Page 1

3M™ Metal Foil Tapes

Expanding

choices

for

applications

success

Performance and

price as you need it

3

Page 2

™

3M

Metal Foil Tapes refl ecting, wrapping, masking,

sealing, and more from air ducts to washing machines

With 3M metal foil tapes, select from

combinations of conformable backings and

adhesives to meet application demands in

many markets:

• Aerospace

• Appliance

• Construction

• Electronics

• Machinery

• Manufacturing

Applications range from heat shielding to

paint strip masking, light refl ection to wire

harness wrapping, thermal conductivity to

duct sealing.

• Metal Finishing

• MRO

• Plastics

• Specialty Vehicle

• Transportation

• and more

Standard Aluminum Foil Tapes

Select acrylic, rubber, or silicone adhesives and

conformable backings ranging from 1.2 to 12 mils.

Appliance Construction

Specialty Vehicle

Metal Finishing

Aerospace

And more

• Resist fl ame, moisture, weather, dirt, UV degradation,

and most chemicals

• Thermally conductive for heating and cooling effi ciency

• Refl ect heat and light

2

With high heat refl ectivity

and thermal conductivity,

3M™ Aluminum Foil Tapes

protect heat-sensitive

components near lights

in a garage door opener

housing.

1

Radiant Heat Source

Refl ection

Heat Conduction

Aluminum Foil

Substrate

3M™ Aluminum Foil Tape bonds on

contact as heat shielding inside an oven

door. Helps keep the exterior cool to the

touch behind the handle and around the

window perimeter.

AbsorptionEmissivity

2

Page 3

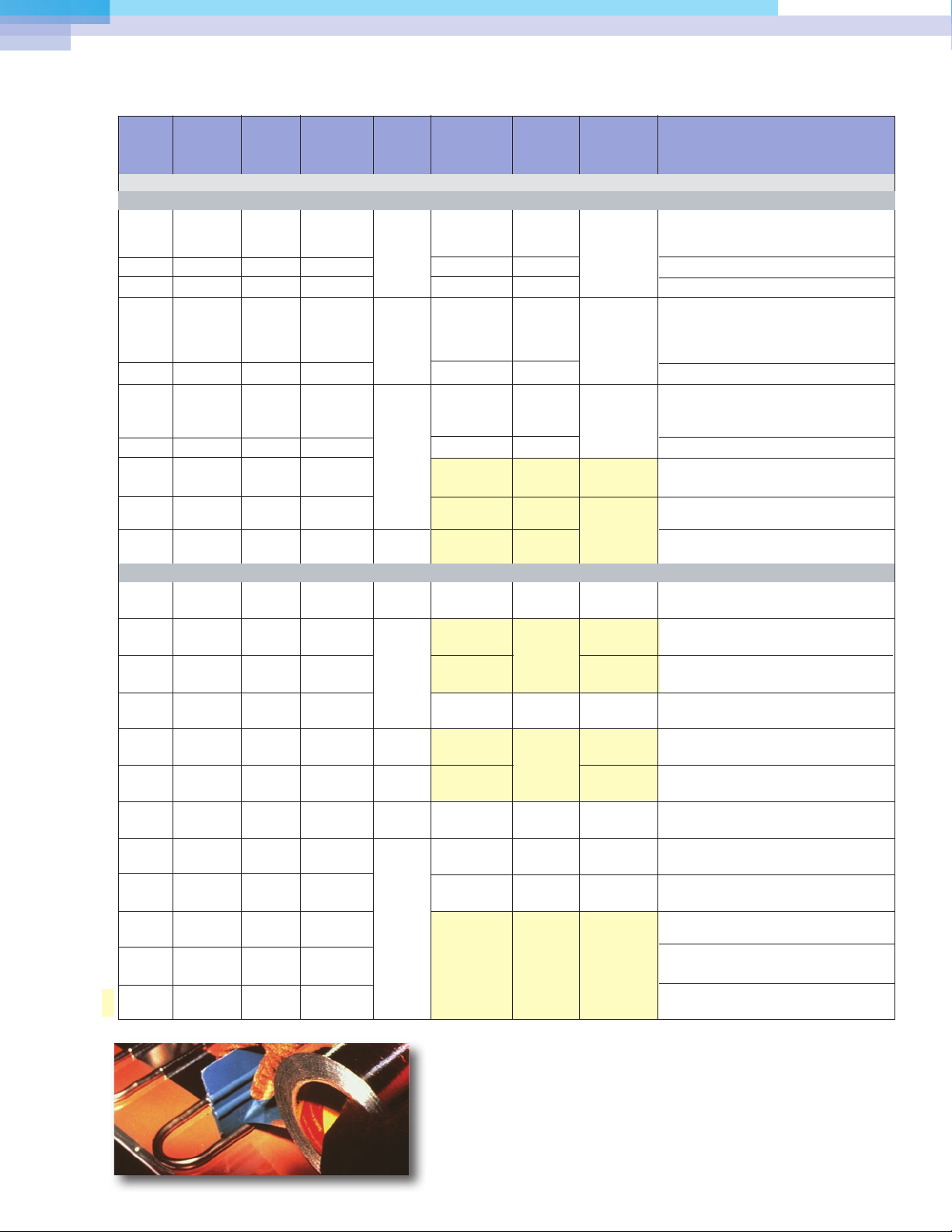

Standard Aluminum Foil Tapes

Product Backing Total Liner/SW Adhesive Adhesion Tensile Temperature Features

Number Thickness Thickness (self-wound) to Steel Strength Range

(mils) (mils) oz./in. lbs./in. °F (C°)

(N/100 mm) (N/100 mm)

ASTM Test Method: D-3652 D-3652 D-3330 D-3759

Premium Performance Aluminum Foil Tapes

425 2.8 4.6 SW Acrylic 47 (51) 30 (525) -65 to 300°F Most versatile aluminum tape. L-T-80B, SAE AMS

(-54 to 149°C) T-23397, UL 723 Classifi ed, UL 746C Recognized,

427 2.8 4.6 Liner 50 (55) 30 (525) Linered version of 425.

431 1.9 3.1 SW 41 (45) 19 (338) Conformable aluminum tape. UL 723 Classifi ed.

433 2.0 3.6 SW Silicone 40 (44) 20 (350) -65 to 600°F Silicone adhesive for high temperature resistance;

(-54 to 316°C) MIL-T-47014, F.A.R. 25.853, UL 746C Recognized;

smooth easy unwind; clean, straight edges with

minimal wrinkling.

433L 2.0 3.5 Liner 38 (42) 20 (350) Linered version of 433.

438 5.0 7.2 SW Acrylic 43 (47) 59 (1033) -65 to 300°F Thickest non-reinforced aluminum tape for heat

(-54 to 149°C) resistance; smooth easy unwind; clean, straight

edges with minimal wrinkling. UL 723 Classifi ed.

439 1.9 3.1 Liner 41 (45) 18 (315) Linered version of 431.

3338 5.0 7.0 Liner 45 (49) 50 (876) -30 to 300°F 66 lb. moisture stable liner.

(-34 to 149°C)

33801 2.0 4.0 Liner 40 (44) 20 (350) -30 to 425°F High temperature acrylic adhesive at 425°F.

(-34 to 218°C) UL 723 Classifi ed.

33806 3.0 5.0 Liner Acrylic 40 (44) 30 (525) High temperature acrylic adhesive at 425°F

General Purpose Aluminum Foil Tapes

3311 2.0 3.6 Liner Rubber 90 (98) 17 (298) -10 to 180°F UL 723 listed.

(-23 to 82°C)

3369 1.2 2.4 Liner Acrylic 35 (38) 10 (180) -30 to 260°F Thinnest aluminum foil tape.

(-34 to 127°C) UL 723 Classifi ed.

3381 1.4 2.7 Liner 40 (44) -30 to 250°F 40 lb. natural kraft paper liner. UL 723 Classifi ed.

(-34 to 121°C)

1449 1.4 2.6 SW 37 (40) 19 (333) -25 to 250°F 1.4 mil backing; thin aluminum foil tape

(-32 to 121°C) for conformability.

33803 1.8 3.6 Liner Rubber 90 (99) 15 (263) 0 to 175°F High tack rubber adhesive. 40 lb. liner.

(-18 to 79°C) UL 723 Classifi ed.

97065 1.8 3.25 Liner Acrylic 40 (44) -30 to 250°F 60 lb. moisture stable liner. Good for die-cut

(-34 to 121°C) applications.

1450 1.9 3.1 SW Rubber 114 (125) 19 (333) -40 to 200°F High tack adhesive for good, instant adhesion to

(-40 to 93°C) many surfaces.

3380 2.0 3.25 Liner Acrylic 40 (44) 10 (175) -30 to 260°F 40 lb. natural kraft paper liner. Good for narrow

(-34 to 127°C) slit rolls. UL 723 Classifi ed.

4380 2.0 3.25 SW 40 (44) 10 (175) -30 to 300°F General purpose aluminum foil tape.

(-34 to 149°C)

34383 2.8 4.5 SW 40 (44) 30 (525) -30 to 260°F General purpose aluminum foil tape.

(-34 to 127°C)

3363 3.0 5 Liner 40 lb. natural kraft paper liner. Good for narrow

slit rolls. UL 723 Classifi ed.

This data has not been verifi ed. Additional testing is required.

3367 3.0 4.4 Liner 66 lb. moisture stable liner. Good for die-cut

applications.

NOTE: This technical information and data should be considered representative or typical only and should not be used for specifi cation purposes.

F.A.R. 25.853.

3

Conformable 3M™ Aluminum Foil Tape securely holds copper cooling tubes to refrigerator panels.

Thermal conductivity helps maximize cooling effi ciency.

3

Page 4

Specialty Foil Tapes

Select a 3M specialty metal tape for applications such as:

• Lead foil tape for acid-resistant masking

during electroplating and anodizing;

radiopacity for x-ray markers

• Copper foil tape with or without conductive

adhesive for EMI/RFI shielding

• Stainless steel tape for sealing and

• Glass cloth-reinforced aluminum foil tape

for bundling wire harnesses

protecting of stainless steel surfaces

Electrical current

Lead Foil Tape Plastic Tape

(Burnished edge) lead foil tape

Electrical current density is uniform across the

4

Tear-resistant 3M™ Reinforced Aluminum Foil Tape

363 bundles wire harnesses and helps protect

wires, cables, and other fl exible parts from heat.

Product Backing Total Liner/SW Adhesive Adhesion Tensile Temperature Features

Number Thickness Thickness (self-wound) to Steel Strength Range

(mils) (mils) oz./in. lbs./in. °F (°C)

(N/100 mm) (N/100 mm)

ASTM Test Method: D-3652 D-3652 D-3330 D-3759

Lead Foil Tapes

420 4.7 6.8 Liner Rubber 45 (49) 20 (350) -60 to 225°F Linered plating tape.

(-51 to 107°C)

421 4.0 6.3 SW 31 (34) 15 (263) Self-wound plating tape.

4201 5.0 6.5 Liner Acrylic 40 (44) 20 (350) -30 to 225°F Permanent acrylic adhesive.

(-34 to 121°C)

34201 5.0 6.25 Rubber 50 (55) 20 (350) 0 to 180°F Removable rubber adhesive.

(-18 to 82°C)

Copper Foil Tapes

3313 1.4 3.0 Liner Conductive Acrylic 30 (33) 33 (578) 0 to 250°F EMI/RFI shielding.

(-18 to 121°C) UL 510 Recognized.

3324 1.25 2.9 Acrylic 40 (44) 20 (350) -30 to 225°F EMI/RFI shielding.

(-34 to 121°C)

3325 1.5 3.0 40 (44) 28 (491) 0 to 225°F EMI/RFI shielding.

(-18 to 107°C) UL 510 Recognized.

33315 1.5 3.3 35 (39) 28 (491) -30 to 300°F “Tinned,” corrosion resistant.

(-34 to 149°C)

33316 1.5 3.0 Conductive Acrylic 30 (33) 33 (578) 0 to 250°F “Tinned,” corrosion resistant.

(-18 to 121°C) UL 510 Recognized.

Stainless Steel Foil Tape

3361 2.0 3.8 Liner Acrylic 40 (44) 100 (1751) -30 to 250°F Corrosion resistant.

(-34 to 121°C)

Specialty Foil Tapes

363 3.4 7.3 SW Silicone 52 (57) 135 (2364) -65 to 600°F Aluminum foil/glass cloth. Highest

(-54 to 316°C) temperature metal foil tape.

363L 3.4 7.3 Liner 52 (57) Linered version of 363.

1430 5.0 5.5 SW Acrylic 22 (24) 19 (333) -65 to 300°F Aluminum foil/non-woven laminate

(-54 to 106°C) Flexible wrapping tape.

3302 2.0 3.6 Liner Conductive Acrylic 30 (33) 20 (350) 0 to 225°F Aluminum foil tape. EMI/RFI shielding.

(-18 to 107°C) UL 510 Recognized.

part because of the electrically conductive lead

foil. Both substrate and foil are plated, resulting

in a uniform plating thickness right up to the

plating stop-off line.

Uniform plating thickness with lead foil tape

distribution

Plating

Metal

substrate

Plastic tape

Electrical current density is intensifi ed at the

plating stop-off line due to the non-conductive

properties of a plastic tape. The resulting plating

build-up necessitates an additional grinding

operation.

Plating build-up without lead foil tape

This data has not been verifi ed. Additional testing is required.

NOTE: This technical information and data should be considered representative or typical only and should not be used for specifi cation purposes.

4

Page 5

HVAC and Construction Tapes

Select from a variety of 3M™ Metal Foil Tapes for any residential or commercial site

application including rigid and fl exible HVAC duct work.

With aggressive adhesive and dead soft aluminum,

3M™ Foil Tape 3380 seals and secures seams and joints

for long-term durability. UL 723 Listed for duct sealing and

general repairs.

3M™ FSK Facing

Tape 3320 is

engineered

specifi cally as

a vapor retardant

tape to seal

mineral wool

foil-faced

insulation, bare

sheet metal ducts,

To seal fi berglass duct board and fl exible duct systems, 3M™ Foil Tape 3340 meets the

performance requirements for UL 181A-P and UL 181B-FX.

Product Backing Total Liner/SW Adhesive Adhesion Tensile Temperature Features

Number Thickness Thickness (self-wound) to Steel Strength Range

(mils) (mils) oz./in. lbs./in. °F (°C)

(N/100 mm) (N/100 mm)

ASTM Test Method: D-3652 D-3652 D-3330 D-3759

HVAC Construction

3320 6.0 6.7 Liner Acrylic 81 (89) 40 (712) -20 to 175°F Aluminum foil/scrim/laminate.

(-29 to 79°C) UL 723 Classifi ed.

3340 2.0 4.0 30 (33) 20 (350) -30 to 250°F Aluminum foil tape. for use with rigid

(-34 to 121°C) and fl exible ducts. UL 181 A-P and

181 B-FX Listed.

3350 1.6 3.1 SW 33 (36) 36 (631) -30 to 230°F Polypropylene tape for use with

(-34 to 110°C) fl exible ducts. UL 181 B-FX Listed.

3380 2.0 3.25 Liner 40 (43) 10 (175) -30 to 260°F General purpose aluminum foil tape.

(-34 to 127°C) Go to product for this market.

UL 723 Classifi ed.

3381 1.4 3.0 40 (44) 10 (180) -40 to 250°F Value grade aluminum foil tape.

(-40 to 121°C) UL 723 Classifi ed.

3382 2.5 4.2 50 (55) 30 (525) -40 to 300°F Foil/PET laminate, tear resistance.

(-40 to 149°C) Roof and gutter repair tape.

NOTE: This technical information and data should be considered representative or typical only and should not be used for specifi cation purposes.

5

7

and blanket style

fi berglass duct

insulation.

6

5

Page 6

™

3M

Sound Damping Foils

when quiet is the sound of quality

Reduce noise and vibration in many applications

With pressure sensitive viscoelastic acrylic polymer

on dead soft aluminum foil, 3M

™

Sound Damping

Foils quiet noise and reduce vibration in many

areas for Aerospace, Automotive, Appliances,

Construction, and MRO (Maintenance and Repair).

• Reduce structure-borne noise in metal and

composite panels and support structures

• Optimized acrylic converts vibrational energy to

negligible heat that readily dissipates

• Reduce vibrational fatigue to decrease wear and

tear on parts and lower the risk of part loosening

and displacement

• Effective damping with as little as 10%

surface coverage

• Pressure sensitive for easy self-fi xturing application

• Long aging performance

• Good performance over a wide temperature range

• Linered construction provides ability to

die-cut product

9

3M™ Damping Foil 2552 on the inside of a washing

machine reduces structure-borne noise and reduces

vibrational fatigue to decrease the risk of part

loosening and displacement.

Applied with a 3M

vibration with as little as 10% surface coverage. Optimized acrylic on a dead soft aluminum constraining layer

converts vibrational energy to negligible heat that readily dissipates.

Product/ Tape Structure Backing Total Adhesion Tensile Temperature Features

Color (Backing/Adhesive) Thickness Thickness to Steel Strength Range

mils (mm) mils (mm) oz./in. lbs./in. °F (°C)

(N/100 mm) (N/100 mm)

ASTM Test Method: D-3652 D-3652 D-3330 D-3759

Damping Foils

434/Silver Aluminum/VEP

(-60 to 20°C)

435/Silver 8.0 (0.20) 13.5 (0.34) 84 (1470)

436/Silver 12.0 (0.31) 17.5 (0.45) 126 (2205)

2542/Silver 5.0 (0.13) 10 (0.25) 65 (71) 40 (700) -25 to 175°F Thinner, general purpose

(-32 to 80°C)

2552/Silver 10.0 (0.25) 15 (0.38) 65 (71) 80 (1400) -25 to 175°F General purpose vibration

(-32 to 80°C)2 damping.

4014/Silver Aluminum-Urethane/Acrylic 3.0 (0.076) 250 (6.35) N/A N/A -94 to 86°F Foil/foam sheet

(-70 to 30°C)

1

Viscoelastic polymer 2 Optimum damping temperature 3 The specimen passed the requirements of FAR 25.853 (a)(1)(ii) per AMDT.25-83 tested in composite on aluminum backer.

NOTE: This technical information and data should be considered representative or typical only and should not be used for specifi cation purposes.

™

PA-1 Wiper to the inside of a car door, 3M™ Damping Foil 2552 effectively damps noise and

1

5.5 (0.14) 7.5 (0.19) 65 (71) 53 (928) -76 to 68°F Low temperature vibration

™

Damping Foil 435 between the ribs and

3M

stringers of an aircraft fuselage helps reduce

vibrational fatigue and noise inside the

passenger cabin.

2

damping.

2

vibration damping.

2

laminate.

6

108

3

3

3

This data has not been verifi ed. Additional testing is required.

Page 7

Converting 3M Foil Tape Technologies

to the form and fi t you need for applications success

3M Converters match 3M™ Foil Tapes to

customer requirements with the exact form,

fi t, and functionality. Converter expertise

includes part design, quick prototyping,

slitting, and die-cutting. Applications range

from small, intricate copper foil EMI/RFI

shields for sensitive electronics to precisely

fi tted masks for commercial aircraft windows

during paint stripping.

11

Many 3M™ Metal Foil Tapes are linered for

easy handling and productive processing.

For example, General Purpose Aluminum

Foil Tape 3367 features a 66# moisture

stable liner for die-cutting. The 40# kraft

liner on General Purpose Aluminum Foil

Tape 3380 holds shape and position when

slit into narrow rolls.

With conformability and chemical resistance,

die-cut masks of 3M™ Aluminum Foil Tape

protect aircraft windows during harsh chemical

paint stripping.

12

14

13

15

7

Page 8

Product Use: Many factors beyond 3M’s control and uniquely within user’s knowledge and control can affect the use and performance of a 3M product in a particular application.

Given the variety of factors that can affect the use and performance of a 3M product, user is solely responsible for evaluating the 3M product and determining whether it is fi t for

a particular purpose and suitable for user’s method of application. Warranty, Limited Remedy, and Disclaimer: Unless an additional warranty is specifi cally stated on the

applicable 3M product packaging or product literature, 3M warrants that each 3M product meets the applicable 3M product specifi cation at the time 3M ships the product. 3M

MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY OR CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. If the 3M

product does not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option, replacement of the 3M product or refund of the purchase price. Limitation of

Liability: Except where prohibited by law, 3M will not be liable for any loss or damage arising from the 3M product, whether direct, indirect, special, incidental or consequential,

regardless of the legal theory asserted, including warranty, contract, negligence or strict liability.

3

Industrial Adhesives and Tapes Division

3M Center, Building 225-3S-06

St. Paul, MN 55144-1000

800-362-3550 . 877-369-2923 (Fax)

www.3M.com/industrialtapes

3M is a trademark of 3M Company.

70-0709-5390-9

Printed in U.S.A

© 3M 2012

Loading...

Loading...