3M AP510 Installation Manual

Installation and Operating Instructions For

AP510 Full Flow Drinking Water System

Installer: Please leave manual with homeowner.

Homeowner: Please retain for operation and

future maintenance instructions.

SAFETY INFORMATION

WARNING

CAUTION

Read, understand, and follow all safety information contained in these instructions prior to

installation and use of the AP510 Full Flow Drinking Water System. Retain these instructions

for future reference.

Intended use:

The AP510 Full Flow Drinking Water System is intended for use in fi ltering potable water in homes and has not

been evaluated for other uses. The system is typically installed under a sink using the existing faucet, and

must be installed as specifi ed in the installation instructions.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

W

To reduce the risk associated with choking:

• Do not allow children under 3 years of age to have access to small parts during the installation of this product.

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or

after the system.

To reduce the risk associated with a hazardous voltage due to an installer drilling through existing electric wiring

or water pipes in the area of installation:

• Do not install near electric wiring or piping which may be in the path of a drilling tool when selecting the position

to mount the fi lter bracket.

Indicates a potentially hazardous situation, which, if not avoided, could result in

death or serious injury and/or property damage.

Indicates a potentially hazardous situation, which, if not avoided, may result in

property damage.

WARNING

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use Instructions before installation and use of this system.

• Installation and Use MUST comply with all state and local plumbing codes.

• Protect from freezing, remove fi lter cartridge when temperatures are expected to drop below 40°F (4.4°C).

• Do not install systems in areas where ambient temperatures may go above 110° F (43.3° C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 100°F

(37.8°C).

• Do not install if water pressure exceeds 125 psi (862 kPa). If your water pressure exceeds 80 psi (552 kPa), you

must install a pressure limiting valve. Contact a plumbing professional if you are uncertain how to check your

water pressure.

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a

water hammer arrester. Contact a plumbing professional if you are uncertain how to check for this condition.

• Where a backfl ow prevention device is installed on a water system, a device for controlling pressure due to

thermal expansion must be installed.

• Do not use a torch or other high temperature sources near fi lter system, cartridges, plastic fi ttings or plastic

plumbing.

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may

deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if overtightening

occurs.

• Do not install in direct sunlight or outdoors.

• Mount fi lter in such a position as to prevent it from being struck by other items used in the area of installation.

• Ensure that the location and fasteners will support the weight of the system.

• Ensure all tubing and fi ttings are secure and free of leaks.

• The disposable fi lter cartridge MUST be replaced ever 6 months, at the rated capacity or if a noticeable reduction in fl ow rate occurs.

IMPORTANT NOTES

• Failure to follow instructions will void warranty.

• Allow a minimum of 3” (7.6 cm) clear space under fi lter to facilitate cartridge change.

• Install with the inlet and outlet ports as labeled. Make sure not to reverse connections.

• Do not crimp copper tubing.

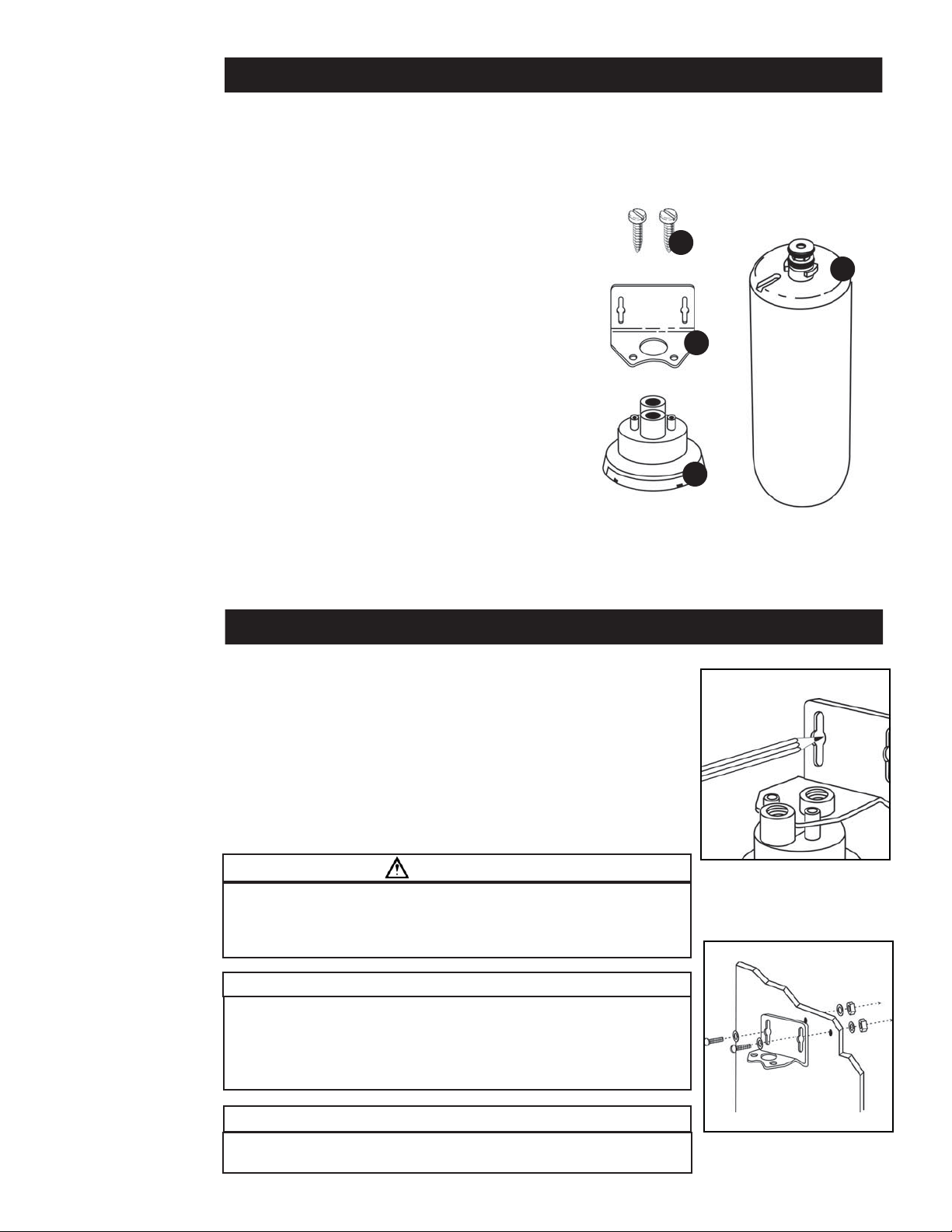

GETTING STARTED

Your new Aqua-Pure® AP510 Full Flow Drinking Water System will reduce chlorine tastes and odors, particulate and

scale from your drinking water. The filter installs under the sink on the cold water line and uses the existing faucet. The

AP510 features its own automatic shut-off, thereby eliminating the need for any external valves. The installation procedure covered in this manual requires the removal of a section of the cold water tube. Soft copper tubing and compression fittings should be purchased locally to complete the installation.

Parts and Materials Included:

1. Two Self-tapping Screws

2. Mounting Bracket

3. Head Assembly

4. Cartridge Model AP517

Tools and Parts Required (not included):

• Choice of:

Two #10 Machine Screws (length to suit), Two Washers and

Two #10 Machine Screw Nuts

OR Two #10 Sheet Metal Screws and Two Washers

OR Two Wood Screws

• Two 3/8” MNPT x 3/8” or 1/2” Compression

Fittings Depending on Existing Plumbing

• PTFE Tape

• Adjustable Wrench

• Drill (Cordless Recommended)

• Phillips Head Screwdriver

• Razor Knife Or Tube Cutter

• 3/8” soft copper or plastic tubing, 5’ length

Empty contents of package and identify all parts as shown in

diagram. Read all instructions carefully before attempting to start

installation. Before starting, close shut-off valve on kitchen

cold water line.

Note: If the filter is not connected to the head assem-

bly upon opening this carton, please refer to the

“Filter Cartridge Replacement Instructions” Section,

Step 3.

1

4

2

3

IMPORTANT INSTALLATION INSTRUCTIONS

1. Position the filter by holding it against the right hand side of the cabinet wall

underneath the sink. Allow at least 3” (7.6 cm) beneath the filter to install cartridge. Determine a desirable location for the filter installation and inlet connection. Attach the mounting bracket to appropriate mounting bosses on filter head

with the self-tapping screws supplied. (Figure 1)

2. For installation using machine screws and nuts, remove drawer from adjacent

cabinet and drill two 7/32” diameter holes through cabinet wall. Fasten filter

bracket to wall with screws, nuts and washers. Use washers on both sides of the

wall. Mounting to the cabinet side wall gives the filter good, rigid support. (Figure

2) For installation using sheet metal screws, simply prick punch at marked location (Step 1), position bracket in place, and install screws with screwdriver.

WARNING

To reduce the risk associated with a hazardous voltage due to an installer drilling through existing electric wiring or water pipes in the area of installation:

• Do not install near electric wiring or piping which may be in the path of a

drilling tool when selecting the position to mount the fi lter bracket.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install on hot water supply lines. The maximum operating water

temperature of this fi lter system is 100°F (37.8°C).

• Do not use a torch or other high temperature sources near fi lter system,

cartridges, plastic fi ttings or plastic plumbing.

Figure 1

IMPORTANT NOTES

• Allow a minimum of 3” (7.6 cm) clear space under fi lter to facilitate

cartridge change.

Figure 2

IMPORTANT INSTALLATION INSTRUCTIONS (Continued)

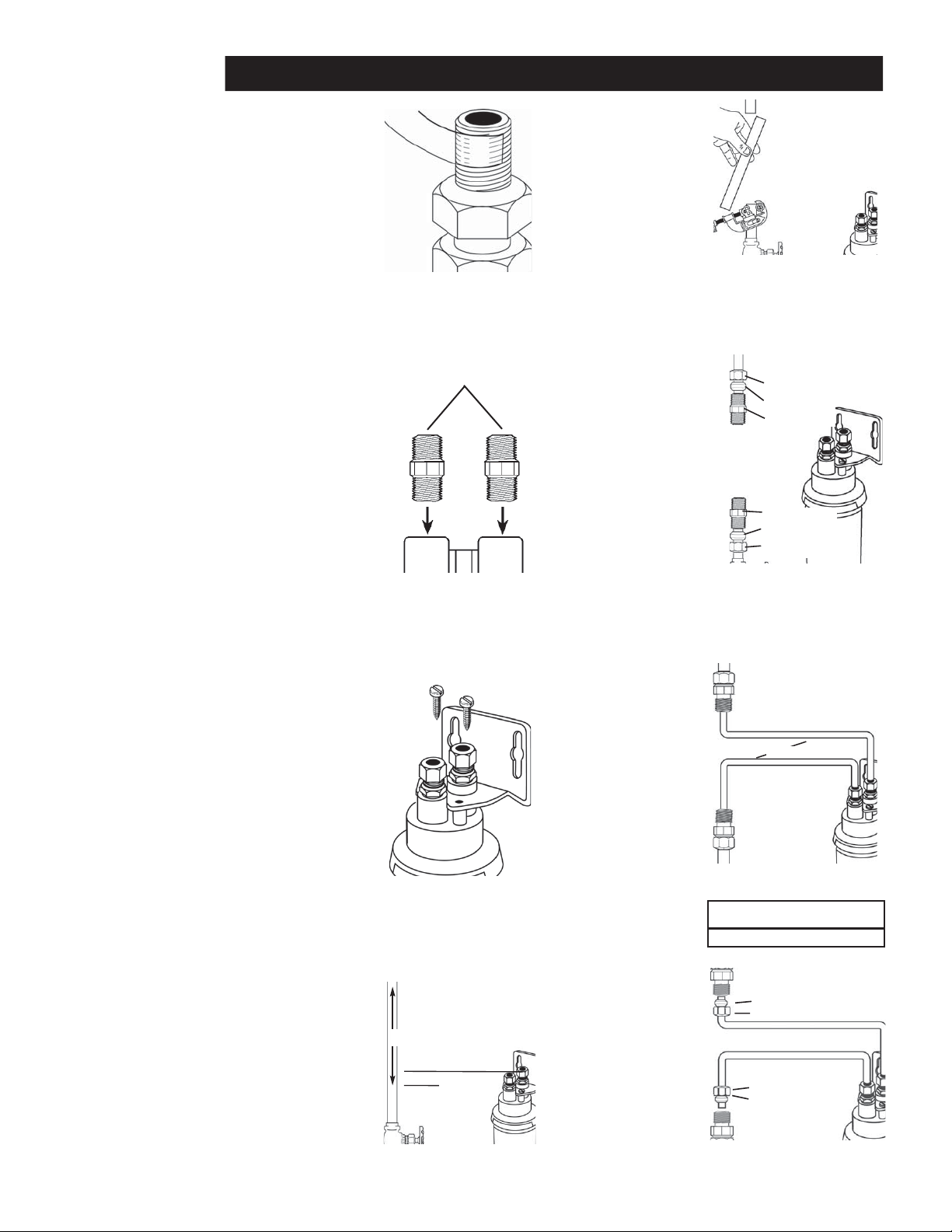

3. Wrap a 3” (7.6 cm)

long piece of PTFE tape

to the right (clockwise)

around the 3/8” MNTP

threads of the fittings.

Wrap tightly so that

it conforms to the

threads of the fitting

and overlaps about

1/2”. (Figure 3) Do

not wrap 3/8” or 1/2”

compression threads

with tape.

4. Screw one fitting

into the filter outlet

and the other fitting

into the filter inlet

(both are labeled on

filter head assembly.)

Tighten both fittings

with a wrench. Do

not overtighten.

Overtightening may

result in a cartridge

crack which may

lead to fluid leaking

(Figure 4)

5. Remove the two

screws at top of head

assembly. Position

either inlet fitting or

outlet fitting through

large hole in bracket

and replace these two

screws. Filter head

is now mounted and

ready for plumbing.

(Figure 5)

6. Measure down from

filter inlet fitting about

1” (3 cm) and mark

existing cold water

tubing. From this

mark, measure up

8” (20 cm) and mark

tubing. This is the

section of tubing to

be removed. If necessary, because of tight

situations, additional

tubing may be cut

away. (Figure 6)

PTFE Tape

Compression

Fittings

Compression Fittings

8”

1”

Figure 3

Figure 4

Figure 5

Cold Water Line

Figure 6

7. Turn off cold water

supply valve and open

cold water tap to

relieve system pressure. Cut cold water

tubing using a tube

cutter or razor knife.

Do not use a hacksaw,

etc. Place a pan under

it to catch any water

present. (Figure 7)

8. Two compression

fittings are required

for tube ends. Check

tube size. Use 3/8”

x 3/8”, 1/2” x 3/8”,

or 5/8” x 3/8” compression fittings as

required. Slip nut

and ferrule on water

tubing as shown

and fasten fittings in

place. (Figure 8)

9. Cut two lengths of

3/8” soft copper

tubing and bend to

shape as shown.

Bend tubing to form

gentle curves rather

than sharp bends.

(Figure 9)

10. Connect both pieces

of tubing to filter and

water tube as shown

with compression

fittings. Do not over-

tighten nuts.

(Figure 10)

11. Open the cold water

faucet to expel

trapped air. Open

the supply valve to

allow water to enter

the filter. If any leaks

occur, close the supply valve and open

the faucet to relieve

the pressure, then

gently tighten the

fitting that is leaking. Flush at least 2

gallons through filter

before use (approximately 1 minute of

flushing). Water may

run cloudy due to air

but will clear quickly.

Figure 7

Nut

Ferrule

Compression Fitting

Compression Fitting

Ferrule

Nut

Figure 8

To existing faucet

(cold water side only)

Tubing

Head

Figure 9

IMPORTANT NOTE

Do not crimp copper tubing.

Ferrule

Nut

Nut

Ferrule

Figure 10

Loading...

Loading...