Zip MT3787Z5, MT3787Z4, MT3787Z10, MT2786Z2, MT2787Z2 Quick Guide

...

QUICK START GUIDE (Celsius Residential)

Note: This quick start guide must be read in conjunction with the main installation and user instructions

•Before proceeding, read the installation and user instructions

•Check all the components are present and correct.

•Check that you have all the necessary tools

•Ensure the underbench can support the product weight when full of water, (Check the specifications in the main book and allow an extra 2kg when full. )

Before installing ensure the following have been provided at the installation site:

•Sufficient space in the cupboard to install all of the undersink units in accordance with these Installation Instructions. Refer to technical specification for dimensions. If required, make allowance for a booster heater. (Refer to the main book, for detailed installation instructions).

•A potable water supply connection with isolating valve inside the cupboard within reach of the flexible braided hose and positioned so that the connection point and the stop cock will not be obstructed when the undersink unit is installed.

•For Celsius taps, a 220-240Vac, 10A GPO will be required.

•NOTE: Check the cable lengths and outlet positions before proceeding.

•A potable cold water supply with a minimum working pressure of 172kPa for BHA & CHA or 250kPa for CSHA units and a maximum working pressure of 700kPa connected via an isolation valve.

•The undersink appliances must be mounted in upright positions, with their base mounted horizontally, as shown in the diagrams.

IMPORTANT! Do not proceed with the installation if these requirements are not met.

Celsius Tap

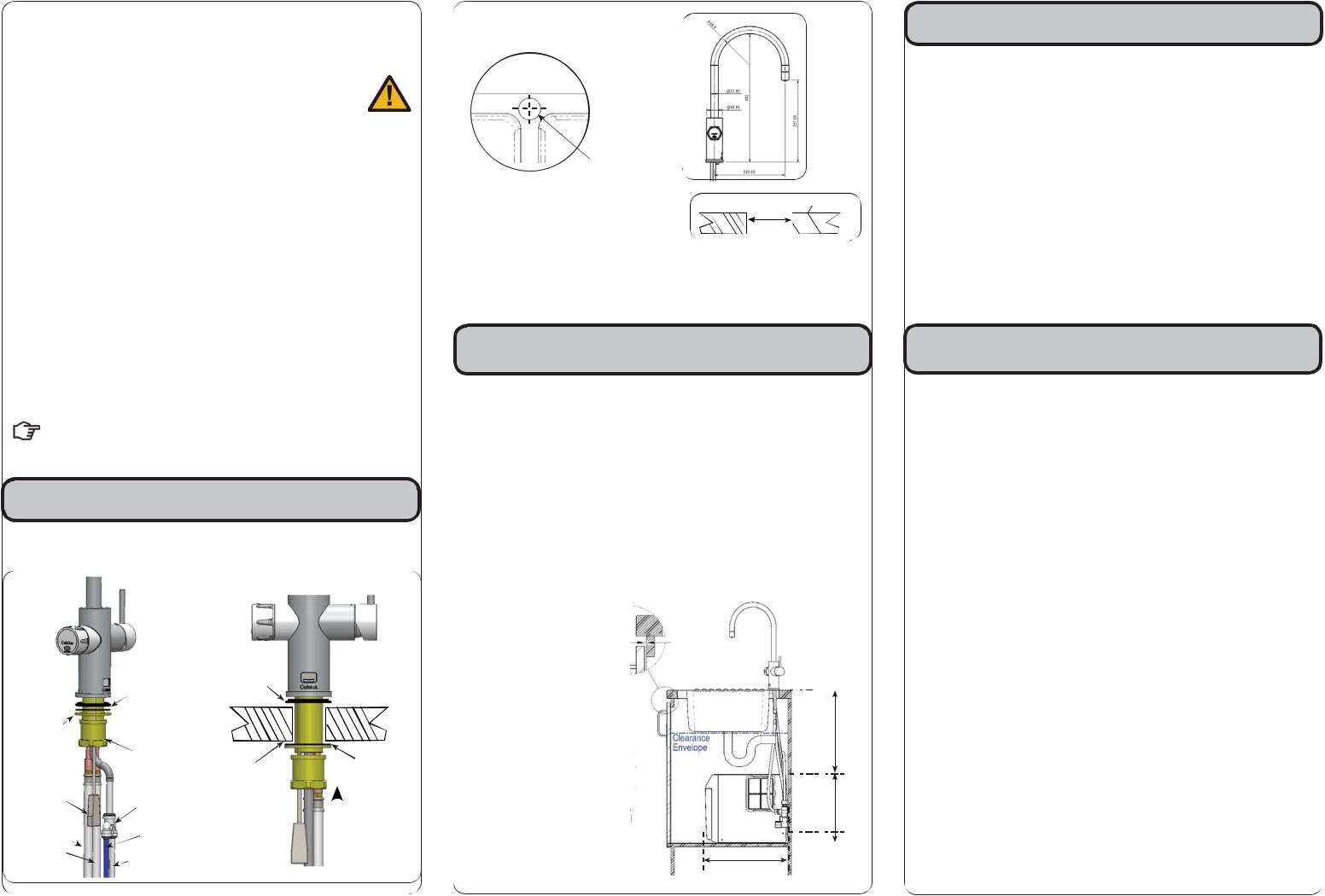

STEP 1- Prepare and fit the Taps

|

BLACK |

UPPER |

|

|

|

RUBBER |

|

|

|

|

RUBBER |

SEAL |

|

|

|

SEALS |

|

|

|

BRASS |

|

|

|

|

WASHER |

BRASS |

|

|

|

|

|

|

LOWER |

|

|

NUT |

|

|

|

|

35mm |

|

RUBBER |

|

|

|

|

||

USB |

JG |

HOLE IN |

|

SEAL |

BENCH |

|

|

||

PLUG |

|

|

||

Y-PIECE |

TOP |

|

|

|

|

|

FIT THE |

||

|

|

|

|

|

|

CHILLED |

|

|

BRASS |

|

|

|

||

HOT & COLD |

TUBE |

|

|

WASHER, |

BRAIDED |

SPARKLING |

|

|

SEAL AND |

HOSES |

|

LARGE NUT |

||

|

TUBE |

|

|

|

Hole positioning: Position the tap such that it dispenses into the sink bowl with ample clearance for a cup or tea pot.

Double Bowl

35mm hole

For Celsius Tap |

BENCH TOP |

|

Ø35mm |

||

cut a 35mm hole in the bench / sink top. |

NOTE: make sure the tap location will allow the nozzle to drain into the sink.

Ventilation

STEP 2- Cut cupboard holes and fit the air vents

2.1 Ventilation for All Models

Proper air circulation must be provided for all Boiling and Chilled models. The system will operate correctly only if the recommended air gaps are achieved during Installation. The minimum requirement is for a 50mm air gap either side and 300mm above of the undersink unit.

It is important that the 4mm door buffers (For all installations ) are fitted to the inside edge of the cupboard door to allow adequate air circulation inside the cupboard. (See the diagram below). Under normal circumstances, these buffers are sufficient for residential models.

4mm Buffer Pad to ensure ventilation gap

Note:

For alternative options, refer to section 2 of the main instructions and See section 4 of the main instructions for clearances.

335mm Min 300mm

392mm

Ventilation continued

2.2 The following instructions are critical only if there is insufficient cupboard air circulation.

If the air flow, using the silicon door buffers, is insufficient, it will be necessary to fit a standard vent kit, which ensures heat dissipation through natural convection via installed vents. Details are supplied in the installation instruction book.

For high use applications, where the cupboard space temperature is near 35°C, or higher, an inlet vent and silicon buffers, may need to be fitted. If the airflow is still insufficient to maintain normal operating temperatures then a door outlet vent will need to be fitted.

Alternatively a fan kit may be installed, using the AUX din plug of the right hand side of the appliance (Contact your local service centre for availability).

Note: If required, the vent kit needs to be installed in a way that allows air to be drawn in from the bottom of the cupboard and expelled through the top of the cupboard. Therefore placement of the outlet vent should be towards the top of the door or on the side of the cupboard.

1.0 KG CO2 Cyl.

STEP 3- Mount the Gas cylinder

This cylinder must be installed in an open plan area or in an enclosed room, with a volume no less than 20 m3. See details on the gas bottle and in the MSDS sheet for a complete list of warnings.

1.Secure the gas bottle supplied to a suitable wall, within 1 metre of the unit, in an upright position. This is done by screwing the metal plate holding the Hook-and-loopstrap to a cupboard wall, 200mm above the floor or base of the cupboard. Make sure the gas bottle can stand before securing to the wall. Due to regulatory requirements the gas bottle must be stored securely and in an upright position.

2.Make sure the regulator knob is turned fully anti-clockwise to the endstop before fitting. Remove the gas bottle from the wall to fit the regulator.

Be aware that some CO2 may be discharged from the connection during assembly. To avoid excess gas leakage, promptly screw the regulator on to the bottle.

3.Connect the braided gas hose to the top of the undersink unit via the John Guest fitting marked ‘Gas IN’ Then connect the threaded end to the

regulator, taking care not to lose the plastic olive located inside the threaded nut. When commissioning, turn the gas ON by rotating the regulator knob clockwise and adjust to 2.7-3.0 bar (270-300kPa). The arrow should sit in the green section of the regulator gauge; it should not fall in the red or yellow sections.

4.When commissioning, use soapy water to perform a leak test. Apply the soapy water to the gas connections using a sponge. If any bubbles appear and grow, there is a gas leak at the connection. Clean away the soapy residue and tighten or refit the leaking connection. Make sure the regulator is turned off when tightening or refitting the leaking connection.

5.Refit the gas bottle to the Hook-and-loopstrap and secure the bottle in an upright position.

NOTE: Care must be taken when working with high pressure carbon dioxide, and in no cases should the normal operating pressure of 2.7-3.0 bar (270-300kPa) be exceeded.

802699 - G4 - Quick Start Guide - 09.2016 - v2.02

Loading...

Loading...