Page 1

MT3000

Capacitive Controller

Reference Guide

Page 2

The information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose, without the

express written permission of MicroTouch Systems, Inc. MicroTouch may have patents or pending patent

applications, trademarks, copyrights, or other intellectual property rights covering subject matter in this

document. The furnishing of this document does not give you license to these patents, trademarks, copyrights, or

other intellectual property except as expressly provided in any written license agreement from MicroTouch.

© 1999 MicroTouch Systems, Inc. All rights reserved.

Printed in the United States of America.

Document Title

Document Number: 19-236, Version 2.0

MicroTouch, the MicroTouch logo, AdLink, ClearTek, DrivePoint, Factura, FinePoint, Ibid, the Ibid logo,

KeyPad, Microcal, PicturePad, P r i vacyTouch, Prospector, The Public Browser, QuickPoint, ScreenWriter Tablet,

SimpleTouch, SurfControl, ThruGlass, TouchMate, TouchPad, TouchPen, TouchWare, TouchTek, TruePoint,

TuffTouch, UnLink, UnMouse, Web Station, and WorldService are either registered trademarks or trademarks of

MicroTouch Systems Incorporated in the United States and/or other countries.

Microsoft, MS-DOS, Windows, and Windows NT are registered trademarks of Microsoft Corporation.

: MT3000 Capacitive Controller Reference Guide

Page 3

Contents

About This Manual

MicroTouch Support Services........................................................5

MicroTouch Technical Support ................................................5

MicroTouch on the World Wide Web......................................6

MicroTouch Corporate Headquarters and Worldwide Offices......7

Chapter 1 Integrating the MT3000 Controller

Overview of the MT3000 Touchscreen Controller......................10

Mounting the MT3000 Controller................................................12

Connecting the Touchscreen Cable..............................................14

Establishing the Data Connection................................................15

Supplying Power to the Controller...............................................17

Using an Internal Power Supply (+5V) to JP2.......................17

Using a Custom Serial Cable Design.....................................18

Using an External Wall-Mount Power Supply.......................18

Using a Keyboard Power Tap Cable......................................18

Mounting the Touchscreen...........................................................19

Turning On Your System.............................................................19

Status Light (LED) Diagnostics ...................................................20

What's Next? ................................................................................22

Installing and Using TouchWare............................................22

Page 4

MT3000 Capacitive Controller Reference Guide4

Calibrating the Touchscreen ..................................................22

Chapter 2 Communicating with the MT3000 Controller

Controller Default Settings .......................................................... 24

Communication Parameters...................................................24

Data Format............................................................................ 24

Operating Mode ..................................................................... 25

Communicating with the Controller ............................................26

Sending Commands to the Controller.................................... 26

Receiving Responses from the Controller..............................27

Summary of Firmware Commands..............................................30

AutoBaud Disable........................................................................34

AutoBaud Enable.........................................................................35

Calibrate Extended....................................................................... 36

Determining Target Areas......................................................36

Guidelines for Calibrate Extended......................................... 37

Calibrate Extended Procedure................................................38

Calibrate Raw............................................................................... 39

Format Decimal............................................................................ 41

Format Raw..................................................................................43

Format Tablet............................................................................... 45

Mode Status..................................................................................47

Mode Stream................................................................................49

Null Command............................................................................. 50

Output Identity.............................................................................51

Parameter Lock ............................................................................ 52

Parameter Set ............................................................................... 53

Reset.............................................................................................55

Restore Defaults........................................................................... 56

Unit Type Verify.......................................................................... 57

Appendix A MT3000 Controller Specifications

Index

Page 5

About This Manual

This reference manual, directed to developers of touchscreen systems,

provides installation and configuration information for the MicroTouch

MT3000 capacitive touchscreen controller.

This document includes information on integrating the MT3000 controller

into your design, communicating with the controller, installing the

TouchWare user interface software, and troubleshooting setup problems. It

also includes a complete description of the firmware commands, a guide to

interpreting status LED conditions, and a table of controller specifications.

MicroTouch Support Services

MicroTouch provides extensive support services through our technical

support organization. You can contact technical support by telephone, fax,

or electronic mail, or obtain updated information and drivers on the World

Wide Web.

MicroTouch Technical Support

Technical Support by telephone is available:

24 hours a day, Monday through Friday (excluding holidays)

•

9:00 a.m. to 5:00 p.m. Eastern Standard Time, Saturday and Sunday

•

(excluding holidays)

The Technical Support Hot Line number is: 978-659-9200

Page 6

MT3000 Capacitive Controller Reference Guide6

Whenever you contact Technical Support, please be ready to provide the

following information:

Part numbers of your controller and sensor

•

Version number of your MicroTouch TouchWare

•

Make and model of your personal computer

•

Name and version number of your operating system

•

Type of mouse connected to your system

•

List of other peripherals connected to your system

•

List of application software installed on your system

•

You can also submit a written description of the problem to MicroTouch

Technical Support at any time by sending a fax or electronic mail.

Technical Support Fax: 978-659-9400

•

Technical Support E-Mail: support@microtouch.com

•

MicroTouch on the World Wide Web

You can download MicroTouch touchscreen software and drivers, obtain

regularly updated technical information on MicroTouch products, or learn

more about our company at the following web site:

http://www.microtouch.com

Page 7

About This Manual 7

MicroTouch Corporate Headquart er s and Worldwide Offices

United States

MicroTouch Systems, Inc.

300 Griffin Brook Park Drive

Methuen, MA 01844

United States

Phone: 978-659-9000; Fax: 978-659-9100

Web Site: http://www.microtouch.com

E-Mail: touch@microtouch.com

Support Hot Line: 978-659-9200

Support Fax: 978-659-9400

Support E-Mail: support@microtouch.com

Australia

MicroTouch Australia, Pty Ltd.

797 Springvale Road

Mulgrave Victoria 3170 Australia

Phone: +613 9582 4799

Web Site: http://www.microtouch.com.au

E-Mail: touch@microtouch.com.au

Support: support@microtouch.com.au

France

MicroTouch Systems SARL

Europarc de Créteil

19, rue Le Corbusier

94042 Créteil Cedex France

Phone: +33 (1) 45 13 90 30

Email:

support@microtouch.fr

Germany

MicroTouch Systems GmbH

Schiess-Straße 55

40549 Düsseldorf Germany

Phone: +49 (0) 211-5 99 07-0

Email:

support@microtouch.de

Hong Kong

MicroTouch Systems Ltd.

Unit 1, 26/F, Westley Square

48 Hoi Yuen Road, Kwun Tong

Kowloon, Hong Kong, SAR, PRC

Phone: +852-2333-6138

Fax: +852-2333-6861

Email: support@microtouch.com.hk

Italy

MicroTouch Systems srl

C.so Milano, 19

20052 Monza (MI) Italy

Phone: +39 (0) 39-230-2230

Email:

support@microtouch.it

Japan

MicroTouch Systems K.K.

Bellevue Miz onokuchi Build ing 3F

3-2-3, Hisamoto, Takatsu-ku

Kawasaki-shi, Kanagawa 213 Japan

Phone: +81 (44) 811-1191

Fax: +81 (44) 811-1138

Email: support@microtouch.co.jp

Korea

MicroTouch Systems, Inc.

#402, 4

th

Floor, Nam-Kyung Building

769-6 Yeoksam-Dong, Kangnam-Gu

Seoul, Korea

Phone: +82 (2) 552-3198

Spain

MicroTouch Systems SL

Via Augusta 13-17 , Oficina 704

08006 Barcelona Spain

Phone: +34 93 415 62 85

Email:

supportspain@microtouch.co.uk

Taiwan R.O.C.

MicroTouch Systems, Inc. Taiwan

9-3 Floor, No. 33, Sec. 1, Minsheng Road

Panchiao, Taipei County 22046

Taiwan, R.O.C.

Phone: +886-2-2959-6647

Fax: +886-2-2959-6747

Email: support@microtouch.com.tw

United Kingdom

MicroTouch Systems, Ltd.

163 Milton Park Abingdon

Oxon OX14 4SD England

Phone: +44 (0) 1235-444400

Email:

support@microtouch.co.uk

Page 8

Page 9

CHAPTER 1

Integrating the MT3000 Controller

The MicroTouch MT3000 controller offers an economical, high

performance solution for capacitive touch applications. Its compact design

makes for easy integration into flat panel displays and mobile devices.

The MT3000 controller works with all the leading operating systems and is

backed by the MicroTouch guarantee of worldwide support.

This chapter covers the following MT3000 controller specifications:

Mounting requirements

•

Power requirements and options

•

Cable connections

•

Data exchange

•

Status LED codes

•

Page 10

MT3000 Capacitive Controller Reference Guide10

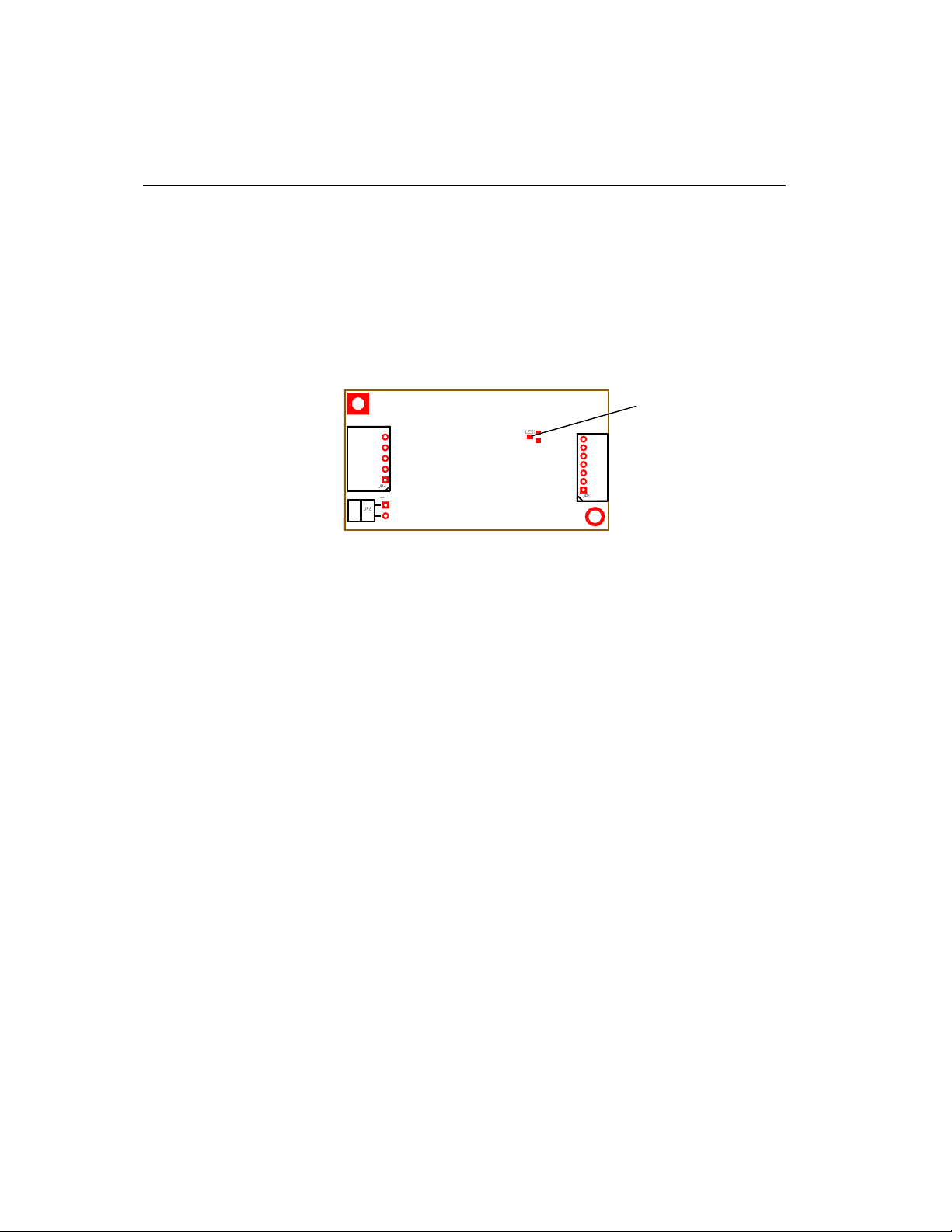

Overview of the MT3000 Touchscreen Control ler

The MT3000 touchscreen controller and touchscreen are supplied as a

matched set. A 25-point linearization procedure has been performed to

determine the physical properties of the screen, and the data is stored in the

NovRAM of the controller that ships with the screen.

The controller and touchscreen are shipped mated by the flex cable with a

serialized label on the sensor, the controller, and over the connector to

identify them as a matched set. If the connection needs to be broken during

the integration process, the components can be matched again by serial

number.

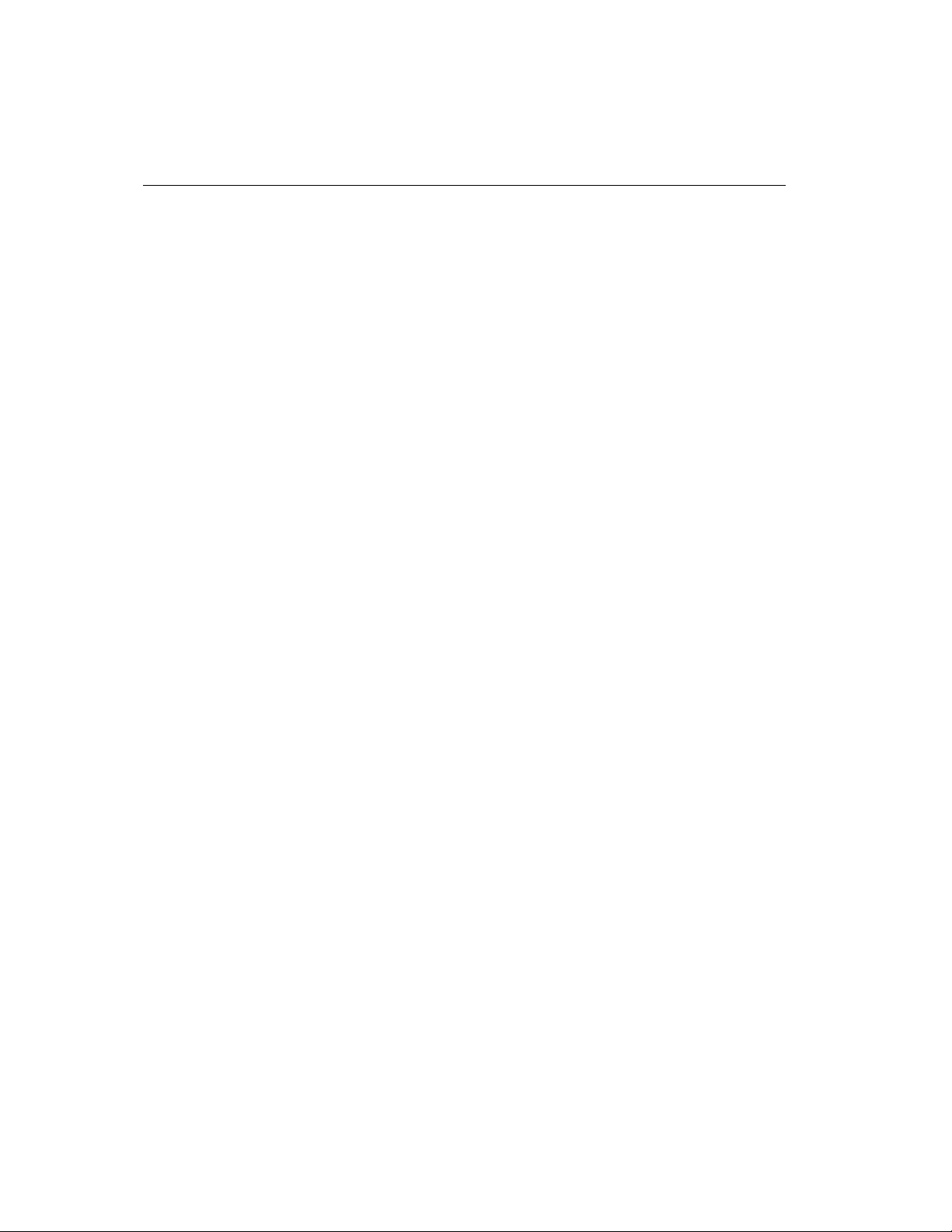

The MT3000 is a compact controller with a standard RS-232 serial

interface. It measures 1.3 x 2.4 inches with a total height profile of 0.4

inches from the thru hole pins on the trace side of the board to the top of the

highest component on the opposite side. The MT3000 has a touchscreen

connector, a serial cable connector, and a power connector. Refer to

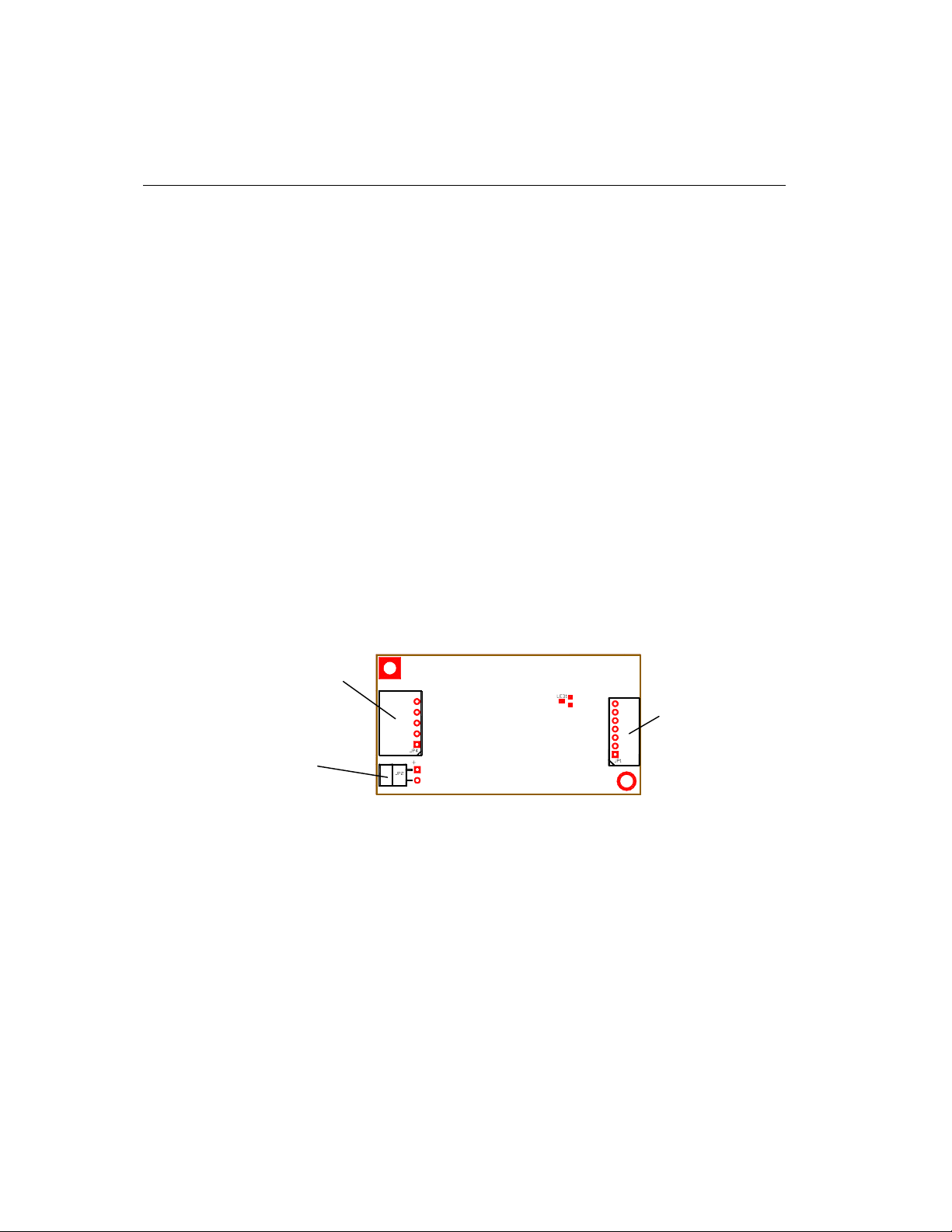

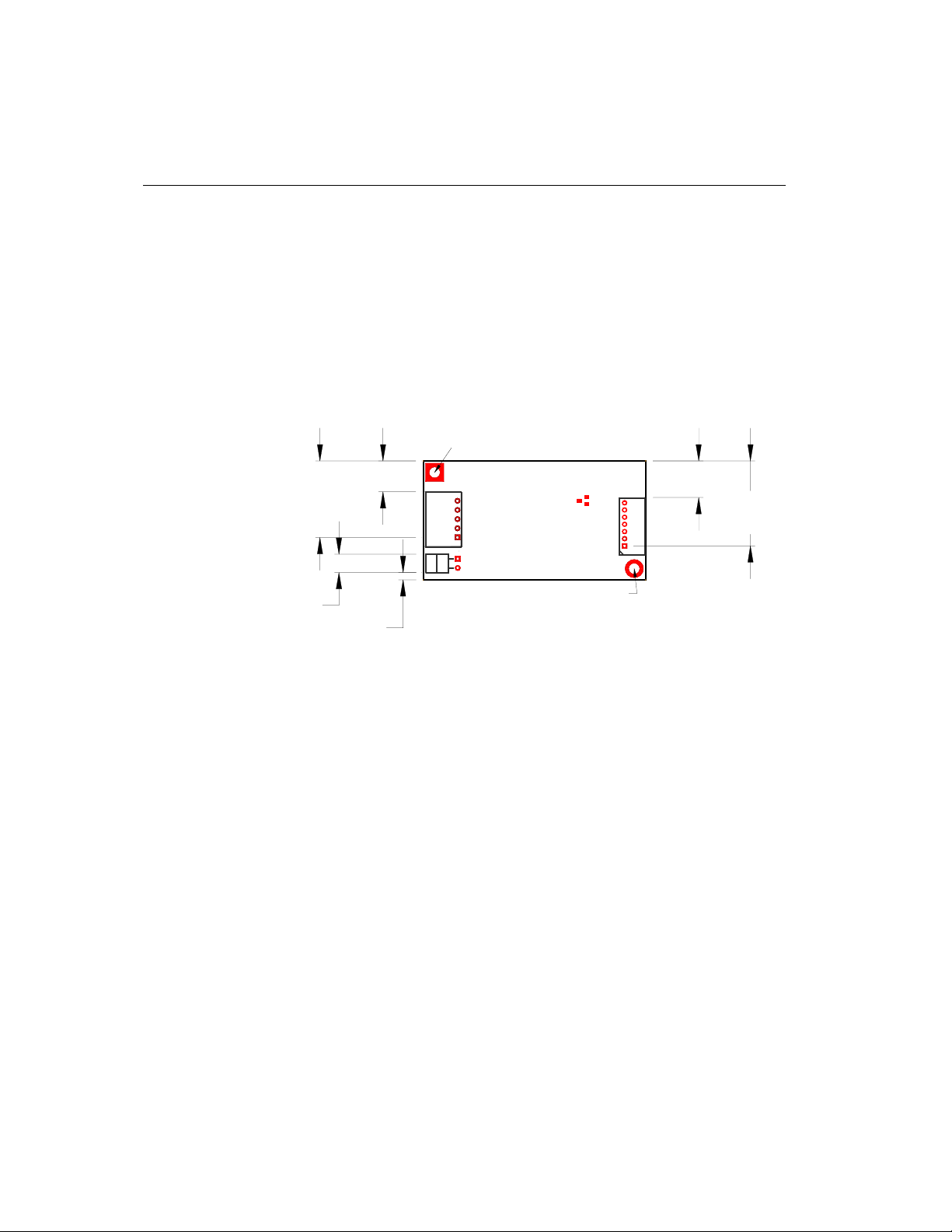

Figure 1 for connector locations and to Figure 2 for the overall dimensions.

5-Wire

Touchscreen

Connector

Power

RS-232 Cable

Connection

Figure 1 MT3000 Connector Locations

Page 11

Chapter 1 Integrating the MT3000 Controller 11

2.435"

0.125"

[3.18mm]

[61.85mm]

JP4

+

JP2

[3.18mm]

0.125"

0.125"

[3.18mm]

LED1

JP1

0.125"

[3.18mm]

Figure 2 MT3000 Overall Dimensions

To properly integrate and test the MT3000 controller, you need the

following items:

A MicroTouch capacitive touchscreen and MT3000, mated as a

•

linearized set. The touchscreens are available in a variety of sizes.

1.300"

[33.02mm]

A method of establishing the serial data communication between the

•

controller and your system. You can use the standard MicroTouch RS232 serial cable (P/N 7310101), or you can build your own cable.

A method of supplying power to the controller. There are several options

•

available including a cable connection to the 0.2 inch power connector

(JP2) or supplying power through the serial cable.

A touchscreen driver with a 2–point calibration routine available to the

•

end user.

Note:

You can use TouchWare, which includes the touchscreen device

driver and utilities software.

Page 12

MT3000 Capacitive Controller Reference Guide12

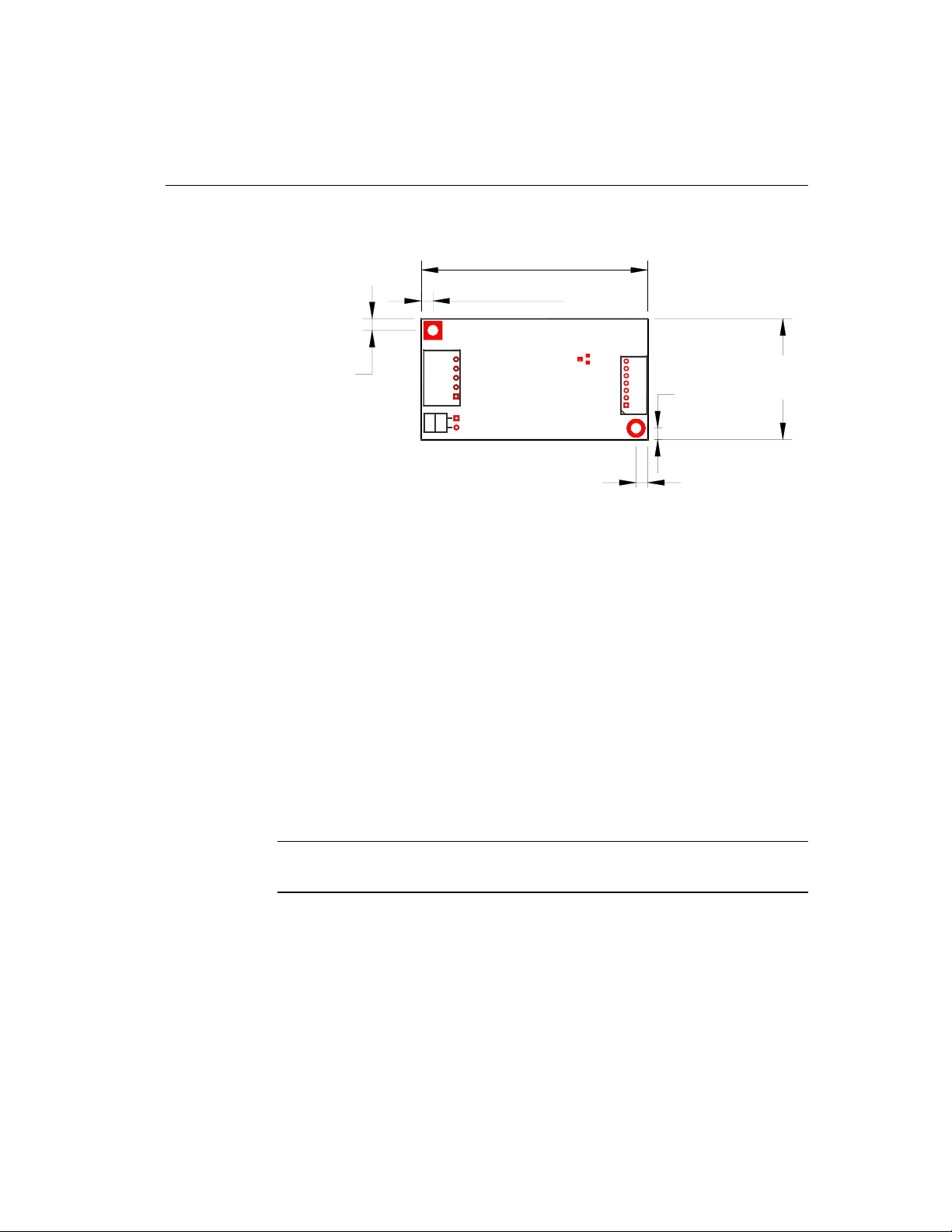

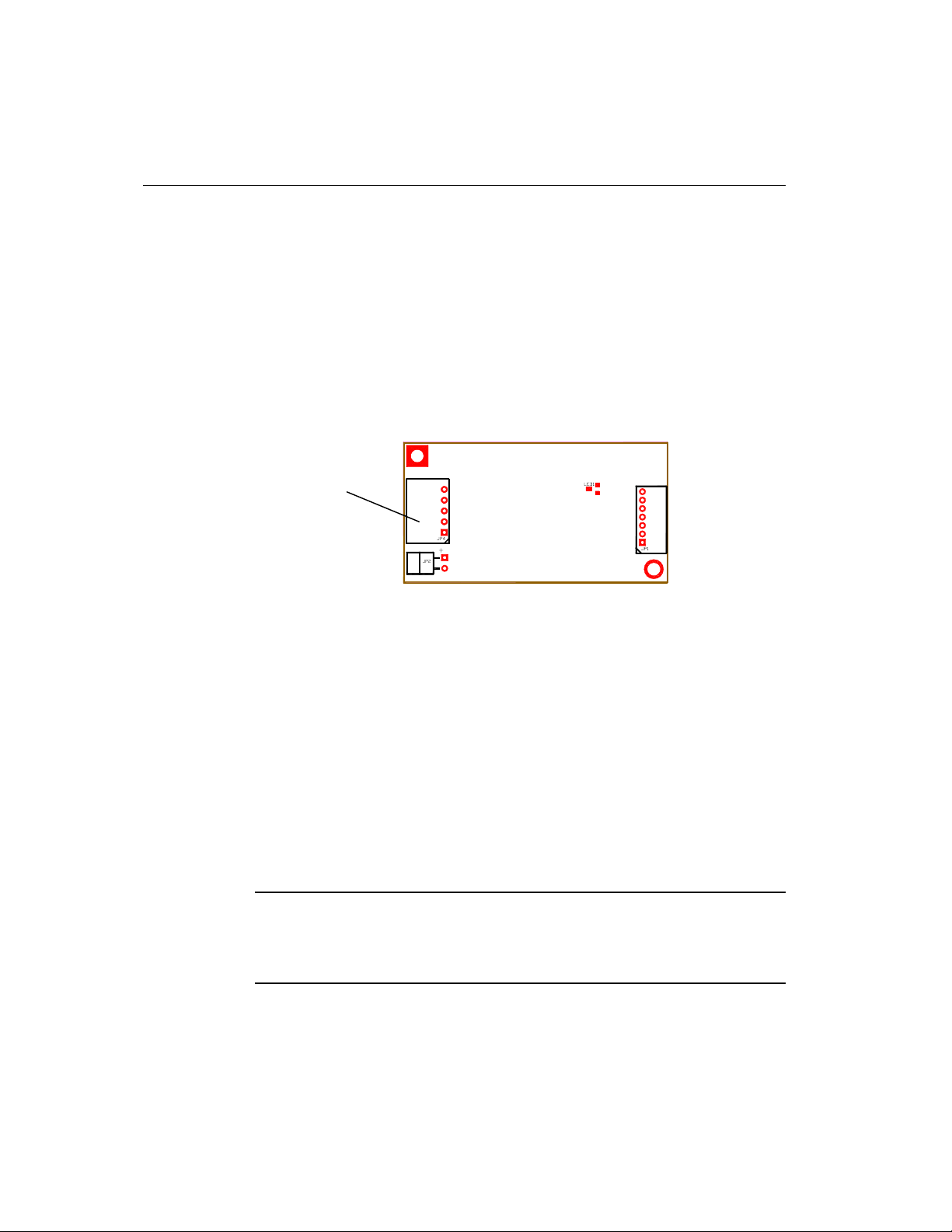

Mounting the MT3000 Controller

You can easily mount the MT3000 controller using standard 4-40 machine

screws and washers through the two existing mounting holes. All the

components and the connectors are mounted on the top side of the PC board

to reduce the overall profile and to minimize clearance requirements.

Figure 3 shows the connector locations and identifies which of the

mounting holes requires grounding.

0.122" (4-40 screw grounding required)

0.336"

0.836"

[21.23mm]

0.200"

[5.08mm]

[8.53mm]

JP4

+

JP2

0.122" (4-40 screw no-grounding required)

0.080"

[2.03mm]

LED1

0.400"

[10.16mm]

0.929"

JP1

[23.60mm]

Figure 3 Connector Locations and Mounting Holes

When you mount the MT3000 controller, remember the following important

rules:

Always mount the controller internally. You can orient the components

•

up or down, but turn the board so that the flex cable is not twisted 180°.

If possible, mount the controller with the component side visible so you

can monitor the status of the LED.

Ground the controller. Mount it to a metal chassis surface if possible. If

•

you must mount it to a non-metal surface, be sure to attach a ground

wire as described in the last paragraph of this section.

Maintain a clearance of at least 1/8 inch from the highest projection on

•

the controller to the chassis.

Try to find a mounting area that is away from heat sources and EMI

•

noise generators such as power supplies and backlight (or CRT) drive

electronics.

Page 13

Chapter 1 Integrating the MT3000 Controller 13

Route the touchscreen flex cable around the display and plug it into the

•

controller connector (JP4). The cable is supplied mated to the controller

and taped over with a part number sticker. If you must disconnect the

cable during assembly, ensure that the controller is re-mated to the

sensor with the same serial number.

To avoid malfunctions or damage due to electrostatic discharge (ESD),

make sure you properly ground the controller through the mounting hole

shown in Figure 3. Ideally, you should mount the controller to a metal

chassis surface that is properly grounded using metal screws and standoffs.

If you use plastic screws, or if you mount the controller to a non-metal

surface, you must connect the mounting hole

connector

(JP4) to a grounded location. See Figure 3. Be sure to route the

nearest the touchscreen

wire to the nearest grounded location, and keep the wire dimensions as short

and as thick as possible. MicroTouch recommends that you use braided

ground cable with a flat lug crimped at both ends.

Page 14

MT3000 Capacitive Controller Reference Guide14

Connecting the Touchscreen Cable

The touchscreen connector (JP4) is a 5-pin AMP 103634-5, locking right

angle male connector with pins on 0.1 inch centers.

The MT3000 controller supports exiting the flex cable in any direction from

the touchscreen– from the top, bottom, left or right. The standard

configuration is with the flex cable exiting from the right side of the sensor,

(3 o’clock position) when viewed from the front.

5-Wire

Touchscreen

Connector

Figure 4 Touchscreen Connector

If you exit from another direction, the controller firmware automatically

determines the pinout configuration when you calibrate the touchscreen

with TouchWare or your equivalent software. This permits flexibility in

orienting the sensor and in mounting the controller to conform to your

hardware requirements.

The automatic pinout configuration feature resides in the controller and is

independent of the driver you are using.

MicroTouch can provide software for performing a 25–point linearization

procedure by the customer, although this is not required with a mated

controller and sensor.

Caution:

If you are equipped to perform a 25–point linearization and

decide to do so, you must orient the sensor with the tail exiting to the right

during the procedure. After linearization, you can re-orient the screen as

required by your OEM design.

Page 15

Chapter 1 Integrating the MT3000 Controller 15

Establishing the Data Connection

The MT3000 controller requires that an RS-232 serial communication cable

be attached to connector JP1.

You can use a standard MicroTouch RS-232 cable (P/N 7310101). You may

need a 9-pin to 25-pin adapter if the only available communication (COM)

port on your PC has 25 pins. One end of this cable plugs into the RS-232

connector (JP1) on the MT3000 controller (Figure 5). The other end, which

has a 9-pin D connector, plugs into a COM port on your PC, directly or

through the adapter. Table 1 describes the interconnections for the

MicroTouch RS-232 cable.

For OEM designs, you can build your own cable using a 7-pin Molex

connector (51004-0700) to mate to the JP1 connector, and design your own

connector or hard-wired configuration at the other end.

As an option, MicroTouch can supply a controller with the RS232

transceiver removed and bypassed to allow a direct serial 5V logic

interface.

Figure 5 Data Connection

RS-232 Cable

Connection

Page 16

MT3000 Capacitive Controller Reference Guide16

Table 1 COM Cable for MT3000 Controller

PC Side

(9-Pin D)

Pin RS-232 Assigned Jumpered to: Color Pin Description

1 Data Carrier Detect

(DCD)

2 Receive Data

(RXD)

3 Transmit Data

(TXD)

4 Data Terminal Ready

(DTR)

5 Signal Ground Blue 5 Power supply ground

6 Data Set Ready

(DSR)

7 Request to Send

(RTS)

4 and 6

DTR and DSR

1 and 6

DCD and DSR

1 and 4

DCD and DSR

Wire Controller Side

(7-Pin Molex)

Brown 2 Transmit Data

Red 3 Receive Data

Black 1 Request to Send

None

(TXD)

(RXD)

None

None

(RTS)

8 Clear to Send

(CTS)

Sleeve White 6 DC power jack

Pin

Shell

Green 4 Clear to Send

(CTS)

(+5 VDC)

7 Cable shield connected

to ground. D C power

jack ground

7 Chassis (earth) ground

Page 17

Chapter 1 Integrating the MT3000 Controller 17

Supplying Power to the Controller

You must supply the MT3000 controller with power. You can use internal

power (that is, tap power from inside the monitor or PC) or external power.

Note:

with a maximum ripple and noise of 50mV peak-to-peak.

You can supply power to the MT3000 controller using any of the following

methods:

•

•

•

•

Caution:

controller. Power from two sources could damage one or both of the power

supplies.

However you supply power, the source must deliver 70 mA typical,

Internal power into JP2 using +5 volts DC at JP2, pin 1 and power

supply ground at JP2, pin 2

Internal power through a custom serial cable configuration

External power (+5 volts DC) from a wall-mount power supply

External power (+5 volts DC) from a keyboard power tap cable

Do not supply both internal power and external power to the

Using an Internal Power Supply (+5V) to JP2

You can power the MT3000 at JP2 using a +5 volt DC power source within

the system.

To provide power directly to the controller using JP2:

!

1.

Obtain a locking, mating connector for JP2

(Molex housing 22-01-3027 with 08-50-0114 contacts).

2.

Attach power and ground to the connector (Pin 1: +5V ,

Pin 2: Ground). The connector is keyed. Pin 1 has continuity to the

trace marked + on the board.

3.

Insert locking connector into JP2.

Page 18

MT3000 Capacitive Controller Reference Guide18

Using a Custom Serial Cable Design

When creating a custom serial cable connection (refer to "Establishing the

!

Data Connection"), you can provide power to the controller through the

mating Molex connector:

1.

Obtain a 7-pin Molex connector 51004-0700.

2.

Attach power and ground to the connector, (Pin 6: +5V, Pin 7: Ground).

Using an External Wall-Mount Power Supply

If you are using a standard MicroTouch RS-232 serial cable (P/N 7310101),

you can use either a 120 volt wall-mount power supply (P/N 19-408) or a

220 volt wall-mount power supply (P/N 19-409).

To connect an external wall-mount power supply:

!

1.

Remove the plastic plug covering the power jack of the 9-pin D

connector on the serial cable.

2. Connect a DC power plug to the power jack built into the 9-pin D

connector.

3. Plug the power supply into a grounded outlet. The power plug supplies

both +5V and ground.

Using a Keyboard Power Tap Cable

If you are using a standard MicroTouch RS-232 serial cable, you can use

either a 5-pin IBM AT compatible keyboard power tap cable (MicroTouch

P/N 19-356) or a 6-pin IBM PS/2 compatible keyboard power tap cable

(P/N 19-357).

To connect a keyboard power tap cable:

!

1. Disconnect the keyboard cable from the back of your computer.

2.

Plug the keyboard cable into the power tap cable.

3.

Plug the power tap cable into the keyboard socket on the back of your

computer.

4.

Remove the plastic plug covering the power jack of the 9-pin D

connector on the serial cable.

Page 19

5.

Connect the DC plug from the power tap cable to the jack built into the

9-pin D connector.

Mounting the Touchscreen

There are several methods for mounting the touchscreen depending on your

application (CRT displays, LCD modules, flat panel displays, each in a

variety of sizes). If you need instructions or recommendations from

MicroTouch on how to incorporate a touchscreen into your OEM design,

you can order the publication Touchscreen Kits Installation Guide

(Document Number 19-215).

Turning On Your System

Before you turn on your custom system, ensure that all cables are connected

properly and that the controller is properly mounted. Be sure to tighten all

cable connector screws.

Chapter 1 Integrating the MT3000 Controller 19

To start up your system:

!

1. Turn on your monitor and computer.

2.

Adjust the contrast and brightness to suit your personal preference and

working environment.

3.

Adjust the horizontal and vertical position controls on the monitor to

center the image on the screen.

The MT3000 controller has a light emitting diode (LED) on the component

side of the board that indicates the status of the touchscreen unit.

If it was necessary for you to mount the controller component side down,

you can determine the status of the LED from its reflected light off the

mounting surface.

If the LED is on, and remains dimly lit, the controller has power and is

operating properly. If the LED is off, the controller is not receiving power.

See the next section for other indications.

Page 20

MT3000 Capacitive Controller Reference Guide20

Status Light (LED) Diagnostics

MicroTouch controllers are highly reliable units, however there may be

occasions when the controller does not perform exactly as you expect. The

MT3000 controller provides diagnostic feedback with an LED as shown in

Figure 6.

Figure 6 Diagnostic LED (component side)

When you power-up the unit, the LED is bright until the controller start-up

sequence is completed. Following start-up, the LED becomes dim and

remains dim as long as you do not touch the sensor. When you touch the

sensor, the LED becomes bright.

LED

A flashing (or blinking) LED during power-up indicates the controller’s

power-on self-test failed. Refer to Table 2 for a description of each error

code.

Page 21

Chapter 1 Integrating the MT3000 Controller 21

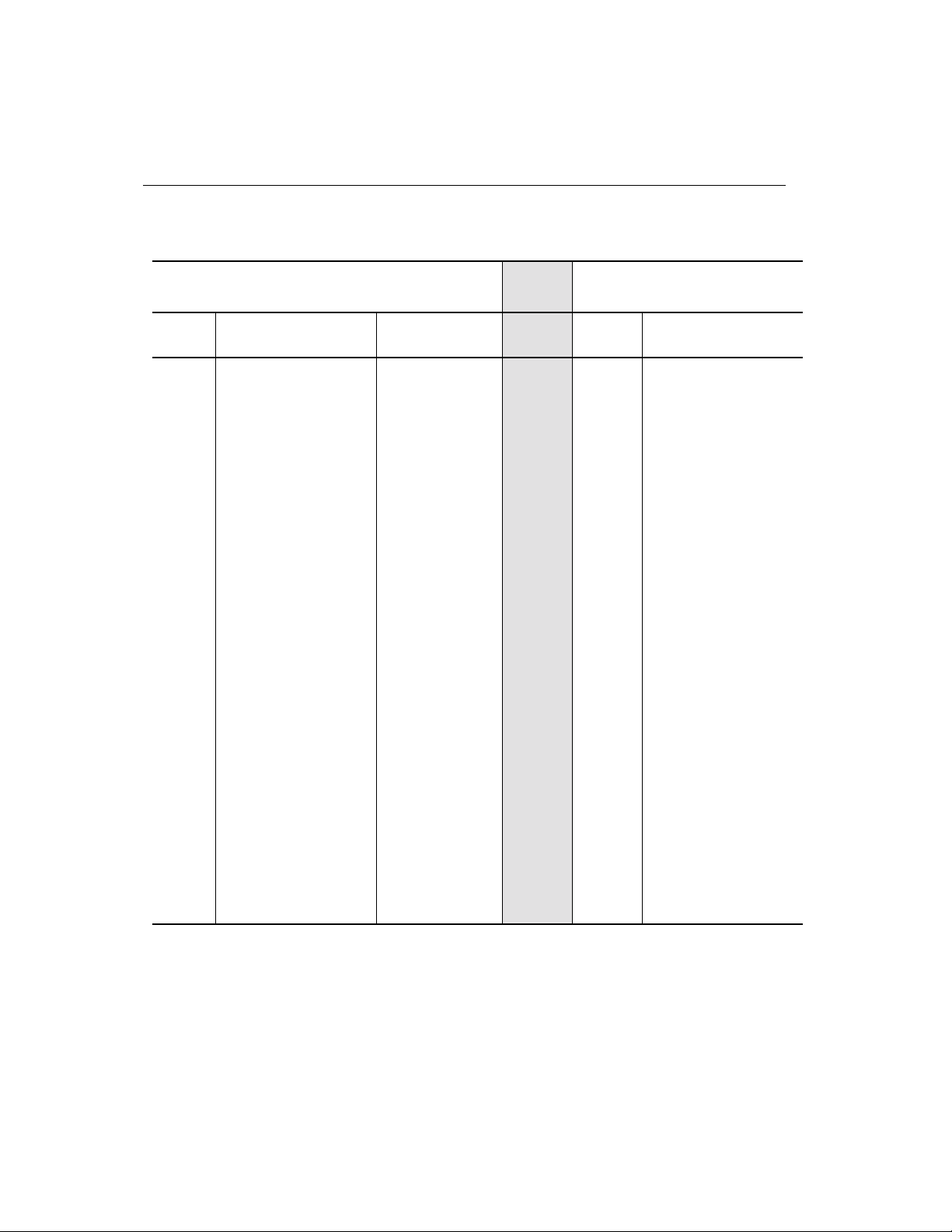

Table 2. LED Diagnostic Codes for MT3000 Controller

LED Flashes

(per 10 seconds)

1 0 Reserved for future assignment.

2 1 ROM error. Firmware checksum verification

3 2 Pulse Width Modulation (PWM) error. Unable to

4 3 Block 1 NovRAM error. The operating

5 4 HDW error. The controller hardware failed

6 5 Reserved for future assignment.

7 6 Reserved for future assignment.

8 7 Block 2 NovRAM error. The linearization data in

Self-Test Bit

(UV Command)

Error Description

error.

establish PWM operating range at power-up.

parameters in the controller NovRAM are

invalid. Using defaults.

(unable to initialize or configure gate array).

Non-recoverable error.

the controller NovRAM is invalid.

Note:

Some errors are non-recoverable, meaning that normal touchscreen

operation cannot occur. Recoverable errors cause the controller to revert to

default values.

Page 22

MT3000 Capacitive Controller Reference Guide22

What's Next?

You have successfully installed the MT3000 controller and connected the

touchscreen to your computer. You are now ready to complete the following

tasks:

•

•

Installing and Using TouchWare

TouchWare includes the software driver that lets your touchscreen work

with your computer. MicroTouch has touchscreen drivers for many

operating systems, including Windows 3.1x, Windows 95, Windows 98,

Windows NT, MS-DOS, and OS-2. Be sure to install the touchscreen

software for the operating system you are using.

TouchWare also includes a control panel for setting user touchscreen

preferences and diagnostic utilities for isolating problems. For more

information on installing and using the touchscreen control panel, refer to

the

Install TouchWare or equivalent software for your touchscreen

Use the software to calibrate the touchscreen

TouchWare User’s Guide

.

Calibrating the Touchscreen

Calibration

the dimensions of the image area on the touchscreen, determining the edges

of the screen’s image, and locating the center of the touchscreen. You must

calibrate the touchscreen and test the calibration to ensure its successful

operation.

See the

touchscreen.

aligns the touchscreen with the underlying video by defining

TouchWare User’s Guide

for instructions on calibrating your

Page 23

CHAPTER 2

Communicating with the MT3000

Controller

This chapter discusses the fundamentals of communicating with the

MT3000 controller. The firmware commands, which are usually issued by a

driver or utility program on the host system, control the operation of the

touchscreen controller, however developers can enter these commands

directly.

This chapter

Describes the controller default settings

•

Lists the recommended firmware commands for current development

•

Describes how to use each of these commands

•

References additional commands developers may need to use

•

The description of each command includes the command syntax, the default

value, how the command works, and the expected response from the

controller.

Page 24

MT3000 Capacitive Controller Reference Guide24

Controller Default Settings

This section describes the default settings for the MT3000 controller.

Communication Parameters

The default operation of the MT3000 controller is N, 7, 2 (no parity, 7 data

bits, and 2 stop bits) at 9600 baud. It also can be programmed to work with

even/odd parity, 8 data bits, and 1 or 2 stop bits.

Data Format

Data format

touch coordinates to the host system.

Format Decimal is the default format for the MT3000 controller operating

at 7 data bits. Format Decimal is provided for compatibility with older

designs,

current development because:

Format Tablet uses only 5 bytes per point and provides the most rapid

•

response time to a touch.

It is the most efficient and most compact data format, sending

•

approximately 192 packets per second at 9600 baud.

Format Tablet includes a status byte. The status byte contains

•

information on whether the X/Y coordinate is generated from a

touchdown, a touch continuation (when the finger is resting on the

screen), or a touch liftoff.

Format Tablet is supported by all current MicroTouch touchscreen

•

controllers.

It is the standard for current MicroTouch product development and is

•

the format used by all touchscreen drivers written by MicroTouch.

To use Format Tablet, you must reinitialize the controller to N, 8, 1. See the

initialization instructions in the following section: Communicating With the

Controller.

refers to the type of packet the controller uses to send the X/Y

however

MicroTouch recommends that you use Format Tablet for

Refer also to the Format Tablet command in the firmware reference section

that follows.

Page 25

Chapter 2 Communicating with the MT3000 Controller 25

Operating Mode

The

operating mode

specifies the conditions under which the controller

sends the X/Y touch coordinates (input data packet) to the host system.

Mode Stream is the default operating mode for the MT3000 controller. In

Mode Stream, the controller sends a continuous stream of data packets

when the screen is touched. The controller sends the data as long as a touch

continues on the sensor.

Because Mode Stream sends touch data continually, it is the most versatile

mode, and it provides the best response time and overall feel.

MicroTouch recommends that the touchscreen generate an interrupt as each

byte in the data stream arrives. Because touchdown and liftoff events are

specially coded, your software always knows exactly what the user is doing,

provided that the interrupts are sent as recommended. This enables instant

feedback and prevents data loss.

Page 26

MT3000 Capacitive Controller Reference Guide26

Communicating wi th the Contr ol ler

This section provides information on sending firmware commands to the

controller and interpreting the responses that the controller returns.

The commands listed in this section are those that Microtouch currently

uses for development. MicroTouch recommends that you use these

commands for MT3000 controller development, however if you need

additional commands for compatibility with older designs, you can find the

complete command set on the TouchWare CD. Refer to Table 5 in this

document and the respective commands in the Touch Controllers Reference

Guide on the TouchWare CD.

Commands to the controller are sent on the signal

as a serial data stream. For each command it receives, the controller sends a

response to the host on the signal

serial data stream.

Transmit Data

Receive Data

(TXD) line– also as a

(RXD) line

Sending Commands to the Controller

When you send a command to the controller, you must use the correct

command format. The general format of a command is as follows:

<Header>Command<Terminator>

Note:

MicroTouch’s terminal emulator key sequences. You may need to enter the

sequence in a different format, depending on your emulator.

The

start-of-header control character SOH. The hexadecimal code for the ASCII

SOH control character is 01. To start the command sequence, use the key

combination Ctrl A (^A). If you are working with an IBM PC compatible

system, the Ctrl A key combination immediately returns an ASCII

character.

The following descriptions of header, command, and terminator, use

header

is the first character in the command string and is the ASCII

!

The

command

uppercase letters and numbers only (printable characters).

The

terminator

carriage return CR. An ASCII CR control character is 0D hexadecimal. To

, which always follows the header, consists of ASCII

is the last character of each command string and is an ASCII

Page 27

Chapter 2 Communicating with the MT3000 Controller 27

enter a carriage return, ending the command sequence, use Enter or the key

combination Ctrl M (^M).

This chapter lists each command as a string of ASCII control characters and

printable characters consisting of a header, the command, and a terminator

as follows:

<SOH>

Command

<CR>

Receiving Responses from the Controller

After executing a command, the controller returns a response or

acknowledgment to the host system. Each controller response consists of a

header, the command response, and a terminator in the following format:

<Header>Command Response<Terminator>

Note:

MicroTouch’s terminal emulator key sequences. The format of controller

responses varies depending on the terminal emulation mode you are using.

The

start-of-header control character SOH. The hexadecimal code for the ASCII

SOH control character is 01. If you are working with an IBM PC compatible

system in terminal mode, the SOH control character returns a ! character to

the screen.

The

characters depending on the type of command received. Responses can be

in many forms.

The following descriptions of header, response, and terminator, use

header

response

is the first character in the response string and is the ASCII

, which always follows the header, is a range of ASCII

For example, one standard response is 0 (ASCII character ‘zero’ or 30

hexadecimal). This response indicates a successful command completion

for most commands, while it indicates a failed completion for other

commands. See the firmware reference section for a description of what the

response indicates for

particular command.

each

Another standard response is 1 (ASCII character ‘one’ or 31 hexadecimal).

In most cases, this response indicates the command failed. The controller

received an invalid command that it could not execute.

Page 28

MT3000 Capacitive Controller Reference Guide28

Some possible reasons for a command failure include:

The command was not formatted correctly.

•

The system parameters were not set up to allow command execution.

•

The controller does not support the command.

•

The

terminator

is the last character of each response string and is an ASCII

carriage return CR. The hexadecimal code for the ASCII CR control

character is 0D hexadecimal. The value returned in the response will be the

ASCII control character for a carriage return, displayed on the screen as the

cursor moving to the next line.

In this chapter, responses are shown as a string of ASCII characters

consisting of a header, the response, and a terminator as follows:

<SOH>

Response

<CR>

Controller Initialization

To initialize the MT3000 controller for new development, send the

sequence of commands shown in Table 3. For controller responses to each

of these commands, see the firmware reference section at the end of this

document.

Page 29

Chapter 2 Communicating with the MT3000 Controller 29

Table 3 MT3000 Initialization Command String

Sequence # Command Format

1 Reset

2 AutoBaud Disable

3 Parameter Set

4 Format Tablet

5 Mode Stream

6 Parameter Lock

<SOH>R<CR>

<SOH>AD<CR>

<SOH>

PN812

<CR>

<SOH>FT<CR>

<SOH>MS<CR>

<SOH>PL<CR>

Page 30

MT3000 Capacitive Controller Reference Guide30

Summary of Firmware Commands

Developers may use this information when writing touch applications,

developing custom drivers or touch configurations, or testing their touch

systems. Developers can use firmware commands to initialize the controller,

select operating modes, specify data formats, and execute diagnostic

functions.

Most touchscreen users do

have to use firmware commands to use their

not

touch systems. For example, users can use TouchWare or equivalent

software to calibrate the touchscreen or to determine the controller type and

firmware version.

Caution:

This document assumes you are familiar with firmware

commands and how to use them. Executing some commands alters the

performance of your touchscreen and can render it inoperable. You should

be aware of the results before executing any firmware commands.

To optimize the performance of the MT3000 touchscreen controller and

simplify the development of custom drivers, MicroTouch recommends you

use the commands listed in Table 4 for current development. Using these

commands ensures compatibility with current MicroTouch controllers.

Table 5 lists the additional commands you can find in the Touch Controllers

Reference Guide located on the TouchWare CD.

Note:

When you enter commands in terminal mode, precede each

command with <CTRL> A to enter the header.

Page 31

Chapter 2 Communicating with the MT3000 Controller 31

Table 4 Firmware Commands for MT3000 Development

Command Name Code Description

AutoBaud Disable AD Turns OFF the automatic baud rate detection feature.

AutoBaud Enable AE Turns ON the automatic baud rate detection feature.

Calibrate Extended CX Initiates an interactive, two-point calibration.

Calibrate Raw CR Collects the raw X and Y coordinates prior to normal

scaling, linearization, and filtering process.

Format Decimal FD Outputs the X/Y touch coordinate data as a 9-byte packet

in a decimal format. Default for MT3000.

Format Raw FR Returns the signal level (amount of touch) of each of the

four touchscreen corners in digital format.

Format Tablet FT Outputs the X/Y touch coordinate data in a five-byte

packet. Preferred for current development.

Mode Status MT Sends a touch status byte preceding the X/Y coordinate

data sent in response to a Format Decimal or Format

Hexadecimal command.

Mode Stream MS Sends a continuous stream of X/Y coordinate data when

you touch the screen.

Null Command Z Queries the controller and waits for a response.

Output Identity OI Identifies the controller type and the firmware version.

Parameter Lock PL Writes and stores the data format and operating mode of

the controller into non-volatile memory (NovRAM).

Parameter Set P

] Lets you adjust the communication parameters (parity,

pds[b

data bits, and stop bits) of the controller.

Reset R Initializes the hardware and the firmware, causes the

controller to stop sending data, and recalculates the

environmental conditions.

Restore Defaults RD Returns the controller to the factory default operating

parameters.

Unit Type Verify UV Identifies the touchscreen controller on your system.

Page 32

MT3000 Capacitive Controller Reference Guide32

Table 5 Additional Commands for Prior Design Compatibility

Command Name Code Description

Calibrate Interactive CI Initiates an interactive, two-point edge calibration.

Calibrate New CN Initiates an interactive, two-point

Filter Number FN

nn

Sets the number of X/Y values that the controller

calibration.

edge

uses to generate an accurate coordinate after the

touchscreen receives an initial touch.

Format Binary [Stream] FB[S] Outputs the X/Y touch coordinate data as a five byte

packet in a binary (or binary stream) format.

Format Hexadecimal FH Outputs the X/Y touch coordinate data as a nine byte

packet in a hexadecimal format.

Format Zone FZ Outputs the X/Y touch coordinate data as a five byte

packet and indicates whether the touch occurred

inside or outside the calibration area.

Frequency Adjust <Ctrl> C

Lets you change the operating frequency of the

sensor drive signal (DRVOUT) that is fed from the

F

nn

controller to the sensor and drives the sensor output.

Get Parameter Block GP Returns all power-up and run time parameters used

by the controller.

Mode Down/Up MDU Send one X/Y coordinate for each touchdown and

each liftoff on the touchscreen.

Mode Inactive MI Sends no X/Y coordinates when the screen is

touched.

Mode Point MP Sends a single X/Y coordinate for each touchdown.

Mode Polled MQ Sends an X/Y coordinate only when requested by the

host system and only when a user touches the screen.

Output Status OS Causes the controller to report the status of its

hardware.

Page 33

Chapter 2 Communicating with the MT3000 Controller 33

Command Name Code Description

Set Parameter Block SP Sets all power-up and run time parameters used by

the controller.

Sensitivity Set SE

n

Changes the sensitivity of the touchscreen.

Page 34

MT3000 Capacitive Controller Reference Guide34

AutoBaud Disable

Syntax:

Description:

Response:

<SOH>AD<CR>

Turns off the automatic baud rate detection feature.

When you disable AutoBaud, the controller maintains the communication

rate currently set in non-volatile RAM (NovRAM). The controller continues

to use this communication rate until you change it with either the Parameter

Set command or the AutoBaud Enable command.

AutoBaud Enable is the factory default for some touchscreen controllers.

However, because this automatic feature is limited to the communication

rate, MicroTouch recommends that you issue an AutoBaud Disable

command to turn off the AutoBaud feature. After you disable AutoBaud,

send a Parameter Set command to change the communication parameters

(parity, number of data bits, number of stop bits, and baud rate).

<SOH>0<CR> Positive response.

Page 35

AutoBaud Enable

Chapter 2 Communicating with the MT3000 Controller 35

Syntax:

Description:

Response:

<SOH>AE<CR>

Turns on the automatic baud rate detection feature.

When you enable AutoBaud, the controller changes its communication rate

to that of the next command from the host system. Thereafter, the controller

sets its communication rate to the first command received from the host

system after powering on the unit.

Although the AutoBaud Enable command sets the communication rate, it

does not automatically set the parity, the number of data bits, and the

number of stop bits. The controller cannot communicate with the host

system unless all communication parameters are the same.

AutoBaud Enable is the factory default for some touchscreen controllers.

However, because this automatic feature is limited to the communication

rate, MicroTouch recommends that you issue an AutoBaud Disable

command to turn off the AutoBaud feature. After you disable AutoBaud,

send a Parameter Set command to change the communication parameters

(parity, number of data bits, number of stop bits, and baud rate).

<SOH>0<CR> Positive response.

Page 36

MT3000 Capacitive Controller Reference Guide36

Calibrate Extended

Syntax:

Description:

<SOH>CX<CR>

Initiates an interactive, two-point calibration.

During the calibration process, you define the active area of the touchscreen

by mapping locations to an absolute X/Y coordinate system. You touch two

target areas

coordinates for those touch points to the controller. The controller

calculates all other touch points based on these two points.

The Calibrate Extended command sets the calibration targets (points)

inward from the corner of the video image. Setting the targets inward makes

the calibration process easier and more accurate.

on the screen. Touching the target areas sends the X/Y

Determining Target Areas

The default calibration targets (points) are located 12.5% (1/8) inward from

the corners of the video image.

For example, suppose the display resolution of your monitor is

1024 x 768. The Calibrate Extended command calculates the amount to

move inward as follows:

Amount to move inward in the X direction: 1024 x 1/8 = 128

•

Amount to move inward in the Y direction: 768 x 1/8 = 96

•

The Calibrate Extended command then positions the first calibration target

inward from the lower left corner (0,767) and the second calibration target

inward from the upper right corner (1023,0). The following illustration

shows how the calibration targets are calculated.

Page 37

(0, 0)

(0, 767)

Chapter 2 Communicating with the MT3000 Controller 37

1023, 0)

(

Upper Right Calibration Target

X = 1023 – (1024 x 1/8) = 1023 – 128 = 895

Y = 0 + (768 x 1/8) = 0 + 96 = 96

(128, 671)

(80, 60)

(895, 96)

(560, 420)

Lower Left Calibration Target

X = 0 + (1024 x 1/8) = 0 + 128 = 128

Y = 767 - (768 x 1/8) = 767 - 96 = 671

Note:

The example in this discussion is in

terms, with the

video

origin (0, 0) in the upper left corner of the screen. Examples from the

controller’s

perspective, however, place the origin at the lower left corner

of the screen.

You can adjust the default calibration points using the Set Parameter Block

command. For more information, contact MicroTouch Technical Support.

Guidelines for Calibrate Extended

Here are several guidelines for using the Calibrate Extended command:

The controller uses the data immediately before liftoff to register a

•

calibration touch. Therefore, users can touch the screen, move their

finger to the target, hold for one second, and then lift off their finger.

Instructing users to touch this way results in a more accurate

calibration.

Page 38

MT3000 Capacitive Controller Reference Guide38

The controller stores the data in non-volatile memory (NovRAM).

•

Therefore, you do not have to calibrate the screen each time you power

on the system. You should, however, recalibrate the touchscreen any

time the video display changes or gets repositioned.

You can cancel a calibration at any time by issuing a Reset command.

•

Calibrate Extended Procedure

To use the CX command:

!

1.

Enter the Calibrate Extended (CX) command.

The controller sends an acknowledgment of <SOH>0<CR>.

2.

Touch the screen at a lower left target, which is located 12.5% (1/8) in

from the corner of the video image.

The controller returns an acknowledgment of <SOH>1<CR>. This is a

positive response. If you receive a negative response, try touching the

screen again.

Response:

3.

Touch the screen at an upper right target, which is located 12.5% (1/8)

in from the corner of the video image.

The controller returns an acknowledgment of <SOH>1<CR>. If you

receive a negative response, try touching the screen again.

Touching the two valid calibration points results in a successful calibration.

If either calibration point is invalid, the calibration fails. The MT3000

controller restores the factory default calibration if the Calibrate Extended

failed.

<SOH>1<CR>

<SOH>0<CR>

No Response Indicates that the user did not touch the target long

Positive response. Indicates that the controller

received a valid touch coordinate (point) when the

target was touched. Two valid touch points indicate

a successful calibration.

Negative response. Indicates that the touch point is

out of range of the expected target area. If you

receive a negative response, try touching the target

area again.

enough to provide an accurate calibration point.

Page 39

Calibrate Raw

Chapter 2 Communicating with the MT3000 Controller 39

Syntax:

Description:

<SOH>CR<CR>

Allows the collection of raw (signed) X and Y coordinates prior to the

normal scaling, linearization, and filtering processes. The controller sends

the coordinates whenever a touch is detected and continues to send a stream

of data as long as a finger remains in contact with the touchscreen.

The Calibrate Raw data is a 5-byte packet that includes 1 status byte and 4

bytes of binary X/Y coordinate data. Each X/Y coordinate includes 10

binary bits and 1 sign bit. The 10 bits represent coordinates within a range

of -1024 to +1023.

To use the Calibrate Raw command, the controller and host system must be

in an 8-bit data communication mode. The Calibrate Raw command returns

a negative response if the controller is not using an 8-bit communication

mode.

To end Calibrate Raw mode, issue a Reset command.

MicroTouch uses the Calibrate Raw command during manufacturing and

testing, and recommends you use this command for diagnostics when you

want raw data. Use the Calibrate Extended command for standard

interactive, two-point calibration.

Response:

<SOH>0<CR> Positive response.

After the controller is in Calibrate Raw mode, touching the screen causes

the controller to return a response in the following format:

SXxYy

Page 40

MT3000 Capacitive Controller Reference Guide40

where:

= Status byte; first byte of data. Refer to Table 6.

S

= X (horizontal) coordinate data; second and third bytes of data

Xx

= Y (vertical) coordinate data; fourth and fifth bytes of data.

Yy

MSB* Bits LSB*

Data Sequence76543210

S- Byte 1 1 S6

X- Byte 2 0 X3 X2 X1 X0 Reserved

x - Byte 3 0 Xs** X9 X8 X7 X6 X5 X4

Y- Byte 4 0 Y3 Y2 Y1 Y0

y - Byte 5 0 Ys** Y9 Y8 Y7 Y6 Y5 Y4

*

MSB = Most Significant Bit, LSB = Least Significant Bit

**

s = sign bit

Reserved

Reserved

Table 6 describes the meaning of the bits in the status byte (Byte 1).

Table 6. Calibrate Raw Status Bits

Bit Description Values

S0 – S5 Reserved —

S6 Proximity

(touch state)

1 = Touchscreen is being touched (a

touchdown or a continued touch).

0 = Touchscreen is not being touched (a

touch liftoff or inactive).

When the proximity bit changes from 1 to 0

(touch liftoff), the controller outputs one

final set of X/Y coordinate data with the bit

equal to 0 and the X/Y coordinate data equal

to the last touch point.

S7 Packet

synchronization

Always 1.

Page 41

Format Decimal

Chapter 2 Communicating with the MT3000 Controller 41

Note:

controllers. To ensure compatibility with all existing and future MicroTouch controllers, do

not use this command when developing your touch drivers and applications.

Syntax:

Description:

MicroTouch provides this command for compatibility with older touchscreen

<SOH>FD<CR>

Outputs the X/Y touch coordinate data as a 9-byte packet in a decimal

format. The packet includes the following 9 bytes:

1 header byte

•

3 bytes of X coordinate data

•

An ASCII comma

•

3 bytes of Y coordinate data

•

A terminator byte

•

Data is sent as a string of decimal ASCII characters (0 to 9). The output

range for both the X and Y data is 000 to 999.

When activated, Format Decimal resets the Mode Status to report the

standard <SOH> header. If the last format command was Format Binary,

then Format Decimal sets the output mode to Mode Stream.

Response:

Format Decimal, which sends approximately 106 packets per second at

9600 baud, is not as efficient as Format Tablet. Format Decimal does not

contain touchdown and liftoff information unless you also use the Mode

Status command.

Format Hexadecimal is the same as Format Decimal except the controller

returns the X/Y coordinates in hexadecimal instead of decimal.

Format Tablet, which sends approximately 192 packets per second at 9600

baud, is the most efficient packet. It also contains touchdown and liftoff

information. Format Tablet is the standard for MicroTouch product

development.

<SOH>0<CR>

Page 42

MT3000 Capacitive Controller Reference Guide42

After the controller is in Format Decimal mode, touching the screen causes

the controller to return a response in the following format:

<HDR>

Xxx,Yyy

<CR>

where:

<HDR> = Start-of-header (Hex 01). If you send a Mode Status command

after a Format Decimal command, this first byte becomes a

status byte. The status byte defines whether the X/Y

coordinates are generated from a touchdown, a touch

continuation (when the finger is resting on the screen), or a

touch liftoff. For more details, refer to the Mode Status

command later in this chapter.

Xxx

= X (horizontal) coordinate data. Total of 3 bytes.

= ASCII comma that separates the X and Y coordinate data.

Yyy

= Y (vertical) coordinate data. Total of 3 bytes.

<CR> = Terminator (Hex 0D).

Page 43

Format Raw

Chapter 2 Communicating with the MT3000 Controller 43

Syntax:

Description:

<SOH>FR<CR>

Returns the signal level (amount of touch) of each of the four touchscreen

corners in digital format. The returned values are not corrected for offset

and stray values. However, you can obtain the offset and stray values using

the Get Parameter Block command. For more information, refer to the

description of the Get Parameter Block command later in this chapter.

The Format Raw data is a 7-byte packet that includes 1 status byte and 6

bytes of binary corner data. The data format for the packet is fixed in order

to provide the most efficient transfer of data. The first byte of each packet

always has its high bit (Bit 7) set to provide synchronization with the host

system. Each corner value is 10 bits, which are delivered in 2 bytes, and has

a range of 0 to 1023.

To use the Format Raw command, the controller and host system must be in

an 8-bit data communication mode. The Format Raw command returns a

negative response if the controller is not using an 8-bit communication

mode.

To terminate Format Raw, issue a Reset command. The controller may

return several bytes of data between the time you issue a Reset command

and the controller receives it. You can either scan the data stream for the

Reset acknowledgment, or you can ignore the response to the first Reset

command and then issue a second Reset after approximately 10 seconds has

passed.

Use the Format Raw command for diagnostics. Use Format Tablet for

standard touchscreen operation.

Page 44

MT3000 Capacitive Controller Reference Guide44

Response:

<SOH>0<CR> Positive response.

After the controller is in Format Raw mode, the controller returns a

response in the following format:

<

7-byte-packet><7-byte-packet

Byte Bits 0 – 7

>...<

7-byte-packet

>...

1 b0 – b3: Drive level (amount of signal sent from controller)

b4 – b6: Reserved

b7: Synchronization bit (Always 1)

2 b0 – b2: 3 most significant bits of upper left (UL) corner

b3: Always 0

b4 – b6: 3 most significant bits of lower left (LL) corner

b7: Always 0

3 b0 – b2: 3 most significant bits of lower right (LR) corner

b3: Always 0

b4 – b6: 3 most significant bits of upper right (UR) corner

b7: Always 0

4 b0 – b6: 7 least significant bits of lower left (LL) corner

b7: Always 0

5 b0 – b6: 7 least significant bits of upper left (UL) corner

b7: Always 0

6 b0 – b6: 7 least significant bits of upper right (UR) corner

b7: Always 0

7 b0 – b6: 7 least significant bits of lower right (LR) corner

b7: Always 0

Page 45

Format Tablet

Chapter 2 Communicating with the MT3000 Controller 45

Syntax:

Description:

<SOH>FT<CR>

Outputs the X/Y touch coordinate data in a 5-byte packet. The packet

includes 1 status byte and 4 bytes of binary X/Y coordinate data. The

protocol also establishes the X and Y coordinate output as 14 binary bits

providing a range of 0 to 16,383.

The low order bits (X3 – X0 and Y3 – Y0) are not significant in a 1024 by

1024 touchscreen because data can fluctuate with each touch, and therefore

may not be completely accurate.

To use Format Tablet, the controller and host system must be in an 8-bit

data communication mode. The Format Tablet command returns a negative

response if the controller is in 7-bit format.

Format Tablet is the most efficient packet (sends approximately 162 packets

per second at 9600 baud). It also contains touchdown and liftoff

information. Format Tablet is the standard for MicroTouch product

development.

For comparison, Format Hexadecimal and Format Decimal (which send

approximately 106 packets per second at 9600 baud) are not as efficient as

Format Tablet. These data formats do not contain touchdown and liftoff

information unless you also use the Mode Status command.

Response:

<SOH>0<CR> Positive response.

After the controller is in Format Tablet mode, touching the screen causes

the controller to return a response in the following format:

SXxYy

= Status byte; first byte of data. Refer to Table 7.

S

= X (horizontal) coordinate data; second and third bytes of data.

Xx

= Y (vertical) coordinate data; fourth and fifth bytes of data.

Yy

Page 46

MT3000 Capacitive Controller Reference Guide46

MSB* Bits LSB*

Data Sequence76543210

S - Byte 1 1 S6 S5 S4 S3 S2 S1 S0

X- Byte 2 0 X6 X5 X4 X3 X2 X1 X0

x - Byte 3 0 X13 X12 X11 X10 X9 X8 X7

Y- Byte 4 0 Y6 Y5 Y4 Y3 Y2 Y1 Y0

y - Byte 5 0 Y13 Y12 Y11 Y10 Y9 Y8 Y7

*

MSB = Most Significant Bit, LSB = Least Significant Bit

Table 7 defines the status bits (Byte 1) for the Format Tablet data.

Table 7. Format Tablet Status Bits

Bit Description Values

S0

S1

Switch 1 status

Switch 2 status

For the TouchPen only.

1 = Switch is on (pressed).

0 = Switch is off.

S2 – S5 Reserved —

S6 Proximity

1 = Touchscreen is being touched (a

(touch state)

0 = Touchscreen is not being touched (a

When the proximity bit changes from 1 to 0

(touch liftoff), the controller outputs one

final set of X/Y coordinate data with the bit

equal to 0 and the X/Y coordinate data equal

to the last touch point.

S7 Packet

Always 1.

synchronization

touchdown or a continued touch).

touch liftoff or inactive).

Page 47

Mode Status

Chapter 2 Communicating with the MT3000 Controller 47

Syntax:

Description:

<SOH>MT<CR>

Sends a touch status byte preceding the X, Y coordinate data sent in

response to a Format Decimal or Format Hexadecimal command. The

format of the data depends on the last format command received by the

controller.

By default, Format Decimal and Format Hexadecimal send a 9-byte data

packet. The first byte is the header byte. If you use the Mode Status

command, the first byte becomes a status byte. This status byte defines

whether the X, Y coordinates are generated from a touchdown, a touch

continuation (when the finger is resting on the screen), or a touch liftoff.

MicroTouch recommends that you use the Mode Status command in

conjunction with Format Decimal and Format Hexadecimal so that the

touch data includes status information in the packet header byte. By

default, Format Decimal and Format Hexadecimal do not contain the status

information in the header byte.

Note:

Hexadecimal) first, and then send the Mode Status command.

You should always send the format command (Decimal and

You do not need to send a Mode Status command if you are using Format

Tablet, Format Binary, or Format Binary Stream.

The Format Tablet protocol automatically includes status information in

•

the first byte of data.

Format Binary and Format Binary Stream automatically issue a Mode

•

Status command.

Page 48

MT3000 Capacitive Controller Reference Guide48

Response:

<SOH>0<CR> Positive response.

If the controller is in Format Decimal or Format Hexadecimal mode and you

receive a positive response to Mode Status, touching the screen causes the

controller to return the following response:

<

Status>Xxx,Yyy

where:

<

Xxx

Yyy

> = Defines how the X, Y coordinates are generated, where:

Status

<CR>

^Y (Hex 19) is a touchdown (first position of finger on the

screen).

^\ (Hex 1C) is a continued touch (position of finger remains

on the screen).

^R (Hex 18) is a touch liftoff (last position of finger on the

screen).

= X (horizontal) coordinate data. Total of 3 bytes.

= ASCII comma that separates the X and Y coordinate data.

= Y (vertical) coordinate data. Total of 3 bytes.

<CR> = Terminator (Hex 0D).

Page 49

Mode Stream

Chapter 2 Communicating with the MT3000 Controller 49

Syntax:

Description:

Response:

<SOH>MS<CR>

Sends a continuous stream of X/Y coordinate data when you touch the

screen. The controller continues to send data as long as you touch the

screen. The controller sends the data even if the touch is stationary and

unchanging.

The format of the coordinate data depends on the last format command

received by the controller.

Format Raw automatically uses Mode Stream to send X/Y coordinate data.

<SOH>0<CR> Positive response.

Page 50

MT3000 Capacitive Controller Reference Guide50

Null Command

Syntax:

Description:

Response:

<SOH>Z<CR>

Queries the controller and waits for a response.

Use Z to determine that you are communicating with the controller or to

make sure that a utility is communicating with the controller. Using this

command does not affect the controller’s current operating parameters.

<SOH>0<CR> Positive response.

Page 51

Output Identity

Chapter 2 Communicating with the MT3000 Controller 51

Syntax:

Description:

Response:

<SOH>OI<CR>

Returns a 6-character identifier, which describes the controller type and the

firmware version number. The output identity for the MT3000 controller is

A30630 or A30670 for APAC.

<SOH>

where:

Cc

Xxxx

CcXxxx

= Two ASCII characters that describe the type of MicroTouch

= Four ASCII characters that indicate the firmware version number

<CR>

controller.

A3 = Excalibur

MT3000

Serial/SMT2

Serial/SMT3V

PC Bus SMT3V

in decimal format. The first two characters represent the version

number; the last two characters represent the revision level. For

example, 0660 means Version 6, Revision 6 (that is, 6.6).

Page 52

MT3000 Capacitive Controller Reference Guide52

Parameter Lock

Syntax:

Description:

Response:

<SOH>PL<CR>

Writes and stores the data format and operating mode of the controller into

non-volatile memory (NovRAM).

Any time you make changes to the data format or the operating mode, you

should issue a Parameter Lock command to store the new settings to the

NovRAM. Therefore, the settings are not lost when the unit is powered

down.

<SOH>0<CR> Positive response.

Page 53

Parameter Set

Chapter 2 Communicating with the MT3000 Controller 53

Syntax:

Description:

<SOH>

where:

p

d=

s=

b

Lets you adjust the communication parameters (parity, data bits, and stop

bits) of the controller. Optionally, you can change the communication rate

by appending an additional character to the command string. Upon

execution of the Parameter Set command, the controller automatically stores

the new settings, the current operating mode, and the current data format in

NovRAM.

P

= Parity type.

= Communication rate.

]<CR>

pds[b

= No parity

N

= Odd parity

O

= Even parity

E

Number of data bits (7 or 8).

Number of stop bits (1 or 2).

= 19200 baud

1

= 9600 baud

2

= 4800 baud

3

4

5

= 2400 baud

= 1200 baud

The communication parameters of the host system must match the present

settings of the controller when the command is given for it to be accepted

and the changes implemented.

The process of changing the parameters takes three steps:

The host system must first communicate with the controller using a

•

matched set of parameters.

The Parameter Set command is issued with the new parameters to the

•

controller. The new settings take effect immediately.

The host system must be changed to the new parameters in order to

•

communicate with the controller again.

Page 54

MT3000 Capacitive Controller Reference Guide54

Examples:

<Ctrl A>PN813<CR> Sets the serial line to no parity, eight

data bits, one stop bit, and 4800 baud.

<Ctrl A>PN81<CR> Sets the parity, data bits, and stop bits;

leaves the baud at its previous value.

Caution:

The settings are immediately written to NovRAM, and all future

communication must occur at the new values. It is possible to set the

parameters to values that prevent future communication with the controller.

For example, using PROCOMM, you enter <Ctrl A>PN815<CR> to set the

communication rate to 1200. However, PROCOMM does not support 1200

baud. The controller will now pass data at 1200 baud, but the host system

will not be able to read the data. The controller will expect to receive all

commands at 1200 baud and will not recognize any attempts to change the

communication rate. The controller is effectively locked up. If AutoBaud is

enabled, you can correct this situation by a power-down/power-up

sequence. If AutoBaud is disabled, you need to use Microcal or another

terminal application to set the communication rate at the new values.

The communication rates that can be set with the AutoBaud command are

the same as the rates you can set with the Parameter Set command.

Therefore, the AutoBaud command no longer finds 7200, 3600, 2000, 1800,

600, 300, 200, 150, 135, and 110 baud. Also, some MicroTouch controllers

do not support the AutoBaud command.

Response:

<SOH>0<CR> Positive response.

Page 55

Reset

Chapter 2 Communicating with the MT3000 Controller 55

Syntax:

Description:

Response:

<SOH>R<CR>

Initializes the hardware and the firmware, causes the controller to stop

sending data, and recalculates the environmental conditions (for example,

stray and offset values). The Reset command also cancels the Format Raw

and Calibrate Raw commands and returns the controller to normal

operation.

MicroTouch recommends that the host system issue a Reset command

whenever the host system is powered on and is attempting to establish

communication with the controller.

The amount of time needed to execute a Reset command ranges from 225

milliseconds to 800 milliseconds. Therefore, the application program should

wait and be sure it receives the command response before issuing another

command to the controller following the reset.

<SOH>0<CR> Positive response.

Page 56

MT3000 Capacitive Controller Reference Guide56

Restore Defaults

Syntax:

Description:

<SOH>RD<CR>

Returns to the factory default operating parameters. The Restore Defaults

command copies the MicroTouch factory default parameters from ROM to

the non-volatile memory (NovRAM) and then executes a Reset command.

Table 8 lists the factory defaults for the MT3000 controller. The Restore

Defaults command is useful in situations where inadvertent commands to

the controller have rendered the touchscreen inoperative.

Table 8 MT3000 Factory Default Settings

Operating Parameter Default

Baud Rate 9600

Serial Communication Settings N, 7, 2

Data Format Format Decimal

Operating Mode Mode Stream

Return to Factory Calibration Yes

The Restore Defaults command requires approximately 75 to 100

milliseconds, plus the execution time of the Reset command (225 to 800

milliseconds). Therefore, the application program should wait and be sure it

receives the command response before issuing another command to the

controller.

Response:

After you issue a Restore Defaults command, calibrate your touchscreen

using the Calibrate Extended command.

<SOH>0<CR> Positive response.

Page 57

Unit Type Verify

Chapter 2 Communicating with the MT3000 Controller 57

Syntax:

Description:

Response:

<SOH>UV<CR>

Responds with an 8-character identity string. This string identifies the type

of controller currently attached to the system, lists the features supported by

the controller, and outputs the status of the controller hardware (a self-test

code).

Refer to the Unit Type command in the Touch Controller’s Reference

Guide on the TouchWare CD for a description of the 8-character identity

string. The Unit Type command and the Unit Type Verify command return

the same information.

Page 58

Page 59

APPENDIX A

MT3000 Controller Specifications

MT3000 Controller: Programmable CMOS small format-size

controller

Circuit Board Dimensions: 1.3 in. x 2.4 in. (33 mm x 61 mm)

Power Requirements: +5 VDC (70 mA typical), 50 mV peak-

to-peak maximum ripple and noise

Operating Temperature: 0 to 60 degrees C

Storage Temperature: -40 to +85 degrees C

Relative Humidity: 90% at 60 degrees C

Optional RS-232

Cable:

Output Port: Bi-directional asynchronous RS-232

Port Parameters: No parity, 7 data bits, 2 stop bits, 9600

Electrostatic Protection:

Regulatory Approvals: UL, FCC-B, and CE compliant

8' shielded cable with 9-pin D connector

for serial port; 9-pin to 25-pin adapter

available

serial communication

baud (N, 7, 2, 9600)

20KV air and ±8KV contact discharge

±

to screen (per IEC 801-2)

Page 60

Page 61

Index

A

acknowledgments to a command 27

AD (AutoBaud Disable) command 34

adapter, 9-pin to 25-pin 15

AE (AutoBaud Enable) command 35

AutoBaud Disable command 34

AutoBaud Enable command 35

B

baud rate

bits

data 39, 43, 59

parity 59

setting data and stop 53

touch state (proximity) 40, 46

C

Calibrate Extended command 36

Calibrate Raw command 39

calibration

commands 36, 39

definition 22

communication rate

See

guidelines 37

targets 36

carriage return <CR> character 26

clearance 12

command syntax 26

commands

receiving responses to 27

sending 26

communication parameters 24

communication rate

setting 53

turning off auto detection 34

turning on auto detection 35

communication settings

defining with Parameter Set

command 53

communication settings, default 24

connecting the touchscreen cable 14

connectors

JP1 15

JP2 17

JP4 14

Molex 18

serial cable 18

touchscreen 14

controllers

identifying type of 51, 57

Page 62

62 MT3000 Capacitive Controller Reference Guide

corporate headquarters 7

CR (Calibrate Raw) command 39

CR (carriage return) character 26

CX (Calibrate Extended) command 36

D

data bits, setting number of 53

data connection 15

data formats

definition and defaults 24

locking 52

raw format 43

tablet format 45

defaults

communication settings 24

data format 24

factory 24

operating mode 25

restoring factory 56

diagnostic codes, LED 21

diagnostics

Unit Type Verify command 57

dimensions 10, 22

drive signal, adjusting 32

driver 11, 14, 22, 23

firmware version, identifying 51

flat panel displays 9, 19

Format Raw command 43

Format Tablet command 45

formats, data 24

FR (Format Raw) command 43

FT (Format Tablet) command 45

G

ground 12, 13, 16, 17, 18

grounding 12

H

hardware, initializing controller 55

header character <SOH> 26

headquarters, corporate 7

help

phone support 5

world wide web 6

I

identity of controller 51, 57

initializing, with Reset command 55

Internet address, MicroTouch 6

E

electrostatic discharge 13

error 20, 21

errors 21

F

factory defaults 24, 56

firmware commands

receiving responses to 27

sending 26

syntax 26

J

JP1 connector 15

JP2 connector 17, 18

JP4 connector 14

K

keyboard power tap 17, 18

Page 63

Index 63

L

LCD modules 19

LED 19, 20, 21

linearization 10, 14, 21, 31, 39

locking parameters 52

M

MicroTouch Internet address 6

Mode Status command 47

Mode Stream command 49

mode, operating 25

modes

status 47

mounting holes 12, 13

MS (Mode Stream) command 49

MT (Mode Status) command 47

MT3000 controller

dimensions 10

factory defaults 56

LED 19

output identity 51

overview 9

power connector 17

serial data connector 15

specifications 59

operating modes

locking 52

orientation 12, 14

Output Identity command 51

P

packet, data

Parameter Lock command 52