Page 1

SC500 USB Resistive

Controller Reference Guide

3M Touch Systems

Read and understand all safety information

contained in this document before using this product.

Page 2

The information in this document is subject to change without notice. No part of this document may be reproduced or

transmitted in any form or by any means, electronic or mechanical, for any purpose, without the express written permission

of 3M Touch Systems. 3M may have patents or pending patent applications, trademarks, copyrights, or other intellectual

property rights covering subject matter in this document. The furnishing of this document does not give you license to these

patents, trademarks, copyrights, or other intellectual property except as expressly provided in any written license agreement

from 3M Touch Systems.

The information provided in this document is intended only as a guide. For the latest detailed engineering specifications,

please contact your 3M Touch Systems Application Engineer. 3M Touch Systems is committed to continually improving

product designs, as a result, product specifications may be subject to change without notification.

NOTICE: Given the variety of factors that can affect the use and performance of a 3M Touch Systems Product (the

“Product”), including that solid state equipment has operation characteristics different from electromechanical equipment,

some of which factors are uniquely within User’s knowledge and control, it is essential that User evaluate the 3M Touch

Systems Product and software to determine whether it is suitable for User’s particular purpose and suitable for User’s method

of application. 3M Touch Systems’ statements, engineering/technical information, and recommendations are provided for

User’s convenience, but their accuracy or completeness is not warranted. 3M Touch Systems products and software are not

specifically designed for use in medical devices as defined by United States federal law. 3M Touch Systems products and

software should not be used in such applications without 3M Touch Systems’ express written consent. User should contact

its sales representative if User’s opportunity involves a medical device application.

IMPORTANT NOTICE TO PURCHASER: Specifications are subject to change without notice. These 3M Touch

Systems’ Products and software are warranted to meet their published specifications from the date of shipment and for the

period stated in the specification. 3M Touch Systems makes no additional warranties, express or implied, inc l uding but

not limited to any implied warranties of merchantability or fitness for a particular purpose. User is responsible for

determining whether the 3M Touch Systems Products and software are fit for User’s particular purpose and suitable for its

method of production, including intellectual property liability for User's application. If the Product, software or software

media is proven not to have met 3M Touch Systems’ warranty, then 3M Touch Systems’ sole obligation and User’s and

Purchaser’s exclusive remedy, will be, at 3M Touch Systems’ option, to repair or replace that Product quantity or software

media or to refund its purchase price. 3M Touch Systems has no obligation under 3M Touch Systems’ warranty for any

Product, software or software media that has been modified or damaged through misuse, accident, neglect, or subsequent

manufacturing operations or assemblies by anyone other than 3M Touch Systems. 3M Touch Systems shall not be liable in

any action against it in any way related to the Products or software for any loss or damages, whether non-specified

direct, indirect, special, incidental or consequential (including downtime, loss of profits or goodwill) regardless of the

legal theory asserted.

© 2004 3M All rights reserved.

Printed in the United States

Document Title: SC500 USB Resistive Controller Reference Guide

Document Number: 19-275, Version 1.0

MicroTouch, the MicroTouch logo, and ClearTek are either registered trademarks or trademarks of 3M in the United States

and/or other countries.

IBM is a registered trademark of International Business Machines Incorporated.

Microsoft, Windows, and Windows NT are registered trademarks or trademarks of Microsoft Corporation.

All other trademarks are the property of their respective owners.

3M Touch Systems Proprietary Information

Page 3

Contents

Overview

What You Need to Know......................................................................................5

Important Safety Information................................................................................ 5

3M Touch Systems Support Services ...................................................................6

3M Touch Systems Worldwide Offices................................................................ 7

Chapter 1 Integrating the SC500 USB Controller

Overview of the SC500 Touch Screen Controller ................................................ 9

Handling and ESD Protection............................................................................. 10

Establishing the Data Connection.......................................................................10

Mounting the Controller...................................................................................... 11

Supplying Power to the Controller...................................................................... 11

Mounting the Touch Screen................................................................................ 12

Touch Screen Cable Connector........................................................................... 12

Turning On Your System.................................................................................... 12

Status Light (LED) Diagnostics.......................................................................... 12

What's Next?.......................................................................................................13

Chapter 2 SC500 USB Controller Communications

Overview of USB Firmware Communications...................................................15

Communication Basics........................................................................................16

Receiving Reports from the Controller............................................................... 16

HID and Packed Touch Reports.......................................................................... 16

USB Command Set.............................................................................................18

Set Feature – Set Asynchronous Report.............................................................. 20

Set Feature – Calibration..................................................................................... 21

Get Feature – Get Status .....................................................................................23

Set Feature - Reset .............................................................................................. 25

Set Feature - Restore Defaults............................................................................. 25

Set Feature - Set Controller Number................................................................... 26

Get Feature – Get Controller Number................................................................. 27

Appendix A SC500 USB Controller Specifications

Technical Specifications ..................................................................................... 30

3M Touch Systems Proprietary Information

Page 4

Page 5

Overview

3M Touch Systems offers several advanced controllers designed for reliability and

easy installation. Each controller provides superior performance and delivers excellent

stability, sensitivity, accuracy, and fast response.

This reference manual, directed to developers of touch screen systems, provides

installation and configuration information for the small outline 3M Touch Systems

SC500 USB touch screen controller. This document includes information on

integrating the SC500 USB controller into your design, communicating with the

controller and troubleshooting setup problems. It also includes a complete description

of the firmware commands, a guide to interpreting status LED conditions, and

controller specifications.

What You Need to Know

This document assumes you are familiar with USB commands and how to use them.

Executing some commands may alter the performance of your touch product. You

should be aware of the results of using these commands before executing them.

Important Safety Information

Read and understand all safety information before using this product. Follow all

instructions marked on the product and described in this document. Pay close

attention to the following installation warnings and safety precautions.

Intended Use

The SC500 USB controller was designed to enable touch in conjunction with other

3M Touch Systems products. This controller is not designed for use in hazardous

locations.

WARNING

To avoid the risk of fire and/or explosion which could result in serious injury or

property damage:

Do not install or use this product in a hazardous location.

Do not use this product in any outdoor environment unless NEMA standards are

followed.

3M Touch Systems Proprietary Information

Page 6

6 SC500 USB Controller Reference Guide

CAUTION

To reduce the risks associated with the improper disposal of the controller board,

which if not avoided may result in minor or moderate injury from ground water

contamination:

• Dispose of the controller board in accordance with local, state and federal regulations.

Explanation of Symbols

Attention: Read accompanying documentation

3M Touch Systems Support Services

3M Touch Systems provides extensive support services through our website and

technical support organization. Visit the 3M Touch Systems website at

http://www.3mtouch.com/

drivers, obtain regularly updated technical documentation on 3M Touch Systems

products, and learn more about our company.

Note that if you purchased this product from another company, contact them before

contacting 3M Touch Systems.

, where you can download touch screen software and

Whenever you contact Technical Support, please provide the following information

(if applicable):

• Part number and serial number from your touch system

• Current driver version

• Operating system used

• Information on additional peripherals

Technical Support is available Monday through Friday 8 a.m. to 8 p.m. US Eastern

Standard Time – 9 a.m. to 5 p.m. throughout Europe. Limited call back service

Saturdays and Sundays.

You can contact 3M Touch Systems Technical Support (US only -- Eastern Standard

Time) by calling the hot line, sending email or sending a fax.

• Technical Support Hot Line: 978-659-9200

• Technical Support Fax: 978-659-9400

• Toll Free: 1-866-407-6666

• Email: US-TS-techsupport@mmm.com

3M Touch Systems Proprietary Information

Page 7

Overview 7

3M Touch Systems Worldwide Offices

All offices can be reached through the website: http://www.3Mtouch.com/.

• United States 978-659-9000

• United Kingdom +44 (0) 1235-444400

• Australia +61 3 9582 4799

• Canada 604-521-3962

• France +33 (1) 30 31 68 32

• Germany +49 (0) 2131 14-4003

• Hong Kong/China (852) 2333-6138

• Italy +39 0 39-230 2230

• Japan +81 (44) 811-1133

• Korea +822 552 3198

• Singapore +65-6450 8851

• Spain +34 934 15 6285

• Taiwan +886-2-2704 9011

3M Touch Systems Proprietary Information

Page 8

Page 9

CHAPTER 1

Integrating the SC500 USB Controller

The MicroTouch™ SC500 Universal Serial Bus (USB) controller is an accurate, small

outline, low cost, temperature stable controller capable of supporting a wide range of

3M Touch Systems resistive touch screens. It is designed to work with Microsoft®

Windows® XP, 2000, 98SE and Windows Me for internal mounting in OEM

applications.

This chapter covers the following SC500 USB controller specifications:

• Cable connections

• Mounting requirements

• Power requirements and options

• Status LED codes

Overview of the SC500 Touch Screen Controller

The SC500 controller is an uncased device using a USB interface.

To integrate and test the SC500 USB controller, you need the following items:

• A 3M Touch Systems 5-wire resistive touch screen. The touch screens are available in a

variety of sizes.

• A method of establishing the USB communication between the controller and your

system. The standard 3M Touch Systems USB communications cable (P/N7319420) is

recommended. This cable is PC99 compliant.

• A touch screen utility or driver with a calibration routine.

Note: You can use MicroTouch™ Software, which includes the touch screen device

driver and utilities software.

The controller measures 1.3 x 2.4 inches, or 1.3 x 2.7 inches total profile over the

connectors. Allow additional clearance for the mating connectors. The total height

profile is 0.40 inches from the thru hole pins on the trace side of the board to the top

of the highest component on the opposite side. The SC500 has a 5-pin touch screen

connector (JP5), and a 5-pin USB cable connector (JP7).

3M Touch Systems Proprietary Information

Page 10

10 SC500 USB Controller Reference Guide

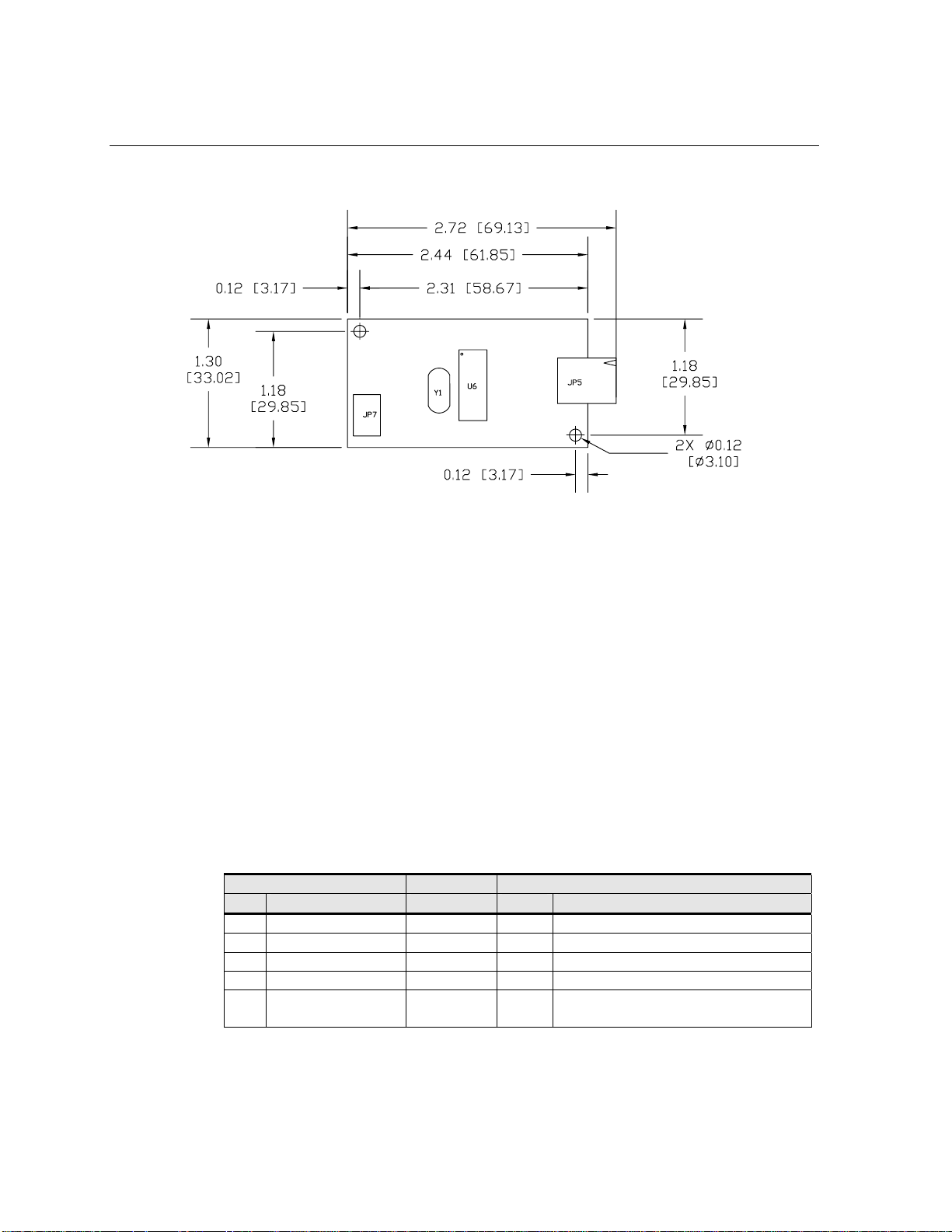

Figure 1. SC500 USB Controller Overall Dimensions

Handling and ESD Protection

When mounting the sensor and controller, use normal precautions for handling

electrostatic sensitive devices. The SC500 has internal protection to ±20 kV for ESD

air discharges to the touch screen (not to the controller directly) that may occur during

normal operation of the touch screen. Refer to Appendix A for further specifications.

Establishing the Data Connection

The SC500 USB Resistive Controller requires a 3M Touch Systems USB

communication cable (P/N 7319420) PC 99 compatible or an equivalent interconnect.

One end of this cable plugs into the USB connector (JP7) on the SC500 USB

Resistive Controller. The other end, which has a Type-A connector, plugs into a USB

port on your PC.

When creating a custom cable, use the Molex 51004-0500 mating connector. Table 1

describes the interconnections of the 3M Touch Systems USB cable.

Table 1. USB Cable for SC500 USB Resistive Controllers

PC Side (USB Type A) Wire Controller Side (5-Pin Molex)

Pin USB Assigned Color Pin Description

1 +5Vdc Red 1 +5Vdc Input Power

2 Data (DN) Gray 2 Data (DN) Differential Pair

3 Data (DP) Green 3 Data (DP) Differential Pair

4 0V Black 4 Power Return

5 Cable Shield Shell Charcoal

Gray

5 Outer Cable Shield around signal and

power lines. Chassis (earth) ground

3M Touch Systems Proprietary Information

Page 11

Integrating the SC500 USB Controller 11

Mounting the Controller

The controller is designed for internal mounting only. Choose a convenient spot away

from high-voltage, high power cables and electronics. Use 4-40 metal screws to

mount the controller using the two diagonal mounting holes in the board. The

controller should be mounted in line with the touch screen cable exit point to

minimize cable flexing. The controller should be mounted internally behind or on the

side of the display on stand offs to allow room for the touch screen cable connector.

Ensure that the tail and controller are aligned such that the tail remains straight (90°),

not pulled or twisted in an odd angle from the touch screen. Good engineering design

avoids awkward electrical connections.

Recommended:

Wrap tail smoothly

Not recommended:

Do not twist the tail

Supplying Power to the Controller

The SC500 USB controller is powered by the USB 5-volt bus power. The typical

current is 15 mA typical, 28 mA touching; ± 5% regulation, with a maximum ripple

and noise of 50mV peak-to-peak.

CAUTION

To avoid possible damage to the controller, you must provide a path for electrostatic

discharge (ESD). The controller mounting hole near the sensor connector should be used to

connect to chassis safety ground and must be attached by the shortest possible route to a good

earth return (chassis) in all applications.

3M Touch Systems Proprietary Information

Page 12

12 SC500 USB Controller Reference Guide

Mounting the Touch Screen

There are several methods for mounting the touch screen depending on your

application (Flat CRT displays or flat panel displays, each in a variety of sizes). If you

need instructions or recommendations from 3M Touch Systems on how to incorporate

a touch screen into your design, refer to the MicroTouch Resistive Integration Guide

(P/N 19-441). All 3M Touch Systems documentation is available from the corporate

website at www.3Mtouch.com

or from the Touch Solutions CD (P/N 19-640).

It is critical for you to understand the tail orientation of your touch screen prior to

connecting the controller. This will affect how the controller interprets your touch on

the screen. Refer to Controller Communications section for additional information.

Touch Screen Cable Connector

The touch screen cable has a 5-pin single row locking female connector that plugs into

the controller. The standard cable pinout is designed for right (3 o’clock) tail exit on

the sensor when viewed from the front.

1. Upper Right

2. Upper Left

3. Top Sheet

4. Lower Left

5. Lower Right

Turning On Your System

Before you turn on your custom system, ensure that all cables are connected properly

and that the controller is properly mounted. Be sure to tighten all cable connector

screws.

To start up your system

1. Turn on your monitor and computer.

2. Adjust the contrast and brightness to suit your personal preference and working

environment.

3. Adjust the horizontal and vertical position controls on the monitor to center the image on

the screen.

Status Light (LED) Diagnostics

3M Touch Systems controllers are highly reliable units; however, there may be

occasions when the controller does not perform exactly as you expected. The SC500

controller provides diagnostic feedback with a light emitting diode (LED) on the

component side of the board that indicates the status of the touch screen unit. During

normal operation, when you touch the sensor the LED becomes bright as long as the

controller detects a touch.

A flashing (or blinking) LED during power-up indicates the controller’s power-on

self-test failed. Refer to Table 2 for a description of each error code.

3M Touch Systems Proprietary Information

Page 13

Integrating the SC500 USB Controller 13

Table 2. LED Diagnostic Codes for SC500 Controllers

Flashes Self Test

Condition

1 Reserved. 0 Reserved

2 ROM Error 1 Firmware EPROM checksum

3 Reserved. 2 Reserved

4 Block 1

checksum Error

5 Hardware error 4 Power-up touch screen

6 Reserved. 5 Reserved

7 Reserved. 6 Reserved

Self Test

Bit

3 Operating parameters invalid

Description What to do…

verification error

(using defaults).

connector voltages that are

out of range.

No recovery. Replace the controller.

Cycle power off and on. If problem

persists, recalibrate

Check connection to the touch screen

What's Next?

Since this is a HID (human interface device) compatible controller, the controller will

operate independent of a 3M Touch Systems driver. You must obtain a HID

calibration utility from the 3M Touch Systems website for initial calibration.

Additional 3M Touch Systems documentation is available from the corporate website

at www.3Mtouch.com

or from the Touch Solutions CD (P/N 19-640).

3M Touch Systems Proprietary Information

Page 14

Page 15

CHAPTER 2

SC500 USB Controller Communications

This chapter discusses the fundamentals of communicating with the SC500 USB

controller. The firmware commands, which are usually issued by a driver or utility

program on the host system, control the operation of the touch screen controller. This

chapter lists the recommended firmware commands and describes how to use each of

these commands.

Overview of USB Firmware Communications

Developers may use this information when writing touch applications, developing

custom drivers or touch configurations, or testing their touch systems. Developers can

issue commands to initialize the controller, select operating modes, and execute

diagnostic functions.

Most touch screen users do not have to use firmware commands to use their touch

systems. For example, users can use MicroTouch™ software or equivalent software

to calibrate the touch screen or to determine the controller type and firmware version.

Note: This document assumes you are familiar with USB standards and modes of

communication with USB devices, as well as firmware commands and how to use them.

Executing some commands may alter the performance of your touch screen and render it

inoperable. You should be aware of the results before executing any firmware commands.

To optimize the performance of the SC500 USB touch screen controller and simplify

the development of custom drivers, 3M Touch Systems recommends you use the

commands listed in this chapter for current development.

3M Touch Systems Proprietary Information

Page 16

16 SC500 USB Controller Reference Guide

Communication Basics

This section provides information on sending firmware commands to the controller

and interpreting the responses that the controller returns. The default operation of the

SC500 USB controller is USB Rev 1.1.

The USB command set is implemented by using vendor requests and vendor reports,

i.e., vendor specific transactions. The controller issues some reports without

prompting the computer. The computer can also send requests to the controller to

change how it operates or receives information about the controller. The controller

issues a synchronous report in response to some of these requests.

You need to know product ID (0102H) and the vendor ID (0596H) to write your own

driver. These values are required for identifying the controller.

The SC500 USB command set utilizes the HID protocol. The HID protocol allows the

controller to be used on most computers with operating systems that supports HID.

The only required software is a calibration tool used for aligning the touch screen to

the display. This calibration tool is available from 3M Touch Systems.

Receiving Reports from the Controller

The controller sends a variety of reports to the computer. The first byte of each report

is the Report ID that defines the structure and content of the report. The controller

sends some reports as a direct response to a computer request (synchronous). The

controller will also send some reports as the result of an external event, such as a

touch (asynchronous).

HID and Packed Touch Reports

The controller sends to the computer reports in response to touches on the touch

screen. The controller normally uses the HID-compatible report. In addition to the

HID-compatible report, there are two versions of packed report available. These

versions return up to two points of data per touch, as opposed to the one touch point in

the HID-compatible report.

The first byte of each report contains the Report ID as shown in Table 3. You can use

the Set Asynchronous Report request to toggle between report types.

Table 3. Asynchronous Reports

Name Report ID Description

REPORT_ID_HID 1 HID-compatible coordinate data

REPORT_ID_PACKED 2 Packed coordinate data for custom

REPORT_ID_UTILITY 7 Packed coordinate data for utilities

Only custom drivers and software can make use of the packed coordinate format.

Refer to the Set Asychronous Report section for details on using packed coordinate

data.

driver

3M Touch Systems Proprietary Information

Page 17

SC500 USB Controller Communications 17

HID-Compatible Coordinate Data – Report 1

This is used to transfer the 10-bit coordinate data to the host. This report, when

activated, is sent to the host whenever new data is available/scheduled for

transmission. It is an asynchronous report that is activated by default at power up.

For HID class driver compatibility

• Throughput is limited to 125 points/sec.

• The coordinate system is upper-left origin, rather than the MicroTouch™ standard lower-

left origin.

Table 4. Coordinate Data Report

Offset Field Size Value Description

0 bReport ID 1 0x01 REPORT_ID_HID

1 bmStatus 1 B7, B6 B5, B

2 bXLsb 1 X7, X6 X5, X

3 bXMsb 1 XfXeXdX

4 B3, B2 B1, B0

4 X3, X2 X1, X0

c XbXaX9X8

4 bYLsb 1 Y7Y6Y5Y4 Y3Y2Y1Y0 Y (0-3FF)

5 bYMsb 1 YfYeYdY

c YbYaY9Y8

6 Not used 2 0 Not used

0x01 if touching, 0x00 if

not

X (0-3FF)

Packed Coordinate Data - Report 2 and Report 7

These are used to transfer the packed coordinate data to a custom driver or utility.

These reports, when activated, are sent to the host whenever new data is available for

transmission. The packed format contains two coordinate reports each with its own

status and Y and Y coordinate data. Because it is packed, the software must rearrange

bits to obtain the individual field values. The status contains a bit indicating if the

subreport is valid. The second subreport only may be invalid.

Table 5. Coordinate Data Report

Offset Field Size Value Description

0 bReport ID 1 0x02 or 0x07

1 bmPackData1 1 X3X2X1X0 B3B2B1B0 X1 bits 3210 and status1 bits

2 bmPackData2 1 XbXaX9X8 X7X6X5X4 X1 bits BA987654

3 bmPackData3 1 Y7Y6Y5Y4 Y3Y2Y1Y0 Y1 bits 76543210

4 bmPackData4 1 B3B2B1B0 YbYaY9Y8 Status2 bits BBBB and Y1 bits

5 bmPackData5 1 X7X6X5X4 X3X2X1X0 X2 bits 76543210

6 bmPackData6 1 Y3Y2Y1Y

0 XbXaX9X8

7 bmPackData7 1 YbYaY9Y8 Y7Y6Y5Y4 Y2 bits BA987654

REPORT_ID_PACKED

REPORT_ID_UTILITY

BBBB

BA98

Y2 bits 3210 and X2 bits BA98

3M Touch Systems Proprietary Information

Page 18

18 SC500 USB Controller Reference Guide

Table 6. Coordinate Data Report Touch Status Byte

Bit Status

0 0 = not touching, 1 = touching

1 0 = data invalid, 1 = data valid

2 Not used

3 Not used

USB Command Set

The USB command set is implemented by using HID Get Feature and Set Feature

commands. The various requests and reports are grouped together by report size

under a common feature ID.

The commands listed below are those that 3M Touch Systems currently use for

communications. 3M Touch Systems recommends that you use only these commands

for SC500 USB controller communications.

Sending Commands to the Controller

To send a command, the computer must construct a USB packet for sending to the

controller. The general packet format is described in Table 7. Any data appended

immediately after this data is referred to as the data stage of request.

If using the Windows you may want to use the Set and Get Feature functions. The

buffers are the same except the first two fields. The bmRequest Type and bRequest

fields are omitted, thus making wValue the first field. For your convenience, each

command is labeled as either a “Set Feature” or “Get Feature” command.

3M Touch Systems Proprietary Information

Page 19

SC500 USB Controller Communications 19

Table 7. General Request Format

Offset Field Size Value Description

0 bmRequestType 1 d0100001 Characteristics of request (dir,type,receipt)

D7: Data transfer direction

0 = Host to device

1 = Device to host

D6…5 Type

0 = Standard

1 = Class (all commands are standard)

2 = Vendor

3 = Reserved

D4…0 Recipient

0 = Device

1 = Interface (all commands are interface)

2 = Endpoint

3 = Other

4….31 = Reserved

1 bRequest 1 0xXX Specific request (our command number)

2 wValue 2 0x03XX Used to specify command parameters.

03 = Feature

XX = Feature Report ID

4 wIndex 2 0 Must be 0 (zero)

6 wLength 2 0xXXXX Number of bytes to transfer, multiple of 8. Same

as Data Stage Bytes in Table 8.

HID Class Requests

The following table summarizes the available HID class requests.

Table 8. Hid Class Requests Summary

HID Report Command Name bmRequest

Type

Set Feature SetAsyncReport 0x21 0x09 0x03 0x05 8

Set Feature Calibrate 0x21 0x09 0x03 0x04 8

Get Feature GetStatus 0xA1 0x01 0x06 --- 8

Set Feature Reset 0x21 0x09 0x03 0x07 8

Set Feature Restore Defaults 0x21 0x09 0x03 0x08 8

Set Feature Set Controller Number 0x21 0x09 0x05 0x01 8

Get Feature Get Controller Number 0x21 0x09 0x03 0x02 8

Some possible reasons for a command failure include:

• The command was not formatted correctly.

• The system parameters were not set up to allow command execution.

• The controller does not support the command.

bRequest Feature

Report ID

Report

Subtype

Data

Stage

Bytes

3M Touch Systems Proprietary Information

Page 20

20 SC500 USB Controller Reference Guide

Controller Initialization

To initialize the SC500 USB controller, 3M Touch Systems recommends that the host

system issue a Reset command whenever the host system is powered on and is

attempting to establish communication with the controller.

Set Feature – Set Asynchronous Report

This starts or stops the sending of various asynchronous reports via the interrupt pipe.

Once a report is turned on, that report is sent whenever data is available. The firmware

defaults to the HID-compatible report after power-up or reset. Only one report may

be activated at a time.

Note: The TOUCH_REPORTS_UTILITY command causes the controller to send Report 7

from the endpoint 0 exclusively. This action is essential in getting a calibration utility to

function. The endpoint 1 does not send any reports at this time. The

TOUCH_REPORTS_RESTORE command causes the controller to send the previously active

asynchronous report (REPORT_ID_HID or REPORT_ID_PACKED) from endpoint 1.

Table 9. Set Asynchronous Report

Offset Field Size Value Description

0 bmRequestType 1 0x21 Host to device

1 bRequest 1 0x09 Set Report

2 wValue 2 0x0303 03 = Feature

03 = Feature Report ID

4 wIndex 2 0 Always 0

6 wLength 2 8 Always 8

Table 10. Data Stage

Offset Field Size Value Description

0 bReport ID 1 0x03 Feature Report ID

1 bmReport Subtype 1 0x05 Indicates a SetAsynchReport

2 Not used 2 0 Not used

4 bReport 0x00 0 TOUCH_REPORTS_OFF

1 TOUCH_REPORTS_ON

2 TOUCH_REPORTS_HID

3 TOUCH REPORTS_PACKED

6

TOUCH_REPORTS_UTILITY

7

TOUCH_REPORTS_RESTORE

5 Not used 3 Not used

Response

The device stalls endpoint 0 if it cannot process this request.

3M Touch Systems Proprietary Information

Page 21

SC500 USB Controller Communications 21

Set Feature – Calibration

This is a request to perform a 2-point calibration. The calibration can be performed at

points inset from the lower left, upper left and upper right corners. The 2-point

calibration defines the active area of the touch screen by mapping two targets

displayed on the video image to absolute X and Y coordinates on the touch screen.

Table 11. Set Feature- Calibration

Offset Field Size Value Description

0 bmRequestType 1 0x21 Host to device

1 bRequest 1 0x09 Set Report

2 wValue 2 0x0303 03=Feature

03=Feature ID

4 wIndex 2 0 Always 0

6 wLength 2 8 Always 8

Table 12. Data Stage

Offset Field Size Value Description

0 Report ID 1 0x21 Host to device

1 Report subtype 1 0x04 Set Report

2 bCalType 1 0xXX 0x01 = Extended Calibration (CX)

0x02 = Corner Calibration (CN)

3 Not used 5 0 Not used

Response

The device stalls endpoint 0 if the command cannot be processed successfully. The

request cannot be processed if an invalid calibration type is given in the wValue field.

During the calibration process, the calibration software polls the Get Status command

to monitor the progress of the calibration.

The calibration will fail if the two calibration points do not fall within certain bounds

established by the firmware. These bounds require that the two calibration points be in

correct quadrants of the sensor.

Calibration software can abort the calibration process with a Reset Request.

During the calibration process, the controller automatically determines screen/display

orientation and touch screen connector pinouts. This information is saved in the

controller non-volatile memory.

3M Touch Systems Proprietary Information

Page 22

22 SC500 USB Controller Reference Guide

Table 13. Calibration Response

Command Status

Byte

0 Calibration Failed

1 Controller is waiting for a touch in the lower left corner

2 Controller is waiting for a touch in the upper right corner

3 Calibration completed successfully

Description

This command corrects for touch screen display orientation and touch screen pinout

variations. This information will be maintained by the controller. The Calibrate 2

Point command initiates an interactive calibration procedure which defines the active

area of the touch screen by mapping locations to an absolute X,Y coordinate system.

Touch points generated subsequent to a successful calibration operation are calculated

based upon these calibration points. Calibrate 2-point utilizes inset calibration points

located 12½ percent inboard from the screen corners (at touch X,Y locations 128,128,

895,895 and 128,895) for accuracy and ease of operation.

Determining Target Areas

The default calibration targets (points) are located 12.5% (1/8) inward from the

corners of the video image. For example, suppose the display resolution of your

Windows-based monitor is 1024 x 768. The Calibration command calculates the

amount to move inward as follows:

• Amount to move inward in the X direction: 1024 x 1/8 = 128

• Amount to move inward in the Y direction: 768 x 1/8 = 96

The Calibration command then positions the first calibration target inward from the

lower left corner (0,767) and the second calibration target inward from the upper right

corner (1023,0). The following illustration shows how the calibration targets are

calculated for a Windows-based system. Your operating system may be different.

3M Touch Systems Proprietary Information

Page 23

SC500 USB Controller Communications 23

(

Figure 2. Calibration Target Locations

(1023, 0) [64K, 64k]*

0,0

Upper Right Calibration Target

X = 1023 – (1024 x 1/8) = 1023 – 128 = 895

Y = 0 +

768 x 1/8) = 0 + 96 = 96

Lower Left Calibration Target

X = 0 + (1024 x 1/8) = 0 + 128 = 128

Y = 767 - (768 x 1/8) = 767 - 96 = 671

(0, 767) [0, 0]* [64k,0]*

*The coordinates are in video terms, with the origin (0, 0) in the upper left corner of the screen. Examples from the

controller’s perspective, however, place the origin at the lower left corner of the screen (numbers in brackets). The

controller outputs 0 to 64K on both axes independent of display screen resolution.

(895, 96)

(128, 671)

Get Feature – Get Status

This is a request to send information that indicates the status of the controller. Among

the uses for this request are determining whether there were any power on check

errors determining whether the last request was completed successfully.

The response to the reset request is sent before the request completes. Polling (via the

status request) is then used to check the completion of those requests.

Table 14. Controller Status

Offset Field Size Value Description

0 bmRequestType 1 0xA1 Host to device

1 bRequest 1 0x01 Get Report

2 wValue 2 0x0306 03 = Feature

06 = Feature Report ID

4 wIndex 2 0 Always 0

6 wLength 2 8 Always 8

Table 15. Data Stage (controller response)

Offset Field Size Value Description

0 bReport ID 1 0x06 Feature Report ID

1 bPOCStatus 1 0xXX Power On Check Status

2 bCmdStatus 1 0xXX Status of last command

3 bTouchStatus 1 0xXX Finger Up/Down

4 bAsynchReports 1 0xXX 0x00 = asynchronous output off

0x01 = normal output

5 Not used 3 0 Not used

3M Touch Systems Proprietary Information

Page 24

24 SC500 USB Controller Reference Guide

POC Status – The status of the Power-on Checks. Various controller systems are

checked at power-up. If any failures in these systems are detected, a POC flag is set.

The POC status field reports the state of these flags. The POC status information is

also flashed on the controller’s LED.

Table 16. Power On Status

Bit Number LED Flashes Description

0 1 Not used

1 2 Program code checksum error

2 3 Not used

3 4 Block 1 parameters invalid (using defaults)

4 5 Power-up touch screen connector voltages are out of range

5 6 Not used

6 7 Not used

7 8 Controller linearization data invalid

Cmd Status – The status for the last command request. This field is used to determine

whether the last request was processed successfully. It is also used to track the

progress of a multi-stage request, such as calibration. The Status Request does not

affect the contents of this field, i.e., successful/unsuccessful processing of a previous

status request does not cause the command status field to be updated.

Table 17. Command Status Field Entries

Response Description

0 Failure in command processing

1 Command being processed

2 Stage 1 processing complete (for multi-stage commands).

3 Command complete

4 Soft reset occurred

5 Hard reset occurred

6 Stage 2 processing complete (for multi-stage commands)

7 Not used

Touch Status – Status information for the most recent coordinate. Information

includes whether the sensor is currently being touched.

Table 18. Power On Check Bit Fields

Bit Number Description

0 1 if the sensor is being touched

1 Always 0

3M Touch Systems Proprietary Information

Page 25

SC500 USB Controller Communications 25

Set Feature - Reset

This is a request to perform a controller reset.

Table 19. Reset Request

Offset Field Size Value Description

0 bmRequestType 1 0x21 Host to device

1 bRequest 1 0x09 Set Report

2 wValue 2 0x0303 03 = Feature

03 = Feature Report ID

4 wIndex 2 0 Always 0

6 wLength 2 8 Always 8

Table 20. Data Stage

Offset Field Size Value Description

0 bReport ID 1 0x03 Host to device

1 bmReport

Subtype

2 bResetType 1 0xXX 0x01=Soft reset

3 Not used 5 0 Not used

1 0x07 Indicates a reset request

Response

The device stalls endpoint 0 if the request cannot be processed successfully. The

request cannot be processed if the reset type specified by the bResetType field is not

valid.

Set Feature - Restore Defaults

This is a request to restore the default values in the controller to the factory presets.

You must recalibrate after this command since this request will also default the

calibration and screen/display orientation.

Table 21. Restore Defaults Request

Offset Field Size Value Description

0 bmRequestType 1 0x21 Host to device

1 bRequest 1 0x09 Set Report

2 wValue 2 0x0303 03 = Feature

4 wIndex 2 0 Always 0

6 wLength 2 8 Always 8

03 = Feature Report ID

3M Touch Systems Proprietary Information

Page 26

26 SC500 USB Controller Reference Guide

Table 22. Data Stage

Offset Field Size Value Description

0 bReport ID 1 0x03 Feature Report ID

1 bmReportSubtype 1 0x08 Indicates a restore defaults request

2 Not used 6 0 Not used

Response

The device stalls endpoint 0 if it cannot process this request.

Set Feature - Set Controller Number

This command is used to get a controller number for application use. The controller

does not use this value. This process is useful for identifying individual controllers in

a multiple controller system.

Table 23. Set Controller Number Request

Offset Field Size Value Description

0 bmRequestType 1 0x21 Characteristics

1 bRequest 1 0x09 Command number

2 wValue 2 0x0305 Parameter number

4 wIndex 2 0x00 Not used

6 wLength 2 0x48 Length of Parameter Data report

Table 24. Data Stage 1 (header data)

Offset Field Size Value Description

0 bReportID 1 0x05 Feature Report ID

1 bReport Subtype 1 0x01 Indicates a set param report

2 bArea 1 0 Memory Area (always 0=Ctrl EEPROM)

3 Not used 1 0 Not used

4 bSubArea 1 0x05 Block number

5 bIndex 1 0x00 Index into block

6 bDataLength 1 0x04 Number of valid data bytes for this xfer

(always padded to 64)

7 Not used 1 0x00 Not used

Table 25. Data Stage 2 through 9 (8 * 8 data bytes)

Offset Field Size Value Description

0-7 wData 1 0xXX 4 bytes of data (trailing pad bytes are ignored )

Data Stage

The controller ID is in the first 4 bytes of data stage, the remaining bytes are padding.

3M Touch Systems Proprietary Information

Page 27

SC500 USB Controller Communications 27

Response

If the command cannot be processed, the device stalls endpoint 0. The command

cannot be processed if the memory area is not valid. It cannot be processed if the

request is attempting to access data that is outside the specified memory area. This

may happen if the index is too large or too much data has been requested.

The host can send a status request, as long as the endpoint is not stalled, to determine

if this request was executed properly.

Get Feature – Get Controller Number

This command is used to get a controller number for application use. The controller

does not use this value. This process is useful for identifying individual controllers in

a multiple controller system.

Due to HID functionality, retrieving data from the controller involves two steps.

1. Requesting the controller number parameter

2. Retrieving the controller number value

Table 26. Get Controller Number Parameter Request

Offset Field Size Value Description

0 bmRequestType 1 0x21 Device to host

1 bRequest 1 0x09 Set Report

2 wValue 2 0x0303 03 = Feature

03 = Feature Report ID

4 wIndex 2 0 Always 0

6 wLength 2 0 Always 8

Table 27. Data Stage

Offset Field Size Value Description

0 bReport ID 1 0x03 Feature Report ID

1 bmReport Subtype 1 0x02 Indicates a set param index

2 bArea 1 0 Memory Area (always 0=Ctrl EEPROM )

3 Not used 1 0 Not used

4 bSubArea 1 0x05 Block number

5 bIndex 1 0x00 Index into block.

6 bDataLength 1 0x04 Number of valid data bytes for xfer (always padded to

64)

7 Not used 1 0 Not used

Table 28. Get Controller Number Request

Offset Field Size Value Description

0 bmRequestType 1 0xA1 Device to host

1 bRequest 1 0x01 Set Report

2 wValue 2 0x0305 03 = Feature

05 = Feature Report ID

4 wIndex 2 0 Always 0

6 wLength 2 0x48 Always 72 (allows for 64 data bytes + 8 byte header)

3M Touch Systems Proprietary Information

Page 28

28 SC500 USB Controller Reference Guide

Table 29. Data Stage 1 (controller response header)

Offset Field Size Value Description

0 Report ID 1 0x05 Feature Report ID

1 Not used 1 0 Not used

2 bArea 1 0 Memory Area (always 0=Ctrl EEPROM )

3 Not used 1 0 Not used

4 bSubArea 1 0x05 Block number (0x01,0x02, 0x05, or 0x65 for Copyright

string )

5 bIndex 1 0x00 Index into block. Use 0 for controller number

6 bDataLength 1 0x04 Number of valid data bytes for xfer (always padded to 64)

7 Not used 1 0 Not used

Table 30. Data Stage 2 through 9 (controller response data 8 * 8 data bytes)

Offset Field Size Value Description

0-7 wData 1 0xXX 4 bytes of data (trailing pad bytes are ignored )

Data Stage

The controller ID is in the first 4 bytes of data stage, the remaining bytes are padding.

Response

If the command cannot be processed, the device stalls endpoint 0. The command

cannot be processed if the memory area is not valid. It cannot be processed if the

request is attempting to access data that is outside the specified memory area. This

may happen if the index is too large or too much data has been requested.

The host can send a status request, as long as the endpoint is not stalled, to determine

if this request was executed properly.

3M Touch Systems Proprietary Information

Page 29

APPENDIX A

SC500 USB Controller Specifications

This section provides controller specifications such as power and environmental

requirements. The SC500 controller is a compact, small outline USB controller. This

controller should be internally mounted in your monitor.

The following figure shows the overall dimensions of the SC500 USB controller and

the locations of the mounting holes and connectors.

Figure 3. SC500 USB Touch Screen Controller Dimensions

Page 30

30 SC500 USB Controller Reference Guide

Technical Specifications

Physical Dimensions

Uncased 2.85 in. x 1.3 in. x 0.45 in. (72.4 mm x 33.0 mm x 11.4 mm)

Board Level Functions

Power 5 VDC (15 mA typical, 28 mA touching); ± 5% regulation

50 mV maximum ripple and noise

Regulatory Requirements

CE Compliance Compliant

EMC Emissions – EN 55022:1998 Compliant

EMC Immunity – EN 55024:1998 Compliant

ESD Susceptibility – IEC 61000-4-2 Compliant

EMI Immunity – IEC 61000-4-3 Compliant

Burst Immunity – IEC 1000-4-4 Compliant

FCC Class B / CISPR22 Class B Compliant

VCCI Class B ITE Emissions (Japan) Compliant

AS/NZS 3548:1995/CISPR 22 Class B ITE Emissions (Aus.) Compliant

UL/cUL Compliant

Ambient Operating and Storage Environmental Conditions

Note: All humidity is non-condensing

Operating Temperature Range 0°C to +65°C

Operating Humidity Range (0 to 95% RH up to +36°C; above 36°C refer to Figure 4 below)

Storage Temperature Range -20°C to +75°C

Storage Humidity Range (0 to 80% RH up to +36°C; above 36°C refer to Figure 4

below)

Performance and Reliability

Minimum Touch Duration 14 ±1 ms

Touch Resolution 1024 x 1024

(Maximum number of addressable coordinates generated by the controller)

ESD Susceptibility

1

±8KV Contact Discharge– Class 2 per section 9 of IEC 61000-4-2 Compliant

1 false touch allowed

±20KV Air Discharge – Class 1 per section 9 of IEC 61000-4-2 Compliant

Normal Operation – No false touches

MTBF (by MIL Std. 217F Calculation) >400,000 Hours

1

ESD discharges to a 3M Touch Systems touch screen connected to the controller

3M Touch Systems Proprietary Information

Page 31

SC500 USB Controller Specifications 31

3M Touch Systems Parameters

Accuracy vs. Dynamic Temperature Change Maintains 1% Accuracy

(tested at 0° C to 65° C with a 0.5° C/minute temperature ramp)

Touch Screen Compatibility 3M Touch Systems Resistive Touch

Screens

Communications Protocol USB Rev 1.1

Figure 4. Storage and Operating Temperature and Humidity Conditions

3M Touch Systems Proprietary Information

Loading...

Loading...