Page 1

Embedded Controller AEC-6611

Compact Embedded Controller

AEC-6611

Intel

®

Atom™ N270 1.6GHz Processor

Dual LAN, 2 USB2.0, 4 COM, 1 VGA

AEC-6611 Manual 2nd Ed.

January 2011

Page 2

Embedded Controller AEC-6611

Copyright Notice

This document is copyrighted, 2011. All rights are reserved. The

original manufacturer reserves the right to make improvements to

the products described in this manual at any time without notice.

No part of this manual may be reproduced, copied, translated, or

transmitted in any form or by any means without the prior written

permission of the original manufacturer. Information provided in

this manual is intended to be accurate and reliable. However, the

original manufacturer assumes no responsibility for its use, or for

any infringements upon the rights of third parties that may result

from its use.

The material in this document is for product information only and is

subject to change without notice. While reasonable efforts have

been made in the preparation of this document to assure its

accuracy, AAEON assumes no liabilities resulting from errors or

omissions in this document, or from the use of the information

contained herein.

AAEON reserves the right to make changes in the product design

without notice to its users.

i

Page 3

Embedded Controller AEC-6611

Acknowledgments

All other products’ name or trademarks are properties of their

respective owners.

• Award is a trademark of Award Software International, Inc.

• CompactFlash

Association.

• Microsoft Windows

Corp.

®

• Intel

, Atom™ are trademarks of Intel Corporation.

• PC/AT, PS/2, and VGA are trademarks of International

Business Machines Corporation.

All other product names or trademarks are properties of their

respective owners.

™

is a trademark of the Compact Flash

®

is a registered trademark of Microsoft

ii

Page 4

Embedded Controller AEC-6611

Packing List

Before you begin operating your PC, please make sure that the

following materials are enclosed:

z 1 AEC-6611 Embedded Controller

z 2 Wallmount Brackets

z 1 Screw Package

z 1 CD-ROM for manual (in PDF format) and drivers

If any of these items should be missing or damaged, please contact

your distributor or sales representative immediately.

iii

Page 5

Embedded Controller AEC-6611

Safety & Warranty

1. Read these safety instructions carefully.

2. Keep this user's manual for later reference.

3. Disconnect this equipment from any AC outlet before cleaning. Do

not use liquid or spray detergents for cleaning. Use a damp cl oth.

4. For pluggable equipment, the power outlet must be installed near

the equipment and must be easily accessible.

5. Keep this equipment away from humidity.

6. Put this equipment on a firm surface during installation. Dropping

it or letting it fall could cause damage.

7. The openings on the enclosure are for air convection. Protect the

equipment from overheating. DO NOT COVER THE OPENINGS.

8. Make sure the voltage of the power source is correct before

connecting the equipment to the power outlet.

9. Position the power cord so that people cannot step on it. Do not

place anything over the power cord.

10. All cautions and warnings on the equipment should be noted.

11. If the equipment is not used for a long time, disconnect it from the

power source to avoid damage by transient over-voltage.

12. Never pour any liquid into an opening. This could cause fire or

electrical shock.

13. Never open the equipment. For safety reasons, only qualified

service personnel should open the equipment.

14. If any of the following situations arises, get the equipment

checked by service personnel:

a. The power cord or plug is damaged.

b. Liquid has penetrated into the equipment.

c. The equipment has been exposed to moisture.

iv

Page 6

Embedded Controller AEC-6611

d. The equipment does not work well, or you cannot get it

to work according to the user’s manual.

e. The equipment has been dropped and damaged.

f. The equipment has obvious signs of breakage.

15. DO NOT LEAVE THIS EQUIPMENT IN AN ENVIRONMENT

WHERE THE STORAGE TEMPERATURE IS BELOW -20°C

(-4°F) OR ABOVE 55°C (131°F). IT MAY DAMAGE THE

EQUIPMENT.

FCC

This device complies with Part 15 FCC Rules.

Operation is subject to the following two

conditions: (1) this device may not cause

harmful interference, and (2) this device must

accept any interference received including

interference that may cause undesired

operation.

Caution:

There is a danger of explosion if the battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the

manufacturer. Dispose of used batteries according to the

manufacturer’s instructions and your local government’s recycling or

disposal directives.

v

Page 7

Embedded Controller AEC-6611

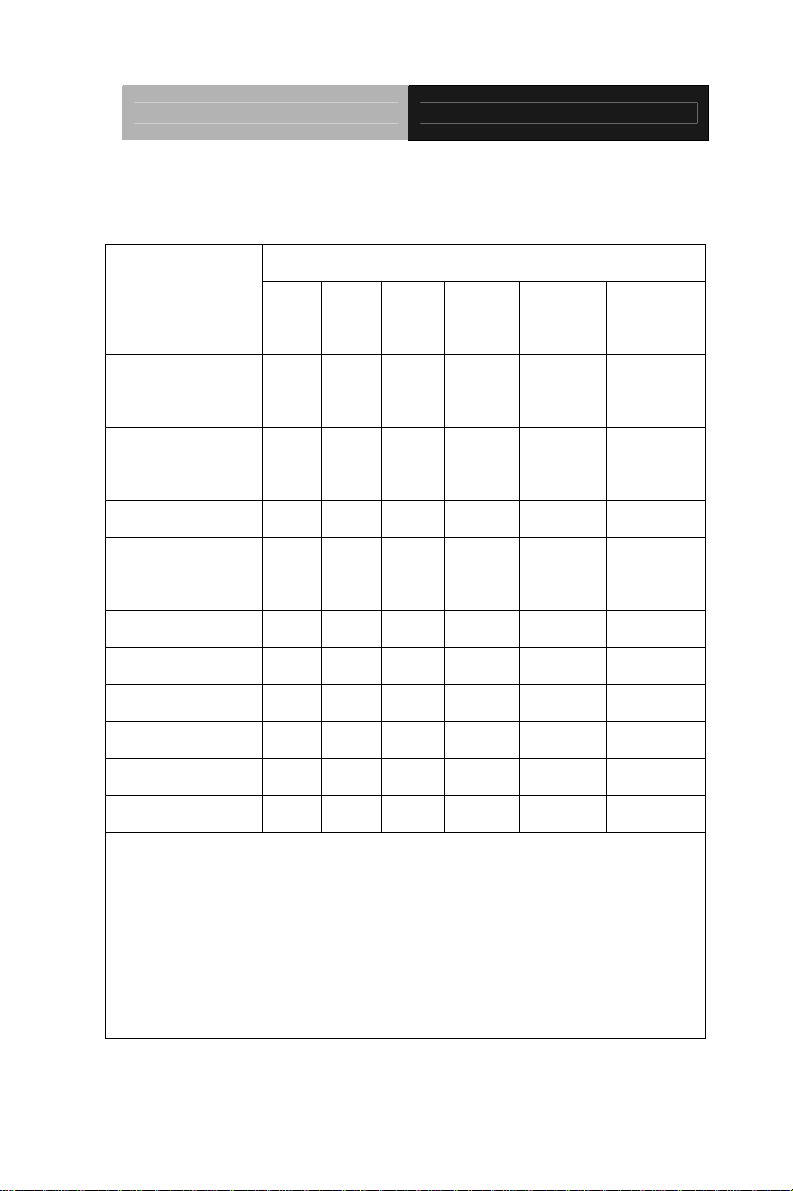

Below Table for China RoHS Requirements

产品中有毒有害物质或元素名称及含量

AAEON Boxer/ Industrial System

有毒有害物质或元素

部件名称

印刷电路板

及其电子组件

外部信号

连接器及线材

外壳 × ○ ○ ○ ○ ○

中央处理器

与内存

硬盘 × ○ ○ ○ ○ ○

电源 × ○ ○ ○ ○ ○

O:表示该有毒有害物质在该部件所有均质材料中的含量均在

SJ/T 11363-2006 标准规定的限量要求以下。

X:表示该有毒有害物质至少在该部件的某一均质材料中的含量超出

SJ/T 11363-2006 标准规定的限量要求。

备注:

一、此产品所标示之环保使用期限,系指在一般正常使用状况下。

二、上述部件物质中央处理器、内存、硬盘、电源为选购品。

铅

(Pb)汞 (Hg)镉 (Cd)

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

六价铬

(Cr(VI))

多溴联苯

(PBB)

多溴二苯醚

(PBDE)

vi

Page 8

Embedded Controller AEC-6611

Chapter 1 General Information

1.1 Introduction................................................................ 1-2

1.2 Features.................................................................... 1-3

1.3 Specifications............................................................ 1-4

Chapter 2 Hardware Installation

2.1 Dimension and I/O of AEC-6611...............................2-2

2.2 Location of Connectors and Jumpers of the Main Board

.........................................................................................2-3

2.3 List of Jumpers..........................................................2-5

2.4 List of Connectors ..................................................... 2-6

2.5 Hard Disk Drive Installation.......................................2-8

2.6 Memory Card Installation..........................................2-13

2.7 Wallmount Kit Installation..........................................2-16

2.8 DIN Rail Kit Installation .............................................2-17

Chapter 3 Award BIOS Setup

3.1 System Test and Initialization. .................................. 3-2

3.2 Award BIOS Setup.................................................... 3-3

Chapter 4 Driver Installation

4.1 Installation.................................................................4-3

Appendix A Programming The Watchdog Timer

A.1 Programming ........................................................A-2

A.2 ITE8781 Watchdog Timer Initial Program ............A-6

vii

Page 9

Embedded Controller AEC-6611

Information

Chapter

1

General

Chapter 1 General Information 1- 1

Page 10

Embedded Controller AEC-6611

1.1 Introduction

The newest Boxer series AEC-6611 has been introduced by

AAEON and it utilizes Intel

®

Atom™ processor. In this era of

information explosion, the advertising of consumer products will not

be confined to the family television, but will also spread to

high-traffic public areas, like department stores, the bus,

transportation station, the supermarket etc. The advertising

marketing industry will resort to every conceivable means to

transmit product information to consumers. System integrators will

need a multifunction device to satisfy commercial needs for such

public advertising.

The AEC-6611 is designed for indoor environments due to the

following reasons; first, the AEC-6611 offers low power

consumption system that while operating in ambient temperatures

ranging from -20° to 55°C. The MTBF (Mean Time Before Failure)

rating states that the AEC-6611 can operate up to 70,000 hours at

40°C ambient temperature, which indicates its careful and long-life

design.

The AEC-6611 is a standalone high performance controller

designed for long-life operation and with high reliability. It can

replace traditional methods and become the mainstream controller

for the multimedia entertainment market.

Chapter 1 General Information 1- 2

Page 11

Embedded Controller AEC-6611

1.2 Features

z Intel

z COM x 4 (Optional COM x 8)

z Gigabit Ethernet x 2

z DC 12V Power Input

z ATX Power Function

z SATA Interface Support

z Wallmount and DIN Rail Design for Industrial Applications

z Windows

®

AtomTM N270 1.6 GHz Processor

®

CE, Windows® XP Embedded, Windows® 7 and

Linux Fedora Support

Chapter 1 General Information 1- 3

Page 12

Embedded Controller AEC-6611

1.3 Specifications

System

z CPU

z Memory DDR2 400/533 SODIMM x 1, Max.

®

AtomTM N270 1.6GHz Processor

Intel

2GB

z VGA D-sub 15P VGA Connector

z Ethernet 10/100/1000Base-TX Ethernet RJ-45

connector x 2

z Hard Disk Drive 2.5” SATA HDD x 1

z Expansion Mini-PCI x 1, Mini Card x 1

z Solid Storage

Disk

z Serial Port RS-232/422/485 x 1, RS-232 x 3 (x 8

Internal Type II CompactFlash

x 1

optional)

z USB USB 2.0 x 2

z Watchdog Timer Generates a time-out system reset

z Power Supply DC power input 12V

Mechanical and Environmental

z Construction Aluminum Alloy Chassis

z Color Dark Gray

z Mounting Wallmount and DIN rail (optional)

z Dimension 7.76”(W) x 2.25”(H) x 4.33”(D)

(197 mm x 57.2 mm x 110 mm)

z Net Weight 4.75 lb (2.16 kg)

TM

slot

Chapter 1 General Information 1- 4

Page 13

Embedded Controller AEC-6611

z Gross Weight 8.36 lb (3.8 kg)

z Operating

Temperature

z Storage

5°F ~ 122°F (-20°C ~ 50°C) (CFD)

5°F ~ 131°F (-20°C ~ 55°C) (HDD)

-4°F ~ 158°F (-20°C ~ 70°C)

Temperature

z Operating

5 ~ 90% @ 40°C, non-condensing

Humidity

z Vibration 5G rms/ 5~500Hz/ random

operation –CFD

1G rms/ 5~500Hz/ random

operation –HDD

z Shock 50G peak acceleration (11msec.

duration) –CFD

20G peak acceleration (11msec.

duration) –HDD

z EMC CE/FCC Class A

Chapter 1 General Information 1- 5

Page 14

Embedded Controller AEC-6611

Hardware

Installation

Chapter

2

Chapter 2 Hardware Installation 2-1

Page 15

Embedded Controller AEC-6611

2.1 Dimension and I/O of AEC-6611

USB

LAN1 LAN2

SYS

HDD

DC IN

12V

COM2 COM3 COM4 COM5

Connectors of AEC-6611

USB

LAN1 LAN2

COM2 COM3 COM4 COM5

DC IN

12V

SYS

HDD

COM1 VGA

COM1

COM6

COM7

COM8

VGA

COM6

COM7

COM8

CFD

Chapter 2 Hardware Installation 2 - 2

Page 16

Embedded Controller AEC-6611

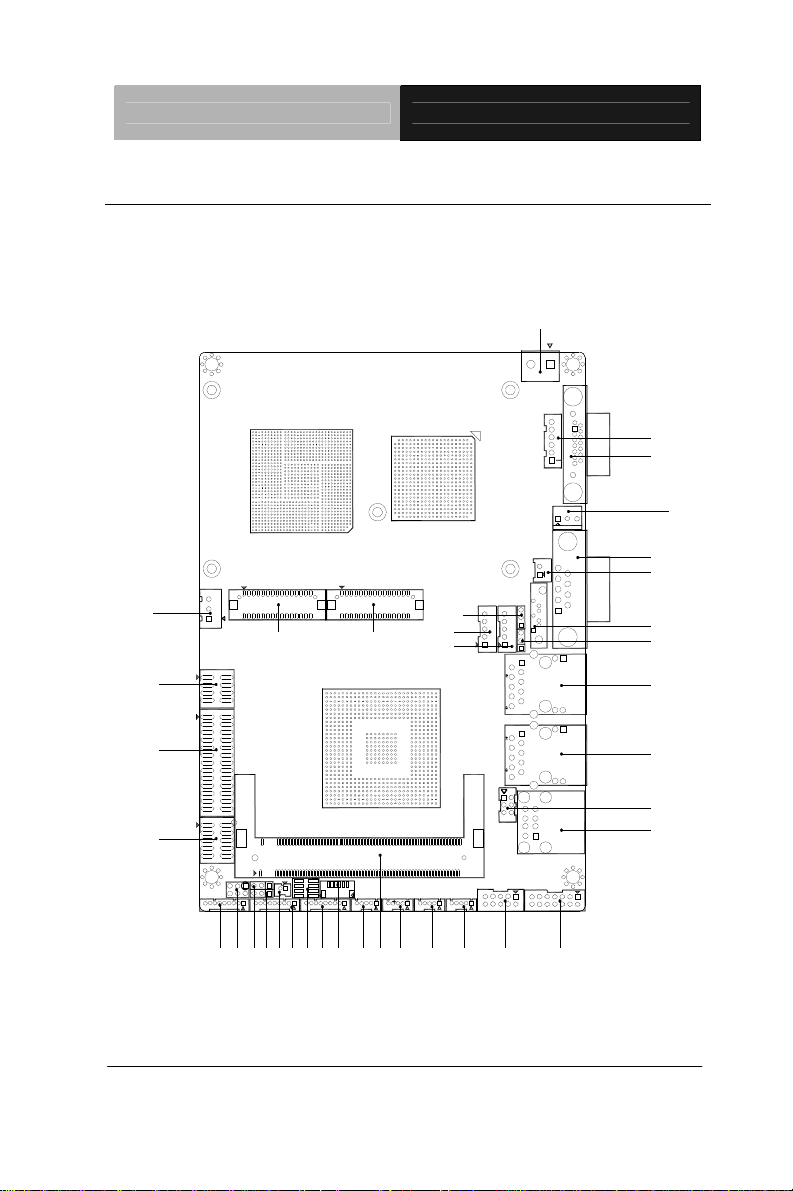

2.2 Connectors and Jumpers of The Main Board

Component Side

CN21

CN25

CN30

CN28

CN31

CN27

CN1

CN4

CN3

CN2

JP5

CN16

CN11

CN18

CN12

CN17

CN15

CN14

CN13

MPCI1

Chapter 2 Hardware Installation

CN26

CN7

JP1

JP3

JP2

CN5

CN8

CN6

CN9

BAT1

CN10

CN20

JP4

CN22

CN23

CN19

CN24

2 - 3

Page 17

Embedded Controller AEC-6611

Solder Side

DIMM1

CFD1

Chapter 2 Hardware Installation 2 - 4

CN32

Page 18

Embedded Controller AEC-6611

2.3 List of Jumpers

The board has a number of jumpers that allow you to configure your

system to suit your application.

The table below shows the function of each of the board's jumpers:

Label Function

JP1 COM2 RI/+5/+12V Selection

JP2 Clear CMOS Front Panel

JP3 AT/ATX Power Mode Selection

JP4 LVDS Inverter Voltage Selection

JP5 LVDS Operating Voltage Selection

Chapter 2 Hardware Installation

2 - 5

Page 19

Embedded Controller AEC-6611

2.4 List of Connectors

The board has a number of connectors that allow you to configure

your system to suit your application. The table below shows the

function of each board's connectors:

Label Function CN1

CN2 Digital I/O Connector

CN3 Parallel Port Connector

CN4 TV-out Connector

CN5 COM Port 2 Connector

CN6 COM Port 3 Connector

CN7 2nd LVDS Connector for 18/24-bit LCD

CN8 Onboard BIOS Programming I/F (Optional)

External +5V Standby Power Input and

PS_ON#

CN9 COM Port 4 Connector

CN10 UIM Connector

CN11 USB Port 1 Connector

CN12 1st LVDS Connector for 18-bit LCD

CN13 USB Port 2 Connector

CN14 USB Port 3 Connector

CN15 USB Port 4 Connector

CN16 2nd LVDS Inverter Connector

CN17 Front Panel

CN18 1st LVDS Inverter Connector

Chapter 2 Hardware Installation 2 - 6

Page 20

Embedded Controller AEC-6611

CN19 Keyboard / Mouse Connector

CN20 SATA 1 Connector

CN21 +12V Power Input Connector

CN22 RJ-45 Ethernet#1 Connector

CN23 RJ-45 Ethernet#2 Connector

CN24 USB Port 5&6 Connector

CN25

CN26 Audio In/Out/CD-in and MIC Connector

CN27 +5V Output Connector for 2.5” SATA Hard Disk

CN28 System FAN Connector

CN30 CRT Display Connector

CN31 COM Port 1 Connector

CN32 Mini-Card Slot

CFD1 Compact Flash Disk

+5V Standby Power Output w/ PS_ON# &

SMBus

MPCI1 Mini-PCI Slot

DIMM1 DDR2 SODIMM Slot

Chapter 2 Hardware Installation

2 - 7

Page 21

Embedded Controller AEC-6611

2.5 Hard Disk Drive Installation

Step 1: Unfasten the screws on the front and rear panel

USB

LAN1 LAN2

COM2 COM3 COM4 COM5

DC IN

12V

SYS

HDD

COM1 VGA

Step 2: Unfasten the four screws on the bottom lid

COM6

COM7

COM8

Chapter 2 Hardware Installation 2 - 8

Page 22

Embedded Controller AEC-6611

Step 3: Fasten the four HDD screws and cover with the four black damper

Black Damper

Black Damper

Chapter 2 Hardware Installation

2 - 9

Page 23

Embedded Controller AEC-6611

Step 4: Assembly the HDD chassis

Step 5: Assembly the damper bracket

Chapter 2 Hardware Installation 2 - 10

Page 24

Embedded Controller AEC-6611

Step 6: Connect the HDD cable

Step 7: Fasten the four screws on the bottom lid of AEC-6611

Chapter 2 Hardware Installation

2 - 11

Page 25

Embedded Controller AEC-6611

Step 8: Fasten the two screws on the front and rear panel

USB

LAN1 LAN2

COM2 COM3 COM4 COM5

DC IN

12V

SYS

HDD

COM1 VGA

COM6

COM7

COM8

Chapter 2 Hardware Installation 2 - 12

Page 26

Embedded Controller AEC-6611

2.6 Memory Card Installation

Step 1: Unfasten the screws on the front and rear panel

USB

LAN1 LAN2

COM2 COM3 COM4 COM5

DC IN

12V

SYS

HDD

COM1 VGA

Step 2: Unfasten the four screws on the bottom lid

COM6

COM7

COM8

Chapter 2 Hardware Installation

2 - 13

Page 27

Embedded Controller AEC-6611

Step 3: Insert the RAM at 30-degree angle to the memory slot and press

Step 4: Close the bottom case of AEC-6611 and faten the four screws of the

bottom lid

Chapter 2 Hardware Installation 2 - 14

Page 28

Embedded Controller AEC-6611

Step 5: Fasten the screws on the front and rear panel

USB

LAN1 LAN2

COM2 COM3 COM4 COM5

DC IN

12V

SYS

HDD

COM1 VGA

COM6

COM7

COM8

Chapter 2 Hardware Installation

2 - 15

Page 29

Embedded Controller AEC-6611

2.7 Wallmount Kit Installation

Get the brackets ready and fasten appropriate four screws on each bracket.

After fastening the two brackets on the bottom lid of AEC-6611, the

wallmount kit installation has been finished.

Chapter 2 Hardware Installation 2 - 16

Page 30

Embedded Controller AEC-6611

2.8 DIN Rail Kit Installation

Get the DIN Rail kit ready and fasten the three screws to mount the DIN Rail

kit to the bottom lid of AEC-6611

Chapter 2 Hardware Installation

2 - 17

Page 31

Embedded Controller AEC-6611

Chapter

3

Award

BIOS Setup

Chapter 3 Award BIOS Setup 3-1

Page 32

Embedded Controller AEC-6611

3.1 System Test and Initialization

These routines test and initialize board hardware. If the routines

encounter an error during the tests, you will either hear a few short

beeps or see an error message on the screen. There are two kinds

of errors: fatal and non-fatal. The system can usually continue the

boot up sequence with non-fatal errors. Non-fatal error messages

usually appear on the screen along with the following instructions:

Press <F1> to RESUME

Write down the message and press the F1 key to continue the boot

up sequence.

System configuration verification

These routines check the current system configuration against the

values stored in the CMOS memory. If they do not match, the

program outputs an error message. You will then need to run the

BIOS setup program to set the configuration information in memory.

There are three situations in which you will need to change the

CMOS settings:

1. You are starting your system for the first time

2. You have changed the hardware attached to your system

3. The CMOS memory has lost power and the configuration

information has been erased.

The AEC-6611 CMOS memory has an integral lithium battery

backup for data retention. However, you will need to replace the

complete unit when it finally runs down.

Chapter 3 Award BIOS Setup 3-2

Page 33

Embedded Controller AEC-6611

3.2 Award BIOS Setup

Awards BIOS ROM has a built-in Setup program that allows users

to modify the basic system configuration. This type of information is

stored in battery-backed CMOS RAM so that it retains the Setup

information when the power is turned off.

Entering Setup

Power on the computer and press <Del> immediately. This will

allow you to enter Setup.

Standard CMOS Features

Use this menu for basic system configuration. (Date, t ime, IDE,

etc.)

Advanced BIOS Features

Use this menu to set the advanced features available on your

system.

Advanced Chipset Features

Use this menu to change the values in the chipset registers and

optimize your system performance.

Integrated Peripherals

Use this menu to specify your settings for integrated peripherals.

(keyboard, mouse etc.)

Power Management Setup

Use this menu to specify your settings for power management.

(HDD power down, power on by ring, KB wake up, etc.)

Chapter 3 Award BIOS Setup 3-3

Page 34

Embedded Controller AEC-6611

PnP/PCI Configurations

This entry appears if your system supports PnP/PCI.

PC Health Status

Use this menu to set PC Health Status.

Frequency/Voltage Control

Use this menu to specify your settings for auto detect DIMM/PCI

clock and spread spectrum.

Load Optimized Defaults

Use this menu to load the BIOS default values that are factory

settings for optimal performance system operations. While AWARD

has designated the custom BIOS to maximize performance, the

factory has the right to change these defaults to meet their needs.

Set Password

Use this menu to set Supervisor Password.

Save and Exit Setup

Save CMOS value changes to CMOS and exit setup.

Exit Without Saving

Abandon all CMOS value changes and exit setup.

You can refer to the "AAEON BIOS Item Description.pdf" file in

the CD for the meaning of each setting in this chapter.

Chapter 3 Award BIOS Setup 3-4

Page 35

Embedded Controller AEC-6611

Installation

Chapter

4

Driver

Chapter 4 Driver Installation 4 - 1

Page 36

Embedded Controller AEC-6611

The AEC-6611 comes with a CD-ROM that contains all

drivers and utilities that meet your needs.

Follow the sequence below to install the drivers:

Step 1 – Install Chipset Driver

Step 2 – Install VGA Driver

Step 3 – Install LAN Driver

Step 4 – Install Mini PCI RS-232 Module Driver

Chapter 4 Driver Installation 4 - 2

Page 37

Embedded Controller AEC-6611

4.1 Installation:

Insert the AEC-6611 CD-ROM into the CD-ROM Drive. And install

the drivers from Step 1 to Step 4 in order.

Step 1 – Install INF Driver

1. Click on the STEP1-CHIPSET folder and double click on

the infinst911_autol.exe

2. Follow the instructions that the window shows

3. The system will help you install the driver automatically

Step 2 – Install VGA Driver

1. Click on the STEP2-VGA folder and select the OS folder

your system is

2. Double click on the .exe in the OS folder

3. Follow the instructions that the window shows

4. The system will help you install the driver automatically

Step 3 – Install LAN Driver

1. Click on the STEP3-LAN folder and select the OS folder

your system is

2. Double click on the PROWin32.exe file in the OS folder

3. Follow the instructions that the window shows

4. The system will help you install the driver automatically

Step 4 – Install Mini PCI RS-232 Module Driver

Installing Mini PCI RS-232 driver in Windows XP and Windows

7

Chapter 4 Driver Installation 4 - 3

Page 38

Embedded Controller AEC-6611

Once the card is installed and the computer is restarted, Windows

will detect the board and attempt to load the drivers for it.

1. Windows will detect a “PCI Serial Port”. Select “Install

from a list or specific location (Advanced)” as the

shown of figure 1 and then click “Next.”

Figure 1

2. Select “Search for the best driver in these locations.”

Next select “Include this location in this search:” and

then click “Browse” to open the “ CD-ROM/Driver/

STEP4-MINI PCI RS-232 Module” file as shown in

figure 2 . Click “Next.”

Chapter 4 Driver Installation 4 - 4

Figure 2

Page 39

Embedded Controller AEC-6611

3. Windows has found an updated driver for this device as

shown in figure 3 and then click “Next.”

Figure 3

4. The “Completing the Found New Hardware Wizard”

dialog. Appears as shown in figure 3, and then click

“Finish.”

5. Repeat the above process for the second, third, fourth,

and fifth AAEON PCI Communications Port.

6. Please re-start your Windows.

Finalizing Mini PCI RS-232 module settings

Check your Windows System/Device Manager to confirm the

proper installations of Mini PCI RS-232 drivers:

Multifunction adapters

AAEON OX16PCI954 PCI UARTs

AAEON OX16PCI95x PCI bridge

Ports(COM & LPT)

Chapter 4 Driver Installation 4 - 5

Page 40

Embedded Controller AEC-6611

4-port Mini PCI module will show 4 AAEON PCI

Communications Port and 2-port Mini PCI module will show 2

AAEON PCI Communications Port as the figure 4 shows 4

ports Mini PCI module

Figure 4

Mini-PCI RS-232 module set up in Linux

If the module is a 4-port Mini PCI module, you don’t need to

proceed with the set up process, you can use it directly. For 2-port

Mini PCI module, please use the following sequences to set up the

module.

1. Open the Terminal screen and make a

cat /proc/tty6/driver/serial command to check your

COM port settings.

As the screen showing, use 16550A to be UART prefi x is

the system COM ports, and we can see this system with

2 COM ports, leave it as ttyS0, ttyS1.

Chapter 4 Driver Installation 4 - 6

Page 41

Embedded Controller AEC-6611

2. Make lspci -v command to find OXmPCI952 IRQ and I/O

address

As the screen showing, we can find “Serial controller:

Oxford Semiconductor Ltd:” this alphabetic string and

then we will see the next line with IRQ number and the

next with I/O address

3. Open the file: /etc/rc.local and add two commands

setserial /dev/ttySX1 port IOADDR1 irq Y uart 16950 baud_base 115200

setserial /dev/ttySX2 port IOADDR2 irq Y uart 16950 baud_base 115200

In above command line X1, X2 are the COM port

numbers and it must be beyond beforehand. In this case,

X1 is 4, X2 is 5, and Y is IRQ number. Finally, we can set

the I/O address individually.

setserial /dev/ttyS4 port 0xe000 irq 9 uart 16950 baud_base 115200

setserial /dev/ttyS5 port 0xe100 irq 9 uart 16950 baud_base 115200

4. Please re-start your computer.

5. Make cat /proc/tty/driver/serial command to see if the

display is shown as below. If yes, this setup has been

done successfully.

Chapter 4 Driver Installation 4 - 7

Page 42

Embedded Controller AEC-6611

Chapter 4 Driver Installation 4 - 8

Page 43

Embedded Controller AEC-6611

A

Appendix

Programming the

Watchdog Timer

Appendix A Programming the Watchdog Timer A-1

Page 44

Embedded Controller AEC-6611

A.1 Programming

AEC-6611 utilizes ITE 8781 chipset as its watchdog

timer controller. Below are the procedures to complete its

configuration and the AAEON initial watchdog timer

program is also attached based on which you can

develop customized program to fit your application.

Configuring Sequence Description

After the hardware reset or power-on reset, the ITE 8781 enters the

normal mode with all logical devices disabled except

KBC. The initial state (enable bit ) of this logical device (KBC) is

determined by the state of pin 121 (DTR1#) at the falling edge of

the system reset during power-on reset.

Appendix A Programming the Watchdog Timer A-2

Page 45

Embedded Controller AEC-6611

There are three steps to complete the configuration setup: (1) Enter

the MB PnP Mode; (2) Modify the data of configuration re gisters; (3)

Exit the MB PnP Mode. Undesired result may occur if the MB PnP

Mode is not exited normally.

(1) Enter the MB PnP Mode

To enter the MB PnP Mode, four sp ecial I/O write operations are to

be performed during Wait for Key st ate. To ensure the initial state of

the key-check logic, it is necessary to p erform four write opera-tio ns

to the Special Address port (2EH). Two different enter keys are

provided to select configuration ports (2Eh/2Fh) of the next step.

(2) Modify the Data of the Regist ers

All configuration registers can be accessed after entering the MB

PnP Mode. Before accessing a selected register, the content of

Index 07h must be changed to the LDN to which the register

belongs, except some Global registers.

(3) Exit the MB PnP Mode

Set bit 1 of the configure control register (Index=02h) to 1 to exit the

MB PnP Mode.

Appendix A Programming the Watchdog Timer A-3

Page 46

Embedded Controller AEC-6611

WatchDog Ti mer Configuration Registers

Configure Control (Index=02h)

This register is write only. Its values are not sticky; that is to say, a

hardware reset will automatically clear the bits, and does not

require the software to clear them.

Watch Dog Timer 1, 2, 3 Control Register (Index=71h,81h,91h

Default=00h)

Appendix A Programming the Watchdog Timer A-4

Page 47

Embedded Controller AEC-6611

Watch Dog Timer 1, 2, 3 Configuration Register (Index=72h,

82h, 92h Default=001s0000b)

Watch Dog Timer 1,2,3 Time-Out Value (LSB) Register

(Index=73h,83h,93h, Default=38h)

Watch Dog Timer 1,2,3 Time-Out Value (MSB) Register

(Index=74h,84h,94h Default=00h)

Appendix A Programming the Watchdog Timer A-5

Page 48

Embedded Controller AEC-6611

A.2 ITE8781 Watchdog Timer Initial Program

.MODEL SMALL

.CODE

Main:

CALL Enter_Configuration_mode

CALL Check_Chip

mov cl, 7

call Set_Logic_Device

;time setting

mov cl, 10 ; 10 Sec

dec al

Watch_Dog_Setting:

;Timer setting

mov al, cl

mov cl, 73h

call Superio_Set_Reg

;Clear by keyboard or mouse interrupt

mov al, 0f0h

mov cl, 71h

call Superio_Set_Reg

;unit is second.

mov al, 0C0H

mov cl, 72h

Appendix A Programming the Watchdog Timer A-6

Page 49

Embedded Controller AEC-6611

call Superio_Set_Reg

; game port enable

mov cl, 9

call Set_Logic_Device

Initial_OK:

CALL Exit_Configuration_mode

MOV AH,4Ch

INT 21h

Enter_Configuration_Mode PROC NEAR

MOV SI,WORD PTR CS:[Offset Cfg_Port]

MOV DX,02Eh

MOV CX,04h

Init_1:

MOV AL,BYTE PTR CS:[SI]

OUT DX,AL

INC SI

LOOP Init_1

RET

Enter_Configuration_Mode ENDP

Exit_Configuration_Mode PROC NEAR

MOV AX,0202h

Appendix A Programming the Watchdog Timer A-7

Page 50

Embedded Controller AEC-6611

CALL Write_Configuratio n_Data

RET

Exit_Configuration_Mode ENDP

Check_Chip PROC NEAR

MOV AL,20h

CALL Read_Configuration_Data

CMP AL,87h

JNE Not_Initial

MOV AL,21h

CALL Read_Configuration_Data

CMP AL,81h

JNE Not_Initial

Need_Initial:

STC

RET

Not_Initial:

CLC

RET

Check_Chip ENDP

Read_Configuration_Data PROC NEAR

MOV DX,WORD PTR CS:[Cfg_Port+04h]

Appendix A Programming the Watchdog Timer A-8

Page 51

Embedded Controller AEC-6611

OUT DX,AL

MOV DX,WORD PTR CS:[Cfg_Port+06h]

IN AL,DX

RET

Read_Configuration_Data ENDP

Write_Configuration_Data PROC NEAR

MOV DX,WORD PTR CS:[Cfg_Port+04h]

OUT DX,AL

XCHG AL,AH

MOV DX,WORD PTR CS:[Cfg_Port+06h]

OUT DX,AL

RET

Write_Configuration_Data ENDP

Superio_Set_Reg proc near

push ax

MOV DX,WORD PTR CS:[Cfg_Port+04h]

mov al,cl

out dx,al

pop ax

inc dx

out dx,al

ret

Superio_Set_Reg endp.Set_Logic_Device proc near

Appendix A Programming the Watchdog Timer A-9

Page 52

Embedded Controller AEC-6611

Set_Logic_Device proc near

push ax

push cx

xchg al,cl

mov cl,07h

call Superio_Set_Reg

pop cx

pop ax

ret

Set_Logic_Device endp

;Select 02Eh->Index Port, 02Fh->Data Port

Cfg_Port DB 087h,001h,055h,055h

DW 02Eh,02Fh

END Main

Note: Interrupt level mapping

0Fh-Dh: not valid

0Ch: IRQ12

.

.

03h: IRQ3

02h: not valid

01h: IRQ1

00h: no interrupt selected

Appendix A Programming the Watchdog Timer A-10

Loading...

Loading...