3M 60440273377, 60440229510, 60440273385, 60440227076, 60440227043 User Manual

...

3M™ Abrasives for Right-Angle Systems

The

Right

Choice

Cut, grind, finish and more…

with a world-class abrasive

system that helps you work

smarter, finish faster!

3

3

Power

For metal fabrication and finishing

Your

Take your shop to the next level of performance and

productivity – by teaming up the unmatched grinding speed

and long life of 3M™ Cubitron™ II Abrasives with the ease-ofuse and versatility of Scotch-Brite™ abrasive products.

The ideal

choice for:

•

Grinding

•

Weld removal

•

Deburring

•

Beveling

•

Cutting

•

Blending

Team

The ideal

choice for:

•

Blending

•

Cleaning

•

Deburring

•

Paint and rust removal

•

Light grinding

•

Finishing and polishing

Complete your lineup

with genuine 3M™ Power Tools

Professional grade sanders, grinders

and cutoff wheel tools, optimized for

use with 3M™ Cubitron™ II Abrasives.

Light, rugged and powerful!

2

For speed, long life and ease of use, nothing comes close

to the power of Cubitron II abrasives

For grinding, weld blending, deburring and other

tough metal finishing jobs, 3M™ Cubitron™ II

Abrasives outperform every other disc in their

class – thanks to a breakthrough 3M technology

that re-writes the rules for speed, consistency and

abrasive life.

Use this table as a

guideline to choose

the disc construction

optimized for your

application.

Recommended

application

Additional

application

Choose the

Right Disc

The secret lies in the revolutionary precision-shaped

ceramic grain technology pioneered by 3M. As the

triangular shaped grain wears, it continuously

fractures to form sharp points and edges that slice

through metal, wear evenly and provide super-long

life and consistency at any grinding pressure.

for the Job

Optimized for

applications including:

• Grinding

• Weld

removal

• Deburring

Used in industries

such as:

• Ship building

• Structural steel

• General metal fabrication

• Oil and gas

• Agricultural, industrial and

construction machinery

• Stainless steel fabrication

• Beveling

• Cutting

• Blending

Cutting

Notching

Gouging

Fillet Weld

Removal

Beveling

Flame Cut

Smoothing

Scale

Removal

Weld

Removal

Contoured

Areas

Fibre Discs

Cut & Grind

Wheels

Flap Discs

Cut-Off Wheels

Depressed Center

Grinding Wheels

3M precision-shaped grains are

electronically oriented to form

sharp peaks that easily “slice”

through metal. They stay cooler,

cut faster and last longer.

Conventional ceramic abrasive

grain tends to “plow” through the

metal, causing heat to build up in

the workpiece and the abrasive –

resulting in a slower cut, shorter

disc life and undesirable effects,

such as burnishing.

3

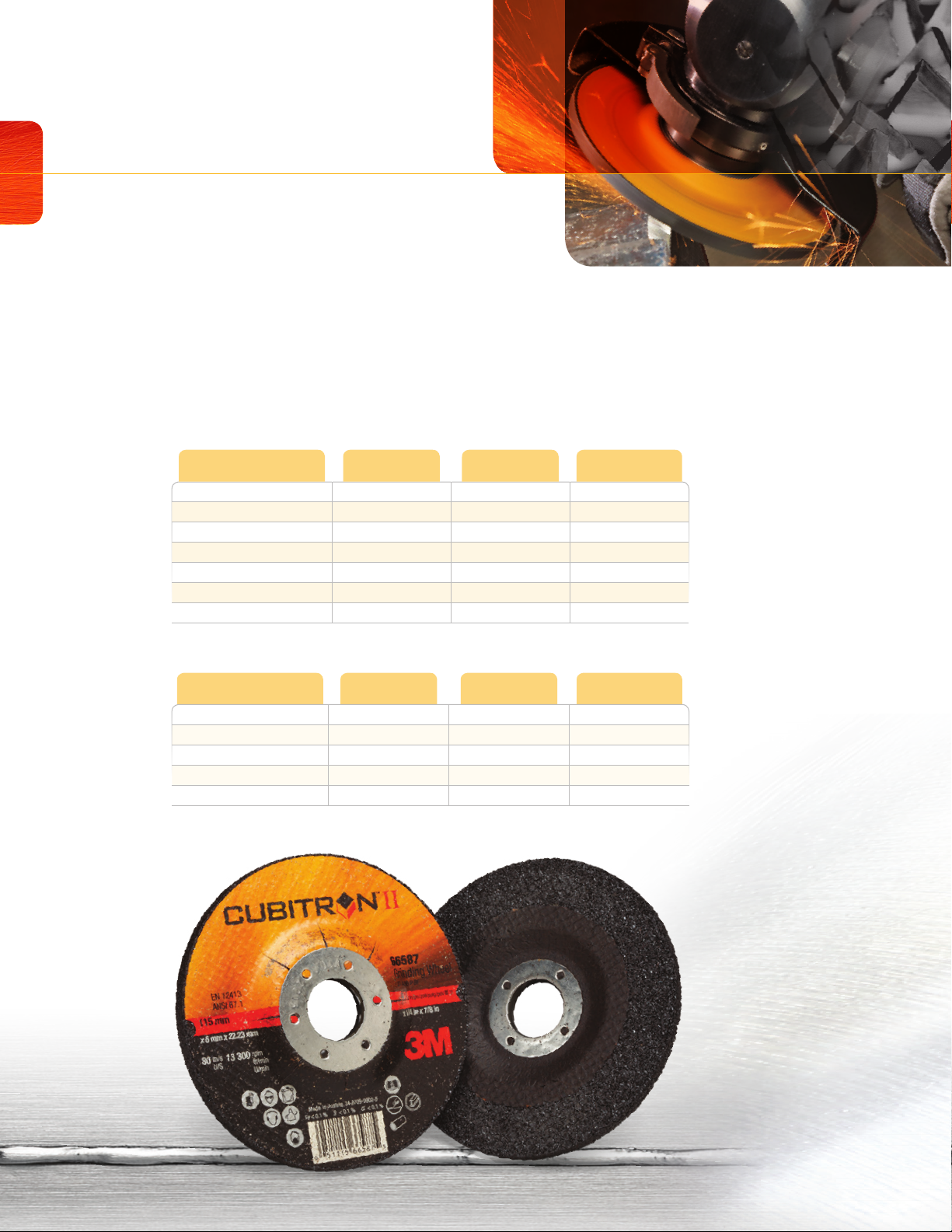

3M™ Cubitron™ II

Depressed Center

Grinding

Wheels

Go the distance

Cubitron II depressed center grinding wheels are fast cutting, long

lasting and require less pressure. These cool cutting wheels are

ideal for heavy grinding and weld removal. Specially formulated

for use on stainless and mild steel. Available with quick change

attachment. DO NOT USE ON TOOLS WITHOUT GUARDS.

3M™ Cubitron™ II Depressed Center Grinding Wheel – T27

Diameter × T hickness

× Arbor Hole (inches)

4 × 1⁄4

× 3⁄ 8

4 × 1⁄4

× 5⁄ 8

4 1⁄ 2

× 1⁄4

× 7⁄ 8

5 × 1⁄4

× 7⁄ 8

66588-2 12,250 10/20

6 × 1⁄4

× 7⁄ 8

66589-9 10,20 0 10/ 20

7 × 1⁄4

× 7⁄ 8

66590-5 8,500 10 /2 0

9 × 1⁄4

× 7⁄ 8

66591-2 6,650 10/ 20

UPC

( 051115 - )

66 598 -1 15,3 00 10/ 20

66 597- 4 15,3 00 10/ 20

66587-5 13,300 10 /20

Max RPM

3M™ Cubitron™ II Depressed Center Grinding Wheel – T27 Quick Change

Diameter × T hickness

× Arbor Hole (inches)

4 1⁄ 2

× 1⁄4

× 5⁄ 8-11

5 × 1⁄4

× 5⁄ 8-11

66592-9 12,25 0 10/ 20

6 × 1⁄4

× 5⁄ 8-11

66593-6 10, 200 10/20

7 × 1⁄4

× 5⁄ 8-11

66594-3 8,500 10 /2 0

9 × 1⁄4

× 5⁄ 8-11

UPC

( 051115 - )

66 59 6-7 13, 300 10/2 0

66595-0 6,650 10/ 20

Max RPM

Quantity

(Inner/Case)

Quantity

(Inner/Case)

4

Loading...

Loading...