Yokogawa UT350 Operating Manual

User’s |

Models UT350/UT320 |

Manual |

|

|

Digital Indicating Controllers |

|

User’s Manual |

IM 05D01D02-41E

IM 05D01D02-41E

2nd Edition

Blank Page

<Toc> <Rev> |

i |

Introduction

Thank you for purchasing the UT350/UT320 digital indicating controller.

■ How to Use the Manuals

Purpose |

|

Title |

Description |

|

|

|

|

Setup |

1. |

Installation |

Describes the tasks (installation, wiring, and others) required |

|

|

|

to make the controller ready for operations. |

|

|

|

|

Basic operation |

2. |

Initial Settings |

Describes examples of setting PV input types, control output |

|

|

|

types, and alarm types. Making settings described herein |

|

|

|

allows you to carry out basic control. |

Operating procedures |

3. |

Operations |

Describes key operation sequences. |

and troubleshooting |

4.1 Troubleshooting |

For operation control through external contact inputs, see |

|

|

|

|

“1.5 Terminal Wiring Diagrams.” |

Brief operation |

5. |

Parameters |

Contains the parameter map used as a guideline for setting |

and setpoint recording |

|

|

parameters and lists of parameters for recording User Settings. |

■Regarding This User’s Manual

(1)This manual should be provided to the end user. Keep an extra copy or copies of the manual in a safe place.

(2)Read this manual carefully to gain a thorough understanding of how to operate this product before starting operation.

(3)This manual describes the functions of this product. Yokogawa M&C Corporation (hereinafter simply referred to as Yokogawa) does not guarantee the application of these functions for any particular purpose.

(4)Under absolutely no circumstances may the contents of this manual, in part or in whole, be transcribed or copied without permission.

(5)The contents of this manual are subject to change without prior notice.

(6)Every effort has been made to ensure that the details of this manual are accurate. However, should any errors be found or important information be omitted, please contact your nearest Yokogawa representative or our sales office.

Media No. IM 05D01D02-41E (CD) |

2nd Edition : Sep 2002 (MC) |

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00 |

All Rights Reserved Copyright © 2000, Yokogawa M&C Corporation |

|

|

<Toc> <Rev> |

ii |

■ Safety Precautions

The following symbol is indicated on the controller to ensure safe use.

This symbol on the controller indicates that the operator must refer to an explanation in the user’s manual in order to avoid the risk of injury or death of personnel or damage to the instrument. The manual describes how the operator should exercise special care to avoid

CAUTION electric shock or other dangers that may result in injury or loss of life.

The following symbols are used in the hardcopy user’s manuals and in the user’s manual supplied on the CD-ROM.

NOTE

NOTE

Indicates that operating the hardware or software in a particular manner may damage it or result in a system failure.

IMPORTANT

IMPORTANT

Draws attention to information that is essential for understanding the operation and/or features of the controller.

■ Regarding Force Majeure

Yokogawa M&C Corporation assumes no liability for any loss or damage, direct or indirect, caused by the use of or unpredictable defects of the product.

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Int> <Rev> |

Toc-1 |

Models UT350/UT320

Digital Indicating Controllers

User’s Manual

|

|

|

IM 05D01D02-41E 2nd Edition |

|

CONTENTS |

|

|

||

Introduction |

........................................................................................................... |

|

i |

|

1. |

Installation .............................................................................................. |

|

1-1 |

|

|

1.1 .................................................................................. |

Model and Suffix Codes |

1-1 |

|

|

1.2 ................................................................................................... |

How to Install |

1-2 |

|

|

1.3 .................................................................................... |

How to Connect Wires |

1-5 |

|

|

1.4 ................................................................................ |

Hardware Specifications |

1-7 |

|

|

1.5 ............................................................................ |

Terminal Wiring Diagrams |

1-12 |

|

2. |

Initial Settings ......................................................................................... |

|

2-1 |

|

|

2.1 ................................................... |

Names and Functions of Front Panel Parts |

2-2 |

|

|

2.2 ......................................... |

Setting PV Input Type (Setting First at Power - on) |

2-3 |

|

|

2.3 ................................................................................. |

Changing PV Input Type |

2-6 |

|

|

2.4 ........................................................................... |

Setting Control Output Type |

2-8 |

|

|

2.5 ..................................................................................... |

Changing Alarm Type |

2-9 |

|

|

2.6 ................................................... |

Description of Multiple Setpoints and PID |

2-12 |

|

3. |

Operations .............................................................................................. |

|

3-1 |

|

|

3.1 ......... |

Monitoring - purpose Operating Displays Available during Operation |

3-1 |

|

|

3.2 ........................................................................... |

Setting Target Setpoint (SP) |

3-3 |

|

|

3.3 ................................................................ |

Performing/Canceling Auto - tuning |

3-4 |

|

|

3.4 ....................................................................................... |

Setting PID Manually |

3-5 |

|

|

3.5 .................................................................................. |

Setting Alarm Setpoints |

3-6 |

|

|

3.6 ................................................. |

Selecting Target Setpoint Numbers (SP.NO) |

3-7 |

|

|

3.7 .................................................................. |

Switching between Run and Stop |

3-8 |

|

|

3.8 ............................................................... |

Switching between AUTO and MAN |

3-9 |

|

|

3.9 ..................................... |

Manipulating Control Output in Manual Operation |

3-10 |

|

4. |

Troubleshooting ........................................................and Maintenance |

4-1 |

||

|

4.1 .............................................................................................. |

Troubleshooting |

4-1 |

|

|

4.2 .................................................................................................... |

Maintenance |

4-4 |

|

|

........................................................................................... |

4.2.1 |

Cleaning |

4-4 |

|

........................................................................... |

4.2.2 |

Replacing Brackets |

4-4 |

|

.................................................................. |

4.2.3 |

Attaching Terminal Cover |

4-4 |

|

....................................... |

4.2.4 |

Replacing Parts with a Limited Service Life |

4-6 |

|

...................................................... |

4.2.5 |

Replacing Control Output Relays |

4-7 |

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Int> <Rev> |

|

|

Toc-2 |

5. |

Parameters .............................................................................................. |

5-1 |

|

|

5.1 |

Parameter Map ................................................................................................ |

5-1 |

|

5.2 |

Lists of Parameters ......................................................................................... |

5-4 |

6. |

Function Block Diagram and Descriptions............................................ |

6-1 |

|

Revision Information ............................................................................................ |

i |

||

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-1 |

1.Installation

This chapter describes installation, wiring, and other tasks required to make the controller ready for operation.

1.1Model and Suffix Codes

Before using the controller, check that the model and suffix codes match your order.

Model |

|

Suffix Code |

Description |

|

|

|

|

|

|

UT350 |

|

|

|

Digital indicating controller (provided with retransmission output and 15 V |

UT320 |

|

|

|

DC loop power supply as standard) |

|

|

|

|

|

|

|

-0 |

|

Standard type |

Type |

|

-2 |

|

Heating/cooling type |

|

|

-3 |

|

Standard type (with 24 V DC loop power supply) |

|

|

|

|

|

|

|

|

0 |

None |

Optional functions |

|

1 |

With communication, heater burnout alarm |

|

|

|

|

2 |

With heater burnout alarm |

|

|

|

|

|

Check that the following items are provided: |

|

|

• Digital indicating controller (of ordered model) ...................... |

1 |

|

• |

Brackets (mounting hardware) ............................................. |

1 pair |

• |

Unit label.............................................................................. |

1 |

• |

User’s Manuals .................................................................... |

3 (A2 size) |

• User’s Manual (Reference) (CD-ROM version) .................... |

1 |

|

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-2 |

1.2How to Install

NOTE

NOTE

To install the controller, select a location where:

1.no one may accidentally touch the terminals,

2. |

mechanical vibrations are minimal, |

|

|

|

|

|

|

|

|

|

|

|

|

3. |

corrosive gas is minimal, |

|

|

150mm |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

4. |

temperature can be maintained at about 23 C and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

the fluctuation is minimal, |

|

150mm |

|

|

|

|

|

|

|

150mm |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

150mm |

|

||||

|

|

|

|

|

|

|

|

|

|

||||

5. |

no direct radiant heat is present, |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

6.no magnetic disturbances are caused,

7.no wind blows against the terminal board (reference junction compensation element),

8.no water is splashed,

9.no flammable materials are around,

Never place the controller directly on flammable items or equipment.

If the controller has to be installed close to flammable items or equipment, be sure to provide shielding panels all around the controller, at least 150 mm away from every side; the panels should be made of either 1.43 mm-thick metal-plated steel plates or 1.6 mmthick uncoated steel plates.

NOTE

NOTE

Never touch the opening at the bottom of the case. It is to be used in the factory at shipping.

● Installation Position

Install the controller at an angle within 30 from horizontal with the front panel facing upward. Do not install it facing downward. The position of right and left sides should be horizontal.

Front panel

of controller Must not exceed 30

30 |

Rear of |

|

controller |

||

|

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-3 |

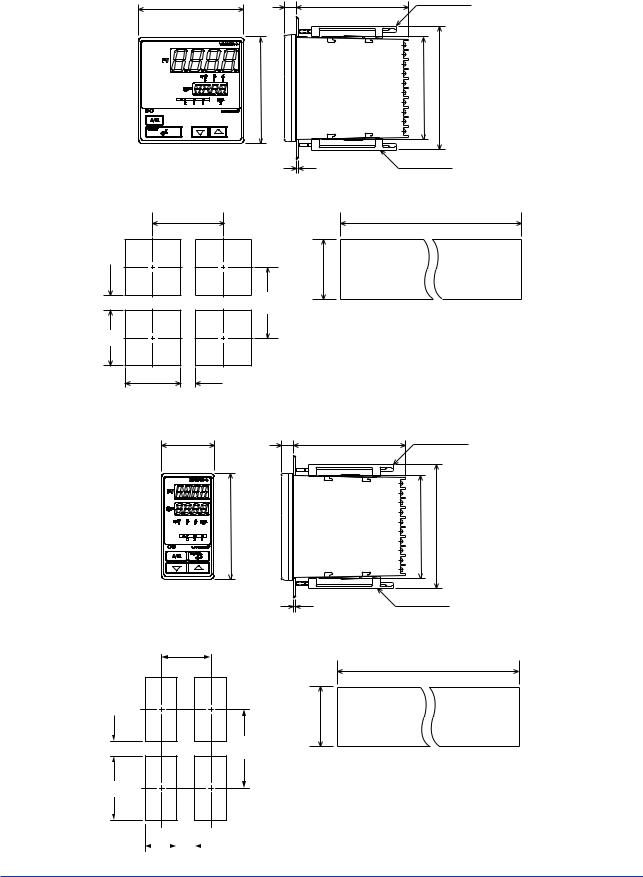

■ External Dimensions and Panel Cutout Dimensions |

|

|

UT350 |

Unit: mm |

|

96 |

11 |

100 |

Large bracket |

96 |

91.8 |

112 |

|

|

Small bracket |

|

|

1 to 10 mm (Panel thickness) |

General installation |

Side-by-side close installation |

|

|

117 min. |

[(N-1) 96+92]+00.8 |

|

|

+0.8 0 |

|

|

92 |

(53) |

|

145 min. |

|

|

"N" stands for the number of controllers to be |

|

|

installed. |

92+00.8 |

|

However, the measured value applies if N 5. |

92+00.8 |

(25) |

|

UT320 |

|

Unit: mm |

48 |

11 |

100 |

Small bracket |

96 |

91.8 |

112 |

Small bracket 1 to 10 mm (Panel thickness)

General installation |

Side-by-side close installation |

70 min.

[(N-1) 48+45] +00.6

|

+0.8 0 |

|

92 |

(53) |

145 min. |

"N" stands for the number of controllers to be installed.

92+00.8 However, the measured value applies if N 5.

45 +00.6 |

|

(25) |

|||

|

|

|

|

|

|

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-4 |

■ How to Install

Turn off the power to the controller before installing it on the panel because there is a possibility of electric shock.

CAUTION

After opening the mounting hole on the panel, follow the procedures below to install the controller:

1.Insert the controller into the opening from the front of the panel so that the terminal board on the rear is at the far side.

2.Set the brackets in place on the top and bottom of the controller as shown in the figure below, then tighten the screws of the brackets. Take care not to overtighten them.

Large bracket

Panel |

(top mounting hardware) |

Direction to insert the controller

Insert the controller into the opening at the front of the panel.

Terminal board

Insert a screwdriver into the brackets to tighten the screws.

Small bracket

(bottom mounting hardware)

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-5 |

1.3How to Connect Wires

1)Before carrying out wiring, turn off the power to the controller and check that the

cables to be connected are not alive with a tester or the like because there is a possibility of electric shock.

CAUTION 2) Wiring must be carried out by personnel who have basic electrical knowledge and practical experience.

NOTE

NOTE

1)Provide power from a single-phase instrument power supply. If there is a lot of noise in the power line, insert an insulating transformer into the primary side of the line and use a line filter (recommended part: ZAC2205-00U from TDK) on the secondary side.

As a countermeasures against noise, do not place the primary and secondary power cables close to each other.

2)For thermocouple input, use shielded compensating lead wires for wiring. For RTD input, use shielded wires that have low conductor resistance and cause no significant differences in resistance between the three wires.

The cables to be used for wiring, terminal specifications, and recommended parts are as shown below.

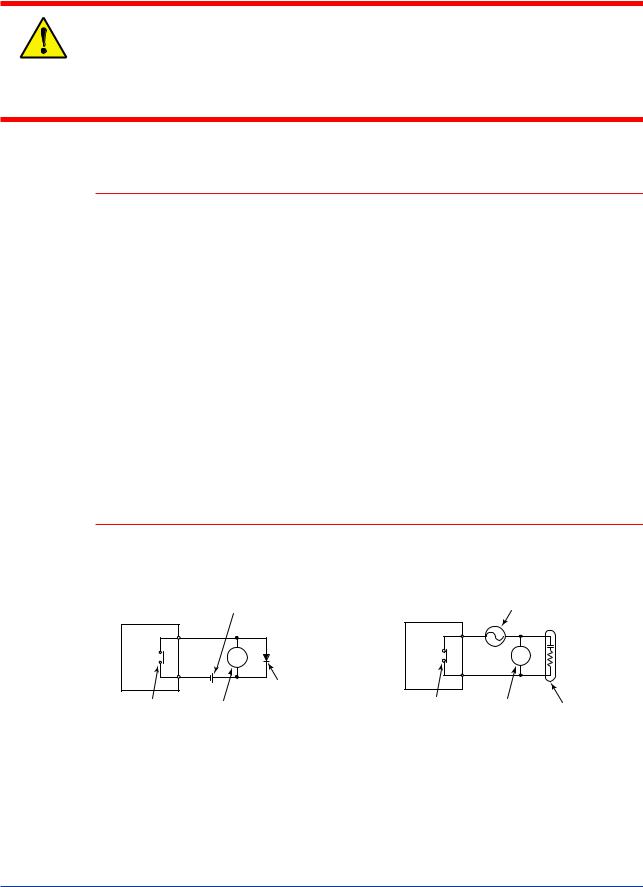

3)Control output relays may be replaced. However, because they have a life of 100,000 times that of the resistance load, use auxiliary relays to turn on/off a load.

4)The use of inductance (L) loads such as auxiliary relays, motors and solenoid valves causes malfunction or relay failure; always insert a CR filter for use with alternating current or a diode for use with direct current, as a spark-removal surge suppression circuit, into the line in parallel with the load.

5)When there is possibility of being struck by external lightening surge, use the arrester to protect the instrument.

■ For DC Relay Wiring |

■ For AC Relay Wiring |

||

UT350/UT320 |

External DC power supply |

UT350/UT320 |

External AC power supply |

|

|

R |

|

|

R |

|

|

|

Diode |

|

|

|

|

UT’s contact |

|

(Mount it directly |

UT’s contact |

Relay |

|

|

Relay |

to the relay coil |

CR filter |

||||

|

||||||

(Use one with a relay coil |

terminal (socket).) |

(Use one with a relay coil |

(Mount it directly |

|||

rating less than the UT’s |

|

rating less than the UT’s |

to the relay coil |

|||

|

contact rating.) |

|

|

contact rating.) |

terminal (socket).) |

|

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

|

|

|

<1. Installation> |

1-6 |

|||||||||

● Cable Specifications and Recommended Cables |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Purpose |

|

|

Name and Manufacturer |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power supply, grounding, relay contact outputs |

600 V PVC insulated wires, JIS C 3307, 0.9 to 2.0 mm2 |

|

|||||||||||

|

Thermocouple |

|

|

Shielded compensating lead wires, JIS C 1610, |

|

X- |

|

- |

|

- |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

(See Yokogawa Electric's GS 6B1U1-E.) |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RTD |

|

|

Shielded wires (three conductors), UL2482 (Hitachi Cable) |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other signals |

|

|

Shielded wires |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

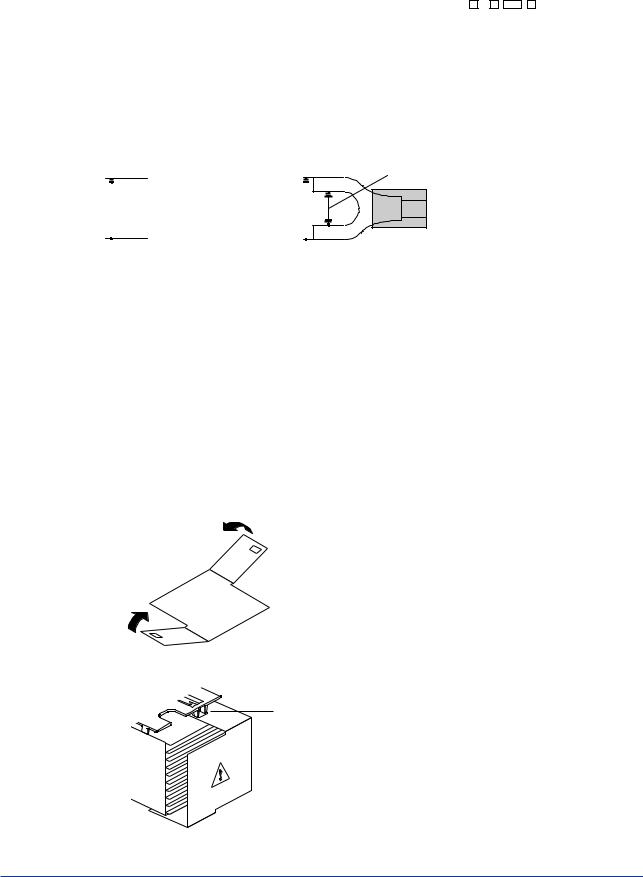

● Recommended Terminal Lugs |

|

|||||||||||||

|

|

|

|

|

|

|||||||||

|

Applicable wire size |

|

Tightening torque |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

0.3 to 1.65 mm2 |

|

0.8 N·m or less |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

3 . 7mm |

3 . 7mm |

|

||||||||||

7 m m o r l e s s

or

7 m m o r l e s s

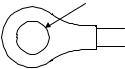

● Terminal Covers (Optional parts)

Target Model |

Part Number |

Sales Unit |

|

|

|

For UT350 |

T9115YD |

1 |

|

|

|

For UT320 |

T9115YE |

1 |

|

|

|

1.Before attaching the terminal cover, bend the side with the groove inward as shown in Fig. A. Be careful not to bend it backwards. This not only marks it harder to attach the cover but will also weaken its hold.

2.Fit the holes on the top and bottom of the terminal cover the projections on the brackets (Fig. B) and lock in place. The figure right shows the attachment of a terminal cover to UT controller.

Fold the cover in the direction of the arrow.

Figure A

Fit the cover hold over the protrusion

on the mounting bracket.

Figure B

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-7 |

1.4Hardware Specifications

PV Input Signals

•Number of inputs: 1 (terminals 11 - 12 - 13 )

•Input type: Universal input system. The input type can be selected with the software.

•Sampling period: 250 ms

•Burnout detection: Functions at TC, RTD, standard signal (0.4 to 2 V or 1 to 5 V) Upscale, downscale, and off can be specified.

For standard signal, burnout is determined to have occurred if it is 0.1 V or less.

•Input bias current: 0.05 A (for TC or RTD b-terminal)

•Measurement current (RTD): About 0.13 mA

•Input resistance: 1 M or more for thermocouple or mV input About 1 M for DC voltage input

•Allowable signal source resistance: 250 or less for thermocouple or mV input Effects of signal source resistance: 0.1 V/ or less

2 k or less for DC voltage input

Effects of signal source resistance: About 0.01%/100

•Allowable wiring resistance: for RTD input

Maximum 150 /wire: Conductor resistance between three wires should be equal However, 10 /wire for a maximum range of -150.0 to 150.0 C.

Wire resistance effect: 0.1 C/10

•Allowable input voltage: 10 V DC for thermocouple, mV, or RTD input20 V DC for DC voltage input

•Noise rejection ratio: 40 dB (50/60 Hz) or more in normal mode 120 dB (50/60 Hz) or more in common mode

•Reference junction compensation error: 1.0 C (15 to 35 C)1.5 C (0 to 15 C, 35 to 50 C)

•Applicable standards: JIS, IEC, DIN (ITS-90) for thermocouples and RTD

Loop Power Supply

Supplies power to a two-wire transmitter.

(15 V DC: terminals 14 - 15 ; 24 V DC: terminals 21 - 22 )

A resistor (10 to 250 ) connected between the controller and transmitter converts a current signal into a voltage signal, which is then read via the PV input terminal. Supply voltage: 14.5 to 18.0 V DC, max. 21 mA (provided with a protection circuit against a field short-circuit); 21.6 to 28.0 V DC, max. 30 mA (only for models with 24 V DC loop power supply)

When using the 24 V DC loop power supply of the UT320, keep the operating ambient temperature between 0 C and 40 C.

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-8 |

Retransmission Output

Either PV, target setpoint, or control output is output.

Either the retransmission output or the loop power supply can be used with terminals

14- 15 .

•Number of outputs: 1 (terminals 14 - 15 )

•Output signal: 4-20 mA DC

•Load resistance: 600 or less

•Output accuracy: 0.3% of span under standard operating conditions (23 2 C, 55 10% RH, power frequency of 50/60 Hz)

Control Output

Universal output system, The output type can be selected with the software.

•Current output

(Standard type: terminals 16 - 17 ; Heating/cooling type: Heating side: terminals 16 - 17 ; Cooling side: terminals 14 - 15 )

Number of outputs |

1 or 2 (two for heating/cooling type), |

|

switched between a voltage pulse output |

|

and current output. |

|

|

Output signal |

4-20 mA DC |

|

|

Load resistance |

600 or less |

|

|

Output accuracy |

0.3% of span under standard operating |

|

conditions (23 2 C, 55 10% RH, |

|

power frequency of 50/60 Hz) |

|

|

•Voltage pulse output

(Standard type: terminals 16 - 17 ; Heating/cooling type: Heating side: terminals 16 - 17 ; Cooling side: terminals 14 - 15 )

Number of |

1 or 2 (two for heating/cooling type), |

outputs |

switched between a voltage pulse output and current output. |

|

|

Output signal |

On-voltage = 12 V or more (load resistance: 600 Ω or more) |

|

Off-voltage = 0.1 V DC or less |

|

|

Resolution |

10 ms |

|

|

•Relay contact output

(Standard type: terminals 1 - 2 - 3 ; Heating/cooling type: Heating side: terminals 1 - 2 - 3 ; Cooling side: terminals 4 - 7 )

Number of outputs |

1 or 2 (two for heating/cooling type) |

|

|

Output signal |

Three terminals (NC, NO, and common) / |

|

Two terminals |

Contact rating |

Terminals 1-2-3 : |

|

250 V AC or 30 V DC, 3 A (resistance load) |

|

Terminal 4-7 : |

|

240 V AC or 30 V DC, 1A (resistance load) |

Resolution |

10 ms |

|

|

Contact Inputs

•Purpose: Selection between target setpoints or Auto/Man modes, or for other purposes

•Number of inputs: 2

•Input type: Non-voltage contact or transistor open collector input

•Input contact rating: 12 V DC, 10 mA or more

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-9 |

•On/off determination: For non-voltage contact input, contact resistance of 1 k or less is determined as “on” and contact resistance of 20 k or more as “off.”

For transistor open collector input, input voltage of 2 V or less is determined as “on” and leakage current must not exceed 100 A when “off.”

•Minimum status detection hold time: About 1 second.

Contact Outputs

•Purpose: Alarm output, FAIL output, and others

•Number of outputs: 3

•Relay contact rating: 240 V AC/1 A or 30 V DC/1 A (COM terminal is common.) (FAIL output : 1b)

Display Specifications

•PV display:

UT350: 4-digit, 7-segment red LED display, character height of 20 mm UT320: 4-digit, 7-segment red LED display, character height of 12 mm

•Setpoint display: 4-digit, 7-segment red LED display, character height of 9.3 mm (for both UT350 and UT320)

•Status indicating lamps: LEDs

Safety and EMC Standards

•Safety: Compliant with IEC1010-1: 1990 and EN61010-1: 1992 Approved by CSA1010

CSA1010 installation category (overvoltage category): CATII (IEC1010-1) Approved by UL508

•EMC standards:

The instrument continues to operate at a measuring accuracy of within 20% of the range during test.

Construction, Installation, and Wiring

•Construction: Only the front panel is dust-proof and drip-proof (protection class IP55) For side-by-side close installation the controller loses its dust-proof and drip-proof protection.

•Material: ABS resin and polycarbonate

•Case color: Black

•Weight: About 1 kg or less

•Dimensions:

UT350 96 (W) 96 (H) 100 (depth from panel face) mm UT320 48 (W) 96 (H) 100 (depth from panel face) mm

•Installation: Panel-mounting type. With top and bottom mounting hardware (1 each)

•Panel cutout dimensions:

UT350 920+0.8 (W) 920+0.8 (H) mm UT320 450+0.6 (W) 920+0.8 (H) mm

•Installation position: Up to 30 upward facing (not designed for facing downward)

•Wiring: M3.5 screw terminals (for signal wiring and power/ground wiring as well)

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-10 |

Power Supply Specifications

•Power supply: Rated voltage of 100 to 240 V AC ( 10%), 50/60 Hz

•Power consumption: Max. 20 VA (8.0 W max.)

•Internal fuse rating: 250 V AC, 1.6A time-lug fuse

•Data backup: Non-volatile memory (can be written to up to 100,000 times)

•Withstanding voltage

-Between primary terminals* and secondary terminals**: At least 1500 V AC for 1 minute (Note)

-Between primary terminals* and grounding terminal: At least 1500 V AC for 1 minute (Note)

-Between grounding terminal and secondary terminals**: At least 1500 V AC for 1 minute

-Between secondary terminals**: At least 500 V AC for 1 minute

*Primary terminals indicate power terminals and relay output terminals

**Secondary terminals indicate analog I/O signal, voltage pulse output, and contact input terminals

Note: The withstanding voltage is specified as 2300 V AC per minute to provide a margin of safety.

•Insulation resistance: 20 M or more at 500 V DC between power terminals and grounding terminal

•Grounding: Class 3 grounding (grounding resistance of 100 or less)

Signal Isolations

•PV input terminals: Isolated from other input/output terminals. Not isolated from the internal circuit.

•15 V DC loop power supply terminals: Not isolated from 4-20 mA analog output and voltage pulse control output. Isolated from other input/output terminals and internal circuit.

•24 V DC loop power supply terminals: Isolated from the 15 V DC loop power supply terminals, 4-20 mA analog output terminals and voltage pulse control output terminals, other I/O terminals and the internal circuitry.

•4-20 mA analog output terminals (for control output and retransmission): Not isolated between 4-20 mA outputs and from 15 V DC loop power supply and voltage pulse control output. Isolated from other input/output terminals and internal circuit.

•Voltage pulse control output terminals: Not isolated from 4-20 mA outputs and 15 V DC loop power supply. Isolated from other input/output terminals and internal circuit.

•Relay contact control output terminals: Isolated between contact output terminals and from other input/output terminals and internal circuit.

•Contact input terminals: Not isolated between contact input terminals and from communication terminals. Isolated from other input/output terminals and internal circuit.

•Relay contact alarm output terminals: Not isolated between relay contact alarm outputs. Isolated from other input/output terminals and internal circuit.

•RS-485 communication terminals: Not isolated from contact input terminals. Isolated from other input/output terminals and internal circuit.

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-11 |

•Power terminals: Isolated from other input/output terminals and internal circuit.

•Grounding terminals: Isolated from other input/output terminals and internal circuit.

Environmental Conditions

•Normal operating conditions:

Ambient temperature: 0 to 50 C (40 C or less for side-by-side close installation) The operating ambient temperature range is between 0 C and 40 C when the 24 V DC loop power supply of the UT320 is used.

Temperature change rate: 10 C/h or less

Ambient humidity: 20 to 90% RH (no condensation allowed) Magnetic field: 400 A/m or less

Continuous vibration at 5 to 14 Hz: Full amplitude of 1.2 mm or less Continuous vibration at 14 to 150 Hz: 4.9 m/s2 or less

Short-period vibration: 14.7 m/s2, 15 seconds or less Shock: 147 m/s2 or less, 11 ms

Installation height: Height above sea level of 2000 m or less Warm-up time: 30 minutes or more after power on

•Transportation and storage conditions: Temperature: -25 to 70 C

Temperature change rate: 20 C/h or less Humidity: 5 to 95% RH (no condensation allowed)

•Effects of changes in operating conditions

-Effects from changes in ambient temperature:

-On voltage or thermocouple input, 1 V/ C or 0.01% of F.S./ C, whichever is larger

-On RTD input, 0.05 C/ C (ambient temperature) or less

-On analog output, 0.05% of F.S./ C or less

-Effects from power supply fluctuation (within rated voltage range)

-On analog input, 1 V/10 V or 0.01% of F.S./10 V, whichever is larger

-On analog output, 0.05% of F.S./10 V or less

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-12 |

1.5Terminal Wiring Diagrams

NOTE

NOTE

Do not use unassigned terminals as relay terminals.

Terminal wiring diagrams are shown on and after the next page.

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-13 |

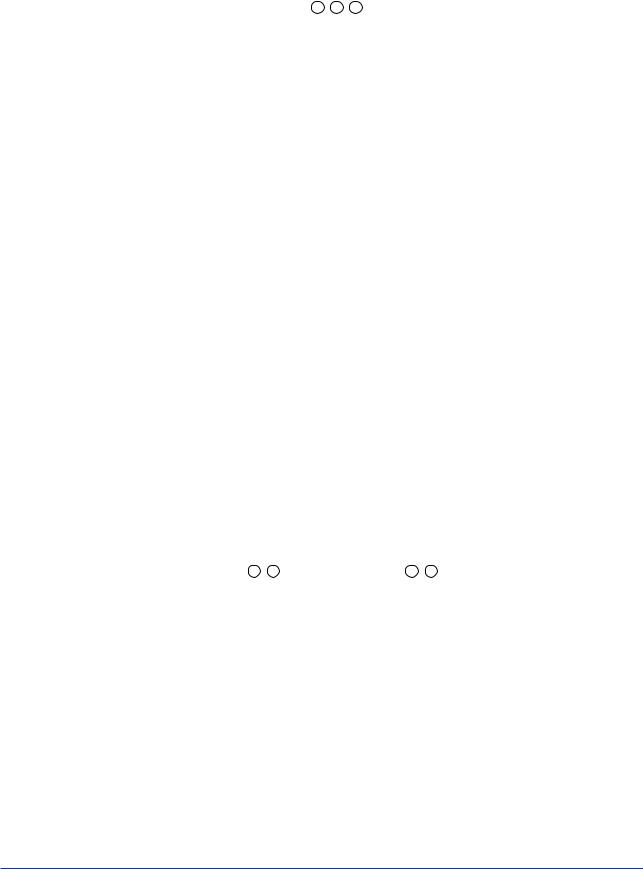

■ UT350 Standard Type (Model UT350-0 or UT350-3 ) or Heating/Cooling Type (Model UT350-2 )

Receiving4-20mADCCurrent |

SignalswiththeController |

*Whenreceiving4-20mADCcurrentsignals, setthePVinputtypeto1-5VDC(setpoint“41”). |

11A |

+12 |

4-20mA |

13 |

inputmV/V |

Ω resistortotheterminalsis |

optional. |

X010Model:-250-2(resistorwithM3.5crimp-onterminal |

lugs) |

13 |

(IEC1010-1) |

beforefactoryatconfiguredNot* shipment moreforSettings,”Initial“2.See |

information. |

inputRTDinput |

12Ω250 |

B13 |

ConnectingNote: 250a |

12 |

Installationcategory(overvoltagecategory):II |

||||||

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE |

|

|

|

|

|

b |

|

|

|

|

|

+ |

|

- |

|

inputPV |

|

TC |

|

12 |

13 |

|

|

|

|

|

|

|

|

|

|

|

|

+ |

- |

|

|

|

|

|

|

|

|

canWiringonly becarried |

controllersforout with |

DCV24looppowersupply. DCV24loop |

supplypower |

21+ |

21.6-28.0VDC |

22 |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

max.)mA(30DC |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- |

|

||

* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wiringcanonlybecarriedout |

forcontrollerswith |

|

communicationfunctions. |

Maximumbaudrate:9600bps |

|

|

|

|

|

|

|

|||||

|

* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RS-485communication |

|

|

|

|

|

|

|

|

|

|

|

RDB(+) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

SDB(+) |

|

|

24SDA(-) |

|

|

|

|

RDA(-) |

||||

|

|

|

|

|

23 |

|

|

|

|

25 |

|

|

26 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

from OTtheparameter. proportionalTime PID |

contactrelayoutputis |

configuredatfactory |

2beforeshipment.NO |

3COM |

|

250rating:ContactVAC,3A 30VDC,3A(resistanceload) |

|||||||||||

Note:SelectthisoptionControloutput |

contactRelayoutput |

|

1NC |

|

|||||||||||||

|

* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

12 |

21 |

22 |

|

|

1 |

2 |

SG |

|

|

|

27 |

|

|

|

|

UT |

|

|

|

6 |

5 |

4 |

output |

AL1 |

AL2 |

AL3 |

Alarm |

output |

output |

output |

|

Alarm-1 |

Alarm-2 |

Alarm-3 |

|

|

Relay |

|

PVretransmissionisconfiguredatfactory |

beforeshipment. |

|

|

ΩorLoadresistance:600less |

If15VDClooppowersupplyisused, |

retransmissionoutputcannotbeused. |

|

|

* |

|

|

|

|

* |

|

|

|

Retransmissionoutput |

14+ |

4-20mADC |

15 |

|

V15DClooppowersupply |

14+ |

14.5-18.0VDC (21mADCmax.) |

15 |

|

|

|

- |

|

|

|

|

- |

23 13

3

Common COM 7

14 |

15 |

24 |

25 |

4 |

5 |

240VAC,1A |

30VDC,1A(resistanceload) |

Relaycontactrating: |

|

Control output

Power supply

Note:Selectthis |

optionfromthe |

OTparameter. |

voltagepulse |

Current/voltage |

outputpulse |

16 |

|

|

|

DC,mA204- |

|

|

|

+ |

|

16 |

17 |

18 |

19 |

26 |

27 |

28 |

29 |

6 |

7 |

8 |

9 |

|

CAUTION |

Beforecarryingoutwiring,turnoffthepower tothecontrollerandcheckthatcablestobe |

connectedarenotalivewithatesterorthelike |

becausethereisapossibilityofelectricshock. |

|

supply |

8 |

|

9 |

|

L |

|

N |

||

Power |

|

|

|

|

(12 V)

17 -

30 20

10

10

Allowable range: 100 to 240 V AC ( 10%)

parameter. setpointallowsyoutochangethefunctionofexternalcontactinput. |

|

DISisasetup |

ChangingDIS |

* |

|

(freevoltage) |

50/60Hzshared |

Correspondence between parameter DIS and external contact input functions

* This wiring is only Heater current

Transistorcontact |

19 |

|

18 |

COM |

20 |

|

+5V |

DI1 |

+5V |

DI2 |

|

||

|

|

|

|

|||

Contact |

|

|

|

|

|

|

|

19 |

|

18 |

|

20 |

|

UT DI1 |

|

DI2 |

|

COM |

||

WhenDIS=4 |

2.SPwhenDI1=ON |

1.SPwhenDI1=OFF |

STOPwhenDI2=ON |

RUNwhenDI2=OFF |

Common |

|

WhenDIS=3 |

Whenswitchingtarget setpoints1to4: |

1.SP2.SP3.SP4.SP |

DI1OFFONOFFON |

DI2OFFOFFON ON |

Common |

|

WhenDIS=2 |

LOCKparameterwhenDI1=ON. |

LOCKparameterwhenDI1=OFF. |

Nofunction |

Common |

||

|

Hidesthe |

Showsthe |

|

|

|

|

DIS=1(Factory-setdefault) |

2.SPwhenDI1=ON |

1.SPwhenDI1=OFF |

AUTOwhenDI2=ON |

MANwhenDI2=OFF |

Common |

|

When |

|

|

|

|

|

|

WhenDIS=OFF |

Nofunction |

|

Nofunction |

Common |

||

input |

29CT1 |

|

28CT2 |

|

30COM |

|

detection |

|

|

|

CT |

CT |

|

possibleforacontroller |

withaheaterburnout |

alarm. |

|

|

|

|

|

inputisOFF,themode |

offwillbecontinued. |

|

|

|

Contactrating:12VDC,10mAormore |

ExternalContactInput Ifthepoweristurnedonwhentheexternalcontact |

(SP.noorA/M)existingbeforethepoweristurned |

(exceptforRUN/STOP) |

|

|

|

Note: |

|

|

|

|

|

|

|

|

|

23and) |

|

|

|

OT=3 |

On-offcontrol |

1output(terminals, |

|

|

|

|

|

Relay |

changethesettingsoftheparameterOTtochangethecontroloutputtype. |

|

CorrespondencebetweenparameterOTandcontroloutputtypes |

OT=2 |

Currentoutput |

(terminalsand)1617 |

information. |

OT=1 |

Timeproportionalcontrol |

Voltagepulseoutput(terminalsand)1617 |

||

OTisasetupparameter.Youcan |

See“2. InitialSettings,”formore |

|

OT=0(factory-setdefault) |

Timeproportionalcontrol |

Relayoutput(terminals,and)123 |

* |

|

|

|

|

|

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-14 |

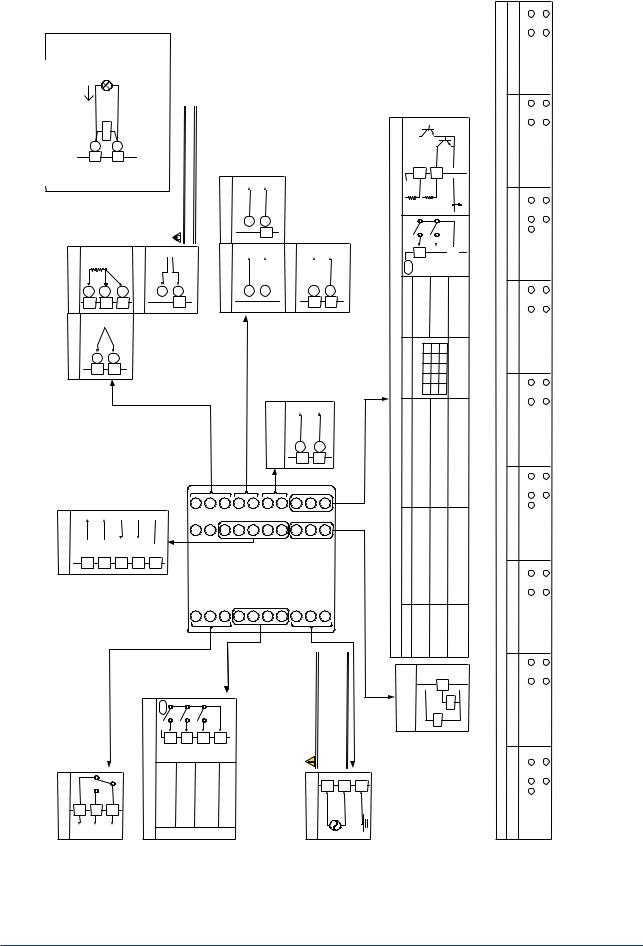

■ UT350 Heating/Cooling Type (Model UT350-2 )

CurrentDC

-4 mA20

Receiving

Not configured at factory before shipment

* inputPV

Signals with the Controller

See “2. Initial Settings,” for more

mADCcurrentsignals, |

to1-5VDC(setpoint“41”). |

Whenreceiving4-20 |

setthePVinputtype |

* |

|

|

RTDinput |

information. |

input |

|

TC |

carriedout |

communication |

Wiringcanonlybe |

forcontrollerswith functions. |

* |

|

|

4-20mA |

|

250Ω |

+ |

- |

12 |

13 |

A |

b |

B |

11 |

12 |

13 |

+ |

|

- |

12 |

|

13 |

Maximumbaudrate:9600bps |

|

|

Heating-side control output

-RS communication485

* Time proportional PID relay contact output

Relay outputcontact

23SDB(+)

factorybeforeshipment. |

or10issetintheOT |

Type)setupparameter. |

isconfiguredat |

Availableif4,7 |

(ControlOutput |

|

* |

|

|

1 |

2 |

|

NC |

NO |

)-SDA(

24

3 COM

25RDB(+)

Contact rating: 250 V AC, 3 A

Note:Connectinga250Ω resistortotheterminalsis |

optional. Model:X010-250-2(resistorwithM3.5crimp-onterminal lugs) |

|

(overvoltagecategory):II(IEC1010-1) |

factorybeforeshipment. |

supply |

|

|

|

|

NOTE |

Installationcategory |

isconfiguredat |

15VDClooppower |

mV/Vinput |

12+ |

13 |

|

PV*retransmission |

Retransmissionoutput |

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

|

11 |

12 |

13 |

21 |

22 |

23 |

RDA(-) |

SG |

26 |

27 |

1 |

2 |

3 |

3DC,V30A(resistanceload) |

output/coolingAlarm-sidecontroloutput |

UT |

Relay orcooling-sidecontrolAL3 |

(Note)output |

Common |

|

output1-Alarm |

||||||

|

|

6 |

5 |

4 |

|

7 |

|

|

AL1 |

AL2 |

|

|

COM |

|

|

|

Alarm-output2 |

Alarm-3output |

|

|

24 14

4

Relay contact rating: 240 V AC, 1 A

14 |

14.5-18.0VDC (21mADCmax.) |

15 |

15IfVDClooppowersupplyisused, retransmissionoutputcannotbeused. |

|

Theretransmissionoutputand15VDC |

looppowersupplyarenotavailableif thecooling-sidecontroloutputissetto “currentoutput”and“voltagepulseoutput.” |

|||

+ |

|

|

- |

|

|

|

|

|

|

|

|

|

|

|

* |

|

* |

|

|

14+ |

|

4-20mADC |

|

Cooling-sidecontroloutput |

|

4-20mADC, voltagepulse(12V) |

|

||

|

|

|

|

|

|||||

|

|

15 |

14+ |

|

|

15 |

|||

|

|

|

- |

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

|

|

load)resistance (A

V30 1DC,

output |

Availableif5,6,8,9,11 |

or12issetintheOT (ControlOutput |

Heating-sidecontrol |

Current/voltage * |

pulseoutput |

15 |

16 |

17 |

25 |

26 |

27 |

5 |

6 |

7 |

Thecooling-sidecontroloutputisselectedif4,5or |

6issetintheOT(ControlOutputType)setup parameter.Thealarm-3outputisnotavailable. Thecontrollerisfactory-settothecooling-sidecontrol output(timeproportionalPIDrelaycontactoutput). |

Note: |

|

Type)setupparameter. |

|

|

4-20mADC, |

voltagepulse |

(12V) |

+ |

|

- |

16 |

|

17 |

18 |

19 |

20 |

28 |

29 |

30 |

8 |

9 |

10 |

|

|

|

power |

tobe |

|

|

offthe |

cables |

supplyPower |

CAUTION |

Beforecarryingoutwiring,turn |

tothecontrollerandcheckthat |

supplyPower |

L |

8 |

|

thelike |

shock. |

alivewithatesteror |

possibilityofelectric |

not |

isa |

connectedare |

becausethere |

9 |

10 |

N |

|

|

|

ExternalContactInput |

Ifthepoweristurnedon |

whentheexternalcontact inputisOFF,themode |

(SP.noorA/M)existing |

|

beforethepoweristurned |

offwillbecontinued. |

|

(exceptforRUN/STOP) |

||||

|

|

Note: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Transistorcontact |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

19 |

18 |

|

|

20 |

|

|

|||||

|

|

+5V |

DI1 |

DI2 |

|

COM |

|

|

||||||

|

|

|

|

+5V |

|

|

|

|

|

|

|

|

||

|

|

Contact |

|

19 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

18 |

|

|

20 |

|

|

||||

|

|

contactinputfunctions |

UT |

DI1 |

1.SPwhenDI1=OFF |

DI2 |

COM |

|||||||

|

|

WhenDIS=4 |

|

2.SPwhenDI1=ON |

STOPwhenDI2=ON |

RUNwhenDI2=OFF |

|

Common |

||||||

|

changetoyouallowssetpointthefunctionofexternalcontactinput. |

DISandexternal |

WhenDIS=3 |

Whenswitchingtarget setpoints1to4: |

1.SP2.SP3.SP4.SP |

DI1OFFONOFFON |

DI2OFFOFFON ON |

|

Common |

|||||

parameter. |

Correspondencebetweenparameter |

WhenDIS=1(Factory-setdefault)WhenDIS=2 |

|

HidestheLOCKparameterwhenDI1=ON.2.SPwhenDI1=ON |

ShowstheLOCKparameterwhenDI1=OFF.1.SPwhenDI1=OFF |

DI2=ONwhenAUTO |

DI2=OFFwhenMAN |

|

Common Common |

|||||

|

|

|

|

|

|

|

functionNo |

|

|

|

|

|||

*DISisasetup |

ChangingDIS |

|

WhenDIS=OFF |

|

Nofunction |

Nofunction |

|

Common |

||||||

|

|

|

|

|

|

|

|

|

28CT2 |

|

|

|

|

|

|

|

Heatercurrent |

detectioninput |

|

29CT1 |

|

|

|

|

30COM |

||||

|

|

|

|

CT |

|

|

CT |

|

|

|||||

Allowablerange:100to240VAC( 10%) |

(freevoltage) 50/60Hzshared |

*Thiswiringisonlypossible |

foracontrollerwithaheater |

burnoutalarm. |

|

|

|

|

|

|

|

|

|

|

Contact rating: 12 V DC, 10 mA or more

changethesettingsoftheparameterOTtochangethecontroloutputtype. |

information. |

Youcan |

formore |

setupparameter. |

InitialSettings,” |

OTisa |

See“2. |

* |

|

Correspondence between parameter OT and heating-side/cooling-side output types

OT=12

OT=11

OT=10

OT=9

OT=8

OT=7

OT=6

OT=4 (factory-set default) OT=5

side:Currentoutput |

(terminalsand)1617 |

side:Currentoutput |

(terminalsand)1415 |

Heating |

|

Cooling |

|

side:Voltagepulseoutput |

(terminalsand)1617 |

side:Currentoutput |

(terminalsand)1415 |

Heating |

(terminals |

Cooling |

(terminalsand)1415 |

Relayside:Heatingoutput |

Currentside:Coolingoutput |

||

|

) |

|

|

|

3 |

|

|

|

and |

|

|

|

2 |

|

|

|

, |

|

|

|

1 |

|

|

Heatingside:Currentoutput |

(terminalsand)1617 |

Coolingside:Voltagepulseoutput |

(terminalsand)1415 |

side:Voltagepulseoutput |

(terminalsand)1617 |

side:Voltagepulseoutput |

(terminalsand)1415 |

Heating |

|

Cooling |

|

Relayside:Heatingoutput |

) |

Voltageside:Coolingpulseoutput |

(terminalsand)1415 |

(terminals |

|||

|

3 |

|

|

|

and |

|

|

|

2 |

|

|

|

, |

|

|

|

1 |

|

|

side:Currentoutput |

(terminalsand)1617 |

side:Relayoutput |

(terminalsand)47 |

Heating |

|

Cooling |

|

side:Voltagepulseoutput |

(terminalsand)1617 |

side:Relayoutput |

(terminalsand)47 |

Heating |

|

Cooling |

|

Relayside:Heatingoutput |

) |

Relayside:Coolingoutput |

(terminalsand)47 |

(terminals |

|||

|

3 |

|

|

|

and |

|

|

|

2 |

|

|

|

, |

|

|

|

1 |

|

|

refertothoseoftimeproportionalcontrol. |

thesetpointoftheproportionalbandto“0.” |

tableabove |

andchange |

“voltagepulseoutput”showninthe |

offcontrol,select“RelayTerminals” |

outputtypes,“relayoutput”and |

thetypetoarelayoutputforon- |

Thecontrol |

Tochange |

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-15 |

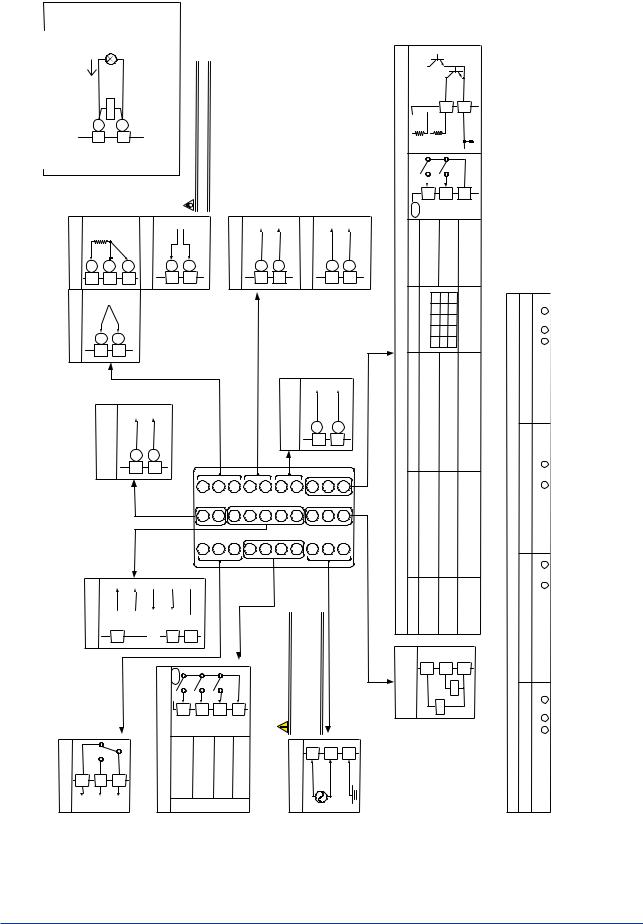

■ UT320 Standard Type (Model UT320-0 or UT320-3 ) or Heating/Cooling Type (Model UT320-2 )

20mADCCurrent |

theController |

Receiving4- |

Signalswith |

|

|

beforeshipment |

formore |

atfactory |

Settings,” |

Notconfigured |

See“2. Initial |

* |

|

PVinput |

|

Control output

*Whenreceiving4-20mADCcurrentsignals, setthePVinputtypeto1-5VDC(setpoint“41”). |

+12 |

250Ω 4-20mA |

13 |

Note:Connectinga250Ω resistortotheterminalsis optional. Model:X010-250-2(resistorwithM3.5crimp-onterminal lugs) |

NOTE |

categoryInstallation(overvoltagecategory):II(IEC1010-1) |

|

|

|

- |

|

|

|

|

RTDinput |

A |

|

b |

information. |

input |

11 |

|

12 |

|

TC |

|

+ |

- |

|

|

|

12 |

13 |

Wiringcanonly becarried outforcontrollerswith 24VDClooppowersupply. |

24VDCloop |

powersupply |

||

* |

|

|

communicationfunctions. Maximumbaudrate:9600bps |

|

|

|

Wiringcanonlybecarriedout |

forcontrollerswith |

|

|

|

* |

|

|

Note:Selectthisoptionfrom |

|

RS-485communication |

|

23SDB(+) |

theOTparameter. |

*TimeproportionalPID relaycontactoutputis |

configuredatfactory |

beforeshipment. |

|

contactoutput |

|

1 |

2 |

3 |

Relay |

|

NC |

NO |

COM |

B |

mV/Vinput |

13 |

|

21.6-28.0VDC |

(30mADCmax.) |

+ |

- |

21 |

22 |

SDA(-) |

|

|

RDB(+) |

24 |

|

|

25 |

250VAC,3A |

30VDC,3A(resistanceload) |

||

Contactrating: |

|

|

|

+ |

- |

12 |

13 |

11 |

12 |

21 |

22 |

1 |

2 |

|

RDA(-) |

SG |

|

|

26 |

27 |

|

|

UT |

|

|

|

6 |

5 |

4 |

output |

AL1 |

AL2 |

AL3 |

Alarm |

output |

output |

output |

|

Alarm-1 |

Alarm-2 |

Alarm-3 |

|

|

Relay |

|

PVretransmissionisconfiguredatfactory |

beforeshipment. |

ΩLoadresistance:600orless |

If15VDClooppowersupplyisused, |

retransmissionoutputcannotbeused. |

* |

|

|

* |

|

Retransmission output

3 23 13

Common COM 7

|

4-20mADC |

|

|

|

+ |

- |

|

|

14 |

|

15 |

|

|

|

Note:Selectthisoption |

|

|

Controloutput |

Current/voltage |

14 |

15 |

|

16 |

24 |

25 |

|

26 |

4 |

5 |

|

6 |

240VAC,1A |

30VDC,1A(resistanceload) |

CAUTION |

Relaycontactrating: |

|

Powersupply |

|

15VDClooppowersupply |

fromtheOT |

parameter. |

output |

20mADC, |

pulse |

4- |

16 |

|

|

+ |

17 |

18 |

27 |

28 |

7 |

8 |

Beforecarryingoutwiring,turnoffthepower |

tothecontrollerandcheckthatcablestobe connectedarenotalivewithatesterorthelike becausethereisapossibilityofelectricshock. |

14.5-18.0VDC |

(21mADCmax.) |

+ |

- |

14 |

15 |

voltagepulse |

(12V) |

|

- |

|

17 |

19 |

20 |

29 |

30 |

9 |

10 |

supply |

L |

N |

10 |

|

8 |

9 |

|

Power |

|

|

|

Allowable range: 100 to 240 V AC ( 10%)

parameter. setpointallowsyoutochangethefunctionofexternalcontactinput. |

|

DISisasetup |

ChangingDIS |

* |

|

(freevoltage) |

50/60Hzshared |

Correspondence between parameter DIS and external contact input functions

* This wiring is only Heater current

Transistorcontact |

19 |

18 |

20 |

+5V |

DI1 |

DI2 |

COM |

+5V |

|

|

|

Contact |

|

|

|

|

19 |

18 |

20 |

UT |

DI1 |

DI2 |

COM |

When DIS=3 When DIS=4

When DIS=2

When DIS=1 (Factory-set default)

DIS=OFFWhen

possible for a controller detection input

|

|

|

|

|

|

|

1.SPwhenDI1=OFF |

|

|

||

2.SPwhenDI1=ON |

||

Whenswitchingtarget setpoints1to4: |

1.SP2.SP3.SP4.SP |

|

HidestheLOCKparameterwhenDI1=ON. |

ShowstheLOCKparameterwhenDI1=OFF. |

|

2.SPwhenDI1=ON |

1.SPwhenDI1=OFF |

|

functionNo 29CT1

with a heater burnout alarm.

STOPwhenDI2=ON |

RUNwhenDI2=OFF |

ON |

ON |

DI1OFFONOFF |

DI2OFFOFFON |

No function

DI2=ONwhenDI2=OFFwhen

AUTOMAN

functionNo

28CT2 CT

CT

Common Common

Common

Common Common

30COM

|

isOFF,the |

offwillbe |

|

|

|

Contactrating:12VDC,10mAormore |

ExternalContactInput Ifthepoweristurnedonwhentheexternalcontactinput |

mode(SP.noorA/M)existingbeforethepoweristurned |

continued.(exceptforRUN/STOP) |

|

|

|

Note: |

|

|

|

|

|

|

|

|

|

23and) |

|

|

|

OT=3 |

On-offcontrol |

1output(terminals, |

|

|

|

|

|

Relay |

tochangethecontroloutputtype. |

|

OTandcontroloutputtypes |

OT=2 |

Currentoutput |

(terminalsand)1617 |

OTisasetupparameter.YoucanchangethesettingsoftheparameterOT |

See“2. InitialSettings,”formoreinformation. |

Correspondencebetweenparameter |

OT=0(factory-setdefault) OT=1 |

Timeproportionalcontrol Timeproportionalcontrol |

Relayoutput(terminals,and)Voltagepulseoutput(terminalsand)1617123 |

* |

|

|

|

|

|

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<1. Installation> |

1-16 |

■ UT320 Heating/Cooling Type (Model UT320-2 )

CurrentDC

-4 mA20

Receiving

Not configured at factory before shipment

* inputPV

Signals with the Controller

See “2. Initial Settings,” for more

Heating-side control output

mADCcurrentsignals, |

to1-5VDC(setpoint“41”). |

Whenreceiving4-20 |

setthePVinputtype |

* |

|

|

RTDinput |

information. |

input |

|

TC |

carriedout |

communication |

|

Wiringcanonlybe |

forcontrollerswith |

functions. |

* |

|

|

RS-485communication |

|

|

TimeproportionalPIDrelaycontact |

outputisconfiguredatfactory |

beforeshipment. |

* |

|

|

contactoutput |

|

|

|

||

1 |

||

Relay |

|

|

NC |

||

+ 12

11 A

12 +

Maximum rate:baud bps9600

23SDB(+)

or10issetintheOT |

Type)setupparameter. |

Availableif4,7 |

(ControlOutput |

* |

|

|

2 |

|

NO |

250 Ω 4-20mA

-

13

b |

B |

12 |

13 |

|

- |

|

13 |

SDA(-) |

RDB(+) |

24 |

25 |

3 |

rating:250VAC,3A |

COM |

Contact |

Note: Connecting a 250 Ω resistor to the terminals is

mV/V input

)-RDA( 26

30 V DC, 3 A (resistance load)

crimp-onterminal |

|

|

|

|

|

optional. Model:X010-250-2(resistorwithM3.5 |

lugs) |

|

(overvoltagecategory):II(IEC1010-1) |

factorybeforeshipment. |

supply |

|

|

NOTE |

Installationcategory |

isconfiguredat |

15VDClooppower |

|

12+ |

13 |

|

PV*retransmission |

Retransmissionoutput |

|

|

- |

|

|

|

|

|

|

|

|

|

|

|

11 |

12 |

|

13 |

|

|

|

21 |

22 |

|

23 |

|

SG |

|

|

|

|

|

|

27 |

|

1 |

2 |

|

3 |

|

Thecooling-sidecontroloutput isselectedif4,5or6issetin |

theOT(ControlOutput Type)setupparameter. |

Thealarm-3outputisnot available.Thecontrolleris |

factory-settothecooling-side |

controloutput(timeproportional |

PIDrelaycontactoutput). |

|

Note: |

|

|

|

|

|

|

output |

UT |

Relay orcooling-sidecontrolAL3 output(Note) |

Common |

|||

output/coolingAlarm-sidecontrol |

output1-Alarm |

|||||

|

6 |

5 |

|

4 |

7 |

|

|

AL1 |

AL2 |

|

|

|

COM |

|

|

Alarmoutput-2 |

Alarmoutput-3 |

|

|

|

14 |

14.5-18.0VDC (21mADCmax.) |

15 |

15IfVDClooppowersupplyisused, retransmissionoutputcannotbeused. |

|

Theretransmissionoutputand15VDC |

looppowersupplyarenotavailableif thecooling-sidecontroloutputissetto “currentoutput”and“voltagepulseoutput.” |

|

+ |

|

- |

|

|

|

|

|

|

|

|

* |

|

* |

|

|

14+ |

4-20mADC |

15 |

Cooling-sidecontroloutput |

14+ |

4-20mADC, voltagepulse(12V) |

15 |

|

|

|

- |

|

|

|

|

- |

4 24 14

Relay contact rating: 240 V AC, 1 A

Heating-side control output

5 25 15

load)resistance (A

V30 1DC,

Power supply

Current/voltage * Available if 5, 6, 8, 9,

6 26 16

CAUTION

Power supply

11or12issetintheOT (ControlOutputType) |

setupparameter. |

|

|

outputpulse |

16 |

voltagepulse |

-17 |

|

DC,mA204- |

|

V)(12 |

|

+ |

|

|

17 |

18 |

19 |

20 |

27 |

28 |

29 |

30 |

7 |

8 |

9 |

10 |

Before carrying out wiring, turn off the power to the controller and check that cables to be connected are not alive with a tester or the like because there is a possibility of electric shock.

8 |

9 |

10 |

|

|

|

|

|

L |

N |

|

|

|

|

|

|

parameter. setpointallowsyoutochangethefunctionofexternalcontactinput. |

|

DISisasetup |

ChangingDIS |

* |

|

100to240VAC( 10%) |

(freevoltage) 50/60Hzshared |

Allowablerange: |

|

Correspondence between parameter DIS and external contact input functions

Heatercurrent possibleonly

iswiring This*

|

ExternalContactInput |

Ifthepoweristurnedonwhenthe externalcontactinputisOFF,the |

mode(SP.noorA/M)existing beforethepoweristurnedoffwillbe continued.(exceptforRUN/STOP) |

|

Note: |

|

|

Transistorcontact |

19 |

18 |

20 |

+5V |

DI1 |

DI2 |

COM |

+5V |

|

||

Contact |

|

|

|

|

19 |

18 |

20 |

UT |

DI1 |

DI2 |

COM |

When DIS=OFF When DIS=1 (Factory-set default) When DIS=2 When DIS=3 When DIS=4

for a controller with a detection input

2.SPwhenDI1=ON |

1.SPwhenDI1=OFF |

Whenswitchingtarget setpoints1to4: |

1.SP2.SP3.SP4.SP |

HidestheLOCKparameterwhenDI1=ON. |

ShowstheLOCKparameterwhenDI1=OFF. |

2.SPwhenDI1=ON |

1.SPwhenDI1=OFF |

functionNo 29CT1

heater burnout alarm.

STOPwhenDI2=ON |

RUNwhenDI2=OFF |

ON |

ON |

DI1OFFONOFF |

DI2OFFOFFON |

Nofunction |

|

AUTOwhenDI2=ON |

MANwhenDI2=OFF |

Nofunction |

|

28CT2 |

|

|

|

|

CT |

CT |

|

Common Common Common

Common Common

30COM

Contact rating: 12 V DC, 10 mA or more

* OT is a setup parameter.

Wiringcanonlybecarriedoutforcontrollerswith24VDC |

looppowersupply. |

24VDCPowerSupplyWiringtoTwo-wireSensor |

|

* |

|

|

|

|

|

15VDCPowerSupplyWiringtoTwo-wireSensor |

|

|

|

|

|

|

|

|

|

changethesettingsoftheparameterOTtochangethecontroloutputtype. |

InitialSettings,”formoreinformation. |

Youcan |

See“2. |

Correspondence between parameter OT and heating-side/cooling-side output types

12 |

External |

resistor250 |

(Note) |

13 |

|

|

transmitterwire-Two |

21 |

Looppower |

4-20mADC21.6to |

28.0VDC 22 |

resistor250aConnectingNote: totheterminalsisoptional. |

(resistor2-250-X010Model:withM3.5crimp-onterminallugs) |

|||||

|

|

input PV |

signal DC V 5 |

|

|

|

|

|

|

|

supply |

|

|

|

|

|||

|

|

|

|

|

to1 |

|

|

|

|

|

|

|

|

|

|

resistor100aConnectingNote:totheterminalsisoptional. |

with(resistor2-100-X010Model:M3.5crimp-onterminallugs) |

|

12 |

External |

resistor |

(Note) |

13 |

|

|

transmitterwire-Two |

14 |

Looppower |

DCmA20-4 |

14.5to |

15 |

||||||

|

|

input PV |

|

signal DC V 2.0 |

|

|

|

|

|

|

|

|

supply |

|

DC V 18.0 |

|

|

|

|

|

|

|

to 0.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

|

|

|

|

|

|

types,outputcontrolThe“voltageandoutput”“relaypulseoutput”showninthetableaboverefertothoseoftimeproportionalcontrol. control,off-onforoutputrelayatotypethechangeTo select“RelayTerminals”andchangethesetpointoftheproportionalbandto“0.” |

|

|

OT=5default)set-(factoryOT=4 OT=6 |

Heatingside:RelayoutputHeatingside:VoltagepulseoutputHeatingside:Currentoutput |

(terminals |

|

Relayside:CoolingoutputRelayside:Coolingoutput Coolingside:Relayoutput |

(terminalsand)(terminalsand)(terminalsand)444777 |

OT=8OT=7 OT=9 |

Heatingside:RelayoutputHeatingside:VoltagepulseoutputHeatingside:Currentoutput (terminals |

Voltageside:CoolingoutputpulseVoltageside:Coolingpulseoutput Coolingside:Voltagepulseoutput |

(terminalsand)(terminalsand)(terminalsand)141514151415 |

|

OT=11OT=10 OT=12 |

Heatingside:RelayoutputHeatingside:VoltagepulseoutputHeatingside:Currentoutput |

(terminals |

Currentside:CoolingoutputCurrentside:Coolingoutput Coolingside:Currentoutput |

(terminalsand)(terminalsand)(terminalsand)141514151415 |

|

||

|

|

(terminalsand)1617 |

|

|

|

|

|

(terminalsand)1617 |

|

|

|

|

|

(terminalsand)1617 |

|

|

|

|

|

|

(terminalsand)1617 |

|

|

|

|

|

(terminalsand)1617 |

|

|

|

|

|

(terminalsand)1617 |

|

|

|

|

|

|

|

|

|

|

|

|

) |

|

|

|

|

|

) |

|

|

|

|

|

|

) |

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

and |

|

|

|

|

|

3 |

|

|

|

|

|

|

|

and |

|

|

|

|

|

2 |

|

|

|

|

|

and |

|

|

|

|

|

|

2 |

|

|

|

|

, |

|

|

|

|

|

2 |

|

|

|

|

|

|

|

, |

|

|

|

|

|

1 |

|

|

|

|

|

, |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<2. Initial Settings> |

2-1 |

2.Initial Settings

This chapter describes examples of setting PV input types, control output types, and alarm types. Carrying out settings described herein allows you to perform basic control. Refer to examples of various settings to understand how to set parameters required. Refer to “5.1 Parameter Map” for an easy to understand explanation of setting various parameters. If you cannot remember how to carry out an operation during setting, press the  key for more than 3 seconds. This brings you to the display (operating display) that appears at power-on.

key for more than 3 seconds. This brings you to the display (operating display) that appears at power-on.

Setup Procedure

Power-on

Set PV input.

Set PV input.  (Factory-set to “Unspecified.”)

(Factory-set to “Unspecified.”)

See “2.2 Setting PV Input Type (Setting First at Power-on),” or “2.3 Changing PV Input Type.”

Denotes a step that must always be followed.

Denotes a step that must always be followed.

Denotes a step that should be followed as necessary.

Denotes a step that should be followed as necessary.

Set the control |

(Factory-set to “Time Proportional Relay Output.”) |

|

output. |

||

|

||

See “2.4 Setting Control Output Type.” |

||

Set the alarm type and other setup

parameters.

Set operating parameters.

Controller operation

The following explanation of operation for the UT350’s panel, shown in the figure, is the same as that of the UT320’s panel.

IM 05D01D02-41E 2nd Edition : Sep 20,2002-00

<Toc> |

<2. Initial Settings> |

2-2 |

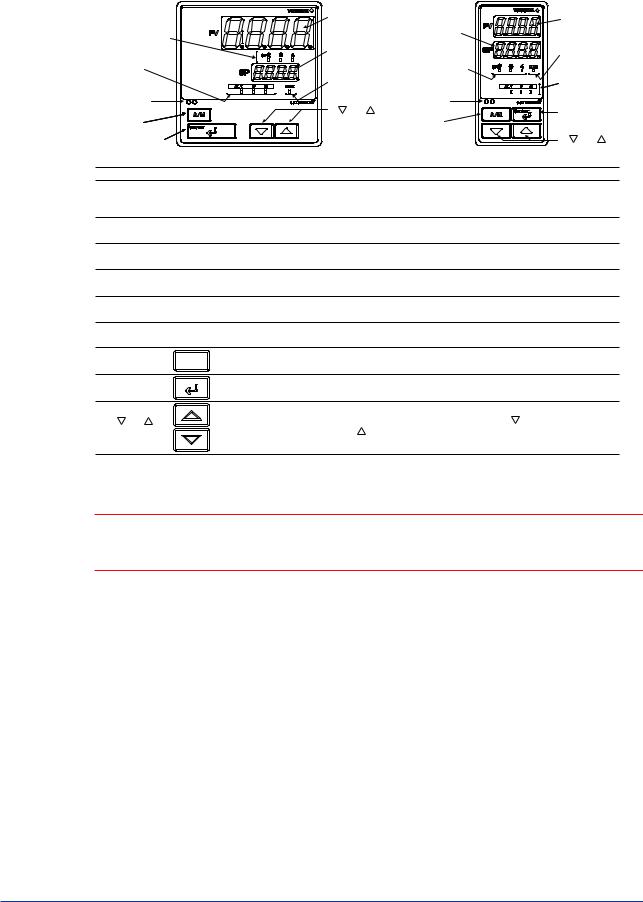

2.1Names and Functions of Front Panel Parts

|

|

|

|

1. Process |

|

1. Process |

|

3. Target setpoint |

|

|

variable (PV) 2. Setpoint |

variable (PV) |

|||

|

(SP) number |

|

|

display |

|

display |

display |

|

|

|

2. Setpoint |

4. Status |

|||

|

indicator lamps |

|

|

|

|||

5. Alarm |

|

|

display |

|

3. Target setpoint |

indicator lamp |

|

|

|

|

|

||||

|

indicator |

|

|

4. Status |

|

(SP) number |

5. Alarm indicator |

|

lamps |

|

|

|

indicator lamps |

||

|

|

|

indicator |

lamps |

|||

6. Light-loader |

|

|

6. Light-loader |

||||

|

|

lamp |

|

|

|||

|

interface |

|

|

|

|

interface |

8. SET/ENT |

|

|

|

|

9. and |

|

keys |

|

|

|

|

|

|

key |

||

7. A/M key |

|

|

|

|

7. A/M key |

||

|

|

|

|

|

|||

8. SET/ENT key |

|

|

|

|

|

9. and keys |

|

|

Name of Part |

|

|

|

|

Function |

|

|

Process variable (PV) |

Displays PV. |

|

|

|

||

1. |

Displays a parameter symbol when you set a parameter. |

|

|||||

display |

|

|

|

||||

|

|

|

Displays an error code (in red) if an error occurs. |

|

|||

|

|

|

|

|

|||

2. |

Setpoint display |

|

Displays the setpoint (SP) or the output value (OUT) during operation. |

|

|||

|

Displays the set value of parameters on the parameter setting display. |

|

|||||

|

|

|

|

|

|||

3. |

Target setpoint (SP) |

When the SP number currently used for operation is 2, 3 or 4, the respective SP No. indicator lamp lighits. |

|||||

number indicator lamps |

When the SP number is 1, the lamp does not lighit. |

|

|||||

|

|

||||||

4. |

Status indicator |

|

Is lit in green during manual operation. MAN: Is lit when in manual mode. |

|

|||

lamp |

|

|

Blinks during auto-tuning. |

|

|

|

|

|

|

|

|

|

|

||

5. |

Alarm indicator lamps |

If any of alarms 1 to 3 occurs, the respective alarm indicator lamp (AL1 to AL3) is lit (in orange). |

|||||

|

|

|

|

||||

6. |

Light-loader interface |

Interface for an adapter cable used when setting and storing parameters from a PC. |

|||||

This requires an optional parameter setting tool. |

|

||||||

|

|

|

|

|

|||

7. |

A/M key |

|

A/M |

Used to switch between the AUTO and MAN modes. Each time you press the key, it switches to the |

|||

|

AUTO or MAN mode alternately. |

|

|

|

|||

|

|

|

|

|

|

|

|

8. |

SET/ENT |

S E T / E N T |