Page 1

3M™Hyper Soft Thermally Conductive Interface Pads

5516 / 5516S

Product Description

3M™ Hyper Soft Thermally Conductive Interface Pads 5516 / 5516S are designed to provide a preferential heat transfer

path between heat generating components and heat sinks, heat spreaders or other cooling devices. These products consist

of a highly conformable slightly tacky silicone elastomer sheet filled with thermally conductive ceramic particles which

provide special features listed as follows.

• Good thermal conductivity and good electrical insulation properties.

• Good softness and conformability even to non-flat surfaces.

• Softness results in low stress on board components.

• “S” version incorporates a thin PEN (polyethylene-naphthalate) film carrier for improved handling and a non-

tacky surface for ease of rework.

• Slight tack allows pre-assembly. Good wettability for better thermal conductivity.

3

Removable Film liner

Construction

Thermally conductive silicone elastomer

Removable Film liner

3M™ Hyper Soft Thermally Conductive Interface Pad 5516

Standard thickness (excludes liner): 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm

Permanent PEN Film (0.009 mm) carrier

Thermally conductive silicone elastomer

Removable Film liner

3M™ Hyper Soft Thermally Conductive Interface Pad 5516S

Standard thickness (excludes liner): 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm

Technical Data December, 2008

Page 2

3M™Hyper Soft Thermally Conductive Interface Pads 5516 / 5516S

Typical Physical Properties

Note: The following technical information and data should be considered representative or typical only and should not be

used for specification purposes.

3M™ Hyper Soft Thermally Conductive Interface Pads 5516 / 5516S

Property Method Value

Thermal Conductivity (W/mK) ASTM D5470 3.1

Flammability UL 94 V-0 (5516 0.5 mm~ & 5516S 1.01 mm~)

V-1 (5516S 0.5-1.0 mm)

Density (g/cm

3

, @ 25°C) – 2.9

Hardness Shore 00

Note 1

5516 @ 50

5516S @ 72

Volume Resistivity ( -cm) ASTM D257 6.9 x 10

14

Dielectric Strength (kV/mm) ASTM D149 3.1

Dielectric Constant ASTM D150 11.0 (1-100 kHz)

100%

80%

60%

40%

20%

0%

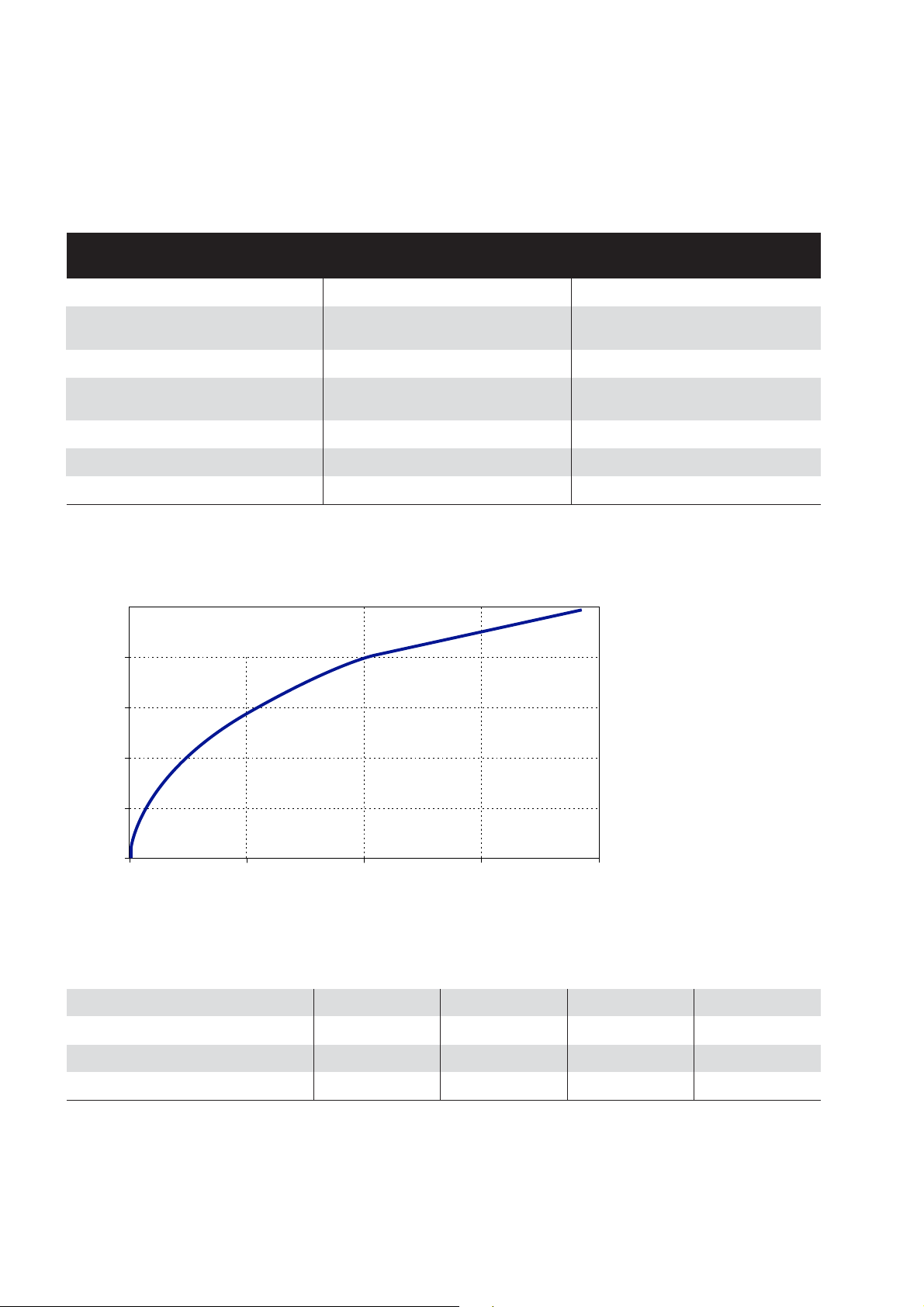

Compression (%)

3M™ Hyper Soft Thermally Conductive

Interface Pad 5516 (1 mm)

Rate: 0.5 mm/min

Stress (MPa)

0 1

2

3

4

Compression vs. Stress

Notes:

1) Shore OO Test Method based on a 6mm thick sample. Results will vary for different thickness samples.

(2)

Duration (hrs) Initial 500 1000 3000

Thermal Conductivity (W/mK) 2.8 2.8 2.8 2.8

Hardness (Asker C) 49 50 50 50

Appearance – No effect No effect No effect

Aged at 130°C in high temperature chamber.

Note: Thermal Conductivity for aging tested using the QTM-500 Hot Wire Test Method. Values can differ from an ASTM-D5470 TM due to TM differences.

Environmental Aging Data

Heat resistance of 1.0 mm 3M™ Hyper Soft Thermally Conductive Interface Pad 5516

Page 3

3M™Hyper Soft Thermally Conductive Interface Pads 5516 / 5516S

3M is a trademark of 3M Company.

Please recycle. Printed in U.S.A.

©3M 2008. All rights reserved.

60-5002-0336-3

3

Electronics Markets Materials Division

3M Electronics

3M Center, Building 21-1W-10, 900 Bush Avenue

St. Paul, MN 55144-1000

1-800-251-8634 phone

651-778-4244 fax

www.3M.com/electronics

3

For Additional Information

To request additional product information or to arrange for sales assistance, call toll free 1-800-251-8634. Address

correspondence to: 3M Electronics Markets Materials Division, Building 21-1W-10, 900 Bush Avenue, St. Paul, MN

55144-1000. Our fax number is 651-778-4244 or 1-877-369-2923. In Canada, phone: 1-800-364-3577. In Puerto Rico,

phone: 1-787-750-3000. In Mexico, phone: 52-70-04-00.

Important Notice

All statements, technical information, and recommendations related to 3M’s products are based on information believed

to be reliable, but the accuracy or completeness is not guaranteed. Before using this product, you must evaluate it and

determine if it is suitable for your intended application. You assume all risks and liability associated with such use.

Any statements related to the product which are not contained in 3M’s current publications, or any contrary statements

contained on your purchase order shall have no force or effect unless expressly agreed upon, in writing, by an authorized

officer of 3M.

Warranty; Limited Remedy; Limited Liability.

This product will be free from defects in material and manufacture at the time of purchase. 3M MAKES NO OTHER

WARRANTIES INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. If this product is defective within the warranty period stated above,

your exclusive remedy shall be, at 3M’s option, to replace or repair the 3M product or refund the purchase price of the 3M

product. Except where prohibited by law, 3M will not be liable for any indirect, special, incidental or consequential

loss or damage arising from this 3M product, regardless of the legal theory asserted.

Certification/Recognition

MSDS: 3M has not prepared a MSDS for these products which are not subject to the MSDS requirements of the

Occupational Safety and Health Administration’s Hazard Communication Standard, 29 C.F.R. 1910.1200(b)(6)(v). When

used under reasonable conditions or in accordance with the 3M directions for use, these products should not present a health

and safety hazard. However, use or processing of the product in a manner not in accordance with the directions for use may

affect their performance and present potential health and safety hazards.

TSCA: These products are defined as articles under the Toxic Substances Control Act and therefore, are exempt from

inventory listing requirements.

RoHS: These products comply with the requirements of EU Directive 2002/95/EC and 2005/618/EC.

(3)

Loading...

Loading...