Yokogawa SE200MJ, SE200NJ, SE100NJ, SE100MJ User Manual

User's

Manual

Models SE100MJ/NJ and

SE200MJ/NJ

Integral Type

Magnetic Flowmeter

IM 1E10B0-01E

IM 1E10B0-01E

10th Edition

|

|

|

|

|

CONTENTS |

|

|

|

|

|

Contents |

|

|

|

|

|

|

|

|

|

1. |

INTRODUCTION |

.............................................................................................. |

1-1 |

|||

2. |

HANDLING PRECAUTIONS .......................................................................... |

2-1 |

||||

|

|

2.1 |

Checking Model and Specifications ............................................................... |

2-1 |

||

|

|

2.2 |

Accessories ...................................................................................................... |

2-1 |

||

|

|

2.3 |

Storage Precautions ......................................................................................... |

2-1 |

||

|

|

2.4 |

Installation Location Precautions .................................................................... |

2-1 |

||

|

|

2.5 |

Cleaning Precautions ....................................................................................... |

2-2 |

||

|

|

2.6 |

Converter Reorientation Precautions .............................................................. |

2-2 |

||

3. |

INSTALLATION ................................................................................................ |

|

3-1 |

|||

|

|

3.1 |

Piping Design Precautions .............................................................................. |

3-1 |

||

|

|

3.2 |

Handling Precautions ...................................................................................... |

3-3 |

||

|

|

|

3.2.1 |

General Precautions ................................................................................. |

3-3 |

|

|

|

|

3.2.2 |

Flowmeter Piping ..................................................................................... |

3-4 |

|

|

|

3.3 |

Mounting ......................................................................................................... |

3-4 |

||

|

|

|

3.3.1 Nominal Diameter 15mm (0.5in) to 40mm (1.5in) Wafer Type .............. |

3-4 |

||

|

|

|

3.3.2 Nominal Diameter 50 mm(2in) to 200 mm(8in) Wafer Type .................. |

3-6 |

||

|

|

|

3.3.3 Nominal Diameter 15 mm (0.5in) to 200 mm (8in) Flange Type ............ |

3-8 |

||

|

|

3.4 |

Wiring Precautions ........................................................................................ |

3-10 |

||

|

|

|

3.4.1 |

Protective Grounding ............................................................................. |

3-10 |

|

|

|

|

3.4.2 |

General Precautions ............................................................................... |

3-10 |

|

|

|

|

3.4.3 Power and Output Cables ...................................................................... |

3-10 |

||

|

|

|

3.4.4 |

DC Connections ..................................................................................... |

3-11 |

|

|

|

|

3.4.5 |

Wiring Ports ........................................................................................... |

3-11 |

|

|

|

|

3.4.6 Connecting to External Instruments ...................................................... |

3-12 |

||

4. |

BASIC OPERATING PROCEDURES ............................................................ |

4-1 |

||||

|

|

4.1 |

Liquid Crystal Display (LCD) ........................................................................ |

4-1 |

||

|

|

4.2 |

Types of Display Data .................................................................................... |

4-2 |

||

|

|

|

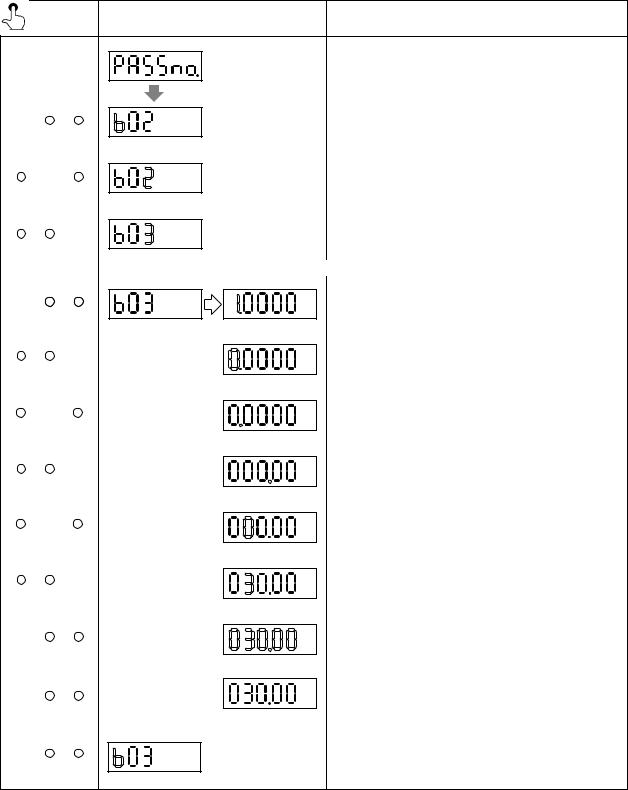

4.2.1 The Initial Procedure to Change the Display Mode ................................ |

4-3 |

||

|

|

|

4.2.2 Flow Rate Display Mode ......................................................................... |

4-5 |

||

|

|

|

4.2.3 |

Setting Mode ............................................................................................ |

4-6 |

|

|

|

|

4.2.4 |

Alarm Display Mode ............................................................................... |

4-7 |

|

|

|

|

4.2.5 |

Auto Zero Mode ...................................................................................... |

4-8 |

|

|

|

|

4.2.6 |

Indicator Error Mode ............................................................................... |

4-8 |

|

5. |

FUNCTION AND DATA SETTINGS ............................................................. |

5-1 |

||||

|

|

5.1 |

Setting Flow Span ........................................................................................... |

5-1 |

||

|

|

5.2 |

Power Frequency (For DC Power Supply Version only) .............................. |

5-4 |

||

|

|

5.3 |

Other Functions and Settings .......................................................................... |

5-4 |

||

|

|

|

5.3.1 |

Pulse Output ............................................................................................. |

5-4 |

|

|

|

|

5.3.2 Display of Internal Totalization Values .................................................... |

5-6 |

||

|

|

|

5.3.3 Resetting for Totalization Display ........................................................... |

5-7 |

||

|

|

|

5.3.4 |

Damping Time Constant .......................................................................... |

5-8 |

|

|

|

|

5.3.5 Current Output during Alarm Occurrence ............................................... |

5-8 |

||

|

|

|

5.3.6 |

Reversing Flow Direction ........................................................................ |

5-8 |

|

FD No. IM 1E10B0-01E |

|

|

|

|

||

10th Edition: Apr. 2002 (YK) |

|

|

|

|

||

All Rights Reserved, Copyright © 1999, Yokogawa Electric Corporation |

|

|

||||

|

|

|

|

i |

IM 1E10B0-01E |

|

|

|

CONTENTS |

5.3.7 |

Limiting Current Output .......................................................................... |

5-9 |

5.3.8 |

Forward and Reverse Flow Measurement ............................................. |

5-10 |

5.3.9 |

Automatic Two Range Switching .......................................................... |

5-11 |

5.3.10 |

Alarm Output at Low Flow Limit (Flow Switch) .................................. |

5-12 |

5.3.11 |

Totalization Switch Output .................................................................... |

5-13 |

5.3.12 |

Alarm Output ......................................................................................... |

5-14 |

5.3.13 |

Data Settings Enable / Inhibit ................................................................ |

5-14 |

5.3.14 |

Procedure of Selecting Special Application Items ................................. |

5-15 |

5.3.15 |

Rate Limit .............................................................................................. |

5-15 |

6. |

OPERATION VIA BRAIN TERMINAL (BT200) ......................................... |

6-1 |

||

|

6.1 |

BT200 Connections ......................................................................................... |

6-1 |

|

|

6.2 |

BT200 Keypad Layout .................................................................................... |

6-2 |

|

|

6.3 |

BT200 Key Functions ..................................................................................... |

6-3 |

|

|

6.4 |

Displaying Flow Rate Data ............................................................................. |

6-4 |

|

|

6.5 |

Setting Parameters ........................................................................................... |

6-5 |

|

|

|

6.5.1 |

Setting Flow Span .................................................................................... |

6-5 |

|

|

6.5.2 Power Frequency (For DC version only) ................................................. |

6-7 |

|

|

6.6 |

Other Functions ............................................................................................... |

6-7 |

|

|

|

6.6.1 |

User-Defined Units .................................................................................. |

6-7 |

|

6.7 |

Other Important Points .................................................................................... |

6-8 |

|

7. |

OPERATION VIA HART COMMUNICATOR ............................................ |

7-1 |

||

|

7.1 |

Conditions of Communication Line ............................................................... |

7-1 |

|

|

|

7.1.1 Interconnection between ADMAG SE and HART Communicator ......... |

7-1 |

|

|

|

7.1.2 |

Communication Line Requirements ........................................................ |

7-2 |

|

7.2 |

Basic Operation of the HART Communicator (Model 275) .......................... |

7-3 |

|

|

|

7.2.1 |

Keys and Functions .................................................................................. |

7-3 |

|

|

7.2.2 |

Display ..................................................................................................... |

7-4 |

|

|

7.2.3 |

Calling Up Menu Addresses .................................................................... |

7-4 |

|

|

7.2.4 Entering, Setting and Sending Data ......................................................... |

7-6 |

|

|

7.3 |

Parameters ....................................................................................................... |

7-8 |

|

|

|

7.3.1 |

Parameters Configuration ........................................................................ |

7-8 |

|

|

7.3.2 |

Data Renewing ......................................................................................... |

7-8 |

|

|

7.3.3 |

Menu Tree ................................................................................................ |

7-9 |

|

|

7.3.4 |

Setting Parameters ................................................................................. |

7-12 |

8. |

ACTUAL OPERATION .................................................................................... |

8-1 |

|

|

8.1 |

Pre-Operation Zero Adjustment ...................................................................... |

8-1 |

|

|

8.1.1 Zero Adjustment Using Data Setting Keys .............................................. |

8-1 |

|

|

8.1.2 Zero Adjustment Using BT200 ................................................................ |

8-2 |

|

|

8.1.3 Zero Adjustment Using HART Communicator ....................................... |

8-3 |

|

8.2 |

Self-diagnostics Functions .............................................................................. |

8-4 |

|

|

8.2.1 Output Status during Alarm Occurrence .................................................. |

8-4 |

|

|

8.2.2 Self-diagnostics Using HART Communicator ........................................ |

8-5 |

|

|

8.2.3 Error Description and Countermeasure ................................................... |

8-6 |

9. |

MAINTENANCE ................................................................................................ |

9-1 |

|

|

9.1 Loop Test (Test output) .................................................................................. |

9-1 |

|

|

9.1.1 ................................... |

Settings for Test Output Using Data Setting Keys |

9-1 |

|

9.1.2 ...................................................... |

Setting for Test Output Using BT200 |

9-2 |

ii |

IM 1E10B0-01E |

|

|

|

|

CONTENTS |

|

9.1.3 Setting for Test Output Using HART Communicator ............................. |

9-3 |

||

|

9.2 |

Trouble Shooting ............................................................................................. |

9-5 |

|

|

9.2.1 |

No Indication ........................................................................................... |

9-5 |

|

|

9.2.2 |

Unstable Zero ........................................................................................... |

9-6 |

|

|

9.2.3 Disagreement of Indication with Actual Flow Rate ................................. |

9-7 |

||

10. |

OUTLINE .......................................................................................................... |

|

|

10-1 |

11. |

PARAMETER LIST ........................................................................................ |

11-1 |

||

|

11.1 |

Parameters for ADMAG SE Indicator and BRAIN Terminal ..................... |

11-1 |

|

|

11.2 |

Parameters for HART Communicator .......................................................... |

11-7 |

|

12. |

EXPLOSION PROTECTED TYPE INSTRUMENT .................................. |

12-1 |

||

|

12.1 |

CENELEC ATEX(KEMA) ........................................................................... |

12-1 |

|

|

12.2 |

FM |

................................................................................................................. |

12-2 |

|

12.3 |

CSA ............................................................................................................... |

12-2 |

|

|

12.4 |

SAA ............................................................................................................... |

12-3 |

|

13. |

PRESSURE EQUIPMENT ......................................................DIRECTIVE |

13-1 |

||

iii |

IM 1E10B0-01E |

1. INTRODUCTION

1.INTRODUCTION

This instrument has been already adjusted at the factory before shipment.

To ensure correct use of the instrument, please read this manual thoroughly and fully understand how to operate the instrument before operating it.

Regarding This Manual

•This manual should be passed on to the end user.

•Before use, read this manual thoroughly to comprehend its contents.

•The contents of this manual may be changed without prior notice.

•All rights reserved. No part of this manual may be reproduced in any form without Yokogawa’s written permission.

•Yokogawa makes no warranty of any kind with regard to this material, including, but not limited to, implied warranties of merchantability and suitability for a particular purpose.

•All reasonable effort has been made to ensure the accuracy of the contents of this manual. However, if any errors are found, please inform Yokogawa.

•Yokogawa assumes no responsibilities for this product except as stated in the warranty.

•If the customer or any third party is harmed by the use of this product, Yokogawa assumes no responsibility for any such harm owing to any defects in the product which were not predictable, or for any indirect damages.

Safety Precautions

•The following general safety precautions must be observed during all phases of operation, service, and repair of this instrument. Failure to comply with these precautions or with specific WARNINGS given elsewhere in this manual violates safety standards of design, manufacture, and intended use of the instrument. YOKOGAWA Electric Corporation assumes no liability for the customer’s failure to comply with these requirements. If this instrument is used in a manner not specified in this manual, the protection provided by this instrument may be impaired.

The following safety symbol marks are used in this manual and instrument;

WARNING

A WARNING sign denotes a hazard. It calls attention to procedure, practice, condition or the like, which, if not correctly performed or adhered to, could result in injury or death of personnel.

CAUTION

A CAUTION sign denotes a hazard. It calls attention to procedure, practice, condition or the like, which, if not correctly performed or adhered to, could result in damage to or destruction of part or all of the product.

IMPORTANT

A IMPORTANT sign denotes an attention to avoid leading to damage to instrument or system failure.

NOTE

A NOTE sign denotes a information for essential understanding of the operation and features.

Protective grounding terminal.

Function grounding terminal. This terminal should not be used as a “Protective grounding terminal”.

Alternating current.

Direct current.

1-1 |

IM 1E10B0-01E |

Warranty

•The guaranteed term of this instrument is described in the quotation. We repair the damages that occurred during the guaranteed term for free.

•Please contact with our sales office when this instrument is damaged.

•If the instrument has trouble, please inform us model code, serial number, and concrete substances or situations. It is preferable to be attached a outline or data.

•We decide after the examination if free repair is available or not.

•Please consent to the followings for causes of damages that are not available as free repair, even if

it occured during the guaranteed term.

A:Unsuitable or insufficient maintenance by the customer.

B:The handling, using, or storage that ignore the design and specifications of the instrument.

C:Unsuitable location that ignore the description in this manual.

D:Remaking or repair by a person except whom we entrust.

E:Unsuitable removing after delivered.

F:A natural disaster (ex. a fire, earthquake, storm and flood, thunderbolt) and external causes.

For Safety Using

For safety using the instrument, please give attention mentioned below.

WARNING

(1) Installation

•The instrument must be installed by expert engineer or skilled personnel. The procedures described about INSTALLATION are not permitted for operators.

•The Magnetic Flow Tube is a heavy instrument. Please give attention to prevent that persons are injured by carrying or installing. It is preferable for carrying the instrument to use a cart and be done by two or more persons.

•In case of high process temperature, care should be taken not to burn yourself because the surface of body and case reach a high temperature.

•When removing the instrument from hazardous processes, avoid contact with the fluid and the interior of the flow tube.

•All installation shall comply with local installation requirement and local electrical code.

1. INTRODUCTION

(2) Wiring

•The instrument must be installed by expert engineer or skilled personnel. The procedures described about WIRING are not permitted for operators.

•Please confirm voltages between the power supply and the instrument before connecting the power cables. And also, please confirm that the cables are not powered before connecting.

•The protective grounding must be connected to

the terminal  in order to avoid personal shock hazard.

in order to avoid personal shock hazard.

(3) Operation

•Wait 10 min. after power is turned off, before opening the covers.

(4) Maintenance

•Please do not carry out except being written to a maintenance descriptions. When these procedures are needed, please contact to nearest YOKOGAWA office.

•Care should be taken to prevent the build up of drift, dust or other material on the display glass and data plate. In case of its maintenance, soft and dry cloth is used.

(5) Explosion Protected Type Instrument

•For explosion proof type instrument, the description in Chapter 12 “EXPLOSION PROTECTED TYPE INSTRUMENT” is prior to the other description in this user's manual.

•Only trained persons use this instrument in the industiral location.

•The protective grounding  must be connected to a suitable IS grounding system.

must be connected to a suitable IS grounding system.

•Take care not to generate mechanical spark when access to the instrument and peripheral devices in hazardous locations.

(6) The Instrument in Compliance with PED

•For the instrument in compliance with PED, the description in Chapter 13 “PRESSURE EQUIPMENT DIRECTIVE” is prior to the other description in this User’s Manual.

1-2 |

IM 1E10B0-01E |

2. HANDLING PRECAUTIONS

2.HANDLING PRECAUTIONS

This instrument has been already tested thoroughly at the factory. When the instrument is delivered, please check externals and make sure that no damage occurred during transportation.

In this chapter, handling precautions are described. Please read this chapter thoroughly at first. And please refer to the relative matter about other ones.

If you have any problems or questions, please make contact with Yokogawa sales office.

2.2 Accessories

When the instrument is delivered, please make sure that the following accessories are in the package.

•Centering device 1-set (for wafer type)

•Hexagonal wrench 1-piece (for special screw of terminal cover)

•Data Sheet 1-sheet

•Unit Labels 1-sheet

•Plug 1-piece (only for DC power supply version)

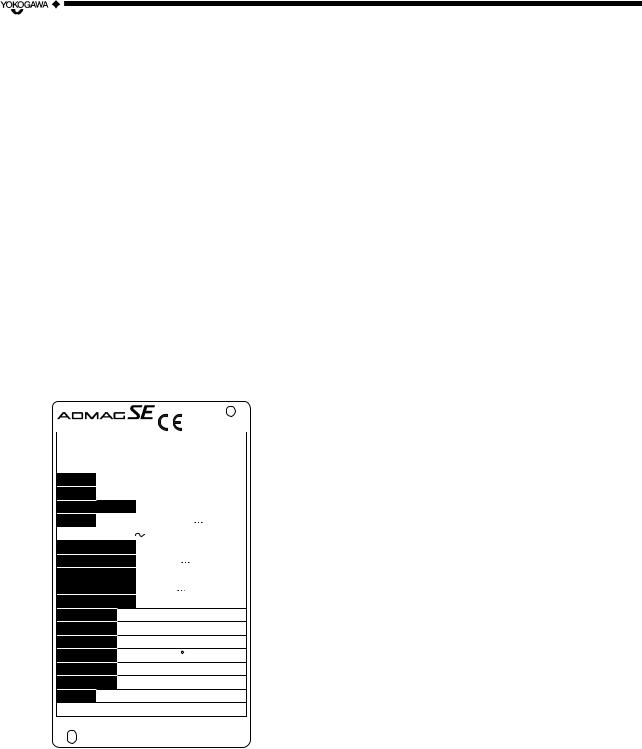

2.1Checking Model and Specifications

The model and specifications are shown on the Data Plate. Please confirm the specifications between the instrument that was delivered and the purchase order (refer to the chapter 5. Outline).

Please let us know Model and Serial No. when making contact with Yokogawa sales office.

MAGNETIC FIOWMETER |

0038 |

|||||||

MODEL |

|

|

|

|

|

|

|

|

SUFFIX |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STYLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SIZE |

mm |

|

|

|

|

|

||

METER FACTOR |

|

|

|

|

|

|

|

|

SUPPLY |

V DC |

|

10Wmax. |

|||||

|

||||||||

|

V AC |

47Hz to 63Hz 10Wmax. |

||||||

FULL SCALE |

|

|

|

|

|

|

|

|

CURRENT OUTPUT |

4-20mA |

|

|

(600Ωmax.) |

||||

|

|

|||||||

PULSE OUTPUT |

|

|

|

|

|

|

|

|

|

|

30V DC |

|

|

|

0.2mAmax. |

||

|

|

|

|

|

||||

LINING MATERIAL |

PFA |

|

|

|

|

|

||

ELECTRODE

FLUID TEMP. - 40 to +130 C (SEE IM)

C (SEE IM)

FLUID PRESS. - 0.1 MPa MIN. (SEE IM)

AMB. TEMP. - 20 to +60 C SEE IM

ENCLOSURE IP 67

TAG NO.

NO.

IM : User’s Manual

Made in Japan |

N200 |

Figure 2.1 |

Data Plate |

2.3 Storage Precautions

In case the instrument is expected to be stored over a long term, please give attention to the followings;

•The instrument should be stored in its original packing condition.

•The storage location should be selected according to the following conditions:

1)The location where it is not exposed to rain or water.

2)The location where there is few vibration or shock.

3)Temperature and humidity should be: Temperature: –40 to 70˚C (–40 to 158˚F) Humidity: 5 to 80% RH (no condensation) Preferable ambient temperature and humidity are 25˚C(77˚F) and about 65% RH.

2.4Installation Location Precautions

Please select the installation location considering the following items to ensure long term stable operation of the flow tube.

•Ambient Temperature:

Please avoid to install the instrument at the location where temperature changes continuously. If the location receives radiant heat from the plant, provide heat insulation or improve ventilation.

•Atmospheric Condition:

Please avoid to install the instrument in an corrosive atmosphere. In case of installing in the corrosive atmosphere, please keep ventilating sufficiently and prevent rain from entering the conduit.

•Vibration or shock:

Please avoid to install the instrument at the location where there is heavy vibration or shock.

2-1 |

IM 1E10B0-01E |

2. HANDLING PRECAUTIONS

2.5 Cleaning Precautions

Care should be taken to prevent the buildup of dirt, dust or other material on the display glass. Such buildup may interfere with the operation of programming keys.

2.6Converter Reorientation Precautions

Please do not change the converter orientation at the customer’s site. If the converter reorientation is required, please contact Yokogawa office or service center.

2-2 |

IM 1E10B0-01E |

3. INSTALLATION

3.INSTALLATION

WARNING

This instrument must be installed by expert engineer or skilled personnel. The procedures described in this chapter are not permitted for operators.

5 D or more 2 D or more |

10 D or more |

Gate valve fully open |

Expander pipe |

5 D or more |

5 D or more |

10 D or more |

Tee |

90° bend |

Various types of valves |

3.1Piping Design Precautions

D: Internal diameter of flowmeter |

F0301.EPS |

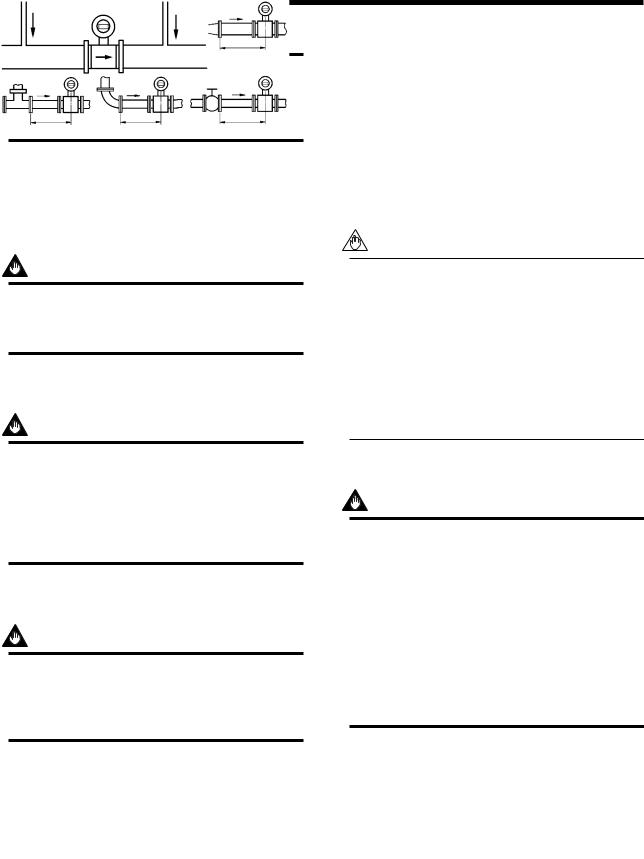

Figure 3.1.1 Minimum Length of Required Straight Run

NOTE

IMPORTANT

Please design the correct piping referring to the followings to prevent damage for flow tube and to keep correct measuring.

(1) Location

IMPORTANT

Please install the flow tube to the location where it is not exposed to direct sunlight and ambient temperature is –20 to + 60°C (–4 to 140°F)*.

*The minimum temperature is –10°C (14°F) in case of the 40mm or lager sizes with the carbon steel flange connection or wafer connection.

(2) Noise Rejection

IMPORTANT

The instrument should be installed away from large electrical motors, transformers and other power sources in order to avoid interference with the measurement.

(3) Length of Straight Run

To keep accurate measuring, JIS B7554 “Electro Magnetic Flow Tubes” explains about upstream piping condition of Magnetic Flowmeters.

We recommend to our customers about the piping conditions shown in Figure 3.1.1 based on JIS B7554 and our piping condition test data.

1.Nothing must be inserted or installed in the metering pipe that may interfere with the magnetic field, induced signal voltages, and flow velocity distribution.

2.These straight runs may not be required on the downstream side of flowmeter. However, if the downstream valve or other fittings cause channeling on the upstream side, provide a straight run of 2 D to 3 D on the downstream side.

(4)Liquid Conductivity

IMPORTANT

Please avoid to install the flow tube at location where liquid conductivity is likely to be nonuniform. Because it is possible to have bad influences to the flow indication by non-uniform conductivity when a chemical liquid is injected from upstream side close to the flow tube. When this occurs, it is recommended that chemical application ports are installed on the downstream side of the flow tube. In case chemicals must be added upstream side, please keep the pipe length enough so that liquid is properly mixed.

(BAD) |

(GOOD) |

Upstream side |

Downstream side |

F0302.EPS

Figure 3.1.2 Chemical Injection

3-1 |

IM 1E10B0-01E |

(5) Liquid Sealing Compound

IMPORTANT

Please give attention in using Liquid Sealing Compound to the piping, because it brings bad influences to measurement by flowing out and cover the surfaces of electrode and earth-ring.

(6) Service Area

Please select the location where there is enough area to service installing, wiring, overhaul, etc.

(7) Bypass Line

It is recommended to install the Bypass Line to facilitate maintenance and zero adjustment.

Bypass valve

Block valve

Block valve |

F0303.EPS |

Figure 3.1.3 Bypass Line

(8) Supporting the Flowmeter

CAUTION

Please avoid to support only the flowmeter, but fix pipes at first and support the flowmeter by pipes to protect the flow tube from forces caused by vibration, shock, expansion and contraction through piping.

(9) Piping Condition

IMPORTANT

The piping should be designed so that a full pipe is maintained at all times to prevent loss of signal and erroneous readings.

Please design the piping that a fluid is always filled in the pipes. The Vertical Mounting is effective for fluids that is easily separate or slurry settles within pipes.

In this case, please flow a fluid from bottom to up.

3. INSTALLATION

(GOOD) |

(BAD) |

(GOOD) |

(BAD) |

|

|

|

h |

|

|

|

h > 0 |

|

h |

|

|

|

h > 0 |

|

|

Horizontal mounting Vertical mounting

F0304.EPS

Figure 3.1.4 Filling the Pipe with Liquid

(10) No Air Bubbles

IMPORTANT

Please give attention to prevent bad influences or measuring errors from air bubbles that gathers inside measuring pipes.

In case the fluid includes air bubbles, please design the piping that prevent to gather air bubbles. In case valves are installed upstream of the flow tube, it is possible that a valve causes air bubbles, please install the flowmeter upstream side of a valve.

F0305.EPS

Figure 3.1.5 Avoiding Air Bubbles

(11) Mounting Direction

IMPORTANT

When the electrodes are vertical to ground, the electrode is covered with air bubbles at upper side or slurry at downside, and it may cause the measuring errors.

Please be sure to mount the terminal box upper side of piping to prevent water penetration into terminal box.

(GOOD) |

(BAD) |

Air Bubbles

Electrodes

Slurry

Electrodes

F0306.EPS

Figure 3.1.6 Mounting Direction

3-2 |

IM 1E10B0-01E |

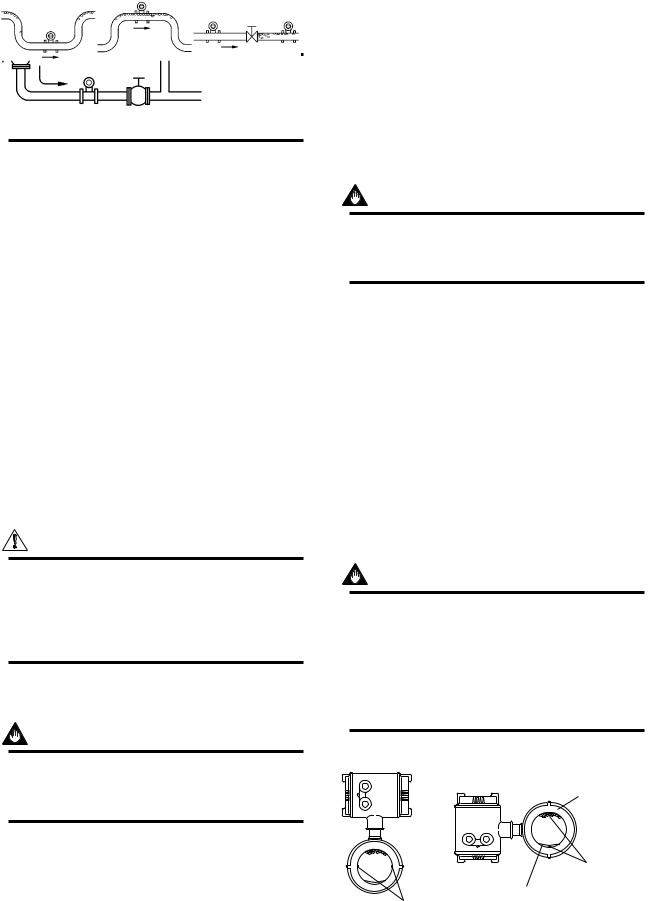

(12) Grounding

IMPORTANT

Improper grounding can have an adverse affect on the flow measurement. Please ensure that the instrument is properly grounded.

The electromotive force of the magnetic flow tube is minute and it is easy to be affected by noise. And also that reference electric potential is the same as the measuring fluid potential. Therefore, the reference electric potential (terminal potential) of the Flow Tube and the Converter/Amplifier also need to be the same as the measuring fluid. And moreover, that the potential must be the same with ground.

Please be sure to ground according to Figure 3.1.7.

600 V vinyl insulated electric cable

(2mm2 or larger)

Note: See “3.4.1 Protective grounding” for information on protective grounding.

Earth ring

Grounding resistance 100Ω or less

In case earth rings are used. In case earth rings are not used. (Available only for metal piping)

F0307.EPS

Figure 3.1.7 Grounding

3.2 Handling Precautions

WARNING

The Magnetic Flowmeter is a heavy instrument. Please be careful to prevent persons from injuring when it is handled.

3. INSTALLATION

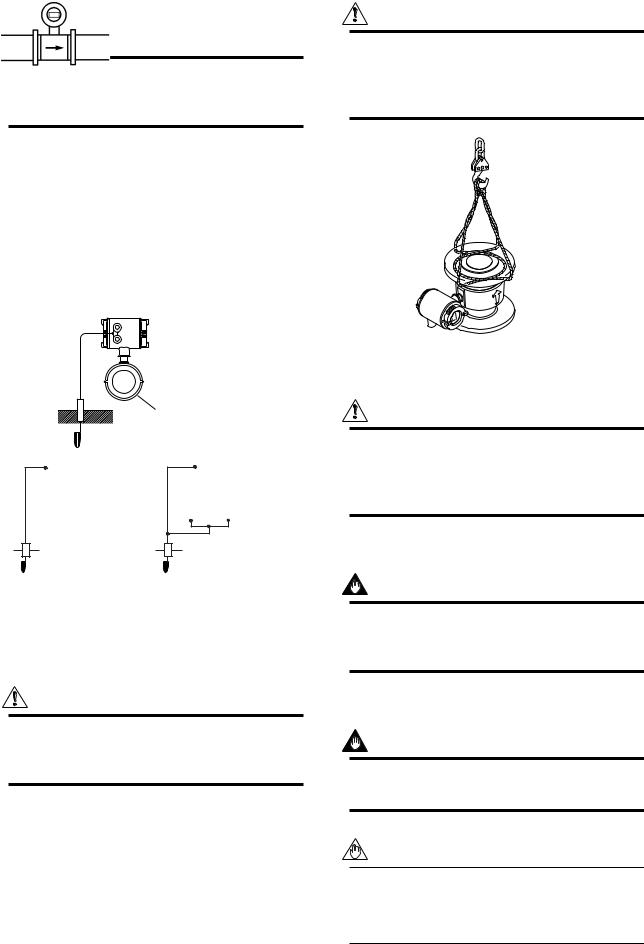

CAUTION

In case the Magnetic Flow Tube without eye-bolt lifts up, please refer to Figure 3.2.1. Please never lift up by using a bar through the flow tube. It damages liner severely.

F0308.EPS

Figure 3.2.1 Vertical Lifting Sling Rigging Method

(2) Precaution for Shock

CAUTION

Care should be taken not to drop the flow tube or subject it to excessive shock. This may lead to liner damage which will cause inaccurate readings.

(3) Flange Protection Covers

IMPORTANT

Please keep the protection cover (ex. corrugated paper or anything possible to protect) attached with flange except when mounting to the pipe.

(4) Terminal Box Cover

IMPORTANT

Please never leave the terminal box cover open until wiring to prevent insulation deterioration.

3.2.1General Precautions

(1) Precaution for Carrying

The Magnetic Flowmeter is packed tightly. When it is unpacked, please give attention to prevent damages to the flowmeter. And to prevent the accident during carry to the installing location, please carry it near the location keeping packed as it delivered.

NOTE

The terminal box cover is locked by special screw. In case of opening the terminal box cover, please use the Hexagonal Wrench attached.

3-3 |

IM 1E10B0-01E |

3. INSTALLATION

CAUTION

Be sure to lock the cover with the special screw using the Hexagonal Wrench attached after tightening the terminal box cover.

(5) Long-term Non-use

IMPORTANT

It is not preferable to leave the flowmeter for long term non-use after installation.

In case the flow tube is compelled to do that, please take care of the flowmeter by the followings.

•Confirmation of Sealing Condition for the Flowmeter.

Please confirm the sealing conditions of the terminal box screw and wiring ports.

In case of the Conduit Piping, please provide the drain plugs or waterproof glands to it to prevent that moisture or water penetrates into the flow tube through the conduit.

•Regular Inspections

Please inspect the sealing condition (as above mentioned) and inside of the terminal box. And when it is suspect that water penetration into the inside flow tube (ex. rain fall), please inspect when it happened.

3.2.2Flowmeter Piping

CAUTION

Mis-aligned or slanted piping can lead to leakage and damage to flanges.

•Please correct mis-alignment or slanted piping and improper distance between mounting flanges before install the flowmeter. (Please refer to Figure 3.2.2)

•Inside a pipeline which is newly installed, some foreign substances (such as welding scrap or wood chips) may exist. Please remove them by flushing piping before mounting the flowmeter.

Slant |

Mis-alignment |

F0309.EPS |

Figure 3.2.2 Slant and Mis-alignment of Flowmeter Piping

3.3 Mounting

3.3.1Nominal Diameter 15mm (0.5in) to 40mm (1.5in) Wafer Type

IMPORTANT

Please use appropriate bolts and nuts according to process connection. In case stud type of through bolts are used, be sure outside diameter of a shank is smaller than a thread ridge’s one. Please use compressed non-asbestos fiber gasket, PTFE gasket or the gasket which has equal elasticity. In case of optional code/FRG, please use rubber gasket or others which has equal elasticity. Be sure the inner diameter of the gasket does not protrude to inner piping. (Refer to Table 3.3.6)

(1) Mounting Direction

Please mount the Magnetic Flowmeter matching the flow direction of the fluid to be measured with the direction of the arrow mark on the flowmeter.

IMPORTANT

If it is impossible to match the direction, please never remodel by changing direction of the terminal box. In case the measuring fluid flows against the arrow direction, please refer to the section 5.3.6 Reversing Flow Direction.

(2) Mounting Centering Devices

To keep concentricity of the Flow Tube with pipes, please mount centering devices on the Mini-Flanges of the Flow Tube. Please give attention to the nominal diameter and flange rating of the centering devices.

3-4 |

IM 1E10B0-01E |

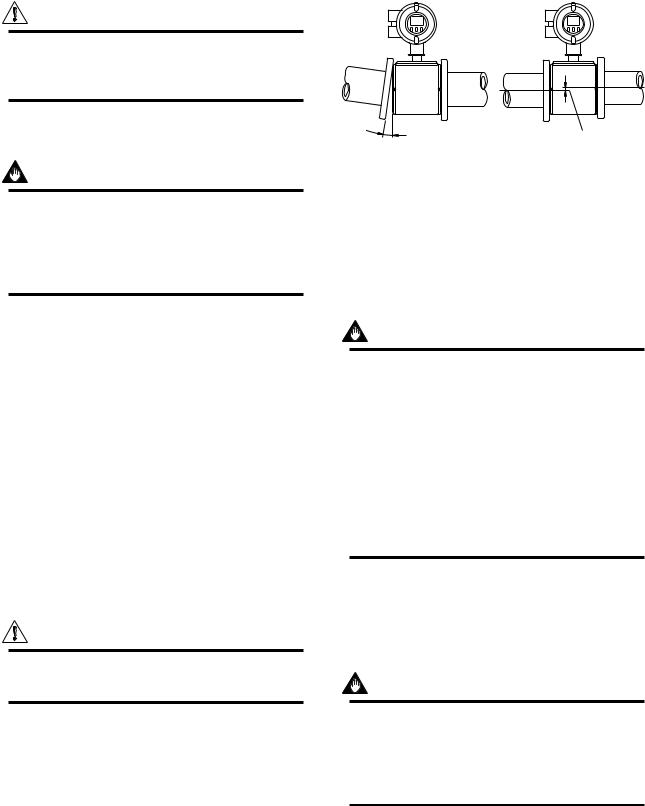

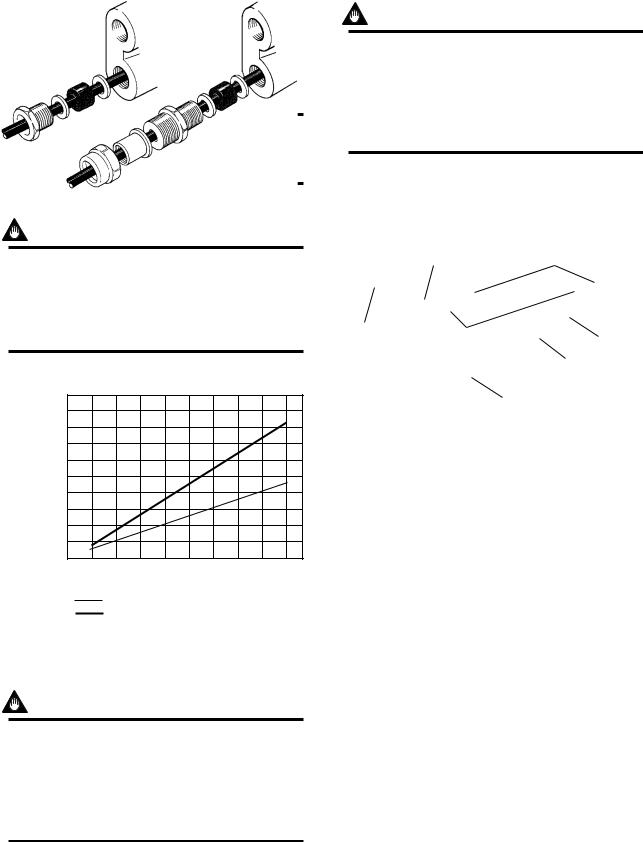

(3) Positioning Flow Tube

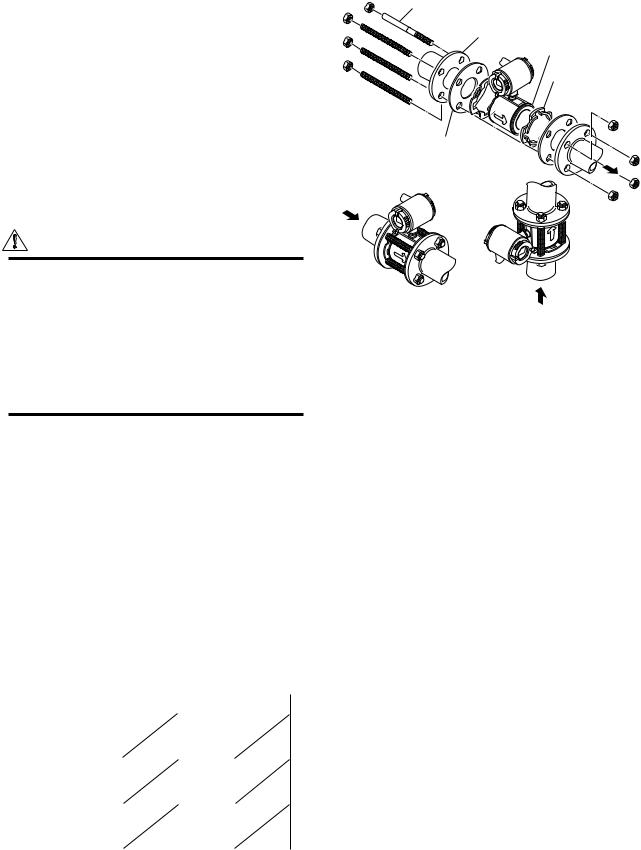

Please pass two through-bolts to adjacent holes of both flanges and mount the Flow Tube, and pass other through-bolts to other holes. (Refer to Figure 3.3.1) In case stud type of through-bolts are used, position them coming in contact centering devices with thread of bolts.

(4) Tightening Nuts

Please tighten the bolts according to Torque Values in Table 3.3.1. In case of PVC piping, please select optional code /FRG, use rubber gasket and tighten with the torque value in Table 3.3.2.

CAUTION

As the lining material is Fluorocarbon PFA, it is possible that nuts may loose by its character as time passes. Please tighten the nuts regularly.

Please be sure to tighten the bolts following prescribed torque values. Please tighten the flange bolts diagonally with the same torque values, step by step up to the prescribed torque value.

3. INSTALLATION

Through-Bolt  and nut

and nut

Gasket

Please use appropriate bolts and nuts according to process connection.

Flange

Mini-Flange

Centering Device 2-piece

Horizontal Mounting |

Vertical Mounting |

F0310.EPS |

Figure 3.3.1 Mounting Procedure (Size: 15 mm(0.5in) to 40 mm(1.5in))

Table 3.3.1 Tightening Torque Values for Metal Piping in N-m{kgf-cm}[in-lbf]

Size mm(inch) |

JIS 10K |

JIS 20K |

ANSI 150 |

|

ANSI 300 |

DIN PN40 |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15(0.5) |

4.5 |

- |

6.5 |

4.5 |

- 6.5 |

|

5.0 |

- 7.0 |

|

5.0 |

- 7.0 |

5.0 |

- 6.5 |

|

|||

|

{46 |

- |

66} |

{46 |

- 66} |

|

{51 |

- 71} |

|

{51 |

- 71} |

{51 |

- 66} |

|

|||

|

[40 |

- |

58] |

[40 |

- 58] |

|

[44 |

- 62] |

|

[44 |

- 62] |

[44 |

- 58] |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25(1) |

14.5 |

- |

19.0 |

14.5 |

- 19.0 |

|

12.0 |

- 15.0 |

|

14.5 |

- 19.0 |

12.5 |

- 14.0 |

|

|||

|

{148 |

- |

194} |

{148 |

- 194} |

|

{122 |

- 153} |

|

{148 |

- 194} |

{128 |

- 143} |

|

|||

|

[128 |

- |

168] |

[128 |

- 168] |

|

[106 |

- 133] |

|

[128 |

- 168] |

[111 |

- 124] |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40(1.5) |

26.0 |

- |

31.0 |

26.0 |

- 31.0 |

|

22.0 |

- 25.0 |

|

30.0 |

- 37.0 |

28.5 |

- 31.0 |

|

|||

|

{265 |

- |

316} |

{265 |

- 316} |

|

{224 |

- 255} |

|

{311 |

- 377} |

{291 |

- 316} |

|

|||

|

[230 - 274] |

[230 - 274] |

|

[195 - 221] |

|

[270 - 327] |

[252 - 274] |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

*Please use compressed non-asbestos fiber gasket, PTFE gasket or the gasket which has equal elasticity. |

T0301.EPS |

||||||||||||||||

Table 3.3.2 |

Tightening Torque Values for PVC Piping in N-m{kgf-cm}[in-lbf] |

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Size mm(inch) |

JIS 10K |

|

JIS 20K |

ANSI 150 |

|

ANSI 300 DIN PN40 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15(0.5) |

1.3 |

|

|

|

|

|

1.3 |

|

|

|

1.3 |

|

|

|

|

|

|

|

{13} |

|

|

|

|

|

{13} |

|

|

|

{13} |

|

|

|

|

|

|

|

[12] |

|

|

|

|

|

[12] |

|

|

|

[12] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25(1) |

3.5 |

|

|

|

|

|

2.8 |

|

|

|

2.7 |

|

|

|

|

|

|

|

{36} |

|

|

|

|

|

{29} |

|

|

|

{28} |

|

|

|

|

|

|

|

[31] |

|

|

|

|

|

[25] |

|

|

|

[24] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40(1.5) |

5.7 |

|

|

|

|

|

4.6 |

|

|

|

5.7 |

|

|

|

|

|

|

|

{58} |

|

|

|

|

|

{47} |

|

|

|

{58} |

|

|

|

|

|

|

|

[50] |

|

|

|

|

|

[41] |

|

|

|

[50] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

*Please select optional code /FRG and use rubber gasket or others which has equal elasticity. |

T0302.EPS |

|

|||||||||||||||

3-5 |

IM 1E10B0-01E |

3.3.2Nominal Diameter 50 mm(2in) to 200 mm(8in) Wafer Type

IMPORTANT

Please use appropriate bolts and nuts according to process connection. In case stud type of through bolts are used, be sure outside diameter of a shank is smaller than a thread ridge’s one. Please use compressed non-asbestos fiber gasket, PTFE gasket or the gasket which has equal elasticity. In case of optional code/FRG, please use rubber gasket or others which has equal elasticity. Be sure the inner diameter of the gasket does not protrude to inner piping. (Refer to Table 3.3.6)

(1) Mounting Direction

Please mount the Magnetic Flowmeter matching the flow direction of the fluid to be measured with the direction of the arrow mark on the flowmeter.

IMPORTANT

If it is impossible to match the direction, please never remodel to change direction of the terminal box. In case the measuring fluid flows against the arrow direction, please refer to the section 5.3.6 Reversing Flow Direction.

3. INSTALLATION

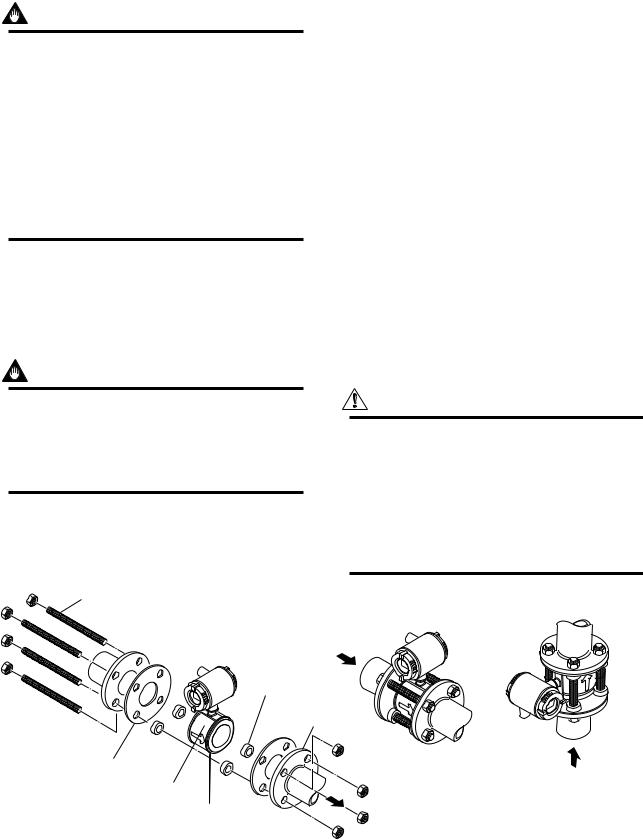

(2) Mounting Centering Devices

To keep concentricity between the Flow Tube and pipes, centering devices must be used. Pass two through-bolts through the four centering devices (two for each) and lower adjacent holes of both flanges. (Refer to Figure 3.3.2)

Please give attention to the nominal size and flange ratings of the centering devices. (Refer to Table 3.3.5)

(3) Positioning Flow Tube

Position the Flow Tube coming in contact four centering devices with Mini-Flanges. At this time, pay attention to avoid four centering devices come in contact with Housing. In case stud type of throughbolts are used, position them coming in contact four centering devices with thread of the bolts. (Refer to Figure 3.3.2) After positioning the Flow Tube, pass remaining through-bolts to remaining holes.

(4) Tightening Nuts

Please tighten the bolts according to Torque Values in Table 3.3.3. In case of PVC piping, please select optional code/FRG, use rubber gasket and tighten with the torque value in Table 3.3.4.

CAUTION

As the lining material is Fluorocarbon PFA, it is possible that nuts loose by its character as time passes. Please tighten the nuts regularly.

Please be sure to tighten the bolts following prescribed torque values. Please tighten the flange bolts diagonally with the same torque values, step by step up to the prescribed torque value.

Through-Bolt

and nut

Gasket

Please use appropriate bolts and nuts according to process connection.

Centering Device

4-piece

Flange

Horizontal Mounting |

Vertical Mounting |

Housing

Mini-Flange

F0311.EPS

Figure 3.3.2 Mounting Procedure (Size: 50mm (2in) to 200mm (8in))

3-6 |

IM 1E10B0-01E |

|

|

|

|

|

|

|

|

|

|

|

|

|

3. INSTALLATION |

|

Table 3.3.3 |

Tightening Torque Values for Metal Piping in N-m{kgf-cm}[in-lbf] |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

Size mm(inch) |

JIS 10K |

JIS 20K |

ANSI 150 |

ANSI 300 |

DIN PN10 |

DIN PN16 |

DIN PN40 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50(2) |

35.0 |

- 39.5 |

16.5 |

- 19.5 |

35.0 |

- 39.5 |

16.5 |

- 19.5 |

|

|

|

39.0 - 39.5 |

|

|

|

{357 |

- 403} |

{168 |

- 199} |

{357 |

- 403} |

{168 |

- 199} |

|

|

|

{398 - 403} |

|

|

|

[310 |

- 350] |

[146 |

- 173] |

[310 |

- 350] |

[146 |

- 173] |

|

|

|

[345 - 350] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

80(3) |

27.5 |

- 32.5 |

33.0 |

- 41.0 |

60.0 |

- 65.5 |

32.0 |

- 39.0 |

|

27.5 |

- 32.5 |

|

|

|

|

{281 |

- 332} |

{337 |

- 418} |

{612 |

- 668} |

{326 |

- 398} |

|

{281 |

- 332} |

|

|

|

|

[243 |

- 288] |

[292 |

- 363] |

[531 |

- 580] |

[283 |

- 345] |

|

[243 |

- 288] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100(4) |

40.0 |

- 42.5 |

48.0 |

- 53.5 |

40.5 |

- 42.5 |

47.0 |

- 51.0 |

|

40.0 |

- 42.5 |

|

|

|

|

{408 |

- 434} |

{490 |

- 546} |

{413 |

- 434} |

{479 |

- 520} |

|

{408 |

- 434} |

|

|

|

|

[354 |

- 376] |

[425 |

- 473] |

[358 |

- 376] |

[416 |

- 451] |

|

[354 |

- 376] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

150(6) |

65.0 |

- 94.0 |

43.0 |

- 68.0 |

68.0 - 100.0 |

41.0 |

- 60.0 |

|

65.0 |

- 94.0 |

|

|

|

|

|

{663 |

- 959} |

{439 |

- 694} |

{694 - 1020} |

{418 |

- 612} |

|

{663 |

- 959} |

|

|

|

|

|

[575 |

- 832] |

[381 |

- 602] |

[602 - 885] |

[363 |

- 531] |

|

[575 |

- 832] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

200(8) |

57.0 |

- 84.0 |

61.0 |

- 92.0 |

69.0 - 101.0 |

65.0 |

- 93.0 |

94.0 - 125.0 |

58.0 |

- 84.0 |

|

|

|

|

|

{581 |

- 857} |

{622 |

- 938} |

{704 - 1030} |

{663 |

- 949} |

{959 - 1275} |

{592 |

- 857} |

|

|

|

|

|

[504 |

- 743] |

[540 |

- 814] |

[611 - 894] |

[575 |

- 823] |

[832 - 1106] |

[513 |

- 743] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*Please use compressed non-asbestos fiber gasket, PTFE gasket or the gasket which has equal elasticity.

T0303.EPS

Table 3.3.4 Tightening Torque Values for PVC Piping in N-m{kgf-cm}[in-lbf]

Size mm(inch) |

JIS 10K |

JIS 20K |

ANSI 150 |

ANSI 300 |

DIN PN10 |

DIN PN16 |

DIN PN40 JIS G3451 |

|

|

|

|

|

|

|

F12(75M) |

|

|

|

|

|

|

|

|

50(2) |

8.2 |

|

8.2 |

|

|

|

8.2 |

|

{84} |

|

{84} |

|

|

|

{84} |

|

[73] |

|

[73] |

|

|

|

[73] |

|

|

|

|

|

|

|

|

80(3) |

6.2 |

|

12.4 |

|

|

6.2 |

12.3 |

|

{63} |

|

{127} |

|

|

{63} |

{126} |

|

[55] |

|

[110] |

|

|

[55] |

[109] |

|

|

|

|

|

|

|

|

100(4) |

8 |

|

8.1 |

|

|

8 |

16.1 |

|

{82} |

|

{83} |

|

|

{82} |

{164} |

|

[71] |

|

[72] |

|

|

[71] |

[142] |

150(6) |

19.8 |

|

18.9 |

|

|

19.8 |

21.6 |

|

{202} |

|

{193} |

|

|

{202} |

{220} |

|

[175] |

|

[167] |

|

|

[175] |

[191] |

200(8) |

17.5 |

|

25.1 |

|

26.2 |

17.5 |

28.7 |

|

{179} |

|

{256} |

|

{267} |

{179} |

{293} |

|

[155] |

|

[222] |

|

[232] |

[155] |

[254] |

|

|

|

|

|

|

|

|

*Please select optional code /FRG and use rubber gasket or others which has equal elasticity.

Table 3.3.5 Centering Device Identification

Size |

JIS |

JIS |

ANSI |

ANSI |

DIN PN |

DIN PN |

DIN PN |

|

10K |

20K |

150 |

300 |

10 |

16 |

40 |

||

|

||||||||

|

|

|

|

|

|

|

|

|

50(2) |

B |

B |

B |

F |

- |

- |

F |

|

|

|

|

|

|

|

|

|

|

80(3) |

B |

F |

F |

C |

- |

G |

- |

|

|

|

|

|

|

|

|

|

|

100(4) |

B |

F |

C |

H |

- |

F |

- |

|

|

|

|

|

|

|

|

|

|

150(6) |

K |

L |

K |

M |

- |

K |

- |

|

|

|

|

|

|

|

|

|

|

200(8) |

K |

L |

L |

M |

K |

K |

- |

|

|

|

|

|

|

|

|

|

T0305.EPS

* Each Centering Device is engraved a character as identification.

Table 3.3.6 Earth Ring Inside Diameter

|

T0304.EPS |

|

Unit:mm(inch) |

|

|

Size |

Earth Ring inside diameter |

|

|

15(0.5) |

15(0.59) |

25(1) |

28(1.10) |

40(1.5) |

41(1.61) |

50(2) |

53(2.09) |

80(3) |

81(3.19) |

100(4) |

102(4.02) |

150(6) |

146.1(5.75) |

200(8) |

193.6(7.62) |

|

|

*Please ensure that the I.D. of the gasket does not protrude into the I.D. of the Earth Ring. (This dimension is also applied when no earth ring is used.)

T0306.EPS

3-7 |

IM 1E10B0-01E |

3.3.3Nominal Diameter 15 mm (0.5in) to 200 mm (8in) Flange Type

IMPORTANT

Please use appropriate bolts and nuts according to process connection. Please use compressed non-asbestos fiber gasket, PTFE gasket or the gasket which has equal elasticity. In case of optional code /FRG, please use rubber gasket or others which has equal elasticity. Be sure the inner diameter of the gasket does not protrude to inner piping. (Refer to Table 3.3.6)

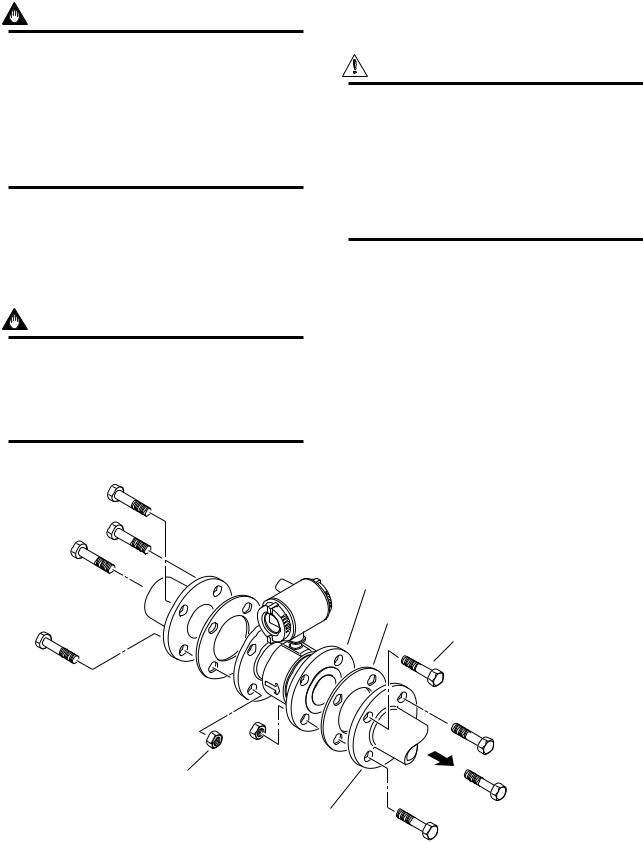

(1) Mounting Direction

Please mount the Magnetic Flowmeter matching the flow direction of the fluid to be measured with the direction of the arrow mark on the flowmeter.

IMPORTANT

3. INSTALLATION

(2) Tightening Nuts

Please tighten the bolts according to Torque Values in Table 3.3.7. In case of PVC piping, please select optional code /FRG, use rubber gasket and tighten with the torque value in table 3.3.8.

CAUTION

As the lining material is Fluorocarbon PFA, it is possible that bolts loose by its character as time passes. Please tighten the nuts regularly. Please be sure to tighten the bolts following prescribed torque values. Please tighten the flange bolts diagonally with the same torque values, step by step up to the prescribed torque value.

If it is impossible to match the direction, please never remodel to change direction of the terminal box. In case the measuring fluid flows against the arrow direction, please refer to the section 5.3.6 Reversing Flow Direction.

Please use appropriate bolts and nuts according to process connection.

Flange

(Flow Tube)

Gasket

Bolt

Nut

Flange (Piping side)

F0312.EPS

Figure 3.3.3 Mounting Procedure (Size: 15 mm (0.5in) to 200 mm (8in))

3-8 |

IM 1E10B0-01E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. INSTALLATION |

|

Table 3.3.7 |

Tightening Torque Values for Metal Piping in N-m{kgf-cm} [in-lbf] |

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Size mm |

|

JIS 10K |

|

JIS 20K |

|

ANSI 150 |

|

ANSI 300 |

DIN PN10 |

|

DIN PN16 |

|

DIN PN40 |

JIS F12(75M) |

|

||||||||

(inch) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15(0.5) |

|

4.5 |

- |

6.5 |

|

|

4.5 |

- 6.5 |

|

4.5 - 7.0 |

|

4.5 |

- 7.0 |

|

|

|

|

|

|

4.5 - 6.5 |

|

|

|

|

|

{46 |

- |

66} |

|

{46 |

- 66} |

|

{46 - 71} |

|

{46 |

- 71} |

|

|

|

|

|

|

{46 - 66} |

|

|

||

|

|

[40 |

- |

58] |

|

|

[40 |

- 58] |

|

[40 - 62] |

|

[40 |

- 62] |

|

|

|

|

|

|

[40 - 58] |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25(1) |

13.5 |

- |

19.0 |

|

13.5 |

- 19.0 |

|

11.5 - 15.0 |

|

14.0 |

- 19.0 |

|

|

|

|

|

|

11.5 - 14.0 |

|

|

|||

|

{138 |

- |

194} |

|

{138 |

- 194} |

|

{117 - 153} |

|

{143 |

- 194} |

|

|

|

|

|

{117 - 143} |

|

|

||||

|

[119 |

- |

168] |

|

[119 |

- 168] |

|

[102 - 133] |

|

[124 |

- 168] |

|

|

|

|

|

[102 - 124] |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40(1.5) |

24.0 |

- |

31.0 |

|

24.0 |

- 31.0 |

|

20.0 - 25.0 |

|

28.0 |

- 37.0 |

|

|

|

|

|

|

25.5 - 31.0 |

|

|

|||

|

{245 |

- |

316} |

|

{245 |

- 316} |

|

{204 - 255} |

|

{286 |

- 377} |

|

|

|

|

|

{260 - 316} |

|

|

||||

|

[212 |

- |

274] |

|

[212 |

- 274] |

|

[177 - 221] |

|

[248 |

- 327] |

|

|

|

|

|

[226 - 274] |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50(2) |

31.0 |

- |

39.5 |

|

15.0 |

- 19.5 |

|

32.0 - 39.5 |

|

15.0 |

- 19.5 |

|

|

|

|

|

|

34.5 - 39.5 |

|

|

|||

|

{316 |

- |

403} |

|

{153 |

- 199} |

|

{326 - 403} |

|

{153 |

- 199} |

|

|

|

|

|

{352 - 403} |

|

|

||||

|

[274 |

- |

350] |

|

[133 |

- 173] |

|

[283 - 350] |

|

[133 |

- 173] |

|

|

|

|

|

[305 - 350] |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

80(3) |

23.5 |

- |

32.5 |

|

28.5 |

- 41.0 |

|

53.5 - 65.5 |

|

28.5 - 39.0 |

|

|

|

23.5 - 32.5 |

|

|

|

51.0 - 65.5 |

|

||||

|

{240 |

- |

332} |

|

{291 |

- 418} |

|

{546 - 668} |

|

{291 - 398} |

|

|

|

{240 - 332} |

|

|

|

{520 - 668} |

|

||||

|

[208 |

- |

288] |

|

[252 |

- 363] |

|

[473 - 580] |

|

[252 - 345] |

|

|

|

[208 - 288] |

|

|

|

[451 - 580] |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

100(4) |

32.5 |

- |

42.5 |

|

40.0 |

- 53.5 |

|

34.5 - 42.5 |

|

40.0 |

- 51.0 |

|

|

|

33 - 42.5 |

|

|

|

72.0 - 85.0 |

|

|||

|

{332 |

- |

434} |

|

{408 |

- 546} |

|

{352 - 434} |

|

{408 - 520} |

|

|

|

{337 - 434} |

|

|

|

{734 - 867} |

|

||||

|

[288 |

- |

376] |

|

[354 |

- 473] |

|

[305 - 376] |

|

[354 - 451] |

|

|

|

[292 - 376] |

|

|

|

[637 - 752] |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

150(6) |

65.0 |

- |

94.0 |

|

43.0 |

- 68.0 |

|

68.0 - 100.0 |

|

41.0 |

- 60.0 |

|

|

|

65.0 - 94.0 |

|

|

|

68.0 - 100.0 |

|

|||

|

{663 |

- |

959} |

|

{439 |

- 694} |

|

{694 - 1020} |

{418 - 612} |

|

|

|

{663 - 959} |

|

|

|

{694 - 1020} |

|

|||||

|

[575 |

- |

832] |

|

[381 |

- 602] |

|

[602 - 885] |

|

[363 - 531] |

|

|

|

[575 - 832] |

|

|

|

[602 - 885] |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

200(8) |

57.0 |

- |

84.0 |

|

61.0 |

- 92.0 |

|

69.0 - 101.0 |

|

65.0 |

- 93.0 |

|

94.0 - 125.0 |

|

58.0 - 84.0 |

|

|

|

69.0 - 101.0 |

|

|||

|

{581 |

- |

857} |

|

{622 |

- 938} |

{704 - 1030} |

{663 - 949} |

|

{959 - 1275} |

|

{592 - 857} |

|

|

|

{704 - 1030} |

|

||||||

|

[504 - 743] |

|

[540 - 814] |

|

[611 - 894] |

|

[575 - 1106] |

|

[832 - 1106] |

|

[513 - 743] |

|

|

|

[611 - 894] |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

* Please use compressed no-asbestos fiber gasket, PTFE gasket or the gasket which has equal elasticity. |

|

|

T0307.EPS |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Table 3.3.8 |

Tightening Torque Values for PVC Piping in N-m{kgf-cm} [in-lbf] |

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

Size mm |

JIS 10K |

|

JIS 20K |

ANSI 150 ANSI 300 |

DIN PN10 |

|

DIN PN16 DIN PN40 |

JIS G3451 |

|

|

|

||||||||||||

(inch) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F12(75M) |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

15(0.5) |

|

1.3 |

|

|

|

|

1.3 |

|

|

|

|

|

|

1.3 |

|

|

|

|

|

|

|||

|

|

{13} |

|

|

|

|

{13} |

|

|

|

|

|

|

{13} |

|

|

|

|

|

|

|||

|

|

[12] |

|

|

|

|

[12] |

|

|

|

|

|

|

[12] |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

25(1) |

|

3.5 |

|

|

|

|

2.8 |

|

|

|

|

|

|

2.7 |

|

|

|

|

|

|

|||

|

|

{36} |

|

|

|

|

{29} |

|

|

|

|

|

|

{28} |

|

|

|

|

|

|

|||

|

|

[31] |

|

|

|

|

[25] |

|

|

|

|

|

|

[24] |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

40(1.5) |

|

5.7 |

|

|

|

|

4.6 |

|

|

|

|

|

|

5.7 |

|

|

|

|

|

|

|||

|

|

{58} |

|

|

|

|

{47} |

|

|

|

|

|

|

{58} |

|

|

|

|

|

|

|||

|

|

[50] |

|

|

|

|

[41] |

|

|

|

|

|

|

[50] |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

50(2) |

|

8.2 |

|

|

|

|

8.2 |

|

|

|

|

|

|

8.2 |

|

|

|

|

|

|

|||

|

|

{84} |

|

|

|

|

{84} |

|

|

|

|

|

|

{84} |

|

|

|

|

|

|

|||

|

|

[73] |

|

|

|

|

[73] |

|

|

|

|

|

|

[73] |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

80(3) |

|

6.2 |

|

|

|

|

12.4 |

|

|

|

|

|

6.2 |

|

|

12.3 |

|

|

|

|

|||

|

|

{63} |

|

|

|

|

{127} |

|

|

|

|

{63} |

|

|

{126} |

|

|

|

|

||||

|

|

[55] |

|

|

|

|

[110] |

|

|

|

|

[55] |

|

|

[109] |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

100(4) |

|

8 |

|

|

|

|

|

8.1 |

|

|

|

|

|

8 |

|

|

16.1 |

|

|

|

|

||

|

|

{82} |

|

|

|

|

{83} |

|

|

|

|

|

{82} |

|

|

{164} |

|

|

|

|

|||

|

|

[71] |

|

|

|

|

[72] |

|

|

|

|

|

[71] |

|

|

[142] |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

150(6) |

|

19.6 |

|

|

|

|

18.8 |

|

|

|

|

|

19.6 |

|

|

21.5 |

|

|

|

|

|||

|

|

{200} |

|

|

|

{192} |

|

|

|

|

{200} |

|

|

{219} |

|

|

|

|

|||||

|

|

[173] |

|

|

|

|

[166] |

|

|

|

|

[173] |

|

|

[190] |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

200(8) |

|

17.5 |

|

|

|

|

25.1 |

|

|

26.2 |

|

17.5 |

|

|

28.7 |

|

|

|

|

||||

|

|

{179} |

|

|

|

{256} |

|

{267} |

|

{179} |

|

|

{293} |

|

|

|

|

||||||

|

|

[155] |

|

|

|

|

[222] |

|

[232] |

|

[155] |

|

|

[254] |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||||||||||||||||

* Please select optional code /FRG and use rubber gasket or others which has equal elasticity. |

T0308.EPS |

|

|

||||||||||||||||||||

3-9 |

IM 1E10B0-01E |

3.4 Wiring Precautions

CAUTION

Confirm that all connections are corrected before applying power to the instrument. Improper wiring may damage the flowmeter.

NOTE

The terminal box and display cover is locked by special screw. In case of opening the terminal box cover, please use the Hexagonal Wrench attached.

CAUTION

Be sure to lock the cover with the special screw using the Hexagonal Wrench attached after tightening the terminal box cover.

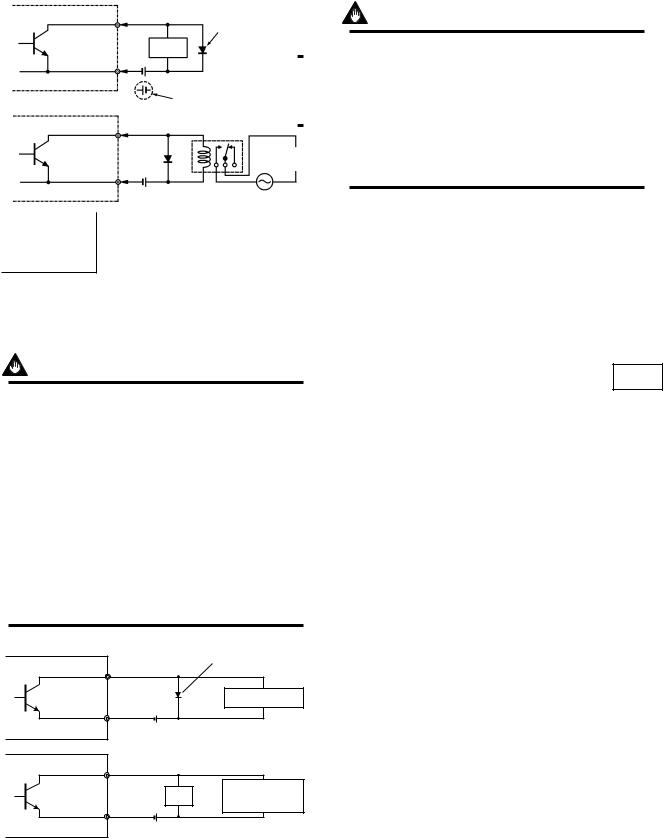

The external signal wirings are connected into the terminal inside the converter. Please connect to each terminal (Please refer to Figure 3.4.1) by taking off a cover backside the converter.

PLS/ALM CUR POWER

L N G

Terminal |

Description |

|

|

|

Symbols |

|

|

||

|

|

|

||

|

Protective grounding |

|

|

|

POWER N– |

Power Supply |

|

|

|

POWER L+ |

|

|

||

|

|

|

||

CUR+ |

Current Output 4 to 20mA DC |

|

|

|

CUR– |

Output |

|

||

|

Power |

|||

PLS/ALM+ |

Pulse, alarm or status output |

|||

Cable |

Cable |

|||

PLS/ALM– |

||||

|

F0313.EPS

Figure 3.4.1 WWiring

3.4.1Protective Grounding

CAUTION

Please be sure to connect protective grounding of ADMAG SE with cable of 2mm2 or larger cross section in order to avoid the electrical shock to the operators and maintenance engineers and prevent the influence of external noise. And further connect the grounding wire to the  mark (100Ω or less).

mark (100Ω or less).

3. INSTALLATION

3.4.2General Precautions

Please give attention to the followings in wiring.

CAUTION

•Please pay attention to avoid the cable is bended excessively.

•Please do not connect cables outdoors in case of rain to prevent damages from dew formation and to keep insulation inside the terminal box of the flowmeter.

•The all cable ends are to be provided with round crimp-on terminal.

•The power cables and output signal cables must be routed in separate steel conduit tubes or flexible tubes.(except 4-core 24VDC cable wiring.)

•When waterproof glands or union equipped waterproof glands are used, the glands must be properly tightened to keep the box watertight.

•Please install a external switch or circuit breaker as a means of power off (capacitance; 15A, conform to IEC947-1 and IEC947-3). The preferable location is either near the instrument or other places to easy operation. Furthermore, please indicate “power off equipment” on the those external switch or circuit breaker.

•Please be sure to fully tighten the terminal box cover before the power is turned on. After tightening the covers, please be sure to fix it withh the special screw using a hexagonal wrench attached.

•Please be sure to turn off the power before opening the covers.

•In case of DC power supply, a plug is attached. When 4-core cable is used, please put that plug into unused electrical connection port.

3.4.3Power and Output Cables

Power Cable:

•Crimp-on Terminal

•Green/Yellow covered conductors shall be used only for connection to PROTECTIVE CONDUCTOR TERMINALS.

•Conform to IEC277, IEC245 or equivalent national authorization.

Output Cable:

• Please use Polyvinyl chloride insulated and sheathed control cables (JIS C3401) or Polyvinyl chloride insulated and sheathed portable power cables (JIS C3312) or equivalents.

3-10 |

IM 1E10B0-01E |

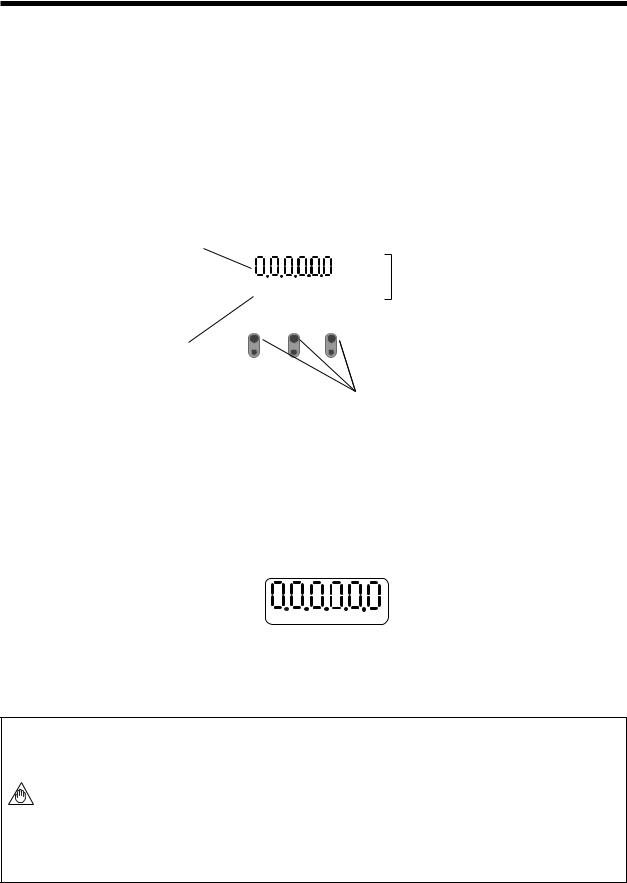

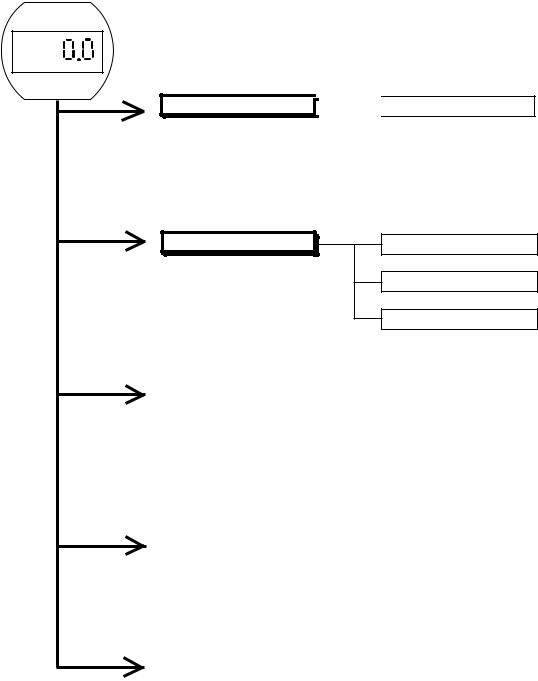

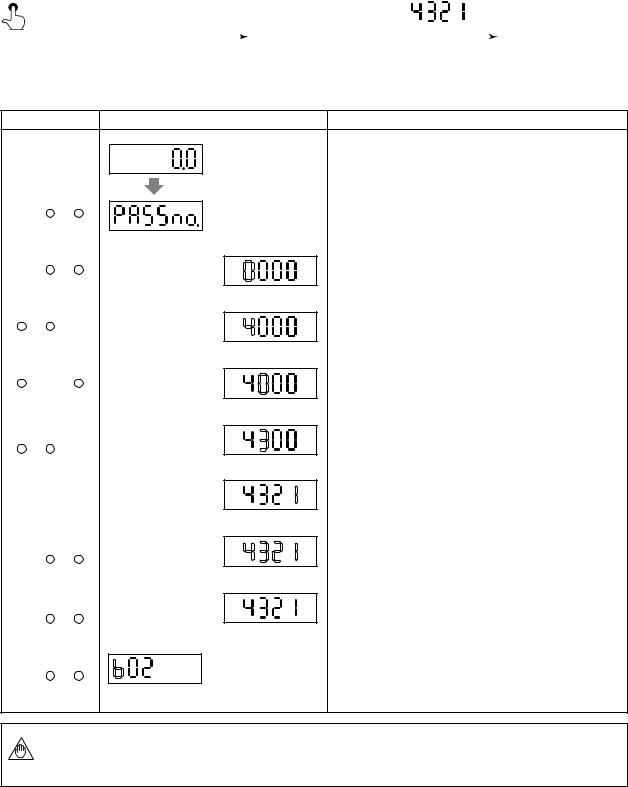

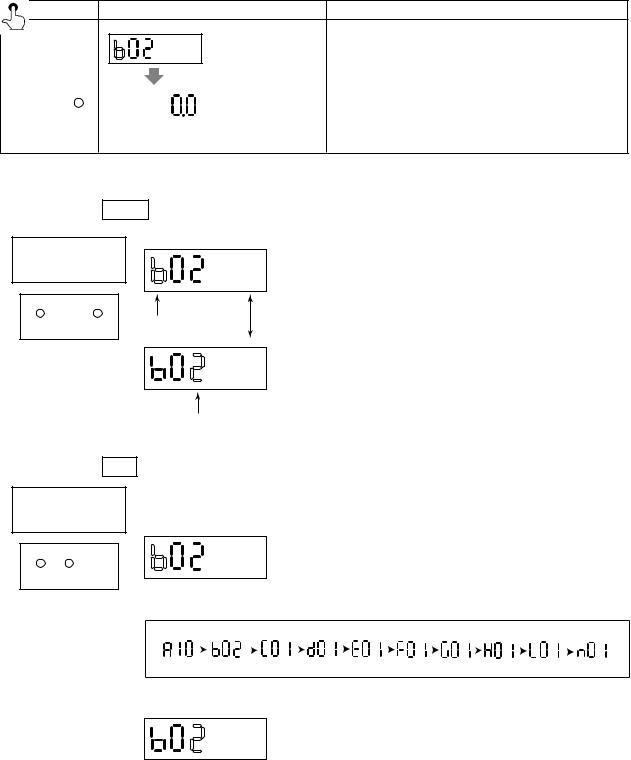

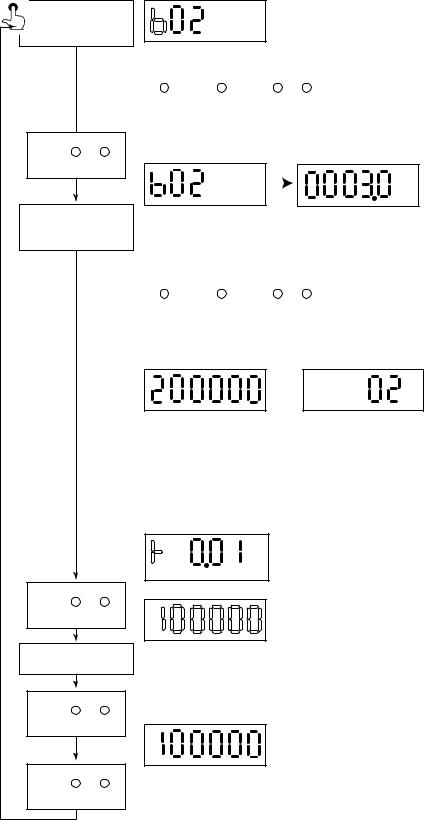

Outer Diameter: