CubeX 3D Printer

Instruction Manual

TM

CubeX 3D printer

User guide

See inside for use and safety information.

INTRODUCTION

Copyright ...............................................................................................................3

FCC notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warranty................................................................................................................3

Limitation of liability .......................................................................................................3

IMPORTANT SAFETY INFORMATION

Safety symbols and denitions...............................................................................................4

Safety guidelines .........................................................................................................4

CUBEX 3D PRINTER FEATURES AND BENEFITS

CubeX 3D printer properties.................................................................................................5

Print materials............................................................................................................5

Material color choices......................................................................................................5

At a glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Requirements for your CubeX ...............................................................................................7

UNPACKING AND SETTING UP THE CUBEX

What’s included ..........................................................................................................7

Unpacking your CubeX...................................................................................................8-9

Activate your CubeX and link to your Cubify account.............................................................................10

Removing the remaining packing materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CubeX main menu overview................................................................................................12

Installing the Print Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Checking the XYZ axis ....................................................................................................13

Checking the Z-gap between the Print Jet tip and the Print Pad ....................................................................14

Installing Material Cartridge .............................................................................................14-15

Replacing a Material Cartridge...........................................................................................15-16

Create a test print........................................................................................................16

INSTALL YOUR CUBIFY INVENT SOFTWARE........................................................................17

DOWNLOADING AND INSTALLING CUBEX SOFTWARE .......................................................... 17-18

CubeX software overview............................................................................................... 18-19

CubeX software user interface

Home Tab ...........................................................................................................19

View Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Settings Tab .........................................................................................................20

CREATION FILE PREPARATION & PRINTING YOUR CREATIONS

How to open les in the CubeX software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-21

Opening a single part le ..................................................................................................21

Opening multiple single part les . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-22

Positioning multiple parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Opening a multi-part assembly le ........................................................................................22-23

Using the shell selector tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Rotating a part ..........................................................................................................24

Scaling a part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Using the CubeX software to build a .cubex le..............................................................................24-25

Saving a .cubex le for printing .............................................................................................25

Printing your creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

FINISHING YOUR CREATION

Removing your creation from the Print Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Removing rafts ..........................................................................................................26

Removing supports with wire cutters .........................................................................................26

1

Removing supports with the Ultrasonic Support Removal Tank.....................................................................27

Hot water method .....................................................................................................27

Caustic soda method ..................................................................................................28

CUBEX MAINTENANCE

Restoring roughness to the Print Pad.........................................................................................29

Leveling the Jet Wiper height ...............................................................................................29

Leveling the Aluminum Print Plate ........................................................................................29-30

Fine-tuning your Print Pad .................................................................................................31

Unblocking the CubeX Print Jet tip...........................................................................................31

Unblocking the CubeX Print Jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Setting the Print Jet gap ................................................................................................31-32

Updating CubeX rmware ..............................................................................................32-34

Restoring the settings your CubeX 3D printer rmware from v1.01 ..................................................................34

How to contact Cubify support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setting up the CubeX Print Jet offsets .....................................................................................34-35

2

INTRODUCTION

Thank you for purchasing the CubeX™ 3D Printer. This printer enables everybody in the family to express their creativity like

never before. With eighteen different material colors to choose from, enjoy the freedom to print in color or mix it up.

CubeX 3D Printer’s ready-to-print technology, provides a new dimension to your imagination and helps you share your

creations with others in the Cubify community at Cubify.com. At Cubify.com you can:

• Upload your creations for sale

• Purchase creations from others

• Get your creations 3D printed and shipped to you

• Buy the CubeX 3D Printer and CubeX Cartridges

• Engage with other creative partners

COPYRIGHT

© 2013 by 3D Systems, Inc. All rights reserved. This document is subject to change without notice. This document is copyrighted and contains

proprietary information that is the property of 3D Systems, Inc. Cubify, CubeX, and the 3D Systems logo are registered trademarks of 3D Systems, Inc.

Use of the Cubify.com website constitutes acceptance of its Terms of Service and Privacy Policy.

FCC NOTICE

This equipment has been tested and found to comply with the limits for a class “B” digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at their

expense.

WARRANTY

3D Systems warrants that the CubeX 3D Printer will be free from defects in materials and workmanship, during the applicable warranty period, when

used under the normal conditions described in the documentation provided to you, including this User Guide. 3D Systems will promptly repair or

replace the CubeX 3D Printer, if required, to make it free of defects during the warranty period. This warranty excludes (i) normal consumable or

expendable parts (such as Material Cartridges), (ii) repairs required during the warranty period because of abnormal use or conditions (such as riots,

oods, misuse, neglect or improper service by anyone except 3D Systems or its authorized service provider), and (iii) repairs required during the

warranty period because of the use of non-integrated, non-approved or non-licensed materials with the CubeX 3D Printer. The warranty period for the

CubeX 3D printer is the shorter of (i) 90 days from the date your CubeX 3D printer is activated or (ii) 24 months after the CubeX 3D Printer is shipped

from 3D Systems to the end customer or intermediary. For consumers who are covered by consumer protection laws or regulations in their country of

purchase or, if different, their country of residence, the benets conferred by our ninety (90) day warranty are in addition to, and operate concurrently

with, all rights and remedies conveyed by such consumer protection laws and regulations, including but not limited to these additional rights.

THIS WARRANTY IS THE ONLY WARRANTY PROVIDED FOR THE CUBEX 3D PRINTER. TO THE MAXIMUM EXTENT PERMITTED BY LAW, 3D

SYSTEMS EXPRESSLY DISCLAIMS ALL OTHER WARRANTIES FOR THE CUBEX 3D PRINTER AND EACH OF ITS COMPONENTS, WHETHER

THOSE WARRANTIES ARE EXPRESS, IMPLIED OR STATUTORY, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

INTENDED OR PARTICULAR PURPOSES.

LIMITATION OF LIABILITY

3D SYSTEMS WILL NOT BE RESPONSIBLE FOR INDIRECT, SPECIAL, CONSEQUENTIAL, EXEMPLARY OR INCIDENTAL DAMAGES (SUCH AS

LOSS OF PROFIT OR EMPLOYEE’S TIME) REGARDLESS OF THE REASON. IN NO EVENT SHALL THE LIABILITY AND/OR OBLIGATIONS OF

3D SYSTEMS ARISING OUT OF THE PURCHASE, LEASE, LICENSE AND/OR USE OF THE EQUIPMENT BY YOU OR OTHERS EXCEED THE

PURCHASE PRICE OF THE CUBEX 3D PRINTER.

3

IMPORTANT SAFETY INFORMATION

SAFETY SYMBOLS AND DEFINITIONS

Hot Surface Hazard: A hot surface is accessible in the vicinity of this sign or at the Print Jet; avoid contact. Hot

surfaces can cause severe burns.

Caution: Indicates something may happen that could cause loss of data, damage to equipment, or could cause

personal injury.

!

Caution: Indicates a pinch point hazard that could cause person injury.

SAFETY GUIDELINES

• Follow all safety rules in this section and observe all cautions and warnings in this guide.

• Do not modify any safety features or make modications to the CubeX. Doing so is prohibited and voids the warranty.

• Use of print materials other than genuine 3D Systems components may void the warranty.

• Adult supervision is required; observe children closely and intervene as necessary to prevent potential safety problems and

ensure the CubeX’s appropriate use. Ensure small 3D prints are not accessible to young children. 3D prints are potential choking

hazards for young children.

• When the CubeX is operating, the tip of the material dispenser (Print Jet) becomes hot; avoid touching this area until it has

cooled down.

4

CUBEX 3D PRINTER FEATURES AND BENEFITS

The CubeX 3D Printer creates the model by pulling lament from the cartridge through the print jets via the delivery tubes.

The lament is then jetted through the print jet tip in a thin string of molten plastic. The print jet movement is coordinated

by the print plate, which lowers incrementally after each layer is deposited so a new layer can be drawn on top of the last,

building the part up.

CUBEX 3D PRINTER PROPERTIES

• Plastic Jet Printing technology

• Houses up to three print jets for multi-color and multi-material prints

• Choice between ABS and PLA plastic, both recyclable

• Prints objects up to 275 x 265 x 240 mm (10.75”x10.5”x9.5”)

• EZ load print cartridge

• Fully automated supports: peel off supports for ABS and PLA; PLA supports can also be removed using the Ultrasonic

Support Removal Tank available at Cubify.com/cubex/store_parts.aspx

PRINT MATERIALS

The CubeX can use two different types of print materials: PLA and ABS. Each material has unique benets and you can

guide your selection based on the properties your part requires.

PLA This is a hard plastic that has a low environmental impact. It is derived from renewable, starch-based

resources.

We recommend using PLA when printing extra-large parts on CubeX as it is a more stable print

material.

PLA is the optimal support material for industrial ABS parts. PLA has the ability to dissolve away in

caustic soda solutions supported by an ultra-sonic tank. (see page 36 for more information)

ABS This is a well-known plastic known for its strength and industrial properties.

As a build material, ABS is good for both small and large parts.

ABS works as an excellent support material for extra-large PLA parts.

MATERIAL COLOR CHOICES

Glow-in-the-

dark Neon

Green

Neon Orange

* Natural is only available in PLA plastic, not ABS.

Glow-in-the-

dark Neon

Blue

Tan

White

Yellow

Black

Neon Green

Silver

Green

Industrial Grey

Blue

Natural*

Teal

Magenta

Purple

Red

Brown

5

AT A GLANCE

Get acquainted with your CubeX 3D Printer before you begin printing. This section identies the important areas that will be

discussed throughout this guide.

CubeX Duo is depicted for illustration purposes only. Locations of important areas are the same for the Cube X and Cube X

Trio.

A

B

H I J

A

Touchscreen

B

Function button

C

D

E

F

Front

G

Bottom

Underneath top cover

H I J

K L M

Top area, inside printer

N

Bottom area, inside printer

I

Print Jet 2

J

Print Jet 3

O

P

C

Jet Wiper

D L

Z-axis

E M

Print Pad & Print Plate

F N

Memory stick USB port and PC connection USB port

Power supply

G

Print Jet 1

H

6

K

Print Jet Tip 1

Print Jet Tip 2

Print Jet Tip 3

Material Cartridge Bay 1 (for Print Jet 1)

Material Cartridge Bay 2 (for Print Jet 2)

O

Material Cartridge Bay 3 (for Print Jet 3)

P

REQUIREMENTS FOR YOUR CUBEX

Weight and dimensions:

• 515mm (w) x 515mm (l) x 598mm (h) (20 ¼” x 20

¼” x 23 ½” inches)

• 36kg (79 lbs)

• 37kg (81.5 lbs) Duo

• 38kg (84 lbs) Trio

Minimum hardware requirements (a PC with these

minimum requirements will be required to run the

software):

• Processor: Multi-core processor - 2GHz or faster

per core

• System RAM: 2 GB

• Screen Resolution: 1024x768

PC requirements:

• Microsoft® Windows® 7

• Microsoft® Windows® XP (SP3 or higher)

• Microsoft® Windows® 8

Software:

• CubeX Client Software, available at Cubify.com

Electrical requirements:

• 110-240v AC

Material storage (although all polymers degrade with time, the

following conditions help ensure that the material remains of

high quality):

• Unpack material only as needed

• Store material at 10-30°C

• Use within 12 months of receipt

UNPACKING AND SETTING UP THE CUBEX

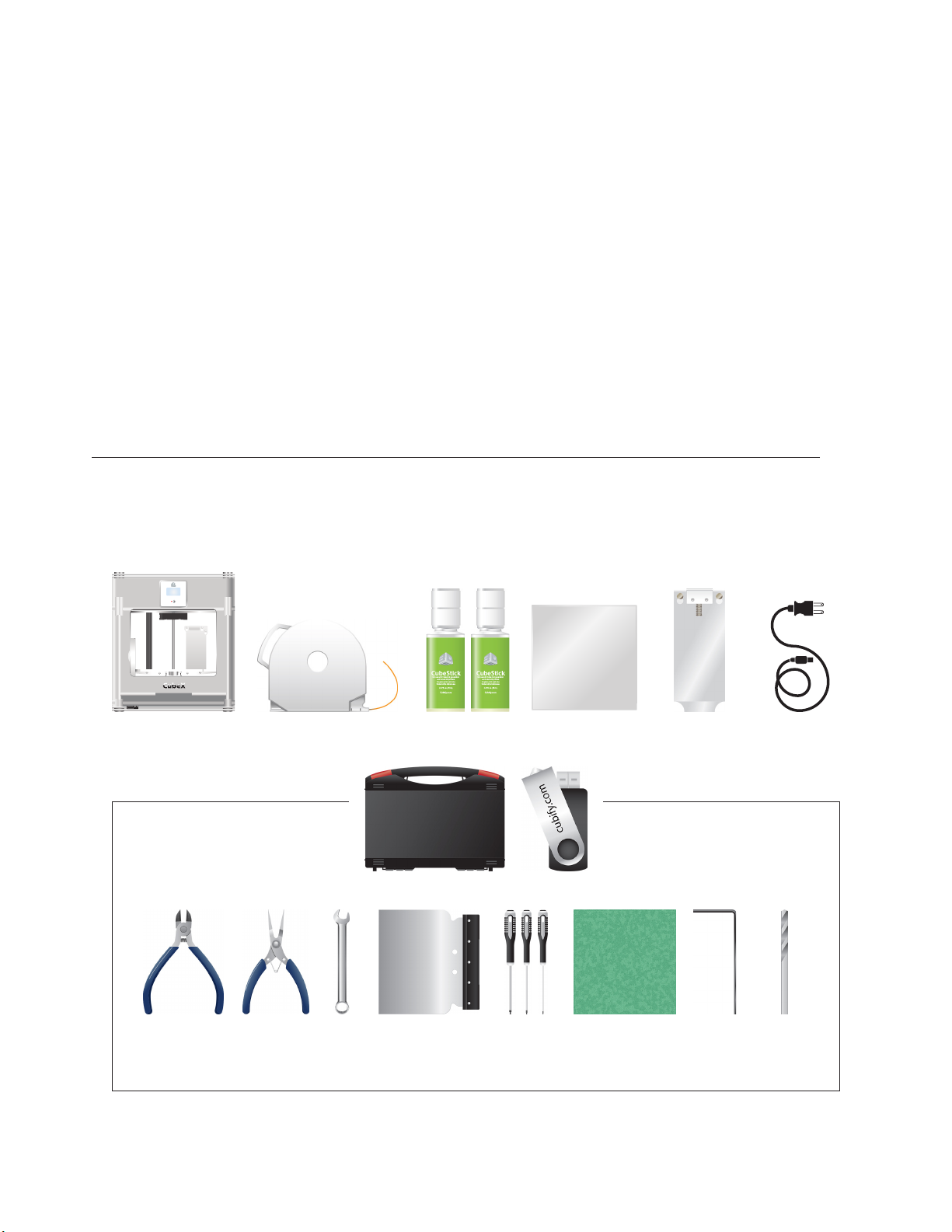

WHAT’S INCLUDED

CubeX printer

Snips Print Pad cleaner

Material cartridge CubeStick (x2) Jet Wiper Power cord

Needle

nose pliers

Wrench Allen

(scraper)

Print Pad

Toolkit USB Stick

screwdrivers

(x3)

7

DrillbitSandpaperHex

Wrench

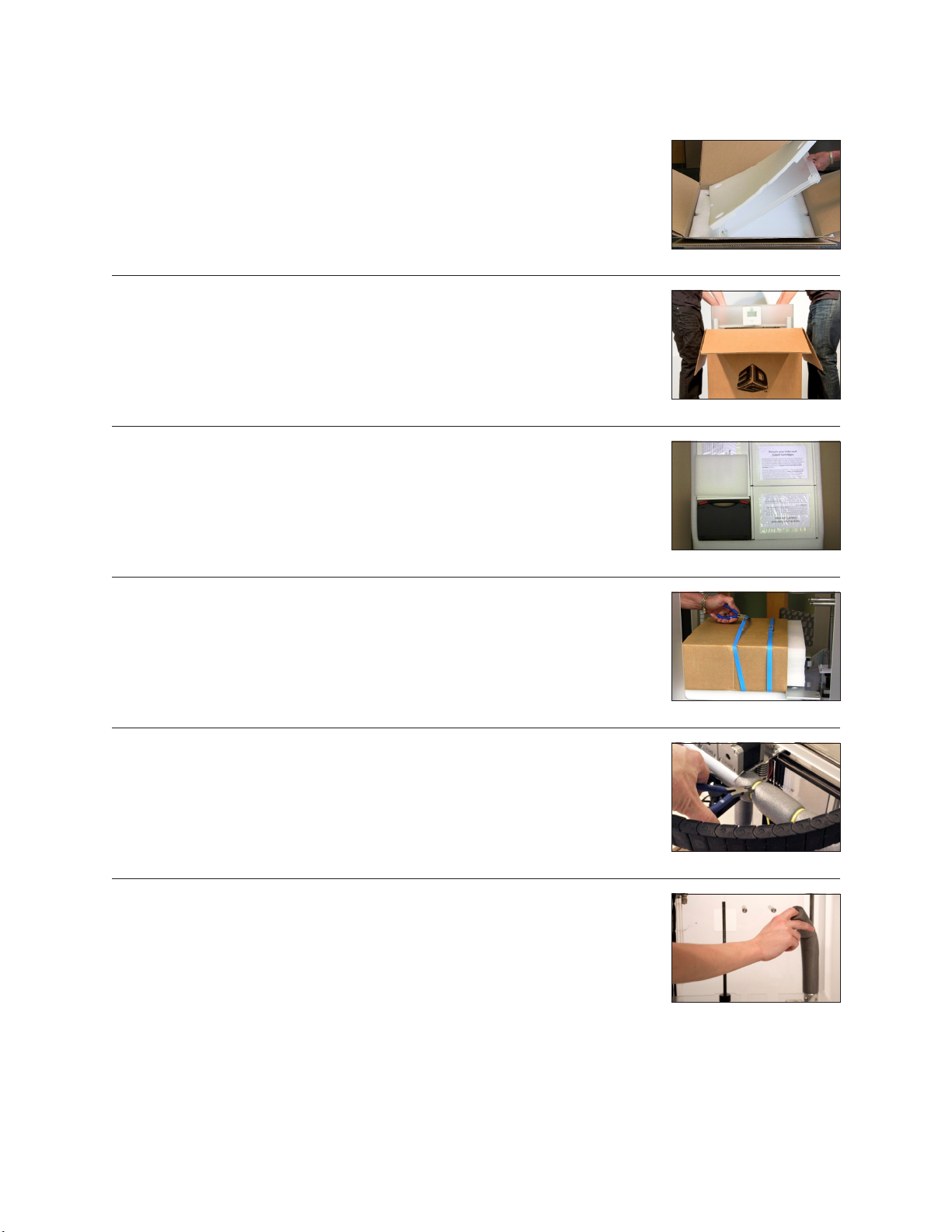

UNPACKING YOUR CUBEX

1. Open the box and remove the top acrylic lid located between two layers of foam. Set

aside the two foam inserts for future packing. (Fig. 1)

2. With two people, remove CubeX from the box, lift from the metal frame on both sides

of the printer. Place CubeX on a table. (Fig. 2)

3. Remove the material cartridges and tool kit from the bottom of box. (Fig. 3)

Fig. 1

Fig. 2

Fig. 3

4. Using the snips located in the tool kit, cut blue straps away from cardboard. Cut away

all blue zip ties securing the printer carriage. (Fig. 4)

5. Using the snips, cut away all yellow zip ties securing the foam parts in place.

Remove foam packing material. (Fig. 5)

6. Remove all foam ttings. (Fig. 6)

Fig. 4

Fig. 5

Fig. 6

8

7. Lift the cardboard piece from the foam package and remove the foam package. This

package includes your power cord, Cube Stick glue and the jet wiper. (Fig. 7)

8. Remove print pad from CubeX. (Fig. 8)

9. Using the 4 x 100 hex screwdriver (located in tool kit), remove plexiglass Z-Axis

guard by unbolting the 4 screws holding it in place and remove plexiglass and bolts.

(Fig. 9)

Fig. 7

Fig. 8

Fig. 9

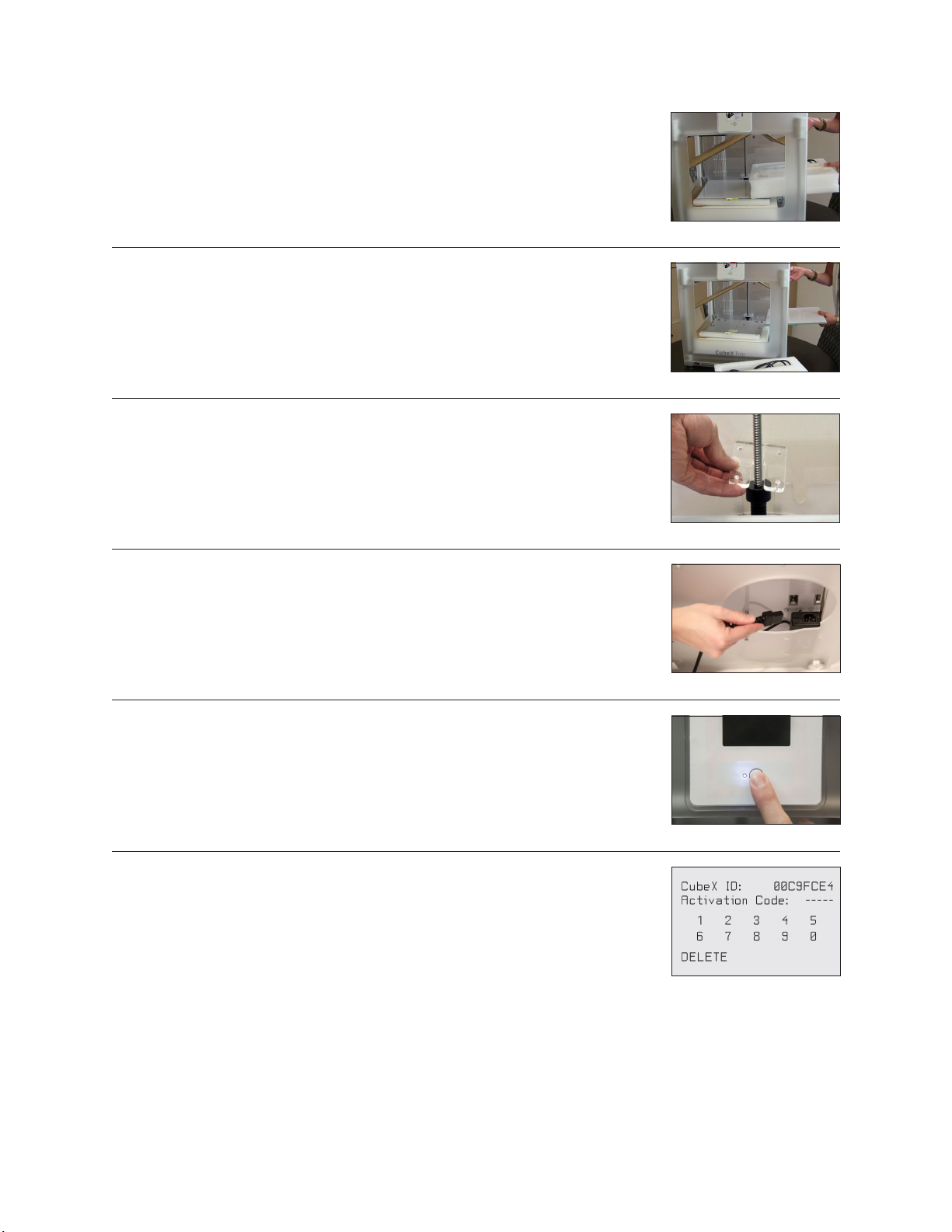

10. To power on, plug the power cord into the power supply located underneath the

printer base. Lift the right side of the printer to gain access to the power supply. (Fig.

10)

11. The LED on the control panel should light up indicating the printer has power.

Remove the “Warning” label from the touchscreen. (Fig. 11)

12. Press the Control button, the CubeX Activation Screen will appear. You will need to

register and activate your CubeX to unlock the printer. (Fig. 12)

Fig. 10

Fig. 11

Fig. 12

9

ACTIVATE YOUR CUBEX AND LINK TO YOUR CUBIFY ACCOUNT

Creating an account on Cubify.com is easy and gives you access to all of the great designs and collections that will drive

and inspire your creativity.

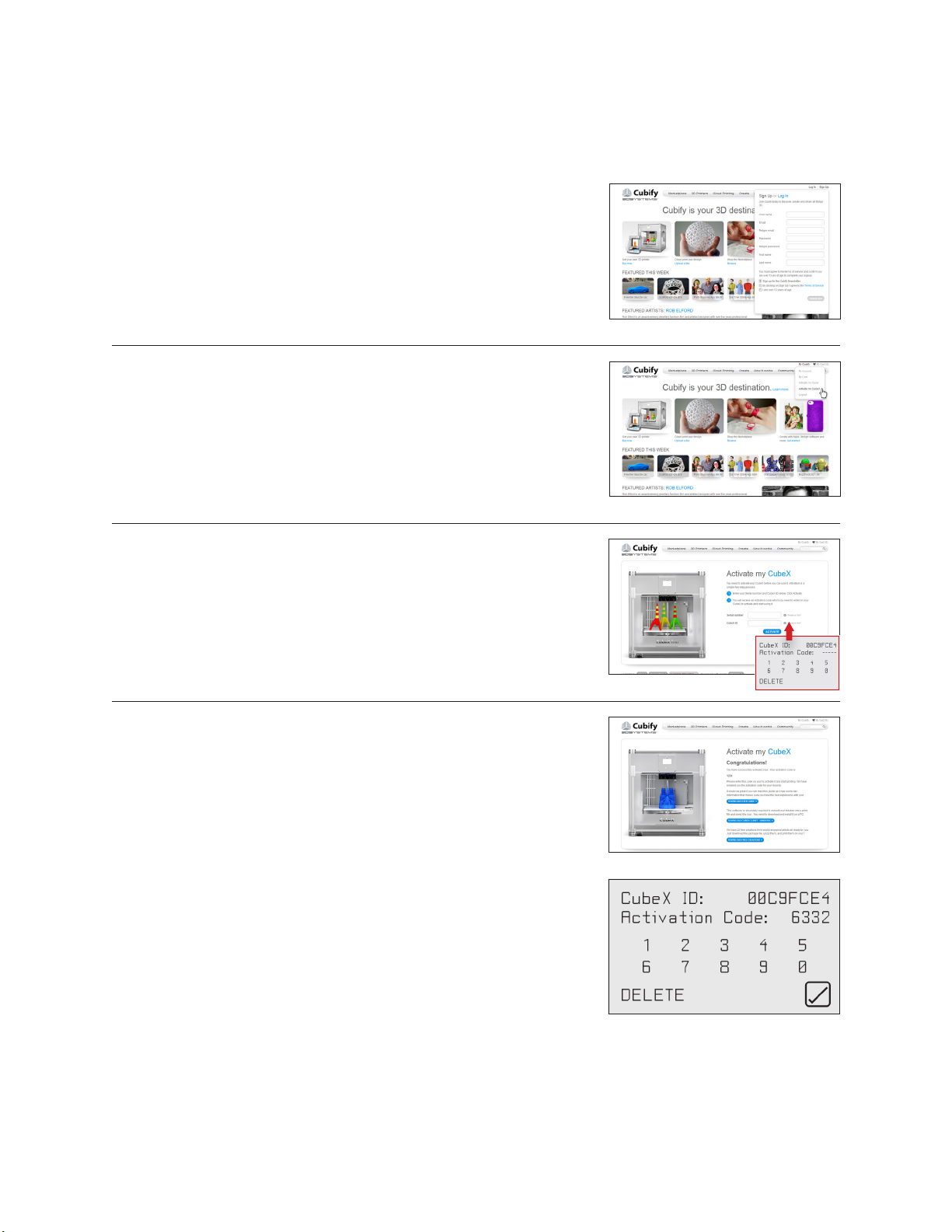

• To create an account, type in Cubify.com in your web browser and click on

Sign Up to open the registration form. If you already have an account, click

on Log In and provide your User ID and Password. (Fig. 13)

Fig. 13

• In My Cubify drop down menu, Click on Activate my CubeX. (Fig. 14)

Fig. 14

• Enter the SERIAL NUMBER; the serial number is located on the interior back

wall and on the back of the CubeX frame. (Fig. 15)

• Enter the CubeX ID; this ID can be found on the upper right corner of the

CubeX touchscreen and click ACTIVATE. (Fig. 15)

• Congratulation, Your CubeX is now activated in Cubify.com. To unlock your

CubeX, the four digit Activation Code that appears on the screen will be

needed. (Fig. 16) Also, an email will be sent to you with your Activation Code.

Click on Marketplace drop down menu and click on Free Files. Download

the free creation les to your USB stick or save them on your computer.

• Enter the Activation ID into your CubeX using the numbers on your

touchscreen and select the check box (Fig. 17); your CubeX is now unlocked.

Make a note of your activation code as this may be required in the future.

Click on the check box again to return to the touchscreen menu.

Fig. 15

Fig. 16

Fig. 17

10

REMOVING THE REMAINING PACKAGING MATERIALS

1. Using left / right arrows on the touch screen, navigate to the MOVE menu. (Fig. 18)

2. Using the up arrow on the right side of screen, move the print plate up far enough to

remove the foam. (Fig. 19)

3. Remove the last foam piece underneath the build plate. (Fig. 20)

Fig. 18

Fig. 19

Fig. 20

4. Move the Print Pad all the way down to install the Jet Wiper. (Fig. 21)

5. To install the Print Wiper, insert the wiper’s two key holes onto the two rods located

at the back, right side of printer. The wiper’s white plastic piece and spring should be

facing the front. (Fig. 22)

Fig. 21

Fig. 22

11

CUBEX MAIN MENU OVERVIEW

TOUCHSCREEN Tap on the touchscreen to navigate to the main menus using the arrows on the bottom

corners of the touchscreen. To return to the touch screen, pressing the control button.

PRINT

INFO

PJ-MAP

PJ-CON

MOVE

PRINT View the .cubex les that are saved on your memory stick and select a .cubex le to print.

INFO Provides Material Cartridge status and printing status during the printing process.

PJ-MAP Allows you to re-map your print jets.

PJ-CON Allows you to manually jet your print jets, giving you control of temperature and RPM.

MOVE Manually moves your print jet carriage in the X, Y and Z directions.

HOME

LEVEL

Z GAP

Z

OFFSET

UPDATE

HOME Sends the print jet carriage to its home position located in the back left corner of the printer.

LEVEL Level your print pad in relation to the print tips.

Z-GAP Set the distance between the print pad and print tips during the rst layer of printing.

OFFSET Set the relative distance between each print tip.

Do not use the offset menu unless you have been advised to do so by Cubify support, changing this

!

may affect the quality of multi-material prints.

UPDATE Used to update CubeX rmware.

12

INSTALLING THE PRINT PAD

1. Scroll to the “MOVE” function screen located on the CubeX control panel. (Fig. 23)

2. Using the Up and Down arrows on the right side of the screen, move the Aluminum

Print Plate to its lowest position.(Fig. 24)

3. To install the Print Pad, align the aluminum foot with front slot on the Print Plate base.

(Fig. 25)

4. Place the Print Pad into position, when properly installed the magnet will lock it in

place. Ensure that print pad is fully seated. (Fig. 25)

MOVE

Fig. 23

Fig. 24

Fig. 25

CHECKING THE X,Y,Z AXIS

During shipping your CubeX, the X, Y and Z axes may have come out of alignment. Before starting your rst creation, please

verify that the X, Y and Z axes are aligned.

X, Y, Z Axis Movements:

• X Axis: Print Jet moves front to back and back to front.

• Y Axis: Print Jet moves left to right and right to left.

CAUTION: Always move the print plate (Z Axis) down rst to avoid collision

with the print jet tips. When moving the print jet (X and Y axis), make sure

you do not stray too far from the home switches (left rear of the printer)

!

as this can cause collision with the printer frame. Excessive collisions will

damage the printer.

1. Scroll to the LEVEL menu and select. (Fig. 26) Tap on the clockwise and

counterclockwise position and observe the print jet’s print jet tip moves around the

print pad from the side of pad. (Fig. 27)

2. After checking that all axes are functioning properly, use the control button to go

back to the main menu. If adjustments are required to the print plate or the print jet

tips, refer to “CubeX Maintenance: Leveling Print Plate.”

LEVEL

Z GAP

Fig. 26

LEVEL BED

OFFSET

Z

13

Fig. 27

CHECKING THE Z-GAP BETWEEN THE PRINT JET TIP AND THE PRINT PAD

CAUTION: Do not overdrive the print jet tip into the print pad. Doing so can cause damage to the print jet.

NOTE: If more than one print jet is equipped on your CubeX, use the rst print jet to set the gap.

!

1. Scroll to “Z GAP” using the arrows on the touchscreen. Select

Z GAP and using the “Up / Down” arrows, move the print pad

up so that it is just touching the tip of the print jet. (Fig. 28 &

29)

Z GAP

SET Z HEIGHT

Offset:-19.82

Z

Fig. 28

2. Using the “Down” arrow, lower the printpad down by 0.1 from the print jet tip.

Click on the Control button, the next screen will allow you to save the setting.

Click on the check mark to save or the X to cancel the setting. (Fig. 30)

INSTALLING MATERIAL CARTRIDGE

NOTE: The REPLACE functions will take you through the process of installing the material cartridge.

1. Press REPLACE on the touchscreen and select the bay that the cartridge will be

installed. Print Jet 1 represents bay 1, Print Jet 2 represents bay 2 and Print Jet 3

represents bay 3. Press “Next” on the touchscreen, a message “Heating Print Jet

Please Wait…” will appear on the control panel. (Fig. 31)

Fig. 29

Fig. 30

1

3

2

2. If the top cover is on, remove cover from the CubeX by lifting up. (Fig. 32)

3. Remove the thumbscrew from the new cartridge and retain thumbscrew to use when

storing the used cartridge that has material inside. This will prevent the material from

unraveling when stored. (Fig. 33)

4. Pull 300mm (11”) of material from the new cartridge.

5. Cut 50mm (1.5”) from the end of the lament. (Fig. 34)

Fig. 31

Fig. 32

Fig. 33

Fig. 34

14

6. Thread the lament under the cartridge clamp bar and into the feed tube. (Fig. 35)

7. Install the new cartridge from the side of CubeX and into the cartridge bay. (Fig. 36)

8. Push lament between the front of cartridge and the eyelet, through the feed tube

and up to the printjet. (Fig. 37)

9. When the material jets from the print jet tip, the next screen will ask if you want to

replace another cartridge. If replacing another or adding cartridge, select the print

jet’s material cartridge to be replaced / added and repeat “LOADING MATERIAL

CARTRIDGE” instructions. (Fig. 38)

NOTE: Test creations have been printed on your CubeX before leaving our

factory. A different material and / or color may have been used for the test

creation and may have a small amount of this test material in the print jet.

Therefore, when the material jets for the rst time, the color may be different

until the test material is completely jetted from the print jet and your choice of

material will become visible during this process.

Fig. 35

Fig. 36

Fig. 37

Fig. 38

10. Once cartridge is installed, press “Next” on the touchscreen. A message “Would you like to load a new Print Jet” will

appear on the touchscreen. If you are adding another cartridge, select the check box and repeat Steps 1-9. Otherwise

select X to return to the main menu.

REPLACING A MATERIAL CARTRIDGE

NOTE: The REPLACE functions will take you through the process of installing the material cartridge.

1. Press REPLACE on the touchscreen and select the bay that the cartridge be

installed. Print Jet 1 represents bay 1, Print Jet 2 represents bay 2 and Print Jet 3

represents bay 3. Press “Next” on the touchscreen, a message “Heating Print Jet

Please Wait…” will appear on the control panel. (Fig. 39)

2. After the print jet is heated, the next message will appear asking to “Gently Pull

Filament From Feed Tube.” Gently pull the lament in between the cartridge front

holder and eyelet as shown. Press “Next” on the touchscreen. (Fig. 40)

15

1 2

Fig. 39

Fig. 40

3. A message “Install Thumbscrew into Cartridge” will appear. If a cartridge is being

replaced, ensure that the thumbscrew is installed into cartridge if it is to be stored.

(Fig. 41)

Fig. 41

4. Press “Next” on the touchscreen. A message “Would you like to load a new Print Jet” will appear on the touchscreen.

Select the check box and refer to “INSTALLING MATERIAL CARTRIDGE” to install the new cartridge.

CREATE A TEST PRINT

PLEASE ENSURE YOU HAVE FOLLOWED ALL CUBEX SETUP INSTRUCTIONS BEFORE STARTING A

PRINT. FAILURE TO DO SO MAY DAMAGE THE CUBEX.

!

Print a test print using one of the creation les that you downloaded from Cubify.com to ensure that your printer is

functioning properly.

1. Insert the USB stick containing your .CUBEX le (creation les) into the USB port on the

CubeX. (Fig. 42)

Fig. 42

2. Use the Magic CubeX Glue to coat the Print Pad with a layer

of glue. Turn the CubeX Glue upside down so the glue ows

to the tip. (Fig. 43)

3. Remove print pad from print plate and apply three layers of

Magic CubeX Glue using a slow circular motion. If the print is

large, ensure that the glue covers the Print Pad surface where

the creation will print. If it is a smaller print, cover the middle

of Print Pad with the glue. Install print pad on to print plate.

(Fig. 44)

4. Select the ‘Print’ option from the main menu. (Fig. 45)

5. Using the arrows at the bottom of the screen, scroll to the

.CUBEX le you wish to print and tap on the le name. Your

creation will begin to print. (Fig. 46)

NOTE: After your creation is printed, please refer to “Finishing Your Creation” in the guide, for instructions on how

to remove your print from the print pad.

Fig. 43

Fig. 45 Fig. 46

Fig. 44

16

INSTALL YOUR CUBIFY INVENT SOFTWARE

Your Cubify Invent license code is on the “Your Cubify Invent” card located in the Cubify toolkit. Your USB stick can also be

found in the toolkit.

1. Plug the USB provided with your CubeX into your computer and click on “Cubify_

Invent.exe” to download the software to your computer. (Fig. 47)

Fig. 47

2. Follow the instructions. (Fig. 48)

Fig. 48

3. Once set up is completed, open Cubify Invent and click

on “Enter License Key;” the license key can be found on

the Installation Card (located in the toolkit). (Fig. 49)

4. Enter the license key in the key eld and select “Finish.”

(Fig. 50)

Fig. 49 Fig. 50

5. Congratulations! You now have access to Cubify Invent.

DOWNLOADING AND INSTALLING CUBEX SOFTWARE

Go to Cubify.com/cubex/index.aspx and click on DOWNLOAD

SOFTWARE FOR WINDOWS to your USB stick or save on your computer.

(Fig. 51)

1. Go to the directory where the CubeX software was downloaded and

unzip the CubeX software folder.

Fig. 51

17

2. Run the CubeX Setup le. (Fig. 52)

3. Follow the installer wizard. (Fig. 53)

4. Select a destination for the installation. (Fig. 54)

5. Click next to begin the installation. A message “if you want to let the

CubeX software make changes to your computer” will appear, select

yes. (Fig. 55 & 56)

Fig. 52

Fig. 53

Fig. 54

Fig. 55 Fig. 56

6. The installation is now complete, you can open the CubeX software from the icon located on

your desktop. (Fig. 57)

CUBEX SOFTWARE OVERVIEW

• The CubeX software is used to create the .cubex les that your CubeX will use to

create your parts. The software allows you to orient, scale, re-size and rotate the

part before printing. (Fig. 58)

• When you rst open the CubeX software you will be greeted with a message

asking you to congure your printer in the CubeX software. (Fig. 59)

Fig. 57

Fig. 58

18

Fig. 59

• Once the printer conguration window opens, select the number of “Print Jets” that

is installed and the material types that are loaded into the Print Jets. Click “OK” to

save these settings. (Fig. 60)

CUBEX SOFTWARE USER INTERFACE

HOME TAB

STL FILE Open Opens a .stl le

Open Model Assembly Open a multi-part assembly of .stl les

Close Close the open .stl le

Save As Save the current open .stl le

Auto Place Automatically places .stl les which are

already open

Fig. 60

Single Shell When checked will automatically select all

parts as one shell

PRINT FILE Open Opens a .cubex le

Close Close the open .cubex le

Save Print File Save the current open .cubex le

SCALE GEOMETRY % Scale Scale your part before creating the .cubex

le

To mm Change a part from inches to mm

To inches Change a part from mm to inches

Revert Undo changes made using the Scale

Geometry options

ROTATE GEOMETRY X / Y / Z Rotate the part in the X, Y, or Z axis

Revert Undo changes made using the Rotate

Geometry options

PICK SHELLS Select which Print Jets print which parts. The available options will vary depending on

how many Print Jets you have active and what colors are loaded into them.

BUILD Opens the build settings window.

19

VIEW TAB

ZOOM Zoom In Press to zoom in

Zoom Out Press to zoom out

VIEW Top View Press to view the part from above

Front View Press to view the part from the front

Left View Press to view the part from the left

Right View Press to view the part from the right

PRINT PATHS Show Print Jet 1 Toggle to show the print paths for print jet

1 in a .cubex le

Show Print Jet 2 Toggle to show the print paths for print jet

2 in a .cubex le

Show Print Jet 3 Toggle to show the print paths for print jet

3 in a .cubex le

Show All Layers Toggle to show all layers or to show one

layer at a time. Scroll through the layers

using the scroll bar found down the right

hand side of the window

SETTINGS TAB

PRINTER

CONFIGURATION

BUILD SETTINGS Opens the build settings window.

FIRMWARE UPDATE Used to update the CubeX 3D Printer rmware.

Opens the printer conguration window.

CREATION FILE PREPARATION & PRINTING YOUR CREATIONS

WARNING: PRINT JET TIPS BECOME EXTREMELY HOT DURING SET-UP AND OPERATION. DO NOT

TOUCH PRINT JET TIP.

DO NOT CHANGE CARTRIDGE COLOR OR MATERIAL TYPE DURING PRINTING; DOING SO MAY DAMAGE

THE CUBEX.

!

HOW TO OPEN FILES IN THE CUBEX SOFTWARE

The CubeX software has three different possible ways to open .stl les. A single part le, multiple single part les on one

Print Pad and a multi-part le assembly.

• A single part le consists of one .stl le with one shell on a Print Pad.

20

• A multiple single part le consist of multiple .stl les opened onto one Print Pad, these can be selected as one, two or

three shells.

• A multi-part assembly le consist of multiple .stl les designed to create one assembly part. These can be treated as one,

two or three shells.

OPENING A SINGLE PART FILE

1. Click on Open Model. (Fig. 61)

Fig. 61

2. Select your .stl le or .creation le and click open. (Fig. 62)

Fig. 62

3. The le will appear in the middle of the bed in the software. (Fig. 63)

4. When printing in a single material be sure to keep Single Shell selected. (Fig. 64)

OPENING MULTIPLE SINGLE PART FILES

1. With your rst .stl le open, return to the open option. (Fig. 65)

2. Open your next .stl le. (Fig. 66)

Fig. 63

Fig. 64

Fig. 65

21

Fig. 66

3. The second part will open in the center of the bed and appear to be merged

with the rst part. (Fig. 67)

POSITIONING MULTIPLE PARTS

• Manual positioning: Right click and hold on one of the

parts, you can now drag it around the bed (when using

this method the bed will automatically switch to top view).

(Fig. 68 & 69)

Fig. 68 Fig. 69

• Autoplace: Clicking the auto place button will

automatically position your parts on the bed for you.

(Fig. 70 & 71)

Fig. 67

Fig. 70 Fig. 71

OPENING A MULTI-PART ASSEMBLY FILE

1. Select the Open Model Assembly. (Fig. 72)

2. Open the rst part of your .stl assembly le, a screen will appear asking if you wish

to add an additional assembly model. Selecting OK will bring back the open le

window. (Fig. 73)

3. Continue following this process until all of your .stl les are open. (Fig. 74)

Fig. 72

Fig. 73

22

Fig. 74

4. When all the .stl les are open, click the done button to nish the assembly le. This

le can now be treated as one .stl le with multiple shells. (Fig. 75)

USING THE SHELL SELECTOR TOOL

The Shell Selector tool is used to select which Print Jets print which parts of a multi-material part/multiple

parts on a Print Pad. The color options available will correspond to the material colors you have set in

printer conguration. (Fig. 76)

1. Select the shell color you wish to use. (Fig. 77)

2. Hover over the shell you wish to select. (Fig. 78)

Fig. 75

Fig. 76

Fig. 77

3. Left click to color the shell. (Fig. 79)

4. Continue this process until all the shells are colored as desired. (Fig. 80)

5. When you have nished using the Shell Selector tool press the done button. Some features of the

software may not be available with the shell selector tool active. (Fig. 81)

Fig. 78

Fig. 79

Fig. 80

Fig. 81

23

ROTATING A PART

Use the rotate buttons to rotate the part in the desired axis. The amount the part will be turned is

defaulted to 90°. This can be changed to suit your needs. (Fig. 82)

Fig. 82

SCALING A PART

You can scale a part by pressing the scale button. The amount your part will be scaled by is defaulted

to 50%. This can be changed to suit your needs. You can also use the – to mm and + to inch to scale by

unit conversion. (Fig. 83)

Fig. 83

USING THE CUBEX SOFTWARE TO BUILD A .CUBEX FILE (Fig. 84)

Fig. 84

BUILD STYLE PROFILE Use this to select previously saved print settings. To save print settings you are using for

future quick selection, press the save as button and give the prole a name.

LAYER THICKNESS This is the resolution your part will be printed at.

• 0.1mm: The CubeX 3D Printers nest resolution. This layer height takes the longest

to print but gives the best quality parts.

• 0.25mm: A middle ground between 0.1mm and

• 0.5mm: This layer height is faster than 0.1mm but is slightly lower quality.

• 0.5mm: The CubeX 3D Printers fastest resolution. This layer height has a lower

quality than 0.1mm and 0.25mm but has a much faster print time.

PART DENSITY This is how much solid ll your part will contain.

• Hollow: The part will have no internal structure.

• Thin: The part will have a small amount of internal structure to give it support.

• Medium: The part will have a good internal structure supporting it.

• Heavy: A heavy part with a strong internal structure.

RAFT MATERIAL Use this to select which material will print your raft or the raftless option. We recommend

printing raftless but some larger parts may require a raft.

SUPPORT MATERIAL Use this to select your support material or the no support option. Support material

may be required when printing parts with overhangs greater than 50°. Before printing

with supports try rotating your model in the software to see if this can eliminate the

overhangs. If this is not possible then supports may be required.

SUPPORT TYPE Choose between points and lines for your support material. Does not affect the print if no

support is selected.

FINE DETAIL

Enabling this will preserve ner details of your part, but may affect accuracy.

PRESERVATION

24

PART MATERIAL Similar to Printer Conguration, this tells the software which materials are loaded into

which print jets. Part materials works in a similar way to Printer Conguration, telling

the software which materials are loaded into which print jets. Please be sure that

the materials selected in part materials correspond to the print jets the materials are

allocated too.

BUILD Once you have selected all of your preferences, press the build button to create the

.cubex le.

SAVING A .CUBEX FILE FOR PRINTING

1. Click the Save Print File button. (Fig. 85)

Fig. 85

2. Your le can be saved on the USB stick or your computer. Choose the location

you wish to save the .cubex le, give it a suitable name and click “Save.”

Transfer the .cubex le to your USB stick for printing or save it on your USB

stick. (Fig. 86)

Fig. 86

PRINTING YOUR CREATION

1. When you are ready to print your creation, insert the USB stick containing your .cubex

le into the USB port on the CubeX. (Fig. 87)

2. Use the Magic CubeX Glue to coat the Print Pad with a layer

of glue. Turn the CubeX Glue upside down so the glue ows

to the tip. (Fig. 88)

3. Apply 3 layers of Magic CubeX Glue using a slow circular

motion. If the print is large, ensure that the glue covers the

Print Pad surface where the creation will print. If it is a smaller

print, cover the middle of Print Pad with the glue. (Fig. 89)

Fig. 88 Fig. 89

4. Select the ‘Print’ option from the main menu. (Fig. 90)

5. Using the arrows at the bottom of the screen, scroll to the

.cubex le you wish to print and tap on the le name. Your

creation will start printing. (Fig. 91)

Fig. 87

25

Fig. 90 Fig. 91

FINISHING YOUR CREATION

REMOVING YOUR CREATION FROM THE PRINT PAD

Before you attempt to remove your creation from the Print Pad, please ensure that the CubeX has nished

printing and that the Print Pad has moved to the bottom of the CubeX.

!

1. Lift the Print Pad from the side and pull up to remove the Print Pad from the

CubeX.

2. Submerge Print Pad and the base of the part in warm water for ve minutes.

(Fig. 92) If you do not have the ability to submerge the Print Pad place Print Pad

in sink and let hot water run over the base of the part for about 5 minutes.

3. Using the scraper (included in tool kit), gently release your creation from the

glass. (Fig. 93)

Fig. 92

Fig. 93

4. Rinse your creation under hot water to ensure all of the Magic CubeX Glue paste has been removed.

5. To clean the Print Pad, rinse the pad under hot water to clean off any remaining Magic CubeX Glue paste.

6. Dry the Print Pad thoroughly before reinstalling it into CubeX.

REMOVING RAFTS

A raft is the at support structure that is attached to your creation. Though we recommend printing without a raft, some larger

or more complicated parts may require one. If you print with a raft, the following instructions will help you remove it:

ABS RAFT / PLA PART - PLA RAFT / ABS PART ABS rafts can be peeled away from PLA parts.

ABS RAFT / ABS PART - PLA RAFT / PLA PART Use pliers to pull away as much of the raft as possible.

Then use a rough-grade sandpaper to remove the

remaining raft, followed by a ne-grade wet and dry

sandpaper to achieve a smoother nish.

REMOVING SUPPORTS WITH WIRE CUTTERS

Use wire cutters to cut away the support structure from your model. You should cut the supports at the point where they

touch the model.

26

REMOVING SUPPORTS WITH THE ULTRASONIC SUPPORT REMOVAL TANK (sold separately)

Caustic soda can burn if handled improperly. Never handle caustic soda without using all of the supplied

Personal Protective Equipment (PPE): gloves, goggles and tongs. If caustic soda touches the skin, wash it away

!

immediately. If caustic soda touches the eyes, immediately use an eyewash treatment.

Never operate the unit without water in the cleaning tank. Damage may occur.

Never use boiling water. Damage may occur.

The Ultrasonic Support Removal Tank automatically removes PLA support material from ABS models. The tank uses one of

two methods to remove or weaken the material:

• Use caustic soda solution in the Ultrasonic Support Removal tank for 3 hours to dissolve the PLA material.

• Weakening the PLA material for manual removal by lightly scraping or by hot water soak for 48 hours

METHOD ADVANTAGES DISADVANTAGES

Hot water Avoid use of corrosive chemicals Support material requires slight physical

force to crumble away.

Support material in hidden cavities may

remain if user is unable to reach them.

Process is relatively extended.

Caustic soda Quick removal.

Support material in hidden cavities will be

dissolved without physical force, provided

the solution can reach the cavity

Requires health and safety procedures.

HOT WATER METHOD

This process uses hot water (approximately 80°C). Wear all Personal Protective Equipment (PPE).

!

Do not operate without water in the cleaning tank. Damage may occur.

Never use boiling water. Damage may occur.

1. Position the unit on a at and stable work surface. Do not knock or move the tank during operation. This risks splashing

water onto electrical components.

2. Pour 0.75 liters of water into the tank.

3. Place the models to be cleaned in the tank.

4. Close the lid, connect the power supply and press the power button to turn on the tank.

5. Use the -5 and +5 buttons to set the temperature. For best results, set the temperature to 80°C.

6. Set an alarm for 48 hours. Do not use the timer on the tank when using the hot water method. This is intended for the

ultrasonic operation used with the caustic soda method and will only run for 180 minutes.

7. After 48 hours, remove your model from the tank using the provided plastic tongs and immediately run under cold water

for 1-2 minutes.

8. Make sure you turned off the Ultrasonic Support Removal Tank.

9. After the model has been washed, the PLA support material should crumble away easily. You can use a blunt knife to

scrape the support away from the model. Additional rinsing may help ush remaining support material fragments from

the model.

27

CAUSTIC SODA METHOD

Caustic soda can burn if handled improperly. Never handle caustic soda without using all of the supplied

Personal Protective Equipment (PPE): gloves, goggles and tongs. If caustic soda touches the skin, wash it

!

away immediately. If caustic soda touches the eyes, immediately use an eyewash treatment.

Never operate the unit without water in the cleaning tank. Damage may occur.

Never use boiling water. Damage may occur.

1. Position the unit on a at and stable work surface. Do not knock or move the tank during operation. This risks splashing

water onto electrical components.

2. Fill the tank with 0.75 liters of cold water. The caustic soda will create an exothermic reaction when added, which will

elevate the temperature of the solution.

Caustic soda is a harmful substance and can cause permanent damage if it touches the skin or eyes.

Use of personal protective equipment is essential. Never handle caustic soda without using the

!

supplied gloves and eye protection. Ensure that the area is cleaned down immediately after use, and

lock the caustic soda away to prevent misuse.

Do not engage the ultrasonic feature while stirring in the caustic soda. This will encourage the

solution to vaporize.

Ensure the area is well ventilated, and do not directly inhale the vapor from the tank.

3. Using scales and a measuring bowl, measure out 200 grams of caustic soda.

4. Pour the caustic soda into the tank in approximately 40-gram increments, stirring thoroughly after each addition. Stirring

is essential to make sure the caustic soda granules do not collect at the bottom of the tank.

5. Immediately clean measuring bowl and scales to ensure removal of all caustic soda.

6. Using the plastic tongs and all the personal protection equipment provided, gently lower the model into the caustic soda

solution being very careful not to spill any of the solution.

7. Close the lid, connect the power supply and press the power button to turn on the tank.

8. Use the -5 and +5 buttons to set the temperature. For best results, set the temperature to 60°C.

Do not set the temperature above 60°C as the reaction between the caustic soda and the water is

exothermic, and will continue to elevate the temperature. Actual temperature should never exceed

!

80°C.

9. Once the tank has reached 60°C, use the -5 and +5 buttons to set the timer for 180 minutes. The ultrasonic process will

begin as soon as you have set the time.

10. After 180 minutes, remove your model from the tank using the plastic tongs and wearing the personal protection

equipment provided. Immediately run under cold water for 1-2 minutes.

Continue wearing your personal protection equipment when handling the model until the manual tells

!

you it is safe to do otherwise.

11. All support material should have dissolved. Any remaining supports can be crumbled or scraped away with a knife, or

rinsed off in the sink.

12. Empty the caustic solution from your Ultrasonic Support Removal Tank. It is safe to pour it in the sink as caustic soda

can be used as a drain cleaner.

13. Rinse the tank and rell it with 0.75 liters of water.

14. Using the plastic tongs, place the model back in the tank.

15. Once you have cleaned all caustic soda from the area, you may remove your personal protection equipment.

16. Repeat the ultrasonic process with the clean water for 30 minutes at 60°C to remove any caustic soda residue that may

remain on the model.

17. Once you have completed the ultrasonic process for the second time, use the provided tongs to remove the model from

the ultrasonic tank and rinse it under cold water for 1-2 minutes.

28

CUBEX MAINTENANCE

RESTORING ROUGHNESS TO THE PRINT PAD

To restore roughness to the Print Pad, run the sandpaper included in your toolkit

diagonally across the bed corner to corner in both directions. (Fig. 94)

LEVELING THE JET WIPER HEIGHT

If your Jet Wiper is set too low or too high, you can adjust it using the orange capped

bolt located under the print jet, screwing it into the oor to set the Jet wipe lower and

unscrewing it to set the Jet Wipe higher. (Fig. 95)

It is important that the Print Pad is level in order to get a good print. To help you out,

we make every effort to ensure that the Print Pad is level when the machine leaves

our factory. However, the Print Pad may move in transit, making it necessary to

check that it is still level when it reaches you.

You will rst need to ensure that your aluminum pad support is level. After this you

can install the Print Pad and ne-tune the leveling.

NOTE: When leveling the Print Pad, always use print tip 1 as your reference.

Fig. 94

Fig. 95

LEVELING THE PRINT PAD

Make sure the Print Pad is securely installed onto the Aluminum Print Plate. Do not perform leveling function without the

Print Pad correctly installed.

The aluminum print plate is mounted on three sprung bolts which allow you to adjust the height of the Print Plate in three

places.

The ‘Level’ function moves the extruder carriage around the corners of the print area so the operator

can adjust the Print Pad support bolts for leveling.

1. Select ‘Level’ on the touchscreen. (Fig. 96)

2. Use the Up and Down arrows to raise and lower the print plate to adjust the

gap between the print jet tip and Print Plate. Start with approximately 10 mm

between the tip and the Print Pad. This distance will enable rough leveling. (Fig.

97)

LEVEL

Fig. 96

Fig. 97

29

3. Touch the ‘Clockwise’ and ‘Counter-clockwise’ buttons to automatically

move the carriage around the corners of the print area. (Fig. 98)

4. From the side of the printer, observe any changes

in distance between the Print Plate and the Print Jet

during each movement along the side of the Print

Plate. (Fig. 99-102)

LEVEL BED

Fig. 98

Fig. 99

Fig. 101 Fig. 102

5. Using the 3mm hex driver from the tool kit, adjust the height of the Print Pad bolts

(Fig. 103) to make each side level.

6. There is a locking nut beneath each of the 3 bed bolts that must be loosened

with the 8mm spanner wrench before the bolt can be adjusted. (Fig. 104)

7. It may take several Print Jet movements and bolt adjustments to ensure that the

Print Plate is level.

Fig. 100

Fig. 103

8. Ensure that axes have been checked from the appropriate side of the printer (to better gauge atness).

30

Fig. 104

FINE-TUNING YOUR PRINT PAD

1. Re-install the Print Pad before ne tuning.

2. Use the Up and Down arrows to reduce the gap between the print jet and Print Pad

to approximately 2 mm. This will enable ner leveling. (Fig. 105)

3. Use the two remaining visible bolts to repeat the leveling process.

4. Click the ‘Function’ button to leave the ‘Level’ menu, and return to the main menu.

CAUTION: Observe each axis movement and ensure the print jet

is not touching the Print Pad. Moving the axis when the print jet is

touching the Print Pad will damage both the print jet and the Print

!

Pad. If the print jet touches the Print Pad, immediately lower the Print

Pad using the Down arrow.

NOTE: Remember to lock the 3 Print Pad bolts into position by tightening the lock nut under each with the 8mm

spanner wrench. To stop the bolt from spinning while you tighten the nut, hold it in position with the 3mm hex

driver found on the top side of the Print Pad.

Fig. 105

UNBLOCKING THE CUBEX PRINT JET TIP

If your CubeX will not jet material, you can unblock the print jet tip by going into ‘PJ-CONN’ from the main menu and heating

the tip to 260°C. Using the 0.5mm drill bit from the tool kit (a drill is not needed), feed the drill bit into the print jet tip, being

careful not to bend the drill bit. Remove the drill bit and set the motor to 3RPM. Repeat this process until the print jet tip jets.

WARNING: THE DRILL BIT AND THE PRINT JET TIP CAN BECOME HOT WHEN UNBLOCKING THE PRINT

!

JET TIP. USE HEAT RESISTANT GLOVES WHEN UNBLOCKING THE CUBEX PRINT JET TIP.

UNBLOCKING THE CUBEX PRINT JET

If the print jet tip still won’t jet material after unblocking it, you may need to unblock the print jet. First remove the delivery

tube face plate and take out the cartridge, removing all lament from the corresponding cartridge bay, delivery tube and print

jet. Then go into ‘PJ-CONN’ from the main menu and set the print jet temperature to 260°C. Once this temperature has been

reached, insert an unfolded paper clip into the print jet through the lament loading hole and push it in as far as possible.

Run the print jet at 2RPM and gently push down on the paper clip until you feel resistance. Start reversing the print jet at

-2RPM and slowly pull the paper clip back out of the print jet. Reload the cartridge and lament back into the print jet and try

to jet material again. If your print jet still won’t jet material at this point, contact Cubify support.

WARNING: PRINT JET TIP BECOMES EXTREMELY HOT DURING SET-UP AND OPERATION. DO NOT

!

TOUCH PRINT JET TIP.

SETTING THE PRINT JET GAP

After leveling the Print Pad, the print jet must be set to the correct height to ensure that the rst printed layer sticks properly

(if the print jet is too high, the lament will not stick to the Print Pad; if the print jet is too low, the Print Pad may obstruct the

print jet). Use the ‘Z Gap’ function to accurately adjust the height of the print jet for the rst layer.

• Select the ‘Z-Gap’ function on the touchscreen. (Fig. 106)

Z GAP

Z

Fig. 106

31

• Observe the gap between the print jet and

Print Pad from the front of the machine.

(Fig. 107) Press and hold the Z +/- buttons

to move the Print Pad. (Fig. 108)

SET Z HEIGHT

Offset:-19.82

Fig. 107 Fig. 108

• Make sure the print jet is clean. For cleaning instructions, see ‘MAINTAINING YOUR CUBEX > Cleaning the Print Jet’).

• Starting with a gap between the Print Pad and the print jet, move the Print Pad towards the print jet using the up (+) “SET

Z HEIGHT” touchscreen. Observe the Print Pad as it approaches the print jet.

• Stop raising the Print Pad as soon as the print jet touches the Print Pad’s surface. If the Print Pad goes too far, simply

move the Print Pad back and repeat the approach.

• Lower the Print Pad by 0.1 to produce a large enough Z gap for printing.

CAUTION: IF THE PRINT JET PUSHES AGAINST THE PRINT PAD TOO HARD, THE PRINT JET WILL BE

FORCED INTO THE PRINT PAD FOR THE ENTIRE FIRST LAYER OF PRINTING. THIS WILL DAMAGE

!

BOTH THE PRINT PAD AND THE PRINT JET. MAKE SURE THE PRINT PAD SPRINGS ARE NOT

COMPROMISED WHEN SETTING THE PRINT JET AGAINST THE PRINT PAD.

• Clicking the ‘Function’ button gives the option to save the gap setting to the printer’s memory, which will be retained even

after the printer is powered off. This Z gap value will be applied for each subsequent print.

UPDATING CUBEX FIRMWARE

If you are unsure what version of rmware is currently installed on your CubeX 3D Printer,

navigate to the UPDATE button on the main menu and the version number will be located

beneath it. (Fig. 109)

5. Plug your USB stick into the CubeX 3D Printer. (Fig. 110)

6. Navigate to the “Update” button on the main menu. Press and hold the function button. (Fig.

111)

Fig. 109

Fig. 110

32

Fig. 111

7. Press the tick on the screen to put the CubeX 3D Printer into boot

loader mode. (Fig. 112 & 113). Release the function button after

“Setting saved” message disappears. Your printer is now in rmware

mode.

8. Remove the USB stick from the CubeX 3D Printer. (Fig. 114)

9. Open the CubeX software on your computer. (Fig. 115)

Fig. 112 Fig. 113

Fig. 114

10. Plug your CubeX into the computer using the PC connection USB

port. (Fig. 116 & 117)

Fig. 116 Fig. 117

11. Navigate to the settings tab to the CubeX software and press the Firmware update button.

(Fig. 118)

12. The CubeX software will then open windows explorer. Navigate to the

rmware you wish to install and open it. (Fig. 119)

13. The CubeX software will now install the rmware onto the CubeX printer. (Fig.

120)

14. Once the rmware is installed unplug the printer from the main power for

30 seconds and unplug the USB from the computer. (If you are upgrading

from rmware version 1.01, please skip to the section RESTORING THE

SETTINGS TO YOUR CUBEX 3D PRINTER FIRMWARE FROM V1.01)

Fig. 115

Fig. 118

Fig. 119

33

Fig. 120

15. Plug the USB stick into the CubeX 3D Printer and press the control button; you will receive

a notication of your settings being restored. (Fig. 121)

Fig. 121

16. Your rmware has now been upgraded. (Fig. 122)

Fig. 122

RESTORING THE SETTINGS YOUR CUBEX PRINTER FIRMWARE FROM V1.01

Before following these instructions, please follow instruction 1-9 in the section UPGRADING YOUR CUBEX PRINTER

FIRMWARE.

1. Turn on the CubeX 3D Printer. You will see the activation screen.

2. Re-activate your printer using your activation code. (if you do not have your activation code, you can locate it be going

to Cubify.com > MY ACCOUNT > MY DEVICES and then viewing your registered CubeX).

3. Once it is re-activated turn off the CubeX 3D Printer.

4. Plug the USB stick into the CubeX 3D Printer and turn it on, touch the screen and you will receive a notication of your

settings being restored.

5. Your rmware has now been upgraded.

HOW TO CONTACT CUBIFY SUPPORT

If you have any problems with your CubeX that cannot be solved using this manual, please contact

cubifysupport@cubify.com for your support related issues.

SETTING THE CUBEX PRINT JET OFFSETS

CAUTION: Do not use the offset menu unless you have

been advised to do so by Cubify Support, as changes to

!

this may affect the quality of multi-material prints.

Fig. 123

34

PRINTING THE

CALIBRATION FILE

Download the CubeX calibration le from Cubify.com.

Print the CubeX calibration le as you would any other print le.

READING THE

CALIBRATION FILE

The lines on the calibration print are offset by 0.1 mm. The amount of misalignment can

be calculated by

counting the amount Scale 2 or 3 is offset from Scale 1.

• Scale 1 is printed by Print Jet 1. This is the reference print jet. All offsets are relative

to Print Jet 1.

• Scale 2 is printed by Print Jet 2. This error amount is the amount Print Jet 2 needs its

offsets to be adjusted.

• Scale 3 is printed by Print Jet 3. This error amount is the amount Print Jet 3 needs its

offsets to be adjusted.

HOW TO ADJUST THE

OFFSETS

Touch the relative offset to activate it, a plus and a minus will appear at the side of the

screen. Use this plus and minus to adjust the offset.

PRINT JET 2 Y OFFSET Compare the lines on “Y scale 1” and “Y scale 2” to nd the ones that most accurately

line up. Because variation is small, it may be easiest to spot 3 that look like they all line

up. If this is the case, use the middle one as the correct one. Mark this line with a pen for

easier identication.

On “Y scale 2” count from the center line (with the arrow) to the marked line. If you are

counting down, the scale the number is negative. If you are counting up, the scale the

number is positive. Write down the offset.

• In the example shown in Figure 123, the Y offset for extruder 2 is -0.4mm.

PRINT JET 3 Y OFFSET Compare the lines on “Y scale 1” and “Y scale 3” to nd the ones that most accurately

line up. Because variation is small, it may be easiest to spot 3 that look like they all line

up. If this is the case, use the middle one as the correct one. Mark this line with a pen

for easier identication. On “Y scale 3” count from the center line (with the arrow) to

the marked line. If you are counting down, the scale the number is negative. If you are

counting up, the scale the number is positive.Write down the offset.

• In the example shown in Figure 123, the Y offset for extruder 3 is +0.6mm.

PRINT JET 2 X OFFSET Compare the lines on “X scale 1” and “X scale 2” to nd the ones that most accurately

line up. Because variation is small, it may be easiest to spot 3 that look like they all line

up. If this is the case, use the middle one as the correct one. Mark this line with a pen for

easier identication.

On “X scale “2 count from the center line (with the arrow) to the marked line. If you are

counting left, the scale the number is negative. If you are counting right, the scale the

number is positive. Write down the offset.

• In the example shown in Figure 123, the X offset for extruder 2 is +0.9mm.

PRINT JET 3 X OFFSET Compare the lines on “X scale 1” and “X scale 3” to nd the ones that most accurately

line up. Because variation is small, it may be easiest to spot 3 that look like they all line

up. If this is the case, use the middle one as the correct one. Mark this line with a pen for

easier identication.

On “X scale 3” count from the center line (with the arrow) to the marked line. If you are

counting left, the scale the number is negative. If you are counting right, the scale the

number is positive. Write down the offset.

• In the example shown in Figure 123, the X offset for extruder 3 is +1.1mm.

35

3D Systems, Inc.

333 Three D Systems Circle | Rock Hill, SC | 29730

Cubify.com

©2013 3D Systems, Inc. All rights reserved.

The 3D Systems logo, CubeX and Cubify are

registered trademarks of 3D Systems, Inc.

pn: 401647-00 Rev. C

Loading...

Loading...