Yaskawa G7 User Manual

Electronic Lineshaft

with Alignment

G7 Drive Software

Technical Manual

Software Number: VSG13311X, Drive Models: CIMR-G7UXXXXXX-064, CIMR-G7UXXXXXX-065

Document Number: TM.G7SW.064, Date: 03/31/09, Rev: 09-03

This document is intended to provide proper installation and use of the Yaskawa drive with custom software. This

document is a supplement to the standard drive technical manual. It describes the effects on the drive parameters

and functions with the software installed. Read and understand this document and the standard drive technical

manuals before attempting to install, adjust, operate, inspect, or maintain the drive. Observe all cautions and

warnings in this document and the standard drive technical manuals. Custom software is written to add

functionality to a standard AC drive to enhance or enable use in a specific application. The software is loaded to

the flash ROM area of the control board, and replaces the standard drive software. Custom software can add new

functions, modify standard functions, or even inhibit standard functions. It can be used to modify display text or

parameter names. Custom software is usually loaded to the drive before delivery. The control board and drive

nameplate are assigned unique part numbers and the software is registered, archived, an d retrievable.

When seeking support for a drive with custom software, it is imperative to provide the unique part number shown

on the drive nameplate. The software has been flashed to the control board memory and the operation of

parameters, functions, and monitors are different than the standard drive software, as described herein.

1.0 Overview

The Electronic Lineshaft (ELS) function allows a drive to precisely follow a master encoder (PG) signal in

speed, direction, and phase. The follower can match its position (phase angle) to the master within several

quadrature encoder counts. The function is used in applications where the machinery being driven requires

two mechanically isolated, moving parts to maintain a constant position relationship. The gear ratio between

the master and the follower is infinitely adjustable. In addition, a gear ratio adjustment (“draw”) can be added

to the speed reference via parameter, analog input, multi-function input, MOP, or network communication.

The drive can also be run in a pure speed follower mode for applications that do not require matched position,

only velocity following.

Both the master and follower encoder signals are fed into the follower drive’s dual encoder (PG) option card.

The master encoder speed is multiplied by the programmed gear ratio to determine the speed reference. The

error between the master and follower position is determined. This is fed into a PI controller, which is in turn

added to the previously calculated speed reference. When the drive is configured as a speed follower, the

position regulator is disabled.

A signed-run mode is also available in ELS. When P1-01 = 5 (Electronic Line Shaft - Sign Run), ELS

functions identically to standard ELS (P1-01 = 4), with the following difference:

• When a reverse run command is given through the terminal S2 digital input, the follower will match the

velocity and phase of the master, but in the opposite direction. If the master runs in the forward direction,

the follower will run in reverse direction. If the master runs in the reverse direction, the follower will run in

the forward direction.

• When a forward run command is present through terminal S1, the follower will run in the same direction is

the master.

The Alignment function allows the follower drive to maintain a phase angle with respect to 2 alignment inputs

(can be sensors or encoder marker pulses). The phase angle, quantified as the Displacement in follower

encoder counts, can be adjusted during run either through keypad, digital multi-function inputs, or network

communication. The phase angle is maintained by monitoring alignment inputs (pulses) from both the master

alignment input and follower alignment input and then measuring the follower encoder counts received

between the two alignment pulses.

The Alignment function is enabled through the Align by Pulse multi-function digital input. When enabled, the

drive will monitor the Z (marker) channel inputs on any of the dual channel encoder option cards.

Please note that the alignment inputs need not come directly from encoder marker pulse channels. However,

special external circuitry may be required to support other input types, such as proximity sensors. Also, the

inputs do not have to be of the same type. Refer to Section 3.0 (Limitations) for application details.

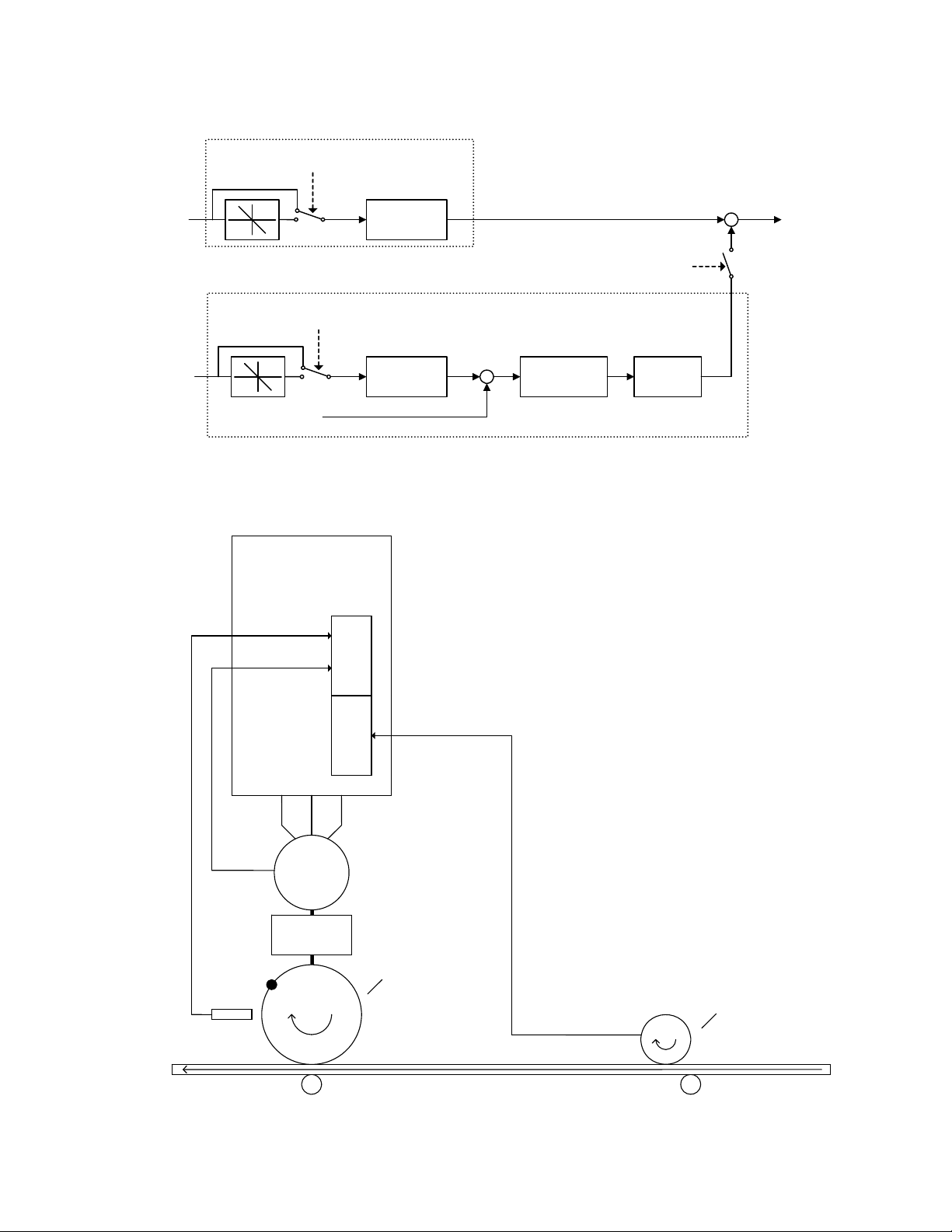

Figures 1 ~ 3 below give overview to the Electronic Lineshaft and Alignment functions.

Date: 03/31/09, Rev: 09-03 Page 2 of 30 TM.G7SW.064

A

A

Speed Calculation

ELS – Sign Mode Enabled

AND Reverse Run Command

Master Encoder

Master Encoder

Pulse Count

Proximity

Sensor for

Follower

Alignment

Speed

Input

+

+

Position Regulator

ELS – Sign Mode Enabled

AND Reverse Run Command

Follower Encoder

Pulse Count

Gear

Calculation

Gear

Calculation

ELS Mode Enabled OR

ELS – Sign Mode

Enabled

+

-

Position Error

Accumulator

PI

Controller

Figure 1: Simplified Block Diagram of the Electronic Lineshaft Function

G7 w/ ELS

PG-W2

Z

, B

Follower

Encoder

Feedback

Motor

Gear Box

Figure 2: Typical Connection Diagram of the Alignment Function

Ch 1

Ch 2

, B, Z

Follower

Machine

Section

Master

Encoder

Feedback

ith Marker

w

Pulse for

Master

Alignment

Input

Master

Machine

Section

Frequency

Reference

Date: 03/31/09, Rev: 09-03 Page 3 of 30 TM.G7SW.064

Input Channel

Monitor Output

Channel 1 Input

Channel 2 Input

Monitor Output

.

.

.

Channel 1 Input

Channel 2 Input

PG-X2

Pulse

Master Drive

PG-W2

Pulse

Follower Drive 1

PG-W2

Follower Drive n

G7

G7

.

.

.

G7

PG

M

PG

M

PG

M

Figure 3: Typical Connection Diagram for Basic Electronic Lineshaft

Date: 03/31/09, Rev: 09-03 Page 4 of 30 TM.G7SW.064

2.0 Changes from Standard Product

a. The Motor 2 Selection (H1-0X = 16) multi-function digital input function is deleted (only Motor 1 can be

used).

b. The kWh monitors (U1-29 and U1-30) are deleted.

c. Parameter E2-04 (Motor Poles) is available in all control modes (Advanced access level only for V/f and

Open Loop Vector).

d. The “User” access level and all of the associated “A2” parameters are deleted.

e. The follower drive uses acceleration and deceleration times of zero during standard Electronic Line Shaft

(P1-01 = 4, 5) and the Alignment function.

3.0 Limitations

a. For ELS modes (P1-01 = 4, 5), Flux Vector control mode must be used (A1-02 = 3).

b. For ELS modes (P1-01 = 4, 5), the gear ratio must be exactly expressed, including remainder, to prevent

phase drift (error). See section 5.0.

c. The Alignment function is available in Flux Vector control mode only (A1-02 = 3) and when P1-01 = 4 or 5

(ELS modes).

d. The Alignment function is only available in the forward direction.

e. The Alignment function is disabled when the motor speed is less than the DC Injection

Frequency (B2-01).

f. The alignment pulse from the master and the alignment pulse from the slave must be at a 1:1 ratio (the

software requires one follower alignment pulse for every one master alignment pulse).

g. The master alignment pulse must occur exactly once per master encoder revolution.

h. The proper encoder (PG) option card must be used based on the control mode and follower mode

selection. The table below shows the supported option cards for each configuration.

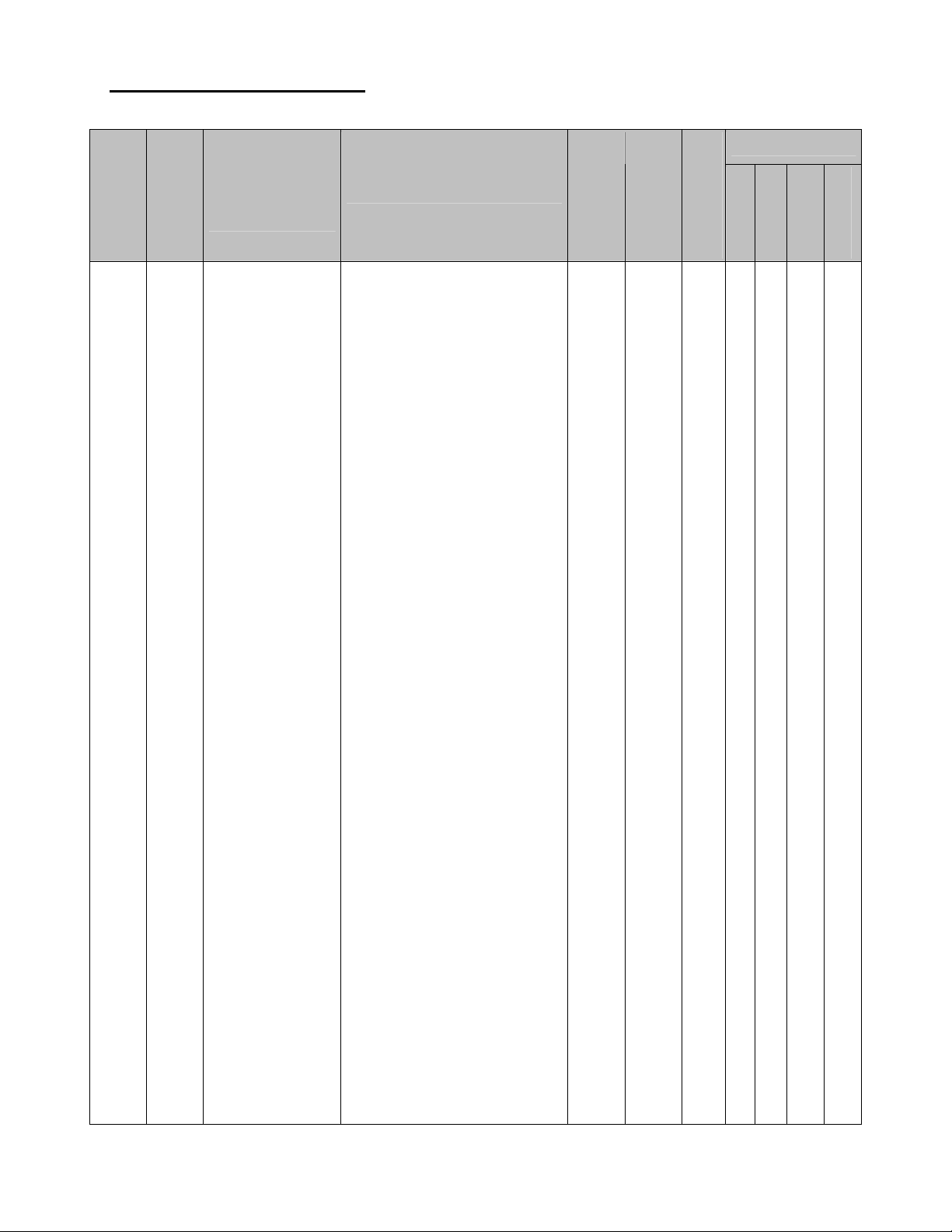

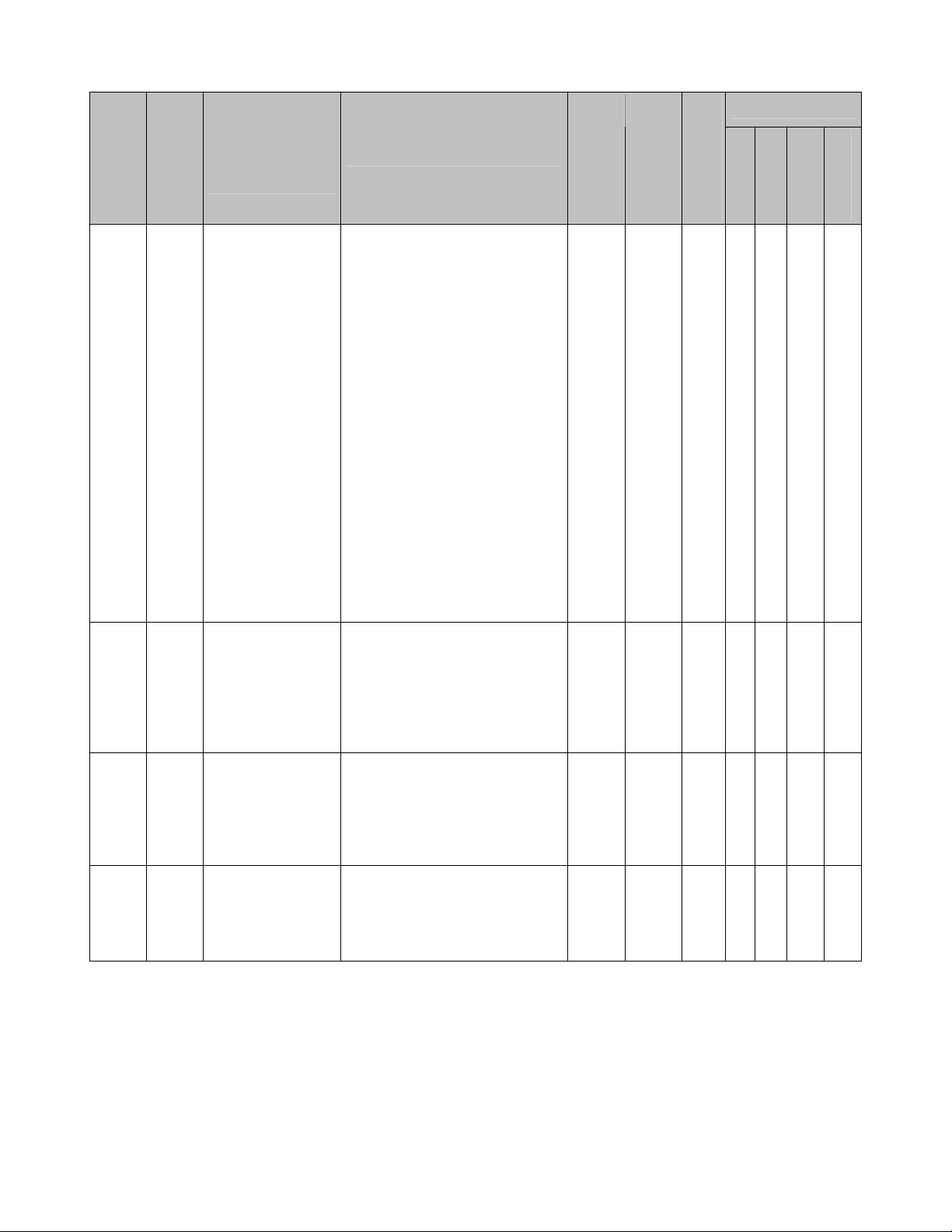

Encoder (PG) Option Card Selection

Control Mode P1-01 = 1, 2, 3 (Speed Follower) P1-01 = 4, 5 (ELS)

V/f w/ PG PG-W2, PG-Y2, PG-Z2

Open Loop Vector PG-B2, PG-T2, PG-X2, PG-W2, PG-Y2, PG-Z2

Flux Vector PG-W2, PG-Y2, PG-Z2

V/f PG-B2, PG-T2, PG-X2, PG-W2, PG-Y2, PG-Z2

PG-W2, PG-Y2, PG-Z2

Note: If the PG-W2 option is used, jumper HDR1 must be set to the “top” position

(using the 2 pins closest to the 4CN connector).

Date: 03/31/09, Rev: 09-03 Page 5 of 30 TM.G7SW.064

4.0 Related Parameters and Functions

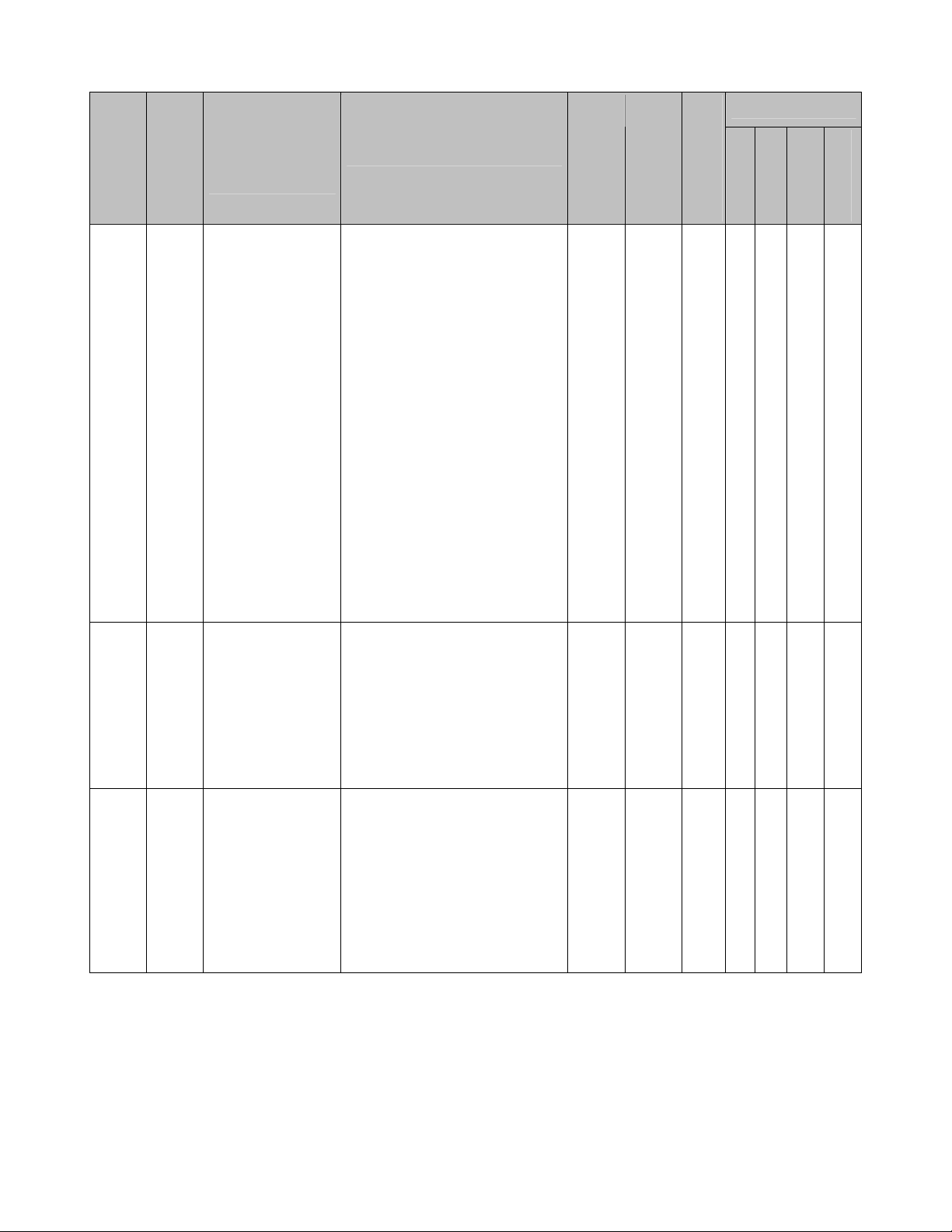

4.1 Parameters

Change During

Parameter

Number

Address

Modbus

Parameter Name

Digital Operator

Range

Description

Default

Run

Display

Selects the follower mode.

0: Disabled

Follower mode is disabled

and the follower drive runs

from the normal frequency

reference (B1-01).

1: Speed – Both Dir

The follower drive follows

the master encoder speed

in both directions.

2: Speed – One Dir

The follower drive follows

the master encoder speed

in the direction of the run

command only.

3: Speed – Abs Val

The follower drive follows

the master encoder speed

but ignores the master

encoder direction (motion is

always in the direction of

P1-01 600H

Follower Mode

Selection

Follower Mode

the run command).

4: Elec Line Shaft

The follower drive follows

the master encoder speed

0 ~ 5 0 No Q Q Q Q

and position (both

directions). Terminals S1 or

S2 can be used to issue the

run command. There is no

directional effect.

5: ELS – Sign Run

The follower drive follows

the master encoder speed

and position (both

directions). When a forward

run command is present

(terminal S1), the drive

follows the master in the

same direction. When a

reverse run command is

present (terminal S2), the

drive follows in the opposite

direction of the master.

Note: Settings 4 and 5 are

available only in the Flux

Vector Mode (A1-02 = 3).

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”, – = Not Available.

Control Mode *1

Open Loop

Vector 1, 2

V/f w/ PG

V/f

Flux Vector

Date: 03/31/09, Rev: 09-03 Page 6 of 30 TM.G7SW.064

4.1 Parameters (continued)

Parameter

Number

Address

Modbus

Parameter Name

Digital Operator

Display

Description

Range

Default

Change During

Run

Control Mode *1

Open Loop

Vector 1, 2

V/f w/ PG

V/f

Flux Vector

P1-02 601H

P1-03 602H

Master Encoder

PPR

Master PG PPR

Ratio Numerator

(Upper 4 Digits)

Ratio Num High

Sets the pulses per revolution

(PPR) of the master encoder

(PG).

Sets the upper 4 digits of the

primary gear ratio numerator.

See section 5.1.

20 ~

60,000

Pulses

0 ~

9999

1024 No Q Q Q Q

1000 Yes Q Q Q Q

Ratio

P1-04 603H

Denominator

(Upper 4 Digits)

Sets the upper 4 digits of the

primary gear ratio

denominator. See section 5.1.

0 ~

9999

1000 Yes Q Q Q Q

Ratio Den High

P1-05 604H

Ratio Numerator

(Lower 4 Digits)

Ratio Num Low

Sets the lower 4 digits of the

primary gear ratio numerator.

See section 5.1.

0 ~

9999

0 Yes A A A A

Ratio

Sets the lower 4 digits of the

primary gear ratio

denominator. See section 5.1.

0 ~

9999

0 Yes A A A A

P1-06 605H

Denominator

(Lower 4 Digits)

Ratio Den Low

Sets the numerator of the

secondary gear ratio. Active

when a multi-function digital

input is set to 81 (Ratio 2

Select) and the input is closed.

Sets the denominator of the

secondary gear ratio. Active

when a multi-function digital

input is set to 81 (Ratio 2

Select) and the input is closed.

1 ~

65,535

1 ~

65,535

1 Yes A A A A

1 Yes A A A A

P1-07 606H

P1-08 607H

Ratio 2

Numerator

Ratio 2 Num

Ratio 2

Denominator

Ratio 2 Den

Selects when the position error

accumulator is enabled in the

follower drive.

P1-09 608H

Position Error

Accumulation

Selection

Pos Accum

Select

0: Only During Run

Position error is only

calculated when the

follower drive is running.

1: Always

Position error is calculated

0 ~ 1 0 No – – – A

whenever power is applied

to the follower drive.

Note: ELS modes only.

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”, – = Not Available.

Date: 03/31/09, Rev: 09-03 Page 7 of 30 TM.G7SW.064

4.1 Parameters (continued)

Change During

Parameter

Number

Address

Modbus

Parameter Name

Digital Operator

Range

Description

Default

Run

Display

Selects the units used for the

follower drive Position Error

Monitor (U1-96).

0: Encoder Counts

Position error is displayed in

quadrature follower encoder

counts (cts).

1: Motor Revs

P1-10 609H

Position Units

Selection

Position Units

Position error is displayed in

follower motor revolutions

(0.001rev).

2: Motor Degrees

0 ~ 3 0 Yes – – – A

Position error is displayed in

follower motor degrees

(0.1°).

3: Motor Radians

Position error is displayed in

follower motor radians

(0.001rad).

Note: ELS modes only.

Sets the digital gear ratio

adjustment of the follower

drive. The gear ratio

adjustment is also influenced

by the analog, MOP and

communication gear ratio

-99.99

~

+99.99

%

0.00 Yes A A A A

P2-01 60AH

Digital Ratio

Adjustment

Digital RatioAdj

adjustments.

Sets the time for the MOP ratio

P2-02 60BH

MOP Adjust Time

MOP Adjust

Time

adjustment to change by

100.00% when the MOP

Adjust Increase or MOP Adjust

Decrease multi-function input

0.0 ~

6000.0

sec

50.0 Yes A A A A

is closed.

P2-03 60CH

Gear Ratio

Adjustment Ramp

Time

Ratio Adj Ramp

Sets the time for the composite

gear ratio adjustment of the

follower drive to change by

100.00%.

0.0 ~

6000.0

sec

10.0 Yes A A A A

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”, – = Not Available.

Control Mode *1

Open Loop

Vector 1, 2

V/f w/ PG

V/f

Flux Vector

Date: 03/31/09, Rev: 09-03 Page 8 of 30 TM.G7SW.064

4.1 Parameters (continued)

Change During

Parameter

Number

Address

Modbus

Parameter Name

Digital Operator

Range

Description

Default

Run

Display

Selects the advance/retard

functionality of the follower

drive.

0: Continuous

The follower will advance or

retard continuously while

the Advance Follower or

Retard Follower multifunction input is closed. P205 sets amount of

advance/retard encoder

counts per second.

1: Step

0 ~ 1 0 No – – – A

P2-04 60DH

Advance/Retard

Mode Selection

Adv/Ret Mode

Sel

The follower will advance or

retard by the amount set in

parameter P2-05 each time

the Advance Follower or

Retard Follower multifunction input is closed.

Note: ELS modes only.

Sets the number of quadrature

follower encoder counts the

follower will advance/retard per

second when P2-04 = 0. Sets

the step amount of the

advance/retard function when

P2-04 = 1.

0 ~

65,535

Counts

2048 Yes – – – A

P2-05 60EH

Advance/Retard

Amount

Adv/Ret Amount

Note: ELS modes only.

Sets the amount of position

error in quadrature follower

encoder counts that will

P2-06 60FH

Follower

Deviation Level

Follower Dev Lvl

activate the follower deviation

detection. Also sets the

scaling for the Position Error

analog output selection (H3-

0 ~

65,535

Counts

4096 No – – – A

05, H3-09 = 94).

Note: ELS modes only.

*1: Access Level (A1-01): Q = “Quick Start”, A = “Advanced”, F = “Factory”, – = Not Available.

Control Mode *1

Open Loop

Vector 1, 2

V/f w/ PG

V/f

Flux Vector

Date: 03/31/09, Rev: 09-03 Page 9 of 30 TM.G7SW.064

Loading...

Loading...