

119

120

121

122

123

124

125

126

127

ll lDDaattaaffoorSSttaa

ss

S

hhoorrtt

r

Naamm

e

C-2

C-8

C-10

C-15

C-20

C-25

C-50

C-75

He-25

He-50

He-75

He-90

A1025

Star29

10%CO2 / 90%Ar 21.609367

15%CO2 / 85%Ar 21.225138

20%CO2 / 80%Ar 20.840474

25%CO2 / 75%Ar 20.455223

50%CO2 / 50%Ar 18.525065

75%CO2 / 25%Ar 16.611552

90%He / 7.5%Ar /

Stargon CS 90%Ar /

nnddaarrddCC

oonnddiittiioonnss((770°°FFaannd 1144..669966

A

Loonng Naamme

2%CO2 / 98%Ar 22.223694

8%CO2 / 92%Ar 21.762981

25%He / 75%Ar 23.043143

50%He / 50%Ar 23.466653

75%He / 25%Ar 23.052769

90%He / 10%Ar 21.816616

2.5%CO2

8%CO2 / 2%O2

bbssoolluutte

Viissccoossiitt

yy

(μμPPaa--ss))

21.314678

21.730903

PPSSIIAA

)

Deennssiittyyg / l

1.6589828 0.99927304

1.6693503 0.9991131

1.672811 0.99905731

1.6814739 0.99891226

1.6901531 0.99875902

1.6988495 0.99859725

1.7426245 0.99764493

1.7870162 0.99639528

1.2822075 1.0000347

0.90972133

0.53762966

0.31445794

0.31866435

1.6627585 0.99911456

Compressibility

1.0004058

1.0005554

1.0005487

1.0005383

6.4.7 Submenu “User-Defined Mixture”

Submenu “User-Defined Mixture” allows the user to create and save up to 20

custom gas mixtures. Each gas mixture may have from 2 to 5 gases from

those listed in Tables X through XVIII.

TABLE XVIII: Welding Gases

A

Fiigguurre

ddddMMiixxttuurree::2200FFrr

115: :AA

dddMMiixxttuurreMMeennuuSSeelleeccttiioon

eeee

By default, the instrument has no preset mixtures in the memory, and there is

room for 20 user-defined mixtures (see Figure 15). Press the joystick

equivalent of an Ent button to assign a name to the new gas mixture (see

Figure 16). The flashing cursor with letter “A” will appear. Move the joystick

UP and DN to change letters and numbers. Once the desired letter (or

number) is set, use the joystick RIGHT command to move the cursor to the

next position. Use LEFT to toggle the letter case. Press the joystick equivalent

of Ent to save the gas mixture name.

33

Page 36

Enntteerr MMiixxttuurreNNaammee:

Å

y

M__i _x

_M_

1

__

UsseeItoCChhaannggeeCCaass

Prree

ssssEEnn

tt

WWhheennDDoonn

Figure 16: Assigning a Name to the Mixture

Once the gas mixture name is saved, the screen shown in

gas component for G1, press the joystick equivalent of an

a screen with a list of gases will appear.

ee

ee

Figure 17

Ent

will appear. To select the

button. As shown in

MyMix1 G:0 Tot: 0.00%

G1 0.00%

G2 0.00%

G3 0.00%

G4 0.00%

G5 0.00%

Save, Esc to Exit

Figure 17: Add Gas Component and Ratio

NOTE:

and Right and Left to switch between Gas Name and Ratio entry.

Use the joystick Up and Down to select another component,

Figure 18

,

G:AIR

Air

Ar Argon

CO2Carbon Dioxide

N2 Nitrogen

O2 Oxygen

He Helium

CO

Carbon Monoxide

Figure 18: Selecting Gas Component

NOTE:

gas. Press the joystick equivalent of Enter to select a gas.

Use the joystick Up and Down to highlight the required

34

Page 37

MyMix1 G:0 Tot:0.00%

G1 Ar

G2

G3

G4

G5

I

Save, Esc to Exit

Figure 19: G1 Component with Selected Gas

Once the gas is selected for component G1, the screen shown in Figure 19

will appear. To select the ratio for component G1, press Right. The screen

shown in the top of Figure 20 will appear. To start entering a ratio value in %,

press the joystick equivalent of Enter. The G1 component will appear at the

bottom of the screen, with a flashing cursor. The user can now enter the

desired ratio value for this gas, as shown second screen in Figure 20:

MyMix1 G:0 Tot: 0.00%

G1 Ar 0.00%

G2

G3

G4

G5

I

Save, Esc to Exit

0.00%

0.00%

0.00%

0.00%

0.00%

0.00%

0.00%

0.00%

0.00%

Ent

MyMix1 G:0

G1 Ar 0.00%

G2

G3

G4

G5

1Ar

Tot: 0.00%

0.00%

0.00%

0.00%

0.00%

10.00%

Figure 20: G1 Component with Highlighted Ratio Value

NOTE:

Use the joystick Up and Down to change numerical value,

and Left and Right to change cursor position. Once the required

ratio value is entered, press the joystick equivalent of Enter to

accept it.

35

Page 38

MyMix1 G:0 Tot: 10.00%

G1 Ar

G2

G3

G4

G5

I

Save, Esc to Exit

10.00%

0.00%

0.00%

0.00%

0.00%

MyMix1 G:0 Tot: 22.00%

G1 Ar

G2 He

G3

G4

G5

I

Save,EsctoExit

10.00%

12.00%

0.00%

0.00%

0.00%

MyMix1 G:0 Tot: 10.00%

G1 Ar 10.00%

G2 He 0.00%

G3 0.00%

G4 0.00%

G5 0.00%

1 He 12.00%

Figure 21: Mixture with 4 Components Ready to be Saved

Continue addi ng up to 5 gases, as required for your appl ication. See

example of a mixture of 4 components ready to be saved. The total mixture must be

100% to be accepted. An error message will appear if the user tries to save a mixture

that does not total 100%. When it is ready, press

will prompt with a

confirmation message (see

**************************

NEW MIXTURE

HAS BEEN SAVED

**************************

Press any key...

Figure 22: Mixture Saved Confirmation Message

Left

Figure 22

MyMix1 G:0Tot:100.0%

G1 Ar

G2 He

G3 CO2

G4 C2H4

G5

I

Save,Esc toExit

to save the mixture. The instrument

):

10.00%

12.00%

46.25%

31.75%

Figure 21

0.00%

for an

As directed in the above screen, press any button on the joystick to move

to the next screen. Now that the mixture has been saved, it will appear

in the “User-Defined Mixture” menu selection (see Figure 23):

36

Page 39

MyMix1

Add Mixture: 19 Free

Figure 23: “User-Defined Mixture” Menu Selection with new MyMix1 Mixture

Any saved mixture can be edited by the user. In order to edit a saved mixture,

highlight it using Up and Down and then pressing Left. The confirmation

message shown in Figure 24 will appear. Select “YES” then press the joystick

equivalent of Enter.

Edit MyMix1 Mixture?

NO

YES

Figure 24:""EEddiit MMiixxttuurree""MMee

In the edit mixture mode, the user can change the mixture name, any gas

component name, and any ratio value.

6..44..88

The DPM provides the user with a flexible Alarm warning system that monitors the Fluid Flow for

all conditions that fall outside configurable limits, as well as visual feedback for the user via the