Page 1

6000DIN Series

Respirator Full Facepiece

User Instructions for 3M™ 6700DIN

Full Facepiece (Small), 6800DIN Full

Facepiece (Medium), 6900DIN Full

Facepiece (Large)

(Keep these instructions for reference)

Page 2

These User Instructions provide information about the facepiece use only. Important information is provided

in the User Instructions with each of the air filtration/supplied air systems. Failure to follow User

Instructions for the air filtration/supply system being used may result in sickness or death.

This respirator helps protect against certain airborne contaminants. Misuse may result in sickness or death.

Do not clean respirator with solvents. Cleaning with solvents may degrade some respirator components and

reduce respirator effectiveness. Inspect all respirator components before each use to ensure proper operating

conditions.

GENERAL SAFETY INFORMATION

Intended Use

The 3M™ 6000 Series Full Facepiece Respirators are designed to help provide respiratory protection against

certain airborne contaminants when used in accordance with all use instructions and limitations and

applicable safety and health regulations.

This product contains no components made from natural rubber latex.

CAUTION:

Failure to properly dispose of spent cartridges, filters, or respirators contaminated by hazardous materials

can result in environmental harm. Handling, transportation and disposal of spent cartridges, filters, or

respirators must comply with all applicable federal, state, and local laws and regulations.

2

Page 3

USE INSTRUCTIONS AND LIMITATIONS

Important

Before use, the wearer must read and understand these User Instructions. Keep these instructions for

reference.

Use For

Respiratory protection from certain airborne contaminants according to NIOSH approvals, OSHA

limitations, in Canada CSA standard Z94.4 requirements, other applicable regulations and 3M instructions.

Do Not Use For

Concentrations of contaminants which are immediately dangerous to life or health, are unknown or when

concentrations exceed 10 times the permissible exposure limit (PEL) in air purifying mode when qualitatively

fit tested, 50 times the PEL in air purifying mode when quantitatively fit tested, 1000 times the PEL in powered

air purifying or supplied air mode, or according to specific OSHA standards or applicable government

regulations, whichever is lower.

Use Instructions

1. Failure to follow all instructions and limitations on the use of this respirator and/or failure to wear this

respirator during all times of exposure can reduce respirator effectiveness and may result in sickness or

death.

2. Before occupational use of this respirator, a written respiratory protection program must be implemented

meeting all the requirements of OSHA 29 CFR 1910.134 such as training and fit testing and applicable

OSHA substance specific standards. In Canada, CSA standard Z94.4 requirements must be met.

3. The airborne contaminants which can be dangerous to your health include those that are so small you

cannot see them.

4. Leave contaminated area immediately and contact supervisor if you smell or taste contaminants or if

dizziness, irritation, or other distress occurs.

5. Store respirator away from contaminated areas when not in use.

6. Dispose of used product in accordance with applicable regulations.

Use Limitations

1. This respirator does not supply oxygen when used in air purifying mode. Do not use in atmospheres

containing less than 19.5% oxygen.

2. Do not use when concentrations of contaminants are immediately dangerous to life and health, are

unknown or when concentrations exceed 10 times the permissible exposure limit (PEL) in air purifying

mode when qualitatively fit tested, 50 times the PEL in air purifying mode when quantitatively fit tested,

1000 times the PEL in powered air purifying or supplied air mode, or according to specific OSHA

standards or applicable government regulations, whichever is lower.

3. Do not alter, abuse or misuse this respirator.

4. Do not use with beards or other facial hair or other conditions that prevent a good seal between the face

and the faceseal of the respirator.

3

Page 4

Time Use Limitations

1. If respirator becomes damaged, leave the contaminated area immediately and repair or replace the

respirator.

2. Replace filters in accordance with the filter Time Use Limitations.

3. Replace cartridges in accordance with an established change schedule or earlier if smell, taste or irritation

from contaminants is detected.

NIOSH Cautions and Limitations

The following restrictions may apply. See NIOSH Approval Label Matrix.

A- Not for use in atmospheres containing less than 19.5 percent oxygen.

B- Not for use in atmospheres immediately dangerous to life or health.

C- Do not exceed maximum use concentrations established by regulatory standards.

D- Air-line respirators can be used only when the respirators are supplied with respirable air meeting the

requirements of CGA G-7.1 Grade D or higher quality.

E- Use only the pressure ranges and hose lengths specified in the User’s Instructions.

F- Do not use powered air-purifying respirators if airflow is less than four cfm (115 lpm) for tight fitting

facepieces or six cfm (170 lpm) for hoods and/or helmets.

G- If airflow is cut off, switch to filter and/or cartridge or canister and immediately exit to clean air.

H- Follow established cartridge and canister change schedules or observe ESLI to ensure that cartridge and

canisters are replaced before breakthrough occurs.

I- Contains electrical parts which have not been evaluated as an ignition source in flammable or explosive

atmospheres by MSHA/NIOSH.

J- Failure to properly use and maintain this product could result in injury or death.

L- Follow the manufacturer’s User’s Instructions for changing cartridges, canister and/or filters.

M- All approved respirators shall be selected, fitted, used, and maintained in accordance with MSHA, OSHA,

and other applicable regulations.

N- Never substitute, modify, add, or omit parts. Use only exact replacement parts in the configuration as

specified by the manufacturer.

0- Refer to User’s Instructions, and/or maintenance manuals for information on use and maintenance of

these respirators.

P- NIOSH does not evaluate respirators for use as surgical masks.

S- Special or critical User’s Instructions and/or specific use limitations apply. Refer to User’s Instructions

before donning.

4

Page 5

S-Special or Critical Use Instructions

3M™ Mercury Vapor Cartridges (6009 and 60929) are equipped with passive 3M™ End of Service Life

Indicators (ESLI). The color change indicator must be readily visible when wearing the respirator without

manipulation. If you cannot readily see the ESLI, do not use. Mercury vapor cartridges must be discarded

when the ESLI changes color; or within 30 days of opening packaging; or when ESLI becomes dirty or

damaged; or when odors of vapors or gases become noticeable, whichever occurs first. Mercury vapor has

no odor.

To assemble 3M™ Dual Airline Combination Breathing Tubes with 3M™ Cartridges/Filters, the facepiece

inhalation valves must be removed.

If the facepiece is to be used in air purifying mode (without using the 3M™ SA-1600 or SA-2600 breathing

tubes), the inhalation valves must be replaced in the facepiece before use.

Use of the 3M™ 6894 Nose Cup Assembly with the 3M™ 6000DIN Series Full Facepieces must be in

accordance with the NIOSH approval for the system being used.

–Nose cup is not to be used with the Powerflow™ Face-Mounted PAPR

–Nose cup use is optional with 3M™ GVP and Breathe Easy™ Belt-Mounted PAPR systems.

–Nose cup must be used for all other 6000DIN facepiece applications.

OSHA Standard 29 CFR 1910.134 requires that employers provide breathing air for supplied air respirator

systems which “shall meet at least the requirements of the specification for Grade D breathing air as

described in the Compressed Gas Association Commodity Specification ANSI/CGA G-7.1-1997.” Testing of

output air from a compressor against this standard is required prior to using with a supplied air respirator.

In Canada, breathing air systems must be supplied with air which meets at least the requirements in Table 1

of CSA Standard Z180.1-2000. Failure to do so may result in sickness or death.

5

Page 6

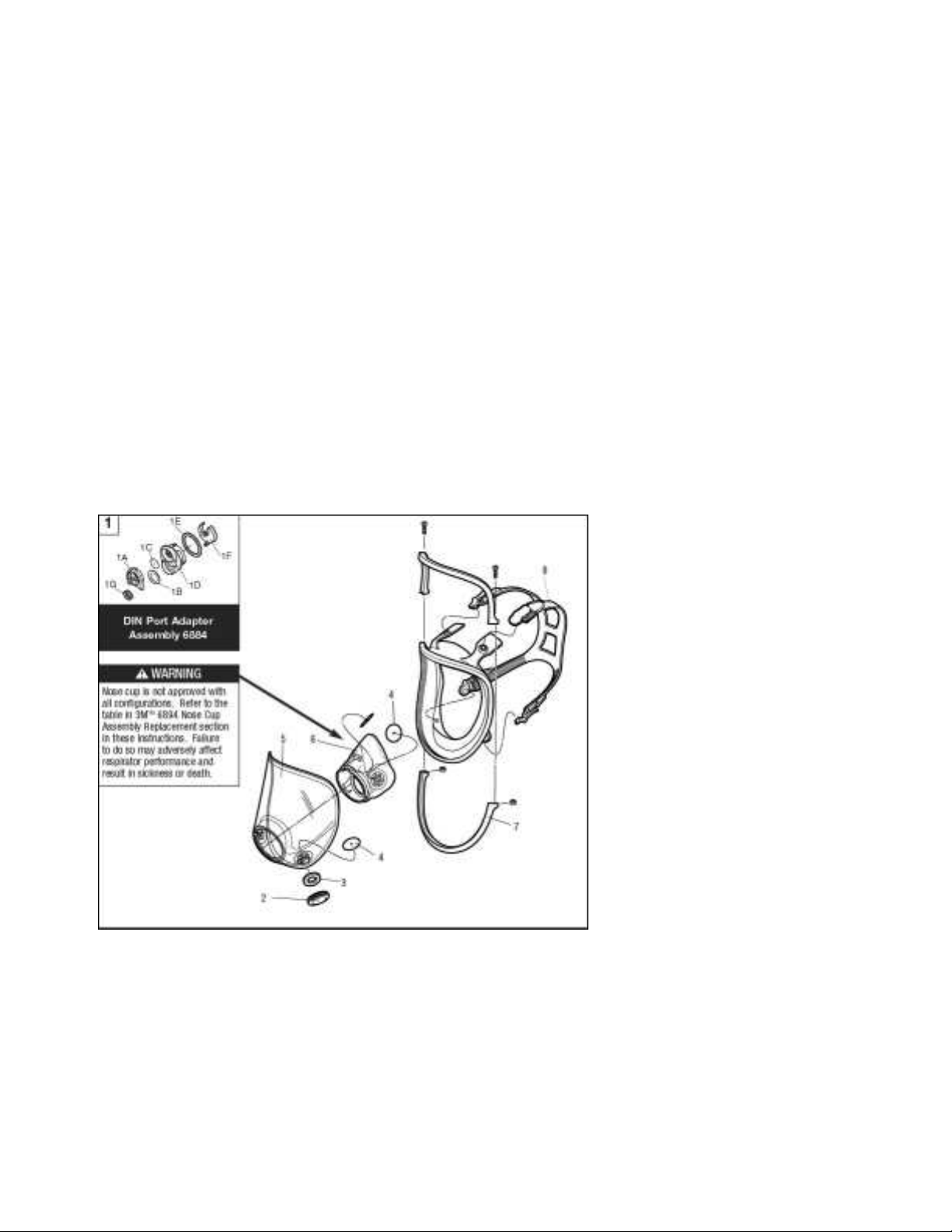

LIST OF PRODUCTS

3M™ 6000 Series Full Facepiece Replacement Parts and Accessories

Full Facepiece with DIN Port Adapter (6884)

6700DIN Small

6800DIN Medium

6900DIN Large

1 6884 DIN Port Adapter Assembly

1A 6882 DIN Cover

1B 6876 Breathing Tube Gasket

1C 6889 Exhalation Valve

1D 6883 DIN Port Base

1E 6896 Center Adapter Gasket

1F 6881 DIN Air Director

1G 7890 Full Face Plug (Accessory not included

w/6884)

2 6880 Bayonet Cap

3 6895 Inhalation Gasket

4 6893 Inhalation Valve

5 6898 Lens Assembly

6 6894 Nose Cup Assembly

7 6899 Frame Assembly w/Screws

8 6897 Head Harness Assembly

6

Page 7

3M™ Accessories

Number Product Name

504 Respirator Cleaning Wipes

601 Quantitative Fit Test Adapter

6878 Spectacle Kit

6885 Lens Cover (100 pack)

6886 Tinted Lens Cover (25 pack)

7883 Neck Strap Assembly

7915-5 Tyvek® Shroud

7993 Welder’s Shroud

3M™ Cartridges

3M™ Responder Cartridge and Canister (Front-Mounted)

Number Product Name

450-02-11R06 CP3N Canister

FR-64 FR-64 Cartridge

Note: Important information is provided in the User Instructions with 3M™ Responder Cartridges and

Canisters, which must be understood by wearer before use.

Alpha chloroacetophenone (CN), ortho

chlorobenzylidene malonitrile (CS); and P100

Organic vapor, chlorine, hydrogen chloride, chlorine

dioxide, sulfur dioxide, ammonia, methylamine,

formaldehyde, hydrogen fluoride, hydrogen sulfide

(escape only), alpha chloroacetophenone (CN), ortho

chlorobenzylidene malonitrile (CS) or phosphine; and

P100

3M™ 6000 Series Filters and Cartridges (Side-Mounted)

Number Product Name NIOSH Approval (for respiratory protection

against the following contaminants up to fifty times

the permissible exposure limit with Quantitative

Fit Test)

6001 Organic Vapor Certain organic vapors

6002 Acid Gas Chlorine, hydrogen chloride, and sulfur

dioxide or chlorine dioxide or hydrogen

sulfide (escape only).

6003 Organic Vapor/Acid Gas Certain organic vapors, chlorine, hydrogen

chloride, and sulfur dioxide or hydrogen sulfide

(escape only) or hydrogen fluoride

6004 Ammonia/Methylamine Ammonia and methylamine

6005 Formaldehyde/Organic Vapor Formaldehyde and certain organic vapors

7

Page 8

6006 Multi-Gas/Vapor Certain organic vapors, chlorine, hydrogen

chloride, chlorine dioxide, sulfur dioxide, hydrogen

sulfide (escape only), ammonia/methylamine,

formaldehyde or hydrogen fluoride

6009 Mercury Vapor/Chlorine Gas Mercury vapor or chlorine gas

60921 Organic Vapor/P100 Certain organic vapors and particulates

60922 Acid Gas/P100 Chlorine, hydrogen chloride, and sulfur dioxide or

chlorine dioxide or hydrogen sulfide (escape only) and

particulates

60923 Organic Vapor/Acid Gas/P100 Certain organic vapors, chlorine, hydrogen

chloride, and sulfur dioxide or hydrogen sulfide

(escape only) or hydrogen fluoride and particulates

60924 Ammonia/Methylamine/P100 Ammonia and methylamine and particulates

60925 Formaldehyde/Organic Vapor/P100 Formaldehyde and certain organic vapors and

particulates

60926 Multi-Gas/Vapor/P100 Certain organic vapors, chlorine, hydrogen

chloride, chlorine dioxide, sulfur dioxide, hydrogen

sulfide (escape only), ammonia/methylamine,

formaldehyde or hydrogen fluoride and particulates

60928 Organic Vapor/Acid Gas/P100 Certain organic vapors, chlorine, hydrogen chloride,

and sulfur dioxide or hydrogen sulfide (escape only)

hydrogen fluoride and particulates

1

60929 Mercury Vapor/Chlorine Gas/P100 Mercury vapor or chlorine gas and particulates

1. 3M recommended for use against methylbromide or radioiodine up to 5 ppm with daily cartridge

replacement.

Service Life of 3M™ 6000 Series Cartridges

3M™ 6000 Series Chemical Cartridges should be used before the expiration date on cartridge packaging.

The useful service life of these cartridges will depend upon activity of wearer (breathing rate), specific type,

volatility and concentration of contaminants and environmental conditions such as humidity, pressure, and

temperature. Cartridges must be replaced in accordance with an established change schedule or earlier if

smell, taste or irritation from contaminants is detected.

8

Page 9

3M™ Filters (Side-Mounted), Adapters and Retainers

Note: Only 3M™ Filters approved under NIOSH 42 CFR 84 are to be used with the 3M™ 6000 Series Full

Facepieces.

Number Product Name

501 Filter Retainer for 5N11 and 5P71 Filters

502 Filter Adapter for 2000 Series and 7093 Filters

2071 P95 Particulate Filter

2076HF P95 Particulate Filter, hydrogen fluoride, with nuisance level acid gas relief

2078 P95 Particulate Filter, 3M recommended for ozone protection2, with nuisance level

organicvapor/acid gas relief

1

2091 P100 Particulate Filter

2096

2097

P100 Particulate Filter, with nuisance level acid gas relief

P100 Particulate Filter, 3M recommended for ozone protection2, with nuisance level organic

vapor relief

1

1

5N11 N95 Particulate Filter

5P71 P95 Particulate Filter

7093 P100 Particulate Filter

1. 3M recommended for relief against nuisance levels of acid gas or organic vapors. Nuisance level refers to

concentrations not exceeding OSHA PEL or applicable exposure limits, whichever is lower. Do not use

for respiratory protection against acid gas/organic vapors.

2. 3M recommended for ozone protection up to 10 times the OSHA PEL or applicable government

occupational exposure limits, whichever is lower (not NIOSH approved for use against ozone)

1

3M particulate filters should be changed when an increase in breathing resistance is noticed.

Filters must be replaced if they become damaged, soiled or if an increase in breathing resistance occurs.

N-series filters should not be used in environments containing oils. R-series filters may be limited to 8 hours

of continuous or intermittent use if oil aerosols are present. In environments containing only oil aerosols, Pseries filters should be replaced after 40 hours of use or 30 days, whichever is first.

9

Page 10

ASSEMBLY INSTRUCTIONS

All 3M™ 6000 Series Full Facepieces equipped with the 3M™ 6884 DIN Port Adapter (full facepiece

assemblies 6700DIN, 6800DIN and 6900DIN) can be used in any of the following configurations:

Powered Air Purifying Respirator (PAPR)

– 3M™ GVP Belt-Mounted PAPR

– 3M™ Powerflow™ Face-Mounted PAPR

– 3M™ Breathe Easy™ Belt-Mounted PAPR

Supplied Air Respirator (SAR)

– 3M™ Dual Airline

– 3M™ Air Control Devices – Continuous Flow (excluding W-3196 Air Regulating Kit and

stainless steel options)

Negative Pressure

– 3M™ Responder FR-64 Cartridge and CP3N Canister (Front-Mounted)

– 3M™ 2000 Series and 7093 Filters and 6000 Series Cartridges (Side-Mounted)

Whenever the air filtration/supply system, including responder canisters or cartridges, are attached to the

center DIN port of the 6884 DIN Port Adapter Assembly, the 3M™ 7890 Full Face Plug must be removed

from the center port and the two bayonet ports must be closed using 6880 bayonet caps and 6895 Inhalation

Port Gaskets.

Note: Make certain 3M™ 6895 Inhalation Port Gaskets are in place on the facepiece bayonet connectors

before installing filters, cartridges or breathing tubes.

3M™ 6000 Series Cartridge (Side-Mounted) Assembly

1. Align the cartridge notch with the small solid bayonet lug on facepiece and push together.

2. Turn cartridge clockwise to stop (1/4 turn). Repeat with second cartridge. (Fig. 1)

3. Check that a 6876 breathing tube gasket (gray) and 7890 plug have been installed in the center DIN port.

Fig. 1

10

Page 11

3M™ 2000 Series and 7093 Filter (Side Mounted) Assembly

1. Align opening of filter with filter attachment on facepiece.

2. Turn filter clockwise until it is firmly seated and cannot be further turned.

3. Repeat for second filter. (Fig. 2)

4. Check that a 6876 breathing tube gasket (gray) and 7890 plug has been installed in the center DIN port.

Fig. 2

Filter Assembly (for 3M™ 5N11 and 5P71 Filters)

1. Place filter into 3M™ 501 Retainer so printed side of filter faces the cartridge.

2. Press cartridge into filter retainer. It should snap securely into filter retainer. When correctly installed,

filter should completely cover face of cartridge. (Fig. 3)

3. To replace filter, remove retainer by lifting on TAB.

Fig. 3

11

Page 12

3M™ 502 Adapter Assembly

1. Align adapter over cartridge. Engage front snap by squeezing front of cartridge and adapter together,

placing thumbs of both hands over top of adapter and fingers along bottom sides of cartridge. (Fig. 4)

2. Engage back snap by squeezing back side of cartridge and adapter together using the same hand

positions. An audible click should be heard as each snap is engaged. (Fig. 5) The 3M 502 adapter

should not be removed or reused once engaged. It is not designed for reuse. Removal and reuse may

result in leakage.

Fig. 4 Fig. 5

3M™ 2000 Series and 7093 Filters/3M™ 502 Adapter Assembly

Place filter onto the filter holder so that filter comes into even contact with gasket. Twist clockwise a quarter

turn until it is firmly seated and filter cannot be turned further. Repeat for second filter.

Note: The 3M 502 adapter, once installed on a 3M 6000 Series Cartridge, is not to be removed or reused.

Removal and reuse may result in leakage.

3M™ Supplied Air Systems

3M™ Air Control Devices – Continuous Flow

User must follow User Instructions provided with approved Air Regulating Valve Assemblies.

3M™ Dual Airline Respirator Assembly

User must follow Dual Airline Supplied Air Respirators User Instructions provided with the 3M™ Dual

Airline Supplied Air Respirators.

Assembly of 3M™ Combination Dual Airline Respirator with Cartridges and Filters

The 3M™ SA-1600 (front-mounted) and SA-2600 (back-mounted) versions of the 3M dual airline breathing

tubes allow use of selected NIOSH approved 3M™ 6000 Series Cartridges and 2000 Series Filters. For the

listing of approved cartridges and filters, reference the NIOSH approval label included with 3M dual airline

adapter kits.

To assemble 3M™ Dual Airline Combination Breathing Tubes with 3M™ Cartridges/Filters, the facepiece

inhalation valves must be removed.

12

Page 13

If the facepiece is to be used in air purifying mode (without using the 3M SA-1600 or SA-2600 breathing

tubes), the inhalation valves must be replaced in the facepiece before use.

Using the 3M™ Combination Dual Airline Breathing Tubes without Cartridges and Filters

To use the 3M combination dual airline breathing tubes (SA-1600 and SA-2600) without cartridges or filters,

attach a 3M™ 6880 Bayonet Cap to each outer bayonet mount on the dual airline breathing tube. When used

as a straight, Type C, continuous flow supplied air respirator, the Assigned Protection Factor is 1000 times

the PEL or TLV guidelines for full facepiece respirators.

The 3M™ Dual Airline is NIOSH approved only with the 6894 nose cup assembly in place. Failure to do so

may result in sickness or death.

------------------------------------------------------------------------------------------------------------------------------------

3M™ Responder Cartridge and Canister Assembly

The 3M CP3N canister and FR-64 cartridge are NIOSH approved only with the 6894 nose cup assembly in

place. Failure to do so may result in sickness or death.

Overtightening may cause damage to the DIN Port Adapter housing and/or gasket and allow unfiltered air to

enter the facepiece, which may result in sickness or death.

Important information on proper use and use limitations is provided in the User Instructions with the CP3N

Canister and FR-64 Cartridge. The two bayonet ports on the lens must be closed using 6880 Bayonet Caps

and 6895 Inhalation Port Gaskets. Before installing the canister, check that the 6876 Breathing Tube Gasket

is in place and in good condition. Screw the responder canister/cartridge into the DIN Port Adapter and

tighten with moderate hand pressure (Fig. 6).

13

Page 14

3M™ GVP PAPR Assembly

Screw 3M™ GVP-123 breathing tube elbow adapter into the center port of the 6884 adapter assembly. User

must follow User Instructions provided with the GVP Belt-Mounted Powered Air Purifying Respirator

Assembly.

Fig. 6

3M™ Breathe Easy™ Turbo PAPR Assembly

Screw the threaded adapter on the 3M™ 520-01-77 Breathing Tube into the center port of the 6884 Din port

adapter assembly. User must follow User Instructions provided with the Breathe Easy™ Turbo PAPR

Assembly.

3M™ Powerflow™ PAPR Assembly

User must follow User Instructions provided with the Powerflow™ PAPR.

The Powerflow systems are not NIOSH approved for use with a nose cup. Use of a nose cup,

may result in sickness or death.

The connection between the Powerflow™ PAPR assembly and the 3M™ 6000DIN Full Facepiece must be

checked every time the unit is assembled or swiveled. This check should be performed outside the

contaminated environment. Entering the contaminated area while the connection between the PAPR

assembly and the facepiece is loose may result in sickness or death.

14

Page 15

FITTING INSTRUCTIONS

Must be followed each time respirator is worn.

Donning and User Seal Check

1. Fully loosen all four head straps, place facepiece on face and pull head harness to back of head (Fig. 7).

2. Pull the ends of the four straps to adjust tightness, starting with the neck straps first, then the forehead

straps. Do not overtighten the straps (Fig. 8).

3. Perform a positive and/or negative pressure user seal check each time the respirator is donned.

Fig. 7 Fig. 8 Fig. 9

Negative Pressure Seal Check

3M™ Powerflow™ PAPR and Responder Canister/Cartridge

1. Place palms of hands over the air inlet of the cartridge/canister.

2. Inhale gently. If you feel the facepiece collapse slightly and pull closer to your face with no leaks between

the face and facepiece, a proper seal has been obtained.

3. If faceseal air leakage is detected, reposition respirator on face and/or readjust tension of straps to

eliminate air leakage If you cannot achieve a proper seal, DO NOT enter the contaminated area. See

your supervisor.

3M™ GVP and Breathe Easy™ PAPRs

1. Place the palm of the hand over the breathing tube opening (Fig. 9).

2. Inhale gently. If you feel the facepiece collapse slightly and pull closer to your face with no leaks between

the face and facepiece, a proper seal has been obtained.

3. If faceseal air leakage is detected, reposition respirator on face and/or readjust tension of straps to

eliminate air leakage. If you cannot achieve a proper seal, DO NOT enter the contaminated area. See

your supervisor.

15

Page 16

Fig. 10 Fig. 11

3M™ 6000 Series Cartridges (Side-Mounted)

1. Place palms of hands to cover face of cartridge or open area of 3M™ 501 Filter Retainer and inhale

gently. If you feel facepiece collapse slightly and pull closer to your face with no leaks between the face

and facepiece, a proper seal has been obtained. (Fig. 10)

2. If faceseal air leakage is detected, reposition respirator on face and/or readjust tension of straps to

eliminate leakage. If you cannot achieve a proper seal, DO NOT enter the contaminated area. See your

supervisor.

Note: Use of 3M 501 filter retainer may aid respirator wearer in conducting a negative pressure seal check.

3M™ 2000 Series Filters (Side-Mounted)

1. Place your thumbs onto the center portion of the filters, restricting airflow through filters and inhale

gently. If you feel facepiece collapse slightly and pull closer to your face with no leaks between the face

and facepiece, a proper seal has been obtained. (Fig. 11)

2. If faceseal air leakage is detected, reposition respirator on face and/or readjust tension of straps to

eliminate the leakage. If you cannot achieve a proper seal, DO NOT enter the contaminated area. See

your supervisor.

3M™ Dual Airline

User must follow User Instructions for Dual Airline Supplied Air Respirators.

3M™ Air Control Devices – Continuous Flow

User must follow User Instructions provided with approved Air Regulating Valve Assemblies.

16

Page 17

Positive Pressure Seal Check

1. Remove breathing tube, Powerflow™ PAPR assembly or cartridge/canister from the center DIN port, as

applicable.

2. With the palm of your hand covering the exhalation valve cover and center DIN port, exhale gently. If

facepiece bulges slightly and no air leaks are detected between your face and the facepiece, a proper seal

has been obtained (Fig. 9).

3. If faceseal air leakage is detected, reposition respirator on face and/or readjust tension of straps to

eliminate air leakage If you cannot achieve a proper seal, DO NOT enter the contaminated area. See

your supervisor.

FIT TESTING

Note: Fit testing is a U.S. Occupational Safety and Health Administration (OSHA) and Canadian CSA Z94.4

standard requirement. Therefore, either quantitative or qualitative fit testing must be conducted prior to the

respirator being issued. (Quantitative Fit Testing [QNFT] can be conducted using a 3M™ 601 Fit Test

Adapter and 42 CFR 84 P100 filters such as the 3M™ 2091 or 7093 Particulate Filters.)

Qualitative Fit Testing (QLFT) with the 3M™ FT-10 or FT-30 Qualitative Fit Test Apparatus can be

conducted using any of the NIOSH approved 42 CFR 84 particulate filters. Use of Qualitative Fit Testing

may reduce the respirator’s Assigned Protection Factor (APF). Reference U.S. OSHA 29 CFR 1910.134.

Note: For further information concerning fit testing contact 3M OH&ESD Technical Service

INSPECTION, CLEANING, AND STORAGE

The 3M™ 6000 Series Respirator must be inspected before each use to ensure that it is in good operating

condition. The facepiece should be repaired or replaced upon observation of damaged or defective parts. The

following inspection procedure is suggested.

1. Check facepiece for cracks, tears and dirt. Be certain facepiece, especially faceseal area, is not distorted.

2. Examine inhalation valves for signs of distortion, cracking or tearing.

3. Make sure that head straps are intact and have good elasticity.

4. Examine all plastic parts for signs of cracking or fatiguing. Make sure filter gaskets are properly seated

and in good condition.

5. Remove exhalation valve cover and examine exhalation valve and valve seat for signs of dirt, distortion,

cracking or tearing. Replace exhalation valve cover.

6. Inspect lens for any damage that may impair respirator performance or vision.

17

Page 18

Cleaning and Storage

Cleaning is recommended after each use.

Do not clean with solvents. Cleaning with solvents may degrade some respirator components and reduce

respirator effectiveness. Inspect all respirator components before each use to ensure proper operating

condition. Failure to do so may result in sickness or death.

1. Remove cartridges, filters and/or breathing tubes. The center adapter, lens and faceseal can also be

removed if necessary.

2. Clean facepiece (excluding filters and cartridges), by immersing in warm cleaning solution, water

temperature not to exceed 120° F (49° C), and scrub with soft brush until clean. Add neutral detergent if

necessary. Do not use cleaners containing lanolin or other oils.

3. Disinfect facepiece by soaking in a solution of quaternary ammonia disinfectant or sodium hypochloride

(1 oz [30 ML] household bleach in 2 gallons [7.5 L] of water), or other disinfectant.

4. Rinse in fresh, warm water and air dry in noncontaminated atmosphere.

5. Respirator components should be inspected prior to each use. A respirator with any damaged or

deteriorated components should be repaired or discarded.

6. The cleaned respirator should be stored away from contaminated areas when not in use.

REPLACEMENT PART INSTRUCTIONS

3M™ Facepiece Assemblies for 6700DIN/6800DIN/6900DIN

The facepiece consists of the head harness assembly, nose cup assembly, center adapter assembly, lens

assembly, faceseal (small, medium or large), and frame assembly (top, bottom, nuts and screws).

To disassemble lens assembly from faceseal, remove the two Phillips screws from top frame. Then, pull the

frame top and frame bottom away from the faceseal. The frame top, frame bottom, faceseal and the lens

assembly have vertical line markings that indicate their positions relative to one another. Make certain these

markings are aligned for reassembly.

3M™ 6884 DIN Port Adapter Assembly Replacement

The DIN port adapter (center adapter) assembly consists of a 3M™ 6883 Din Port Base, 6882 DIN Cover,

6881 DIN Air Director, 6889 Exhalation Valve, 6876 Breathing Tube Gasket and 6896 Center Adapter

Gasket. It is secured to the center of the lens with a bayonet-style twist lock connection which compresses the

6896 center adapter gasket. The 6884 DIN port adapter assembly is locked in position by the 6881 DIN air

director.

To remove the center adapter from the facepiece

1. Remove nose cup assembly (except in 3M™ Powerflow™ Systems) by pulling away from center adapter

inside facepiece (Fig. 12).

2. Squeeze the locking tab at the back of the 6881 air director and pull back to disengage from the 6883 DIN

port base (Fig. 13).

18

Page 19

3. Grasp center adapter at cover and twist counter-clockwise 1/4 turn to disengage bayonet from facepiece

lens.

4. Withdraw center adapter from lens center port.

Fig. 12 Fig. 14

Fig. 13 Figure 15

To install the center adapter into the facepiece

1. Remove the 6881 DIN air director from the 6883 DIN base.

2. Align tabs on center adapter base with notches in center port of facepiece lens.

3. Slide adapter into lens port (Fig. 14).

4. Grasp center adapter at cover and twist clockwise 1/4 turn to stop. Be certain center adapter gasket is

properly in place and sealed, and that the adapter assembly is fully engaged.

5. Align the lug at the bottom of the 6881 air director with the slot at the bottom of the 6883 DIN port base

(Fig. 13). Slide forward and press the center knob until the locking tab clicks into place.

6. Replace nose cup assembly, where applicable. Refer to the table in 3M™ Nose Cup Assembly

Replacement section in these instructions.

7. Attach the 3M™ 6880 Bayonet Caps to side inlet ports on the facepiece if using in one of the following 3M

configurations: belt-mounted or face-mounted PAPR systems, or the responder cartridge or canister in

the negative pressure mode.

19

Page 20

3M™ 6894 Nose Cup Assembly Replacement

The 6894 nose cup assembly consists of a nose cup and inhalation valves. It is designed to install onto the

center adapter and comfortably fit over the respirator wearer’s mouth and nose to aid in purging exhaled

breath and prevent lens fogging.

1. Remove the nose cup assembly by pulling away from center adapter inside facepiece (Fig. 12).

2. To replace, position nose cup assembly onto center adapter aligning arrows (Fig. 15).

Nose Cup Requirements

Use of the 3M™ 6894 Nose Cup Assembly with the 3M™ 6000DIN Series Full Facepiece must be in

accordance with the following table.

Nose Cup Use Requirements for 3M™ 6000DIN Series Full Facepiece

3M™ Respirator

System

Belt-Mounted

PAPRs

Powerflow™ FaceMounted PAPR

Supplied Air

6000 Series

Cartridges

2000 Series Filters

CP3N Canister

FR-64 Cartridge

Dual Airline

NIOSH Approved Only

With Nose Cup

NIOSH Approved Only

Without Nose Cup

NIOSH Approved With

or Without Nose Cup

! WARNING

Failure to use or not use the 3M 6894 nose cup in accordance with the above requirements may adversely

affect respirator performance and result in sickness or death.

20

Page 21

3M™ 6896 Center Adapter Gasket Replacement

The 3M™ 6896 Center Adapter Gasket is designed to seal the interface between the center adapter and the

lens of the 6000 Series Full Facepiece.

1. Remove nose cup assembly and center adapter assembly as described in previous DIN Port Adapter and

Nose Cup Replacement sections.

2. Remove old 6896 gasket from center adapter and replace with new 6896 gasket.

3. Re-install center adapter and nose cup into facepiece..

3M™ 6893 Inhalation Valve Replacement

Inhalation valves are located on posts at the inside of the facepiece inhalation ports and inside the nose cup

inhalation ports. These valves should be inspected before each respirator use and replaced whenever valves

become damaged or lost.

1. Remove existing valve(s) by lifting from post(s).

2. Install new valve(s) onto post(s). Be certain valve(s) is fully engaged under all three lugs on post(s), lays

flat, and moves freely (spins) on post (Fig. 18).

3M™ 6889 Exhalation Valve Replacement

1. Remove center adapter cover by pulling out from bottom latch.

2. Grasp valve and pull valve stem out from valve seat.

3. Inspect valve seat making certain it is clean and in good condition.

4. Place new 6889 over the exhalation port and push or press valve stem into center hole. Be certain the

valve is fully seated and spins freely in mount (Fig. 16).

5. Replace adapter cover by engaging top and bottom snaps (latches).

Note: Conduct a negative pressure user seal check to ensure exhalation valve is functioning properly.

3M™ 6895 Inhalation Port Gasket Replacement

The 6895 gasket is designed to seal the interface between the bayonet attachment inhalation ports on the

facepiece and filters/cartridges, or dual airline breathing tubes installed on the facepieces. The gaskets should

be inspected with each filter/cartridge change and replaced whenever damaged or seal integrity is questionable.

1. Remove gaskets from facepiece inhalation port bayonet fittings.

2. Install new gaskets onto facepiece inhalation port bayonet fittings. Be certain gaskets are in proper

position under all three bayonet lugs (Fig. 17).

Figure 16 Figure 17 Figure 18

21

Page 22

3M™ 6897 Head Harness Replacement

The 6897 head harness assembly consists of the head harness and buckles for the 3M 6000 series full

facepiece. To replace the head harness assembly:

1. Remove existing harness by pulling attachment buttons out of holes in faceseal tabs.

2. Attach new harness by pressing attachment buttons into holes in faceseal tabs with twisting motion. Be

certain buttons are fully seated. Head harness should be assembled with 2 short straps to top of

respirator and 3M and 6897 marking on harness facing away from respirator (Fig. 19).

3M™ 6898 Lens Assembly

The 6898 lens assembly consists of a hard-coated polycarbonate lens with installed bayonet attachment

inhalation port fittings, inhalation valves, and inhalation port filter/cartridge gaskets. The 6898 lens is

replaceable by following these steps:

1. Remove nose cup assembly and center adapter assembly as described in previous DIN port adapter and

nose cup replacement sections.

2. Remove the (2) Phillips screws from the lens/faceseal frame. Pull the frame top and frame bottom away

from faceseal.

3. Remove faceseal from lens.

4. Place new lens and faceseal together aligning marks at top and bottom. Position top and bottom frame,

again aligning marks top and bottom (Fig. 20). Install and securely tighten screws. Make certain

alignment marks are properly aligned top and bottom with all components.

5. Install center adapter assembly.

6. Replace nose cup assembly.

3M™ 6899 Frame Kit

The 6899 frame kit includes a frame top, frame bottom, (2) Phillips head screws and (2) hex head nuts. The

frame kit secures and seals the 3M 6000 series full facepiece faceseal to the 3M 6898 lens assembly.

1. After assembling the faceseal onto the lens, matching top and bottom alignment marks, position top

frame, over lens and faceseal, aligning center vertical marks, then press in place.

2. Position bottom frame, aligning center vertical mark, and press in place (Fig. 20).

3. Insert and tighten Phillips head screws. Make certain parts are properly aligned and sealed together.

Fig. 19 Fig. 20

22

Page 23

FOR MORE INFORMATION and assistance on 3M occupational health and environmental safety

fax: (858) 488-6320 tel: (858)488-3300 sales@NBCsafety.com

World Leaders in Defense Technology

NBC Safety

products, contact your local 3M representative

U.S. PATENTS 5,924,420

Des. 378,610

Des. 379,160

Des. 388,872

Des. 409,744

Des. 421,116

Des. 421,118

Des. 433,751

Des. 434,847

Exported by/

3M Occupational Health and

Environmental Safety Division

©3M 2001 38-9017-2485-6

Printed in U.S.A.

Loading...

Loading...