Billy Goat DL1301H, DL1201L, DL1801V, DL1801VE, DL1401SE User Manual

DL12/13/14/18 Owner’s Manual

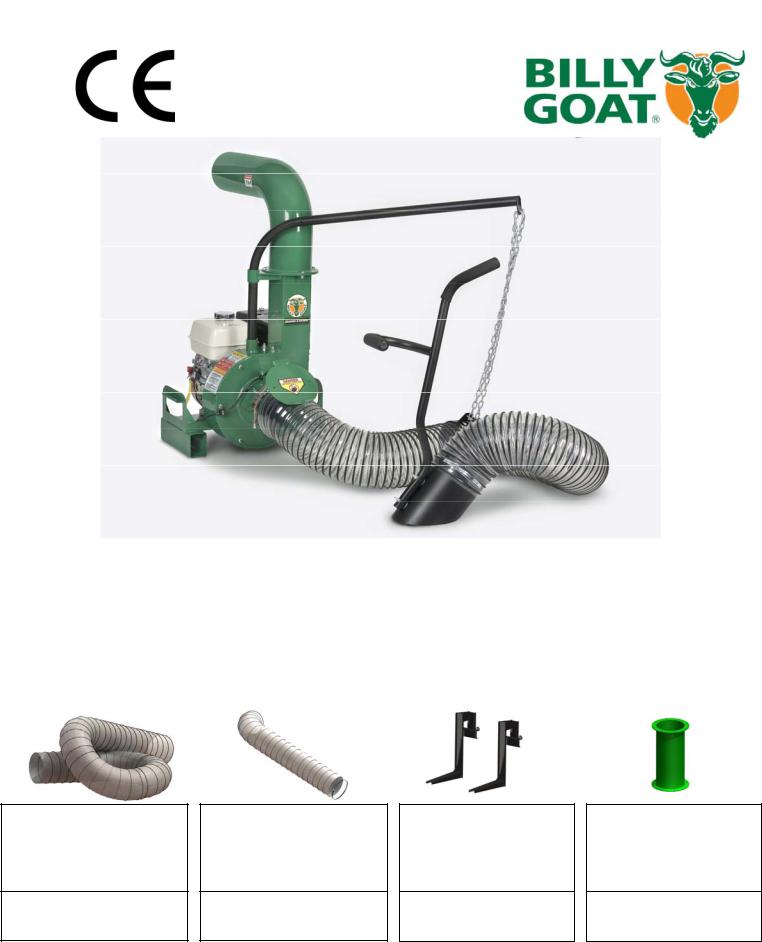

BILLY GOAT DL TRUCK LOADER VACUUM

Owner's Manual

DL1201L, DL1301H, DL1401SE, DL1801V, DL1801VE

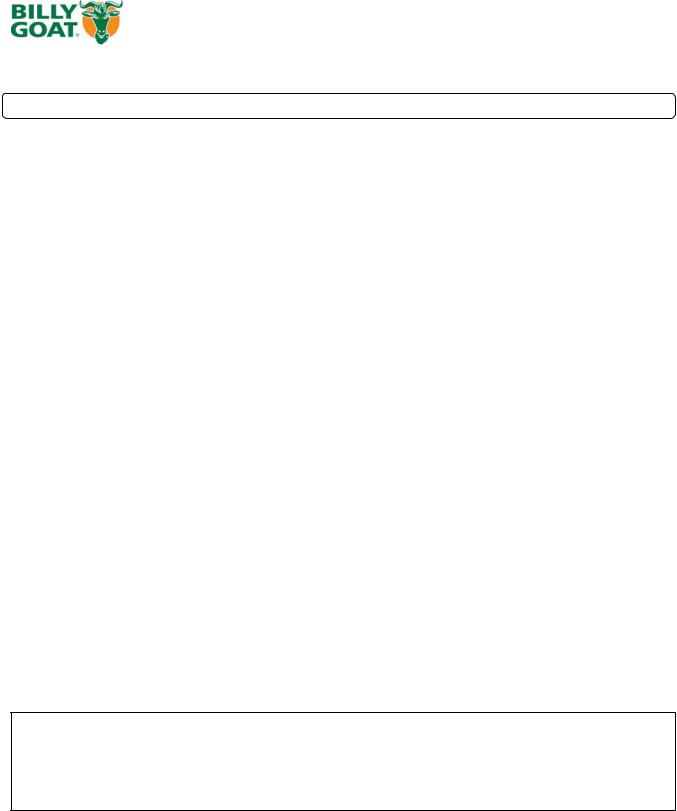

Accessories

INTAKE |

EXHAUST |

|

|

|

|

|

HOSE REPLACEMENT KIT |

|

EXHAUST HOSE KIT |

|

HANGING EXTENSION KIT |

|

EXHAUST EXTENSION KIT |

|

|

|

|

|

|

|

Standard on DL units. [8"(203mm) x 10' (3.0m)] [10”(254mm) X 10’(3.0m)]

8” Hose P/N 811244

10” Hose P/N 791033

[7"(203mm) x 5' (1.5m)] flexible hose increases exhaust distance.

7” Flexible Hose P/N 812300

Allows the Debris loader to hang from a vertical side panel. (Not for use in transport)

P/N 812260

Allows the height of the exhaust chute to be raised.

P/N 812273

Part No 812379 |

1 |

Form No F060711B |

DL12/13/14/18 Owner’s Manual

CONTENTS |

|

|

|

|

|

|

||||||

SPECIFICATIONS AND SOUND/VIBRATION |

|

3 |

||||||||||

INSTRUCTION LABELS |

|

|

4 |

|

||||||||

PACKING CHECKLIST ____________ |

|

5 |

|

|

|

|||||||

ASSEMBLY AND MOUNTING |

|

|

6 |

|

|

|

|

|||||

OPERATION |

|

|

|

7 |

|

|

||||||

MAINTENANCE________________________________ |

8 |

|

|

|||||||||

|

|

|

|

|||||||||

TROUBLE SHOOTING__________________________________________________9 |

||||||||||||

ILLUSTRATED PARTS & PARTS LISTS |

|

10-12 |

||||||||||

Go to http://www.billygoat.com for French-Canadian translations of the product manuals. Visitez http://www.billygoat.com pour la version canadienne-française des manuels de produits

Part No 812379 |

2 |

Form No F060711B |

DL12/13/14/18 Owner’s Manual

Specifications

|

|

|

DL1201L |

DL1301H |

DL1401SE |

DL1801V |

DL1801VE |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Engine: HP |

|

12 (8.95 kW) |

|

13 (9.69 kW) |

|

|

14 (9.69 kW) |

|

|

|

18 (13.4 kW) |

|

18 (13.4 kW) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Engine: Model |

|

HK291150124P-BPQE2 |

|

GX390U1QA2 |

|

|

EX400DE5030 |

|

|

|

3564420186EI |

|

3564470288B1 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Engine: Type |

|

LCT OHV |

|

HONDA |

|

|

SUBARU |

|

BRIGGS AND STRATTON |

|

BRIGGS AND STRATTON |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Engine: Fuel Capacity |

|

6 qt. (5.68 L) |

|

6.9 qt. (6.5 L) |

|

|

7.4 qt. (7.0 L) |

|

|

|

9qt. (8.52 L) |

|

9qt. (8.52 L) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Engine: Oil Capacity |

|

0.875 qt. (0.8 L) |

|

1.16 qt. (1.1 L) |

|

|

1.3 qt. (1.2 L) |

|

|

1.75 qt. (1.66 L) |

|

1.75 qt. (1.66 L) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Total Unit Weight: |

|

204 lbs (92.5 kg) |

207 lbs (93.9 kg) |

|

|

267 lbs (93.9 kg) |

|

|

267 lbs (121.1 kg) |

|

267 lbs (121.1 kg) |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Max operating slope |

|

|

250 |

|

250 |

|

250 |

|

|

250 |

|

250 |

|||||

Overall Height |

|

74 7/8” (1.90m) |

74 7/8” (1.90m) |

|

|

74 7/8” (1.90m) |

|

|

74 7/8” (1.90m) |

|

74 7/8” (1.90m) |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Overall Height with |

|

91”(2.31m) |

|

91”(2.31m) |

|

|

91”(2.31m) |

|

|

|

91”(2.31m) |

|

91”(2.31m) |

||||

optional trailer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Overall Width |

|

32 ¼” (0.82m) |

|

32 ¼” (0.82m) |

|

|

32 ¼” (0.82m) |

|

|

|

32 ¼” (0.82m) |

|

32 ¼” (0.82m) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Overall Length |

|

60” (1.52m) |

|

60” (1.52m) |

|

|

60” (1.52m) |

|

|

|

60” (1.52m) |

|

60” (1.52m) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

In compliance with |

|

121 dB(a) |

|

121 dB(a) |

|

|

121 dB(a) |

|

|

|

121 dB(a) |

|

121 dB(a) |

||||

2000/14/EEC standards |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Sound at operators |

|

105 dB(a) |

|

105 dB(a) |

|

|

105 dB(a) |

|

|

|

105 dB(a) |

|

105 dB(a) |

||||

position |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Vibration at operator |

|

|

0.02g |

|

|

0.02g |

|

|

0.02g |

|

|

|

0.02g |

|

0.02g |

||

position |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Battery (Electric Models Only) |

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

Model |

|

CCA @ 0° F |

|

AH Rating |

|

Length |

|

|

Width |

Height |

|||||

DL14 |

|

ETX12 |

|

180 |

|

|

10 |

|

|

5.9” (150mm) |

|

|

3.4” (86mm) |

5.2” (132mm) |

|||

DL18 |

|

U1 Group |

|

275 |

|

|

19 |

|

|

6 7/8” (175mm) |

|

4” (100mm) |

6 1/8” (155mm) |

||||

Battery not |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

included with |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

machine |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SOUND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SOUND LEVEL 105 dB(a) at Operator Position

Sound tests were conducted in accordance with 2000/14/EEC, and were performed on 6/18/07 under the conditions listed below.

Sound power level listed is the highest value for any model covered in this manual. Please refer to serial plate on the unit for the sound power level for your model.

Sound power level listed is the highest value for any model covered in this manual. Please refer to serial plate on the unit for the sound power level for your model.

General Conditions: |

Cloudy |

Temperature: |

74oF (23.2oC) |

Wind Speed: |

3.7 mph (21.6 kmh) |

Wind Direction: |

South |

Humidity: |

83.5% |

Barometric Pressure: |

29.8 Hg (756 mm Hg) |

VIBRATION DATA

VIBRATION LEVEL 0.02g

Vibration levels at the operator’s handles were measured in the vertical, lateral and longitudinal directions using calibrated vibration test equipment. Tests were performed on 7-10-07 under the conditions listed below.

General Conditions: |

|

Sunny |

Temperature: |

|

86oF (17oC) |

Wind Speed: |

|

13 mph (20 kph) |

Wind Direction: |

|

North |

Humidity: |

|

49% |

Barometric Pressure: |

|

29.8”Hg (756mm Hg) |

Part No 812379 |

3 |

Form No F060711B |

DL12/13/14/18 Owner’s Manual

INSTRUCTION LABELS

The labels shown below were installed on your BILLY GOAT ® DL Vacuum. If any labels are damaged or missing, replace them before operating this equipment. Item numbers from the Illustrated Parts List and part numbers are provided for convenience in ordering replacement labels. The correct position for each label may be determined by referring to the Figure and Item numbers shown.

DANGER KEEP HANDS |

EAR EYE BREATHING |

WARNING SECURE |

DANGER FLYING DEBRIS |

AND FEET AWAY |

ITEM# 31 P/N 890254 |

ITEM#62 P/N 790232 |

ITEM #61 P/N 810736 |

ITEM #18 P/N 400424 |

|

|

|

READ OWNERS MANUAL |

EXPLOSIVE FUEL |

LABEL SPARK ARRESTOR |

ITEM #30 P/N 830301 |

ITEM #32 P/N 400268 |

ITEM #15 P/N 100252 |

WARNING ENGINE OVERHEAT |

SECURE NOZZLE |

DL INSTRUCT/WARN |

ITEM #14 P/N 811215 |

ITEM #59 P/N 790232 |

ITEM #28 P/N 790142 |

ENGINE LABELS |

|

HONDA |

B&S VANGUARD |

OIL ALERT |

|

WHEN OIL LEVELLOW, |

|

ENGINE STOPS IMMEDIATELY. |

|

READ OWNER’S MANUAL BEFORE OPERATION.

READ OWNER’S MANUAL BEFORE OPERATION.

LIRE LE MANUEL D UTILISATEUR AVANT USAGE.

LIRE LE MANUEL D UTILISATEUR AVANT USAGE.

VOR INBETRIEBNAHME UNBEDINGHT BEDIENUNGSANLEITUNG DURCHLESEN.

VOR INBETRIEBNAHME UNBEDINGHT BEDIENUNGSANLEITUNG DURCHLESEN.

NO UTILIZAR SINANTES NO HABER LEIDO EL MANUAL

NO UTILIZAR SINANTES NO HABER LEIDO EL MANUAL

HONDA MOTOR CO. , LTD. MADE IN JAPAN

Part No 812379 |

4 |

Form No F060711B |

Loading...

Loading...