Page 1

3M™Bonding Film 583

Product Description

3M™ Bonding Film 583 is a high strength, flexible, nitrile phenolic based thermoplastic bonding film. It can be heat or

solvent activated for bonding. 3M™ Bonding Film 583 can also be lightly crosslinked using a post heat exposure. This

crosslinking will provide additional heat and solvent resistance as well as somewhat higher shear strengths.

3M™ Bonding Film 583 must be stored at or below 40°F (4°C) for maximum storage life.

3

Typical Physical Properties

Note: The following technical information and data should be considered representative or typical only and should not be

used for specification purposes.

Technical Data September, 2008

Base Resin

Nitrile phenolic

Adhesive Thickness

2 mil (0.05 mm)

Tack

Slight

Color

Brown

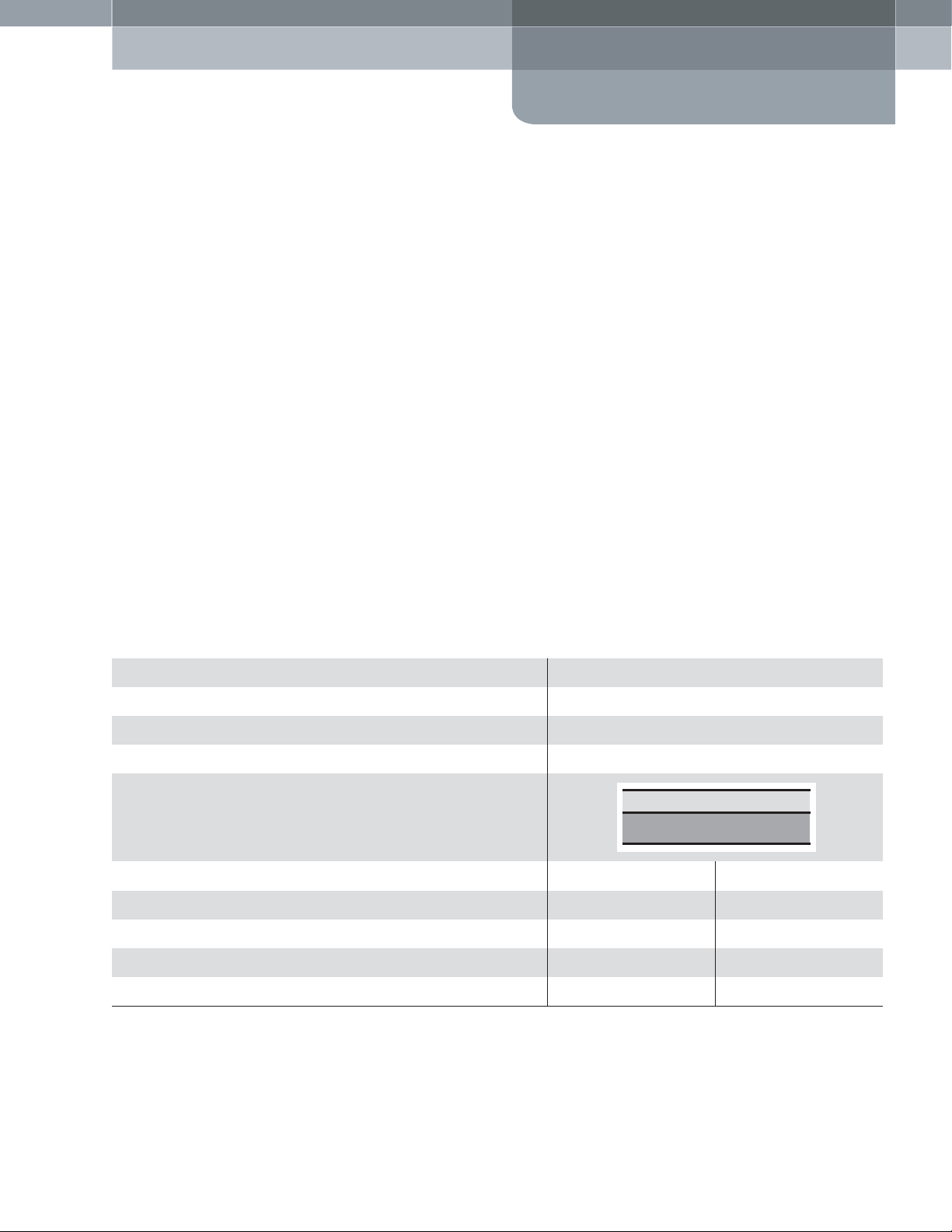

Construction

Before Crosslinking After Crosslinking

Tensile (psi) 400 3,140

Elongation (%) 800 180

Modulus (psi) 240 13,800

2 Lb. Dead Load Overlap Shear Heat Resistance 160°F (71°C) >300°F (149°C)

Key Features

• Flexible • Slight surface tack

• Heat or solvent activation • Heat crosslinkable option

• Can be die-cut

• Tensile and elongation conducted on Sintech 5/GL at 0.2"/minute speed. ASTM D638.

• 2 lb. dead load overlap shear conducted in oven environment (reference ASTM D4502-85).

2 mil adhesive

3 mil silicone paper liner

Page 2

3M™Bonding Film 583

Directions For Use – Heat Activation

To make a bond, remove the liner and place the adhesive film between the two substrates. The bond is then made through

heat and pressure using a heated press, a hot roll laminator, a hot shoe thermode method or similar equipment.

Alternatively, the adhesive can be first tacked (lightly bonded) to one of the substrates using low heat, the liner can then be

removed and second substrate placed to the exposed adhesive surface, and a bond made using heat and pressure. Since

3M™ Bonding Film 583 has a slight surface tack, in some cases it may be tacked to a substrate with pressure only (no

Suggested TACKING Conditions

100°F to 120°F (38°C to 49°C) bondline temperature

2-5 seconds dwell time

5-20 psi pressure

Suggested BEGINNING Bonding Conditions

225°F to 300°F (107°C to 149°C) bondline temperature

2-5 seconds dwell time

15-20 psi pressure

Application Equipment Suggestions

Note: Appropriate application equipment can enhance bonding film performance. We suggest the following equipment for

the user’s evaluation in light of the user’s particular purpose and method of application.

The type of application equipment used to bond 3M™ Bonding Film 583 will depend on the application involved and on

the type of equipment available to the user. Thin films and flexible substrates can be bonded using a heated roll laminator

where heat and pressure can be varied to suit the application. Larger, thicker substrates can be bonded using a heated static

press or, in some cases, an autoclave. For applications where a shaped adhesive is to be transferred to a flat or three-

dimensional part, a hot shoe or thermode method may be appropriate.

It is recommended that whatever method of bonding is chosen by the user, the optimum bonding conditions should

be predetermined with substrates specific to user’s application.

For optimum bonding, the heat, pressure and dwell time for using 3M™ Bonding Film 583 will depend upon the type and

thickness of the substrates being bonded together.

A suggested starting point, however, is to use the bonding conditions described below.

(2)

Page 3

3M™Bonding Film 583

Directions For Use – Heat Activation

(continued)

One approach to establishing the correct/optimum bonding conditions for a user’s application is to evaluate a series of

bonding temperatures, for example 200, 225, 250, 275 and 300°F (93, 107, 121, 135 and 149°C). Time and pressure will be

dictated by the thickness of the substrate and the type of substrate being bonded. Thicker substrates and surfaces that may

be more difficult to bond will require longer times, higher pressures and higher temperatures. If voids are experienced in

the bondline, they can be minimized by increasing pressure.

Once the bond is made, the bondline should be allowed to cool somewhat before stress is applied to the bond. Generally,

cooling the bondline below 150°F (66°C) is adequate to allow the bonded parts to be unfixtured/unclamped and handled.

For reference, the following table shows typical bond strengths for bonds made at various temperatures. Such data can be

used to evaluate optimum bondline temperatures. It is important to note that this table is valid only for the specific

substrates shown. Varying temperature, pressure, or substrates can affect bond strengths. User should develop a similar

table with substrates specific to user’s application.

Note: Temperatures shown are bondline temperatures and not heat block or roll settings!

90° Peel Strengths of Bonds made at Various Temperatures

(2 and 20 sec. Dwell at Bondline Temperature) using 3M™ Bonding Film 583

Bondline FR-4 / Aluminum CRS / Aluminum

Temperature 2 sec. 20 sec. 2 sec. 20 sec.

75°F (24°C) 9 piw 9 piw 5 piw 6 piw

95°F (35°C) 9 piw 9 piw 6 piw 6 piw

115°F (46°C) 9 piw 9 piw 6 piw 6 piw

135°F (57°C) 10 piw 10 piw 6 piw 7 piw

155°F (68°C) 11 piw 11 piw 7 piw 9 piw

175°F (79°C) 12 piw 13 piw 8 piw 10 piw

195°F (90°C) 13 piw 14 piw 9 piw 12 piw

215°F (101°C) 14 piw 14 piw 11 piw 14 piw

235°F (113°C) 14 piw 13 piw 12 piw 13 piw

255°F (124°C) 12 piw 12 piw 13 piw 13 piw

275°F (135°C) 12 piw 12 piw 12 piw 12 piw

295°F (146°C) 12 piw 11 piw 12 piw 12 piw

315°F (157°C) 11 piw 11 piw 11 piw 12 piw

335°F (168°C) 11 piw 11 piw 10 piw 11 piw

355°F (179°C) 11 piw 10 piw 6 piw 9 piw

(3)

• Peel values given in piw (pounds per inch width). ASTM D1876.

• Peel bonds were 1/2" wide using 4 mil etched aluminum bonded to either FR-4 printed circuit board substrate (alcohol wiped) or cold rolled steel

(MEK wiped).* Bonds made on Sencorp device using 20 lbs. pressure.

*Note: When using solvents, extinguish all ignition sources and follow the manufacturer’s precautions and directions for use.

Page 4

3M™Bonding Film 583

Directions For Use – Solvent Activation

There are advantages and disadvantages with heat and solvent activation. Under normal conditions, heat activation is the

suggested method of bonding and will provide the greatest immediate adhesion strength. However, solvents such as MEK,

toluene and/or acetone can also be used to activate bonding if user is working with substrates that are heat-sensitive or have

irregular surface or shape.*

The solvent may be applied to the film by brushing, wiping, spraying or dipping. It is important that the solvent be allowed

sufficient activating time to solvate the adhesive and bring it to a tacky, pressure sensitive state (typically 10-30 seconds).

Adhesive legs should appear during touch-testing before substrate is bonded. Bonding should occur before tackiness

disappears. If film is too wet, substrate may slip from bonding position; if too dry, a good bond may not develop.

When a solvent activation method is used, maximum adhesion strength will not be achieved immediately because it will be

related to the drying time of solvent from the adhesive. If the bond undergoes natural drying in ambient temperatures, bond

build-up may continue for 30 days until maximum adhesion is achieved. If the bond is exposed to constant low heat

(~150°F/66°C) after initial solvent activation, maximum adhesion can often be reached within 24-30 hours.

*Note: When using solvents, extinguish all ignition sources and follow the manufacturer’s precautions and directions for use.

Directions For Use – Crosslinking

3M™ Bonding Film 583 may also be slightly crosslinked to enhance adhesion performance. Crosslinking of this film can

typically be achieved by heating the bondline at 350°F (177°C) for five minutes.

Note: All reported data has not undergone crosslinking unless otherwise stated.

(4)

Page 5

3M™Bonding Film 583

(5)

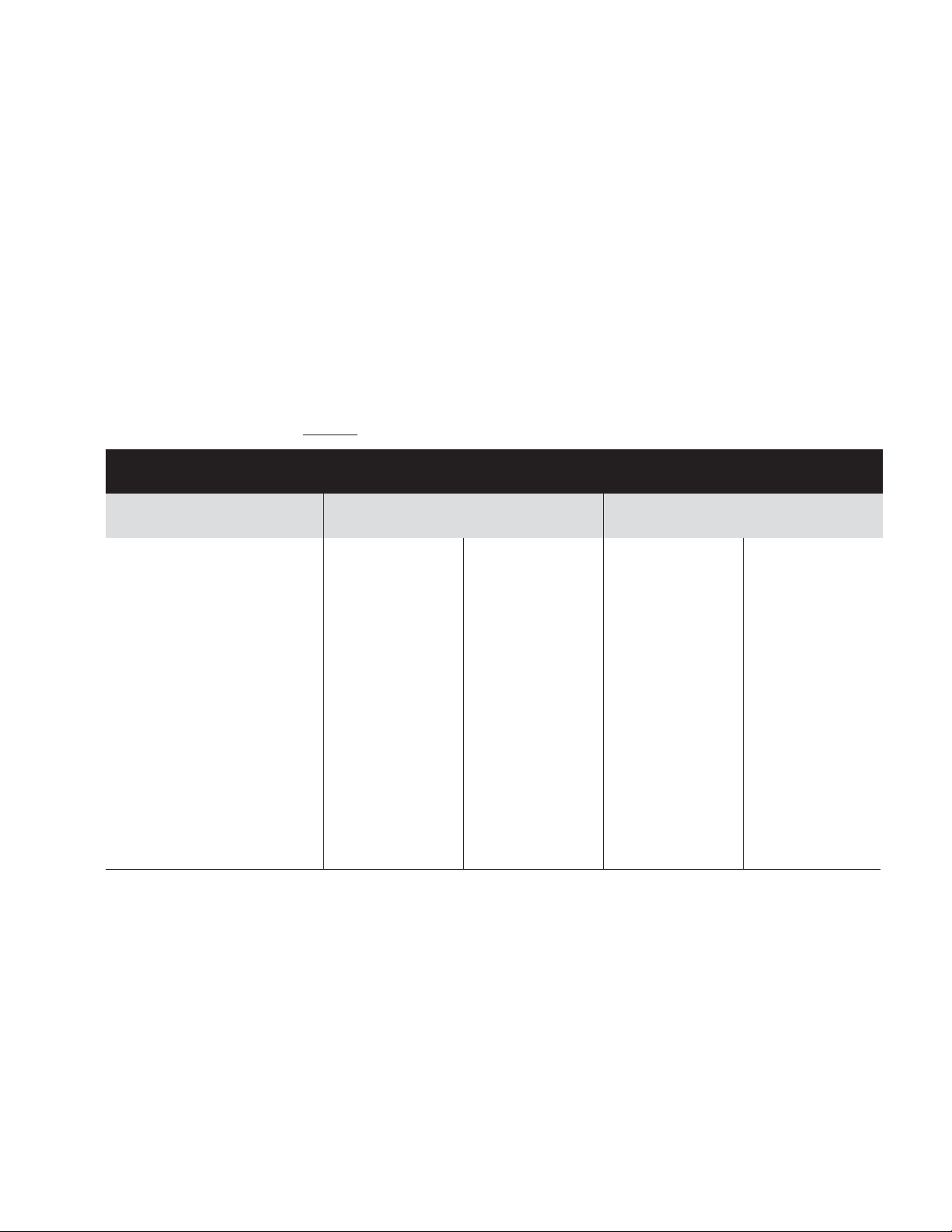

Adhesion to Various Substrates Using 3M™ Bonding Film 583

Test Substrate Overlap Shear (OLS) 90° Peel

Aluminum (solvent wiped) 580 psi 10 piw

Aluminum

(etched) 630 psi 10 piw

Aluminum

(sanded, solvent wiped) 640 psi 10 piw

Aluminum

(scour pad abraded, solvent wiped) 660 psi 10 piw

FR-4

(printed circuit board substrate) 600 psi 11 piw

Phenolic Board 500 psi 9 piw

Cold Rolled Steel 750 psi 11 piw

Stainless Steel NT 10 piw

ABS

(acrylonitrile-butadiene-styrene) NT 10 piw

Ultem 1000

(polyetherimide) NT 10 piw

Soda Lime Glass NT 9 piw

PVC

(polyvinyl chloride) NT 10 piw

Acrylic NT 10 piw

Polypropylene NT <1 piw

HDPE

(high density polyethylene) NT <1 piw

HIPS

(high intensity polystyrene) NT 9 piw

EPDM

(ethylene-propylene-diene monomer rubber) NT <1 piw

Neoprene

(Shore A60) NT 6 piw

Nitrile

(Shore A60) NT 7 piw

SBR

(styrene butadiene resin) NT 16 piw

Kapton 200E

(polyimide film) NT 5 piw

PET

(polyester film) NT 3 piw

PEN

(polyethylene naphthalate film) NT 2 piw

Denim Fabric NT 8 piw

Typical Performance Characteristics

Note: The following technical information and data should be considered representative or typical only and should not be

used for specification purposes.

• “NT” represents “Not Tested”.

• OLS values given in psi (pounds per square inch). ASTM D1002. Peel values given in piw (pounds per inch width). ASTM D1876.

• OLS bonds were 1" x 1" using 20 mil etched aluminum bonded to each test substrate. Sintech 5/GL shear rate was 0.2"/minute.

• Peel bonds were 1/2" wide using 4 mil etched aluminum bonded to each test substrate. Sintech 5/GL peel rate was 2"/minute.

• Solvent wiped (MEK or alcohol)*; 3M™ Scotch-Brite™ Scour Pad (green) abraded; sanded (500 grit sandpaper).

• Samples were bonded on Sencorp device for 5 seconds dwell (+10 seconds ramp time) at 315°F (157°C), 20 pounds pressure.

*Note: When using solvents, extinguish all ignition sources and follow the manufacturer’s precautions and directions for use.

Page 6

3M™Bonding Film 583

(6)

Typical Performance Characteristics (continued)

Note: The following technical information and data should be considered representative or typical only and should not be

used for specification purposes.

Adhesion Strength after Environmental Aging using 3M™ Bonding Film 583

Overlap Shear 90° Peel

Aging Pameters FR-4 / FR-4 FR-4 / Aluminum

30 days at room temperature (control) 810 psi 12 piw

30 days at 160°F (71°C) oven 780 psi 8 piw

30 days at 120°F (49°C) oven/100% RH 730 psi 13 piw

30 days immersion in distilled water 770 psi 10 piw

• OLS values given in psi (pounds per square inch). ASTM D1002. Peel values given in piw (pounds per inch width). ASTM D1876.

• OLS bonds were 1" x 1" using FR-4 printed circuit board substrate bonded to FR-4 (alcohol wiped).* Sintech 5/GL shear rate was 0.2"/minute.

• OLS samples were oven bonded at 315°F (157°C) for 30 minutes. Sample was clamped between 63 mil aluminum using two #50 binder clips during

bonding process.

• Peel bonds were 1/2" wide using 4 mil etched aluminum bonded to FR-4 (alcohol wiped). Sintech 5/GL peel rate was 2"/minute.

• Peel samples were bonded on Sencorp device for 5 seconds dwell (+10 seconds ramp time) at 315°F (157°C), 15 pounds pressure.

*Note: When using solvents, extinguish all ignition sources and follow the manufacturer’s precautions and directions for use.

Adhesion Strength TESTED at Various Temperatures using 3M™ Bonding Film 583

OVERLAP SHEAR

FR-4 / Aluminum CRS / Aluminum

Test Temperature No X-link X-linked No X-link X-linke d

-67°F (-55°C) 600 psi 380 psi 740 psi 670 psi

75°F (24°C) 650 psi 860 psi 680 psi 950 psi

250°F (121°C) 40 psi 270 psi 7 psi 170 psi

90 DEGREE PEEL

FR-4 / Aluminum CRS / Aluminum

Test Temperature No X-link X-linked No X-link X-linke d

-67°F (-55°C) 2 psi 1 psi 2 psi 2 psi

75°F (24°C) 11 psi 9 psi 11 psi 10 psi

250°F (121°C) 4 psi 5 psi 2 psi 6 psi

• OLS values given in psi (pounds per square inch). ASTM D1002. Peel values given in piw (pounds per inch width). ASTM D1876.

• OLS bonds were 1" x 1" using either FR-4 printed circuit board (alcohol wiped) or cold rolled steel (MEK wiped)* bonded to 20 mil etched aluminum.

Sintech 5/GL shear rate was 0.2"/minute.

• Peel bonds were 1/2" wide using either FR-4 printed circuit board (alcohol wiped) or cold rolled steel (MEK wiped) bonded to 4 mil etched aluminum.

Sintech 5/GL peel rate was 2"/minute.

• Samples not crosslinked (“no x-link”) were bonded on Sencorp device for 5 seconds dwell (+10-15 seconds ramp time) at 300°F (149°C), 20 pounds

pressure.

• Crosslinked (

“x-linked”) samples underwent Sencorp bond previously stated, plus oven bond at 350°F (177°C) (8 minutes ramp time and 5 minutes

dwell at temperature). Sample was clamped between 63 mil aluminum using two #50 binder clips during bonding process

.

*Note: When using solvents, extinguish all ignition sources and follow the manufacturer’s precautions and directions for use.

Page 7

(7)

3M™Bonding Film 583

Test Method Before X-Link After X-Link

Dielectric Constant @ 1kHz ASTM D-150 3.1 5.7

Dissipation Factor @ 1 kHz ASTM D-150 .064 .037

Dielectric Breakdown Strength (volts/mil) ASTM D-149 3000 (on 1.5 mil) 990 (on 8 mil)

Surface Resistivity (ohms/sq.) ASTM D-257 3.14 x 10

10

3.43 x 10

10

Volume Resistivity (ohms-cm.) ASTM D-257 1.44 x 10

12

2.13 x 10

13

Electrical Data

Test Method Before X-Link After X-Link

Weight Loss by TGA Perkin-Elmer Series 7 1% wt. loss 159°C 260°C

(Thermogravimetric analysis)

RT to 600°C, 10°C/min. 5% wt. loss 274°C 318°C

in air 10% wt. loss 352°C 371°C

Coefficient of Thermal Perkin-Elmer Series 7 Below Tg CTE/°C 280 x 10

-6

—

Expansion

by TMA

-40°C to 125°C @ 10°C/min. Above Tg CTE/°C 740 x 10

-6

380 x 10

-6

(Thermomechanical analysis)

(2 heat cycles, 2nd cycle reported)

Tg (extrapolated onset) Perkin-Elmer Series 7 4°C 20°C

-40°C to 125°C @ 10°C/min.

Thermal Data

Storage and Shelf Life

Storage: Store product at or below 40°F (4°C) for maximum storage life. Higher temperatures reduce normal storage life.

Shelf Life: Shelf life is 6 months from date of shipment at 75°F (23°C) and 18 months from date of shipment at 40°F (4°C).

Page 8

(8)

3M™Bonding Film 583

3M and Scotch-Brite are trademarks

of 3M Company.

Please recycle. Printed in U.S.A.

©3M 2008. All rights reserved.

78-9236-7069-5

3

Electronics Markets Materials Division

3M Electronics

3M Center, Building 21-1W-10, 900 Bush Avenue

St. Paul, MN 55144-1000

1-800-251-8634 phone

651-778-4244 fax

www.3M.com/electronics

3

For Additional Information

To request additional product information or to arrange for sales assistance, call toll free 1-800-251-8634. Address

correspondence to: 3M Electronics Markets Materials Division, Building 21-1W-10, 900 Bush Avenue, St. Paul, MN

55144-1000. Our fax number is 651-778-4244 or 1-877-369-2923. In Canada, phone: 1-800-364-3577. In Puerto Rico,

phone: 1-787-750-3000. In Mexico, phone: 52-70-04-00.

Important Notice

All statements, technical information, and recommendations related to 3M’s products are based on information believed to

be reliable, but the accuracy or completeness is not guaranteed. Before using this product, you must evaluate it and

determine if it is suitable for your intended application. You assume all risks and liability associated with such use.

Any statements related to the product which are not contained in 3M’s current publications, or any contrary statements

contained on your purchase order shall have no force or effect unless expressly agreed upon, in writing, by an authorized

officer of 3M.

Warranty; Limited Remedy; Limited Liability.

This product will be free from defects in material and manufacture at the time of purchase. 3M MAKES NO OTHER

WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. If this product is defective within the warranty period stated above,

your exclusive remedy shall be, at 3M’s option, to replace or repair the 3M product or refund the purchase price of the 3M

product. Except where prohibited by law, 3M will not be liable for any indirect, special, incidental or consequential

loss or damage arising from this 3M product, regardless of the legal theory asserted.

Certification/Recognition

MSDS: 3M has not prepared a MSDS for this product which is not subject to the MSDS requirements of the Occupational

Safety and Health Administration’s Hazard Communication Standard, 29 C.F.R. 1910.1200(b)(6)(v). When used under

reasonable conditions or in accordance with the 3M directions for use, the product should not present a health and safety

hazard. However, use or processing of the product in a manner not in accordance with the directions for use may affect its

performance and present potential health and safety hazards.

TSCA: This product is defined as an article under the Toxic Substances Control Act and therefore, it is exempt from

inventory listing requirements.

RoHS: This product complies with the requirements of EU Directive 2002/95/EC and 2005/618/EC.

Loading...

Loading...