Page 1

INSTALLATION AND OPERATING

INSTRUCTIONS

APIF SERIES RESDENTIAL

IRON REDUCTION SYSTEMS

Models

APIF100 APIF100J APIF100M APIF100PT APIF100MPT APIF100MJ

APIF150 APIF150J APIF150M APIF150PT APIF150MPT APIF150MJ

APIF200 APIF200J APIF200M APIF200PT APIF200MPT APIF200MJ

APIF300 APIF300J APIF300M APIF300PT APIF300MPT APIF300MJ

Installer, please leave with homeowner.

Homeowner, retain for future reference.

INSTR2188 0710

Page 2

Page 3

Read, understand, and follow all safety information contained in these instructions prior to installation and use of the APIF Series Residential Iron Reduction System.

Retain these instructions for future reference. Failure to follow installation, operation and maintenance instructions may result in property damage and will void warranty.

Intended use:

The APIF Series Residential Iron Reduction Systems are intended for use in homes and have not been evaluated for other uses. These systems are intended to be installed

near the entry point of a home water line, and must be installed by qualifi ed professional installers or licensed plumbing contractors according to in accordance with state and

local plumbing codes and these installation instructions.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

SAFETY INFORMATION

WARNING

CAUTION

CAUTION

To reduce the risk associated with choking:

• Do not allow children under 3 years of age to have access to small parts during the installation of this product.

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

To reduce the risk of physical injury:

• Shut off inlet water supply and depressurize system as shown in manual prior to service.

To reduce the risk associated with a hazardous voltage:

• If the home electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection across

the fi lter installation piping — refer installation to qualifi ed personnel.

• Do not use the system if the power cord is damaged — contact qualifi ed service personnel for repair.

To reduce the risk associated with back strain due to the heavy weight of the various system components:

• Follow safe lifting procedures.

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury and/or property damage.

Indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate injury and/or property damage.

Indicates a potentially hazardous situation, which, if not avoided, may result in property damage.

WARNING

CAUTION

To reduce the risk associated skin, eye, and respiratory tract irritation from gravel and fi lter media during installation:

• Gravel and several types of fi lter media may be used in this product, depending upon the application. During installation, dust may cause irritation to skin, eyes, and

respiratory tract.

• Utilize a NIOSH-approved dust fi lter mask, protective gloves, and appropriate eye protection when handling and pouring gravel and fi lter media.

• To request an MSDS relating to this product call 203-238-8965 or visit the web at http://solutions.3M.com/WPS/Portal/3M/EN_US/MSDS (click MSDS search). For

emergencies, call 800-364-3577 or 651-737-6501 (24 hours).

CAUTION

To reduce the risk associated with skin, eye, and respiratory tract irritation from water treatment chemicals:

• Several types of water treatment chemicals may be used in this product, depending upon the application. During installation and use, exposure may cause irritation

to skin, eyes, and respiratory tract.

• Utilize a NIOSH-approved dust fi lter mask, protective gloves, and appropriate eye protection when handling and pouring gravel and fi lter media.

• To request an MSDS relating to this product call 203-238-8965 or visit the web at http://solutions.3M.com/WPS/Portal/3M/EN_US/MSDS (click MSDS search). For

emergencies, call 800-364-3577 or 651-737-6501 (24 hours).

Page 4

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

• Do not install if water pressure exceeds 100 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a plumbing

professional if you are uncertain how to check your water pressure.

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer arrester. Contact a plumbing professional if you are uncertain how to check for this condition.

• Where a backfl ow prevention device is installed on a water system, a device for controlling pressure due to thermal expansion must be installed.

• Do not use a torch or other high temperature sources near fi lter system, cartridges, plastic fi ttings or plastic plumbing.

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

• Do not install in direct sunlight or outdoors.

• Mount system in such a position as to prevent it from being struck by other items used in the area of installation.

• Ensure all tubing and fi ttings are secure and free of leaks.

• SHUT OFF FUEL OR ELECTRIC POWER SUPPLY TO WATER HEATER after water is shut off.

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

• Do not apply heat to any fi tting connected to bypass or control valve as damage may result to internal parts or connecting adapters.

• Install on a fl at/level surface. It is also advisable to sweep the fl oor to eliminate objects that could pierce the media tank.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

IMPORTANT NOTES

• Failure to follow instructions will void warranty.

Page 5

TABLE OF CONTENTS

SECTION DESCRIPTION

1 GENERAL INFORMATION

2 BEFORE INSTALLATION

3 IMPORTANT INSTALLATION INSTRUCTIONS

4 PLUMBING SYSTEM CLEAN-UP

5 BACKWASHING INSTRUCTIONS

6 TROUBLESHOOTING

7 SPECIFICATION AND OPERATING DATA

8 MAINTENANCE

9 LIMITED WARRANTY

SECTION 1: GENERAL INFORMATION

Congratulations on your purchase of an Iron Reduction System! The Iron Reduction System reduces dissolved, precipitated and bacterial iron from your water supply.

Contrary to conventional methods, your Iron Reduction System requires NO chemicals (either added to the water supply or the fi lter). This unique process requires

ONLY periodic backwashing for a few minutes to fl ush out entrapped iron that has accumulated in the fi lter tank.

When properly installed, operated and maintained, the Iron Reduction System will provide many years of dependable service. Read this manual all the way through

fi rst, and then follow the instruction steps in the proper sequence.

The Iron Reduction System is intended to be used on residential water systems which use a standard submersible well pump, one that utilizes a pressure tank and

a pressure switch to stop and start the well pump. If you have a jet pump or a constant pressure pump you will need to utilize another product type to address your

iron, manganese and hydrogen sulfi de problems. Please contact our technical department should you have any questions at 1-866-693-2543 and select option 1.

• Professional Installation Required: Installation requires shutting water off to home, cutting home water supply pipe and using a welding torch to add

piping and fittings. Specialized tools and skills are required. Not a do-it-yourself type of project. Professional installation required!

Description and Operation of the System:

The Iron Reduction System consists of two major components which are:

1) HYDRO-CHARGER located between the well head and the pressure tank, which adds a small amount of air to the iron-laden water whenever the well pump

runs.

2) A backwashing type fi lter containing a special media that causes the iron in the “Hydro-Charged” water to precipitate throughout the fi lter bed (rather than

on the surface as in chemical oxidizing fi lters). This process produces an iron reduction capacity of 30,000 to 50,000 parts per million (ppm) compared to

6,000 to 8,000 ppm for chemical oxidation processes. The media DOES NOT require a chemical regenerant (such as potassium permangante) for oxygen

enrichment, salt, chlorine or any other chemicals.

Your Iron Reduction System automatically adjusts the pH to neutral or higher on acid water WITHOUT an acid neutralizer (a required piece of equipment with chemical oxidation fi lters whenever the pH is less than 6.7). The ability to raise pH when it is below neutral (7 or less) greatly enhances the Iron Reduction System’s ability

to reduce iron effi ciently.

IMPORTANT NOTE

• Replenishment of the component of the fi lter media that adjusts pH, MpH Adder, may be required periodically, the frequency of which is dependent on the raw water pH,

the manganese (Mn) concentration in the water (if any) and the water consumption rate.

Periodic backwashing of the fi lter bed fl ushes the precipitated iron to the drain and readies the fi lter for use again. The duration of the backwash procedure will vary

depending on several factors, but generally totals just 10 minutes (factory setting). The frequency of backwashing depends on iron concentration and water usage,

and ranges from daily to once every 99 days. The volume of water consumed during the entire backwashing procedure is approximately 50 gallons at the factory

backwash settings (one (1) cubic foot models).

1-1

Page 6

SECTION 2: BEFORE INSTALLATION

IM PORTANT NOTES

Inspecting And Handling Your Filter:

Inspect the equipment for shipping damage. If damaged, notify the transportation company and request a damage inspection. Handle the fi lter with care. Damage

can occur if dropped or set on sharp, uneven projections on the fl oor. Do not turn the fi lter upside down. Installation must comply with state and local laws and

regulations.

Make Sure Your Water Has Been Thoroughly Tested:

An analysis of your water should be made prior to the selection of your water conditioning equipment. Your dealer will generally perform this service for you,

and may send a sample to the factory for analysis and recommendations. Enter your analysis below for your permanent record.

Analysis of Your Water:

Hardness gpg Tannins (Humic Acid) ppm

Iron (Fe) ppm Hydrogen Sulfi de (H2S) ppm

Manganese (Mn) ppm Other ppm

pH ppm

IMPORTANT NOTES

Hydrogen sulfi de (H2S) must be tested for at the well site. For accuracy, the sample must be drawn with the pump RUNNING, and the test be completed

within ONE minute after the sample is drawn.

Other ppm

Iron (Fe)

Iron concentrations as low as 0.3 ppm (0.1 ppm under some conditions) will cause staining. The iron concentration, together with the fl ow rate demand and the

consumption rate of the water determines the size of the fi lter system required. The higher these factors are, the larger the required system. The Iron Reduction

System is capable of reducing the three main types of iron found in water supplies: Soluble Iron (also known as clear water iron); Precipitated Iron (also known as

red iron); and Bacterial Iron. There is an upper limit of 15 ppm iron concentration for the Iron Reduction System; special care must be taken when selecting a fi lter

model if your water has a combination of high iron, very low pH and/or manganese levels above 0.2 ppm.

The Iron Reduction System is not bactericidal, i.e. it does not remove or kill “bacterial iron”. It reduces the iron upon which the bacteria may live or which it deposits

in your plumbing fi xtures, thus helping to minimize its effects.

Manganese (Mn)

The presence of manganese can be bothersome, even for an Iron Reduction System (and is problematic for chemical oxidizing systems because the chemicals may

not allow for the correct pH for Manganese Reduction). As little as 0.05 ppm of manganese can produce a brownish or black stain. The ability of the Iron Reduction

System to reduce manganese depends on its concentration and the pH of the water.

Although not specifi cally designed for the reduction of manganese, the oxidation of manganese is very similar to that of iron, therefore, a pH of 8.2 or higher must be

obtained. When this pH level is achieved, the precipitation of manganese may more readily occur. To accomplish this, models are available where the media contains

additional quantities of MpH Adder, the pH raising component (model designations with “M” suffi x). In any application involving manganese, a larger model fi lter is

generally recommended (but only if the pumping rate is suffi cient to backwash the larger size).

If, however, the manganese concentration is low (0.1 ppm or less) and the pH is 6.5 or higher, an Iron Reduction System containing standard Iron Reduction System

media will generally perform satisfactorily, although backwashing should be performed at more frequent intervals. Under more severe conditions where the pH is

very low and/or the manganese concentration is high, an acid neutralizer installed ahead of the Iron Reduction System will maintain the required 8.2 pH level longer

than the Chem-Free media will between replenishment with MpH Adder.

pH

The pH of water measures its acidity. Water with a pH of less than 7.0 is acidic, above 7.0 it is alkaline, and a pH of 7.0 is neutral. The lower the pH value, the greater

the acidity, and the higher the pH value, the more alkaline. Acidic water (pH less than 7.0) is corrosive to pipes, appliances, etc. A pH of 7.0 or higher facilitates iron

reduction, which is why the Iron Reduction System is designed to increase the pH when it is less than 7.0.

The pH increasing component of Chem-Free media is “sacrifi cial”, that is, it slowly dissolves during the process of increasing pH. The rate at which this occurs is

proportional to the degree of the pH increase and the water consumption rate (i.e., the greater the pH increase and water consumption, the greater the sacrifi cial

rate). Thus, when the pH is increased to 8.2 or more, as is necessary when manganese is present, the sacrifi cial rate is even greater. Under the most severe conditions, the MpH Adder component of the media may have to be replenished two to four times per year. On the other hand, if the raw water pH is 7.0 or above and no

manganese is present, the sacrifi cial rate is very slight (see IMPORTANT NOTE, Section 1).

2-1

Page 7

Tannins (Humic Acid)

Tannins (a humic acid), which may be present in some water supplies, are the result of various forms of decaying vegetation (the test for tannins can be performed

by your dealer). Tannins can cause problems in the operation of the Iron Reduction System by forming a sticky coating on the media, thus rendering it incapable

of fi ltering the iron. Generally with tannin concentrations of 0.5 ppm or less, more frequent backwashing will help prevent the sticky coating from forming. It does

appear, however, that the level of tannin concentration affects the operation of the Chem-Free fi lter differently in different geographical areas (in some areas, the

Iron Reduction System will perform satisfactorily when tannin concentration is considerably greater than 0.5 ppm). It is therefore recommended that if the tannin

concentration is 0.5 ppm or more, contact your dealer BEFORE installing the system.

Hydrogen Sulfi de (H2S)

Hydrogen sulfi de (often referred to as “sulfur”), is easily detected by its objectionable “rotten egg” odor. Sulfur corrodes iron, brass, copper and silver. While the Iron

Reduction System is not intended to be used as a sulfur fi lter, it has the capability of reducing sulfur in concentrations of up to 2 or 3 ppm, and sometimes as high

as 5 ppm. Whenever hydrogen sulfi de is present, backwashing must be performed at more frequent intervals, and the pumping system MUST include a standard

air-to-water pressure tank with an air-relief valve. The air to water pressure tank must be installed between the Hydro-Charger and existing pressure tank.

Check Your Water Pressure and Pumping Rate:

Two water system conditions must be checked carefully to avoid unsatisfactory operation or equipment damage:

1) MINIMUM water pressure required at the fi lter tank inlet is 20 psi. If pressure is over 80 psi, a pressure reducing valve must be installed in the

water supply line ahead of the Hydro-Charger. NOTE: If you have a municipal or community water supply and daytime water pressure is 80 psi

or more, nighttime pressure may exceed 100 psi. Call your local water department or plant operator to obtain pressure readings. If you have a

private well, the gauge on the pressure tank will indicate the high and low system pressure. Record your water pressure date below:

Water Pressure

Low ________PSI High ________PSI

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

2) The pumping rate of your well pump must be suffi cient for satisfactory operation of the Hydro-Charger and to backwash the fi lter. For model APIF100, the

required rate is 5 gpm (refer to Specifi cations and Operating Data for the backwash requirements for other models). To measure the pumping

rate of your pump, follow these instructions:

a. Make certain no water is being drawn. Open spigot nearest pressure tank. When pump starts, close spigot and measure time (in seconds) to

refi ll pressure tank (when pump shuts off). This fi gure represents Cycle Time.

b. With the pressure tank full, draw water into a container of known volume, measure the number of gallons drawn until the pump starts again.

This is the Draw-Down. Divide this fi gure by Cycle Time and multiply the result by 60 to arrive at the Pumping Rate in gallons per minute (gpm).

To aid in your calculation, insert the data in the following formula:

Draw-Down _______(gallons) ÷ Cycle Time ________(seconds) x 60 = Pumping Rate _______ (gpm)

Example: Cycle Time is 63 seconds; Draw-Down is 8 gallons, then Pumping Rate equals:

8 gallons ÷ 63 seconds x 60 = 7.8 gpm

NOTE: The addition of the Hydro-Charger to the pumping system or plumbing and other water treatment devices (such as an acid neutralizer) may

reduce the fl ow rate at the drain to an inadequate level to properly backwash the system. If you are uncertain whether your fl ow rate is adequate, contact

your dealer BEFORE installing your Iron Reduction System so that corrective action, if required, may be taken.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Install on a fl at/level surface. It is also advisable to sweep the fl oor to eliminate objects that could pierce the media tank.

• Protect from freezing, remove fi lter cartridge when temperatures are expected to drop below 40° F (4.4° C);

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F;

• Do not install if water pressure exceeds 100 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a plumb-

ing professional if you are uncertain how to check your water pressure;

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer arrester. Contact a plumbing

professional if you are uncertain how to check for this condition;

• Do not install in direct sunlight or outdoors.

2-2

Page 8

Locate Water Conditioning Equipment Correctly:

Select the location of your Iron Reduction System with care. Various conditions which contribute to proper location are as follows:

1) Locate as close as possible to water supply source.

2) Locate as close as possible to a drain.

3) Locate in correct relationship to other water conditioning equipment (Figure 1, page 3-1).

4) Locate the system in the supply line BEFORE the water heater. Temperatures above 110°F (43.3°C) will damage the system and void the factory

warranty.

5) DO NOT install the system in a location where freezing temperatures occur. Freezing may cause permanent damage and will also void the factory

warranty.

6) Allow suffi cient space around the installation for easy servicing.

7) Provide a non-switched 110V, 60Hz (220V, 50Hz for specifi ed systems) power source for the control valve.

WARNING

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

The Importance of Your Pressure Tank:

The pressure tank found on private well systems becomes an integral part of the Iron Reduction System by providing necessary mixing and “residence time” to the

“Hydro-Charged” water. While the Iron Reduction System will perform satisfactorily with either a captive-air (bladder) type pressure tank or a standard air-to-water

type with an air volume control (air-relief valve), the bladder type requires more careful adjustment of the Hydro-Charger to prevent gasses from collecting in the

pressure tank and the head area of the fi lter tank.

IMPORTANT: A properly sized pressure tank of either style will require a minimum pump cycle of 60 seconds to refi ll from the well pump on-to-off

pressure settings.

Under more severe operating conditions (low pH, high iron, manganese, and small concentrations of sulfur), a standard air-to-water type pressure tank with an

air-relief valve MUST be used (if a bladder type tank is already in place, do not remove it, install the air-to-water pressure tank between the Hydro-Charger and the

bladder type tank).

IMPORTANT NOTE

If your pressure tank (or any part of your water system) is not functioning properly, corrective action MUST be taken before installation of your

Iron Reduction System.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not use a torch or other high temperature sources near fi lter system, cartridges, plastic fi ttings or plastic plumbing;

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic;

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

2-3

Page 9

Facts to Remember While Planning Your Installation:

1) All installation procedures MUST conform to local and state plumbing codes.

2) If lawn sprinkling, a swimming pool, or geothermal heating/cooling or water for other devices/activities are to be treated by the Iron Reduction System,

a larger model MUST be selected to accommodate the higher fl ow rate plus the backwashing requirements of the Iron Reduction System. Consult our

Customer Service Department at 1-866-990-9785 for alternative instructions if the pumping rate is insuffi cient.

3) Remember that the Iron Reduction System INLET is attached to the pipe that supplies water (i.e. runs to the pump) and the OUTLET is the line that

runs toward the water heater.

CAUTION

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

4) Before commencing the installation it is advisable to study the existing piping system and to determine the size, number and type of fi ttings

required.

WARNING

To reduce the risk associated with a hazardous voltage:

• If the home electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection

across the fi lter installation piping — refer installation to qualifi ed personnel.

5) Sweep the fl oor to eliminate objects that could pierce the media tank.

2-4

Page 10

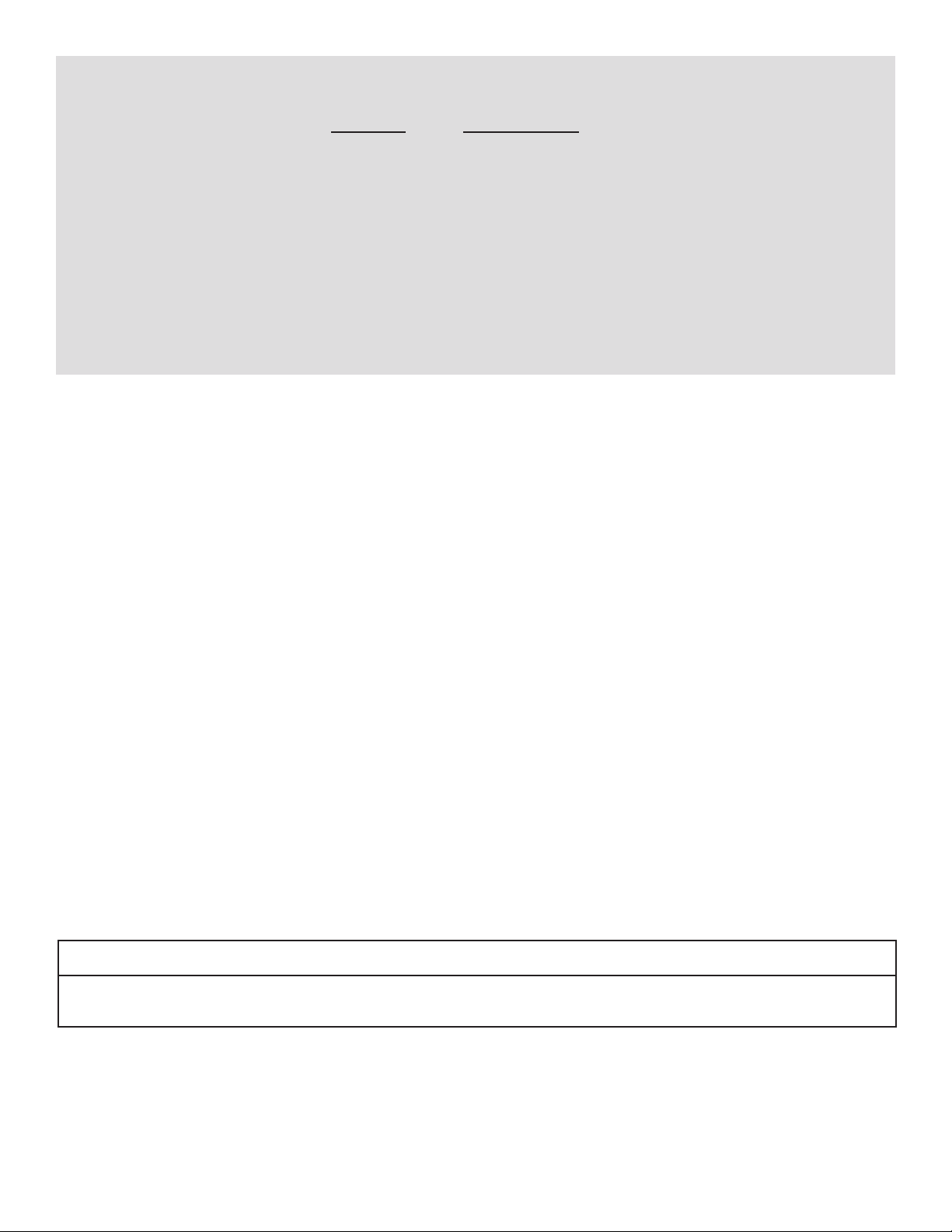

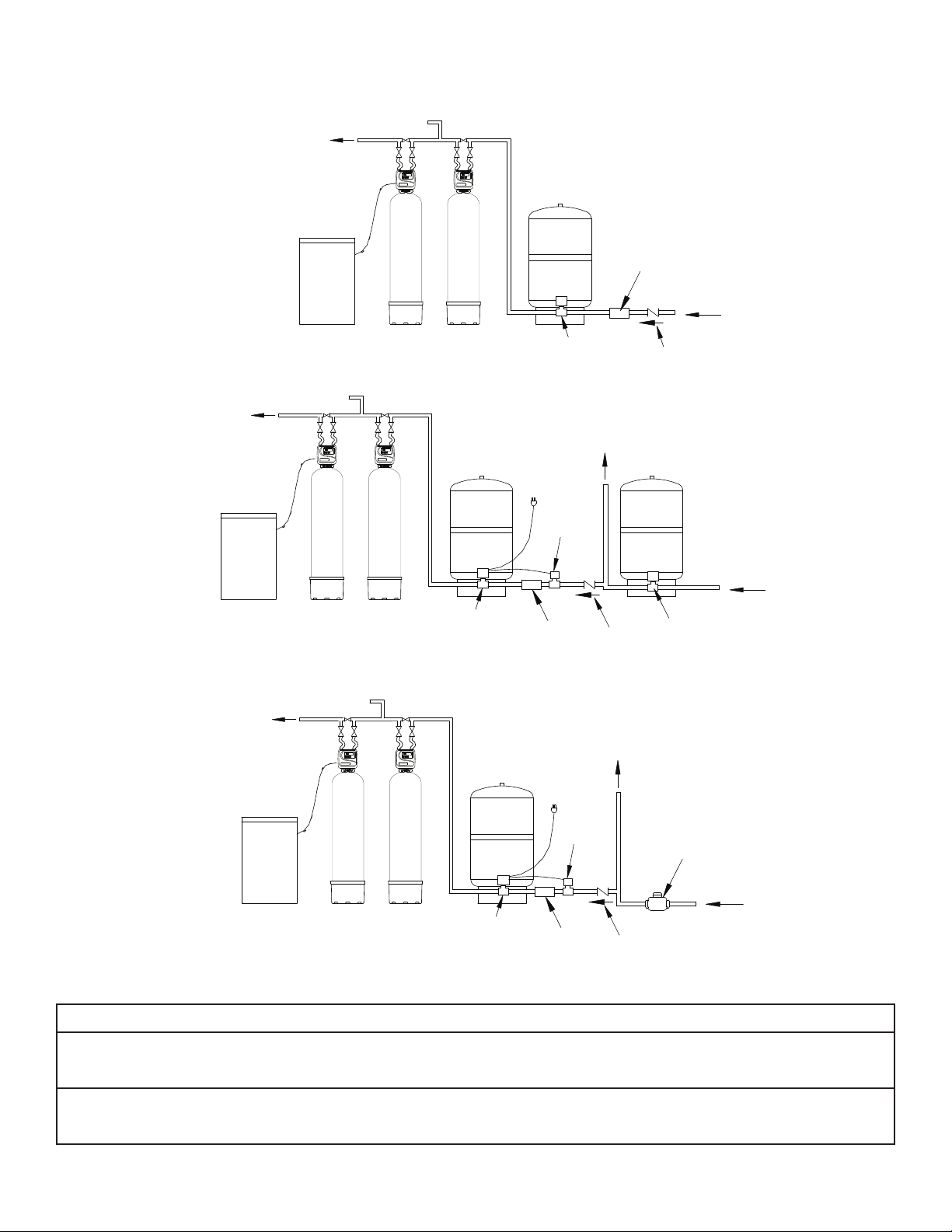

SECTION 3: IMPORTANT INSTALLATION INSTRUCTIONS

Proper installation sequence of water conditioning equipment is very important. Refer to the following diagram for your particular water supply. Failure to follow installation,

operation, and maintenance instructions may result in property damage due to leakage and will void warranty.

TREATED

SOFT WATER

TREATED WATER

TREATED

SOFT WATER

BRINE

MAKER

TREATED WATER

SOFTENER IRON

BRINE

MAKER

SOFTENER

REDUCTION

SYSTEM

PRESSURE

TAN K

IRON

REDUCTION

SYSTEM

PRESSURE

SWITCH.

STANDARD WELL INSTALLATION

TO

110 V

OUTPUT

SECONDARY

PRESSURE

TANK

SECONDARY

PRESSURE

SWITCH.

SOLENOID

VALVE

HYDRO-CHARGER

SPLIT-STREAM INSTALLATION

WATER FOR

LAWN SPRINKLERS

OR OTHER

HIGH DEMAND

CHECK VALVE

HYDRO-CHARGER

CHECK VALVE

PRIMARY

PRESSURE

TAN K

PRIMARY

PRESSURE

SWITCH.

RAW

WELL

WATER

RAW

WELL

WATER

BRINE

MAKER

TREATED WATER

SOFTENER

IRON

REDUCTION

SYSTEM

PRESSURE

PRESSURE

SWITCH.

TAN K

TO

110 V

OUTPUT

SOLENOID

VALVE

HYDRO-CHARGER

WATER FOR

LAWN SPRINKLERS

OR OTHER

HIGH DEMAND

CHECK VALVE

METER

RAW

WATER

TREATED

SOFT WATER

PUBLIC WATER SUPPLY INSTALLATION

Figure 1

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

3-1

Page 11

NOTE: Have you read “ Section 4”, PLUMBING SYSTEM CLEANUP, for instructions on some procedures that may need to be performed fi rst?

GRAVEL AND CHEM-FREE MEDIA SCHEDULE

Unit Model Number

APIF100 Models

(APIF100, APIF100J, APIF100M,

APIF100PT, APIF100MPT, APIF100MJ)

Filter Media MC-10P

NOTE: If you ordered an “M” model Iron Reduction System, the fi lter pack media would be designated by an M at the end of the part number i.e. MC-10MP.

To load the fi lter media into the fi lter tank please use the follow steps. This is necessary to ensure that the distributor tube has not been pulled up when

the control valve was removed from the top of the fi lter tank.

Step 1

a) Remove from the shipping carton the fi lter unit

b) Carefully remove the control valve from the fi lter vessel by releasing the latch on the clamping collar (see fi gure 7 on 3-13).

c) Set all items aside for future use. Ensure that the following items have been shipped entirely with the unit to allow for proper and complete installation. If any

item is missing or has been damaged in transit contact our technical department for help and replacement at 866-693-2543 (option 1) from 7:30 am to

4:30pm EST. Please be prepared to supply the model and serial number when you call should you need help.

i. Control valve

ii. Media tank (also a reducing bushing and fl anged adapter on APIF300)

iii. Bypass valve

iv. 1” Male NPT Connection Kit

v. Media (amount will vary by fi lter size)

vi. Distributor Tube

vii. Drain line assembly kit

viii. Parts bag

ix. Valve wrench

x. Installation and Operating Instruction

xi. Loading funnel

xii. Tube extension device and cap

d) Remove the distributor tube in the fi lter vessel, set aside and pour the gravel into a clean pail for later use.

e) Reinsert the distributor tube into the fi lter vessel and ensure the tube is centered in the tank; a dimple is in the center of the fi lter vessel to help in doing so.

Using the tube extension device and cap, cover the distributor tube opening to prevent fi lter media and gravel from entering the distributor tube during the

loading of the fi lter vessel.

f) Place the funnel provided, in the opening of the media tank to aid in loading the gravel and fi lter media. Pour the QC gravel into the fi lter vessel slowly. While

holding the distributor tube in place, shake the fi lter vessel from side to side gently, to aid in leveling the QC gravel. Do not allow gravel to get under the basket

of the distributor tube during the loading of gravel. If this happens, pour out the gravel and remove the distributor tube once again. Next locate the fi lter media

and slowly pour into the fi lter vessel. Again shake the fi lter vessel from side to side to aid in leveling the media. Next, using a hose or clean pail, fi ll the fi lter

vessel with water to saturate the fi lter media and expel any air that may be present, remove the extension tube, cap and funnel, and save for future servicing.

g) Using a clean dry rag, wipe the opening of the media tank to remove any dust or residue from the opening to receive the control valve. Apply silicone lubricant

to the fi lter vessel fl anged opening and control valve O-rings that seal against the fi lter vessel and pilot tube O-ring in the center of the control valve. Place

the center of the control valve over the distributor tube and push down on the control valve until it contacts the fl ange on the fi lter vessel. Using one swift

and even push downward, seat the control valve into the opening of the fi lter vessel. Do not use a rocking motion to seat the control valve as this could roll

or pinch the O-ring, causing a leak between the control valve and fi lter vessel. Place the clamp assembly around the fl ange of the fi lter vessel and the control

valve, paying particular attention to the proper orientation of the clamp. To secure the clamp in place install the latch. Refer to Figure 7 on 3-12 to determine

the proper orientation for the clamp. The latch needs to be installed with the smaller opening toward the clamp. Attach the bypass to the control valve as

shown in Figure 7 on page 3-12.

APIF150 Models

(APIF150, APIF150J, APIF150M,

APIF150PT, APIF150MPT, APIF150MJ)

MC-10P

MC-050P

APIF200 Models

(APIF200, APIF200J, APIF200M,

APIF200PT, APIF200MPT, APIF200MJ)

(APIF300, APIF300J, APIF300M,

APIF300PT, APIF300MPT, APIF300MJ)

MC-10P (2) MC-10P (3)

APIF300 Models

Step 2

Shut off water at main supply. On a PRIVATE WELL SYSTEM turn off the power to the WELL PUMP and drain PRESSURE TANK. Make certain all water pressure

has been relieved from complete water system by opening nearest faucet to drain water system. SHUT OFF FUEL SUPPLY TO WATER HEATER OR BOILER.

Step 3

Cut main supply line as required to fi t Hydro-Charger in plumbing between well pump and pressure tank (Hydro-Charger may be installed in a vertical or

horizontal position). The Hydro-Charger has been supplied with both 1” threaded and 1” barbed (insert) fi ttings to allow for installation with various types of

piping materials. When using the threaded nipples, use thread tape only. When using barbed (insert) fi ttings, appropriate pipe clamps must be used. Once

installed the quick release nipples allow the Hydro-Charger to be rotated, so the air draw adjustment screw is accessible for adjustment by a small bladed

screwdriver. Allow at least 10 inches of straight run of 1” pipe on both INLET and OUTLET side of the Hydro-Charger. Refer to Figure 2 for correct assembly.

The quick release nipples also acts as a union to facilitate the Hydro-Charger removal, inspection and cleaning as needed. With an installation on PVC pipe

and copper tubing it may require the addition of a normal plumbing union to aid in removal from the plumbing due to the rigidity of that type of material. Make

certain the directional arrows on the Hydro-Charger points toward the pressure tank and the pressure control switch is located on the pressure tank side

of Hydro-Charger as in Figure 1. Rapid cycling of pump may occur if the pressure control switch is located on well side. If a check valve is located between

hydrocharger and pressure tank, it may prevent the Hydro-Charger from performing properly. Relocate to well side of Hydro-Charger.

3-2

Page 12

Step 4

Step 4

Turn back on the power to the well pump and pressurize the water lines to allow for

Turn back on the power to the well pump and pressurize the water lines to allow for

adjustment of the Hydro-Charger. Check for leaks and adjust as necessary.

adjustment of the Hydro-Charger. Check for leaks and adjust as necessary.

IMPORTANT NOTES

IMPORTANT NOTES

• Do not apply heat near Hydro-Charger, as damage may occur. On badly scaled, older

• Do not apply heat near Hydro-Charger, as damage may occur. On badly scaled, older

plumbing systems, it may be advantageous to install a WYE STRAINER to help pre-

plumbing systems, it may be advantageous to install a WYE STRAINER to help prevent plugging of the Hydro-Charger nozzle with scale or debris. The use of a WYE

vent plugging of the Hydro-Charger nozzle with scale or debris. The use of a WYE

STRAINER must precede the hydrocharger on the inlet side by a MINIMUM

STRAINER must precede the hydrocharger on the inlet side by a MINIMUM

OF 10”.

OF 10”.

• If existing water system includes a captive-air type pressure tank (bladder) and it is

• If existing water system includes a captive-air type pressure tank (bladder) and it is

desirable to install an additional air to water type with an air release (not as a split

desirable to install an additional air to water type with an air release (not as a split

steam type installation) install an air to water type pressure tank between the Hydro-

steam type installation) install an air to water type pressure tank between the Hydro-

Charger and the existing captive air type pressure tank.

Charger and the existing captive air type pressure tank.

• Before proceeding with Hydro-Charger installed, re-verify adequate pump-

• Before proceeding with Hydro-Charger installed, re-verify adequate pumping rate pumping by following the procedure described in SECTION 2. After

ing rate pumping by following the procedure described in SECTION 2. After

verifi cation of adequate fl ow, depressurize system as described previ-

verifi cation of adequate fl ow, depressurize system as described previously.

ously.

• If installation is to be split streamed prior to fi lter vessel or is it a public

• If installation is to be split streamed prior to fi lter vessel or is it a public

water supply (see fi gure 1), or refer to special instructions on page 3-13.

water supply (see fi gure 1), or refer to special instructions on page 3-12.

Step 5

Step 5

Set Hydro-Charger by following the following steps:

Set Hydro-Charger by following the following steps:

a) Open nearest faucet until well pump starts, then close faucet.

a) Open nearest faucet until well pump starts, then close faucet.

b) Place a fi nger lightly over the SUCTION PORT (Figure 4). A slight suction should be detected for approximately ONE THIRD (1/3) of pumping cycle time. (Do not

b) Place a fi nger lightly over the SUCTION PORT (Figure 4). A slight suction should be detected for approximately ONE THIRD (1/3) of pumping cycle time. (Do not

confuse with ONE THIRD (1/3) of pressure range).

confuse with ONE THIRD (1/3) of pressure range).

c) If suction is too short, increase by turning air adjustment screw (Figure 4), CLOCKWISE. To decrease duration, turn COUNTERCLOCK WISE.

c) If suction is too short, increase by turning air adjustment screw (Figure 4), CLOCKWISE. To decrease duration, turn COUNTERCLOCK WISE.

d) Repeat steps (a) through (c) until proper setting is obtained. The optimum cycle time is 60 seconds or more, with

d) Repeat steps (a) through (c) until proper setting is obtained. The optimum cycle time is 60 seconds or more, with

an air draw of 20 seconds minimum. Position DRAIN LINE over drain and secure fi rmly. To prevent back-siphoning of sewer water, provide an air gap of at

an air draw of 20 seconds minimum. Position DRAIN LINE over drain and secure fi rmly. To prevent back-siphoning of sewer water, provide an air gap of at

least 2 inches or 2 pipe diameters between end of drain hose and drain (Figure 6). Do not raise DRAIN LINE more than 10 ft. above fl oor.

least 2 inches or 2 pipe diameters between end of drain hose and drain (Figure 6). Do not raise DRAIN LINE more than 10 ft. above fl oor.

Figure 2: HYDRO-CHARGER INSTALLATION

IMPORTANT NOTE

IMPORTANT NOTE

When the duration of the suction is too long, the cold water may have a milky appearance caused by excess air in the water system. Correct this condi-

When the duration of the suction is too long, the cold water may have a milky appearance caused by excess air in the water system. Correct this condition by reducing the duration of suction. This condition is commonly associated with bladder type pressure tanks. In extreme cases where elimination

tion by reducing the duration of suction. This condition is commonly associated with bladder type pressure tanks. In extreme cases where elimination

of excess air prevents system from performing satisfactorily, it may be necessary to install an air to water pressure tank with an air release valve.

of excess air prevents system from performing satisfactorily, it may be necessary to install an air to water pressure tank with an air release valve.

Step 6

Step 6

Turn off the electrical source to the water well pump or the close the water shut off valve on a municipal water supply to the dwelling once again. Depressurize

Turn off the electrical source to the water well pump or the close the water shut off valve on a municipal water supply to the dwelling once again. Depressurize

the water system by opening the nearest faucet to drain water from the water system in order to allow the installation of the Iron Reduction System.

the water system by opening the nearest faucet to drain water from the water system in order to allow the installation of the Iron Reduction System.

Step 7

Step 7

Determine location and cut the water line on the supply side of the pressure tank as required to fi t the plumbing to the control valve connection fi ttings.

Determine location and cut the water line on the supply side of the pressure tank as required to fi t the plumbing to the control valve connection fi ttings.

You may want to install a separate three valve bypass prior to the control valve in case the supplied bypass valve requires maintenance in order to provide

You may want to install a separate three valve bypass prior to the control valve in case the supplied bypass valve requires maintenance in order to provide

undisturbed water use.

undisturbed water use.

3-3

Page 13

Step 8

Assemble and attach bypass valve to the control valve. See Figure 3 if needed. Next locate

and assemble the 1” NPT connection fi ttings before attaching them to the bypass valve.

Use the appropriate method of connection to ensure a permanent connection. Please refer

to fi gure 5 to correctly assemble the connection fi ttings. Install the fi tting into the bypass

valve, attach the plumbing to the 1” NPT male connection fi ttings, hand tighten the fi ttings

nuts only. Make certain the water enters inlet and discharges through the outlet side of the

bypass valve. Arrows can be viewed on the bypass valve to confi rm the correct fl ow path. At

this time make certain the bypass valve is in the bypass position and leave in that position

until instructed to place in the service position. Refer to Figure 3 for proper operation.

INOUT

OFF

OFF

DRAIN LINE FLOW

CONTROL ASSEMBLY

NORMAL OPERATIO BN YPASS OPERATION

Treated

Water

Exits

Supply Water

Enters

OFF

OFF

Supply (Untreated)

Water Exits

BYPASS VALVE

CONTROL VALVE BODY

Supply

Water

Enters

OFF

OFF

Figure 3

Figure 4

OFF

OFF

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not use a torch or other high temperature sources near fi lter system, cartridges, plastic fi ttings or plastic plumbing;

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic;

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

Step 9

Fitting Installation Instructions

1) The installation fi ttings are designed to accommodate minor plumbing line and fi ttings.

2) Thread tape is the only type of thread sealant allowed to be used; the use of paste of any kind

will void the factory warranty. Do not let the connection fi ttings support the plumbing, properly

support the plumbing as required.

3) Slide the nut on fi rst (closed and against the threads), then slip ring onto the fi tting, ensuring it

set correctly in groove, then the O-ring last. Use Silicone lubricant to allow for easier insertion of

parts into one another.

4) Hand tighten the nut only, the use of pliers or wrenches of any type will void the factory warranty

and may cause damage to fi ttings and water will leak in your home or facility.

1

2

3

4

OFF

OFF

OFF

OFF

Figure 5

Use customer supplied fi ttings to adapt the drain line to the control valve. Support of the drain line is required to prevent damage to the drain line elbow which could

lead to a water leak in the dwelling. Suitable drain line material can be Copper, PVC or CPVC pipe or PE tubing can be used to adapt to the ¾ NPT threads on the drain

elbow for long or high drain lines. Use only thread sealing tape to seal the threads, hand tighten the threaded joint. To utilize polyethylene tubing as a drain line, remove

the supplied nut and fi nd the insert that was shipped in the parts kit box. Slide the nut over the polyethylene tubing and insert the sleeve into the tubing. Slide the end of

the tubing into the elbow, using your hand thread the nut onto the elbow and hand tighten only. No thread tape is required to seal the threads with compression fi ttings.

3-4

Page 14

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

Typical examples of proper drain line diameters and lengths are:

1/2” ID up to 15 feet when discharge is lower than the inlet.

5/8” ID up to 15 feet when discharging is slightly higher than the inlet.

3/4” ID when drain is 25 feet away and not higher than 4 feet above control valve.

Avoid installing drain line overhead or using fl exible vinyl tubing, either may result in the fi lter not operating properly in reducing iron, manganese or turbidity.

Some areas prohibit the use of fl exible drain lines. Check with the local code offi cials prior to installation to ensure you conform to local, state and national

plumbing codes.

Step 10

Position the DRAIN LINE over the waste drain pipe and secure fi rmly. To prevent back siphoning of

sewer water or grey water, provide an air gap of at least two inches or 2 times the pipe diameters

between the end of drain line tubing and waste drain (Figure 6). Do not raise the DRAIN LINE more

than 10 feet above the fl oor. Check with local code offi cials to ensure you conform to local, state

and national plumbing codes.

Step 11

Plug the control valve into a properly grounded 110/120V 60 Hz non switched electrical outlet.

Check with your local code enforcement offi ce to determine if it meets local codes.

Step 12

Turn back on the power source to well pump and slowly open the shut off valve to pressurize the

water system. If on a public or community water supply open the main shut off valve to the dwelling.

Step 13

Set the time of day by referring to Page 3-8 “How to set Time of Day”.

EQUIPMENT

DRAIN LINE

DRAIN

AIR GAP

2" REF

Figure 6: DRAIN

Step 14

Open the valve on the water supply as required to pressurize the water lines to the dwelling or fuel source. The power to the water heater or boiler needs to

be established once water has been allowed to fl ow back into the device, if it was drained at any time during the installation. Turn back on the power or fuel

source to either the water heater or boiler if it was drained at any time during the installation. Check for leaks on all connections before leaving the job site,

correct as required.

Step 15

Manually initiate regeneration of the Iron Reduction System by referring to the “How To Manually Initiate Immediate Regeneration” section of Control

Valve settings on Page 3-8.

Step 16

Once the valve is in the backwash position (C1 appears on the display) slowly open the inlet side of the bypass valve to allow water to fl ow into the fi lter

vessel. Water should start to fl ow into the drain. Allow for any air that might have been trapped to leave the fi lter and go to drain. This will be detected by

changes in noise in the drain line or is visible in the semi-transparent tubing. Once the air is entirely gone slowly increase the water fl ow to drain by opening

the inlet side of the bypass valve until fully open. Refer to Figure 3 for correct positioning. At the end of C1 position the water should be clear. If not, allow

the valve to complete the manual regeneration process and initiate once again. It is very important to allow the unit to purge all fi nes to the waste drain from

the media in the fi lter vessel prior to using the water. Once the fl ushing process has been completed you now can open the outlet side of the bypass valve to

allow for fi ltered water to fl ow into the dwelling.

IMPORTANT NOTES

Due to the nature of the Iron Reduction media, on start up it sometimes requires 2 or 3 days for the Iron Reduction System to reduce Iron and Manganese below staining levels. Do not be alarmed if this occurs. During the initial start up and subsequent fi rst couple automatic regeneration cycles,

a small amount of fi ne white and beige media may be observed in the drain water and or drain area. This is normal and benefi cial for the effi cient

operation of your Iron Reduction System.

Step 17

The frequency of backwash is factory preset at every 4 days. If the Iron content is greater than 5 ppm, is red water or bacterial iron the unit should be washed

more frequently. See tables to determine the frequency. Also if the water has tannin-lignin or hydrogen sulfi de present, the fi lter should backwash every day.

Refer to Section 5 for backwashing instructions and frequency.

3-5

Page 15

BACKWASH FREQUENCY SCHEDULE

Models: APIF100, APIF100J, APIF100M, APIF100PT, APIF100MPT, and APIF100MJ

Persons

IRON CONTENT - (PPM)

in

Family

246810121416

1 1212121212121212

2 12121266666

3 1212666444

4 1212664443

5 1212664333

6 126643222

Models: APIF150, APIF150J, APIF150M, APIF150PT, APIF150MPT, and APIF150MJ

Persons

IRON CONTENT - (PPM)

in

Family

246810121416

1 1212121212121212

2 12 12 12 12 12 12 6 6

3 121212126664

4 12121266644

5 12121266443

6 12121264443

7 66444322

8 64443222

3-6

Page 16

Models: APIF200, APIF200J, APIF200M, APIF200PT, APIF200MPT, and APIF200MJ

Persons

IRON CONTENT - (PPM)

in

Family

5 1012141618202224262830

1 121212121212121212121212

2 1212121212121266666

3 121212666666644

4 12126666644444

5 1266644444333

6 1266444433322

7 1264433332222

8 1264433322222

9 644333222211

10 643332222111

Models: APIF300, APIF300J, APIF300M, APIF300PT, APIF300MPT, and APIF300MJ

Persons

IRON CONTENT - (PPM)

in

Family

10 12 14 16 18 20 22 24 26 28 30 32

1 121212121212121212121212

2 1212121212121212121212 6

3 12121212612666666

4 121212666666664

5 12126666664444

6 1266646444433

7 666644446333

8 666444433332

9 664444333222

10 664443332222

Step 18

The installation of your Iron Reduction System is now complete. If your water system installation is something other than a

private well system, please familiarize yourself with the SPECIAL INSTRUCTIONS FOR SPLIT-STREAM AND PUBLIC WATER

SUPPLY TYPE INSTALLATIONS on page 3-12.

3-7

Page 17

HOW TO SET TIME OF DAY

STEP 1 - Press SET HOUR and release.

STEP 2 - Set the clock display to the closest hour by pressing the

in the display pointing to PM during PM hours.

STEP 3 - Press SET HOUR to return to the display mode.

Note: After an extended power outage the time of day may need to be reset.

or . An arrow will appear

HOW TO MANUALLY INITIATE IMMEDIATE REGENERATION

STEP 1 - Press and hold and buttons simultaneously until valve motor starts

(usually about three (3) seconds).

Note: Once a manual regeneration has been initiated, it cannot be stopped.

STEP 2 - Once the valve display is in C1, it is in Backwash mode. To advance to Rapid Rinse press and hold

and buttons simultaneously until valve motor starts (usually about three (3) seconds).

STEP 3 - Once the valve display is in C4, it is in Rapid Rinse. To advance to the display mode press and

and buttons simultaneously until valve motor starts (usually about three (3) seconds).

hold

HOW TO MANUALLY INITIATE DELAYED REGENERATION

STEP 1 - Press and release the and buttons simultaneously.

Note: An arrow will appear in the display pointing to Regen indicating regeneration will

occur at the programmed time.

3-8

Page 18

HOW TO CHANGE DAYS BETWEEN REGENERATION

STEP 1 - Press and hold SET HOUR and buttons simultaneously for three (3) seconds and release.

STEP 2 - Press SET HOUR button.

STEP 3 - Press

STEP 4 - Press SET HOUR to return to the display mode.

Note: Your Iron Reduction System is factory preset for 4 days between regenerations.

or buttons to change the number of days between regenerations.

HOW TO CHANGE TIME OF REGENERATION

STEP 1 - Press and hold SET HOUR and buttons simultaneously until the display begins fl ashing (usually

about three (3) seconds).

STEP 2 - Set the clock display to the closest hour by pressing or button. An arrow will appear in the

display pointing to PM during PM hours.

STEP 3 - Press and release SET HOUR and buttons simultaneously to return to the display mode.

Note: Your Iron Reduction System is factory set to regenerate at 1:00 AM.

HOW TO CHANGE THE REGENERATION PROGRAM SETTINGS

STEP 1 - Press and hold SET HOUR and buttons simultaneously until the display begins fl ashing (usually

about three (3) seconds).

STEP 2 - Press and hold SET HOUR and

about three (3) seconds).

STEP 3 - Press the button to change the display to P8 or P9.

STEP 4 - Press the SET HOUR button fi ve (5) times to return to the display mode. The time of day should be

in the display.

buttons simultaneously until the display begins fl ashing (usually

3-9

Page 19

Control Valve Function and Cycles of Operation

The AC adapter comes with a 15 foot power cord that is designed for use with the control valve. The AC adapter is for dry location

use only. If the power goes out, only the time of day needs to be reset. All other settings are permanently stored in the non-volatile

memory.

The following chart shows the time for the backwash and rapid rinse cycles for the three available programming options.

Regeneration Cycles and Times for Different Programs

Program Number Length of Cycle Times (Minutes)

BACKWASH (C1) RAPID RINSE (C4)

P7 6 4

P8 10 6

P9 14 8

Note: Your Iron Reduction System is factory preset to program number P7, changing the setting to P8 or P9 is rarely needed. But if

a change is desired, please refer to “How to Change the Regeneration Program Settings” on page 3-9.

3-10

Page 20

HOW TO SET TIMER CONTROL

Power Loss

If the power goes out, current time of day will need to be reset. If the power goes out while the system is

regenerating, the cycle picks up where it was when the power went out.

Error Message

If “E1” “E2” or “E3” appears on the display, contact 3M Purifi cation Inc.’s Technical Support Services @1866-692-2543. These are error codes and will need to be resolved before the control valve will function.

These codes indicate that the control valve did not function properly.

USER DISPLAYS

Regen

Min. Fill

Regen

Hour

HOUR

SET

Time - Hour

PM

Days To Regen

General Operation

When the system is operating, one of two displays will be shown. Pressing

or button will alternate between the displays. One of the displays is always the current time of day (to the nearest hour). The second

display is the days remaining until the next regeneration. If the days remaining is equal to one, a regeneration will occur at the next preset regeneration time. The user can scroll between displays as desired.

If the system has called for a regeneration that will occur at the preset time of regeneration, the arrow

will point to Regen.

Regeneration Mode

Typically system is set to regenerate at a time of low water usage. Your Iron Reduction System is factory

preset to regenerate at 1:00 AM. If there is a demand for water during the regeneration period, untreated

water will be used.

When the system begins to regenerate, the display will change to indicate the cycle of the regeneration

process that is occurring and an arrow will also point to REGEN. The system will run through the steps

automatically and will reset itself to provide treated water when the regeneration is completed.

Regen

Min. Fill

Regen

Hour

SET

HOUR

Regen

Min. Fill

Regen

Hour

HOUR

SET

or

Time - Hour

PM

Days To Regen

Time - Hour

PM

Days To Regen

3-11

Page 21

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Installation and use MUST comply with existing state or local plumbing codes;

Special Instructions For Split-Stream and Public Water Supply Type Installation:

For SPLIT-STREAM type installation, a secondary PRESSURE TANK must be installed as in Figure 1. On PUBLIC WATER SUPPLY type installations, a PRESSURE

TANK must be installed as in Figure 1. It is recommended in both applications to use a standard air-to-water type pressure tank with air volume control (air

release valve). The pressure tank should be of same capacity as would normally be installed if water systems were a standard private well type. Also note both

applications require a NORMALLY-CLOSED SOLENOID VALVE. Follow standard installation procedures above with following additions and modifi cations.

1) Install PRESSURE TANK (SECONDARY PRESSURE TANK in Figure 1) as indicated by appropriate diagram.

2) Install NORMALLY-CLOSED SOLENOID VALVE, 110/120V, 60Hz after water meter and AFTER a line split for

untreated water (if there is one).

3) On both types installation, install HYDRO-CHARGER between PRESSURE TANK (SECONDARY PRESSURE TANK

on SPLIT-STREAM type installation) and NORMALLY-CLOSED SOLENOID VALVE.

4) Install PRESSURE SWITCH after HYDRO-CHARGER and wire it to SOLENOID VALVE (SECONDARY

PRESSURE SWITCH on SPLIT-STREAM) Set HIGH pressure on PRESSURE SWITCH (which controls opening

and closing of SOLENOID VALVE) 2 to 3 psi LOWER than LOW pressure on PRIMARY PRESSURE SWITCH.

EXAMPLE: If PRIMARY PRESSURE SWITCH is set at 40/60 psi, set SECONDARY PRESSURE SWITCH

at 20/38 psi.

For PUBLIC WATER SUPPLY type installations, contact your local water department or plant operator and ask what the normal LOW system pressure is. Set HIGH

pressure on PRESSURE SWITCH 2 to 3 psi LOWER than this fi gure.

IMPORTANT NOTE

Failure to set PRESSURE SWITCH as described above will NOT allow proper closing of SOLENOID VALVE during periods of low system pressure. Improper function of SOLENOID VALVE will cause total failure of system.

Special Service Instructions:

Under normal circumstances removal of valve should never be required. However, if it must be removed, it can be done by disassembling the quick release clamp, by

removing latch. Pressure should be relieved before attempting any disassembly. Upon reassembly, all O-rings should be lubricated with silicone grease. Reassemble

clamp as shown in Figure 7. MAKE SURE ARROWS ON LATCH SIDE OF CLAMP ARE ALIGNED.

Figure 7

3-12

Page 22

Figure 8

Figure 9

Figure 10

Figure 11

3-13

Page 23

SECTION 4: PLUMBING SYSTEM CLEAN UP

The following procedures are guidelines only but have proven successful in most instances. Under no circumstances should any procedure

outlined below be followed if contrary to the appliance manufacturer’s instructions. Should there be any questions concerning the advisability

of performing a procedure, it is strongly recommended the manufacturer’s authorized service outlet be consulted prior to performing the procedure.

The plumbing system and water using appliances that have been exposed, even for a short time, to iron-fouled water need to be cleaned of the precipitated iron that

has collected in them or iron “bleed” (staining) will continue to be a problem.

Depending on the amount of iron in the water and the length of time the water system has been exposed to iron fouling, select the following procedures that apply

to the type of system and appliances that need cleaning to help assure better quality water at the points of use.

It is not uncommon that a softener was installed in an effort to reduce ferrous (“clear water”) iron from the water supply. Typically, a softener will reduce some

ferrous iron until the resin bed becomes fouled to the extent that it will lose both hardness reduction capacity and the limited capacity for iron reduction. This is the

condition to expect the softener to be in when planning a system clean-up.

Prior to closing main supply valve or turning power off to a private well system and preparatory prior to installing the Iron Reduction System on a system where a

softener has already been installed, do the following:

1) Disconnect brine draw line from media tank and place the loose end into a fi ve gallon plastic pail fi lled with a solution of hot water and 10 ozs. of resin

mineral cleaner (IRON-X).

2) Manually advance control timer to BRINE DRAW position (refer to instructions provided with your softener), and allow all hot mineral cleaner solution to

be drawn into mineral bed. Then IMMEDIATELY:

3) Close main water supply valve or turn power off to pump and proceed with fi lter installation. During time required to install fi lter system, iron-fouled

softener resin will be chemically cleaned.

4) After fi lter installation is completed, fi nal adjustments made with water turned and the brine draw tube reconnected, manually reposition timer on

softener to BACK-WASH position. Allow timer to perform an automatic complete backwash and regeneration cycle. During backwashing of softener, iron

cleaned from the resin will be washed down drain. It is advisable after chemically cleaning softener to regenerate system twice to fully restore capacity

lost due to iron-fouling.

Water Heater

If the water heater has been exposed to both iron and hardness for a long period of time, replacement of the heater tank may be the only practical solution to

prevent continued staining originating from the source.

After completing the installation of the Iron Reduction System, clean the water heater by following these

instructions:

1) Shut off fuel supply to water heater and close heater inlet water valve.

2) Drain hot water tank completely. Open inlet water valve allowing heater tank to be refi lled with iron-free water. Continue fl ushing until water runs clear

to drain.

3) If after approximately 30 minutes fl ushing, water does NOT clear, terminate fl ushing operation. Refi ll water heater with water and pour approximately

1/2 gallon of household bleach into top of heater tank. Allow bleach solution to stand in tank for 20 to 30 minutes. Flush tank again until water is clear

at drain. Turn fuel supply on.

Note: If water does not clear in approximately 10 minutes, water heater probably should be replaced.

Dishwasher

Consult owner’s handbook and follow manufacturer’s instructions.

Toilet Flush Tanks

Prior to commencing installation of the Iron Reduction System, pour 4 to 6 ounces of resin mineral cleaner (IRON-X) or inhibited muriatic acid into fl ush tanks and

bowls and let stand. When installation is completed, fl ush toilets several times with treated water. If iron deposits or stains remain, repeat procedure until clear.

4-1

Page 24

SECTION 5: BACKWASHING INSTRUCTIONS

Periodic Backwashing (Regeneration) of the Iron Reduction System bed is required to fl ush out the entrapped iron that has accumulated. This procedure is performed

automatically at 1:00 a.m. for a period of approximately 10 minutes and will not interfere with a softener regeneration, which is usually set for 2:00 a.m.

TO SET BACKWASH FREQUENCY FOR NORMAL HOUSEHOLD APPLICATIONS:

To determine and set Backwash Frequency, follow these instructions:

1) Select Backwash Frequency Schedule corresponding to your model (page 3-7 and 3-8).

2) Locate box intersected by number of persons in your family and iron concentration of water (if iron concentration is between two numbers in Schedule,

use higher number.)

3) Number in box represents number of days, between regenerations. Refer to How to Change Days Between Regeneration on page 3-9.

Example: You have model APIF100, 4 people in family, and 8 ppm iron. Refer to Schedule for model APIF100 and locate box intersected by 4 in family and 8 ppm iron. The

fi gure indicates the number of days between each regeneration period.

IMPORTANT NOTE

The Backwashing Frequency Schedules are based on average water consumption rates and are merely guides. They are NOT intended to be used if

water is used by outside spigots, a swimming pool, geothermal heat pump, or other high water usage devices or activities. If your application includes

any of these, and you have already determined your model Iron Reduction System is capable of handling the fl ow rates involved, refer to the next

paragraph for instructions on setting Backwash Frequency.

TO SET BACKWASH FREQUENCY FOR COMMERCIAL MODELS AND

NON-STANDARD HOUSEHOLD APPLICATIONS:

If your fi lter is to be used for a commercial application or for reasons covered above, the Backwashing Frequency Schedule is not applicable.

Determine the backwashing frequency as follows:

1) Estimate Daily Iron Reduction by multiplying iron concentration by estimated daily water consumption (use 60 gallons per person per day for normal

household applications):

Est. Daily Water Usage ______ gal. X Iron Concentration ______ ppm =

Daily Iron Reduction ______ (ppm - gal.)

2) Calculate Backwash Frequency by inserting Daily Iron Reduction from above into following formula (refer to specifi cations for Iron Reduction Capacity

of your model):

Iron Reduction Capacity of Model ______(ppm-gal.) ÷ Daily Iron Reduction ______ (ppm - gal.) =

Backwashing Frequency ______ days

If your water contains high iron concentration, manganese, tannins, or hydrogen sulfi de, it may be advisable to increase the backwash frequency to daily, if neces-

sary. It should be noted, however, that increasing the frequency or duration of backwashing WILL NOT overcome an insuffi cient pumping rate.

5-1

Page 25

SECTION 6: TROUBLESHOOTING - CONTROL VALVE

Problem Possible Cause Solution

1. Timer does not display time of day a. AC adapter unplugged a. Connect power

b. No electric power at outlet b. Repair outlet or use working outlet

c. Damaged AC adapter c. Replace C Adapter

d. Damaged PC board d. Replace PC board

2. Timer does not display correct time of day a. Switched outlet a. Use an unswitched outlet

b. Time of day not set correctly b. Reset time of day

3. Control Valve regeneration at wrong

time of day

4. Error followed by a code number

Error code E1- Unable to recognize

start of regeneration

Error code E2- Unexpected stall

Error code E3- Motor ran too long.

Timed out trying to reach next cycle

position

If other codes appear contact factory

5. Control valve stalled in regeneration a. Motor not operating a. Replace motor

a. Power outages a. Reset control valve to correct time of day

b. Time of day not set correctly b. Reset to correct time of day

c. Time of regeneration incorrect c. Reset regeneration time

a. Control valve has just been serviced a. Press SET HOUR and DOWN for 3 seconds

or unplug power source jack (black wire)

from the circuit board and plug back in to

reset control valve

b. Foreign matter is lodged in control valve b. Check piston and spacer stack assembly

for foreign matter

c. High drive forces on piston c. Replace piston(s) and spacer stack assembly

d. Control valve piston not in home position d. Press SET HOUR and DOWN for 3

seconds or unplug power source jack

(black wire) from the circuit board and

plug back in to reset control valve.

e. Motor not inserted fully to engage pinion, motor

wires broken or disconnected, motor failure

f. Drive gear label dirty or damaged, missing or broken

gear

g. Drive bracket incorrectly aligned to drive bracket g. Reseat drive bracket properly

h. PC board incorrectly aligned to drive bracket h. Replace PC board

i. PC board incorrectly aligned to drive bracket i. Ensure PC board is correctly snapped on to

b. No electric power at outlet b. Repair outlet or use working outlet

c. Damaged AC adapter c. Replace AC adapter

d. Damaged PC board d. Replace PC board

e. Check motor and wiring. Replace motor if

necessary

f. Replace or clean drive gear

drive bracket

6. Control valve does not regenerate

automatically when UP and DOWN

buttons are depressed and held.

7. Control valve does not regenerate

automatically, but does when UP and

DOWN buttons are depressed and

held

e. Broken drive gear or drive cap assembly e. Replace drive gear or drive cap assembly

f. Broken piston retainer f. Replace piston retainer

g. Broken main or regerant piston g. Replace main or regenerant piston

a. AC adapter unplugged a. Connect AC adapter

b. No electric power at outlet b. Repair outlet or use working outlet

c. Broken drive gear or drive cap assembly c. Replace drive gear or drive cap assembly

d. Damaged PC board d. Replace PC board

a. Damaged PC board a. Replace PC board

b. Set-up error b. Check control valve set-up procedure

6-1

Page 26

SECTION 6: TROUBLESHOOTING - FILTER UNIT

Problem Possible Cause Solution

1. Water CLEAR when drawn, turns RED upon standing

(Stain producing)

2. Water RED when drawn from tap a. Filter bed overloaded with precipitated iron due to

3. Excessive pressure loss through fi lter a. Filter bed overloaded with precipitated iron. a. Refer to Section 2 above.

a. Insuffi cient air-draw by Hydro-Charger. a. Check Hydro-Charger adjustment. If unable to

b. Bypass open or leaking b. Close bypass valve and/or repair as necessary.

c. Filter bed overloaded with precipitated iron due to

insuffi cient backwash, or failure to backwash due

to malfunction of control timer or unplugged

control valve power cord.

d. Presence of manganese or tannins. d. Recheck water analysis

e. Flow rate excessive for model. e. Reread Sec. 2, FACTS TO REMEMBER WHILE

f. Check-valve located between Hydro Charger and

pressure tank, disrupting water fl ow.

g. Pumping cycle too short, limiting residence time in

pressure tank (may be water-logged).

h. pH of treated water too low (should be 7.0 or

higher; with manganese, pH must be 8.2).

insuffi cient back-wash fl ow rate.

b. Filter bed over loaded with precipitated iron due

to insuffi cient back-wash, or failure to backwash

due to malfunction of control timer or unplugged

control valve power cord.

c. Hydro-Charger drawing too much air, causing early

precipitation of iron.

d. Hydro-Charger installed too far from pressure tank

or pressure tank located too far from fi lter tank

causing iron to precipitate before fi lter tank.

e. Solenoid valve (SPLIT-STREAM or PUBLIC WATER

SUPPLY type installation) malfunction or inadequate

supply system pressure/fl ow rate.

b. Control inlet/outlet valve(s) not fully open. b. Open as necessary.

c. Sand, silt or mud collecting in fi lter bed. c. Check well for these conditions.

d. Filter bed not properly “classifi ed.” d. Manually backwash to reclassify.

e. “Cementing” or “channeling” of fi lter media. e. Prod (stir) fi lter bed to break up hardened layer.

adjust for long enough draw, check pumping rate.

c. Upon correction of problem (increase backwash

frequency if problem determined to be insuffi cient

frequency), manually backwash until backwash water

starts to clear ( in more severe iron fouling cases, fi lter

bed may need chemical cleaning - contact dealer).

PLANNING YOUR INSTALLATION.

f. Relocate check-valve.

g. Correct condition.

h. Replenish MpH Adder component in media (contact

dealer).

a 1. Recheck well pumping rate and repair or replace

as required.

2. Check for obstructions or kink in drain line.

3. Check for improper drain line fl ow controller (see

specs.) Upon correction of this problem, if

manually backwashing does not clear bed of

iron, fi lter bed may need chemical cleaning - contact

dealer.

b. Upon correction of problem (increase backwash

frequency if problem determined to be insuffi cient

frequency), manually backwash until backwash

water starts to clear (in more severe iron-fouling

cases, fi lter bed may need chemical cleaning - contact

dealer).

c. Reduce Hydro-Charger air-draw.

d. Relocate to a location closer to fi lter inlet.

e. Repair or replace solenoid valve and verify adequate

supply system pressure and fl ow rate.

Increase backwash frequency to prevent reoccurrence.

4. “Milky” or “bubbly” water (Appears to contain

small bubbles)

a. Excess Hydro-Charger air-draw. a. Check adjustment for duration of draw in excess

b. Excess gases in water (carbon dioxide, hydrogen

sulfi de, methane).

6-2

of one-third pumping cycle (see Sec.3, Step 10).

b. May require draining of water system or instal

lation of air-relief control on the fi ll port cap of

valve adapter base, (contact dealer).

Page 27

SECTION 7: VALVE SPECIFICATION AND OPERATING DATA

Maximum Service Flow Rate:

27 gpm (102.2 lpm) @15 psig (103 kPa) drop

Includes Bypass Valve

Maximum Backwash Flow Rate:

27 gpm (102.2 lpm) @15 psig (103 kPa) drop

Includes Bypass Valve

Minimum/Maximum Operating Pres-

20 psi (138 kPa) - 125 psi (862 kPa)

sure:

Minimum/Maximum Operating Tem-

40°F (4.4°C) - 110°F (43.3° C)

perature:

AC Adapter:

Supply Voltage

120 V. AC

Supply Frequency

Output Voltage

Output Current

Drain Line Flow Control Unit Size Number on

12 V. AC

500 mA

Backwash Flow

Drain Line

Flow Control

1.0 ft

1.5 ft

2.0 ft

3.0 ft

3

3

3

3

053 5.3 20.1

053 5.3 20.1

075 7.5 28.4

100 10.0 37.9

Inlet/Outlet Tube Opening (a) 1” Universal Elbow

(b) 1” Straight brass sweat fi tting

(c) 1” Plastic male NPT fi tting

Distributor Tube Opening 1.05” OD (3/4 NPS)

Tank Thread 2 1/2”- 8 NPSM to Flanged Adapter

Control Valve Weight 4.5 lbs. (2.0 kg)

PC Board Memory Nonvolatile EEPROM

(electronic erasable programmable read only memory)

U.S.

60 Hz

Rate (gpm)

Backwash Flow

Rate (lpm)

Note: After completing any valve maintenance involving the drive assembly or the drive cap assembly and pistons, unplug the power source from the

jack on the printed circuit board (black wire) and plug back in. This resets the electronics and establishes the service piston position.

7-1

Page 28

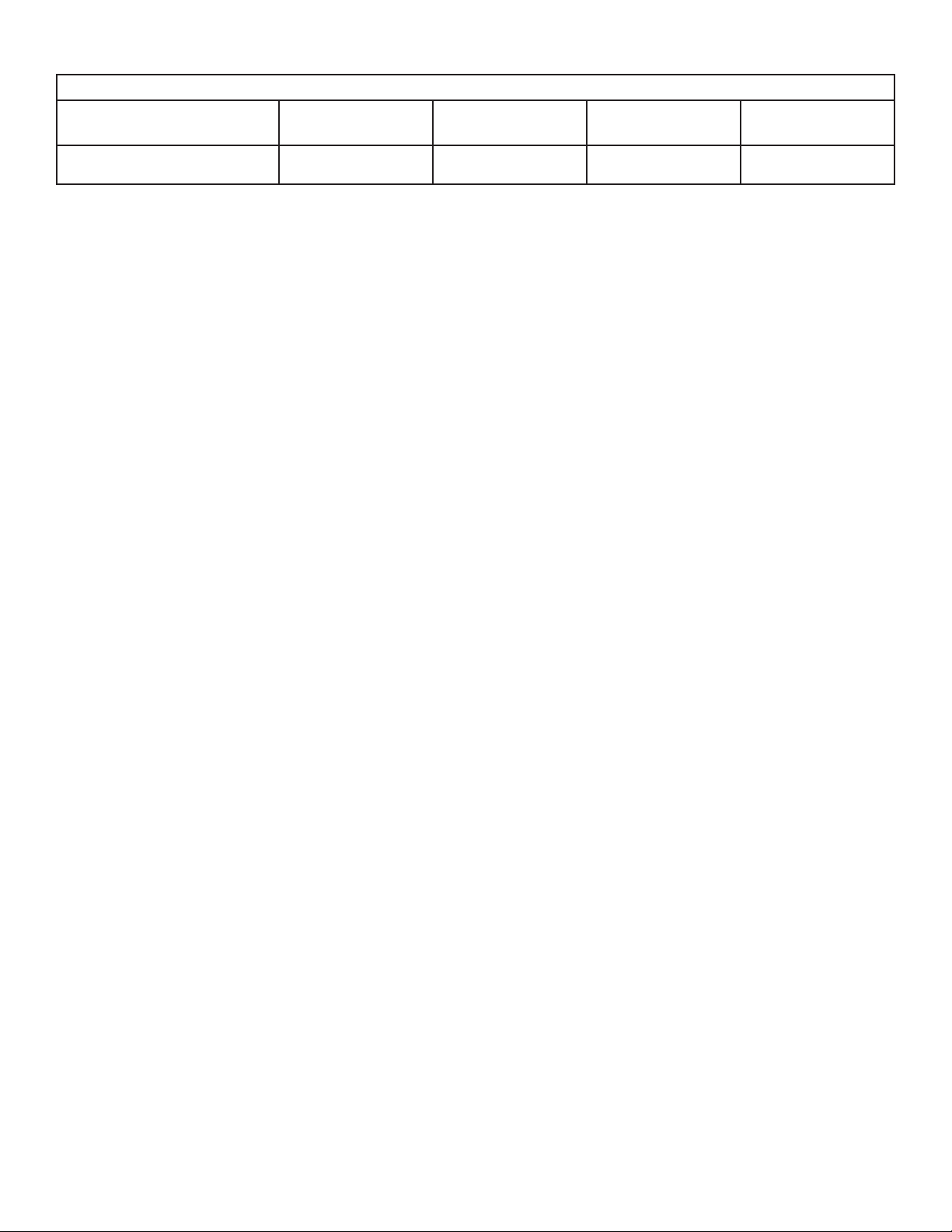

SECTION 7: SPECIFICATION AND OPERATING DATA

ITEM

Media Volume, cu. ft. (cu. mtr.) (Note 1):

Gravel Underbed, lbs. (kg)

Nominal Capacity, ppm-gal.

Operating Flow Rate, gpm (lpm) (Note 2):

Continuous

Service

Pressure Loss @ Flow Rates, psi (kPa)

Continuous

Service

Backwash Flow Rate, gpm (lpm) Note 3

Service Pipe Size, in. (cm) (Note 4)

Filter Tank Diameter x Height, in. (cm)

Minimum Space Required, in. (cm):

Width

Depth (w/Bypass)

Height

APIF100

APIF100J

APIF100M

APIF100PT

APIF100MPT

APIF100MJ

1.0 (0.03)

13 (5.9)

30,000

3 (11.4)

6 (22.7)

2 (13.8)

5 (34.5)

5.3 (20.1)

1 (2.5)

10 x 44

(26 x 112)

12 (30)

16 (41)

53 (135)

APIF150

APIF150J

APIF150M

APIF150PT

APIF150MPT

APIF150MJ

1.5 (0.04)

13 (5.9)

45,000

3 (11.4)

7 (26.5)

2 (13.8)

7 (48.2)

5.3 (20.1)

1 (2.5)

10 x 54

(26 x 137)

12 (30)

16 (41)

63 (160)

APIF200

APIF200J

APIF200M

APIF200PT

APIF200MPT

APIF200MJ

2.0 (0.06)

18 (8.2)

60,000

4 (15.1)

9 (34.1)