Page 1

Welcome to a Revolution with No Limits!

ENGLISH USER MANUAL

Rev 1.1

Page 2

Introduction to the manual

Before starting, read carefully this manual to guarantee the proper use of the equipment.

Pay close attention to the warnings and security measures indicated in the manual.

The pictures of the equipment are subject to change.

3DLimitLess will not be responsible for performance issues due to changes done by the user to

the parameters of the firmware and software provided.

Page 3

TABLE OF CONTENTS

1. Safety instructions

2. Package contents

3. Product detail

4. Printer unpacking and proper handling

5. First look at the Printer 3D LimitLess ILC

5.1 Features and functions

6. Start Up

6.1 Manual printing (from SD)

6.2 Computer printing

7. Recommendations for proper use and maintenance

8. Printing problems

8.1 Lack of extrusion starting the printing

8.2 First layer does not adhere to the printing base

8.3 Lacking extrusion

8.4 Over extrusion

8.5 Holes on the top part of the pieces

8.6 Detecting fine lines on the pieces

8.7 Excessive heating

8.8 Marks on the top side

8.9 Layers sliding

8.10 Clogged nozzle

8.11 Plastic bubbles in the piece

8.12 Spaces in the top surface between parameters and filling

8.13 Warping

8.14 Layers gap

8.15 Split filament

9. Product proper disposal

10. Informative links

11. Warranty

12. EC Declaration of conformity

Page 4

1. SAFETY INSTRUCTIONS

Non-compliance of the security measures could lead to personal and material damages

(burns, cuts and bruises, even fires.) The following security and safety directions can

protect your health, of others, and the product’s. In the case of giving this machine to

someone else, be sure to pass the manual as well.

This machine should not be handle by people insensitive to heat and/or dependent

people who can not react quickly to overheating. In the same matter, the use of this

machine should be limited to people who have physical, sensorial or mental

difficulties, as well as lack of knowledge and experience, unless it has been explained

properly and understands the risks that entails.

Prevent children from unsupervised access to the printer.

This machine generates high heat temperatures. Let it cool down before

handling the printer.

The machine could keep warm for few minutes after printing.

The printer includes movable parts that could cause injuries. Assure yourself that

the machine has fully stopped and it has no electrical power supply before

handling it.

Do not open the lower and upper lids of the printer. The interior contents are all

electrical (power supply, control panel, and a Solid State Relay) could cause an

electric shock. The interior component should be manipulated by a professional.

There are air intakes on the sides and a fan in the back of the printer, these

elements should not be cover up for the correct operation of the device.

In case of emergency, disconnect the printer from the power outlet.

Do not leave the machine unattended while functioning.

Keep out of reach of children and always under adult supervision. It could have small

parts and material remains.

The device melts down plastics and other materials which could let out odors during

regular functioning. Place the machine in a well ventilated area.

Page 5

Keep in mind the risks of the movable parts (catching, pinching, cutting or smashing)

to your body or someone else’s not following the safety measures. The motor and

movable parts don’t have enough strength to cause any severe damage under

normal use conditions.

About the hot areas, the hotend could reach very high temperatures, if touched,

could cause severe burns. The impression surface could reach temperatures high

enough to cause moderate burns.

DO NOT TOUCH ANY HOT PART OF THE MACHINE, ESPECIALLY

THE HOTEND. BURNING DANGER!!!!!!

Page 6

If you need to remove filament glued to nozzle, use metal tweezers or

another heat resistant utensil.

The LCD screen shows the actual temperatures of hotend and impression

surface. Before touching or intervene in the machine, make sure the heat has

gone down to room temperature.

In need of the hot glass removal from the printer, use gloves or other form of

protection. The glass will keep hot for a long while after been finished.

The tempered glass is heat resistant but be careful not to damage, hit or

break it. There is a risk of cutting yourself in case of breakage. Dispose of it

properly and after that, it needs to be replaced.

Show caution with long hair and loose garments around pulleys, belts, gears,

and fans due to the possible risk of getting stuck in them.

Do not manipulate any electrical connection while functioning or connected

to the power supply. Make sure the device is disconnected from the main

power outlet, before any maintenance is done.

Place the printer on a flat, stable and even surface, avoiding blocking the air

supply.

The 3D Printer is equipped with safety measures against overheating which

will prevent from reaching the established limits, by stopping the heating

process. A warning will appear on the screen “MAX TEMP”. When it happens,

restart the printer.

Do not hold or lift the printer by the arm of the printing hotend (X-Axis) as

well as the lifting shaft spindle (Z Axis); these are non-structural movement

elements.

If/when it’s needed to move the printer, unplug all cables and hold with two

hands on each side of the lower structure.

If you notice any damage on the elements of the printer, do not use it; you

should contact us through the technical support channel to receive the

relevant instructions.

Avoid dissembling, loosening up, tightening up or substituting any of the

printer’s fastening elements. These should be done by the technical support.

High accelerations of movement and changes will happen while the device is

working. Do not access the full volume of printing while is performing.

Page 7

2. PACKAGE CONTENTS

3D Limitless ILC Printer

USB Cable for connection to PC

Power Cord

PLA Filament Spool of 1.75 mm diameter, 750 grs.

SD Card 2GB (with preloaded 3D samples)

Printed test piece

Software CD and Documentation

Recommended Material (not included)

Small sharp Spatula

Hair Spray

Small Tweezers

3. PRODUCT DETAIL

Sturdy and durable construction in aluminum; maintenance free.

Precision linear movements with double bearings and spindle for the Z axis

Useful printing area 200 x 200 x 260mm

Precision movement XYZ: 0,018 x 0,018 x 0,0025mm

All metal hotend, max. Temperature of 300º C (572ºF)

Printer hotend of 0,4mm

1,75mm Filament diameter

Printing speed: 30 to 150mm/sec

Integrated self-leveling surface printing system

Heated impression surface to 130º C (260ºF), fast heating controlled by solid

state relay

Prints any thermoplastic: PLA, ABS, ASA, Copolymer, Nylon, Polycarbonate, PET,

special Filaments (Carbon fiber, Kevlar, Bronze, Bamboo, etc…).

Tempered glass printing surface

High torque stepper motor

Autonomous printing from SD card (2 GB card included)

Backlit LCD screen to control

Dimensions (width, depth, height): 480 x 370 x 520 mm

Weight: 10.2 kg

Page 8

Power: 220v, EU cable 1,8m.

Electric consumption: 440W, 1.8 amps MAX.

Connection: 2.0 USB Cable included

Software: Repetier Host, CuraEngine, Slic3r for Windows, Linux and Mac.

Internal Software: Marlin Open Source, USB upgradeable

Supports object printing: STL, OBJ, DMF, and AMF

Limited warranty up to 12 months.

Printer mounted, calibrated and tested individually

Page 9

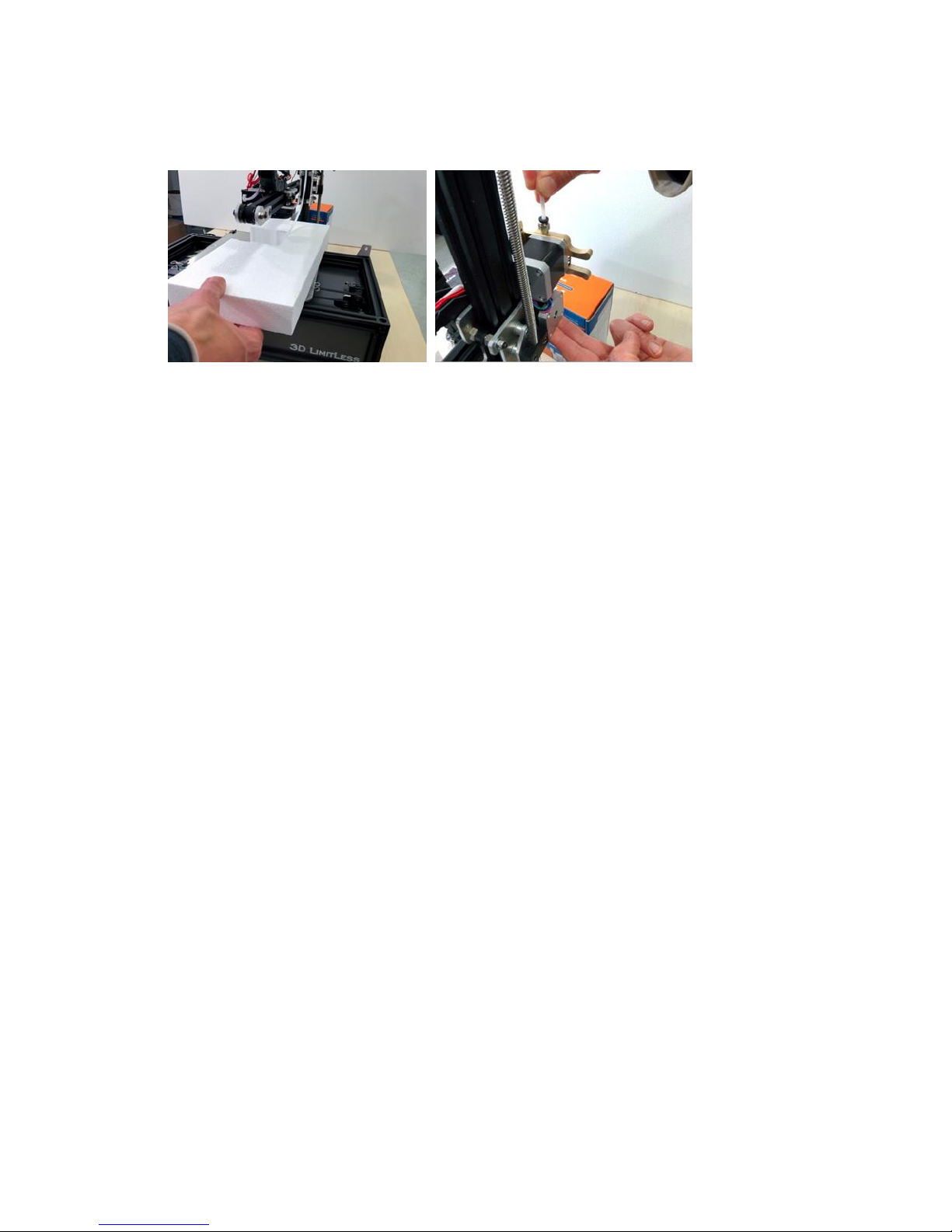

4. PRINTER UNPACKING

Open upper box lapels and take out the accessories bag and foam protections.

Bag contents: power cable, USB cable, CD containing documentation and software, and

spool holder.

Remove the top layer and afterwards, the foam at the four corners. Lift the machine

holding the sides and place it on a stable table

Page 10

Take off the foam from both sides of the Y spindle. Turn manually the spindle shaft Z

clock wise, holding on to the top and bottom sides until hotend surpasses completely

the support foam

Remove the protective hotend foam from the front side. Lastly, introduce the Teflon

pipe into the extruder fitting until stops

Page 11

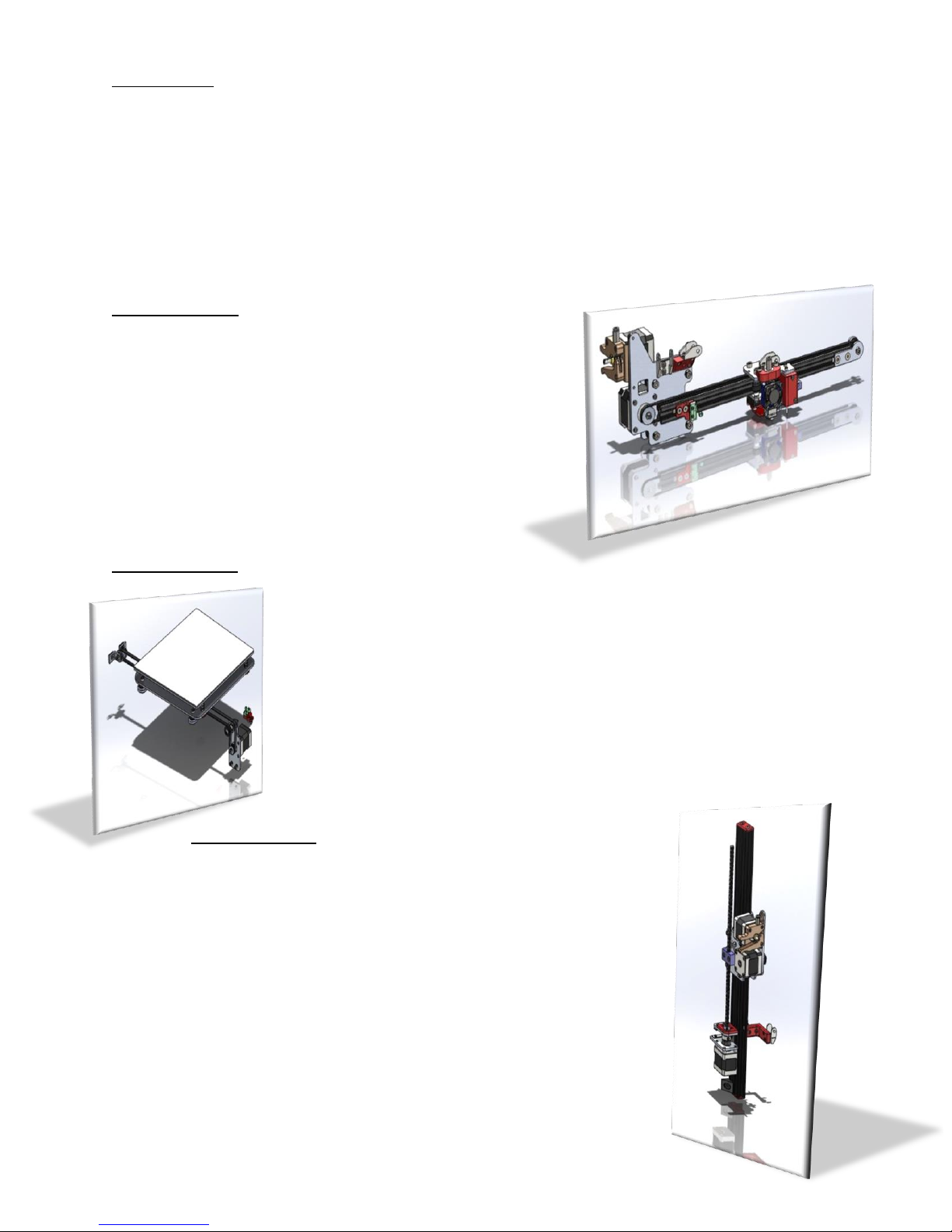

5. First look at the Printer 3 ILC

Important characteristics:

The 3D Printer ILC is built to last with

quality materials to ensure continuous

printing accuracy overtime. Therefore it

does not have functional printed parts

and the materials with which it has been

manufactured give it fluid movement.

It has an innovative design for printers of

its kind.

Crane style, lightened structure

Self-leveling system that allows compensating small unevenness that might exist on the printing

surface with the integration of a correction algorithm.

Displacement carriages on the 3 axis are equipped with elements used in robotics to reduce

friction and vibrations this way achieving a very high speed-precision printing ratio

The printing surface with includes a 220v hot plate, controlled by a solid state relay, will allow a

wide variety of printing materials and considerably reduce the waiting time for the start of

printing compared to the ones with 12/24v.

The Bowden tube filament feeding system lightens the print hotend, reducing inertia due to

weight and vibrations that could have an impact on print quality and achieving higher speeds

Page 12

Printer Part description:

BACK

4. Fan

5. USB Connector

6. Power switch

FRONT

1. SD Card Reader

2. LCD Screen

3. Dial

PRINTER HEAD

8. Hotend with fan

9. Box with self-ventilation system

EXTRUDER

7. Drag element with Nema 17 motor

Page 13

5.1 Features and functions

Important printer components and their function

Extruder

This printer uses a Bowden system, as previously said, in which the extruder assembly and the

hotend are not work together to improve performance

Extruder Assembly

Element responsible for dragging the filament consists of:

The Extruder Motor is responsible to power the element that drags the filament to the hotend

Extruder Assembly includes pressure lever, traction spring, toothed and towing pulleys, guiding

the filament and holding elements to the motor

Printer Head

Printer Hotend is in charge of fusing the material to form the layers of the object printed, this

consists of:

Hotend: Element that heats the filament for extrusion, formed by a Heat-Break (calibrated allmetal inner tube), fan, heater block, thermistor and nozzle.

Layer Fan: Element that controls the extruded filament temperature. It includes an axial fan

and a pipe oriented in such a way as to project the air to the hotend nozzle’s outlet and

regulate the filament’s temperature newly finished.

Self-levelling system: It is placed on the hotend and it is responsible for making a map of the

base of the impression by obtaining the height with respect to the origin of the Axis Z in 9

points. Together with the application of a calculating algorithm, provides a system for

correction of possible unevenness on the printed surface.

At the beginning of the print program, a scheduled routine performs the previously cited

process (initial G Code) it’s available in the software included with the device.

Page 14

Printing Base

The surface where the extruded filament is deposited, the printed object will be formed layerby-layer.

It consists of a silicone resistor of 220v and 400w, which provides the right temperature to

perform the printing with different materials. This temperature is transmitted to a 4mm

aluminum surface and is controlled through a solid-state relay and a thermistor. The last

element of this ensemble is a 4mm tempered glass that is in direct contact with the aluminum

surface and it is the base where the material is deposited.

X-Axis Assembly

Allows the hotend movement, it consists of:

An anodized aluminum profile in cantilever.

Sliding carriage with double roller bearing where

the hotend is located.

Toothed belt movement.

Nema 17 Motor.

Limit switch to set the X Axis origin.

Y-Axis Assembly

Allows the printing base movement throughout the Y Axis, it consists of:

Sliding carriage with double roller bearing where the printing

surface is located.

Toothed belt movement.

Nema 17 Motor.

Limit switch to set the Y Axis origin.

Z-Axis Assembly

The Z axis assembly is in charge of elevating the X Axis assembly and

the extruder, giving the height to the object to be printed. It consists of:

An anodized aluminum profile

A displacement car that raises the X-Axis and the extruder

formed by a system of double bearing wheels.

Spindle with flexible coupling and bearing support.

Nema 17 Motor.

Limit switch used in this case as an emergency stop, since this

Axis origin

Is provided by the self-leveling system.

Page 15

6. START UP

The printer will be ready to make the first impression after unpacking, so the 3DLimitless ILC

printer’s surface is leveled, and the offsets (distance between the nozzle and the impression

surface) are configured in the Firmware. As well as having a self-leveling system that can

correct small deviations from the initial adjustments.

Steps to follow for printing the first object:

Assembly of the spool holder:

Place the spool holder formed by the threaded rod with the set of nuts, the two pieces

of the spool holder and the locking nut, elements that come in the packaging. As shown

in the next picture:

Filament charge:

It is necessary for the hotend to be at minimum temperature so the filament can be

charged; otherwise the system will not allow the motor to move. It is recommended to

follow the instructions indicated by the filament manufacturer (information that can be

seen on the filament packaging or on the spool itself).

Access the LCD menu to Prepare by turning the dial to it and click on it. Select the

option Preheat PLA. The temperature will start rising to its target (200 C in the case of

the supplied filament).

Once it has reached its temperature, proceed to introduce the filament, as seen in the

next pictures, through the lower hole of the extruder. Manually push it until it

overpasses the sprocket and hits the Teflon pipe, pressing the extruder lever.

Page 16

Continue pushing the filament through the Teflon pipe till the end.

Using the dial go back to Prepare in the initial menu and turn it until Move Axis, click on

Advance (in this case 1mm) and press again on the dial. Next, the selection of the axis

will appear on the screen and click on the Extruder Field.

The value 0,00 will show, turn the dial clockwise seeing the value increasing while the

extruder drags the filament through the hotend, coming out through the nozzle as seen

on the lower picture. It is recommended to extrude 10mm minimum as soon as the

filament begins to flow through the extrusion nozzle.

CAUTION!! HIGH TEMPERATURE, DO NOT TOUCH ANY PARTS.

Page 17

Preparation of the printing surface

How the material is adhered to the printing surface and more exactly the firsts few layers, it will

be determent to the quality of the end product. To obtain the correct adhesion, follow the next

recommendations:

The tempered glass must be completely clean. To be able to do it, loosen the clamps

from the aluminum base, take out the glass from the printer and clean it (it is

recommended to use soapy water and a clean rag).

Once the glass is clean, dried and put back on the aluminum base, spray a very thin layer

of hairspray on it to help the material stick more easily.

The printer will be ready for the first impression with these two simple steps.

There is an object made from this printer included to prove correct operation after assembly.

Let’s see how to proceed with the first printing:

6.1. Manual Printing from SD Card

The SD card is inserted in the reader after the display, and

the sense of introduction is with the label back and the

gold contacts forward. It is inserted in the reader this way:

to insert or remove the SD card, hold it with the index

finger and the thumb for more comfort. You will not be

able to be inserted upside down as it will not enter into

the reader.

There are a couple of files included in the SD Card: one is a file of the tested piece and

the other is a test piece to determent the ideal temperature point of PLA (temperature

range from 190 C to 210 C, 5 by 5 ºC).

The SD card is already included in the reader, so only the printer will need to be turned

on, access the menu of the LCD’s SD card and choose the print file. For example, the

ship sample piece (BENCHY.GCODE)

Startup routine will begin immediately, by zeroing all axes and performing a leveling

measurement of the printing base, taking the height data in 9 points of the surface, so a

Page 18

map of the printing base is established. An algorithm is programmed to correct any

unevenness that could happen on the hotend.

The printer will start the warm up of the hotend and the extruder after the self-leveling

is performed. Once both temperatures are reached, it will position itself on the center

to start printing.

Options while printing:

We can stop the printing in two ways:

Pause (printing’s temporary stop)

is very useful when you need to

introduce a new fixing element to the

previous model (for example a recessed nut inside

the piece) and then continue printing.

Stop Printing will fully stop the printing process.

Other modifying options are:

Flow Parameters: Filament amount that comes out of nozzle

(measured in percentage).

Printing Speed: You can increase or decrease the speed of the

printing. Keep in mind that increasing the speed could have repercussions

in the quality of the final print.

Ex. shown: The hotend’s (nozzle) and bed’s temperatures, as well as ventilation’s speed (layer

fan).

6.2. Computer Printing

Software installation

- Run with administrator permits “setupRepetierHost_1_6_1” application

included on the CD or download the latest version of:

http://www.repetier.com/download-now

The version must be updated when required (Windows 7, 8, 10). NOTE: The

program requires Microsoft .Net 4 or higher.

Page 19

- Select LANGUAGE.

- Click on CONTINUE to start the installation program.

- Accept the installation agreement of the software manufacture.

Page 20

- Specify the folder where the program will be installed.

-

- Select the options you want to install, Uncheck the option “Repetier-server”

and continue.

- Click Next.

Page 21

- Create an Icon on the desktop.

- Click Next.

- The program will copy the necessary files on your computer.

Page 22

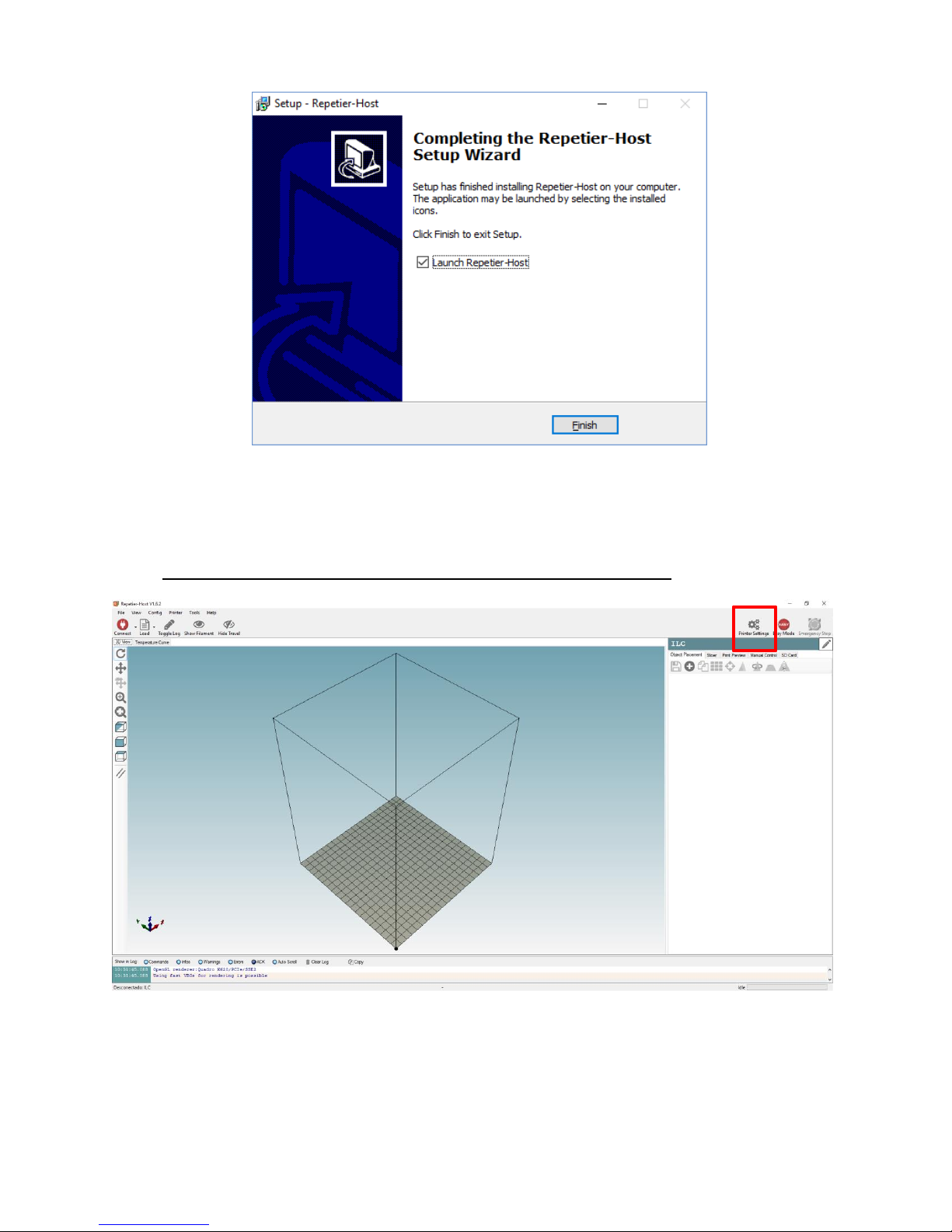

- Once it is finished, click on End and it will open the program directly.

This installation program process is similar to all Microsoft Windows applications. There can be

some differences for Linux and Mac OS systems.

This is the initial screen in the program, a 3D object will appear to demonstrate, that you can

erase. After the first installation you must click the Configure Printer icon.

Page 23

You will enter the following data in the Connecting tab. Make sure to select the right port COM

since it could be different in your computer.

Page 24

On the Printer tab adjust the parameters as shown:

Page 25

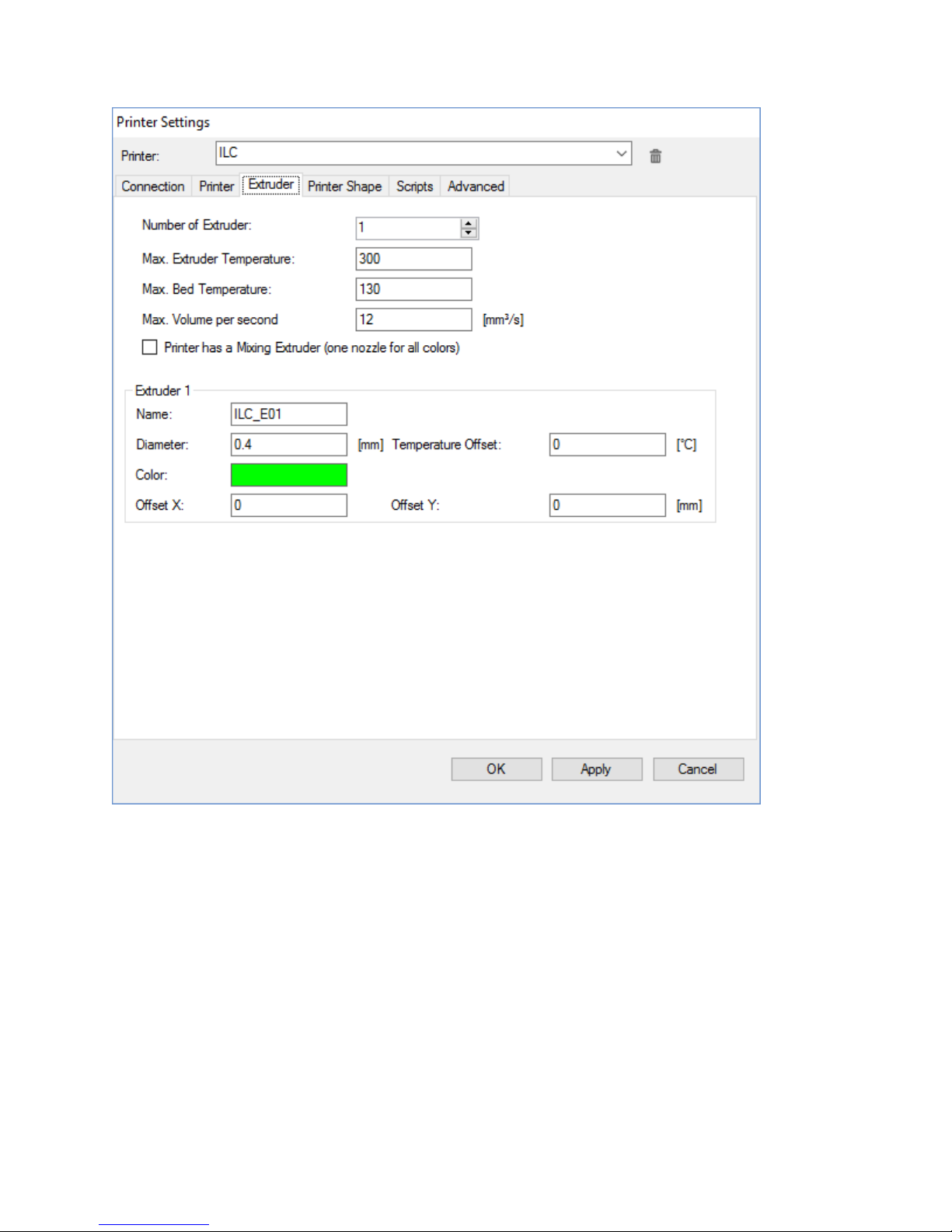

On the Extruder tab adjust the parameters as shown:

Page 26

On the Printer Dimensions tab adjust the parameters as shown:

Note: The parameters dimensions are located on the printer firmware so introducing higher

dimensions will have no effect on the printing surface. In the contrary, lowering the dimensions

of the already specified ones will reduce the printer’s useful surface area. It is recommended

not to modify the printer’s hardware specifications.

The scripts and advanced tabs will be set by default.

Page 27

The working interface consists of several zones:

A 3D display that you can move with the mouse and an option zone (object, slicer, preview,

manual control and SD card) are on the right.

The 3D object display menus are on the left, as well as the tab to CONNECT to the printer and a

FILE to load a 3D file.

You can view at the bottom a log of commands sent to the printer that you can enable or

disable with the top VIEW LOG tab.

There are two possible slicing programs at the SLICER tab (CuraEngine and Slic3r), choose the

one you want.

A 3D model must be separated into layers or slices in order to be printed; this software is in

charge of doing so, processing and sending the code (GCode) to the printer.

CuraEngine is simple to use and the SLICER by default. We recommend starting with this one if

you are a beginner with the 3D printer.

Page 28

Proceed to configure the default CuraEngine parameters by introducing the following

information on each tab, or you can click on the IMPORT tab to transfer all the printing profiles.

You will find them in the CuraEngine file on this CD.

Page 29

Page 30

Page 31

VERY IMPORTANT!!: Introduce the Start and End GCodes as detailed next and make

sure you use them ALWAYS in all jobs, without them the self-leveling and other

operations will not work correctly.

See also the Print Profiles Cura and Slic3r Manual included in this CD.

START

START GCODE SCRIPT

Page 32

VERY IMPORTANT!!: Introduce the Start and End GCodes as detailed next and make

sure you use them ALWAYS in all jobs, without them the self-leveling and other

operations will not work correctly.

See also the Print Profiles Cura and Slic3r Manual included in this CD.

END

END GCODE SCRIPT

Page 33

Press CONNECT to start communication to the printer; if the connection is successful, it will

turn green. Once connected, you can continue on MANUAL CONTROL:

Slic3r is advanced slicer software with more options than CuraEngine, it also allows you to set

your own printing codes. Once you open the program, select from the dropdown the

CONFIGURE tab and a new window will open with Slic3R program:

As done with the CuraEngine program, Slic3R allows you to set the parameters by introducing

the information on each tab, or you can click on the IMPORT tab to transfer all the printing

profiles by going on FILE> LOAD CONFIG BUNDLE and select the corresponding file. The profiles

are in the SLICER PROFILE of the CD provided.

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

VERY IMPORTANT!!: Introduce the Start and End GCodes as detailed next and make sure

you use them ALWAYS with any job, without them the self-leveling and other operations

will not work correctly.

In Slic3r, Start and End Gcode’s are slight different from the Cura’s gcode, as you can observe.

Page 40

The installation and configuration of the program is done. If you like to experiment with

different values, we recommend setting new Slicer and Filament Profiles.

Page 41

HOW TO WORK WITH REPETIER HOST:

Open the program:

Home Screen:

You can find more functions by going into the Repetier Host manufacturer’s manual.

Download here.

Select FILE which usually comes in the STL format and click on the OBJECT tab at

the right corner of the screen.

Then select the location in your computer or network where your printing file is.

Remember that this should be in any of the compatible formats (refer to the manual). It

will be in our 3DBenchy.stl file.

Once selected, the program will transport and place it in the center of the printing

surface with a preselected orientation. In many cases, it will be necessary to modify the

orientation as well the location depending on the geometry, surface types, refrigeration

needs, etc.

Page 42

After the object is correctly placed, the Repetier program will show the configuration

options. We’ll see each one:

Coping the object

When you click on it, it will ask how many copies are required.

Note: If the copy will be of several different objects, they should be placed inside the

blue square, as shown in the picture.

Page 43

Self-positioning

This option will position the objects in the most optimal space. Let’s look at what

happens when you click on the Self-position tab.

We’ll observe that the objects are placed much closer, optimizing the time of printing by

decreasing the displacements through the printing surface.

Page 44

Center

This option will join together the center of the chosen object with the center of the

printing base.

Page 45

Scale

When you tap on this option a menu will appear:

The scale will be the same on the 3 axis by keeping the lock closed. If what you want is

to scale the axis differently deforming them, you need to tap on the lock.

Note: Scaling can be used to reduce the original size of the objects. For example, by

setting 0.9 would be a 10% reduction equal to 90%. In the contrary a 1.2 would be a 20%

increase corresponding to 120%.

Using the sample at hand we will increase the size by 2.5 equally to 250%, the result is

shown in the next picture:

Page 46

Rotate object

When you go to Rotate option the following menu will appear:

You can rotate positive or negative numbers in 360 degrees on each axis.

Note: You can see the axes orientation by looking at the axes coordinates

representation.

Page 47

You can rotate the object in different ways and forms with the axes orientation as

shown in the sample:

Cut viewer

This option is simply to visualize the internal structure by cutting the object. See the

software’s manual for more details.

Page 48

Mirror

This option will allow you a change of the object’s orientation taking the XY plane

(printing base) as reference, the sample will show the result:

After revising all the different modification options that Repetier offers, you can continue with

the next tab: Slicer.

We will continue with the initial parameters of the sample used previously (Scale, Rotation,

etc.)

Page 49

In this tab you will find the LAYERING options (converting the object into layers). Two layering

motors are integrated in the software, the CuraEngine and Slic3R as part of the Repetier

program (you can get all the details on how to configure them later in this manual).

Let’s see their functions:

The Drop down

It allows you to choose from the two slicing motor options.

Page 50

Slic3R OPTIONS

Cura OPTIONS

This one will allow you to choose the Print

Quality (Print Setting), the Printer (Printer

Settings), and the Filament Configuration

(Extruder I). At the CONFIGURE tab you

must preset the previous adjustable options

which in turn will allow you to see the

program’s as well (refer to the manual).

When you go to the Override Slic3R Settings

you can modify the parameter

configuration (the common ones) without

having to change the preset profile

configuration parameter.

Enable Support will activate the support

placement.

Enable Cooling will activate the layer fan.

Layer Height will set the layer values.

Infill Density will allow establishing the

filling density.

When you go to CuraEngine options you

can select the Printer (Printer

Configuration), Adhesion Type giving you

two options to choose from:

BRIM will create a waste surface attached

to the piece to prevent the printing base

from rising, especially the corners; and

RAFT will create a first layer for the same

reason. Both of them should be removed

and disposed of after printing the object.

Quality tab will define through the layer

height the printing quality.

Support Type will establish the support

options TOUCHING BED and EVERYWHERE,

more detailed explanations on the

CuraEngine manual.

Speed tab will define how quickly the

printing will be between the limits set in the

configuration.

Infill Density, will allow establishing the

filling density.

Extruder 1, will select the Filament

Configuration.

Page 51

You can tap on SLICE with CuraEngine or Slick3R after you defined the slicer motor and its

parameters. The software will start the process in which it will generate the layer and the

GCode necessary to print the object.

The quantity and complexity of the object chosen will determent the amount of time needed

for the process.

As soon as it is finish the program will automatically go to the next tab (Print Preview)

reviewing the print layers:

Page 52

The information you’ll obtain is the following:

Printing Statistics

Estimated Printing Time

Layer Count

Line Count (generated code’s total line number)

Filament Needed (the necessary mm amount for the object)

Display

It allows you to choose the options to preview the object the way it will be done.

Page 53

Show Entirely

Show One Layer

Page 54

Show Range of Layers

Page 55

Once verified the above, click on the PRINT tab and the printing will start by going automatically

to the next tab MANUAL CONTROL where, as explained earlier, you can modify the parameters

while printing.

With the MANUAL CONTROL tab you can use the printer from the application just as the DIAL

and the LCD Screen.

The upper controls will only work when the printer is not operative and they look as shown

next.

You can see if the printer is ON/OFF at the top of the screen.

In the GCode box you can give direct orders to the printer (advanced users only).

In the next box:

You can observe the three axes positions in which the printer is located at the time.

Page 56

You can find the Movement Control. The first one is for the XY Plane.

The empty house icon at the bottom left corner will be used to take all axes back to zero.

VERY IMPORTANT!! When you need to move any axis you must go back to zero (Home)

before so the printer will know where and how much should it move. You should never

move it manually under normal operation conditions.

To move the axis on both directions you need to press on each arrow.

The keys X Y Z will take each axis to HOME (Zero).

The vertical arrows are for the X axis and the horizontal arrows are for the Y axis.

Note: Be aware that the positive direction in the case of the Y is from right to left and of the X

axis is from the back towards the front of the printer.

The Z axis control is located to the right of the previous control.

In the case of the Z axis, Home will be located on the printing surface and its

positive direction corresponds to the increase in quota, meaning elevation

with respect to the printing base.

Page 57

The Extruder is the last control.

With this control you can push the filament with two possible speeds, one faster

than the other.

The retraction however will always perform in the slowest mode.

The rest of the controls are at the bottom of the screen. These are the ones you can

modify while the printing is going on:

Printing Speed starts at 100% and you can increase or decrease it. At higher speed the

quality of printing can be reduced.

Extrusion control can modify the filament quantity that the printer is using, increasing it

when the extrusion is low or reducing it on the contrary.

Ventilation controls the speed of the layer fan for cooling of the extruded material.

Bed Temperature corresponds with the printing surface and it controls its working

temperature.

Extruder 1 is the last control and allows you to control the filament temperature when

exiting nozzle or hotend, adjusting it to each filament.

Page 58

7. Recommendations for proper use and maintenance

Keep the printer clean of debris from materials, especially where the shafts wheels run and

fans.

It can be cleaned with a dry or lightly damp microfiber cloth. When you start cleaning, the

printer’s hot parts must be cold and unplugged from the electrical and USB connections as

well. Plug the printer back on after dry.

The Teflon tube where the extruder filament flows to the hotend must be kept without

folds. If it is removed from the hotend, keep in mind when it is reintroduced that the tube

should go all the way to the bottom (not less than 48mm). This part is very important so to

avoid clogging of the hotend. If the tube is pinched or damaged it must be changed, just as

if the push-fit connectors of both sides are not holding on firmly to the tube.

The cleanliness of the hotend fan must be check frequently since the filament could clog it if

it doesn’t turn as fast as it was established due to dust, debris or obstructions; the hotend

could stop working for lack of cooling. Turn it off when you are cleaning it; you can use

tweezers and small brush. If it’s damaged or it doesn’t turn properly, it must be replaced.

The glass can be clean with dishwashing detergent to remove any debris. In case of

adhesive or material are stuck to it, you can use a glass scraper. Dry it well after that. To

finish it up, you can use a damped microfiber cloth with a little of Isopropyl alcohol to

remove fingerprints or lint that could prevent the proper adhesion of the first layer. In case

the timing belts deteriorate or become loose from using it very frequently, ask the 3D

LimitLess technical support department for replacements.

Keep the vents very clean with a small brush or a regular vacuum cleaner.

The printer should have a yearly maintenance to look for loose screws, bolts or parts. Tight

them up and call the technical support department in case of misalignment or vibrations.

We recommend not leaving any filament in the hotend as well as using a special one for

cleaning and keeping it in perfect condition.

Due to a sealing problem at the tip, melted filament could be coming out between the

hotend trigger and the heating block. Please contact the technical support department.

Usually, the debris clogging the tip or the heating block can be removed by tweezers or

small metal brush while still warm, keeping in mind all the precautions needed not to get

burn.

Page 59

8. PRINTING PROBLEMS

We include some of the most common printing problems and where they come from.

8.1 Lack of Extrusion starting the printing. Common problem among beginners on the

3D printing and it is very easy to resolve.

There are 4 possible causes:

The Extruder has not been purged before printing: It doesn’t

have enough material inside the Hotend due to inertia in the

heating and cooling of it. In the printer software beginning

GCode it has an established routine to purge a 10 mm filament

head before printing that is deposited on one of the surface

corner to prevent this problem.

It is recommended when you are configuring the printing to give a SKIRT to the

object which consists of an exterior parameter separated from the printing

object that will allow you to purge the nozzle and the adhesiveness of the first

layer.

The Nozzle is too close to the printing surface: The Nozzle will clog up if there is

not enough space to deposit the material on the printing surface. It is due to the

Z Axis Offset been too small. The 3DLimitless ILC has preconfigured and tested all

levels. If you want to modify the parameters, you would have to start a new

leveling process to the printing base. You will have to contact our technical

support department and we’ll help you through it.

The Filament has been bitten by the Extruder gear: This happens when the

Extruder pushing gears let out some of the material decreasing the filament

section causing it not having enough contact to keep pushing, the solution is on a

specific chapter of this manual.

Hotend obstruction: If the problem is none of the previous causes then, most

likely the Extruder is clogged up. It could happen when some of the material has

accumulated inside the heatbreak where the temperature is not enough to heat

it up, or after a change of material that requires a higher temperature and not all

remains have been removed from inside the Hotend. To resolve this problem,

you will have to contact our technical support department and we’ll help you

through it since there are many solutions depending on the origin and nature of

used filament.

Page 60

8.2 First layer does not adhere to the printing base.

Another common problem occurs when the first layer (very important) of the printed

object does not adhere correctly and it is coming apart from the printing base.

The Nozzle too far apart from the printing base:

This is the opposite of the lack of Extrusion

starting the printing (8.1). This means, the

filament will not be closed enough to adhere to

the base, because of the nozzle being too far apart

from the printing base. The solution will be

changing the Z Axis Offset’s value for which you

need to do a new leveling process to the printing

base. You will have to contact our technical support department and we’ll help

you through it.

Higher printing speed of first layer: The first layer’s printing speed is usually

slower than the rest of layers. The parameters will be different depending of the

configuration of the Slicer software chosen (SLic3R or CuraEngine). Refer to the

software’s instructions for this case. The recommended value is between 50%

and 70% of the defined speed for the normal printing.

Temperature values and cooling system: When the filament is deposited on the

printing base with a higher temperature difference, it will cool down faster as

well causing it not to adhere correctly. 3DLimitless ILC is equipped with an

electric resistance in the printing surface to add enough temperature and solve

this problem. It is also recommended to use hairspray or PVA glue to the printing

base depending of the material you are using. In the other hand, too much

ventilation at the end of nozzle will have the same effect as before, in this case

you should inhabit the first layer’s cooling function. Refer to the chosen software

instructions.

Brim and Rafts: If the base of the printing object is very small, you should create

a brim around it. It consists of making wings to improve the adherence of the

object avoiding any peeling off from the printing surface.

Another option is a raft that will create a support under the printing object as a

first layer that will not be a part of the end result.

These additions are easily removable after the printing is done.

Page 61

8.3 Lacking Extrusion.

It is a low extrusion because the filament contribution is not enough, it is noticeable that

the perimeters did not join properly and/or material shortages appear in the filling; the

reasons for that are:

Increase Extrusion value: The problem could continue even thou the filament

diameter is properly adjusted. To resolve this, as mentioned previously, you can

change the Extrusion value while the printing is going on or when you are setting

the different filament profiles. Modifying the parameters will depend on which

software you are using and if you are printing manually (with dial and LCD) or

remote printing on the manual control tab of the software.

Incorrect filament diameter configuration: The

3DLimitless ILC printer has an Extruder Assembly for a

1.75 mm filament diameter, for this reason you need

to make sure that this is the value in the software and

each of the filament profiles that you have created. We

recommend measuring the filament at various points

to get an average diameter since filament

manufactures have several tolerances.

8.4 Over Extrusion.

It is the opposite of the previous section and it means

that too much material is deposited mainly on the

upper surface. In this case it will be done in the same

way but in reverse. You will modify the extrusion

coefficient or FLOW by decreasing the extrusion

multiplier value. The way of doing so it will be

different depending on the software you use. Slick3R

will be like a 0.9 equivalent t 90% which is a 10% less

of extruder. CuraEngine will use percentages, i.e. 80%, 90%, etc.

8.5 Holes on the top part of the pieces.

If you can see holes on the top layers of the object while the rest are correct, the

probable causes are:

Fewer upper layers: As you previously saw, some of the

printing parameters to configure before printing are the

number of upper and lower layers. If the value is too low

the problem will occur. We recommend you configure at

least 3 top layers.

Page 62

For example, when you go to CuraEngine settings:

Go to Print/Structures where Top/Bottom Thickness will determent the amount

of upper layers.

To determent the number of layers, you multiply the value of height already

chosen in Quality (0.2 in this case) by the number of layers you want (4 in total in

this case, it will always round it down).

In the case of Slic3R, as soon as you put the number of layers you want it will set

the parameters by itself.

Page 63

When you go to Slicer screen and the Printer Settings:

You will see Horizontal Shells then you’ll find Solid Layers TOP

You will put the desired amount

The infill percentage is too low: When it happens, the upper layers support

surface is small and it will cause the detachment/sinking of them.

Lack of Extrusion: After making sure that the previous ones are not the cause of

the problem; the next possibility could be the lack of extrusion. The solution will

be in the next section.

Page 64

8.6 Detecting fine lines on the pieces

Sometimes when you are printing a hollow object or the deposit of material is spaced

between two points, you can see fine lines. Even thou the lines are easily removable

when the printing has finished, it requires an intervention. The causes for this are:

Value of the filament retraction: When the hotend is

moving with no need of applying any material, the

extruder motor is moving in reverse. You will have to

retract it and trying to avoid deposits of material

where it is not needed.

If the parameter is not correct, the deposit of

material in non wanted places might occur. Using the

Bowden Extrusion system, you will have to introduce a new value (i.e. 4,5mm)

depending on the type of material; you can increase or decrease it to be able to

correct the problem. And optimal retraction value is 1.8 to 2.0 mm.

This is where:

Slic3R

Printer Settings/Extruder tab / Retraction-Length Option:

Page 65

Cura

Cura Tab – Print – Extrusion – Distance Retraction Option:

High Retraction Speed: It could cause bubbles inside nozzle. A regular parameter

would be 40-50mm/sec, keeping in mind that it changes depending on the

material’s hardness you are using. To do so, you will have to go back to the

previous tabs and modify the value on Speed (Slic3R) and on Retraction Speed

(CuraEngine).

High Filament Temperature: If the temperature configuration is not set correctly

and it is too high, the filament becomes very fluid and extrudes without request.

This can be changed in the filament temperature configuration and it can be

done while is printing, as previously explained.

The filament manufacturer will establish the ideal temperature range for the

extrusion.

Page 66

8.7 Excessive heating

You can see some details in the object are not well formed. Probable causes are:

Insufficient Cooling: Most likely the air flow parameters for the

fan are not properly set. This value depends mostly on the

material used. We’ll show you where to do it.

Slic3R

Filament Setting Tab – Cooling Section

You have to set the speed values: minimum, maximum, in bridges and initial

layers; where you don’t wish to use the cooling to promote adherence. The Min

Print Speed parameter will reduce the preset speed value when the printing time

is less than the indicated in “Slow down If Layer Printing Is Bellow”.

Page 67

Cura

Filament Tab – Cooling section

Here you can adjust the minimum and maximum cooling values and the printing

speed in the “Minimum Layer Time” as well, so it will not be less than the

already set.

The cooling percentage value is different from the previously seen and it can

be adjust while printing.

High Printing Temperature: Another possible cause could be a high Extrusion

Printing even when the cooling system is used. If this is the case, you can change

the value on the manual printing or from the software, as previously shown.

High Printing Speed: If the printing speed is very high and the time is too low for

the size of the layer, it might not be enough time for this to cool down and when

the next hot filament is deposited over it, it can cause a deformation in the layer.

“Slow down If Layer Printing Is Bellow” and “Minimum Layer Time” are the

parameters to use to adjust the min printing time of each layer. See Cooling

Deficiency section.

Printing few objects at the same time could be another solution, this way the

printing time used for one layer is higher as well as the cooling time.

Page 68

8.8 Marks on the top side

This happens when you see grooves in the filling of the upper faces. The possible causes

are:

Slic3R and “Z HOP” in CuraEngine where you can lift the Hotend during the

traveling without extrusion, going back to the original position when it is

necessary to continue the extrusion.

Slic3R

Printer Settings Tab - Extruder 1 – Option: Retraction - Lift Z

Very High Extrusion Flow: Please refer to the 8.4 Over

Extrusion. The effect of the hotend’s heat while moving

over the already printed layers. If the displacement

strategy is done inside the same layer and the filling comes

out irregularly, geometrically speaking, the hotend can

travel through the already printed surface leaving marks

on it because the heat effect. To avoid it, go to “LIFT Z” in

Page 69

Cura

Print Tab – Extrusion - Z Hop

8.9 Layers Sliding

Some sliding could happen of the X/Y Axes while printing. The possible causes are:

Slic3R

Print Settings Tab – Speed – Speed for Non-Print Moves – Travel

High Hotend Speed: If a high travel speed is set up without

extrusion, it is recommended to lower it to 70%.

Page 70

Cura

Print Tab – Speed and Quality – Travel

Page 71

Mechanical or Electronic Problems: The step-by-step adjustments of the motor

controls which could have an incorrect current setting. In the case of the X/Y

Axes, it may also be due to an excess or strain on the belts. If this is the case,

please contact our technical support department.

Note: All our printers have been individually tested with particular emphasis

on this point, among others.

8.10 Clogged Nozzle

This happens when you see the filament is not coming out of nozzle when the extrusion

is being done. The possible causes are:

The Filament temperature is too Low: It happens sometimes when you change

one type of filament for another (i.e. ABS to PLA), with the first one having a

higher melting point and you perform the initial purge to clean the hotend of

debris from previous material, you need to set the temperature closer to the ABS

melting point than the PLA’s otherwise it could form a plug in the Heatbreak. Do

not exceed the max temperature recommended by the filament manufacturer or

it could create crystallized debris in the Heatbreak and Tip.

Deformed Filament End: It can happen after the printing is finished or a long

retraction due to cooling conditions. In this case, pull out the filament from the

Heatbreak, cut a 2-3 cm piece and reintroduce.

If the problem continues after trying these options, the Heatbreak is blocked with

filament. Please contact our technical support to help you.

8.11 Plastic Bubbles in the Piece

There are bubbles on the exterior perimeters of the object. Possible causes are:

Printing Temporary Stops: It usually happens when you are

printing directly from the PC and there are communication

failures from the PC to the Printer due to background

programs, PC’s limited resources, memory, etc. Try to free the

PC as much as possible of activity both, memory and

microprocessor. It could also be an error of the PC’s USB Port

connected to the printer, try changing it. Much data is sent in

real time from the PC while printing is going on, so you should

prioritize the printing activity.

degrees at the time until the problem stops.

Excessive Temperature: The filament becomes very fluid when

the temperature is too high and it will come out of nozzle even

when it is making displacements in non-extrusion zones. You

will need to decrease the extrusion temperature gradually 5

Page 72

8.12 Spaces in the Top Layer between Perimeters and Filling

There is a lack of material at the joining of the filling with the top layer perimeters. The

possible causes are:

Lack of Overlap between Filling and Perimeters: An overlap is always needed

between the layers so the union of the two parts occurs, for this matter you have

the INFILL OVERLAP Tab.

Slic3R

Print Settings Tab – Advance – Overlap Infill/Perimeters Overlap

Page 73

Cura

Print Tab – Extrusion – Infill Overlap

Printing Speed of the Upper layers is too High: If this happens the upper layers

will not adhere properly. You will need to configure it and reduce this value until

you reach a solution to the problem.

Slic3R

Print Settings Tab – Speed for Print Moves – Top Solid Infill

Page 74

Cura

This option does not exist when using other algorithms.

8.13 Warping

100 C). This is the reason why you should add hairspray when printing with this

material.

It usually happens when you print with ABS

and other materials. It is a deformation with a

slight lifting of the corners due to the lack of

adhesion of the first layer.

Lack of Fixative (Hairspray): With ABS is

required to use another fixation or adherent

besides a very hot printing surface (more than

In addition to that, the use of the BRIM option is also recommended. It consists

of adding wings around the perimeter of the object to be printed to reduce the

possibility of getting stuck to each other, as well as generating small circles

around the corners of the object so that they don’t lift up in few layers. (pg. 79)

Page 75

Slic3R

Print Settings Tab – Skirt and Brim – Brim Width

Cura

Print Tab – Structure – Skirt and Brim – Brim Width Parameter, this value will

define the wing size.

When using CuraEngine it will be necessary adding the BRIM option on the left

corner of the SLICER Dropdown. See in detail.

Page 76

Air drafts: We recommend to keep the printer away from air drafts since many

of the materials used, especially ABS, are very sensitive to temperature changes.

8.14 Layers Gap

You can see there are holes between the layers for lack of union among them. The

possible causes are:

Cover Height: You have to keep in mind the

nozzle diameter you are using when you are

setting the cover height since if this one is

higher, the layers will not stick together. As a

general rule, you should establish the maximum

height as 20% less than the nozzle diameter.

I.E.: if you use the 3D-ILC’s 0.4 mm nozzle, the

layer’s maximum height will be 0.32 mm. Nozzle

can be substituted with a higher or lower

diameter depending of the printing needs.

Page 77

Low Extrusion Temperature: If the extrusion temperature is configured too low,

the cooling down will happen rapidly and the upper layer will not adhere to the

previous one, even if the filament reaches a high temperature.

For that reason keep always in mind the temperature range as the filament

manufacture suggests.

Excess of Ventilation: Printing materials as ABS, Nylon, etc.., are very sensitive to

a quick cooling of the layers creating delamination and poor adherence between

them and possible warping mentioned earlier is aggravated. We recommend

turning off or reducing to the minimum the layer fan to resolve the problem, it

can be done manually or in the filament profile, and this way you will get longer

cooling time and more homogeneous.

You can download different filament profiles with the optimum parameters from

our web page so you can print without these problems.

8.15 Split Filament

out an amount of filament greater than the actual output capacity of the nozzle

section. Verify the installed nozzle parameters.

A decrease of the filament section is observed

because the extruder motor moves forward while

the filament does not advance so the dragging gear

“bites” it. The possible causes are:

Miss-configured Nozzle: If the diameter of the nozzle

configured in the Slicer software is higher than the

Hotend nozzle installed, the dragging system will give

Page 78

Cura

Slic3R

Printer Settings Tab – Extruder – Size – Nozzle Diameter

You will have to go to the Repetier Host configurations to get all the values. To

verify them go to Printer Settings Tab (top right side) – Extruder – Diameter

Extrusion Temperature too Low: It will cause the extrusion flow to be lower and

it will be harder to come out of the nozzle exerting a counter pressure that

prevents the extrusion giving the “bite” effect on the filament. We recommend

Page 79

increasing the temperature between the ranges already established by the

filament manufacturer.

Printing Speed too high: High speed printing could have the same effect

described before due to the same causes. We recommend lowering the speed

parameters until the “bite” effect disappears. It can happen as well with the

combination of low temperature and high speed. If you wish to keep high speeds

you must slightly raise the melting temperature.

Clogged Hotend: filament is not coming out of the hotend nozzle. Stop the

printing and follow instructions as of 8.10 section. Check all the parts of the

printing: Extruder, Teflon Tube, Heatbreak, Nozzle, Speeds, and Temperature.

Page 80

9. Proper Product Disposal

(It means electrical and electronic equipment waste. Applicable in the European Union and in

the European Countries with selective waste collection systems)

If you see this symbol on the product, accessories, or any informative material that

come with the equipment, it indicates that at the end of its useful life neither the

product nor the electronic accessories (Extruder, cables, etc…) should be disposed

of with other domestic waste.

Please recycle correctly and separate from all other waste to avoid possible health and

environmental issues. In this way it promotes the sustainable reuse of material.

Contact the distributor of this product or relevant local authorities to inform you about how

and where it can be subjected to ecological and safe recycling.

Page 81

10. Informative Links

You can find great resources in these links many of them Open Source and for free.

http://www.thingiverse.com

https://www.youmagine.com

https://grabcad.com

http://www.turbosquid.com

https://sketchfab.com

http://www.123dapp.com/Gallery/content/all

https://3dwarehouse.sketchup.com/index.html

https://pinshape.com/

We also propose a series of links to 3D design and modeling applications, most of them are

free:

Autodesk

Sketchup

Thinkercad

Freecad

Blender

Rhino

SolidWorks

Catia

3DBuilder

The original file included in the SD: 3DBenchy.STL, it comes from:

http://www.thingiverse.com/thing:763622

Repetier-Host is license of Hot-World GMBH & Co. KG, Slick3R is license of Alessandro

Ranellucci, Cura and CuraEngine are license of UltiMaker B.V.

The different operative systems mentioned in this manual are respectively license of: Microsoft

Corporation, Apple Inc, and Linux Foundation.

The links provided are license of their respective manufacturer.

Page 82

11. Warranty

Warranty Time Period

The warranty will start when you make your purchase (invoice or delivery date).

Warranty time is up to 12 months. Elements are subject to wear and tear are not

covered by this warranty.

Warranty time will not be extended or renewed, nor will it be affected otherwise due to

the subsequent resale, repair, or product exchange. In case of product repair or

exchange during this time, they will be covered until the end of the warranty or 6

months, whichever comes first.

Warranty will be invalid in case of incurring any of the assumptions included in

“Warranty Exclusions”.

Warranty Management

In case of product defect, proceed as follows:

1. Notify our Technical Support Chanel (soporte@3dlimitless.com) of any defect or

incidence within the first month of detecting any, never after the warranty time

period.

2. Have available proof of purchase with at least the date, serial and model

numbers.

3. The product must be sent or taken to the original purchase place or to the 3D

Limitless address, at buyer’s expense. After inspecting the problem, if it is not

within the assumptions of the “Warranty Exclusions”, 3D limitless will take care

of returning the product to the costumer free of charge; in the case of being one

of them, we will repair the machine at a cost; budget sent to costumer’s for

approval.

4. The performance criteria will be exclusively determined by 3D Limitless.

5. This criterion will be as follows: repairing, element’s replacement, or complete

product exchange.

6. Defective or replaced elements will be 3D Limitless property.

7. The buyer will receive a detail report of the incident and actions taken once the

warranty management is finished.

Warranty Exclusions

The next cases are not under warranty:

1. The normal wear-and-tear of the product including, without limitations, mobile

parts wear, control panels and elements that interact with the product’s

operation.

2. Damage caused by misuse or neglect when using the product.

Page 83

3. Damage caused by: accidents, fires, liquids, chemical products, other substances,

floods, vibrations, excessive heat, inadequate ventilation, voltage outage,

incorrect or excessive voltage, radiation, electrostatic discharge including

lightning and other external forces or impacts.

4. Deterioration caused by improper transportation and handling like using

different packaging from the one provided, including the element’s protection

(Expanded polystyrene).

5. Repairs or attempts of repairs done by third parties not by 3D Limitless.

6. Modifications done to the product to adapt to rules and safety regulations of

particular countries, outside of what the design or manufacture was produced

for, are not covered.

7. Warranty covers the product hardware components, not software or firmware

other than that provided by 3D Limitless.

Limitations and Disclaimers

This warranty is valid and current in the country where the product was bought and

restricted to the countries in the European Economic Union (EEU).

This warranty is the only and exclusive guaranty before 3D Limitless and the unique and

exclusive responsibility of 3D Limitless to the defects of its products. Therefore this

warranty will substitute any other issued by 3D Limitless oral, written or legal (not

mandatory).

With the exception of the previously mentioned cases, 3D Limitless will not give other

warranties (explicit, implicit, statutory or others) related to the product, the software

quality or its annexes, operation, accuracy, reliability or adaptability of the logic

equipment or any other. If this exception is not tendered or contemplated by the

current laws, 3D Limitless will limit or exclude the warranty only to the extent of these

laws. Any warranty that cannot be completely excluded shall be limited to the duration

of this. This warranty will not exclude or limit any legal rights (mandatory) under the

applicable national law or any of its rights against the vendor.

3D Limitless is not responsible for: damages or loss of product, services, this warranty or

others, including economic loss or invaluable damages; benefits, income or information

losses; use of this product or associated ones or loss of it or indirect, accidental or

critical damages.

3DLimitless will not be responsible for any wrong installation or improper use of this

product as explained in this manual.

It will not be our responsibility if the maintenance of the product is not done as

recommended in the manual.

Page 84

3DLimitless will not be responsible for the wrong installation or use of this product that

does not respect the technical or safety rules of the country where it was installed

and/or used.

Consumers have legal rights (statuary) under the national laws in relation to the

consumer products. This warranty will not affect their statuary rights, nor the nonexcludable, nor limitable, nor the rights of the person from whom this product was

purchased. You can assert your rights as you see fit.

Page 85

12. CE Conformity Declaration

3D Limitless Sociedad Limitada

Calle Falperra, 55

15007 A Coruña (España)

VAT ID: ESB70490149

www.3DLimitLess.com

info@3DLimitLess.com

It Declares:

Product: 3D Printer

Model: ILC

Manufacturer: 3D LimitLess

Made in: Spain

Meets all the rules and regulations on the 2006/42/CE norm,

Complying with the harmonized standards:

UNE EN ISO 12100:2012

UNE EN 13849-1:2008

EN 60204-1:3007

The technical documentation is deposited in the address of the manufacturer’s

headquarters.

A Coruña, Spain. March 2016

Marcos Souto Fernández

Co-Founder 3D LimitLess

Page 86

Address:

C/ Falperra, 55 bajo

15007 A Coruña

Spain

Contact:

www.3DLimitLess.com

Http://www.facebook.com/3dlimitless

Twitter: @3dlimitless

info@3dlimitless.com

3D LIMITLESS

Welcome to a Revolution with No Limits!

Loading...

Loading...