3M AWT User Manual

Transportation Safety Division

3M™ All Weather Thermoplastic

Product Bulletin AWT

April 2020

Replaces Product Bulletin All Weather Thermoplastic Dated January 2010

1 Description

3M™ All Weather Thermoplastic (“AWT”) is a traffic marking system consisting of a high performance

thermoplastic, 3M Connected Roads All Weather Elements (“Elements”), and an accompanying second drop of

glass beads. Designed for use as long line markings, all weather thermoplastic delivers exceptional levels of all

weather reflective performance in a thermoplastic marking.

Thermoplastic is available in two intermix options. Both options are part of a matched component system (“MCS”)

that includes surface drop Elements.

1 Intermediate performance product: AWT with Type 3. This product has Type 3 and Type 1 beads intermixed

into the thermoplastic binder and should be applied at a thickness of at least 90 mils (2.3 mm).

2 Value product: AWT. This product contains Type 1 beads intermixed into the thermoplastic binder and should be

applied at a thickness of at least 90 mils (2.3 mm).

Table 1 presents a comparison chart that summarizes the performance characteristics of the two available products.

Table 1. Product comparison chart.

AWT with

Type 3

Reflectivity Performance

Initial all weather

Retained dry

Intermixed Optics

Type 3 glass beads

Type 1 glass beads

Surface optics

Element double drop X X

Standard thermo equipment X X

X

X

X

XX

AWT

X

2 3M™ All Weather Thermoplastic April 2020

1.1 3M Connected Roads All Weather Elements

Elements consist of an outer layer of microcrystalline ceramic beads partially embedded into composite cores

to provide optimal performance under dry and/or wet conditions. Elements are used in AWT as the first drop

of a double drop system. Elements provide initial levels of all weather performance. Elements are visible when

dry, during rainfall, and after rainfall, providing marking visibility for motorists under all weather conditions.

1.2 Thermoplastic

AWT has been specially formulated for the intended applications and consists of a mixture of high quality

resins, pigments, and optics. Type 3 and Type 1 glass beads are intermixed into the thermoplastic binder in the

highest performance product option, whereas only Type 1 glass beads are intermixed into the thermoplastic in

the value product.

AWT is an ideal pavement marking system for situations where thermoplastic equipment is already available.

1.3 Second Drop Glass Beads

A second drop of glass beads is used to improve the durability of the finished marking and provide increased

visibility during dry conditions.

2 Specifications

2.1 Retroreflectivity

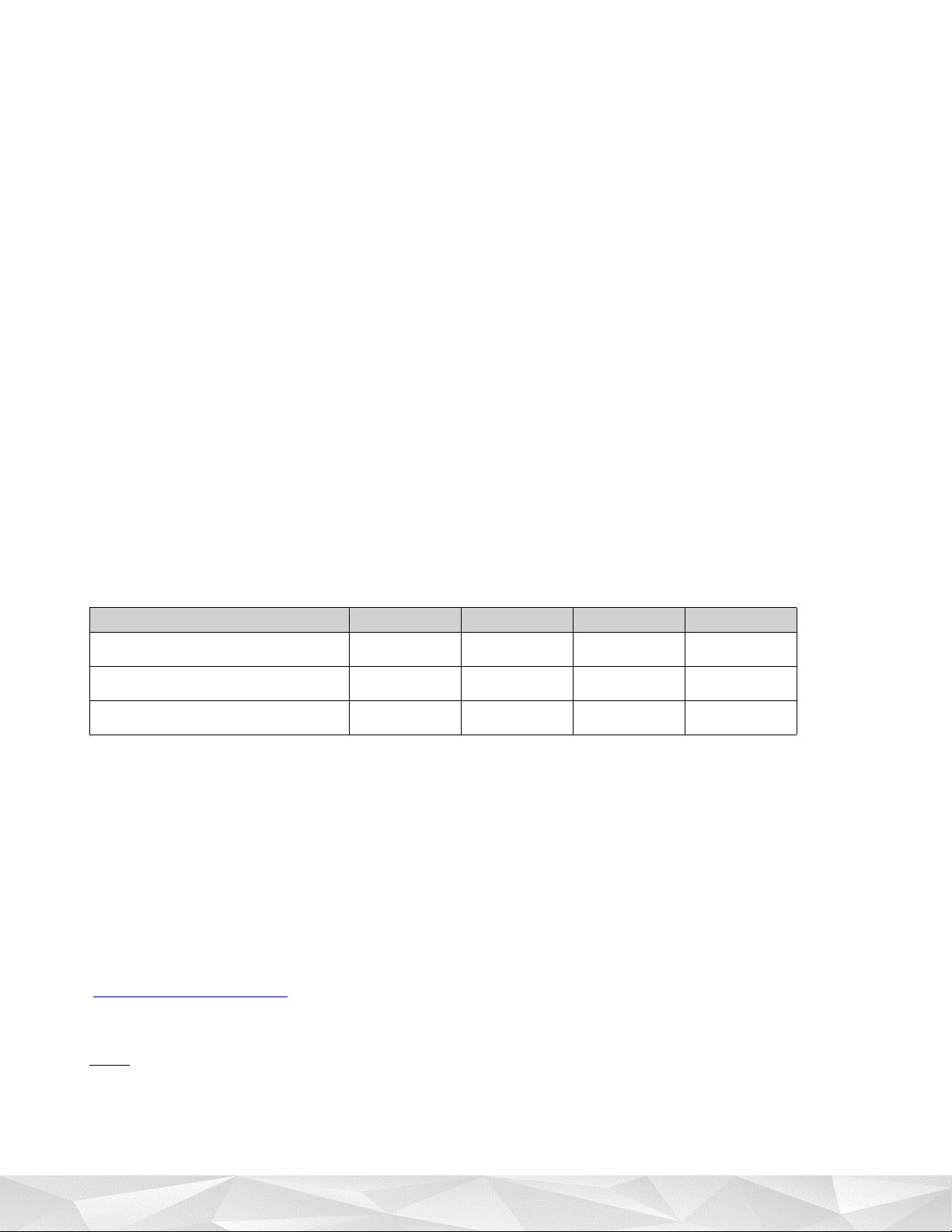

Typical initial retroreflectance values are shown in Table 2 below. Some variance should be expected across

applications, and all values represent initial properties unless otherwise noted.

Table 2. Typical average initial coefficients of retroreflected luminance

Property/test method Series Dry Series 50 Series 90 Series Wet

Retroreflectivity, Dry Average

ASTM E1710

Retroreflectivity, Wet Recovery Average

ASTM E2177

Retroreflectivity, Wet Continuous Average

ASTM E2832

a. Typical retroreflectivity results represent average performance for smooth pavement surfaces. Results may vary

due to differences in pavement type and surface roughness. Increased Elements drop rate may be necessary to

compensate for increased surface area characteristic of rough pavement surfaces. Wet retroreflectivity testing of

markings applied in grooved or recessed surfaces is difficult since water pools in recesses. In such cases, consider

installing sections of pavement markings for testing on either a smooth section of the pavement surface, or on rigid

panels (50 mil aluminum). If markings are applied to panels, allow them to cure, then move them carefully for

retroreflectivity testing - make sure to protect the optics when transporting.

White: 1250

Yellow: 900

N/A

N/A

White: 700

Yellow: 525

White: 275

Yellow: 225

White: 200

Yellow: 150

a

[mcd/m2/lx].

White: 500

Yellow: 375

White: 375

Yellow: 300

White: 275

Yellow: 225

N/A

White: 400

Yellow: 325

White: 300

Yellow: 250

3 Installation

The installer of the markings is required to comply with the following installation conditions and procedures.

3.1 Weather and Pavement Conditions

Thermoplastic should be applied according to the established application guidelines, see

3M Information Folder 5.24

pavement temperature of at least 50 ºF (10 ºC) and rising. Thermoplastic should be applied at a temperature

of 385–420 ºF (196–227 ºC), as measured at the die, to ensure proper adhesion to the pavement.

for details. Optimal performance is achieved when AWT is applied at an air and

Note:

Under some conditions, more restrictive application temperatures are required. Contact you 3M

Application Engineer for details.

Loading...

Loading...