Billy Goat F902SPS, F1302SPH, F902SPH, F1802SPV User Manual

FORCE BLOWER Self-propelled Owner’s Manual

Accessories

HOLD DOWN KIT

To secure blower for

transportation on

trailer floors.

Patent #6,253,416 and other patents pending

F902SPS, F902SPH, F1302SPH, F1802SPV

BILLY GOAT FORCE BLOWER

Owner's Manual

SOLID FRONT TIRE

Solid flat-free front tire.

PARKING BRAKE

Effective and Easy to

use to prevent blower

from rolling.

CASTER KIT

For greater

maneuverability on

hard surfaces.

P/N 440120

Part No 440314 Form No F060811E

P/N 440279

P/N 440140

1

P/N 440293

FORCE BLOWER Self-propelled Owner’s Manual

CONTENTS

SPECIFICATIONS AND SOUND/VIBRATION ___ 3

INSTRUCTION LABELS 4

PACKING CHECKLIST 5

ASSEMBLY 6

OPERATION _ 7-8

MAINTENANCE 9

TROUBLESHOOTING___________________________ 10

ILLUSTRATED PARTS LIST 11

PARTS LIST 12

Go to http://www.billygoat.com for French-Canadian translations of the product manuals.

Visitez http://www.billygoat.com pour la version canadienne-française des manuels de produits

Part No 440314 Form No F060811E

2

FORCE BLOWER Self-propelled Owner’s Manual

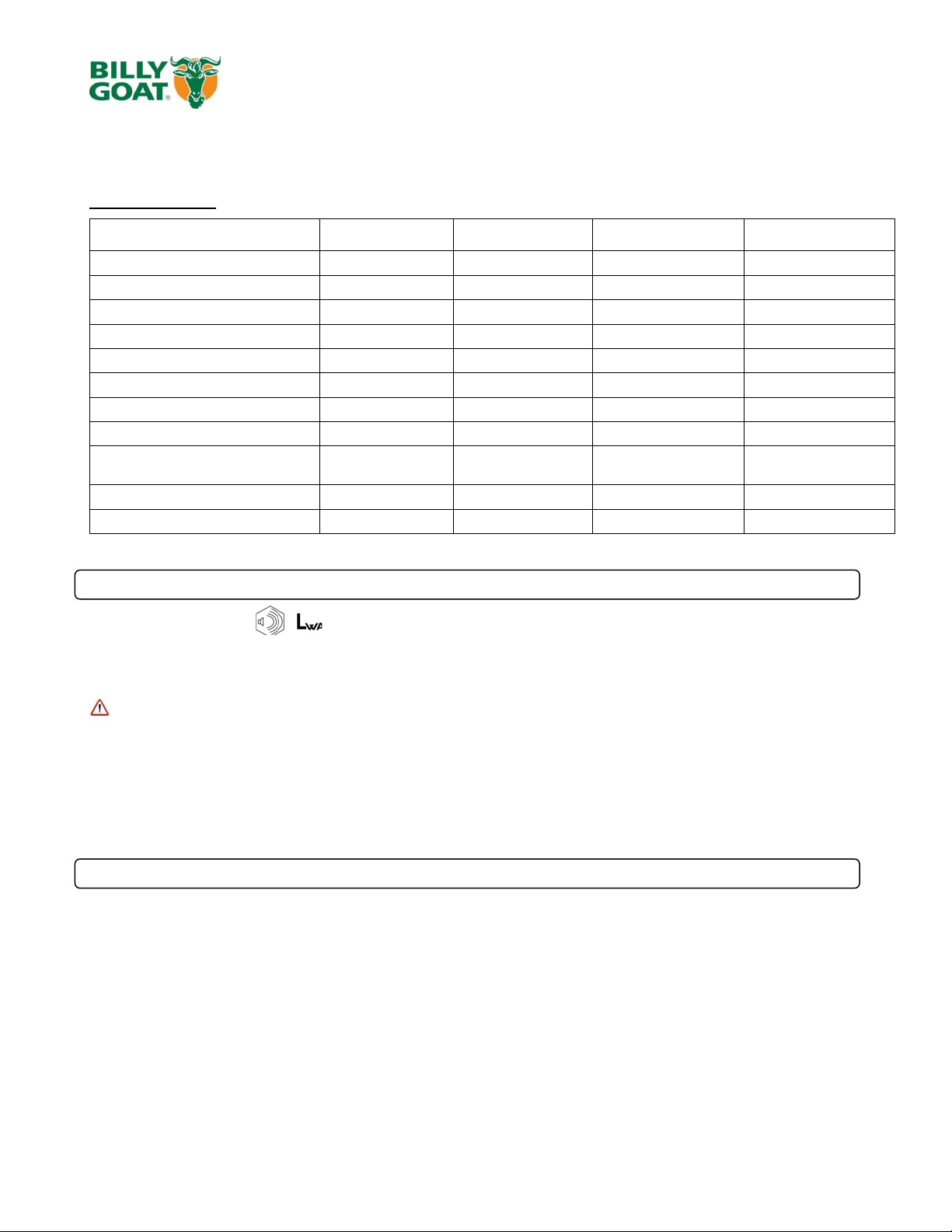

Specifications F902SPS F902SPH F1302SPH F1802SPV

Engine: HP 9.0 HP (6.6kW) 9.0 HP (6.6kW) 13.0 HP (9.6kW) 18 HP (13.42kW)

Engine: Model EX270D50021 GX270K1QA2 GX390K1QAA2 3564420224E9

Engine: Type SUBARU OHC HONDA OHV HONDA OHV B & S VANGUARD

Engine: Fuel Capacity 6.4 qt. (6.1L) 6.3 qt. (6.0L) 6.5 qt. (6.1L) 9 qt. (8.52L)

Engine: Oil Capacity 1.05 qt. (1.0L) 1.16 qt. (1.1L) 1.16 qt. (1.1L) 1.75 qt. (1.66L)

Total Unit Weight: 141 # (64 Kg) 152 # (68.9 Kg) 167 # (75.7 Kg) 182 # (82.6 Kg)

Overall Length: 58"(1.43m) 58"(1.43m) 58"(1.43m) 58"(1.43m)

Overall Width 29.25” (0.74m) 29.25” (0.74m) 29.25” (0.74m) 29.25” (0.74m)

Overall Height 45" (1.14m) 45" (1.14m) 45" (1.14m) 45" (1.14m)

In compliance with 2000/14/EEC

standards

Sound at Operator’s ears 87dB(a) @ 3340 rpm 89dB(a) @ 3660 rpm 90dB(a) @ 3640 rpm 97dB(a)

Vibration at operator position .96 g (9.44 m/s2) 1.05 g (10.30 m/s2) .81 g (7.96 m/s2) 1.2 g (11.9 m/s2)

SOUND

Sound tests were conducted in accordance with 2000/14/EC, as well as ISO 11094, and were performed on 12-12-2006 under the conditions

listed below.

Sound power level listed is the highest value for any model covered in this manual. Please refer to serial plate on the unit for the sound

power level for your model.

117 dB

General Conditions: Sunny

Temperature: 40.4

Wind Speed: 6.1 mph (9.9kph)

Wind Direction: Southwest

Humidity: 93.6%

Barometric Pressure: 30Hg (101.85kpa)

VIBRATION DATA

Vibration levels at the operator’s handles were measured in the vertical, lateral and longitudinal directions using calibrated vibration test

equipment. Tests were performed on 12-13-2006 under the conditions listed below.

General Conditions: Sunny

Temperature: 57.2

Wind Speed: 11.8 mph (19.1kph)

Wind Direction: South

Humidity: 46.4%

Barometric Pressure: 30.1Hg (101.96kpa)

107dB(a) @3340

rpm

SOUND LEVEL 97 Db(a) at Operators Position

VIBRATION LEVEL 1.2g (11.9m/s2)

109dB(a) @ 3660

rpm

110dB(a) @ 3640 rpm 117dB(a)

o

F (4.7oC)

o

F (14.3oC)

Part No 440314 Form No F060811E

3

FORCE BLOWER Self-propelled Owner’s Manual

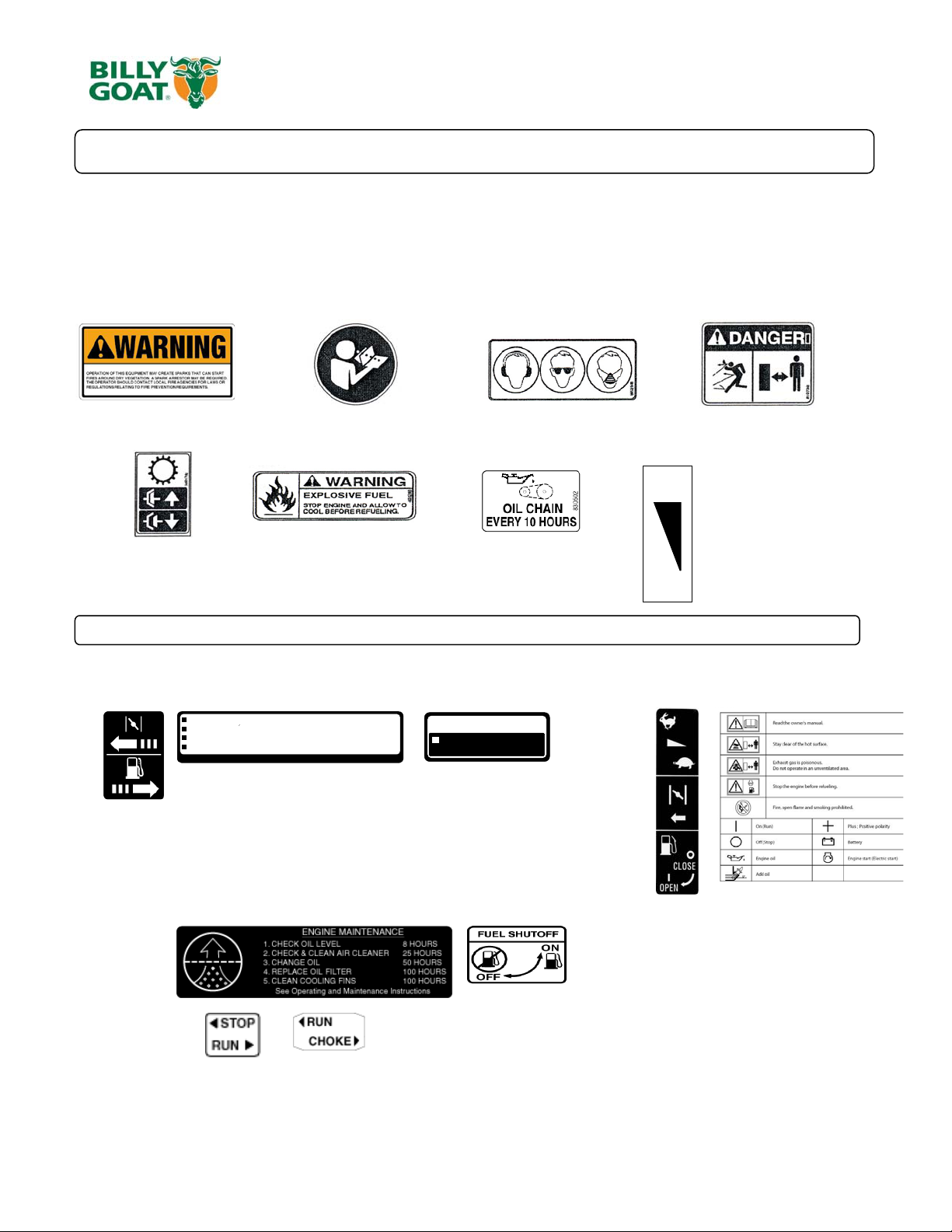

INSTRUCTION LABELS

The labels shown below were installed on your BILLY GOAT ® FORCE Blower. If any labels are damaged or

missing, replace them before operating this equipment. Item numbers from the Illustrated Parts List and part

numbers are provided for convenience in ordering replacement labels. The correct position for each label may be

determined by referring to the Figure and Item numbers shown.

LABEL READ OWNERS MANUAL LABEL EAR EYE BREATHING DANGER FLYING DEBRIS

LABEL SPARK ARRESTOR

ITEM #44 P/N890301 ITEM# 45 P/N890254 ITEM # 46 P/N 810736

P/N 100252

LABEL EXPLOSIVE FUEL LABEL THROTTLE CONTROL

LABEL CLUTCH ENGAGE

ITEM # 43 P/N 400268 ITEM # 42 P/N 810656

P/N 500176

ENGINE LABELS

START

LABEL OIL CHAIN

ITEM #119 P/N 830502

STOP

HONDA SUBARU

READ OWNER’S MANUAL BEFORE OPERATION.

LIRE LE MANUEL D UTILISATEURAVANT USAGE.

VOR INBETRIEBNAHME UNBEDINGHT BEDIENUNGSANLEITUNG DURCHLESEN.

NO UTILIZAR SINANTES NO HABER LEIDO EL MANUAL

HONDA MOTOR CO. , LTD. MADE IN JAPAN

OIL ALERT

WHEN OIL LEVEL LOW,

ENGINE STOPS IMMEDIATELY.

BRIGGS AND STRATTON VANGUARD

Part No 440314 Form No F060811E

4

Loading...

Loading...