Page 1

3

Water Contact Indicator Tape

5557

Product Description

3M™ Water Contact Indicator Tape 5557 is a 10.2 mil thick printable, self-adhesive

product that shows area specific, long lasting indication when contacted by water.

When liquid comes in contact with the product, the color RAPIDLY changes

from white to red. This product is designed to withstand heat and humidity aging

without giving water indication and it will continue to show indication even after

prolonged submersion in water. The construction is readily die cuttable, making

small custom shapes easy to produce. The adhesive is a high performance acrylic

protected by a silicone coated film release liner.

Technical Data December, 2004

Product Construction

Backing T op Film Adhesive Color Standard Roll Length

Paper Polyester Acrylic White 12 in. x 180 yd.

Typical Physical

Properties

ASTM Test Method

Adhesion to Stainless Steel: 82 oz./in. width (88 N/100 mm) D-3330

(90° Peel Adhesion, 12 in./min.

peel rate, 72 hr. Dw ell)

Adhesion to Polycarbonate: 47 oz./in. width (52 N/100 mm) D-3330

(90° Peel Adhesion, 12 in./min.

peel rate, 72 hr. Dw ell)

Tape Thickness: 10.2 mils (0.259 mm) D-3652

Release Liner Thickness: 2.0 mils (0.051 mm) D-3652

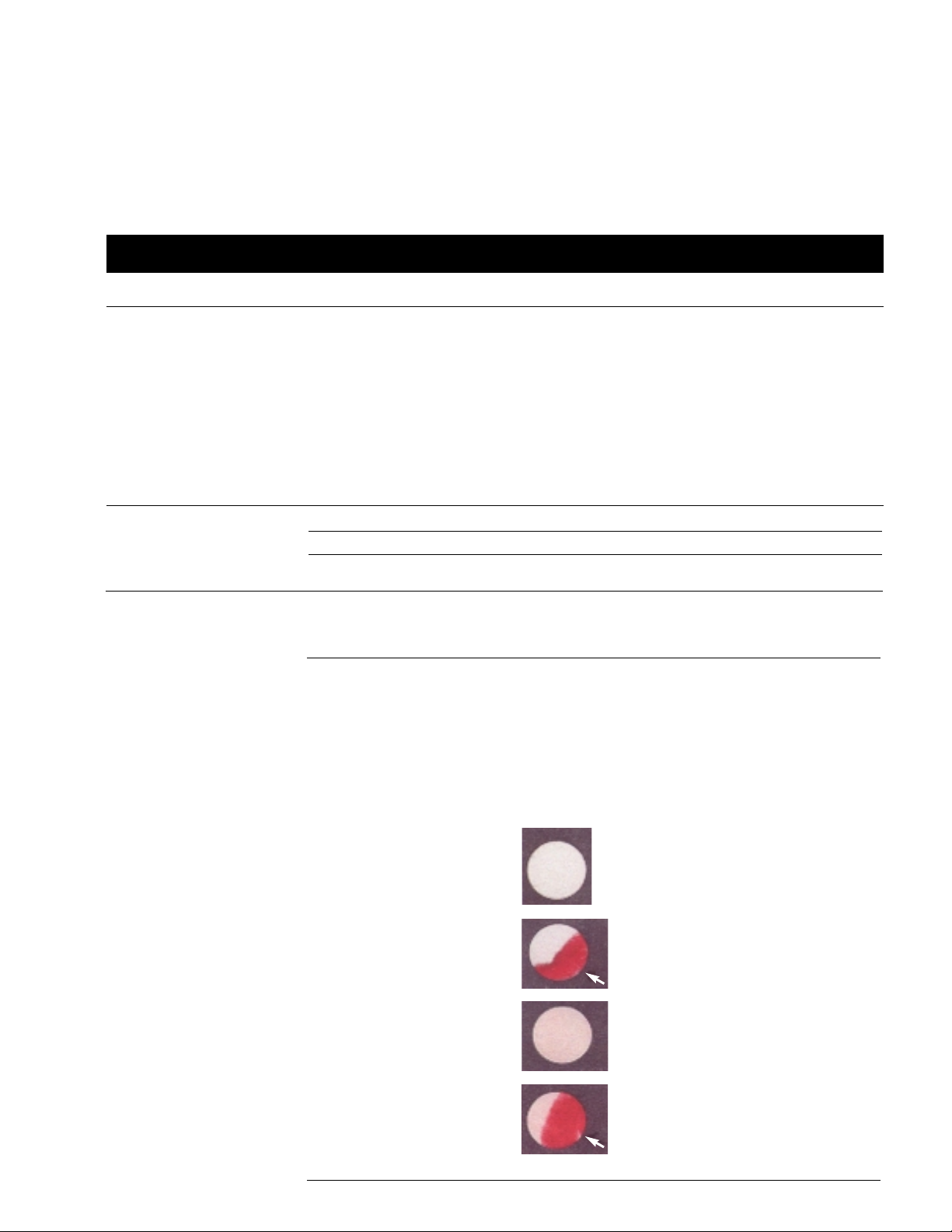

Humidity Resistance:*

Control, t = 0 days

Control, t = 0 days

Indicator w/1 drop H

2

O for

one minute at arrow .

7 days @ 55°C, 95%R.H.

7 days @ 55°C, 95%R.H.

indicated w/1 drop H

2

O for

one minute at arrow .

*Tape is applied to polycarbonate panel and hung vertically in heat/humidity chamber.

Note: The following technical information and data is based on limited 3M testing

conditions and should not be used for specification purposes.

Page 2

3M™Water Contact Indicator Tape

5557

- 2 -

• Tape may be die cut using rotary die cutting process.

• Substrate should be smooth, clean, dry and oil-free to insure good wet-out and

adequate adhesion.

• Adhesive should not be applied at temperatures < 50°F (10°C) [best if room

temperature or higher].

• Maximum roll length depends upon width.

• Maximum roll width = 12 in. (304.8 mm)

• Temperature resistance is -40°C to 65°C for days or weeks and up to 121°C for

minutes or hours.

General

• Use as a water contact indicator in handheld or portable electronic devices such

as cell phones, PDA’s, pagers, MP3 players, game players, CD players, cordless

phones, two-way radios, laptops, digital or film cameras, video cameras, etc.

• Other applications where positive indication of water or aqueous solution contact

is desired.

Application Ideas

Features

Features

Film top layer

Paper backing

Acrylic adhesive

2.0 mil film liner

Benefits

Printable by thermal transfer, flexographic, and screen

printing methods. Can be used for identification.

Top coated film for improved ink receptivity.

Provides protection from soiling and moisture during

handling. Indication remains after prolonged immersion.

Highly absorbent, quickly transports water to show

indications.

Does not falsely indicate water contact in high humidity

environments.

Performance not degraded by past high humidity

exposures.

Rotary die cuttable. Can readily form a variety of labels.

Excellent UV, chemical, temperature resistance.

Very high bond strength to most surfaces including lo w

surface energy plastics such as polypropylene and po wder

coatings.

Excellent die cuttability .

Page 3

- 3 -

3M™Water Contact Indicator Tape

5557

Storage

Store under normal conditions of 60° to 80°F (16° to 27°C) and 40 to 60% R.H. in

the original carton.

Shelf Life

To obtain best performance, use this product within 18 months from date of

manufacture.

Underwriters

Laboratories Inc.

3M™ Water Contact Indicator Tape 5557 material is Recognized by Underwriters

Laboratories Inc. Representative samples of this component have been evaluated by

UL and meet applicable UL requirements.

The UL recognition information per UL-969 “Marking and Labeling Systems” and

file MH-16411 can be verified on-line at the Underwriters Laboratories Inc. Web

Site. To view the verification information follow the path below:

“www.ul.com”

“Certifications”

“Keyword Search”

“5557”

3M Company comes up on the top of the search list

“Link to File”

“PGJ12.MH16411”

For 5557 per UL-969 the following entries apply:

“3M Brand 5557” unprinted label stock and printer/ink combination 6.”

Affixed to porcelain, aluminum, stainless steel, polyurethane powder paint,

smooth acrylic powder paint, epoxy powder paint (smooth and textured),

polyester powder paint (smooth and textured), alkyd paint, galvanized steel,

nylon, polypropylene, polyphenylene oxide, polycarbonate, high density

polyethylene (HDPE), acrylonitrile butadiene styrene (ABS) and high impact

polystyrene, maximum temperature 60°C (140°F), minimum temperature

-20°C (-4°F); polystyrene and low density polyethylene (LDPE), maximum

temperature 40°C (104°F), minimum temperature -20°C (-4°F). Suitable where

exposed to indoor dry location use.

3M Brand 5557 unprinted label stock and printer/ink combination 6.

“6) Armor “AXR-7”, “AXR-7+”, Dasco “DR-74”, “DR-84”, Great Ribbon “SDR”,

Iimak “SP-330”, Intermec “053258-2”, “054048-4”, NCR “Matrix Resin”,

“PaceSetter”, “Ultra V”, Ricoh “B110C”, “B110CX”, Sato “Premier 1”, Sony

“4070”, “Signature Series™ Resin”, UBI “HR03”, “HR04” thermal transfer ink

with thermal transfer printing equipment.”

Page 4

3M™Water Contact Indicator Tape

5557

All statements, technical information and recommendations contained in this document are based upon

tests or experience that 3M believes are reliable. However, many factors beyond 3M’s control can affect

the use and performance of a 3M product in a particular application, including the conditions under

which the product is used and the time and environmental conditions in which the product is expected to

perform. Since these factors are uniquely within the user’s knowledge and control, it is essential that the

user evaluate the 3M product to determine whether it is fit for a particular purpose and suitable for the

user’s method of application.

Product Use

Unless stated otherwise in 3M’s product literature, packaging inserts or product packaging for individual

products, 3M warrants that each 3M product meets the applicable specifications at the time 3M ships the

product. Individual products may have additional or different warranties as stated on product literature,

package inserts or product packages. 3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED T O, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE OR ANY IMPLIED W ARRANTY ARISING OUT OF A COURSE OF

DEALING, CUSTOM OR USAGE OF TRADE. User is responsib le for determining whether the 3M product

is fit for a particular purpose and suitable for user’s application. If the 3M product is def ective within the

warranty period, your exclusiv e remedy and 3M’s and seller’s sole ob ligation will be, at 3M’s option, to

replace the product or refund the purchase price.

W arranty and

Limited Remedy

To request additional product information or to arrange for sales assistance, call toll free 1-800-251-8634.

Address correspondence to: 3M Electronics Markets Materials Division, Building 21-1W-10, 900 Bush

Avenue , St. Paul, MN 55144-1000. Our fax number is 651-733-9175. In Canada, phone: 1-800-364-3577.

In Puerto Rico, phone: 1-787-750-3000. In Mexico, phone: 52-70-04-00.

For Additional

Information

This product does not require Toxic Substance Control Act (TSCA) listing.

Regulatory Information

Except where prohibited by law, 3M and seller will not be liable for any loss or damage arising from the

3M product, whether direct, indirect, special, incidental or consequential, regardless of the legal theory

asserted, including warranty, contract, negligence or strict liability.

Limitation of Liability

Printed in U.S.A.

©3M 2004 70-0709-5279-4 (12/04)

Recycled Paper

40% pre-consumer

10% post-consumer

- 4 -

3

Electronics Markets Materials Division

3M Center, Building 21-1W-10, 900 Bush A venue

St. Paul, MN 55144-1000

1-800-251-8634 phone

651-733-9175 fax

www.3M.com/electronicmaterials

Loading...

Loading...