Page 1

3M™ Attest™ Steam

Chemical Integrator

Technical Information

STEAM

Dynamics of Steam Sterilization

Steam sterilization has been used for over 100 years. Decades of research have

shown that the ecacy of a steam sterilization process is the function of three

basic parameters: time, temperature and the presence of saturated steam. All

three are critical process variables for eective steam sterilization.

The importance of saturated steam is demonstrated when dry heat sterilization

is compared with steam sterilization. The use of steam allows faster sterilization

than dry heat. For example, dry heat sterilization requires a sterilization time of

60 minutes at 320°F (160°C), while steam sterilization at the same temperature

would take less than a minute.1 Clearly, steam quickens the kill time of living

organisms by many orders of magnitude and is generally preferable to dry heat.

Page 2

2

3M™ Attest™ Steam Chemical Integrator Technical Information

Once a saturated steam environment is obtained, the

independent variables of time and temperature can be

determined by the following formula:

t = Fo × 10

Where

t = time for 100% kill at temperature T

(2 50-T )/Z

2

T = processing temperature (0°F)

Fo = kill time for Geobacillus

stearothermophilus with a z-value of

18°F (10°C) and D-value of 1 minute at 250˚F

(121˚C)

z = rise in temperature required to increase

the rate of kill by a factor of 10 (usually

about 18˚F (10˚C))

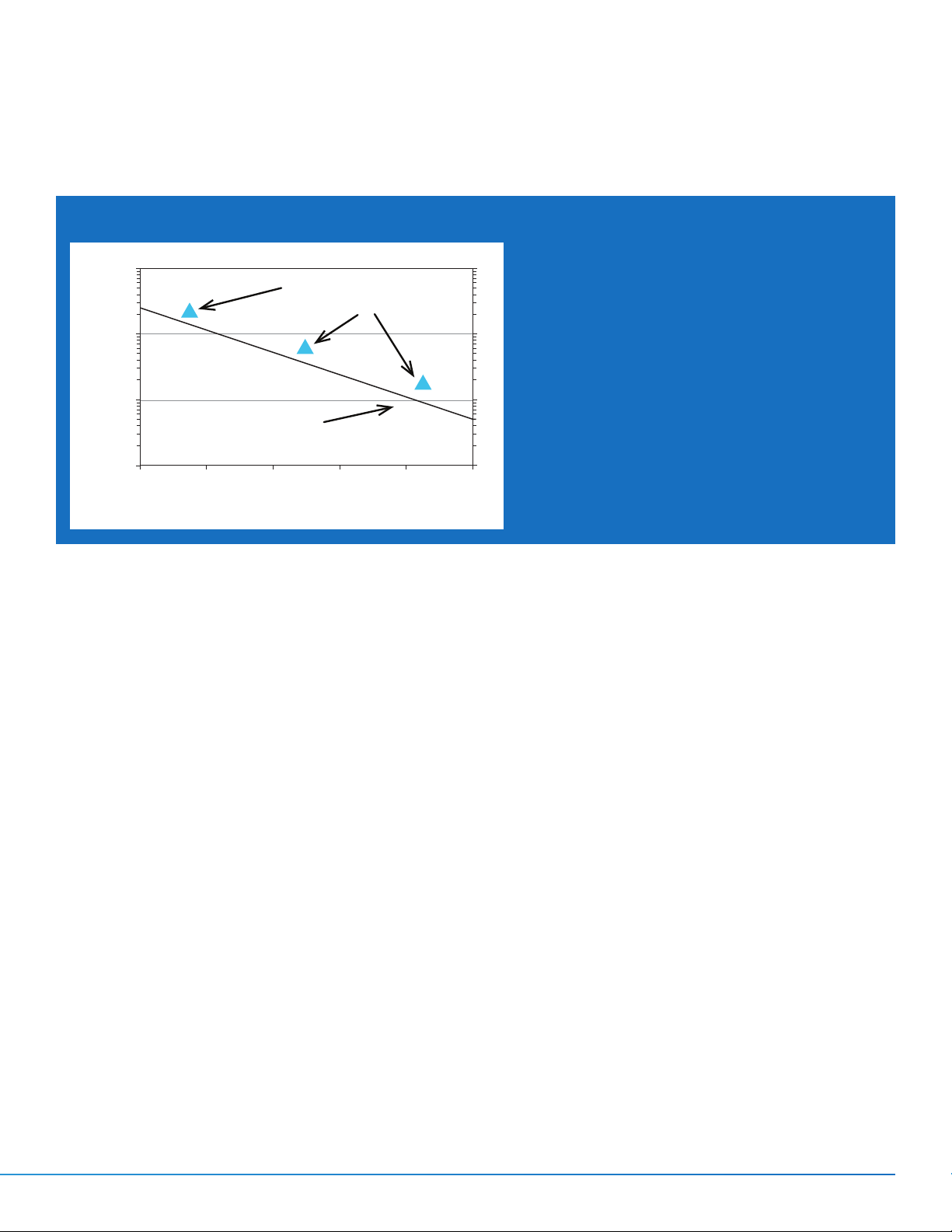

Interpretation of this formula shows that the

relationship of processing time (t) versus temperature

(T) can be plotted as a logarithmic function. Expressed

dierently, it means that a small uctuation in the

temperature results in a large change in the actual

processing time required for 100% kill. Figure 1 shows

the thermal death time at dierent temperatures for

1 million live spores of Geobacillus stearothermophilus.3

This curve can be expressed mathematically by the

following formula which shows that it takes 12 minutes

to kill 1 million living spores in a 250°F (121°C) steam

sterilization cycle.

t = (12)10

(250-T)/18

Where

Fo = 12 min for G. stearothermophilus

z = 18°F (10°C) for G. stearothermophilus

In order to show the high sensitivity of kill time to

temperature, the above formula can be solved for

247°F (119°C).

t = (12)10

t = (12)10

(250-247)/18

(0.167)

= (12)(1.47)

t = 17.6 minutes

In theory, therefore, if the inside temperature of a

sterilizer were actually operating at 247°F (119°C)

instead of 250°F (121°C), a time of 17.6 minutes

would be required to kill the 1 million spores of G.

stearothermophilus at 247°F (119°C) versus the 12

minutes needed to kill the spores at 250°F (121°C).

This interdependence of time and temperature (in

saturated steam) is an important relationship which

should be understood by all personnel responsible

for providing sterility assurance for steam sterilized

items. Consider the ramications if a sterilizer was

inadvertently set at a processing temperature at

247°F (119°C) instead of 250°F (121°C). Or, if the load

was processed at 247°F (119°C) as a result of a minor

malfunction of the sterilizer (e.g., air pocket or small air

leak), a slight calibration error or a natural drift in the

temperature monitoring system, incorrect loading or

packaging.

Because even small decreases in temperature during

steam sterilization may signicantly increase the time

necessary for assurance of sterility, an accurate means

of monitoring internal sterilizer and pack conditions

are essential.

Page 3

3M™ Attest™ Steam Chemical Integrator Technical Information

Integrating Indicator vs. Biological Death Curve

3

100.00

10.0

1.0

Time (min.)

Theoretical G. stearothermophilus

Thermal Death Time

0.1

118 122 126 130 134 138

Three Typical Stated Values

™

Attest™ Steam

for 3M

Chemical Integrators

Temp (°C)

Pack and Load Control

The dynamics of steam demonstrate the need for

accurate monitoring of internal sterilization conditions.

Pack control is the use of chemical indicators for the

internal monitoring of packs, trays, containers, and peel

pouches. Internal chemical indicators should be used

inside each type of packaging to address the potential

for interference with proper steam sterilization

conditions in all of these types of packaging.

Several problems can occur in the packaging and

loading of individual packs that can inhibit air removal

and steam penetration which leads to a lower

temperature. Packing problems include:

• Incorrect packaging or container system chosen

for the cycle parameters;

• Incorrect preparation of the container for use

(i.e., lters and valves or inappropriate bottom tray);

• Placing a folded peel pouch inside another

peel pouch;

• Placing a peel pouch inside of an instrument tray

or container system (if not recommended by the

manufacturer);

• Preparing textile packs that are too dense to sterilize

in the cycle parameters chosen;

4,5,6

Figure 1. Graph comparing three

typical Stated Values of 3M™ Attest™

Steam Chemical Integrators with the

theoretical death curve of Geobacillus

stearothermophilus spores.

• Over loading the individual packaging or container

system chosen (an over weight package).

Loading problems include:

• Stacking container systems (if not recommended

by the manufacturer);

• Laying peel pouches at or on top of each other

instead of on edge;

• Improperly placing peel pouches on edge (plastic

sides not facing all in one direction);

• Turning instrument trays on edge;

• Laying fabric packs or basins at;

• Placing packages too close to each other impeding

air removal and sterilant penetration around and

through the load;

• Rigid containers systems loaded above wrapped

or pouched items.

Malfunctioning equipment can also result in

insucient sterilization conditions inside of

packaging as the result of:

• Incomplete air removal;

• Inadequate cycle temperature;

Page 4

4

3M™ Attest™ Steam Chemical Integrator Technical Information

• Insucient time at temperature;

• Poor steam quality and quantity.

As discussed above, small reductions in time at

temperature can reduce the margin of safety with

steam processing. Problems that limit air removal or

steam penetration in individual packs may reduce

the eective time at temperature. Type 5 Integrating

Integrators that meet ISO 11140-1:2014 Sterilization

of healthcare products-Chemical Indicators-Part 1:

General requirements used inside each pack to monitor

time, temperature and steam exposure conditions can

provide the necessary sterilization assurance on

a pack-to-pack basis.

Load control is the process by which a load is

monitored and released based on the result of a

Biological Indicator (BI) in a process challenge device

(PCD). A BI PCD should be used, preferably every

day the sterilizer is used, for routine sterilizer ecacy

testing. BI PCDs are also recommended for sterilizer

qualication testing.

5 Integrating Indicator should be used to monitor each

implant load. The load should be quarantined until the

results of the BI testing are available.

loads, a PCD containing a Type 5 integrating indicator

or Type 6 emulating indicator may be used to release

the load.

Using a BI in every load (ELM) is considered best

practice. When you monitor every load with a BI you

provide the same level of care to each and every

patient served by the facility. Every load monitoring

allows only one load to be recalled, aecting fewer

departments, and protecting the reputation of the

department and the facility overall. It allows the CSD

Manager to streamline workow, simplify training and

reduce the opportunity for human error which leads to

consistent/standardized practice. Follow the process

for every load and reduce the risk of failing to properly

monitor an implant load.

7

4,5

A BI PCD that includes a Type

4,5

In non-implant

The chemical pellet melts and migrates as a dark color

along the paper wick. The migration is visible through a

green window marked ACCEPT or red window marked

REJECT; the extent of migration depends on steam,

time, and temperature. 3M™ Attest™ Steam Chemical

Integrators are Type 5 (Category i5) Integrating

Indicators as categorized by ISO 11140 1:2014.

This product comes with an extender strip axed to

one end of a 3M™ Attest™ Steam Chemical Integrator.

The axed 1243RE extender is a 17.8cm (7 in) long by

1.8cm (0.7 in) wide rigid strip. The axed 1243RES

extender is a 5.1cm (2 in) long by 1.8cm (0.7 in) wide

rigid strip. The extender serves as a handle to retrieve

processed integrators from inner packs.

Indications for Use

Outside the United States

Use 3M™ Attest™ Steam Chemical Integrators for pack

control monitoring of all 121–135ºC (250–275ºF) steam

sterilization cycles.

Inside the United States

The 3M™ Attest™ Steam Chemical Integrators are

designed to respond to all critical parameters over

a specied range of steam sterilization cycles. The

integrating indicator is intended to be placed in each

pack, pouch, container, tray or other containment

device to function as an independent monitor of

critical parameters for sterilization cycles. Please see

Instructions for Use for specic cycle indications for

use in the U.S.

Contraindications

None.

Product Description

3M™ Attest™ Steam Chemical Integrators 1243A,

1243B and 1243RE are chemical indicators consisting

of a paper wick and steam and temperature sensitive

chemical pellet contained in a paper/lm/foil laminate.

Precautions

Do not use 3M™ Attest™ Steam Chemical Integrators to

monitor dry heat, ethylene oxide, hydrogen peroxide,

or other low temperature sterilization processes.

Page 5

3M™ Attest™ Steam Chemical Integrator Technical Information

Clear Plastic

Display Window

Paper/Film Top Cover

Steam Penetration

1

Rate Controlling

Paper Wick Strip

2

Steam and Temperature

3

Sensitive Chemical Pellet

5

Technical Design

The 3M™ Attest™ Steam Chemical Integrator is made

of four functional components. These components are

arranged in a sandwich conguration held together

with a pressure-sensitive adhesive: (See above)

Steam penetration rate controlling paper/lm

1

top cover

Paper strip (for chemical wicking)

2

Steam and temperature sensitive chemical pellet

3

Aluminum foil bottom cover

4

The base of the 3M™ Attest™ Steam Chemical

Integrator is made of aluminum foil several mils

thick which acts as a moisture barrier against steam

penetration during sterilizing. A cavity embossed in the

foil holds the temperature and steam sensitive chemical

pellet. The pellet has a very high dry heat melting point

to ensure 3M™ Attest™ Steam Chemical Integrators

require the presence of steam in order to respond.

However, it is designed to melt at lower temperatures

Bottom Cover

4

when subjected to a steam environment. The top cover

of the 3M™ Attest™ Steam Chemical Integrator is a

paper/polymeric lm which allows steam to penetrate

at a certain rate. As steam penetrates the polymeric

cover lm, it lowers the melting point of the chemical

causing the tablet to begin melting.

When melting occurs, the liquid chemical is absorbed

by the paper wick and, as time elapses, moves along

the scale. The more the chemical melts, the farther the

color front advances towards the ACCEPT area of the

display window. This is in part a function of the movingfront technology. The rate at which the chemical pellet

melts is a function of the time, temperature, steam and

the inherent design of the 3M™ Attest™ Steam Chemical

Integrator. The combination of these factors provides

a rate of melting at various temperatures which closely

follows the spore death curve of G. stearothermophilus

(proven to be the best challenge in a steam sterilization

process) (see Figure 1).

Page 6

6

3M™ Attest™ Steam Chemical Integrator Technical Information

Chemical Indicator Types

3M™ Attest™ Steam Chemical Integrators meet the

requirements of ISO 11140-1:2014 for Type 5 Integrating

Indicators. These indicators are designed to monitor all

three of the critical variables of the steam sterilization

process (time, temperature and steam) across full range

of steam sterilization temperature use.

Third Party Testing

As part of our compliance process, 3M hired BSI, a

leading global independent product testing services

company, to conrm that 3M™ Attest™ Steam Chemical

Integrators meet the Type 5 Integrating Indicator

performance requirements of ISO 11140-1:2014.

Through rigorous product testing, BSI conrmed these

products meet the performance requirements of ISO

11140-1:2014. A copy of the BSI Kitemark™ Certication

is available upon request from 3M.

Performance Characteristics

The 3M™ Attest™ Steam Chemical Integrator has been

tested at various time and temperature intervals in

saturated steam in a test vessel (called a resistometer)

to determine compliance to the chemical indicator

standards listed in the Chemical Indicator Types

section above. To meet the Type 5 Integrating

Indicator performance standards, the 3M™ Attest™

Steam Chemical Integrator must have a response

that correlates to the performance of a BI at three

temperatures (121°C/250°F, 135°C/275°F, and one or

more equally spaced temperature points in the range of

121°C/250°F to 135°C/275°F, such as 128°C/263°F).7

These responses are called Stated Values. Stated

Values are “value or values of a critical process variable

at which the indicator is designed to reach its endpoint

as dened by the manufacturer.”7 In addition, the

Stated Value at 121°C/250°F must be >16.5 minutes and

the 135°C/275°F stated value must be >1.2 minutes.7

These are the most important Stated Values to ensure

that chemical indicators labeled for use in 132°C/270°F

do not change too quickly or inappropriately at lower

and higher temperatures (to ensure the performance

of the CI is consistent between all temperatures)

and to ensure that all temperatures correlate to the

performance of a BI. Furthermore, all of the ISO 11140-

1:2014 Type 5 performance requirements must be met

to ensure that the CI can detect improper sterilization

conditions inside of each pack/container. Figure 1

shows three typical Stated Values for the 3M™ Attest™

Steam Chemical Integrators.

Instructions For Use

Placement and Processing

1. Carefully tear or use scissors at the tear notch at the

top of the foil package to make the initial opening.

Remove only the number of 3M™ Attest™ Steam

Chemical Integrators needed. Reseal the package.

2. Place a 3M™ Attest™ Steam Chemical Integrator in

each pack, peel pouch, container system or tray to

be steam sterilized in the area determined to be the

least accessible to steam penetration.

3. Process the load according to established

procedures.

Note: Refer to the package insert for a complete set

of instructions.

After processing, the dark color should have entered

the ACCEPT window of the 3M™ Attest™ Steam

Chemical Integrators 1243A, 1243B and 1243RE. If the

dark color has not entered the ACCEPT window, this

indicates a REJECT result which means that the items

in the pack, peel pouch, container system, or tray were

not exposed to sucient steam sterilization conditions.

These items should be returned for reprocessing.

Page 7

3M™ Attest™ Steam Chemical Integrator Technical Information

Interpretation of Results

Unprocessed

Processed — ACCEPT Processed — REJECT

7

If the color bar reaches or crosses into the ACCEPT

window, it is a pass and the necessary conditions

of time, temperature and steam have been met for

sterilization.

ACCEPT

If the color bar is in the REJECT region or on the line, it

is considered a fail. The pack should be reprocessed and

the cause of sterilization failure should be investigated.

REJECT

Page 8

Safety

The design of the 3M™ Attest™ Steam Chemical Integrator prevents the indicating chemicals of the CI from coming in

contact with sterilized materials or personnel handling the device. The chemical, as a pellet before processing or as a

melted color front after processing, is contained in an envelope of impermeable top and bottom layers.

Storage and Shelf Life

• Best stored at normal room temperature conditions, 15–30ºC (59–86ºF) and 40–60% relative humidity. Store

away from direct sunlight. Do not store near strong alkaline or acidic products such as cleaning/disinfecting agents.

• After use, the indicator will not change visually within 6 months when stored at above conditions.

• 3M™ Attest™ Steam Chemical Integrators contained in an unopened package have a shelf life as labeled from date

of manufacture when stored at recommended conditions. The expiration date is printed on the package label and

is also contained in the barcode on each device.

References

1

Perkins, J.J., Principles and Methods of Sterilization In Health Sciences, ed 2, Springeld, IL,

Charles C. Thomas, 1976.

2

Validation of Moist Heat Sterilization Processes: Cycle Design, Development, Qualication and Ongoing

Control, Technical Report No. 1 (Revised 2007), PDA Journal of Pharmaceutical Science and Technology,

Supplement Vol. 61, No. S-1, 2007.

3

International Standard. Sterilization of health care products Biological indicators — Part 7: Guidance

for the selection, use and interpretation of results, ANSI/AAMI/ISO 11138-7:2019.

4

Association for the Advancement of Medical Instrumentation. Comprehensive guide to steam sterilization

and sterility assurance in health care facilities, ANSI/AAMI ST79: 2017.

5

The Association of periOperative Registered Nurses (AORN) Recommended Practices for Sterilization in

Perioperative Practice Settings, 2020.

6

The Association of periOperative Registered Nurses (AORN) Recommended Practices for Selection and Use

of Packaging Systems for Sterilization, 2020.

7

International Standard. Sterilization of health care products-Chemical indicators-Part 1: General requirements,

ISO 11140-1:2014.

3M Medical Solutions Division

3M Health Care

3M Center, Building 275-4E-01

St. Paul, MN 55144 USA

Phone 1-800-228-3957

Web 3M.com/Medical

Learn more on our website:

3M.com/Attest

© 3M 2020. All rights reserved. 3M and Attest are marks and/or registered marks of 3M.

Used under license by 3M subsidiaries and aliates. Unauthorized use prohibited. Please recycle.

Printed in USA. 70-2009-0710-6_US

Loading...

Loading...