Page 1

Hard-to-grind

materials cut

down to size.

Courtesy of

Abbott Machine Co.

From rough grinding to nal

nishing, 3M brings you a

complete range of abrasive

solutions designed to meet today’s

tough processing challenges.

3M.com/abrasives

Page 2

Cut to the

science of

the matter.

3M abrasive technologies.

The precision-shaped grain found in

3M™ Cubitron™ II Abrasives combines

the advanced material properties of our

original Cubitron grain with the precise

microreplicated structures pioneered in

3M™ Trizact™ Abrasives. As the triangular

shaped grain wears, it continuously

fractures to form sharp points and edges.

Conventional ceramic abrasive grain is

irregular and blocky in shape. Instead of a

clean, machining action, the grain tends to

“plow” through the metal, causing heat to

build up in the workpiece and the abrasive —

resulting in a slower cut, shorter belt life and

undesirable eects, such as burnishing.

Shaping a new era of

grinding performance.

Precision-shaped

Grain

Conventional

Page 3

The fast yet forgiving cut and consistent

TM

performance of Scotch-Brite™ Abrasives

allows you to improve surfaces without

signicantly changing the shape of

dimension or the workpiece —and helps

prevent undercutting and gouging.

Revolutionary 3M technologies

deliver required geometry

tolerances without sacricing cut

rates on hard-to-grind materials.

Consistently and easily achieve

nishing specs part after part.

Flexible, non-woven construction

with high concentration of active

mineral sites for fast, consistent

cutting without compromising

nal nish. Specially coated

to minimize loading. Produces

controlled, uniform scratch

throughout life of the abrasive.

Trizact

™

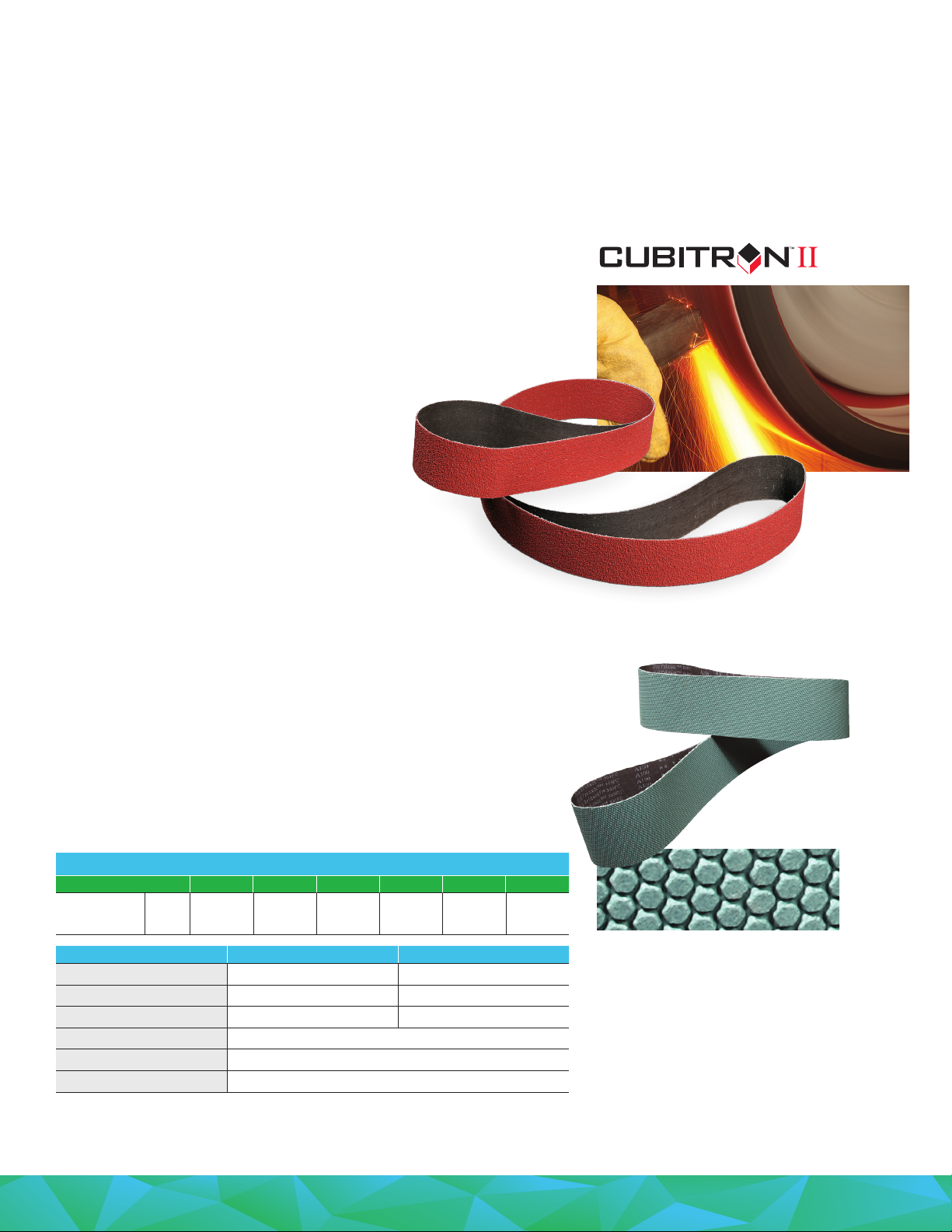

Derived from patented 3M microreplication

technology, 3M™ Trizact™ Abrasives consist

of precisely-shaped three-dimensional

structures distributed uniformly over the

substrate. Unlike conventional abrasives,

which are constructed from randomlyspaced and irregular-shaped minerals, the

uniform conguration of Trizact abrasives

helps deliver consistent performance.

Conventional abrasives start

out sharp, but dull quickly.

The three-dimensional structures

of 3M™ Trizact™ Abrasives contain

multiple layers of mineral. As

these structures wear, fresh, sharp

mineral is constantly exposed

to the workpiece, resulting in

faster, more consistent cutting

throughout the life of the belt.

Page 4

Base Steel Dimensioning

3M™ Cubitron™ II Abrasive Belt 984F

New 3M™ Cubitron™ II Abrasive Belts have raised the bar for

grinding performance and productivity — thanks to a breakthrough

3M technology that re-writes the rules for speed, consistency and

belt life.

• Cuts cooler —diverts heat from the workpiece

and belt to the swarf

• Helps eliminate burnishing and heat stress

• 3M’s highest performing belt in most metal

working applications

3M™ Trizact™ Cloth Belt 363FC

3M’s newest belt for cylindrical and centerless grinding provides outstanding performance

when dimensioning the base material prior to thermal spray coating of parts. Combine

the unmatched consistency of this Trizact abrasive with the ease and versatility of a belt

dimensioning process for fast, predictable results on stainless, mild and hardened steel.

Grade A300 provides quick cutting and accurate dimensioning of base metal prior to thermal

spray coating. Finer nishes can be quickly achieved through simple belt changes to the

appropriate abrasive grade.

Base Material Prep and Dimensioning with 3M™ Trizact™ Cloth Belt 363FC

Sequential Surface Finishes Obtained

Roll Material A300 A160 A100 A65 A45 A35

Mild Steel

Operating Conditions Recommended Acceptable Range

Belt Speed (SFPM) 6,000 4,000 –7,000

Workpiece Speed 75 50–150

Traverse Rate 1/4 inch/rev 1/10–1/2 inch/rev

Contact Wheel

Alternate Contact Wheel 90 Shore A, smooth or serrated

Coolant Water with 4–8% synthetic coolant

Ra 60–70 55–65 40–50 30–35 20–25 12–18

Target

Removal

0.010–

0.015

Ra (micro inch) Target Removal (inches o the diameter)

0.005–

0.0075

0.005 0.004 0.0025 0.001

Incompressible Aluminum, Steel, Polymer;

1/4" wider than abrasive belt

3M™ Trizact™ Cloth Belt 363FC

is available in A300 to A35 grades.

• Faster than conventional bonded wheels

• Up to 5 times extended belt life over

conventional coated abrasives

• Improved nish consistency

• Reduced taper on long parts

• Improved part-to-part size

Page 5

Chrome Grinding

3M™ Trizact™ Cloth Belt 347FC

Similar to Trizact belts 363FC, the new 347FC belts feature a unique

formulation and abrasive pattern well suited for hard chrome grinding

and nishing. 347FC belts deliver consistent grinding performance

without loading and dulling. Available in grades A300 for quick stock

removal to A30 for ne nishes in belts up to 25" wide.

Base Material Prep and Dimensioning

with 3M™ Trizact™ Cloth Belt 347FC

Sequential Surface Finishes Obtained

Roll Material A160 A65 A45

Chrome

Operating Conditions Recommended Acceptable Range

Belt Speed (SFPM) 6,000 4,000–7,000

Workpiece Speed 75 50–150

Traverse Rate 1/4 inch/rev

Contact Wheel

Alternate Contact Wheel 90 Shore A, smooth or serrated

Coolant Water with 4–8% synthetic coolant

Ra 5–12 3–4 2–3

Infeed 0.0004 0.00025 0.00025

Ra (micro inch) Infeed (inches on radius)

1/10 inch/rev –

Incompressible Aluminum, Steel, Polymer;

1/4" wider than abrasive belt

1/2 belt width /rev

Grade A160 strips and

nishes. Rely on A160

for ecient stock

removal and also to

achieve a ne nish!

3M™ Cloth Belt 966F

Constructed with tough, durable

ceramic abrasive grain, 966F belts

are ideally suited for stripping chrome

from old parts as they are being rebuilt.

966F belts are also suited for wet

grinding and nishing of heat sensitive

high nickel alloys, where a coolant

ood is needed, as well as titanium and

stainless steel.

Base Material Prep and Dimensioning with 3M™ Cloth Belt 966F

Operating Conditions

Contact Wheel Incompressible Aluminum, Steel, Polymer; 1/4" wider than abrasive belt

Alternate Contact Wheel 90 Shore A, smooth or serrated

Abrasive Speed 6000–7000 sfpm

Coolant Water with 4–8% synthetic coolant

Rod Rotation 100 sfpm

Head Traverse Speed .020"–.070"/revolution (depending on chrome/coating thickness)

Head Motor Load 33% over no-load

Page 6

Thermal Spray Grinding

TM

Contour/Complex Shapes

Scotch-Brite™ 645DC Diamond Unitized Wheels

Scotch-Brite™ 645DC Diamond Unitized Wheels are a must-see

for thermal spray, composites, carbon ber and ceramic

processing jobs. Scotch-Brite™ 645DC provides opportunities for

step consolidation and consistent nishes. Scotch-Brite™ 645DC

removes and nishes thermal spray parts in one step with Ra in the

12–16 range. Available in 12", 6" and 3" diameters and in multiple

thicknesses.

Consistently Fine, Burr-Free Finish with

Scotch-Brite™ 645DC Diamond Unitized Wheel

Operating Conditions

Wheel Diameter Maximum RPM

3" 15,100

6" 6,000

12" 2,200

3M™ Diamond Micronishing

Film Belt 675L

Designed with superior exibility, 675L lm belts

can be used wet or dry to nish highly contoured

thermal sprayed surfaces such as progressive cavity

pumps and extruder screws. Available in grades 125

and 74 micron to rene thermal sprayed surfaces and

45, 30, 20 and 9 micron for ner nishes.

™

Diamond Cloth Disc 674W

3M

3M Diamond Cloth Discs 674W are designed to provide long-

lasting cutting performance when used for nishing ceramics,

carbides and hard coated materials. The unique construction

allows Diamond Cloth 674W to deliver outstanding consistency

throughout the life of the disc, for improved control and fewer

rejects. They provide optimal performance when run wet, but

can also be run dry. Compared to exible metal bond diamond

abrasives, 3M Diamond Cloth Discs 674W last longer, and deliver a

faster, more consistent cut. They also provide a ner nish, with less

chance of burn through— helping you improve productivity.

Page 7

Cylindrical Parts

3M™ Diamond Wheel 637BI

3M Diamond Wheels 637BI feature a breakthrough technology

for hard-to-grind materials that enables faster, non-stop grinding

performance— with little to no need for wheel conditioning.

Dressing stick use is reduced or eliminated allowing for higher

throughput, lower cost-per-part, and greater worker safety. These

fast-cutting, long-lasting wheels are available in a wide range of

grades, shapes and sizes— from 3" cup wheels to 24" centerless

grinding wheels.

3M™ Resin Bond Superabrasive Wheels

3M manufactures a full line of bonded and single layer

superabrasive products utilizing the latest induction and furnace

heating techniques. They provide excellent form retention as well

as abrasion and heat resistance when grinding tough materials

such as carbides, quartz, ceramics and hard metals.

Faster, safer and more cost-eective way

to achieve desired size and nish.

• Consistent and fast-cutting —at rates up

to 25% higher than typical wheels

• Reduced consumables cost —can

eliminate the need for dressing sticks

• Higher productivity — allows increased

feed rates, while reducing or eliminating

the need for wheel conditioning

• Lower maintenance costs — reduces

debris in coolant, minimizing wear

and tear on equipment and reducing

the particle load on the ltration system

• Enhanced worker safety—can avoid the

risks associated with manual sticking

3M™ Trizact™ Diamond Cloth Belt 663FC

3M Trizact Diamond Cloth Belt 663FC represents the next

generation in abrasive technology—combining the predictable

dimensioning traditionally associated with bonded wheels with

the speed, consistency and ease of use of 3M abrasive belts.

663FC belts cut up to 70% faster than typical bonded wheels.

And because they are easy to use, even less-experienced

operators can achieve consistent, eective stock removal

throughout the life of the belt. This also means that lower

grinding forces can be used, minimizing the chance

of deformation, chatter and other grinding defects on

lightweight/thin-walled components.

Courtesy of

Abbott Machine Co.

Roll Grinding with 3M™ Trizact™ Diamond Cloth Belt 663FC

Sequential Surface Finishes Obtained

Roll Material 70µ 40µ 20µ

Tungsten Carbide

Chrome Carbide

Nickel Based

Chrome Oxide

Operating Conditions Recommended Acceptable Range

Belt Speed (SFPM) 6,000 4,000–7,000

Workpiece Speed 75 50 –150

Traverse Rate 1/4 inch/rev

Contact Wheel

Alternate Contact Wheel 90 Shore A, smooth or serrated

Coolant Water with 4–8% synthetic coolant

Ra 20–30 10–20 4–10

Infeed 0.0008 0.0005 0.00025

Ra 25–35 15–25 6–12

Infeed 0.0012 0.0008 0.0005

Ra 40–50 30–40 20–30

Infeed 0.0017 0.0012 0.0006

Ra 60–80 40–50 20–30

Infeed 0.0 03 — —

Ra (micro inch) Infeed (inches on radius)

1/10 inch/rev –

1/2 belt width /rev

Incompressible Aluminum, Steel, Polymer;

1/4" wider than abrasive belt

Page 8

Supernishing/Finishing

3M™ Diamond Micronishing Film Rolls 675L

Designed especially for fast nish reduction on hard materials, new

675L lm allows target nishes to be achieved in fewer passes for

greater productivity. Can cut supernishing time in half or more,

compared to stones. Currently available in grades ranging from 125 to

9 micron, 675L lm oers an ecient, economical alternative in most

applications except those requiring the nest possible nishes. Use

3M Diamond Lapping Film to achieve nishes <2 Ra Micro Inch.

Supernishing with 3M™ Diamond Micronishing Film 675L

Sequential Surface Finishes Obtained (Ra Micro Inch)

Roll Material 74µ 45µ 30µ 20µ

Tungsten

Carbide

Chrome

Carbide

Nickel

Based

Chrome

Oxide

Ra 12–16 8–12 5–8 2.5–5

Ra 15–20 10–14 6–10 4–6

Ra 20–55 14–19 6–10 4–6

Ra ~55 ~45 — —

Operating Conditions Recommended Acceptable Range

Workpiece Speed 300 sfpm 150-350

Traverse Rate 0.07 inch/rev 0.03-0.1

Abrasive Support 65 Shore A Roller —

Abrasive Speed 0.5–1.0 inch/min —

Pressure 20 lbs/inch width 10–40

Oscillation Alternating Moderate/None

Coolant Water with 4–8% synthetic coolant

3M™ Diamond Lapping Film 661X and 663X

Diamond Lapping Films are widely used for nishing and polishing

hard-to-grind materials such as carbide, ceramics, hardened

metals, exotic alloys and composites. They combine micron-graded

diamond particles, a resin bonding system and a highly uniform

polyester lm backing for a more consistent, cleaner and faster

alternative to diamond compounds or slurries. Use 3M Diamond

Lapping Film to achieve nishes <2 Ra micro inch.

661X and 663X lms both have a 3 mil

polyester backing.

661X lm is available in 0.1–30 micron

grades. 663X lm is available in coarser

grades of 15, 30, 45 and 60 microns.

Page 9

3M™ Diamond Polishing Cloth Belts

651WY and 652WY

Constructed with micron-graded diamond particles bonded to a

durable water-resistant backing. These tough belts perform well

in both wet and dry applications.

Ideal for many hard-to-nish

materials, including:

• Thermal spray parts

• Ceramics

• Composites

• HVOF coatings

• Chilled iron

• Non-ferrous metal

651WY is available in

grades 100-1800 mesh.

652WY is available in

3,000-50,000 mesh.

™

3M

Flexible Diamond

Rolls and Belts

Used in rolls on supernishers or in belt

form, 3M Flexible Diamond products allow

you to achieve your required nish. A metal

bond securely anchors micron-graded

diamonds to a variety of exible backings

in an open dot pattern. This provides

durability and long life while allowing

conformance on a variety of contours.

Large dots for anti-loading

(Pattern 21)

Medium dots for aggressive cutting

(Pattern B2)

Small dots for ne nishes

(Pattern 18)

Page 10

3M™ Abrasive Selection Guide

for Hard-to-Grind Materials

3M Abrasive

3M™ Cubitron™ II

Abrasive Belt 984F

3M™ Trizact™ Cloth

Belt 363FC

3M™ Cloth Belt 966F

3M™ Trizact™ Cloth

Belt 347FC

3M™ Trizact™ Diamond

Cloth Belt 663FC

3M™ Diamond Polishing Cloth

Belts 651WY and 652WY

3M™ Diamond Lapping

Film 661X and 663X

3M™ Diamond Micronishing

Film 675L

Base Steel

Dimensioning

s

s

s s

Chrome

Grinding

s

Thermal Spray

Grinding

s

s s

s s

Supernishing

and Finishing

s

3M™ Flexible Diamond

Rolls and Belts

3M™ Diamond Cloth

Disc 674W

3M™ Diamond Wheel 637BI

3M™ Resin Bond

Superabrasive Wheels

Scotch-Brite™ 645DC

Diamond Unitized Wheels

s s

s

s

s

s

Page 11

The CAM Center is Your

Resource for Surface

Modication Solutions

Let’s work together.

The 3M Customer Abrasive Methods (CAM) Center can help your business reduce process

steps, increase throughput, and lower overall manufacturing costs. When you work with

3M, your company can benet from the industry’s foremost technical experts on surface

modication. Utilizing a 30,000 sq foot facility with over 80 grinding and nishing machines

and portable tools, CAM Center engineers can help you specify new equipment to optimize

your process or work with you to develop a new or improved nishing method.

Contact your 3M representative

for more details.

Page 12

3M Abrasive Systems Division

3M Center, Building 21-1W-10

St. Paul, MN 55144 USA

Phone 1-866-279-1235

Web 3M.com/abrasives

Product Use: All statements, technical information and recommendations contained in this document are based

on tests or experience that 3M believes are reliable. However, many factors beyond 3M’s control can aect the

use and performance of a 3M product in a particular application, including conditions under which the product is

used and the time and environmental conditions in which the product is expected to perform. Since these factors

are uniquely within the user’s knowledge and control, it is essential that the user evaluate the 3M product to

determine whether it is t for a particular purpose and suitable for the user’s method of application.

Warranty and Limited Remedy: Unless stated otherwise in 3M’s product literature, packaging inserts or product

packaging for individual products, 3M warrants that each 3M product meets the applicable specications at the

time 3M ships the product. Individual products may have additional or dierent warranties as stated on product

literature, package inserts or product packages. 3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY ARISING OUT OF A COURSE OF DEALING, CUSTOM OR

USAGE OF TRADE. User is responsible for determining whether the 3M product is t for a particular purpose and

suitable for user’s application. If the 3M product is defective within the warranty period, your exclusive remedy

and 3M’s and seller’s sole obligation will be, at 3M’s option, to replace the product or refund the purchase price.

Limitation Of Liability: Except where prohibited by law, 3M and seller will not be liable for any loss or damage

arising from the 3M product, whether direct, indirect, special, incidental, or consequential regardless of the legal

theory asserted, including warranty, contract, negligence or strict liability.

3M, Cubitron and Scotch-Brite, Trizact are

trademarks of 3M. Used under license by

3M subsidiaries and aliates.

Please recycle. Printed in USA © 3M 2015.

All rights reserved. 61-5002-8137-5

Loading...

Loading...