Page 1

3

Nib Removal Sander 3125

Owner’s manual

A table of contents:

a. SAFETY INFORMATION 1

b. OPERATING INSTRUCTION 3

c. SPARE PARTS INFORMATION (exploded view) 4

d. DISASSEMBLY METHOD 6

e. GUIDELINE FOR PARTS EXCHANGE 10

f. ASSEMBLY METHOD 11

Appendix. - TROUBLESHOOTING SPIDER CHART

a. SAFETY INFORMATION

Please read, understand, and follow all safety information contained in these instructions prior to the use of this tool.

Retain these instructions for future reference.

Intended Use:

This tool is designed for repairing painted automobile bodies and parts as well as FRP (Fiber Reinforced Plastic) and wood. It

should not be operated in water or in an excessive wet application. All users should review this document and be trained in the

safe use of this tool.

Improper use can cause this tool to break apart and may cause injury to operators and bystanders. **

* For eye and face protection, see ANSI standard Z87.1

** For further information on coated abrasive products, consult ANSI standard B7.7, “Safety Requirement for Abrading

Material with Coated Abrasive Systems” Both are available from American Standard Institute, Inc., (212)642-4900

SPECIFICATION

Motor RPM Orbit Dia. Air flow Air Pressure Weight Pad Size

7,500 0.118 inch 5.3 SFM 58. 5 - 95.0 PSI 1.06 pounds 1.18 inch

(3 mm) (150 LPM) (0.40 - 0.65 Mpa) (0.48 kg) (30 mm)

1

Page 2

HOW TO HANDLE

• This tool is designed for repairing painted automobile bodies and parts as well as FRP (Fiber Reinforced Plastic) and

wood. It should not be operated in water or in an excessive wet application.

• Check for loose screws and missing parts before operation.

• Connect air hoses after cleaning connecting part to reduce contamination from foreign objects, dust, sand, etc.

• During inspection of each part make sure to detach air hoses.

• When connecting air hoses with an air tool, do not squeeze the trigger.

• Do not throw the tool.

• Do not drag the tool while holding the air hose.

• Do not use the tool in a non-recommended application.

• Operation without lubricants will cause rapid wear on the motor and can lead to rotation failure.

• Prior to storing lubricate the tools at a low speed to spread oil inside the motor.

• Select a dry and safe place for storage.

• Frequent cleaning of air connections will reduce contamination of the motor.

• Abnormal noise or vibration during operation indicates an immediate need for tool repair.

• If repair is necessary notify sales office or repair center from where you purchased this tool regarding inspection and

repair.

• Use only 3M-recommended replacement parts.

PRIOR TO THE OPERATION

• Keep the work area clean, orderly and free of obstacles.

• Inspect for loose parts (tool and attachment) prior to operation.

• Confirm that air pressure supply is at recommended pressure (95psi/0.65 MPa).

• When connecting to an air hose ensure a secure connection that will not loosen during operation.

• Center the abrasive on the backup pad.

• Press the abrasive securely into place.

START AND STOP

• Place the tool in contact with the work piece.

• Start the tool by pressing the lever/trigger lightly.

• Start the tool on the polishing plain during work.

• Slow the tool down before removing from the work piece.

• Remove tool at a 90 degree angle from the work piece.

• Detach air hose when the tool is not in use.

• Detach the tool from the air source when transporting.

DURING OPERATION

• Speed can be adjusted from low to high with the speed controller knob. Adjust the speed in accordance to the work being

done.

• Do not apply excessive force to the tool. Excessive force can lead to inefficient tool performance and decrease tool life.

Product Use:

or experience that 3M believes are reliable. However, many factors beyond 3M’s control can affect the use and performance of a

3M product in a particular application, including the conditions under which the 3M product is used and the time and

environmental conditions in which the product is expected to perform. Since these factors are uniquely within the user’s

knowledge and control, it is essential that the user evaluate the 3M product to determine whether it is fit for a particular purpose

and suitable for the user’s method of application.

All statements, technical information and recommendations contained in this document are based upon tests

Warranty and Limited Remedy: Unless stated otherwise in 3M’s product literature, packaging inserts or product

packaging for individual products, 3M warrants that each 3M product meets the applicable specifications at the time 3M ships the

product. Individual products may have additional or different warranties as stated on product literature, package inserts or product

packages.

3M MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO,

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY

IMPLIED WARRANTY ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE

responsible for determining whether the 3M product is fit for a particular purpose and suitable for user’s application. If the 3M

product is defective within the warranty period, your exclusive remedy and 3M’s and seller’s sole obligation will be, at 3M’s

option, to repair or replace the product or refund the purchase price.

law, 3M and seller will not be liable for any loss or damage arising from the 3M product, whether direct, indirect, special,

incidental or consequential, regardless of the legal theory asserted, including warranty, contract, negligence or strict liability.

Limitation of Liability: Except where prohibited by

. User is

Submitting a Warranty Claim

Contact your dealer when submitting a warranty claim in accordance with the restrictions listed above. Please note that all

warranty claims are subject to manufacturer’s approval. Be sure to keep your sales receipt and Product Inspection Certificate in a

safe place. These must be submitted when filing a warranty claim, within 90 days from the date of purchase.

Product Repair after Warranty Has Expired

3M does not offer repair service for product out of warranty. Please contact your dealer for the repair parts listing. For further

technical information, visit: http://solutions.3m.com/en_US/Products/ and go to Abrasives & Sandpaper link and follow the

instructions.

2

Page 3

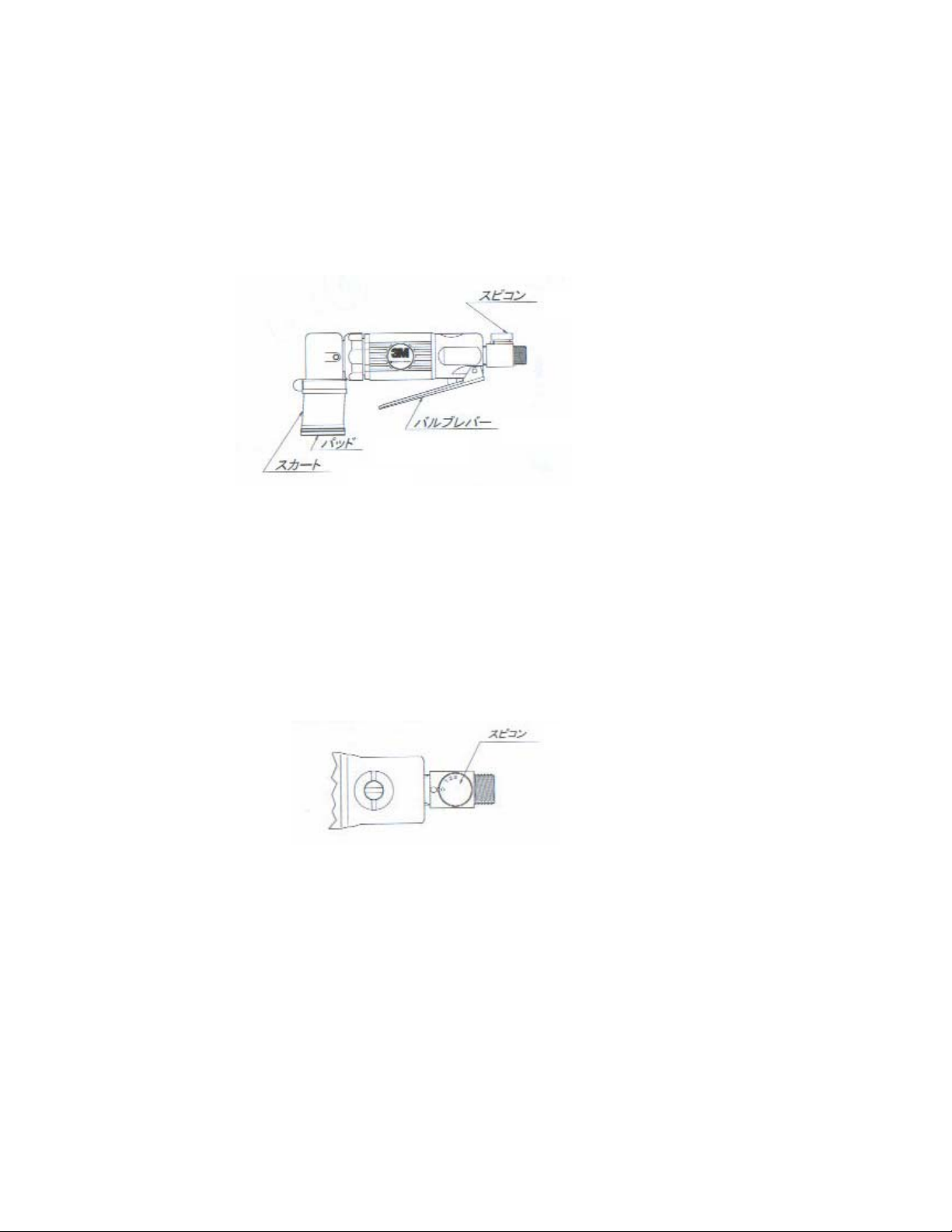

b. OPERATING INSTRUCTION

At work

- Check to see that the workplace is in order and is appropriate for the work.

- Inspect for loose parts.

- Confirm the proper air pressure (0.4 to 0.65 MPa)

- Tighten all couplings securely so that they will not be loosened by vibration.

- Attach buffing material or paper by pressing it uniformly with the palm of hand to attach it

securely.

Speed control

Valve lever

Pad

Skirt

Starting and stopping

- The tool starts when the valve lever is pressed lightly. It stops when the lever is

released.

- Operate the lever as the abrasive contacts the surface to be polished. When the tool is

transported, be sure to remove the air hose.

During use

- The tool can be adjusted continuously from low to high speed by the speed control.

Adjust it according to the work.

- Do not press it onto the surface to be polished with excess force. This does not

increase efficiency, but it shortens tool life.

Speed control

After use

- ⋅Apply spindle oil to the air supply opening and operate the tool at low speed. After use,

be sure to remove the air hose and store the tool in a safe, dry place.

3

Page 4

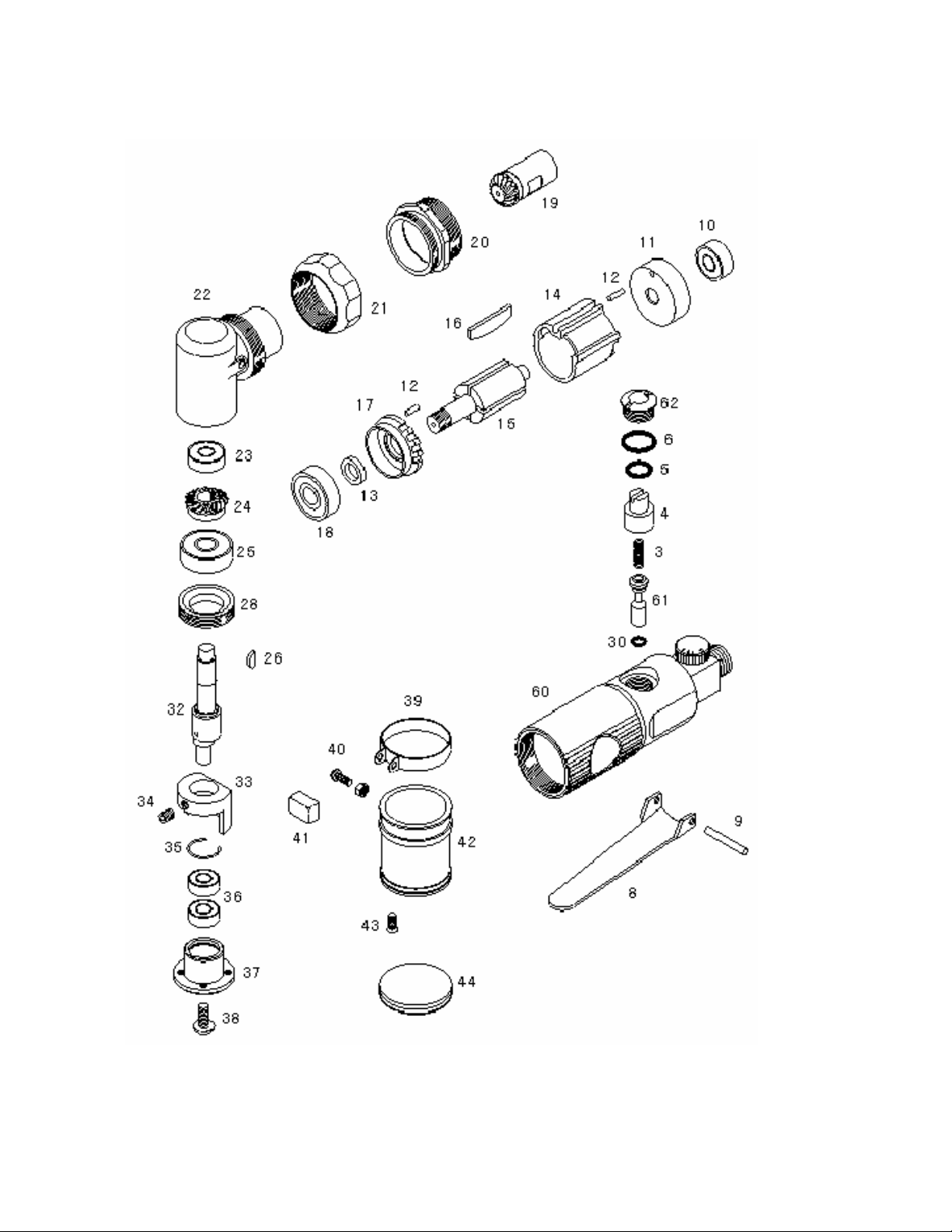

c. Spare Parts information

4

Page 5

c. Spare Parts information - continued

PARTS No. CODE ITEM QTY.

3 S3305 Spring 1

4 S3322 Air Regulator 1

5 S3323 O-Ring (P-7) 1

6 P101 O-Ring (P-10A) 1

8 S3401 Throttle Lever 1

9 S3402 Roll Pin 1

10 696ZZ Bearing (696ZZ) 1

11 S3326 Rear End Plate 1

12 S3411 Roll Pin 2

13 S3333 Rotor Collar 1

14 60743 Cylinder 1

15 S3329 Rotor 1

16 S3212 Rotor Blade 4

17 S3424 Front End Plate 1

18 608ZZ Bearing (608ZZ) 1

19 S3217 Pinion 1

20 S3215 Cup Lock 1

21 S3119 Cup 1

22 S3118 Angle Housing 1

23 696ZZ Bearing (696ZZ) 1

24 S3336 Gear 1

25 608ZZ Bearing (608ZZ) 1

26 S3338 H/R Key (φ8x1.5) 1

28 S3340 Clamp Nut 1

30 S3321 O-Ring (P-4) 1

32 60730 EX.Shaft 1

33 60731 Balancer 1

34 171408 Set Screw (M4x8) 1

35 60737 Snap Ring 1

36 686ZZ Bearing (686ZZ) 2

37 60732 Shoe Bearing Case 1

38 150406 Screw (M4x6) 1

39 60736 Skirt Band 1

40 110310A Screw Set 1Set

40-1 110310 Screw (M3x10) (1)

40-2 2103 Nut (M3) (1)

41 60739 Cap 1

42 60733A Skirt 1

43 130305 Screw (M3x5) 4

44 * Disc Pad

45 607381 Regulator (φ1.6) 1

60 60740 Housing 1

61 60741 Throttle Valve 1

62 60742 Valve Plug 1

*Available in 3M: Disc Pad Soft (UPC 051111-60537-0)

Disc Pad Hard (UPC 051111-20207-5)

Special tools for the repair operation – see Page 10

PARTS No. CODE ITEM QTY.

1) ST041 Clamp nut wrench 1

2) ST501 Bearing puller 1

3) ST028 Air motor disassembly punch 1

4) ST015 Needle punch 1

5) ST039 F. R. bearing case puller stand 1

6) ST040 Bearing puller stand 1

7) ST018 626 bearing punch 1

8) ST017 608 bearing punch 1

9) ST007 3mm pin punch 1

5

Page 6

d. Disassembly method

Disconnect air hose first. Disassembling the tool without disconnecting air hose is very dangerous.

1. Remove the skirt

- Remove four screws (43) from skirt (42) Hook-it side.

- Remove the screw (40) from the skirt clamp (39) and remove the skirt band.

- Remove the skirt (42).

2. Remove pad holder.

- Remove the thrust screw (38) and remove the case assembly (35-37).

3. Remove balancer

- Remove set screw (34) which holds balancer (33) and remove balancer.

6

Page 7

4. Remove parts from housing

- Place housing (60) in a vise and rotate cup (21) counterclockwise and remove the angle

housing assembly (22-32).

- Rotate the cup lock (20) counterclockwise and remove it.

5. Remove motor

- Remove motor assembly (10-19).

- Drive out rear bearing (11) using special tool and a hammer.

- Remove rear end plate. Drive out bearing (10) using special tool.

- Remove the cylinder (14).

- Remove the vanes (16).

- Hold the rotor (15) carefully. Rotate the pinion (19) counterclockwise and remove.

- Use a plastic hammer to strike the rotor axle (15).

- Remove the rotor from the front end plate.

- Remove the rotor collar (13).

- Drive out the bearing (18) from the front end plate (17) using the special tool.

7

Page 8

6. Disassemble the angle housing

- Clamp the angle housing assembly (22-32) in a vise. Rotate clamp nut (28) clockwise

and remove.

- Remove EX shaft assembly (32, 23-26) and remove cup (21).

- Use gear puller to remove gear (24) in the EX shaft assembly (32, 23-26) and remove

gear.

- Remove the half-moon key. Use gear puller on bearing (25) and remove.

7. Disassemble case

- Remove snap ring (35) and remove bearing (36) using special tool.

8

Page 9

8. Valve disassembly

- Remove plug (62). Remove regulator (4) and o-ring (5). Remove o-ring (6) from valve

plug (62). Remove valve assembly (3,2,30).

- Remove spring (3) and 0-ring (30) from valve assembly.

- Remove throttle valve (61).

9. Special tools for the repair operation (to help the disassembly)

1)

2)

3)

4)

5)

6)

7)

8) 9)

From top left :

1) ST041 Clamp nut wrench

2) ST501 Bearing puller

3) ST028 Air motor disassembly punch

4) ST015 Needle punch

Middle row:

5) ST039 F. R. bearing case puller stand

Bottom row:

6) ST040 Bearing puller stand

7) ST018 626 bearing punch

8) ST017 608 bearing punch

9) ST007 3mm pin punch3125 clamp nut tool - (see Page 5)

9

Page 10

e. Guideline for parts exchange

Parts no.

3 3305 Spring 1 When bent or damaged, or when it doesn’t

4 3322 Air regulator 1

5 3323 O ring (p-7) 2 When damaged

6 3501 O ring (P-10A) 1 When damaged

8 3401 Throttle lever 1 When deep wear marks occur in the part

9 3402 Roll pin 1 Lever hinge is worn badly

10 3465 Ball bearing

11 3326 Rear end plate 1 When bearing is loose or when other

12 3411 Roll pin 2

13 3333 Rotor collar 1

14 3210 Cylinder 1 When internal scratches cannot be

15 3329 Rotor 1 When the vane groove is worn

16 3212 Rotor blade 4

17 3424 Front end plate 1 When the bearing joint is loose or when

18 3464 Ball bearing

19 3217 Pinion 1 When the gear is damaged or heavily worn

20 3215 Cup lock 1

21 3119 Cup 1

22 3118 Angle housing 1

23 3466 Ball bearing

24 3336 Gear 1

25 3464 Ball bearing

26 3338 Half moon key

28 3340 Clamp nut 1

30 3321 O ring (P-4) 1 When damaged or it won’t seal

32 60730 EX shaft 1 When the bearing juncture is loose

33 60731 Balancer 1

34 170408 Stopper screw with

35 60737 Snap ring 1 When bent or severely deformed

36 686ZZ Bearing (686ZZ) 2 When the balls are worn and there is too

37 60732 Shoe bearing case 1 When the bearing is loose or deformed.

Figure no.

(ID number)

Part name Qty Guideline for parts exchange

work properly

that contacts the valve pin

1 Ball is worn and gap becomes big, or is

(696ZZ)

(608Z)

(696ZZ)

(608Z)

(1.5 x 8)

hexagonal hole (M4 x

8, tip of bar)

locked up

dangerous deformation is seen. If the

marks made by the rotor are not bad, it can

be repaired with paper wrap.

repaired.

When the width is −0.5 less than the

original size (7), or when the length

becomes −0.25 less than the original size

(25.4)

other dangerous damage is seen. If the

marks made by the rotor are not bad, it can

be repaired with paper wrap.

1 1) When the ball bearing is worn or seized

up. 2) There is too much play.

1 1) When the ball bearing is worn or seized

up. 2) There is too much play.

1 1) When the ball bearing is worn or seized

up. 2) There is too much play.

1

1

much play or the bearing is or locked up

10

Page 11

Parts no.

38 150406 Tras bis (M4 x 6) 1

39 60736 Skirt band 1 When the deformed or damage is found.

40-1 110310 Screw (M3 x 10) (1)

40-2 2103 Nut (M3) (1)

41 Cap 1

42 60733 Skirt 1 When cut or cracked or worn-out.

43 130305 Screw (M3 x 5) 4

44 60735

45 60738 Speed controller

60 60740 Housing 1

61 60741 Throttle Valve 1 When outer diameter is worn and air leaks

62 60742 Valve Plug 1

Figure no.

(ID number)

Part name Qty Guideline for parts exchange

φ30 x 4t pad

(exclusive product)

1 When surface flatness is lost

1 When parts become worn such as the inlet

screws

seriously from the valve pin sleeve joint

f. Assembly method

- Before assembly, clean each part and check for wear or damage. Use only proper

spare parts.

- Apply lubricant oil lightly on each part.

- Replace damaged O rings. Install O rings using grease (multipurpose grease - Military

Specifications G-46006, or equivalents).

- Assemble the parts carefully in reverse order from disassembly.

- Carefully confirm end clearance in the motor.

- Do not over-tighten the cup lock.

- When installing the angle housing, install the cap in the end of the angle housing

beforehand. Tighten the cup lock while confirming the position of the angle housing.

- Install the EX, shaft Assy., while confirming proper meshing of the gears. Never

assemble the gears to hit tooth to tooth.

- After assembly, look for loose or missing screws.

- Apply lubricant oil into the air inlet, and run the tool at a medium pressure to make sure

it rotates freely.

Repair services after Warranty period & Parts supply contact

Tool Warehouse Inc.

Contact: Jeff Houk

3410 East 42

Minneapolis, MN 55406-3333

Phone: 1-612-722-4260 Fax: 1-612-722-3415

e-mail:

sales@ToolWarehouseInc.com

3M Industrial Business Quality Direct / abrasives

Phone: 1-800-362-3550 (USA only)

3M Industrial Business Customer Response Center

900 Bush Avenue, Building 21-1W-10

St. Paul, MN 55106

Phone: 1-866-279-1235

www.3M.com/abrasives © 3M 2006

nd

Street,

11

Page 12

Trouble shooting Chart

d

No run No sound Regulator problem or constricted airline Check Regulator

Sound

Air motor rotates

(manually) Vane stuck because of dirt or oil If it won't rotate manually, service is require

Won't rotate Motor is locked up, because of dirt It is required overhaul

Rotates Rotates without Valve is dirty Press lever repeatedly

throttle lever

Deffected valve Replace valve or valve seat (O-ring)

O-ring is damaged Replace O-ring

Loaded

Won't rotate Dirt in air motor Overhaul

Overloading Reduce load

Bearings are damaged Replace bearing

Low RPM Dirt in air motor Lubricate, disassemble and clean

Overloading Reduce load

Vane is worn-out Replace the vane

Low air pressure Air compressor's capacity is too small

Air leak Tighten the connectors

Excessive vibration Excess air pressure Reduce air pressure

Parts are worn-out or damaged Replace worn-out or damaged parts

Pad is damaged Replace the pad

Boot is damaged Replace the boot

Excessive noise

High frequency Bearings are damaged Replace the bearing

Muffler is damaged or choked Replace or repair the muffler

Too much backlash in gears Ajust or replace the gears

Balancer is defect Replace the barancer

Groam noize Mechanical interference in motor Overhaul

The balancer screw is loose Tighten balancer

Shutting up Vanes are stacking Lubricate freely

Starting is unstable Mechanical interference in motor Overhaul

Balancer is defect Tighten balancer

Loading...

Loading...