3M ASB1001 Installation Manual

MODELS:

ASB1001

ASB2001

ASB3001

INSTALLATION AND OPERATING

INSTRUCTIONS

ASB SERIES RESIDENTIAL

ARSENIC REDUCTION FILTER SYSTEM

Units Not for sale in California, Iowa, Wisconsin or Quebec.

Installer, please leave with homeowner.

Homeowner, retain for future reference.

INSTR2199 0710

SAFETY INFORMATION

WARNING

CAUTION

CAUTION

CAUTION

Read, understand, and follow all safety information contained in these instructions prior to installation and use of the ASB

Series Residential Arsenic Reduction Filter Systems. Retain these instructions for future reference.

Intended use:

The ASB Series Residential Arsenic Reduction Filter Systems are intended for use in reducing arsenic levels in water in homes and have not been evaluated for other uses. The system is intended for indoor installations near the entry point of a home water line, and must be installed by qualifi ed professional

installers in accordance with these installation instructions and local plumbing codes. Units Not for sale in California, Iowa, Wisconsin or Quebec.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

WARNING

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury and/or property

damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury and/or property

damage.

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, may result in property damage.

WARNING

To reduce the risk associated with choking:

• Do not allow children under 3 years of age to have access to small parts during the installation of this product.

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

To reduce the risk of physical injury:

• Shut off inlet water supply and depressurize system as shown in manual prior to service.

To reduce the risk associated with a hazardous voltage:

• If the home electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection across the fi lter installation piping — refer installation to qualifi ed personnel.

• Do not use the system if the power cord is damaged — contact qualifi ed service personnel for repair.

To reduce the risk associated with back strain due to the heavy weight of the various system components:

• Follow safe lifting procedures.

CAUTION

To reduce the risk associated with skin, eye, and respiratory tract irritation from dust from fi lter media during installation:

• Titanium Oxide granules and two grades of gravel are used for fi lter media in this product. During installation, dust may cause irritation to skin, eyes, and respiratory tract, and may affect lungs.

• Utilize a NIOSH-approved dust fi lter mask, protective gloves, and appropriate eye protection when handling and pouring gravel and fi lter media.

• To request an MSDS relating to this product, call 203-238-8965 or visit the web at http://solutions.3m.com/wps/portal/3M/en_US/MSDS (click MSDS search). For

emergencies, call 1-800-364-3577 or 1-651-737-6501.

CAUTION

IMPORTANT NOTES

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

• Do not install if water pressure exceeds 100 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a

plumbing professional if you are uncertain how to check your water pressure.

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer arrester. Contact a plumbing

professional if you are uncertain how to check for this condition.

• Where a backfl ow prevention device is installed on a water system, a device for controlling pressure due to thermal expansion must be installed.

• Do not use a torch or other high temperature sources near fi lter system, cartridges, plastic fi ttings or plastic plumbing.

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

• Do not install in direct sunlight or outdoors.

• Mount system in such a position as to prevent it from being struck by other items used in the area of installation.

• Ensure all tubing and fi ttings are secure and free of leaks.

• SHUT OFF FUEL OR ELECTRIC POWER SUPPLY TO WATER HEATER after water is shut off.

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

• Do not apply heat to any fi tting connected to bypass or control valve as damage may result to internal parts or connecting adapters.

• Install on a fl at/level surface. It is also advisable to sweep the fl oor to eliminate objects that could pierce the media tank.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

IMPORTANT NOTES

• Failure to follow instructions will void warranty.

TABLE OF CONTENTS

SECTION DESCRIPTION

1 BEFORE INSTALLATION

2 INSTALLATION

3 MAINTENANCE

4 TROUBLESHOOTING

5 EQUIPMENT SPECIFICATION AND OPERATING DATA

6 COMPONENT LIST & ASSEMBLIES

7 LIMITED WARRANTY

SECTION 1: BEFORE INSTALLATION

Inspecting And Handling Your Filter System:

Inspect the equipment for shipping damage. If damaged, notify the transportation company and request a damage inspection.

Handle the fi lter with care. Damage can occur if dropped or set on sharp, uneven projections on the fl oor. Do not turn the fi lter upside down. Installation must

comply with state and local laws and regulations.

Titanium Oxide

Titanium Oxide fi lter media is used to reduce heavy metals in water. It is manufactured as a granular material, is white in color and shipped dry. Titanium Oxide

has the ability to reduce Arsenic Arsenate and Arsenite (otherwise referred to as AS (V) and AS (III), if applied and installed properly. The material is sold in cubic

foot equivalent quantities for use in backwashing vessels and performs its task by adsorption. Adsorption is performed as the water passes through the fi lter

medium in the pressure vessel and the Arsenic is attracted to the media. Once adsorption takes place, the Arsenic is permanently retained by the Titanium

Oxide granules. Occasional backwashing of the fi lter will prevent channeling of the fi lter media and wash away any sediment and color to a waste drain while

not reducing any Arsenic from the Titanium Oxide. This will help provide better quality water and help extend the life of the fi lter. The life of this fi lter medium

can vary depending on the amount of other heavy metals in the water.

IMPORTANT NOTE

Have the water tested thoroughly prior to the installation of this fi lter system.

Test of the following constituents are recommended prior to installation, but are not limited to the following.

1. Arsenate (AS V) 7. Tannins 13. Selenium

2. Arsenite (AS III) 8. Total Dissolved Solids 14. Vanadium

3. Total Hardness 9. Hydrogen Sulfi de Gas 15. Cadmium

4. Total Iron 10. Silica 16. Phosphates

5. Manganese 11. Zinc

6. pH 12. Lead

Titanium Oxide has the ability to treat thousands of gallons of water prior to the need for replacement. Under normal household applications it could last several

years before the need to replace it. Only testing the fi nished water will determine when it is time to change out the fi lter media bed. The water should be tested

at six (6) month intervals to confi rm there is a reduction of Arsenic in the treated water. The target level of Arsenic reduction in the treated water is less than

10 ppb, which is the USEPA maximum contaminant level (mcl). Changing of the Titanium Oxide fi lter media should take place when test results shows greater

than 10 ppb in the treated water. Dispose of exhausted Titanium Oxide in accordance with your state and local ordinances and regulations.

One can expect the useful life of Titanium Oxide to vary from various aspects. It should be understood that the higher the Arsenic concentration the shorter

the life one could expect from the Titanium Oxide. The life expectancy can vary depending on the amount of other heavy metals that would compete for sites

of the Titanium Oxide media, the amount of water being treated, and how well the fi lter unit is backwashed. Backwashing requirements are driven by a pressure drop. Usually backwashing once every 30 days is suffi cient. The fi ltered Arsenic cannot leach from the Titanium Oxide

1

Jing, Chuanyong, Sugin Liu, Manish Patel, and Xiaoguang Meng. “Arsenic Leachability in Water Treatment Adsorbents.” Environmental Science &

Technology 39 (2005): 5481-5487.

1-1

1

during the regeneration process.

Analysis of your Water

It is extremely important to have your water tested for the following items prior to installation of this fi lter into your home. Record your results below for future

reference:

Constituent Maximum Contaminant Allowed per EPA Result

Hardness (gpg) 100 ppm

Total Iron (ppm) 0.3

Manganese (ppm) 0.05

pH (units) 6.8 - 8.5

Tannins (ppm) 0.5

Total Dissolved Solids (ppm) 500

Copper (ppm) 1.0

Hydrogen Sulfi de (ppm)* <0.1

Total Arsenic (ppb)

Arsenite (AS III)

Arsenite (AS V)

* Note: Hydrogen Sulfi de gas (H2S) must be checked and tested prior to installation of an Arsenic Reduction Filter System For accuracy, the sample must be drawn with the

well pump RUNNING and the test be completed within ONE (1) minute after the sample is drawn from the water system.

** Suggested upper limit. Please contact Technical Services for additional information.

Other heavy metals such as lead, mercury, copper, cadmium and zinc may also be reduced in your water by the Arsenic Reduction Filter System and will reduce

the life of your media. In addition, pH, silica and phosphates may also affect adhesion performance. Testing your treated water is the only effective way to

know when it is time to replace your media. 3M Purifi cation Inc. recommends you do this every six months.

10 Combined**

Check Your Pumping Rate and Water Pressure:

Two water system conditions must be checked carefully to avoid unsatisfactory operation or equipment damage:

1) MINIMUM water pressure required at the water inlet is 20 psi (138 kPa). IF WATER PRESSURE IS OVER 80 psi (552 kPa), A PRESSURE REDUCING

VALVE MUST BE INSTALLED IN THE WATER SUPPLY LINE AHEAD OF THE SYSTEM.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install if water pressure exceeds 100 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a plumbing professional if you are uncertain how to check your water pressure.

NOTE: If you have a municipal or a community water supply and daytime water pressure is 85 psi or more, nighttime pressure may exceed 100

psi. Call your local water department or plant operator to obtain pressure readings. If you have a private well, the gauge on the pressure tank

will indicate the high and low system pressure. Record your water pressure data below:

Water Pressure:

Low psi High psi

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

The installer should take appropriate measures if there is the possibility a vacuum may occur. This would include the installation of an ap-

propriate device in the supply line to the system, i.e., a vacuum breaker or backfl ow prevention device. Vacuum damage voids the factory

warranty.

2) The pumping rate of your well must be suffi cient for satisfactory operation and BACKWASHING of the system. (See EQUIPMENT SPECIFICA-

TIONS AND OPERATING DATA, Section 5)

1-2

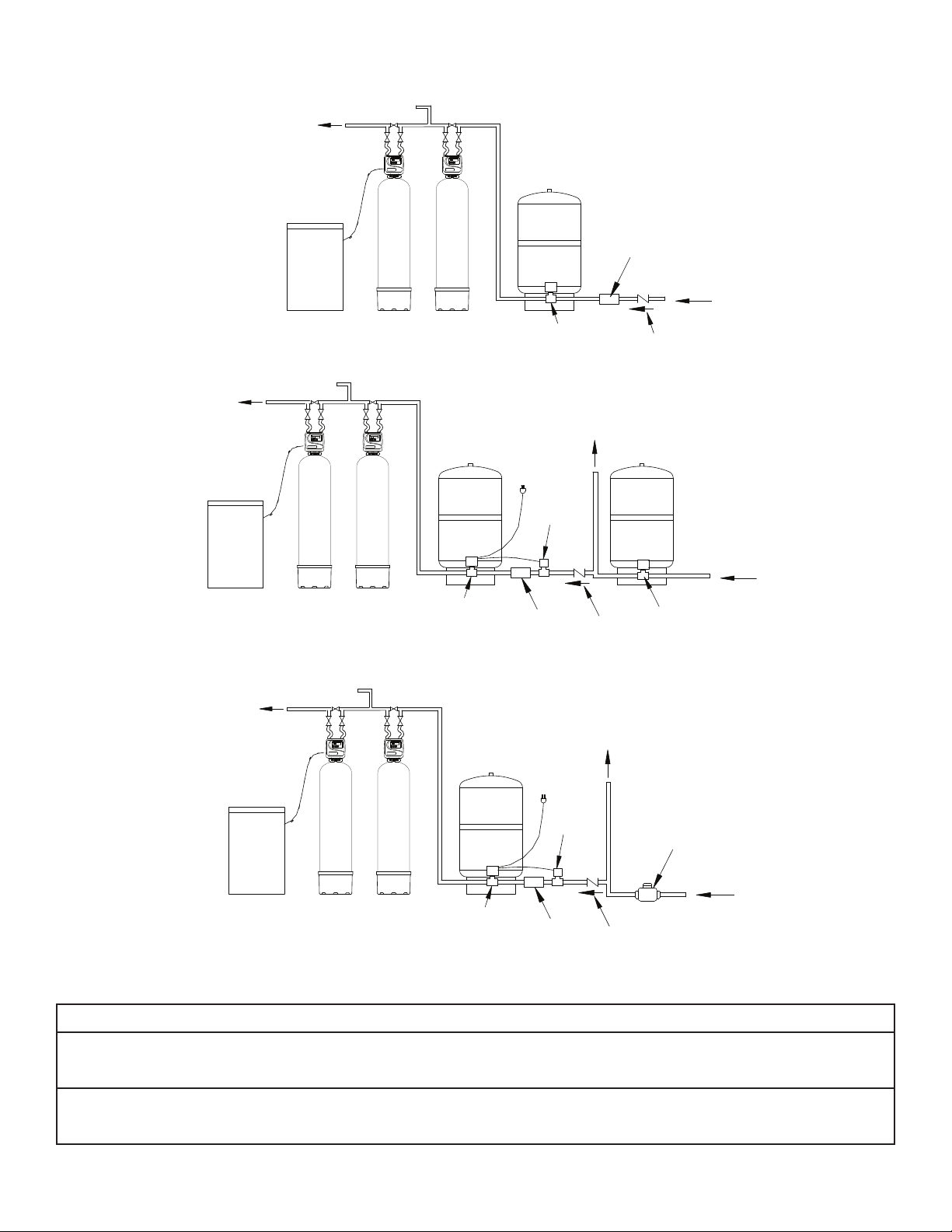

Locate Water Conditioning Equipment Correctly:

Select the location of your Arsenic Reduction Filter System with care. Various conditions which contribute to proper location are as follows:

1) Locate as close as possible to water supply source.

2) Locate as close as possible to a drain.

3) Locate in correct relationship to other water conditioning equipment (Figure 1, page 2-1).

4) Locate the Arsenic Reduction Filter System in the supply line BEFORE the water heater. Temperatures above 110°F (43.3°C) will damage the

Arsenic Reduction Filter System and void the factory warranty.

5) DO NOT install the Arsenic Reduction Filter System in a location where freezing temperatures occur. Freezing may cause permanent damage

and will also void the factory warranty.

6) Allow suffi cient space around the installation for easy servicing.

7) Provide a non-switched 110V, 60Hz (220V, 50Hz for specifi ed systems) power source for the control valve.

WARNING

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

1-3

Facts to Remember While Planning Your Installation:

1) All installation procedures MUST conform to local and state plumbing codes.

2) If lawn sprinkling, a swimming pool, or geothermal heating/cooling or water for other devices/activities are to be treated by the Arsenic Reduction

Filter System, a larger model MUST be selected to accommodate the higher fl ow rate plus the backwashing requirements of the Arsenic Reduction

Filter System. Consult our Customer Service Department at 1-866-990-9785 for alternative instructions if the pumping rate is insuffi cient.

3) Remember that the Arsenic Reduction Filter System INLET is attached to the pipe that supplies water (i.e. runs to the pump) and the OUTLET is

the line that runs toward the water heater.

CAUTION

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

4) Before commencing the installation it is advisable to study the existing piping system and to determine the size, number and type of fi ttings

required.

WARNING

To reduce the risk associated with a hazardous voltage:

• If the home electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection

across the fi lter installation piping — refer installation to qualifi ed personnel.

5) Sweep the fl oor to eliminate objects that could pierce the media tank.

1-4

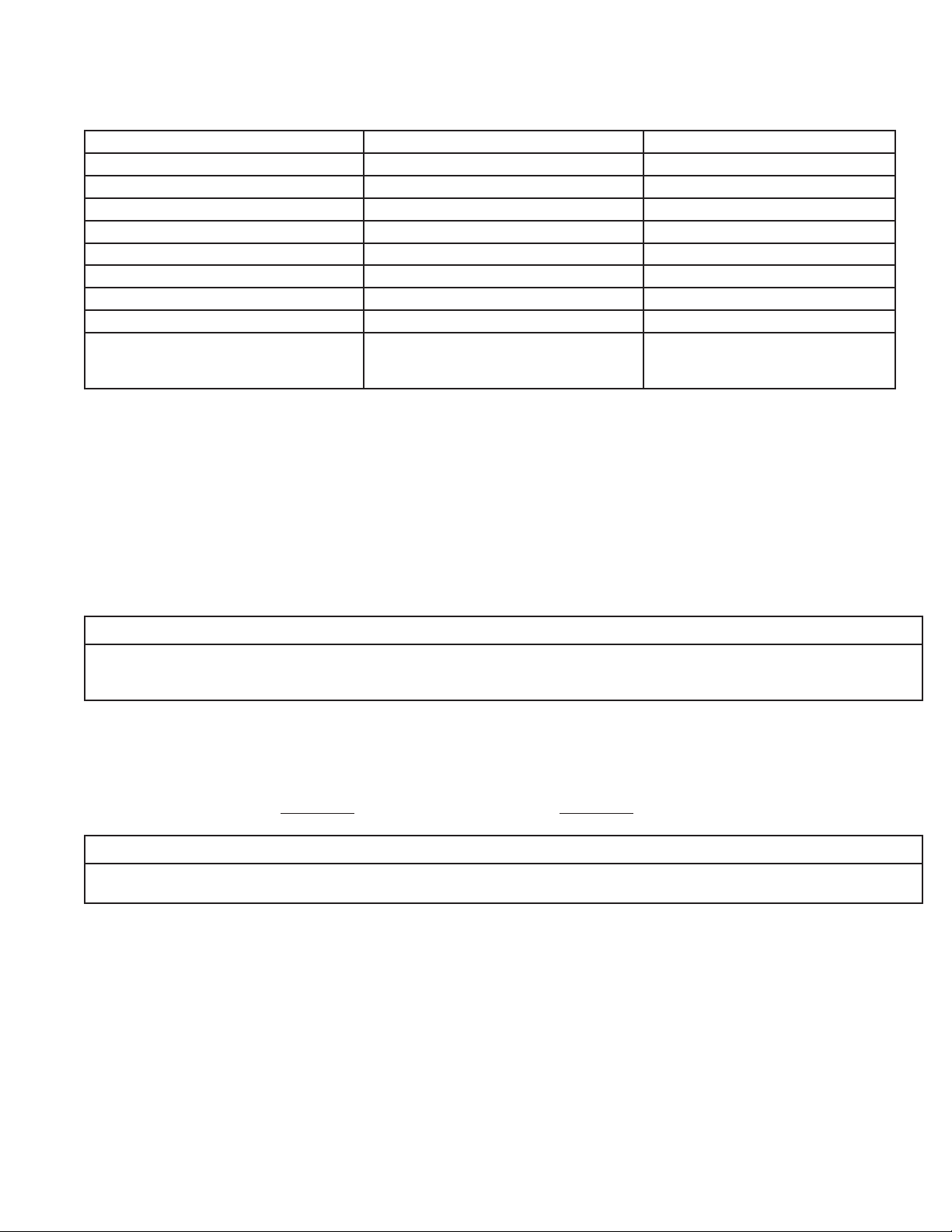

SECTION 2: INSTALLATION

Proper installation sequence of water conditioning equipment is very important. Refer to the following diagram for your particular water supply.

TREATED

SOFT WATER

TREATED WATER

TREATED

SOFT WATER

BRINE

MAKER

TREATED WATER

BRINE

MAKER

SOFTENER

SOFTENER

ARSENIC

FILTER

STANDARD WELL INSTALLATION

SECONDARY

PRESSURE

ARSENIC

FILTER

SECONDARY

PRESSURE

SWITCH.

SPLIT-STREAM INSTALLATION

TANK

PRESSURE

TAN K

PRESSURE

SWITCH.

TO

110 V

OUTPUT

SOLENOID

VALVE

HYDRO-CHARGER

WATER FOR

LAWN SPRINKLERS

OR OTHER

HIGH DEMAND

CHECK VALVE

HYDRO-CHARGER

CHECK VALVE

PRIMARY

PRESSURE

TAN K

PRIMARY

PRESSURE

SWITCH.

RAW

WELL

WATER

RAW

WELL

WATER

BRINE

MAKER

TREATED WATER

SOFTENER

ARSENIC

FILTER

PRESSURE

PRESSURE

SWITCH.

TAN K

TO

110 V

OUTPUT

SOLENOID

VALVE

HYDRO-CHARGER

WATER FOR

LAWN SPRINKLERS

OR OTHER

HIGH DEMAND

CHECK VALVE

METER

RAW

WATER

TREATED

SOFT WATER

PUBLIC WATER SUPPLY INSTALLATION

Figure 1

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

2-1

Loading...

Loading...