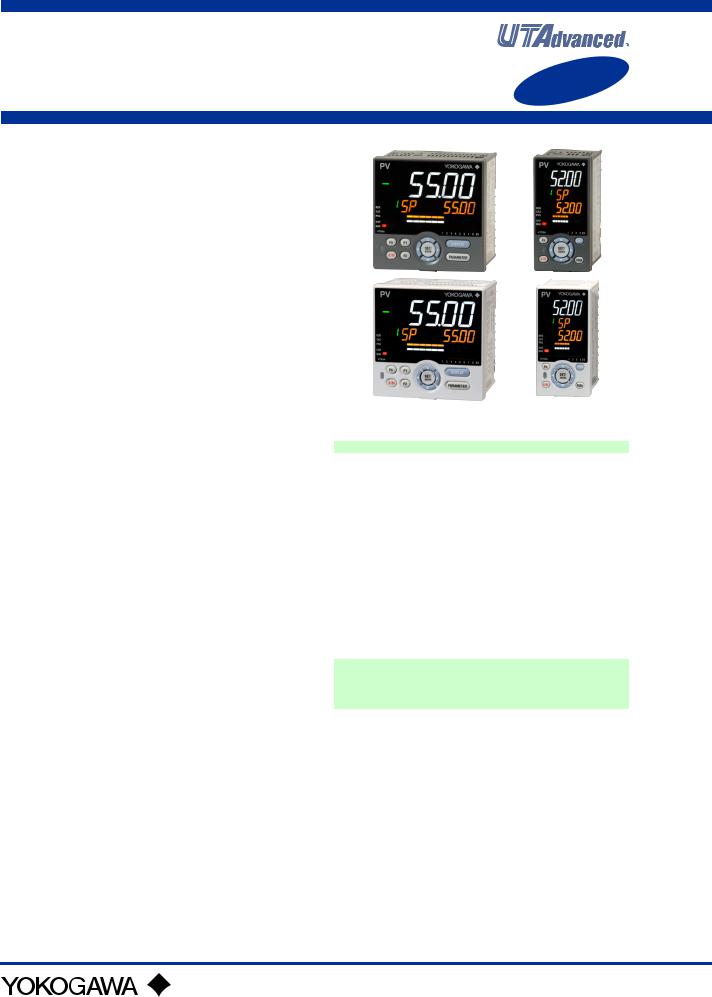

Yokogawa UT55A, UT52A Specifications

General |

UT55A, UT52A |

Specifications |

Digital Indicating Controller |

|

(Panel Mounting Type) |

GS 05P01C31-01EN |

|

Functional

Enhancement

nOverview

The UT55A and UT52A digital indicating controllers employ an easy-to-read, 14-segment large color LCD display, along with navigation keys, thus greatly increasing the monitoring and operating capabilities. A ladder sequence function is included as standard.

The short depth of the controller helps save instrument panel space. The UT55A and UT52A also support open networks such as Ethernet communication.

The UT55A and UT52A have a DIN rail mounting type (with option code /MDL). For more details, please see

General Specification GS 05P01C81-01EN.

nFeatures

•A 14-segment, active (PV display color changing function) color LCD display is employed.

Two five-digit, high-resolution displays are possible. Alphabet letters can be displayed in an easy-to-read manner. The guide display shows parameter names.

•Easy to operate

Navigation keys (SET/ENTER and Up/Down/Left/ Right arrow keys) are employed to facilitate making settings.

•65 mm depth

The small depth enables the mounting in a thin and small instrumented panel.

•Ladder sequence function is included as standard. This function allows for creating a simple sequence control. Dedicated LL50A Parameter Setting Software (sold separatly) allows for performing programming using a ladder language.

•Various built-in open network functions such as Ethernet are available.

Easy connection with various vendors’ PLCs is possible.

(UT52A support CC-Link and RS485 communication only.)

•Quick setting function

Setting only the minimum necessary parameters for operation is possible. (For single-loop control only)

•Equipped with a multitude of functions

Universal I/O, eight control modes (cascade control, etc), and retransmission output are included as standard. PID control, heating/cooling control, feed forward control, etc. are available.

•LL50A Parameter Setting Software (sold separately) The parameters and ladder programs of UTAdvanced digital indicating controller can be built from a PC using this software. It makes data management even easier.

•Dust-proof and drip-proof

IP66 (for front panel) (Not applicable to side-by-side close mounting.)

NEMA4 (Hose-down test only)

nFunctional Specifications

Control Specifications

(1) Control Mode

Control functions of the controller can be set as control modes.

UT55A |

UT52A |

|

|

|

|

Control mode |

Function |

|

SGL (1) |

Single-loop control |

|

CAS1 (2) |

Cascade primary-loop control (*1) |

|

CAS2 (3) |

Cascade secondary-loop control (*1) |

|

CAS (4) |

Cascade control (*1) |

|

BUM (5) |

Loop control for backup(*1) |

|

PVSW (6) |

Loop control with PV switching (*1) |

|

PVSEL (7) |

Loop control with PV auto-selector (Max./Min./Ave./Diff.) (*1) |

|

PVHD (8) |

Control with PV-hold function |

|

*1: Remote auxiliary analog input is required.

2) Control period

Selectable from 50 ms (*2), 100 ms, and 200 ms

*2: |

Cascade control (Control mode 4) cannot be used. |

|||||

|

“Super” function or “Super 2” function cannot be used. |

|||||

|

Table of Number of Inputs and Outputs |

|||||

|

|

|

|

|

|

|

Model and |

Number |

Number |

Number |

Number of |

||

suffix code |

of analog |

of analog |

of contact |

contact |

|

|

(See the |

input |

output |

input |

output |

|

|

model code) |

points |

points (*3) |

points (*4) |

points (*5) |

|

|

UT55A |

|

|

|

|

|

|

|

-×0× |

1 |

1 |

3 |

3 |

|

|

-×1× |

2 |

1 |

9 (8) |

8 |

|

|

-×2× |

2 |

1 |

4 (3) |

3 |

|

|

-×3× |

1 |

1 |

8 |

8 |

|

|

-×4× |

2 |

1 |

4 (3) |

3 |

|

|

-×5× |

2 |

1 |

9 (8) |

8 |

|

|

-×6× |

1 |

1 |

8 |

18 |

|

|

-×7× |

4 |

1 |

6 (5) |

3 |

|

UT52A |

|

|

|

|

|

|

|

-×0× |

1 |

1 |

3 |

3 |

|

|

-×1× |

2 |

1 |

3 |

3 |

|

|

-×2× |

2 |

1 |

4 (3) |

3 |

|

|

-×3× |

1 |

1 |

5 |

5 |

|

*3: |

Excluding control output |

|

|

|

||

*4: |

The numbers in parentheses show the numbers |

|||||

|

of points in each model with RSP direct input.(/DR |

|||||

|

option. |

|

|

|

|

|

*5: |

Excluding control output relays |

|

|

|||

Yokogawa Electric Corporation |

GS 05P01C31-01EN |

||

2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 Japan |

1st Edition Jan. 16, |

2009 |

(KP) |

Tel.: 81-422-52-7179 Fax.: 81-422-52-6619 |

9th Edition Mar.14, |

2016 |

(YK) |

2

Control Computation Specifications

(1) Combination of types of control and control modes

Types of control |

|

|

Control mode |

|

|

|||||

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|||

|

|

|||||||||

|

PID control |

√ |

√ (*6) |

√ |

√ |

√ |

√ |

√ |

√ |

|

ON/OFF control (*6) |

√ |

N/A |

N/A |

N/A |

N/A |

√ |

√ |

N/A |

||

Two-position, two- |

√ |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

||

level control (*7) |

|

|

|

|

|

|

|

|

||

Heating and cooling |

√ |

N/A |

√ |

√ |

√ |

√ |

√ |

√ |

||

|

control (*7) |

|||||||||

|

|

|||||||||

Sample PI control |

√ |

N/A |

N/A |

N/A |

N/A |

√ |

√ |

√ |

||

Batch PID control |

√ |

N/A |

N/A |

N/A |

N/A |

√ |

√ |

√ |

||

Feedforward control |

√ |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

√ |

||

√: |

Available |

|

N/A: |

|

NotAvailable |

|

|

|||

*6: |

Not selectable for Position proportional type |

|

|

|||||||

*7: |

Selectable for heating and cooling control |

|

|

|||||||

(2)Control Computation Function

(a)Target setting point and the number of PID parameter groups

Respectively, eight sets of target setpoints, alarm setpoints, and PID parameters can be set. For cascade control, respectively, eight sets can be set for main

(primary side) and slave (secondary side).

(b)Selecting the PID parameter group

The following PID parameter groups can be selected.

•Target setpoint number (SPNO) (The PID number can be set arbitrarily.)

•Measured input zone PID

•Target setpoint zone PID

•Reached target setpoint zone PID

(c) Auto-tuning

•Tuning results can be selected from two options, Normal or Stable.

•Tuning output limit can be set. (It cannot be used in

heating/cooling control.)

(d)“Super” function: Overshoot-suppressing function

(e)“Super 2” function: Hunting-suppressing function

(f)STOP preset output function

(g)Input ERROR preset output function

(h)MANUAL preset output function

(3) Operation Mode Switching

Operation mode |

AUTO/MANUAL and RUN/STOP switching |

|

CASCADE/AUTO/MANUAL switching |

||

switching |

||

REMOTE/LOCAL switching |

||

|

||

(4) Control Parameter Setting Range |

||

Proportional band |

0.1 to 999.9% |

|

Integral time |

1 to 6000 sec. or OFF (using manual reset) |

|

Derivative time |

1 to 6000 sec. or OFF |

|

ON/OFF control |

|

|

hysteresis (one or two |

0.0 to 100.0% of measured input range width |

|

hysteresis points) |

|

|

Preset output |

-5.0 to 105.0% (however, 0 mA or less cannot |

|

value |

be output) |

|

High/low output |

-5.0 to 105.0% |

|

limiter |

Low limit setpoint < high limit setpoint |

|

Tight shut |

When manual control is carried out with 4 to |

|

20 mAoutput, control output can be reduced to |

||

function |

||

about 0 mA. |

||

|

||

Rate-of-change |

0.1 to 100.0%/sec., OFF |

|

limiter of output |

||

|

||

Output |

For heating and cooling control: -100.0 to 50.0% |

|

deadband |

For position proportional control: 1.0 to 10.0% |

|

|

|

(5) Ladder computation period

Ladder computation period is the same as control period.

Alarm Functions

• Types of Alarm

|

PV (measured value) high/low limit alarm |

|

Measured value |

Deviation high/low limit alarm |

|

Deviation high and low limits alarm |

||

alarm |

Deviation within high and low limits alarm |

|

Deviation alarm |

Analog input PV high/low limit alarm |

|

Rate-of-change |

Analog input RSP (ROMOTE) SP high/low limit alarm |

|

alarm |

Auxiliary analog input high/low limit alarm |

|

|

Feedback input high/low limit alarm |

|

|

PV rate-of-change alarm |

|

|

SP (setpoint) high/low limit alarm |

|

Setpoint alarm |

Target SP high/low limit alarm |

|

Target SP deviation high/low limit alarm |

||

|

Target SP deviation high and low limits alarm |

|

|

Target SP deviation within high and low limits alarm |

|

Output alarm |

Control output high/low limit alarm |

|

Cooling control output high/low limit alarm |

||

|

||

Other alarms |

Heater disconnection alarm (for /HA option) |

|

Self-diagnosis alarm |

||

|

FAIL |

• Alarm Functions

Alarm output |

Alarm stand-by action |

|

Alarm latch (forced reset) function |

||

action |

Alarm hysteresis |

|

|

Alarm ON/OFF delay timer |

|

Number of alarm |

8 (per loop) |

|

settings |

||

|

||

Number of alarm |

Up to 18 (differs by model code) |

|

output points |

|

Contact I/O Function

This function allows for allocating the input error condition, operation condition, alarm condition or other conditions to the contact input and contact output.

AUTO/MANUAL switching

REMOTE/LOCAL switching

STOP/START switching

Switching to CASCADE

Switching to AUTO

Switching to MANUAL

Switching to REMOTE

Switching to LOCAL

Contact input AUTO-TUNING START/STOP switching OUTPUT TRACKING switching

Two-input switching

PV Hold

LCD backlight ON/OFF switching

Message interrupt displays 1 through 4

SP number specification

PID number specification

Manual preset output number specification

Loop 1 alarms 1 through 8

Contact output Loop 2 alarms 1 through 8 (for cascade control) Status output

Ladder Sequence Function

(1) Number of I/O Points

|

UT55A |

UT52A |

Number of digital input points |

Up to 9 |

Up to 5 |

Number of digital output points |

Up to 18 |

Up to 5 |

This is limited by the number of contact I/O signal points. (See the model code.)

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation |

GS 05P01C31-01EN |

Mar.14, 2016-00 |

3

(2) Types of Command

|

Number of |

Remark |

|

|

commands |

||

|

|

||

Number of basic |

13 |

Load, AND, OR, Timer, |

|

command types |

Counter, etc. |

||

|

|||

Number of applica- |

|

Comparison, reverse, addition/ |

|

73 |

subtraction/multiplication/ |

||

tion command types |

division, logic operation, high/ |

||

|

|||

|

|

low limiter, etc. |

(3) Sequence Device

|

Types of device |

Number of points |

|

Digital I/O |

Input relay |

9 (max) |

|

Output relay |

18 (max) |

||

|

|||

|

M relay (bit data) |

256 |

|

Internal device |

DAT register (data) |

28 |

|

P register (parameter) |

10 |

||

|

|||

|

K register (constant) |

30 |

|

Special device |

Special relay (bit data) |

12 |

*Process data and process relay can be used besides the above-mentioned.

(4) Program capacity

Max. Program capacity: 500 steps *

*: |

Available number of steps differs according to the |

|

parameters, using command and control period. |

(5) Ladder computation period

Ladder computation period is the same as control period.

Communication Function

|

|

Function |

Method |

Interface |

Targets |

|

Max connection |

Communication |

|

|

|

|

|

|

|

|

Data |

|

|

|

Server |

Ethernet |

PLC and others |

2 connections |

|

|

Modbus/TCP |

A standard industry protocol |

Gateway |

Ethernet |

RS-485: UT75A, UT55A, |

|

|

||

UT52A, UT35A, UT32A, |

31 units |

|

||||||

|

|

allowing communications |

+RS-485 |

|

||||

|

|

|

UP55A,UP35A,UM33A (*1) |

|

|

|||

|

|

between the controller and |

|

|

|

|

|

|

|

|

|

|

PLC and others, |

|

|

||

Modbus |

|

devices such as PCs, PLCs, |

|

|

|

|

||

|

|

|

UT75A, UT55A, UT52A, |

|

|

|||

|

and DCSs. |

Slave |

RS-485 |

31 units |

|

|||

(RTU/ASCII) |

UT35A, UT32A, UP55A, |

|

||||||

|

|

|

|

|

||||

|

|

|

|

|

UP35A, UP32A, UM33A(*2) |

|

|

|

|

|

|

Slave |

RS-485 |

PLC and others |

Number of nodes: |

|

|

PROFIBUS- |

|

126 |

|

|||||

|

|

|

|

|

|

|||

|

|

|

UT75A, UT55A, |

31 Units |

|

|||

DP |

|

|

Modbus master |

RS-485 |

|

|||

|

|

UT52A, UT35A, |

(Main Controller |

|

||||

|

|

|

function |

|

UT32A, UP55A, UP35A |

is included.) |

|

|

|

|

|

|

|

|

|||

|

|

Used for communication |

Slave |

RS-485 |

PLC and others |

Number of nodes: |

|

|

|

|

42 (Remote device) |

|

|||||

CC-Link |

|

between PLCs and |

|

|

|

|

|

|

|

|

|

UT75A, UT55A, UT52A, |

31 Units |

|

|||

|

remote I/O, enabling high- |

Modbus master |

RS-485 |

|

||||

|

|

UT35A, UT32A, UP55A, |

(Main Controller |

|

||||

|

|

speed data transmission. |

function |

|

UP35A, UP32A, UM33A |

is included.) |

|

|

|

|

|

|

|

PV, SP, OUT, |

|||

|

|

|

Slave |

RS-485 |

PLC and others |

Number of nodes: |

||

|

|

|

64 |

ALM etc |

||||

DeviceNet |

|

|

|

|

|

|||

|

Modbus master |

RS-485 |

UT75A, UT55A, |

31 Units |

|

|||

|

|

|

UT52A, UT35A, |

(Main Controller |

|

|||

|

|

|

function |

|

UT32A, UP55A, UP35A |

is included.) |

|

|

|

|

|

|

|

|

|||

|

|

A protocol allowing multiple |

|

|

|

|

Read/Write: 4 |

|

|

|

controllers to send and |

|

RS-485 |

UT75A, UT55A, UT52A, |

|

||

Peer to peer |

|

units |

|

|||||

receive data between |

Multi-drop |

(2 wire |

UT35A, UT32A, UP55A, |

|

||||

Read only : 28 |

|

|||||||

|

|

one another. The Ladder |

|

only) |

UP35A, UP32A |

|

||

|

|

|

units |

|

||||

|

|

Program is used. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Coordinated |

A protocol to coordinate the |

|

|

UT75A, UT55A, UT52A, |

|

|

||

operation of two or more |

|

|

Master : 1 unit |

|

||||

Communica- |

Master/Slave |

RS-485 |

UT35A, UT32A, UP55A, |

|

||||

instruments controlling the |

Slave : 31 units |

|

||||||

tion |

|

|

|

UP35A, UP32A |

(*2) |

|

||

|

same process. |

|

|

|

|

|

||

|

|

The proprietary Yokogawa |

|

|

PC and others, |

|

|

|

PC link |

|

protocol allowing |

|

|

|

|

||

|

communications to PCs, |

Slave |

RS-485 |

UT75A, UT55A, UT52A, |

31units |

|

||

|

|

PLCs and touch panels. |

UT35A, UT32A, UP55A, |

|

||||

|

|

|

|

|

|

|||

Ladder |

|

A protocol to communicate |

|

|

UP35A, UP32A, UM33A(*2) |

|

|

|

|

to PLCs. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*1: |

UT digital indicating controller, Signal conditioner JUXTA, Power monitor POWERCERT can be connected. |

|

||||||

*2: |

UT digital indication controllers can be connected. |

|

|

|

|

|

||

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation |

GS 05P01C31-01EN |

Mar.14, 2016-00 |

4

Physical Interface |

|

|

Ethernet |

Standard : IEEE802.3 (10BASE-T, 100BASE-TX) |

|

|

Max segment length : 100m |

|

|

Max. Connecting Configguration : Cascade Max. 4 level (10BASE-T), Max. 2 level (100BASE-TX) |

|

RS-485 |

Standard : EIA RS-485 |

|

|

Communication method : Two-wire harf-duplex or four-wire harf-duplex, start-stop synchoronization |

|

|

and non-procedural |

|

|

Baud rate : 600, 1200, 2400, 4800, 9600, 19200 or 38400bps(*3), Peer to peer communication is fixed at |

|

|

19200bps |

|

|

Maximum communication distance : 1200m |

|

|

Terminating resistor : 220Ω (External) |

|

*3: |

“38400 bps” is available only for UT55A(Type 3 code = 1) and UT52A(Type 2 code = 1) |

|

PROFIBUS-DP |

Standard : Field bus (IEC61158) |

|

|

Corresponding version : DP V0 |

|

|

Baud rate : 9.6k, 19.2k, 45.45k, 93.75k, 187.5k, 0.5M, 1.5M, 3M, 6M, 12M, AUTO (*4) |

|

|

Communication distance : 1200m (9.6k to 93.75k) |

1000m (187.5k) |

|

400m (0.5M) |

200m (1.5M) |

|

100m (3M to 12M) |

|

*4: |

AUTO automatically sets the baud rate to that of the host controller (PROFIBUS-DP master). |

|

CC-Link |

Supported version : Remote device (Ver.1.10, Ver.2.00) |

|

|

Baud rate : 156k, 625k, 2.5M, 5M, 10M bps |

|

|

Transmission distance : 1.2km (156k bps), 600m (625k bps), 200m (2.5M bps), 150m (5M bps), |

|

|

100m (10M bps) |

|

|

When using optical repeater : 7.6 km (156k) to 4.3 km (10M) |

|

DeviceNet |

Field bus (IEC61158) |

|

|

Baud rate: 125k, 250k, 500k bps |

|

|

Transmission distance: 500m (125k bps), 250m (250k bps), 100m (500k bps) |

|

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation |

GS 05P01C31-01EN |

Mar.14, 2016-00 |

nHardware Specifications

Display Specifications

•PV display

5-digit, 14-segment active color LCD (white/red) Character height: 21.5 mm for UT55A and 13.0 mm for UT52A

•Data display

5-digit, 11-segment color LCD (orange)

•Bar graph display

12-segment color LCD (orange and white)

Universal Input Specifications

•Number of input points: 1

•Types of input, instrument range, and measurement accuracy (see the table below)

|

Types of input |

Instrument range |

Accuracy |

|||

|

°C |

°F |

||||

|

|

|

|

|

||

|

|

|

|

-270.0 to 1370.0°C |

-450.0 to 2500.0°F |

±0.1% of instrument |

|

|

|

K |

-270.0 to 1000.0°C |

-450.0 to 2300.0°F |

range ±1 digit for 0°C |

|

|

|

|

-200.0 to 500.0°C |

-200.0 to 1000.0°F |

or more |

|

|

|

J |

-200.0 to 1200.0°C |

-300.0 to 2300.0°F |

±0.2% of instrument |

|

|

|

|

-270.0 to 400.0°C |

-450.0 to 750.0°F |

range ±1 digit for less |

|

|

|

|

|

|

than 0°C |

|

|

|

|

|

|

However, ±2% of |

|

|

|

|

|

|

instrument range |

|

|

|

T |

|

|

±1 digit for less than |

|

|

|

0.0 to 400.0°C |

-200.0 to 750.0°F |

-200°C of thermocouple |

|

|

|

|

|

|||

|

|

|

|

|

|

K ±1% of instrument |

|

|

|

|

|

|

range ±1 digit for less |

|

|

|

|

|

|

than -200°C of thermo- |

|

|

|

|

|

|

couple T |

|

|

|

|

|

|

±0.15% of instrument |

|

|

|

|

|

|

range ±1 digit for 400°C |

|

|

|

B |

0.0 to 1800.0°C |

32 to 3300°F |

or more |

|

|

|

±5% of instrument |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

range ±1 digit for less |

|

Thermocouple |

|

|

|

|

than 400°C |

|

|

S |

0.0 to 1700.0°C |

32 to 3100°F |

±0.15% of instrument |

|

|

|

R |

0.0 to 1700.0°C |

32 to 3100°F |

range ±1 digit |

|

|

|

|

|

|

±0.1% of instrument |

|

|

|

N |

-200.0 to 1300.0°C |

-300.0 to 2400.0°F |

range ±1 digit |

|

|

|

±0.25% of instrument |

||||

|

|

|

|

|

range ±1 digit for less |

|

|

|

|

|

|

than 0°C |

|

|

|

E |

-270.0 to 1000.0°C |

-450.0 to 1800.0°F |

±0.1% of instrument |

|

|

|

|

L |

-200.0 to 900.0°C |

-300.0 to 1600.0°F |

range ±1 digit for 0°C |

|

|

|

|

-200.0 to 400.0°C |

-300.0 to 750.0°F |

or more |

|

|

|

|

|

|

±0.2% of instrument |

|

|

|

|

|

|

range ±1 digit for less |

|

|

|

U |

|

|

than 0°C |

|

|

|

0.0 to 400.0°C |

-200.0 to 1000.0°F |

However, ±1.5% of |

|

|

|

|

|

|||

|

|

|

|

|

|

instrument range ±1 digit |

|

|

|

|

|

|

for less than -200.0°C of |

|

|

|

|

|

|

thermocouple E |

|

|

|

W (*2) |

0.0 to 2300.0°C |

32 to 4200°F |

±0.2% of instrument |

|

|

|

|

|

|

range ±1 digit |

|

|

|

Platinel |

0.0 to 1390.0°C |

32.0 to 2500.0°F |

±0.1% of instrument |

|

|

|

2 |

|

|

range ±1 digit |

|

|

|

|

|

|

±0.5% of instrument |

|

|

|

PR20-40 |

0.0 to 1900.0°C |

32 to 3400°F |

range ±1 digit for 800°C |

|

|

|

or more |

|||

|

|

|

|

|

|

Accuracy not guaran- |

|

|

|

|

|

|

teed for less than 800°C |

|

|

|

W97 |

|

|

±0.2% of instrument |

|

|

|

Re3-W75 |

0.0 to 2000.0°C |

32 to 3600°F |

|

|

|

|

range ±1 digit |

|||

|

|

|

Re25 |

|

|

|

|

|

|

|

|

|

|

|

Resistance-temperature detector (RTD) 3-wire |

|

-200.0 to 500.0°C |

-300.0 to 1000.0°F |

±0.1% of instrument |

|

|

JPt100 |

range ±1 digit (*1) |

||||

|

-150.00 to 150.00°C |

-200.0 to 300.0°F |

±0.1% of instrument |

|||

|

|

|||||

|

|

range ±1 digit |

||||

|

|

|

|

|||

|

|

-200.0 to 850.0°C |

-300.0 to 1560.0°F |

±0.1% of instrument |

||

|

|

-200.0 to 500.0°C |

-300.0 to 1000.0°F |

range ±1 digit (*1) |

||

|

Pt100 |

-150.00 to 150.00°C |

-200.0 to 300.0°F |

±0.1% of instrument |

||

|

|

|||||

|

|

range ±1 digit |

||||

|

|

|

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Standard |

0.400 to 2.0000 V |

- |

|

|

|

|

1.000 to 5.000 V |

- |

|

||

|

|

signal |

|

|||

|

|

4.00 to 20.00 mA |

- |

±0.1% of instrument |

||

|

|

|

|

|||

|

|

|

|

0.000 to 2.000 V |

- |

|

|

DC voltage |

range ±1 digit |

||||

|

0.00 to 10.00 V |

- |

||||

|

|

|||||

|

|

|

|

-10.00 to 20.00 mV |

- |

|

|

DC current |

0.00 to 20.00 mA |

- |

|

||

5

The accuracy is that in the standard operating conditions: 23 ±2°C, 55 ±10%RH, and power frequency at 50/60 Hz.

*1: |

±0.3°C and ±1 digit in the range between 0 and 100°C |

|

±0.5°C ±1 digit in the range between -100 and 200°C |

*2: |

W-5% Re/W-26% Re (Hoskins Mfg.Co.), ASTM E988 |

•Applicable standards: JIS, IEC and DIN (ITS-90) for thermocouples and resistance-temperature detectors (RTD)

•Input sampling period: Synchronized to control period

•Burnout detection

Upscale and downscale of function, and OFF can be specified for the standard signal of thermocouple and resistance-temperature detector (RTD).

For integrated signal input, 0.1 V or 0.4 mA or less is judged as a burnout.

•Input bias current: 0.05 μA (for thermocouple and resistance-temperature detector (RTD))

•Resistance-temperature detector (RTD) measured current: About 0.16 mA

•Input resistance

1 MΩ or more for thermocouple/mV input About 1 MΩ for voltage input

About 250 Ω for current input (with built-in shunt resistance)

• Allowable signal source resistance

250 Ω or less for thermocouple/mV input

Effect of signal source resistance: 0.1 μV/Ω or less 2 kΩ or less for DC voltage input

Effect of signal source resistance: about 0.01%/100 Ω

• Allowable wiring resistance

Up to 150 Ω per line for resistance-temperature detector (RTD) input (conductor resistance between the three lines shall be equal)

Effect of wiring resistance: ±0.1°C/10 Ω

• Allowable input voltage/current

±10 V DC for thermocouple/mV/mA or resistancetemperature detector (RTD) input

±20 V DC for V input ±40 mA DC for mA input

• Noise reduction ratio

40 dB or more (at 50/60 Hz) in normal mode 120 dB or more (at 50/60 Hz) in common mode

• Reference junction compensation error ±1.0°C (15 to 35°C)

±1.5°C (-10 to 5°C and 35 to 50°C)

Auxiliary Analog Input Specifications

•This function can be used for remote setpoint setting, external compensating input, auxiliary input for computation, etc.

•Number of input points: see the model code table.

•For types of input, instrument range, and measurement accuracy, see the table below.

Types of input |

Instrument range |

Accuracy |

|

|

0.400 to 2.000 V |

±0.2% of instrument range |

|

Integrated signal |

±1 digit |

||

|

|||

1.000 to 5.000 V |

±0.1% of instrument range |

||

|

|||

|

±1 digit |

||

|

|

||

|

0.000 to 2.000 V |

±0.2% of instrument range |

|

DC voltage |

±1 digit |

||

|

|||

0.00 to 10.00 V |

±0.1% of instrument range |

||

|

|||

|

±1 digit |

||

|

|

||

DC voltage with High input |

0.000 to 1.250 V |

±0.1% of instrument range |

|

impedance |

±1 digit |

||

|

•Input sampling period: Synchronized to control period

•Input resistance: about 1 MΩ

However, 10 MΩ or more for high input impedance

•Burnout detection: Functions at standard signal Burnout is determined to have occurred if it is 0.1 V or less.

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation |

GS 05P01C31-01EN |

Mar.14, 2016-00 |

Loading...

Loading...