York YPAL 050, YPAL 060, YPAL 051, YPAL 061 User Manual

PACKAGED ROOFTOP

AIR CONDITIONING UNITS

INSTALLATION, OPERATION & MAIN TE NANCE

SIMPLICITY ELITE CONTROL

New Release

YPAL 050

YPAL 051

YPAL 060

YPAL 061

DESIGN LEVEL F

Form 100.50-NOM6 (1207)

035-21979-002

LD13271

IMPORTANT!

READ BEFORE PROCEEDING!

GENERAL SAFETY GUIDELINES

FORM 100.50-NOM6 (1207)

This equipment is a relatively complicated ap pa ra tus.

Dur ing installation, operation, maintenance or service,

in di vid u als may be exposed to certain com po nents or

conditions in clud ing, but not limited to: re frig er ants,

oils, materials un der pressure, rotating com po nents,

and both high and low voltage. Each of these items

has the po ten tial, if misused or handled im prop er ly, to

cause bodi ly injury or death. It is the obligation and

re spon si bil i ty of operating/service per son nel to iden ti fy

and rec og nize these inherent hazards, protect them selves,

and pro ceed safely in completing their tasks. Failure to

com ply with any of these requirements could re sult in

se ri ous dam age to the equipment and the prop er ty in

which it is sit u at ed, as well as severe personal injury or

death to them selves and people at the site.

This document is intended for use by owner-authorized

operating/service personnel. It is expected that this

in di vid u al possesses independent training that will

en able them to perform their assigned tasks properly

and safe ly. It is essential that, prior to performing any

task on this equipment, this individual will have read

and un der stood this document and any referenced

materials. This in di vid u al will also be familiar with and

comply with all ap pli ca ble governmental standards and

regulations per tain ing to the task in question.

SAFETY SYMBOLS

The following symbols are used in this document to alert the reader to areas of potential hazard:

DANGER indicates an im mi nent ly

hazardous situation which, if not

avoid ed, will re sult in death or se ri ous

injury.

CAUTION identifi es a hazard which

could lead to damage to the ma chine,

damage to other equip ment and/or

en vi ron men tal pollution. Usually an

in struc tion will be given, together with

a brief ex pla na tion.

WARNING indicates a potentially

haz ard ous sit u a tion which, if not

avoid ed, could result in death or se-

NOTE is used to highlight ad di tion al

information which may be helpful to

you.

ri ous in ju ry.

External wiring, unless specifi ed as an optional connection in the man u fac tur er’s prod uct

line, is NOT to be connected inside the micro pan el cab i net. De vic es such as re lays, switch es,

transducers and controls may NOT be installed inside the mi cro pan el. NO external wiring

is al lowed to be run through the micro panel. All wir ing must be in ac cor dance with JOHNSON CONTROLS’s pub lished spec i fi ca tions and must be per formed ONLY by qual i fi ed

JOHNSON CONTROLS personnel. JOHNSON CONTROLS will not be re spon si ble for

dam ag es/problems re sult ing from im prop er con nec tions to the con trols or ap pli ca tion of

im prop er con trol sig nals. Failure to fol low this will void the man u fac tur er’s warranty and

cause serious dam age to property or injury to per sons.

2

JOHNSON CONTROLS

CHANGEABILITY OF THIS DOCUMENT

d

P

d

P

FORM 100.50-NOM6 (1207)

In complying with JOHNSON CONTROLS’s policy

for continuous prod uct improvement, the in for ma tion

con tained in this doc u ment is subject to change without

notice. While JOHNSON CONTROLS makes no

com mit ment to update or provide current in for ma tion

au to mat i cal ly to the manual owner, that in for ma tion, if

ap pli ca ble, can be ob tained by con tact ing the nearest

JOHNSON CONTROLS Applied Systems offi ce.

It is the responsibility of operating/service personnel

to verify the ap pli ca bil i ty of these doc u ments to the

equip ment in question. If there is any question in

the mind of operating/service personnel as to the

applicability of these doc u ments, then prior to work ing

on the equip ment, they should verify with the owner

whether the equip ment has been modifi ed and if current

literature is avail able.

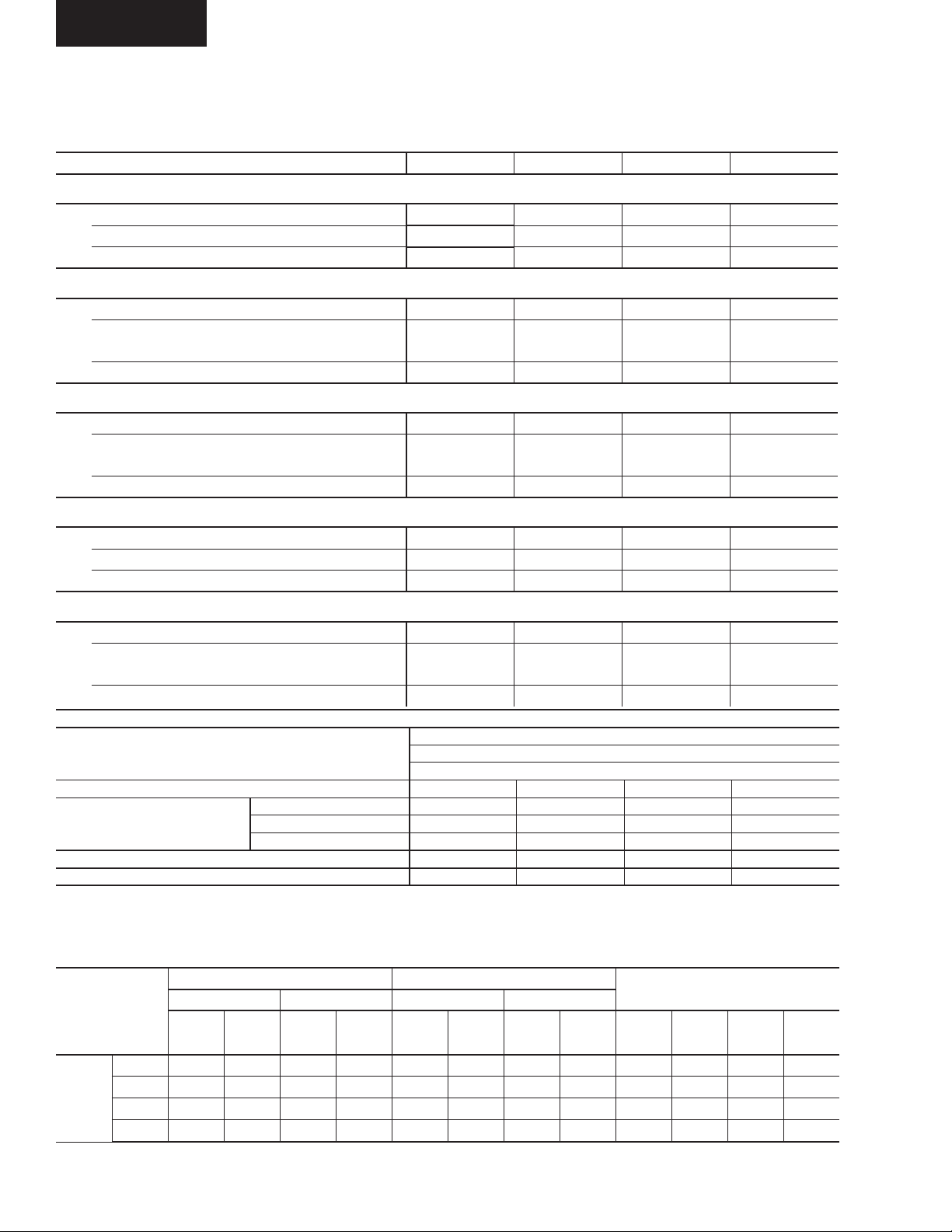

NOMENCLATURE

BASE MODEL NUMBER

YPAL050-061

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Base Type Refrigerant Supply

Product Nominal Capacity Application

Y :YORK 5 0 :50 Ton Capacity :208/3/60

P :Packaged Rooftop 0 5 1 :51 Ton Capacity C :R-22 :230/3/60

A :Air Cooled 0 6 0 :60 Ton Capacity E :R-410A 4 6 :460/3/60

L :Scroll 0 6 1 :61 Ton Capacity 5 8 :575/3/60

0 B :R-407C

C :Constant Volume

V :VAV, VFD

F :Flexsys

C :Cooling Only

N :Staged Natural Gas Heat

G :Staged Natural Gas Heat SS HX

M :Full Modulating Gas Heat

F :Full Modulating Gas Heat SS Staged HX

E :Electric Heat

H :Hot Water Heat

S :Steam Heat

Voltage

25

4 0 :380/3/60

4 5 :400/3/50

Openings

B :Bottom Supply

L :Left Supply

R :Right Supply

Return

Openings

B :Bottom Return

R :Rear Return

S :Side Return

Design Special

X :Standar

S :Special

A :Standar

B :Special

F :Revision Level F

LD13270

JOHNSON CONTROLS

3

FORM 100.50-NOM6 (1207)

TABLE OF CONTENTS

BASE MODEL NUMBER ..............................................................................................................................3

CHANGEABILITY OF THIS DOCUMENT .....................................................................................................3

NOMENCLATURE .........................................................................................................................................3

TABLE OF CONTENTS ................................................................................................................................4

LIST OF TABLES ........................................................................................................................................ 11

LIST OF FIGURES ......................................................................................................................................12

SECTION 1 – INTRODUCTION .........................................................................................................13

ECOLOGICAL AND ECONOMICAL DESIGN ............................................................................................13

Condensing Section .............................................................................................................13

Heating Section .....................................................................................................................14

AIR MANAGEMENT ....................................................................................................................................15

CONTROLS .................................................................................................................................................15

INDOOR AIR QUALITY ..............................................................................................................................15

ELECTRICAL ..............................................................................................................................................16

SERVICE AND INSTALLATION ..................................................................................................................16

SECTION 2 – INSTALLATION ...........................................................................................................17

APPROVALS ...............................................................................................................................................17

LIMITATIONS ...............................................................................................................................................17

UNIT INSPECTION ......................................................................................................................................17

LOCATIONS AND CLEARANCES .............................................................................................................17

RIGGING AND HANDLING .........................................................................................................................19

UNIT WEIGHTS ...........................................................................................................................................20

Unit Placement ......................................................................................................................21

Roof Curb Installation ..........................................................................................................22

PHYSICAL DATA .........................................................................................................................................23

GENERAL ARRANGEMENT DRAWING – 050-061 MODELS .................................................................25

Bottom Supply / Bottom Return ..........................................................................................25

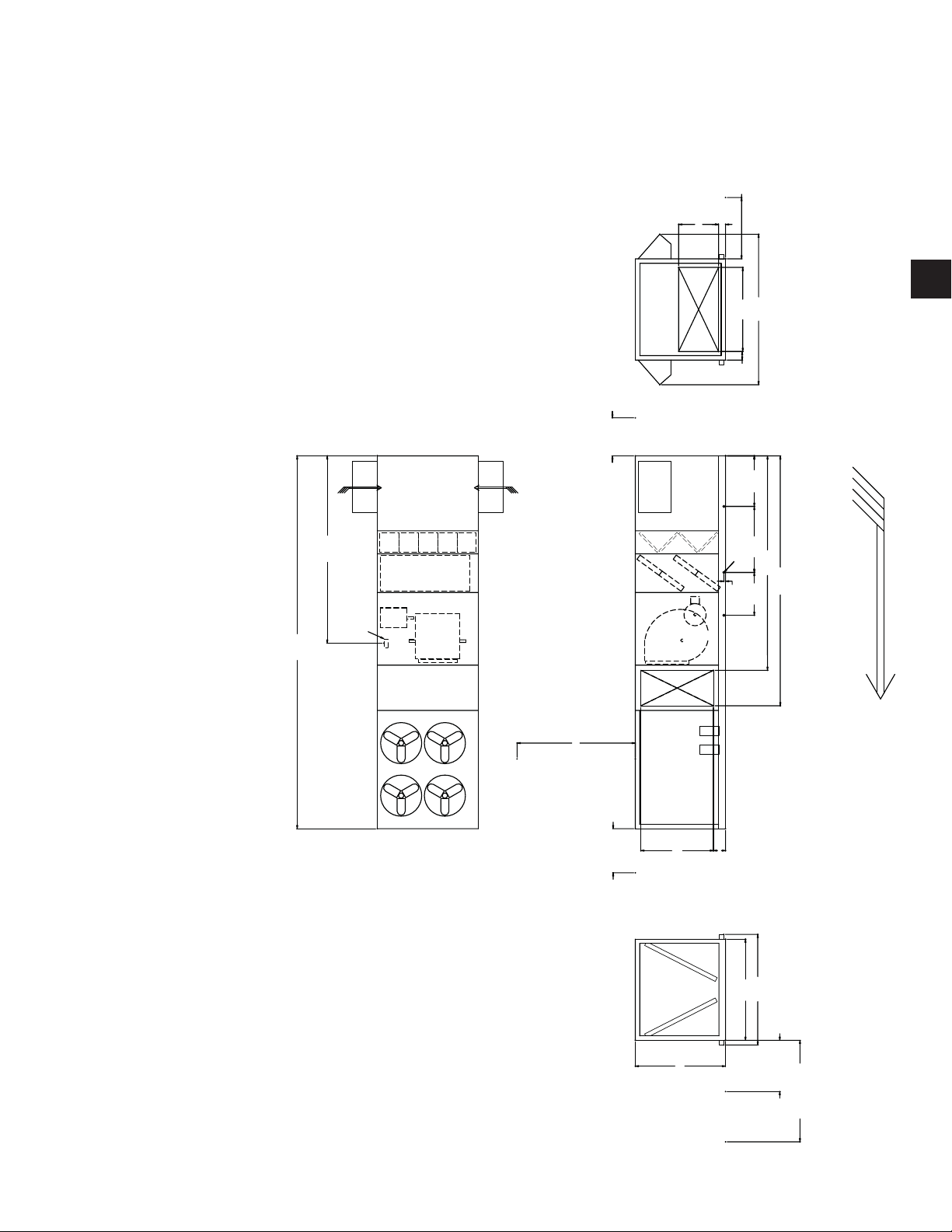

Bottom Supply / Side Return ...............................................................................................26

Bottom Supply / Rear Return ...............................................................................................27

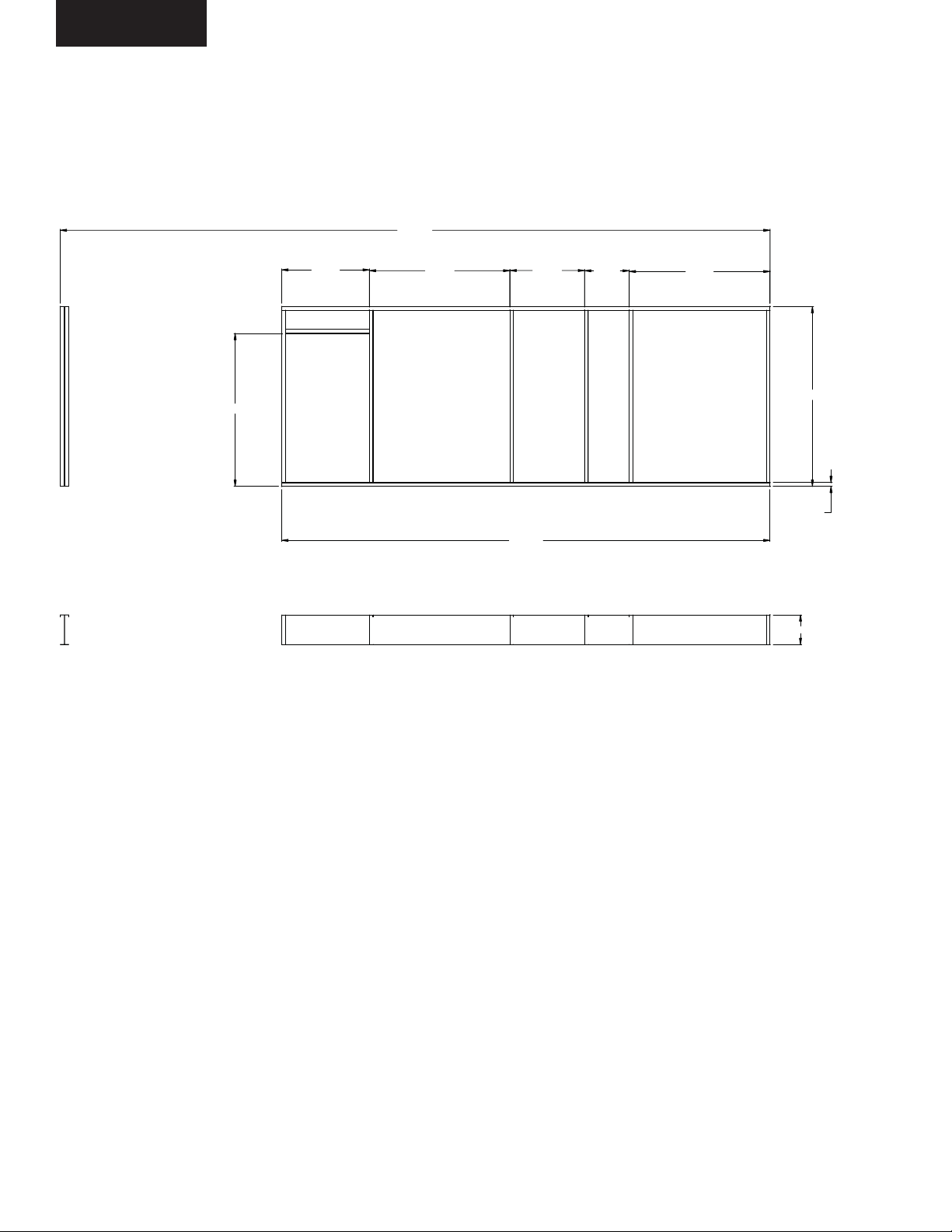

Curb Layout Drawing / 050-061 Models ..............................................................................28

ELECTRICAL DATA ....................................................................................................................................29

Electrical Service Sizing ......................................................................................................29

Load Defi nitions: ..................................................................................................................29

FILTERS ......................................................................................................................................................32

CONDENSATE DRAIN ................................................................................................................................32

Condensate Drain Piping .....................................................................................................32

Condensate Drain Trap ........................................................................................................32

AIR HOODS FOR ECONOMIZER ...............................................................................................................33

AIR HOODS FOR FIXED OUTSIDE AIR (UNITS WITHOUT ECONOMIZER) ...........................................33

AIR HOODS FOR EXHAUST AIR ...............................................................................................................33

4

JOHNSON CONTROLS

FORM 100.50-NOM6 (1207)

TABLE OF CONTENTS

FIELD WIRING ............................................................................................................................................33

Thermostat ............................................................................................................................33

Fan input ................................................................................................................................33

Space Sensor ........................................................................................................................33

CO2 Sensor ...........................................................................................................................34

Occupied / Unoccupied Input ..............................................................................................34

Shutdown Input .....................................................................................................................34

Smoke Purge Input ...............................................................................................................34

BAS Economizer Input .........................................................................................................34

Fault Output ..........................................................................................................................34

VAV Heat Relay Output .........................................................................................................35

Supply Air Temperature Reset .............................................................................................35

COMMUNICATION ......................................................................................................................................35

DIRTY FILTER SWITCH ..............................................................................................................................35

FIELD CONTROL WIRING CONNECTIONS ..............................................................................................36

POWER WIRING .........................................................................................................................................37

ELECTRICAL SERVICE SIZING .................................................................................................................37

SINGLE-POINT POWER SUPPLY WIRING ...............................................................................................38

SINGLE-POINT POWER SUPPLY WIRING WITH NON-FUSED DISCONNECT SWITCH .......................39

DUAL-POINT POWER SUPPLY WIRING ...................................................................................................40

CONTROLS .................................................................................................................................................41

TRANSDUCER PNEUMATIC TUBING .......................................................................................................42

Static Pressure Control Plastic Tubing .............................................................................42

Duct Static Transducer .........................................................................................................42

Building Pressure Transducer .............................................................................................42

Static Pressure Probe Installation ......................................................................................42

DUCT SYSTEM ...........................................................................................................................................44

Duct Connection Guidelines ................................................................................................44

SOUND AND VIBRATION TRANSMISSION ..............................................................................................44

GAS HEATING ............................................................................................................................................45

GAS PIPING ................................................................................................................................................45

GAS CONNECTION ....................................................................................................................................45

Gas Piping Recommendations ............................................................................................45

COMBUSTION VENT ..................................................................................................................................46

SECTION 3 – START-UP ...................................................................................................................47

CRANKCASE HEATERS ............................................................................................................................47

CHECKING THE SYSTEM PRIOR TO INITIAL START (NO POWER) ......................................................47

Unit Checks ...........................................................................................................................47

UNIT CHECKS – POWER APPLIED ..........................................................................................................49

Verifying Compressor Rotation ...........................................................................................49

Compressor Oil Level Check ...............................................................................................49

JOHNSON CONTROLS

5

FORM 100.50-NOM6 (1207)

TABLE OF CONTENTS

INITIAL START-UP ......................................................................................................................................50

Refrigerant Charge ..............................................................................................................50

Checking Superheat and Subcooling .................................................................................50

Subcooling (R-410A) ............................................................................................................50

Superheat (R-410A) ..............................................................................................................50

Leak Checking ......................................................................................................................51

GAS HEAT MODELS ..................................................................................................................................53

Pre-Start Checks: ..................................................................................................................53

Post Start Checks: ................................................................................................................53

SECTION 4 – MAINTENANCE ..........................................................................................................55

GENERAL ...................................................................................................................................................55

PERIODIC MAINTENANCE – MONTHLY ...................................................................................................55

Filters .....................................................................................................................................55

Linkages ................................................................................................................................55

Compressors .........................................................................................................................55

Fan Bearing Lubrication .....................................................................................................55

Recommended Lubricant for Fan Bearings .......................................................................55

Condenser Coils ...................................................................................................................56

PERIODIC MAINTENANCE – THREE TO SIX MONTHS ..........................................................................56

Motor Bearing Lubrication ...................................................................................................56

Belt Tension ..........................................................................................................................56

PERIODIC MAINTENANCE – YEARLY ......................................................................................................56

Entire Unit Inspection ...........................................................................................................56

Sheave Alignment: ...............................................................................................................56

Belts .......................................................................................................................................56

Belt Replacement ..................................................................................................................57

Belt Tensioning: ....................................................................................................................57

Filter Drier Replacement ......................................................................................................58

Forward Curved Fans ...........................................................................................................58

Fan Motor ..............................................................................................................................59

Fan Shaft Bearings ...............................................................................................................59

Bearing Lock Devices ..........................................................................................................60

Eccentric Type ......................................................................................................................60

Torquing of Set-screws .......................................................................................................61

SECTION 5 – SEQUENCE OF OPERATION ....................................................................................63

UNIT TYPE ..................................................................................................................................................63

OCCUPIED / UNOCCUPIED MODE ...........................................................................................................63

CONSTANT VOLUME MODE (CV) .............................................................................................................63

Thermostat Input ..................................................................................................................64

Occupied Cooling ............................................................................................................64

Unoccupied Cooling ........................................................................................................64

Occupied Heating ............................................................................................................65

Unoccupied Heating ........................................................................................................65

6

JOHNSON CONTROLS

FORM 100.50-NOM6 (1207)

TABLE OF CONTENTS

Space Sensor – Hard Wired or Communicated .................................................................65

Cooling Operation – Occupied or Unoccupied .............................................................65

Heating Operation – Occupied or Unoccupied .............................................................66

Stand Alone ...........................................................................................................................66

Cooling Operation – Occupied or Unoccupied .............................................................67

Heating Operation – Occupied or Unoccupied .............................................................67

VARIABLE AIR VOLUME (VAV) .................................................................................................................68

Cooling - Occupied with Thermostat ..................................................................................68

Cooling – Unoccupied with Thermostat .............................................................................69

Occupied or Unoccupied Heating with a Thermostat .......................................................69

Occupied Cooling with Hard Wired or Communicated Space Sensor ............................69

Cooling – Unoccupied with a Hard Wired or Communicated Space Sensor .................70

Heating – Occupied with a Hard Wired or Communicated Space Sensor ......................70

Heating – Unoccupied with a Hard Wired or Communicated Space Sensor ..................70

Occupied Cooling – Stand Alone ........................................................................................71

Cooling – Unoccupied Stand Alone ...................................................................................72

Heating – Occupied Stand Alone ........................................................................................72

Heating – Unoccupied Stand Alone ....................................................................................72

CONDENSER FAN OPERATION ...............................................................................................................72

COOLING COMPRESSOR LOCKOUT .....................................................................................................72

Sequence of Operation .......................................................................................................72

LOW AMBIENT OPERATION ....................................................................................................................73

Operation and Pressure Control Range .............................................................................73

Confi guration (Jumpers and Potentiometers) ...................................................................73

SUPPLY FAN OPERATION .........................................................................................................................74

Constant Volume (CV) ..........................................................................................................74

Variable Air Volume (VAV) ....................................................................................................75

VAV Supply Fan Speed Control ...........................................................................................76

ECONOMIZER .............................................................................................................................................76

Dry Bulb .................................................................................................................................76

Single Enthalpy .....................................................................................................................77

Dual Enthalpy ........................................................................................................................77

BAS ECONOMIZER OPERATION .............................................................................................................77

Sequence of Operation .......................................................................................................78

Constant Volume Economizer Set Point ............................................................................78

Variable Air Volume Economizer Set Point ........................................................................78

Economizer / Compressor Operation .................................................................................79

Economizer PI Loop (Proportional and Integral) ...............................................................79

ECONOMIZER LOADING ...........................................................................................................................79

Constant Volume ..................................................................................................................80

Variable Air Volume ..............................................................................................................80

JOHNSON CONTROLS

7

FORM 100.50-NOM6 (1207)

TABLE OF CONTENTS

COMFORT VENTILATION ..........................................................................................................................81

Sequence of Operation ........................................................................................................82

Conditions of Operation .......................................................................................................82

EXCESSIVE SAT (SUPPLY AIR TEMPERATURE) CONTROL .................................................................82

Cooling ..................................................................................................................................82

Heating ...................................................................................................................................83

SPACE SENSOR WITH SET POINT ADJUSTMENT .................................................................................84

Sequence of Operation ........................................................................................................84

SPACE SENSOR FAULT OVERRIDE ENABLE ........................................................................................85

Sequence of Operation ........................................................................................................85

REMOTE CONTROL ...................................................................................................................................85

Sequence of Operation ........................................................................................................85

REDLINE .....................................................................................................................................................85

Sequence of Operation ........................................................................................................85

LOADSHED .................................................................................................................................................86

Sequence of Operation ........................................................................................................86

DIRTY FILTER .............................................................................................................................................86

Sequence of Operation ........................................................................................................86

METRIC OPERATION .................................................................................................................................86

INTELLI-START ..........................................................................................................................................86

Sequence of Operation ........................................................................................................87

Subsequent Operation .........................................................................................................87

MORNING WARM-UP .................................................................................................................................88

Sequence of Operation ........................................................................................................88

HYDRONIC HEAT .......................................................................................................................................89

Sequence of Operation ........................................................................................................89

HYDRONIC HEAT FREEZE STAT ..............................................................................................................89

VENTILATION .............................................................................................................................................89

Manual ...................................................................................................................................90

Fixed Minimum ......................................................................................................................90

Sequence of Operation ........................................................................................................90

Demand Ventilation ..............................................................................................................90

Defi nitions ........................................................................................................................91

Sequence of Operation ....................................................................................................91

VENTILATION LOW AMBIENT MINIMUM POSITION RESET ..................................................................91

Sequence of Operation ........................................................................................................91

EXHAUST FAN OPERATION .....................................................................................................................92

On/Off Control Based on Outdoor Damper Position .........................................................92

Sequence of Operation ....................................................................................................92

On/Off Control Based on Building Pressure ......................................................................92

Sequence of Operation ....................................................................................................93

8

JOHNSON CONTROLS

FORM 100.50-NOM6 (1207)

TABLE OF CONTENTS

Modulating Damper with Fixed Speed Exhaust .................................................................93

Sequence of Operation ....................................................................................................93

Modulating Exhaust with a VFD ..........................................................................................93

Sequence of Operation ....................................................................................................94

PRE-OCCUPANCY PURGE ........................................................................................................................94

Criteria for Operation ...........................................................................................................94

Sequence of Operation ........................................................................................................94

ENERGY RECOVERY VENTILATOR .........................................................................................................95

Sequence of Operation ........................................................................................................95

LOW VOLTAGE PROTECTION ..................................................................................................................95

OUTDOOR AIR HEATING LOCKOUT ........................................................................................................95

HOT GAS BYPASS .....................................................................................................................................95

SPACE TEMPERATURE ALARM ...............................................................................................................95

Sequence of Operation ........................................................................................................96

SAT ALARM FOR HEATING .......................................................................................................................96

Sequence of Operation ........................................................................................................96

“Supply Air Temp Alarm Setpoint for Heating” Alarm .................................................96

“Economizer Minimum Position” Alarm ........................................................................97

SAT ALARM FOR COOLING ......................................................................................................................97

Sequence of Operation ........................................................................................................97

“Supply Air Temp Alarm Setpoint for Cooling” Alarm .................................................97

“Economizer Minimum Position” Alarm ........................................................................98

ALARM HISTORY .......................................................................................................................................98

SECTION 6 – USER INTERFACE .....................................................................................................99

UNIT CONTROLLER INTERFACE .............................................................................................................99

PROGRAM BUTTON ..................................................................................................................................99

TEST/UP BUTTON ....................................................................................................................................100

ADDRESS/DOWN BUTTON .....................................................................................................................100

ALARM/CHANGE .....................................................................................................................................100

CHARACTER DISPLAY ADDRESSES & CODES ...................................................................................100

COMMUNICATION USING SIMPLICITY PC ............................................................................................104

Simplicity PC Download .....................................................................................................104

USB Adapter Drive - Simplicity Pocket PC .......................................................................106

Establishing Communication ............................................................................................107

Simplicity PC Data Screens ............................................................................................... 111

Revising Settings ................................................................................................................126

SECTION 7 – PARAMETER DESCRIPTIONS AND OPTIONS ......................................................141

SECTION 8 – SERVICE ...................................................................................................................153

ANALOG INPUT OPERATION .................................................................................................................153

Temperature Sensors .........................................................................................................153

Duct Pressure Transducer .................................................................................................153

JOHNSON CONTROLS

9

FORM 100.50-NOM6 (1207)

TABLE OF CONTENTS

Return Fan Pressure Transducer ......................................................................................154

Discharge Pressure Transducer ........................................................................................154

Building Pressure Transducer ...........................................................................................154

Suction Pressure Transducer ............................................................................................155

Humidity Sensors ...............................................................................................................155

Sensor ..........................................................................................................................156

CO

2

Furnace Status Input ..........................................................................................................156

FAULTS AND LOCKOUTS .......................................................................................................................160

Light Emitting Diode ...........................................................................................................160

Alarm Codes ........................................................................................................................160

Alarm Trouble Shooting .....................................................................................................163

Refrigerant System Alarm Codes (01, 02, 03, 04, 09, 10, 11, 12) ................................163

Low Pressure Cutout Alarm (09, 10, 11, 12) .................................................................164

Limit Switch Alarms (13, 14, 15) ...................................................................................164

Gas Heating Alarms (16, 17, 18) ....................................................................................164

Space Temperature Sensor Alarm (19) ........................................................................164

Supply Air Temperature Sensor Alarm (20) .................................................................165

Return Air Temperature Sensor Alarm (21) .................................................................165

Outdoor Air Temperature Sensor Alarm (22) ...............................................................165

Dirty Filter Switch Alarm (23) ........................................................................................165

Supply Fan Air Proving Switch (24) .............................................................................165

Supply Fan Air Proving Switch Closed Alarm (25) .....................................................165

Microelectronics Failure Alarm (26) .............................................................................165

Microelectronics Failure Alarm (27) .............................................................................165

Supply Fan Overload Alarm (28) ...................................................................................165

Outdoor Humidity Sensor Alarm (29) ...........................................................................166

Return Humidity Sensor Alarm (30) .............................................................................166

IAQ (CO2) Sensor Alarm (31) ........................................................................................166

Time Clock Error Alarm (32) ..........................................................................................166

Space Temperature Offset Alarm (33) ..........................................................................166

CV/VAV Input Alarm (34) ................................................................................................166

Low Voltage Alarm (35) ..................................................................................................166

Smoke Purge Mode Alarm (36) .....................................................................................166

High Duct Static Pressure Alarm (37) ..........................................................................166

Supply Air Temperature Cooling Alarm (38) ................................................................167

Supply Air Temperature Heating Alarm (39) ................................................................167

Economizer Minimum Position Alarm (40) ..................................................................167

Space Temperature Trending Alarm (41) .....................................................................167

Duct Static Low Pressure Alarm (42) ...........................................................................167

Hot Water Coil Freeze Alarm (43) .................................................................................167

10

JOHNSON CONTROLS

FORM 100.50-NOM6 (1207)

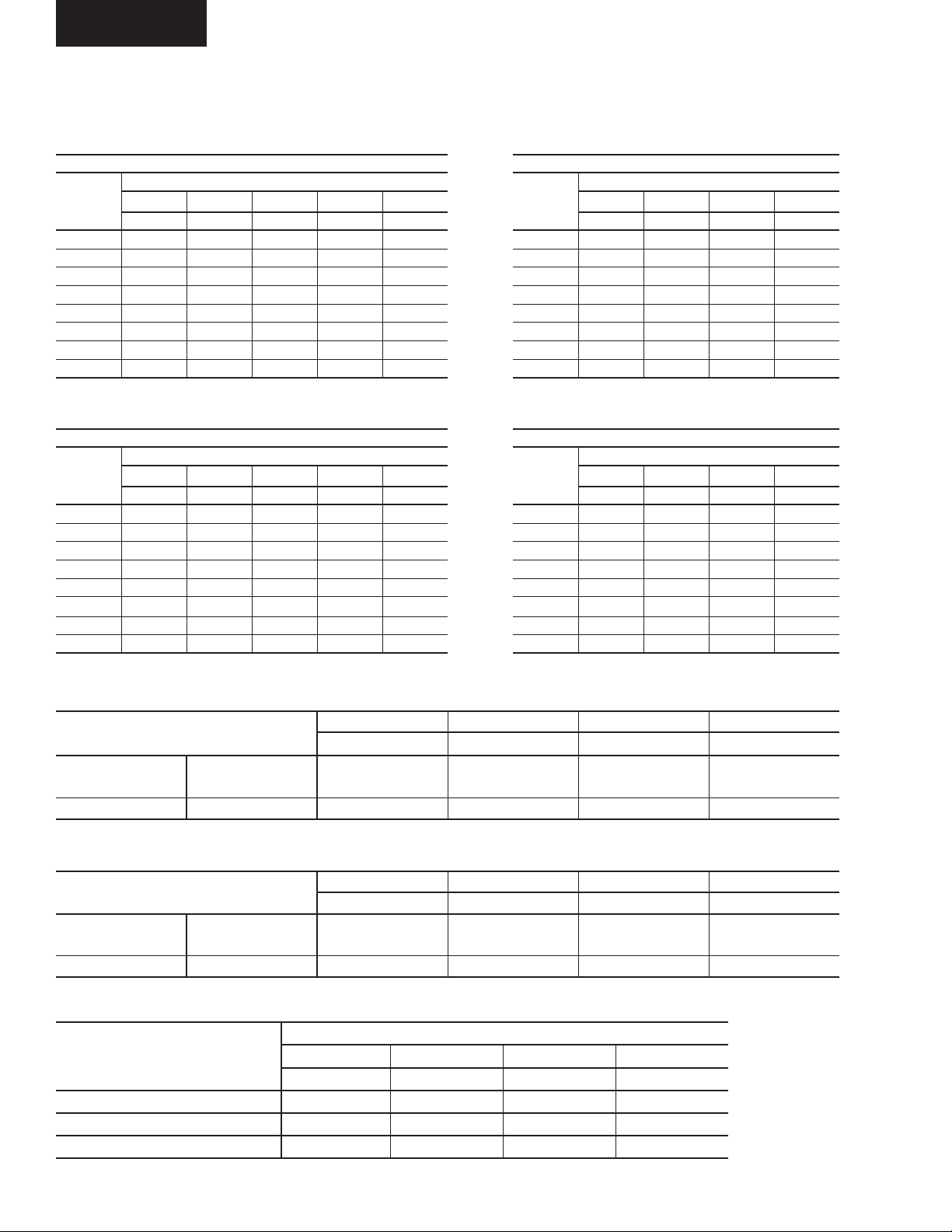

LIST OF TABLES

TABLE 2-1 – VOLTAGE LIMITATIONS .............................................................................................17

TABLE 2-2 – UNIT WEIGHTS - 050-061 MODELS ...........................................................................20

TABLE 2-3 – UNIT CENTER OF GRAVITY .......................................................................................20

TABLE 2-4 – UNIT CORNER WEIGHTS - 050-061 MODELS ..........................................................21

TABLE 2-5 – PHYSICAL DATA – 050-061 MODELS .......................................................................23

TABLE 2-6 – PHYSICAL DATA - COMPRESSORS ..........................................................................24

TABLE 2-7 – COMPRESSOR DATA - R410A ...................................................................................29

TABLE 2-8 – POWER SUPPLY VOLTAGE LIMITS ..........................................................................29

TABLE 2-9 – SUPPLY AND EXHAUST FAN MOTOR DATA - ODP .................................................30

TABLE 2-10 – SUPPLY AND EXHAUST FAN MOTOR DATA - TEFC .............................................30

TABLE 2-11 – CONDENSER FAN MOTOR RLA - STANDARD FAN ...............................................30

TABLE 2-12 – CONDENSER FAN MOTOR RLA - LOW SOUND FAN (FUTURE OPTION) ...........30

TABLE 2-13 – MISCELLANEOUS ELECTRICAL DATA ..................................................................30

TABLE 2-14 – ELECTRIC HEAT .......................................................................................................31

TABLE 2-15 – AIRFLOW AND ENTERING AIR/AMBIENT LIMITATIONS .......................................31

TABLE 2-16 – THREE PHASE POWER SUPPLY CONDUCTOR SIZE RANGE .............................41

TABLE 2-17 – SUPPLY AIR DUCT CONNECTION CONFIGURATIONS .........................................44

TABLE 2-18 – RETURN AIR DUCT CONNECTION CONFIGURATIONS ........................................44

TABLE 2-19 – PIPE SIZES ................................................................................................................45

TABLE 3-1 –R410-A PRESSURE / TEMPERATURE CHART .........................................................52

TABLE 3-2 – LOW FIRE / HIGH FIRE PRESSURES ............................................................................54

TABLE 3-3 – GAS HEAT PERFORMANCE DATA ............................................................................54

TABLE 4-1 – FAN BEARING – LUBRICATION INTERVALS ...........................................................55

TABLE 4-2 – SET SCREW TORQUE ................................................................................................61

TABLE 5-1 – BINARY OUTPUTS ......................................................................................................73

TABLE 5-2 – VFD JUMPERS ............................................................................................................73

TABLE 5-3 – POTENTIOMETER SETTINGS ....................................................................................73

TABLE 5-4 OPERATION DURING OFF CYCLE ..............................................................................81

TABLE 5-5 COMPRESSOR ON WHEN SPACE INPUT SATISFIED ................................................81

TABLE 5-6 HEAT STAGE ON WHEN SPACE INPUT SATISFIED ..................................................82

TABLE 6-1 - PARAMETER POINTS LIST .......................................................................................101

TABLE 6-2 - SIMPLICITY ELITE DATA MAP .................................................................................130

TABLE 7-1 – DEFINITIONS .............................................................................................................141

TABLE 8-1 – TEMPERATURE SENSOR RESISTANCE ................................................................153

TABLE 8-2 – DUCT PRESSURE TRANSDUCER ...........................................................................154

TABLE 8-3 – BUILDING PRESSURE TRANSDUCER OUTPUT ...................................................154

TABLE 8-4 – RETURN FAN PRESSURE TRANSDUCER OUTPUT ..............................................154

TABLE 8-5 – PRESSURE TRANSDUCERS ...................................................................................155

TABLE 8-6 – HUMIDITY SENSOR OUTPUTS ................................................................................155

TABLE 8-7 – CO2 SENSOR OUTPUT ............................................................................................156

TABLE 8-8 – WIRING DATA ............................................................................................................157

TABLE 8-9 – ALARM CODE DESCRIPTIONS ...............................................................................161

JOHNSON CONTROLS

11

FORM 100.50-NOM6 (1207)

LIST OF FIGURES

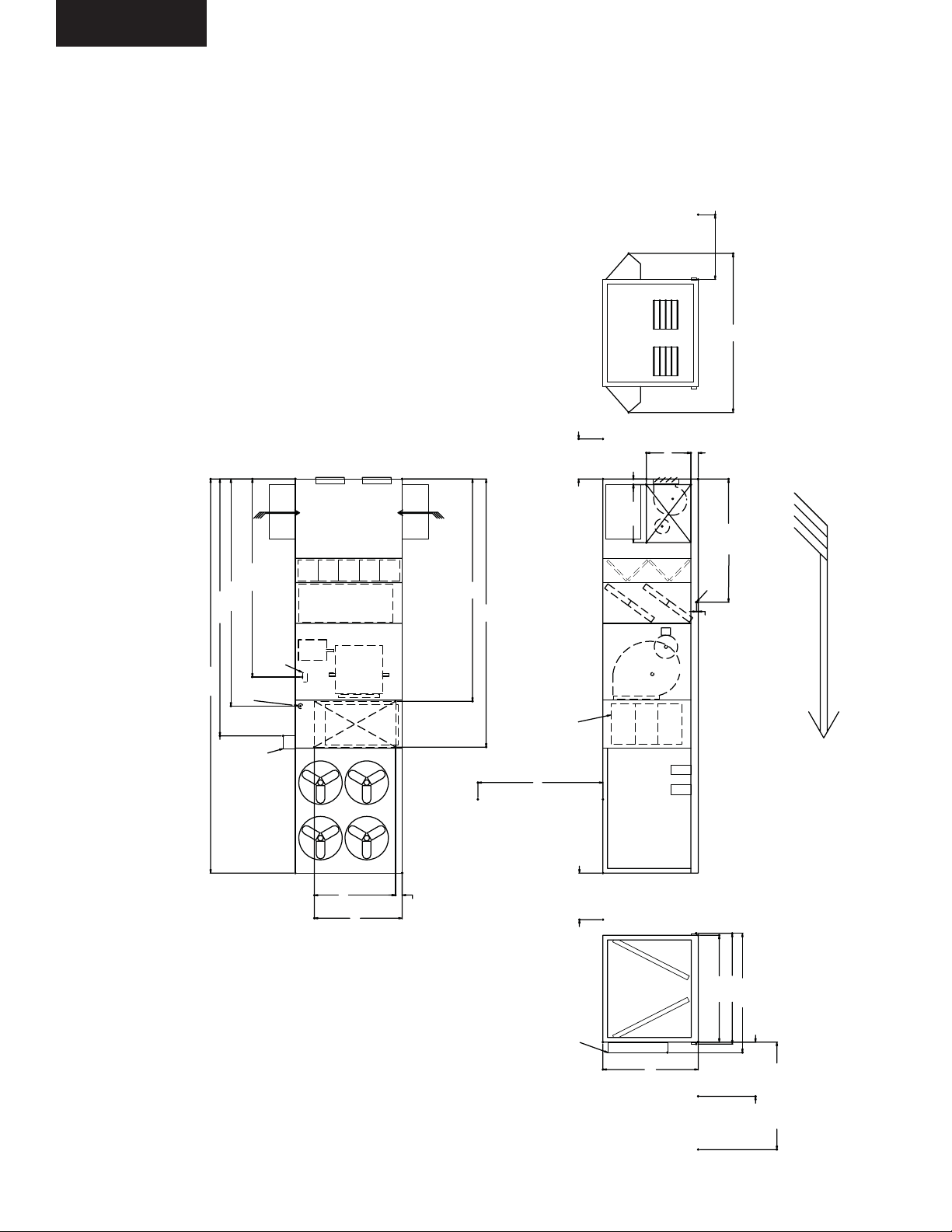

FIG. 1-1 – PACKAGED ROOFTOP AIR CONDITIONING UNIT ......................................................13

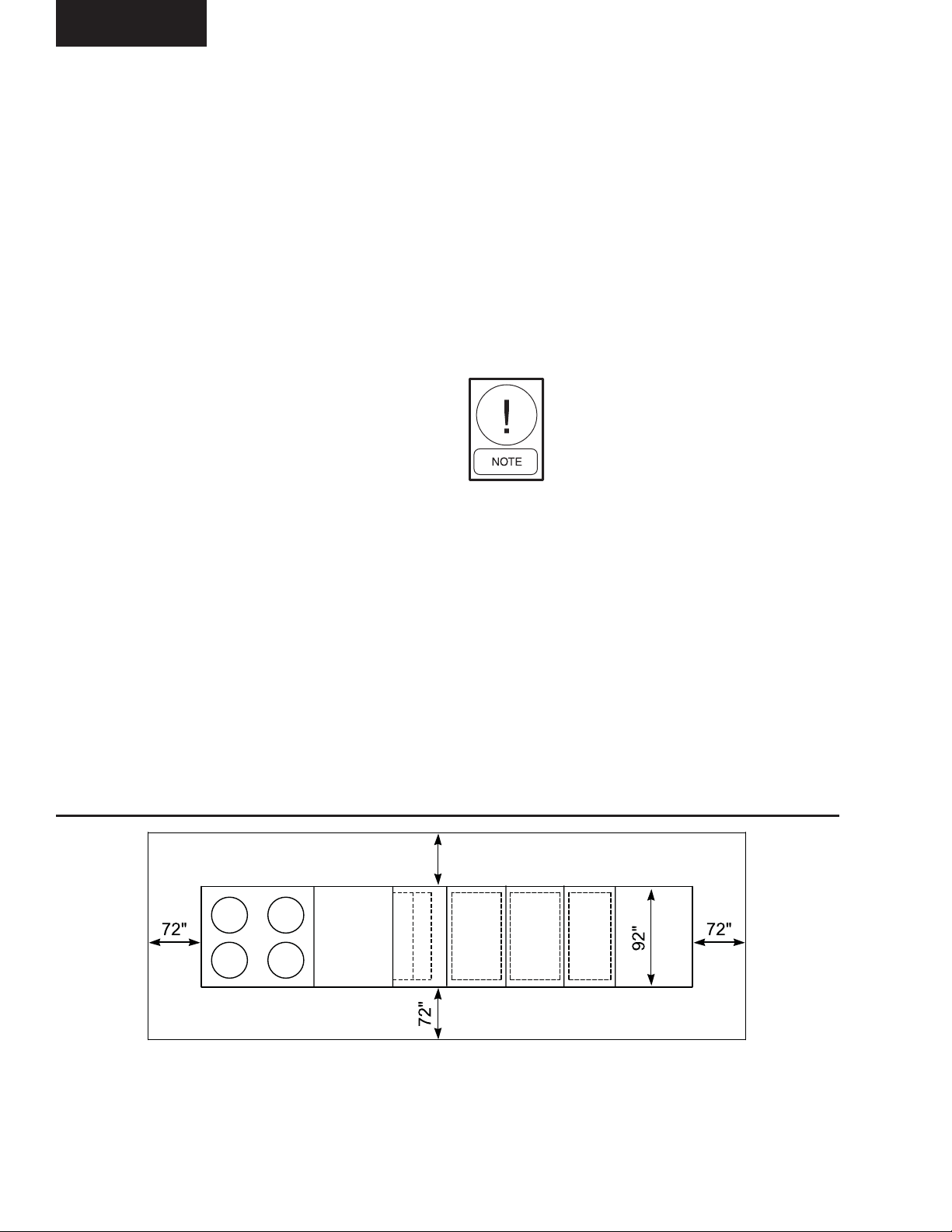

FIG. 2-1 – UNIT CLEARANCES ........................................................................................................18

FIG. 2-2 – LIFTING LUG LOCATIONS ..............................................................................................19

FIG. 2-3 – UNIT RIGGING .................................................................................................................19

FIG. 2-4 – GENERAL ARRANGEMENT DRAWING .........................................................................25

FIG. 2-5 – GENERAL ARRANGEMENT DRAWING ........................................................................28

FIG. 2-6 – DRAIN TRAP SHOWING WATER LOCATION DURING DRAW THROUGH

OPERATION STAGES ......................................................................................................32

FIG. 2-7 – TRAP DETAIL FOR DRAW THROUGH APPLICATION ..................................................32

FIG. 2-8 – FIELD CONTROL WIRING CONNECTIONS ...................................................................36

FIG. 2-9 – SINGLE-POINT POWER SUPPLY WIRING .....................................................................38

FIG. 2-10 – SINGLE-POINT POWER SUPPLY WIRING WITH NON-FUSED DISCONNECT .........39

FIG. 2-11 – DUAL-POINT POWER SUPPLY WIRING ......................................................................40

FIG. 2-12 – ATMOSPHERIC SENSOR PROBE ................................................................................43

FIG. 2-13 – TYPICAL GAS PIPING CONNECTION ..........................................................................45

FIG. 2-14 – COMBUSTION VENT .....................................................................................................46

FIG. 3-1 – FAN HOLD DOWN BRACKETS .......................................................................................48

FIG. 3-2 – MANIFOLD GAS PRESSURE ADJUSTMENT ................................................................54

FIG. 4-1 – SHEAVE ALIGNMENT ......................................................................................................56

FIG. 4-2 – FAN DATA PLATE - BELT TENSION ...............................................................................57

FIG. 4-3 – BELT TENSIONING GAUGE ............................................................................................57

FIG. 4-4 – EXAMPLE OF FC FAN SHAFT/WHEEL MARKING ........................................................58

FIG. 4-5 – BEARING WITH SETSCREW TYPE LOCKING DEVICE ................................................60

FIG. 4-6 – BEARING WITH ECCENTRIC CAM ................................................................................60

FIG. 4-7 – ECCENTRIC CAM LOCKING COLLAR BEARING INSTALLATION ..............................61

FIG. 4-8 – SPLIT BEARING ...............................................................................................................61

FIG. 5-1 – CONDENSER FAN VFD POTENTIOMETER SETTINGS ................................................73

FIG. 6-1 – UNIT CONTROLLER INTERFACE ...................................................................................99

FIG. 8-1 – CONNECTOR LOCATIONS ...........................................................................................157

12

JOHNSON CONTROLS

SECTION 1 – INTRODUCTION

FORM 100.50-NOM6 (1207)

1

FIG. 1-1 – PACKAGED ROOFTOP AIR CON DI TION ING UNIT

ECOLOGICAL AND ECONOMICAL DESIGN

• High Effi ciency eco

2

rooftop units are optimized

Condensing Section

for HFC-410A refrigerant. YORK provides the

FIRST standard product offering that meets the

latest ASHRAE 90.1 energy effi ciency requirements.

• Cooling and Heating – Superior op er at ing per-

for mance provides lower operating costs. Smaller

steps of cool ing capacity pro vide tighter con trol

of build ing environment and oc cu pant comfort

while optimizing energy effi ciency.

• Indoor Air Quality (IAQ) – Outside air econ-

o miz ers pro vide en er gy sav ings in free cooling

mode, and can pro vide a health i er and more

comfortable build ing en vi ron ment by in tro duc ing

fresh outside air into the build ing as needed. Indoor Air Quality (IAQ) re quire ments for building

ventilation and com fort are con trolled through

the microprocessor con trol pan el.

• Premium-Effi ciency Motors – Premium-effi -

ciency motors are available for optimum energy

effi ciency. All mo tors used on the eco2 pack aged

roof top air con di tion er meet U.S. EPACT 1992

min i mum re quire ments.

High-effi ciency motors are standard. Motors are

available in ODP or TEFC construction.

LD13271

• Scroll Compressors – Reliable, efficient,

trouble-free operation is the true measure of a

packaged rooftop’s value. That’s why YORK

2

eco

Packaged Rooftop Air Conditioners use

established scroll-compressor technology to

deliver dependable, eco nom i cal performance

in a wide range of ap pli ca tions. With the eco

Packaged Rooftop, you get the latest generation

of compressor en hance ments added to the scroll’s

inherent strengths. The sim plic i ty of a hermetic

scroll compressor allows the use of fewer moving

parts to minimize breakdown.

• Multiple Compressor Staging – Through the

2

use of the scroll compressor, the eco

ity to stage it’s cooling by enabling and disabling

mul ti ple single stage compressors on multiple

circuits. These compressors are manifolded together in two independent circuits.

• Compressor Circuiting – The eco

so that only 2 scroll compressors are in tandem

within one refrigeration circuit. This means more

reliable com pres sors, and less equipment down

time. With multiple circuits, if a compressor

should ever fail on one circuit, the other circuit/s

will re main op er a tion al to work to maintain occupied loads. The eco2 sys tem has 2 circuits in

the unit.

has the abil-

2

is designed

2

JOHNSON CONTROLS

13

Introduction

FORM 100.50-NOM6 (1207)

Compressor Sound Blankets – Optional factory

•

in stalled sound blankets can be installed to further

reduce com pres sor sound attenuation.

• Replaceable core fi lter driers – The optional

2

re place able core fi lter driers on the eco

provides

a con ve nient means for maintaining and optimizing the units refrigeration system. Eliminating

ad di tion al fi eld pen e tra tions into the refrigerant

circuit, which could lead to potential problems,

reduce the worry of re frig er ant circuit contamination.

• Low Ambient Operation – Head-pressure con-

trol is accomplished via a VFD motor controller

rather than an ineffi cient and noisy condenser fan

damper. By varying the speed of the condenser

fan, better control and quieter operation is obtained during the colder months. Low ambient

controls are available on all systems offering

higher rooftop cooling capacity than competitive

units.

• Condenser Fan Motors – The condenser fan

2

mo tors used on the eco

unit are Totally Enclosed

Air Over (TEAO) to provide maximum durability

through any season.

• Condenser Coils – Are available in various

ma te ri als and coatings to suit almost any type of

ap pli ca tion. Alu mi num or copper fi ns, pre-coat ed

or post-coated fi ns are available. The coating is

applied us ing an epoxy coating on the aluminum

coil. Each coil option is benefi cial when the unit

must operate under ex treme con di tions. The use

of an epoxy coated coil is recommended for units

installed in a corrosive environment.

Heating Section

• Staged gas heat – The eco

2

rooftop gas furnace

is an induced-draft gas furnace designed for

high ef fi cien cy and reliability. The furnace uses

an alu mi nized steel tubular heat exchanger and

op er ates at tem per a tures suffi cient to prevent

acidic ex haust gases from con dens ing in the

heat ex chang er at low fi re rates, unlike drum and

tube style fur nac es that generate condensation

for ma tion. Up to three stages of heat are available.

An optional stainless steel heat exchanger is also

available.

• Electric – The eco

2

is also available with an

elec tri cal heater that can range from 40kW up to

50kW. De pend ing on the size of the heat re quired,

2

the eco

can have 3 steps of control helping to

provide tighter control of the supply and zone

con di tioned air. With the uti li za tion of this multi

step func tion, the eco2 can ef fec tive ly reduce en er gy con sump tion by bring ing on smaller stages

of heat while main tain ing the max i mum level of

com fort.

• Steam and Hot water – This option will be

available in the future.

• Hot Gas By-pass – Is standard on VAV units.

• Condenser Coil Protection – The eco

able with a wire mesh guard for optimum coil

protection.

14

2

is avail-

JOHNSON CONTROLS

AIR MANAGEMENT

FORM 100.50-NOM6 (1207)

1

• DWDI Airfoil fans – High effi ciency fans are

used to im prove ap pli ca tion fl exibility, and address sound and ap pli ca tion con cerns.

• Building pressure control – Ex haust fans and

barometric relief dampers are available to meet

building pressure control requirements. Select

the most appropriate option for a given ap pli ca tion.

• Low sound options – Allow for application of

the eco2 unit in sound-sensitive applications

such as the aters and downtown areas. Contact

JOHNSON CONTROLS for more details on

site-specifi c requirements.

• Variable Frequency Drives – When a VAV unit

is or dered, the eco2 comes standard with vari able

fre quen cy drives (VFD’s). The VFD can optimize

a sys tems performance by modulating the sup ply

fan motor speed to reduce energy con sump tion

by as much as 40% while maximizing oc cu pant

comfort.

• Fan Spring Isolation – Two-inch spring iso la tion

is used to prevent vibration transmission from the

roof top unit’s supply fan to the building.

The control can also be connected to a computer

for greater access to programming and operating

information.

• Communication -The controller is designed

to communicate using Modbus RTU protocol.

Through the addition of a ModLINC translator,

the unit can also communicate using BACnet

MS/TP protocol.

INDOOR AIR QUALITY

• Double Sloped Stainless Steel Drain Pan – The

eco2’s standard Stainless Steel drain pan meets

ASHRAE 62 requirements for condensate drain-

age to improve indoor air quality. Solid wall liners

encase insulation and prevent moisture dam age.

Additional benefi ts include easy cleanability and

isolates insulation from conditioned airstream.

• Double Wall Construction – Is the standard

con struc tion of the eco2 and incorporates powder

coat ed pre-fabricated outer panels and corner post

for max i mum exterior surface protection.

CONTROLS

• Rooftop Controller - The unit is designed to

use the Simplicity Elite control. This control

has been used with the 25 to 40 ton Millennium

product for many years. The control is designed

to operate with conventional room control input.

This allows the same control to be used on installations requiring 25 to 60 tons of cooling.

The board is equipped with four program but-

tons and two character displays for use by the

technician. They allow for access to the most

important board functions, current operating

data, and current alarms as well as the last fi ve

alarms in the history memory buffer. The buttons

and displays are also used to program the control

with the correct confi guration and set points.

JOHNSON CONTROLS

15

Introduction

FORM 100.50-NOM6 (1207)

Factory Shrinkwrap – All eco2 rooftop units

•

can be ordered from the factory with an optional

factory-fresh shrinkwrap pack ag ing. This eliminates the contractors worries about dirt and debris

clogging up condenser coils or moisture leaking

into the air han dler on the units way to the job

site or rigging yard.

• Demand Ventilation Option – Can be incorpo-

rated into the unit to improve indoor air quality

and help manage indoor pollutants such as CO

or other harmful air borne con tam i nates out of

the occupied spaces for maximum comfort and

safety. Activation of this se quence can easily be

ac com plished using a CO2 sensor installed in the

conditioned space. CO2 sensors are typically

used with de mand ventilation; however other

sensors may be applied to control indoor con tam i nants such as volatile or gan ic com pounds

(VOCs).

• Smoke Purge – Is also available to evacuate

smoke due to fi re from a room or zone.

• Filtration – The eco

types of fi ltration to meet the different needs and

re quire ments of today's rooftop applications,

including 2-inch throwaway, pleated, carbon,

and cleanable fi l ters and 12-inch high effi ciency

rigid fi lters.

ELECTRICAL

• Single Point Power – The eco

dard with single point power connections to make

in stal la tion quick and easy.

2

is confi gured for various

2

unit comes stan-

SERVICE AND INSTALLATION

• Access Doors – Full-sized access doors provide

easy access into the unit for routine maintenance

and inspection.

The unit can be purchased with a “Both Side

Access” option for additional accessibility.

• Service Valves – Oversized ser vice valves to

pro vide iso la tion and quick rec la ma tion and

2

charg ing of sys tem re frig er ant are avail able as

an option to min i mize down time and sim pli fy

the service and repair task.

• Convenience Outlet – For maintenance tasks

re quir ing power tools, an optional 110V GFCI

pow er supply can power lights, drills or any other

power hand tool needed.

• Factory Run-Tested – Each unit is subjected

to a series of quality assurance checks as well

as an au to mat ed quality control process before

being run-tested. Fans and drives are balanced

at the fac to ry during testing. The factory run-test

ensures safe proper operation when the unit is

installed, and reduces installation and commissioning time.

• Gas Heat Sections – Are factory and leaked

checked.

• Replaceable Core Filter Drier Option – Pro-

vides a means to remove moisture, dirt and debris

from the re frig er a tion circuit in the event it is

opened.

• Dual Point Power – Can be factory installed for

ap pli ca tions that require the mechanical heating

and cooling functions to be separated from the

air han dling functions. This enables the unit to

be op er at ed in an emergency condition while

minimizing power consumption.

• Unit-Mounted Disconnect – Is available as an

op tion to minimize time at installation of equipment and to reduce necessary field installed

items.

16

JOHNSON CONTROLS

SECTION 2 – INSTALLATION

FORM 100.50-NOM6 (1207)

APPROVALS

Designed certifi ed by CSA, ETL, CETL as follows:

1. For use as a forced air furnace with cooling unit

(gas heat models).

2. For outdoor installation only.

3. For installation on combustible ma te ri al and may

be installed directly on combustible fl oor ing or

Class A, Class B or Class C roof covering ma te ri als.

4. For use with natural gas or LP.

5. When used with LP propane gas one of the following conversion kits must be installed before the gas

heat section is fi red:

375,000 BTU Input - 385-01866-001

750,000 BTU Input - 385-01866-002

1,125,000 BTU Input - 385-01866-003

Not suitable for use with conventional venting

systems.

LIMITATIONS

The installation of this unit must conform to local

build ing codes, or in the absence of local codes, with

ANSI 223.1 Natural Fuel Gas Code and /or CAN/CGA

B149 in stal la tion codes.

In U.S.A.:

1. National Electrical Code ANSI/NFPA No. 70 - Latest Edition.

2. National Fuel Gas Code Z223.1 - Latest Edition.

3. Gas-Fired Central Furnace Standard ANSI Z21.47

- Latest Edition.

4. Local gas utility requirements.

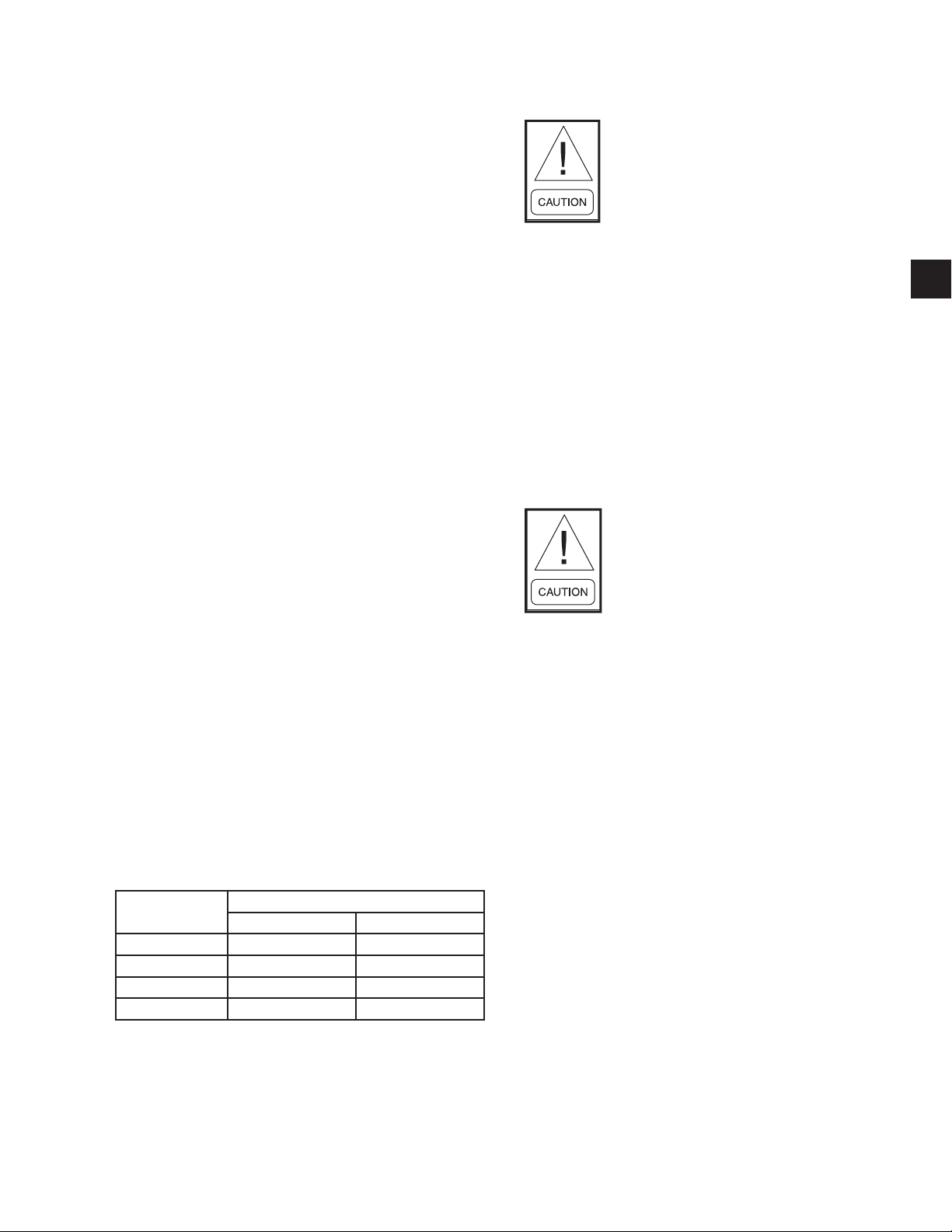

TABLE 2-1 – VOLTAGE LIMITATIONS

UNIT POWER

SUPPLY

575-3-60 518 632

480-3-60 415 506

230-3-60 207 253

200-3-60 187 228

VOLTAGE VARIATIONS

MIN. VOLTS MAX. VOLTS

Refer to Table 2-15 for airfl ow and entering air/ambient

conditions limitations, and Table 2-1 for voltage

limitations.

If the VAV boxes in the conditioned

space have hydronic heating coils

installed, it is the responsibility of the

installing contractor to take appropriate measures to protect the hydronic

coils against low unit supply air temperatures that could result in the freeze

up and rupture of the coils.

UNIT INSPECTION

Immediately upon receiving the unit, it should be

in spect ed for possible damage, which may have

oc curred during transit. If damage is evident, it should

be noted in the car ri er’s freight bill. A writ ten re quest

for in spec tion by the carrier’s agent should be made at

once. See “In struc tion” man u al, Form 50.15-NM for

more in for ma tion and de tails.

To ensure warranty cov er age, this

equip ment must be commissioned and

serviced by an authorized JOHNSON

CONTROLS ser vice mechanic or a

qual i fi ed service person ex pe ri enced

in pack aged roof top in stal la tion.

In stal la tion must comply with all ap pli ca ble codes, par tic u lar ly in regard

to elec tri cal wir ing and other safety

el e ments such as relief valves, HP

cut-out settings, de sign work ing pres sures, and ven ti la tion re quire ments

con sis tent with the amount and type

of re frig er ant charge.

Lethal voltages exist within the con trol

panels. Before servicing, open and tag

all dis con nect switches.

LOCATIONS AND CLEARANCES

GENERAL

The eco2 air conditioning units are designed for outdoor

installation. When selecting a site for installation, be

guided by the following conditions:

• Unit must be installed on a level surface.

• For the outdoor location of the unit, select a place

having a minimum sun exposure and an adequate

supply of fresh air for the condenser.

2

JOHNSON CONTROLS

17

Installation

FORM 100.50-NOM6 (1207)

• Also avoid locations beneath windows or between structures.

• Optional condenser coil protection should be used

for seashore locations or other harsh environments.

• The unit should be installed on a roof that is structurally strong enough to support the weight of the unit

with a minimum of defl ection. It is recommended

that the unit(s) be installed not more than 15 feet

from a main support beam to provide proper

structural support and to minimize the transmission of sound and vibration. Ideally, the center of

gravity should be located over a structural support

or building column.

• Location of unit(s) should also be away from

building fl ue stacks or exhaust ventilators to

prevent possible reintroduction of contaminated

air through the outside air intakes.

• Be sure the supporting structures will not obstruct

the duct, gas or wiring connections.

away from sound sensitive areas such as conference

rooms, auditoriums and executive offi ces and any other

room that may have potential for tenant occupancy.

Possible locations could be above hallways, mechanical

or utility rooms.

Finally, service clearances should be maintained in

rooftop design to insure safe access to the unit. Unit

clearances are designed so that technicians have enough

space between units, building walls, and edges of

building to gain access safely. In cases where space is

limited, please call your local York representative for

additional information.

The clearances shown are to provide

adequate condenser airfl ow and service access to inside the unit. Additional clearance should be considered

for component replacement such as

compressors, evaporator coils, and

supply or exhaust fans.

LOCATION

Of the many factors that can effect the location of

equipment, some of the most important to consider are

Structural, Acoustical and Service clearances. Proper

attention should be made at the design stage to ensure

proper structural support. In cases where equipment is

being replaced, be aware of building design to insure

support is adequate for the application.

The next most important consideration in applying roof

top equipment is that of sound from the equipment.

Special care should be made to keep the roof top unit

While it is a common practice to operate the fan as soon as possible (air

movement during construction) on the

job site, the incomplete ductwork and

missing diffuser grilles will greatly

reduce air resistance and will allow

the fan to operate beyond design parameters. This practice may result in

water carry over and fl ooding of the

unit. Also, the supply fan motor may

overamp and become damaged.

96"

NOTES:

1. 10' clearance minimal over the top of the condensing unit.

2. Only one adjacent wall can exceed unit height.

3. 12' clearance required to adjacent units.

FIG. 2-1 – UNIT CLEARANCES

18

LD13267

4. 8' service access recommended on one side.

5. Economizer and exhaust hoods, where applicable, are folded

inside unit for shipment.

6. Dim. is to outside of lifting lugs.

JOHNSON CONTROLS

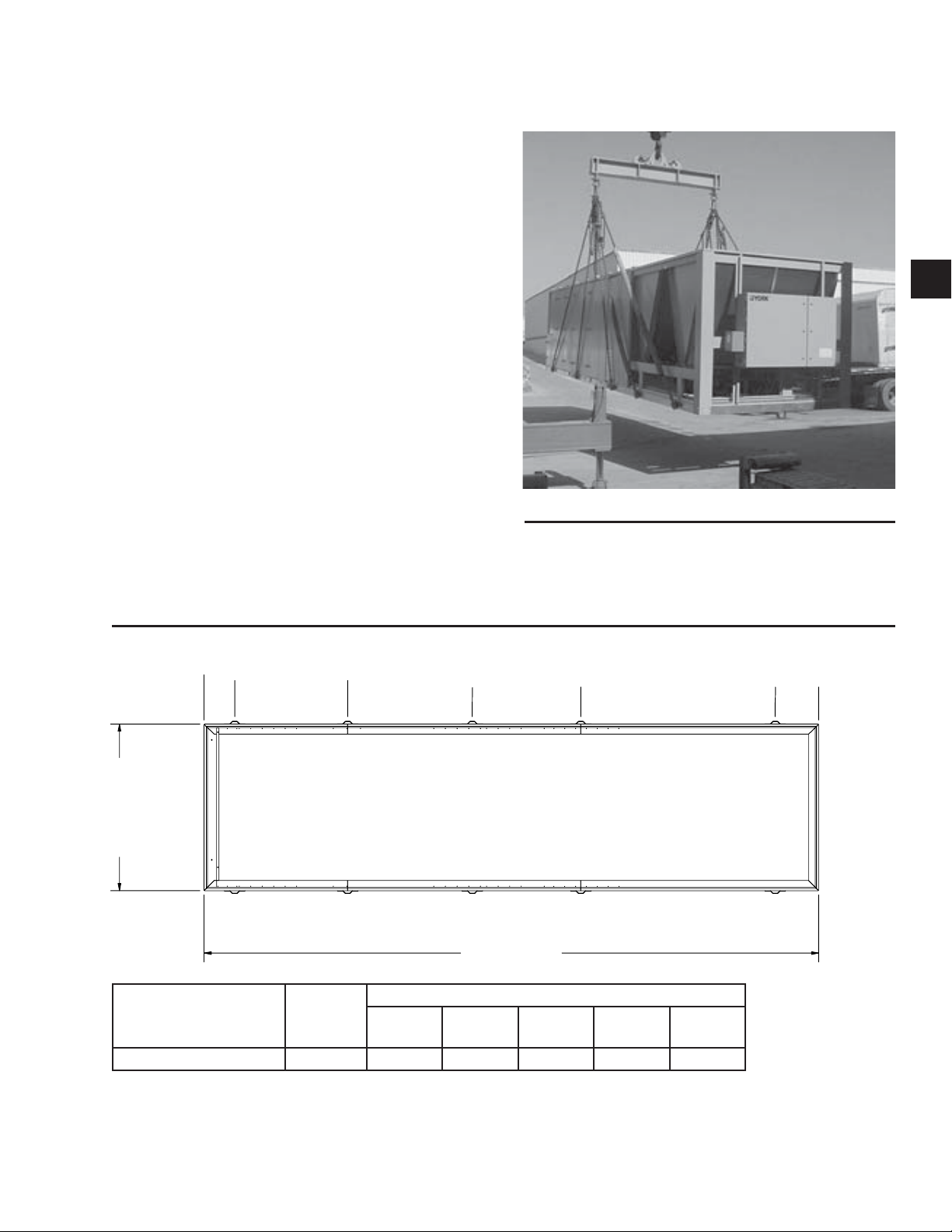

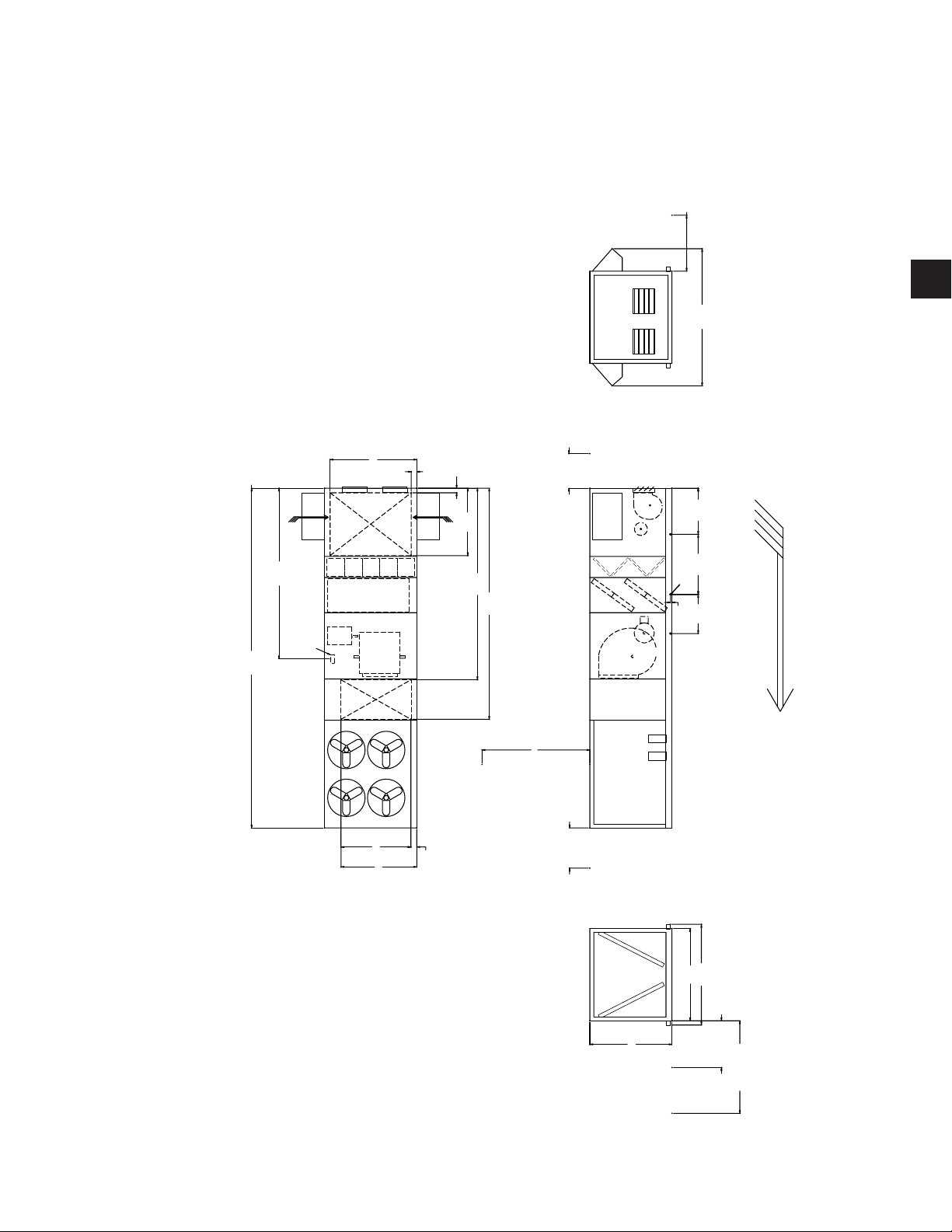

RIGGING AND HANDLING

Proper rig ging and handling of the equip ment is

man da to ry during un load ing and setting it into position

to re tain warranty status. All lifting lugs must be used

to pre vent twisting and damage to the unit.

Care must be taken to keep the unit in the upright

po si tion during rigging and to prevent damage to the

water-tight seams in the unit casing. Avoid unnecessary

jar ring or rough handling.

Typical rigging using proper spreader bars and cables

is shown in Figure 2-3. See Figure 2-2 for number

and location of the lifting lugs by unit size. It is also

mandatory that an ex pe ri enced and reliable rigger be

selected to han dle un load ing and fi nal place ment of

the equipment. The rig ger must be advised that the unit

contains internal com po nents and that it be han dled in

an upright po si tion. Care must be exercised to avoid

twisting the equip ment struc ture.

Unit weights are listed under Table 2-2 in this manual.

These weights must be re ferred to when selecting a crane

for rig ging and fi guring roof weight loads. Con tact your

FORM 100.50-NOM6 (1207)

2

00543vip

FIG. 2-3 – UNIT RIGGING

JOHNSON CONTROLS Sales Offi ce if you have any

ques tions re gard ing unit weights.

%

+

7

'

,

:

(

'

,

6

7

8

2

$

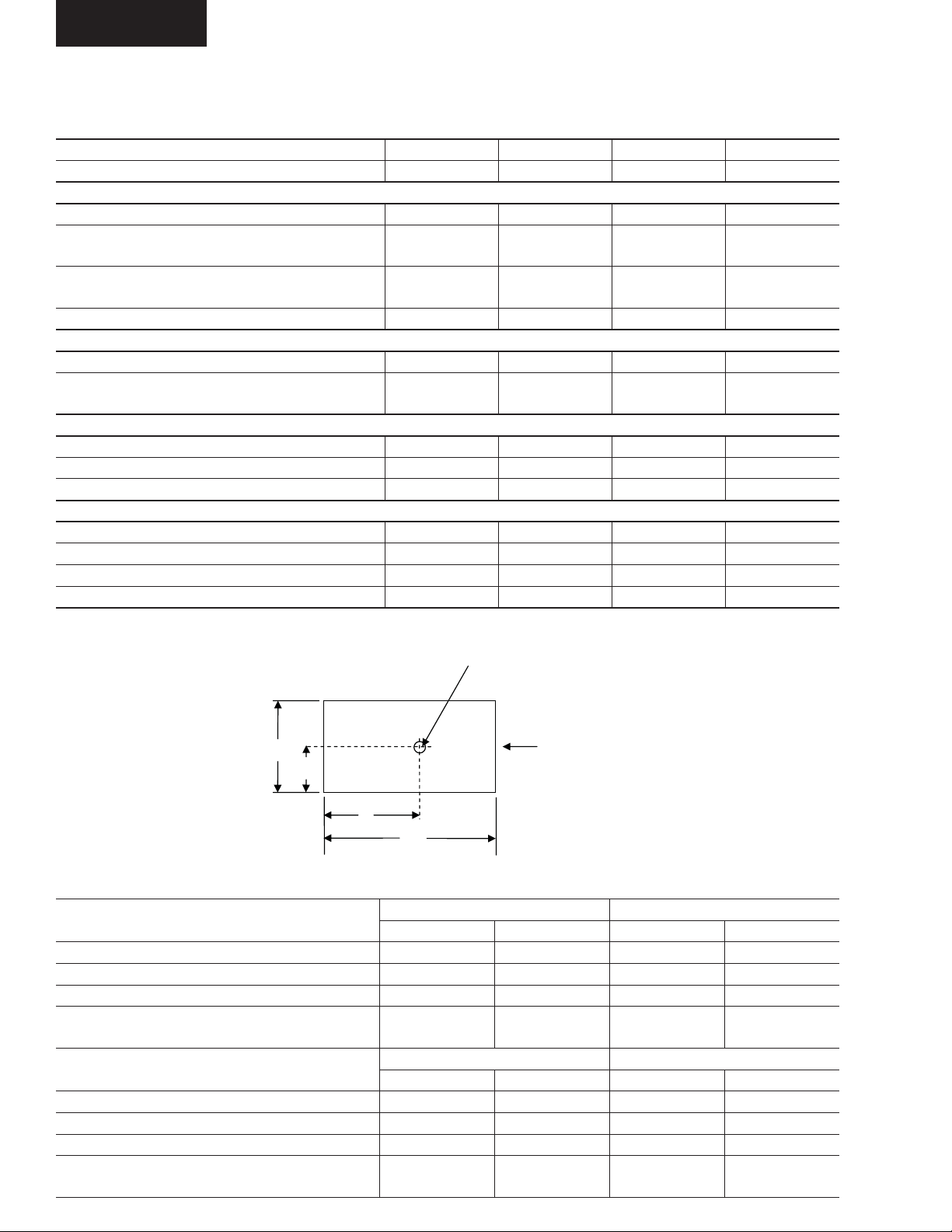

UNIT SIZE TONS

LENGTH

INCHES

UNIT

2876,'(/(1*7+

DIMENSION

1-2 3-4 5-6 7-8 9-10

50 - 61 STD CABINET 339 16.91 79.21 147.93 207.81 315.04

FIG. 2-2 – LIFTING LUG LOCATIONS

LD13272

&

&21'(16(5(1'

'

JOHNSON CONTROLS

19

Installation

FORM 100.50-NOM6 (1207)

UNIT WEIGHTS

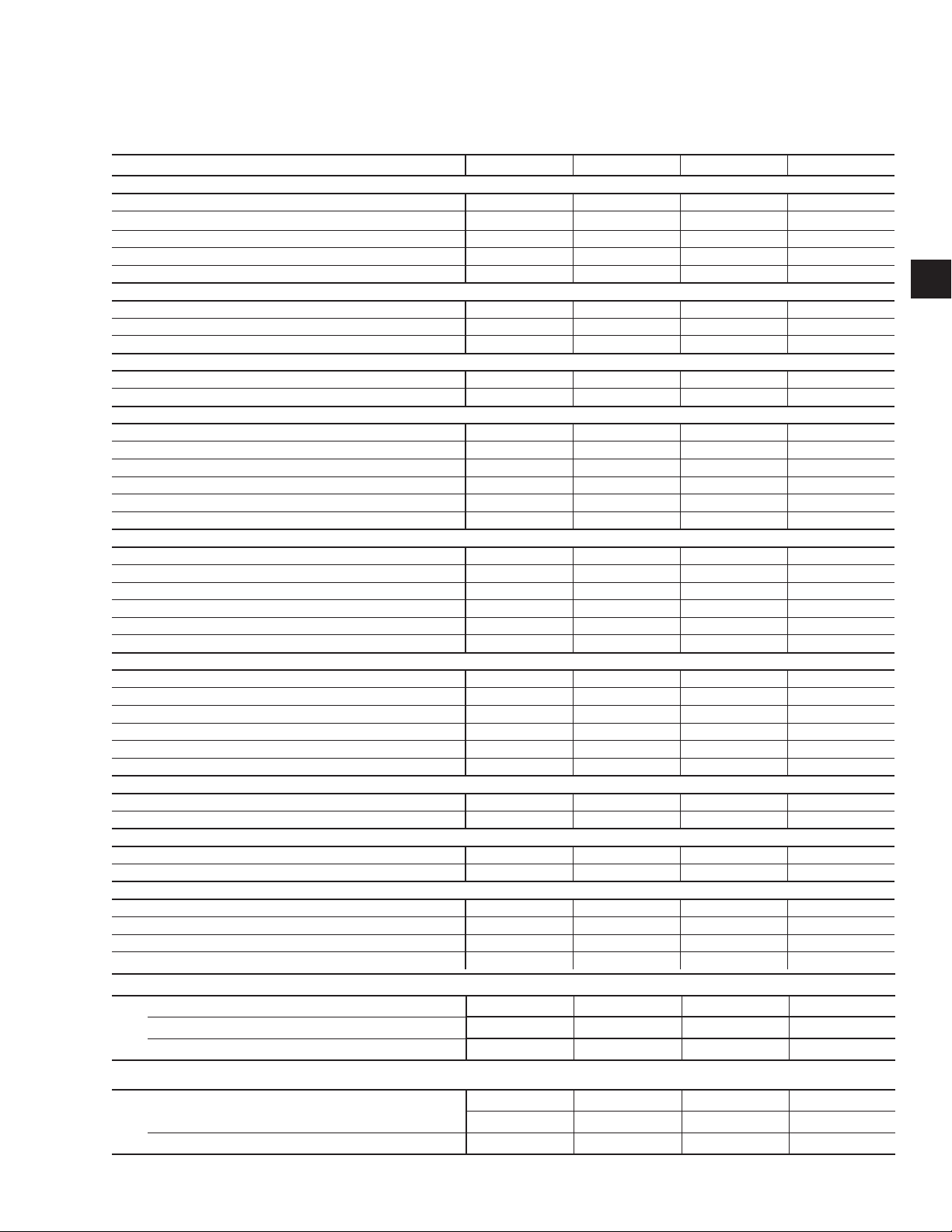

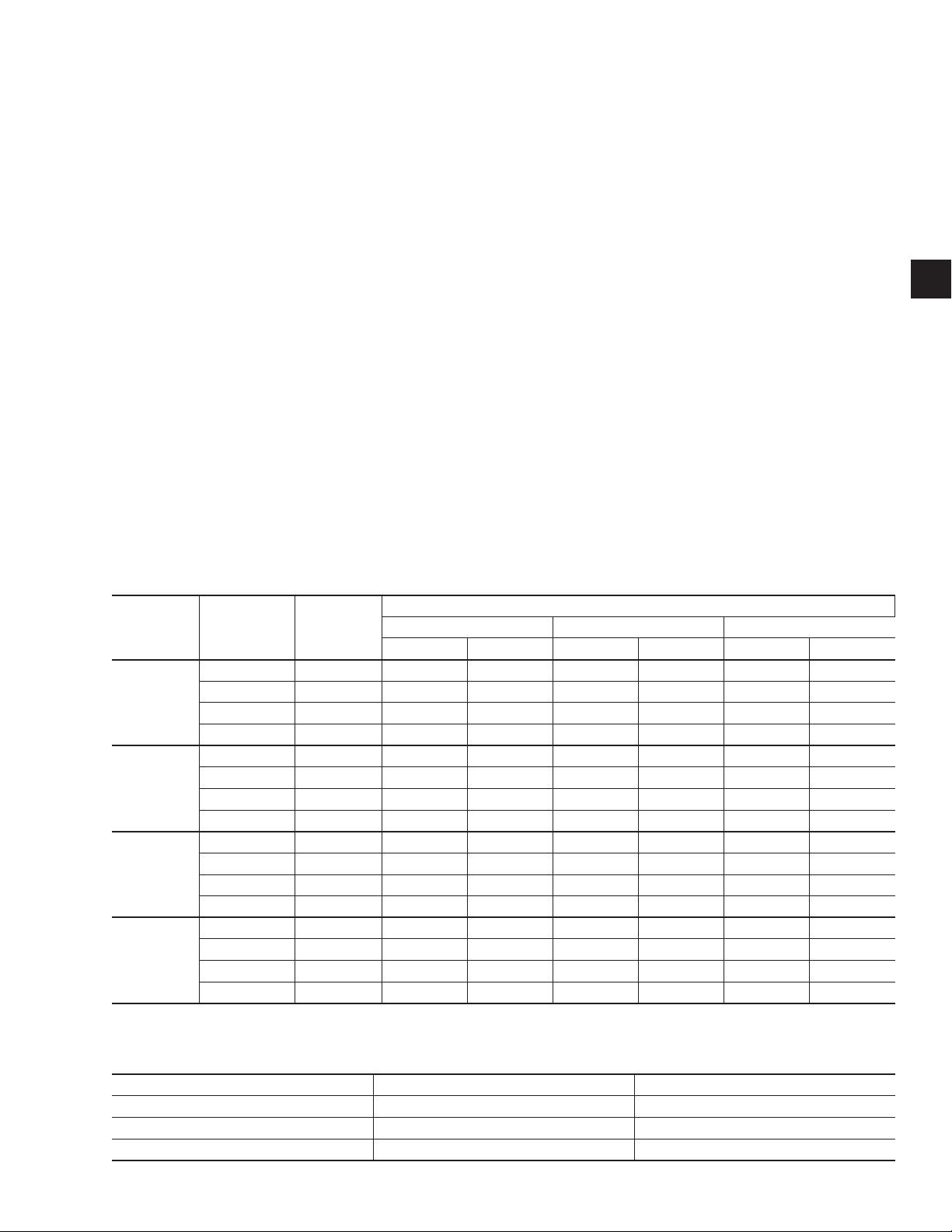

TABLE 2-2 – UNIT WEIGHTS - 050-061 MODELS

MODEL SIZE 050 051 060 061

BASIC UNIT* 7433 7433 7800 7819

ECONOMIZERS

NO OUTSIDE AIR 240 240 240 240

25% OUTSIDE AIR FIXED POSITION MAUAL

DAMPER

25% OUTSIDE AIR 2 POSITION ACTUATED

DAMPER

FULL MODULATION WITH MINIMUM POSITION 476 476 476 476

POWER EXHAUSTS

FAN, MOTOR, MODULATING DAMPER AND HOOD 501 501 501 501

FAN, MOTOR, VFD, BAROMETRIC DAMPER AND

HOOD

GAS HEAT

375 MBH 162 162 162 162

750 MBH 324 324 324 324

1125 MBH 486 486 486 486

OPTIONS

OPEN PERIMETER CURB 544 544 544 544

CONDENSER COIL WIRE GUARD 64 64 64 64

COPPER CONDENSER COILS (ADDITIONAL) 516 516 773 773

12” RIGID FILTERS (ADDITIONAL) 319 319 319 319

*UNIT INCLUDES FC FAN W/ 20 HP MOTOR, VFD AND 2” THROWAWAY FILTERS

446 446 446 446

476 476 476 476

506 506 506 506

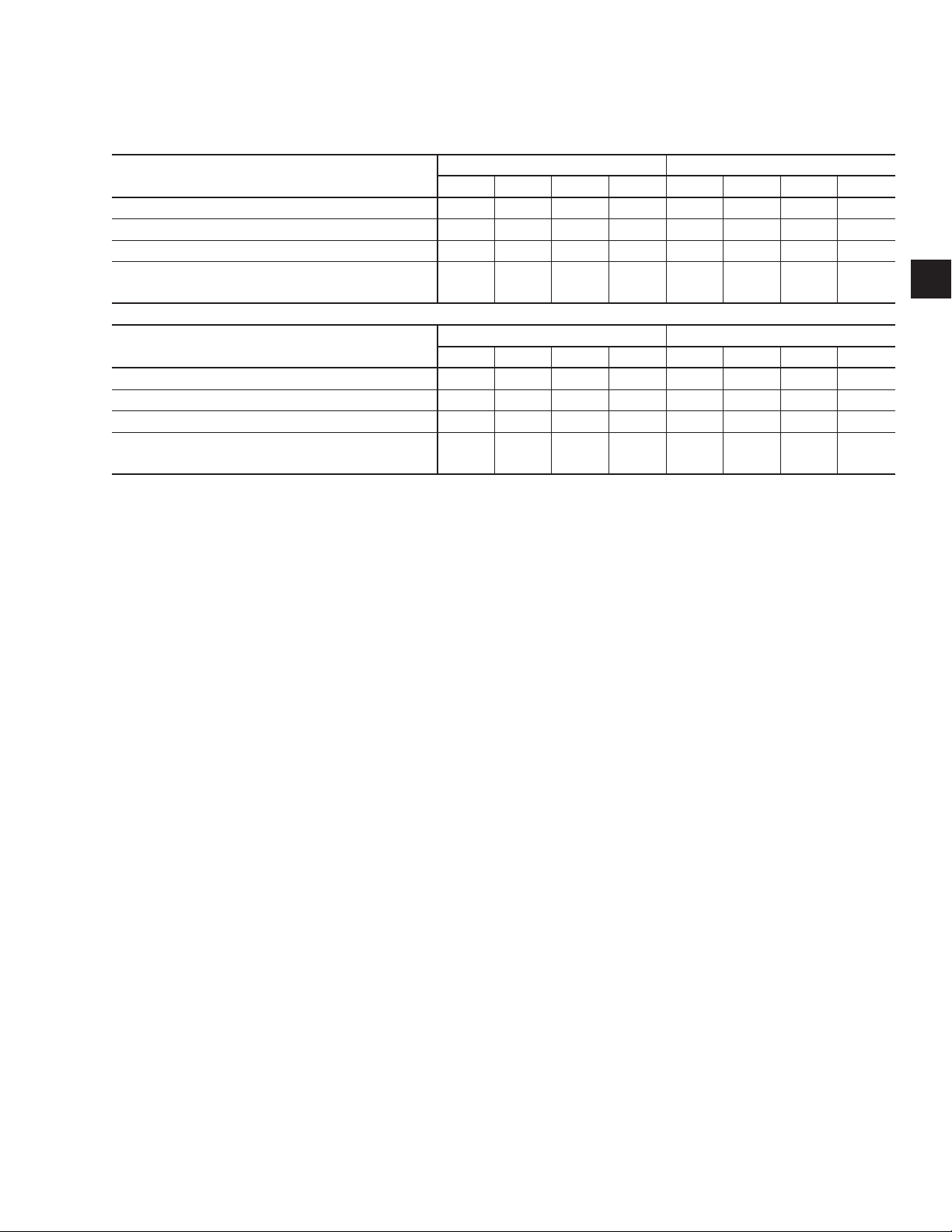

Center of Gravity

B C

Condenser

92

Y

A

D

Coil End

339

LD08298

TABLE 2-3 – UNIT CENTER OF GRAVITY

MODEL

BASIC UNIT 184.1 50.2 184.1 50.2

BASIC UNIT W/ ECON. 191.0 49.9 191.0 49.9

BASIC UNIT W/ ECON. & HEATING 187.4 50.0 187.4 50.0

BASIC UNIT W/ ECON. & HEATING & POWER

EXHAUST

MODEL

BASIC UNIT 179.8 49.9 179.6 50.0

BASIC UNIT W/ ECON. 186.7 49.7 186.5 49.7

BASIC UNIT W/ ECON. & HEATING 183.5 49.8 183.2 49.8

BASIC UNIT W/ ECON. & HEATING & POWER

EXHAUST

XYXY

194.9 49.5 194.9 49.5

XYXY

190.9 49.3 190.7 49.3

20

050 051

060 061

JOHNSON CONTROLS

FORM 100.50-NOM6 (1207)

UNIT WEIGHTS (CONTINUED)

TABLE 2-4 – UNIT CORNER WEIGHTS - 050-061 MODELS

MODEL

BASIC UNIT 1835 2201 1852 1545 1835 2201 1852 1545

BASIC UNIT W/ ECON. 2039 2417 1873 1580 2039 2417 1873 1580

BASIC UNIT W/ ECON. & HEATING 2118 2521 2041 1715 2118 2521 2041 1715

BASIC UNIT W/ ECON. & HEATING & POWER

EXHAUST

ABCDABCD

2366 2751 2034 1750 2366 2751 2034 1750

050 051

2

MODEL

BASIC UNIT 1894 2244 1986 1676 1893 2250 1997 1680

BASIC UNIT W/ ECON. 2097 2461 2008 1711 2096 2466 2018 1715

BASIC UNIT W/ ECON. & HEATING 2177 2565 2175 1846 2176 2570 2185 1850

BASIC UNIT W/ ECON. & HEATING & POWER

EXHAUST

ABCDABCD

2424 2795 2168 1881 2423 2801 2178 1885

060 061

Unit Placement

• Elevated – Elevated roof curbs or dunnage steel

can be used to support the unit in order to raise it

to specifi c heights. When this type of placement

is required, be sure to keep unit access in mind.

Cat walks or other forms of unit access may be

required to one or both sides of the unit, depending on your area of the country and the local codes

that are enforced. Please check with local offi cials

to ensure the application conforms to local codes

and regulations.

• Ground Level Locations – It is important that

the units be installed on a substantial base that

will not settle, causing strain on the refrigerant

lines and sheet metal and resulting in possible

leaks. A one piece concrete slab with footers

extended below the frost line is highly recommended. Additionally, the slab should be isolated

from the main building foundation to prevent

noise and vibration transmission to the building

structure.

For ground level installations, precautions should

be taken to protect the unit from tampering by, or

injury to, unauthorized persons. Erecting a fence

around the unit is common practice.

JOHNSON CONTROLS

21

Installation

ROOF CURB INSTALLATION

YORK offers an optional roof curb designed specifi cally