Yaskawa E7B User Manual

E7B Drive/Bypass

Technical Manual

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model: E7B |

Document Number: TM.E7B.01 |

||||

|

|

|

|

|

|

|

|

Quick Reference for Bypass Parameters

Parameter |

Factory |

User |

Parameter |

Factory |

User |

Parameter |

Factory |

User |

Parameter |

Factory |

User |

|

Number |

Setting |

Setting |

Number |

Setting |

Setting |

Number |

Setting |

Setting |

Number |

Setting |

Setting |

|

A1-00 |

0 |

|

b5-04 |

100 |

|

E1-05 |

240V or 480V |

|

|

L1-05 |

0.2 |

|

A1-01 |

2 |

|

b5-06 |

100 |

|

E1-06 |

60 |

|

|

L2-01 |

2 |

|

A1-03 |

0 |

|

b5-07 |

0 |

|

E1-07 |

3 |

|

|

L2-02 |

0.1 |

|

A1-04 |

0 |

|

b5-08 |

0 |

|

E1-08 |

18 |

|

|

L2-03 |

0.1 |

|

A1-05 |

0 |

|

b5-09 |

0 |

|

E1-09 |

1.5 |

|

|

L2-04 |

0.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-01 |

|

|

b5-10 |

1 |

|

E1-10 |

10.8 |

|

|

L2-05 |

190 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-02 |

|

|

b5-11 |

0 |

|

E1-11 |

0 |

|

|

L3-01 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-03 |

|

|

b5-12 |

0 |

|

E1-12 |

0 |

|

|

L3-02 |

120 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-04 |

|

|

b5-13 |

0 |

|

E1-13 |

0 |

|

|

L3-04 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-05 |

|

|

b5-14 |

1 |

|

E2-01 |

kVA Dep. |

|

|

L3-05 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-06 |

|

|

b5-15 |

0 |

|

E2-03 |

kVA Dep. |

|

|

L3-06 |

120 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-07 |

|

|

b5-16 |

0 |

|

E2-05 |

kVA Dep. |

|

|

L4-01 |

0 |

|

A2-08 |

|

|

b5-17 |

0 |

|

F6-01 |

3 |

|

|

L4-02 |

2 |

|

A2-09 |

|

|

b5-18 |

0 |

|

F6-02 |

0 |

|

|

L4-05 |

0 |

|

A2-10 |

|

|

b5-19 |

0 |

|

F6-03 |

1 |

|

|

L4-06 |

80 |

|

A2-11 |

|

|

b5-20 |

1 |

|

F6-05 |

0 |

|

|

L5-01 |

10 |

|

A2-12 |

|

|

b5-21 |

1 |

|

H1-01 |

70 |

|

|

L5-02 |

0 |

|

A2-13 |

|

|

b5-22 |

0 |

|

H1-02 |

|

|

|

L5-03 |

600 |

|

A2-14 |

|

|

b5-23 |

0 |

|

H1-03 |

See Table 2 of |

|

|

L6-01 |

6 |

|

|

|

|

the bypass |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-15 |

|

|

b5-24 |

0 |

|

|

|

|

L6-02 |

15 |

|

|

|

|

|

|

schematic |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-16 |

|

|

b5-25 |

0 |

|

|

|

|

L6-03 |

10 |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-17 |

|

|

b5-26 |

0 |

|

H1-04 |

4 |

|

|

L8-01 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-18 |

|

|

b5-27 |

60 |

|

H1-05 |

6 |

|

|

L8-02 |

95 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-19 |

|

|

b5-28 |

0 |

|

H2-01 |

0 |

|

|

L8-03 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-20 |

|

|

b5-29 |

1 |

|

H2-02 |

3B |

|

|

L8-06 |

kVA Dep. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-21 |

|

|

b5-30 |

0 |

|

H3-02 |

See Table 2 of |

|

|

L8-09 |

1 |

|

A2-22 |

|

|

b8-01 |

1 |

|

|

the bypass |

|

|

L8-10 |

0 |

|

|

|

|

|

schematic |

|

|

|

|||||

A2-23 |

|

|

b8-04 |

kVA Dep. |

|

|

|

|

L8-11 |

300 |

|

|

|

|

|

|

|

|

|

|

|||||

A2-24 |

|

|

b8-05 |

20 |

|

H3-03 |

0 |

|

|

L8-12 |

45 |

|

A2-25 |

|

|

b8-06 |

0 |

|

H3-08 |

See Table 2 of |

|

|

L8-15 |

1 |

|

A2-26 |

|

|

C1-01 |

60 |

|

|

the bypass |

|

|

L8-18 |

1 |

|

|

|

|

|

schematic |

|

|

|

|||||

A2-27 |

|

|

C1-02 |

60 |

|

|

|

|

L8-19 |

20 |

|

|

|

|

|

|

|

|

|

|

|||||

A2-28 |

|

|

C1-03 |

30 |

|

H3-09 |

See Table 2 of |

|

|

n1-01 |

1 |

|

A2-29 |

|

|

C1-04 |

30 |

|

|

the bypass |

|

|

n1-02 |

1 |

|

|

|

|

|

schematic |

|

|

|

|||||

A2-30 |

|

|

C1-09 |

10 |

|

|

|

|

n3-01 |

5 |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-31 |

|

|

C1-11 |

0 |

|

H3-10 |

100 |

|

|

n3-02 |

150 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A2-32 |

|

|

C2-01 |

0.2 |

|

H3-11 |

0 |

|

|

n3-03 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b1-01 |

See Table 2 of |

|

C2-02 |

0.2 |

|

H3-12 |

0.3 |

|

|

n3-04 |

40 |

|

|

the bypass |

|

|

|

|

|

|

|

|

|

|

|

|

|

C4-01 |

1 |

|

H3-13 |

See Table 2 of |

|

|

o1-01 |

6 |

|

|

|

schematic |

|

|

|

|

|

||||||

|

|

|

|

|

|

the bypass |

|

|

|

|

|

|

|

|

C4-02 |

200 |

|

|

|

|

o1-02 |

1 |

|

||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

schematic |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

b1-02 |

1 |

|

C6-02 |

kVA Dep. |

|

|

|

|

o1-03 |

0 |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

b1-03 |

0 |

|

C6-03 |

kVA Dep. |

|

H4-01 |

2 |

|

|

o1-05 |

3 |

|

b1-04 |

1 |

|

C6-04 |

kVA Dep. |

|

H4-02 |

100 |

|

|

o1-06 |

0 |

|

b1-07 |

1 |

|

C6-05 |

0 |

|

H4-03 |

0 |

|

|

o1-07 |

2 |

|

b1-08 |

1 |

|

d1-01 |

10.0 |

|

H4-04 |

8 |

|

|

o1-08 |

3 |

|

b1-11 |

0 |

|

d1-02 |

6.0 |

|

H4-05 |

50 |

|

|

o2-01 |

1 |

|

b1-12 |

0 |

|

d1-03 |

0 |

|

H4-06 |

0 |

|

|

o2-02 |

0 |

|

b2-01 |

0.5 |

|

d1-04 |

40 |

|

H4-07 |

0 |

|

|

o2-03 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b2-02 |

50 |

|

d1-17 |

6 |

|

H4-08 |

0 |

|

|

o2-04 |

kVA Dep. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b2-03 |

5.0 |

|

d2-01 |

100 |

|

H5-01 |

1F |

|

|

o2-05 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b2-04 |

0 |

|

d2-02 |

0 |

|

H5-02 |

3 |

|

|

o2-06 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b2-09 |

0 |

|

d2-03 |

0 |

|

H5-03 |

0 |

|

|

o2-07 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b3-01 |

2 |

|

d3-01 |

0 |

|

H5-04 |

3 |

|

|

o2-08 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b3-02 |

120 |

|

d3-02 |

0 |

|

H5-05 |

1 |

|

|

o2-10 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b3-03 |

2 |

|

d3-03 |

0 |

|

H5-06 |

5 |

|

|

o2-12 |

0 |

|

b3-05 |

0.2 |

|

d3-04 |

1 |

|

H5-07 |

1 |

|

|

o2-14 |

0 |

|

b3-14 |

1 |

|

d4-01 |

0 |

|

H5-08 |

0 |

|

|

o2-15 |

0 |

|

b4-01 |

0 |

|

d4-02 |

10 |

|

H5-09 |

2 |

|

|

o3-01 |

0 |

|

b4-02 |

0 |

|

E1-01 |

208, 240V or |

|

L1-01 |

1 |

|

|

o3-02 |

1 |

|

b5-01 |

0 |

|

|

480V |

|

L1-02 |

8 |

|

|

T1-02 |

kVA Dep. |

|

|

|

|

|

|

|

|

||||||

b5-02 |

2 |

|

E1-03 |

F |

|

L1-03 |

3 |

|

|

T1-04 |

kVA Dep. |

|

b5-03 |

5 |

|

E1-04 |

60 |

|

L1-04 |

1 |

|

|

|

|

|

Warnings and Cautions

This Section provides warnings and cautions pertinent to this product, that if not heeded, may result in personal injury, fatality, or equipment damage. Yaskawa is not responsible for consequences of ignoring these instructions.

WARNING

WARNING

YASKAWA manufactures component parts that can be used in a wide variety of industrial applications. The selection and application of YASKAWA products remain the responsibility of the equipment designer or end user. YASKAWA accepts no responsibility for the way its products are incorporated into the final system design. Under no circumstances should any YASKAWA product be incorporated into any product or design as the exclusive or sole safety control. Without exception, all controls should be designed to detect faults dynamically and fail safely under all circumstances. All products designed to incorporate a component part manufactured by YASKAWA must be supplied to the end user with appropriate warnings and instructions as to that part’s safe use and operation. Any warnings provided by YASKAWA must be promptly provided to the end user. YASKAWA offers an express warranty only as to the quality of its products in conforming to standards and specifications published in the YASKAWA manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS OFFERED. YASKAWA assumes no liability for any personal injury, property damage, losses, or claims arising from misapplication of its products.

WARNING

WARNING

•Read and understand this manual before installing, operating, or servicing this Drive and Bypass Unit. All warnings, cautions, and instructions must be followed. All activity must be performed by qualified personnel. The Drive must be installed according to this manual and local codes.

•Do not connect or disconnect wiring while the power is on. Do not remove covers or touch circuit boards while the power is on.

•Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power supply is turned off. Status indicator LEDs and Digital Operator display will be extinguished when the DC bus voltage is below 50 VDC. To prevent electric shock, wait at least five minutes after all indicators are OFF and measure DC bus voltage level to confirm safe level.

•Do not perform a withstand voltage test on any part of the unit. This equipment uses sensitive devices and may be damaged by high voltage.

•The Drive and Bypass unit is not suitable for circuits capable of delivering more than the specified RMS symmetrical amperes. Install adequate branch short circuit protection per applicable codes. Refer to the specification. Failure to do so may result in equipment damage and/or personal injury.

•Do not connect unapproved LC or RC interference suppression filters, capacitors, or overvoltage protection devices to the output of the Drive. These devices may generate peak currents that exceed Drive specifications.

•To avoid unnecessary fault displays caused by contactors or output switches placed between Drive and motor, auxiliary contacts must be properly integrated into the control logic circuit.

•YASKAWA is not responsible for any modification of the product made by the user; doing so will void the warranty. This product must not be modified.

•Verify that the rated voltage of the Drive and Bypass unit matches the voltage of the incoming power supply before applying power.

•To meet CE directives, proper line filters and proper installation are required.

i

WARNING

WARNING

•Some drawings in this manual may be shown with protective covers or shields removed, to describe details. These must be replaced before operation.

•Observe electrostatic discharge procedures when handling circuit cards to prevent ESD damage.

•The equipment may start unexpectedly upon application of power. Clear all personnel from the Drive, motor, and machine area before applying power. Secure covers, couplings, shaft keys, and machine loads before energizing the Drive and Bypass unit.

•Please do not connect or operate any equipment with visible damage or missing parts. The operating company is responsible for any injuries or equipment damage resulting from failure to heed the warnings in this manual.

Intended Use

Drives and Bypass Units are intended for installation in electrical systems or machinery.

For use in the European Union, the installation in machinery and systems must conform to the following product standards of the Low Voltage Directive:

EN 50178, 1997-10, Equipping of Power Systems with Electronic Devices EN 60201-1, 1997-12 Machine Safety and Equipping with Electrical Devices

Part 1: General Requirements (IEC 60204-1:1997)/

EN 61010, 1997-11Safety Requirements for Information Technology Equipment (IEC 950:1991 + A1:1992 + A2:1993 + A3:1995 + A4:1996, modified)

Other

The Drive and Bypass unit is suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical amperes, 240Vac maximum (240V Class) and 480Vac maximum (480V Class).

This manual is for reference only and subject to change without notice.

ii

Introduction

This Section describes the applicability of the Manual

Product Description

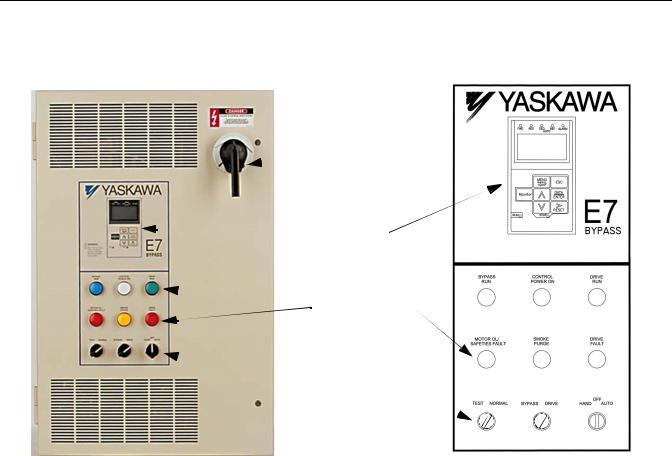

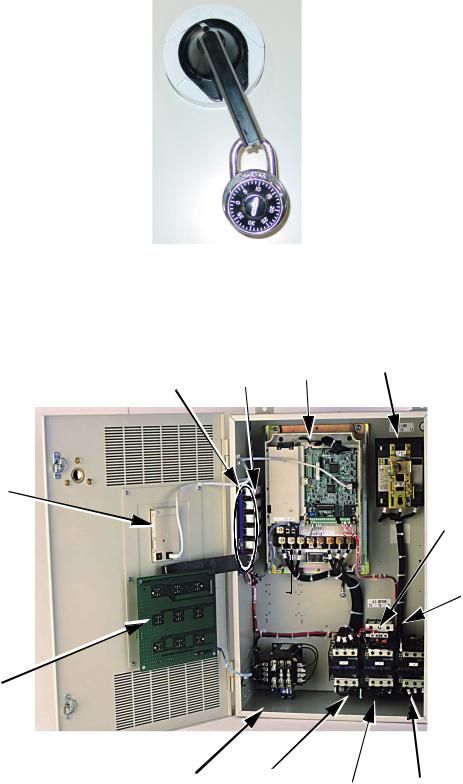

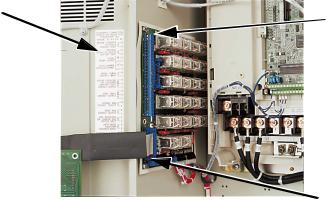

The E7 Bypass unit provides a means of bypassing the Drive while allowing the motor to operate at full speed, directly from the AC line. It incorporates an AC Drive and three contactor Bypass arrangement in a single UL listed enclosure. The three electrically interlocked IEC rated contactors isolate the Drive when operating in Bypass mode.

Control logic provides industry standard Hand/Off/Auto functions and safety circuit interlocks in both drive and Bypass operating modes.

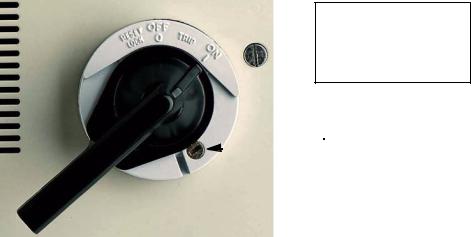

E7 Bypass components include: a fused 120 VAC control circuit transformer, an input Motor Circuit Protector (MCP) circuit breaker/disconnect, motor overload relay, selector switches and indicating lights.

The E7 Drive, a component of the E7 Bypass package, is a Pulse Width Modulated Drive for 3-Phase AC induction motors. This type of Drive is also known as an Adjustable Frequency Drive, Variable Frequency Drive, AC Drive, AFD, ASD, VFD, and Inverter. In this manual, the E7 Drive will be referred to as the “Drive”.

The Drive is a variable torque AC drive, designed specifically for HVAC applications in building automation, including fans, blowers and pumps. A new benchmark for size, cost, performance, benefits, and quality, the Drive includes numerous built-in features such as network communications, H/O/A, PI, parameter storage and copy functions.

The Drive has embedded communications for the popular building automation protocols, Johnson Controls Metasys® N2 and Siemens APOGEE™ FLN, as well as Modbus®. An optional LONWORKS® interface card is also available.

The LCD keypad/operator is equipped with Hand/Off/Auto functions, copy feature, 7 language choices, and 5 lines of display with 16 characters per line. User parameter settings can be recovered at any time via “User Initialization”. Optional DriveWizard software allows upload/download, as well as graphing and monitoring of drive parameters from a PC for ease of drive management.

Built-in PI control eliminates the need for closed loop output signals from a building automation system. It includes feedback display, inverse, square root and differential control functions, and maintains setpoint for closed loop control of fans and pumps for pressure, flow, or temperature regulation.

This manual is applicable to E7 Drives defined by model numbers CIMR-E7U_ _ _ _ contained within Bypass units defined by model numbers E7B_ _ _ _. This manual reflects the software version 4010.

This manual is subject to change as product improvements occur. The latest version of the manual can be obtained from the Yaskawa website www.yaskawa.com . The date shown on the rear cover is changed when revisions are made.

Introduction iii

This manual may describe trademarked equipment, which is the property of other companies. These trademarks are the property of the registered owner companies and may include the following:

APOGEETM FLN, trademark of Siemens Building Technologies, Inc.

Metasys®, trademark of Johnson Controls Inc.

Modbus®, trademark of Schneider Automation, Inc.

LONWORKS®, trademark of Echelon Corporation

Other Documents and Manuals are available to support special use or installation of this product. These documents may be provided with the product or upon request or downloaded from www.drives.com. Documents may include the following:

TM.E7.02.Programming … Manual included on CD ROM with product

TM.E7.11.Modbus … Manual included on CD ROM with product

TM.AFD.20.LONWORKS … Manual included on CD ROM with product

TM.E7.21.APOGEE … Manual included on CD ROM with product

TM. E7.22. Metasys … Manual included on CD ROM with product

DriveWizard … Software and Manual…Included on CD ROM with product

Option Instructions … Included on CD ROM with product

Definitions of Acronyms and Abbreviations

AC |

Alternating Current |

LRA |

Locked Rotor Amperes |

AIC |

Amps Interrupting Capacity |

MCP |

Motor Circuit Protector |

CB |

Circuit Breaker |

MTBF |

Mean Time Between Failures |

CIMR |

Control Induction Motor Rotation |

NC |

Normally Closed |

CN |

Connector |

NEC |

National Electrical Code |

CPT |

Control Power Transformer |

NEMA |

National Electrical Manufacturers Association |

CPU |

Central Processing Unit |

NO |

Normally Open |

DIP |

Dual Inline Package |

OLR |

Over Load Relay |

FLA |

Full Load Amperes |

PCB |

Printed Circuit Board |

FVFF |

Forced Ventilated, inlet Filter, outlet Filter |

PI |

Proportional plus Integral control action |

HOA |

Hand/Off/Auto |

RTS |

Request To Send |

HP |

Horsepower |

SFS |

Soft Start |

IEC |

International Electrotechnical Commission |

TB |

Terminal Block |

IGV |

Inlet Guide Vanes |

THD |

Total Harmonic Distortion |

IPM |

Intelligent Power Module |

VA |

Volt Amperes |

KVA |

Kilo Volt Amperes |

VAC |

Volts Alternating Current |

LED |

Light Emitting Diode |

VAV |

Variable Air Volume |

Terminology in This Manual

“Standard” or “Configured” options - are available with standard lead times

“Engineered” or “Custom” options - are available only with extended lead times

Introduction iv

Resources Available

|

|

Table of Resources |

|

|

|

|

Manuals, Installation Guides, and CD’s |

|

|

|

|

Document Number |

|

Description |

|

|

|

TM.E7.01 |

E7 Drive User Manual |

|

|

|

|

TM.E7.02 |

E7 Drive Programming Manual |

|

|

|

|

TM.E7.21 |

E7 APOGEE™ FLN Technical Manual |

|

|

|

|

TM.E7.22 |

E7 |

Metasys® N2 Technical Manual |

|

|

|

IG.AFD.20 |

LONWORKS® Option Installation Guide |

|

|

|

|

IG.AFD.23 |

BACnet Option Installation Guide |

|

|

|

|

IG.AFD.50 |

3-15 PSI Pressure Transducer Installation Guide |

|

|

|

|

IG.E7B.02 |

E7B Drive Bypass System with Touchpad Control Panel Option |

|

|

|

|

CD.E7.01 |

CD ROM, Drives for Building Automation |

|

|

|

|

|

|

Software |

|

|

|

Document |

|

Description |

|

|

|

DriveWizard® Software |

DriveWizard® Software Version 5.3 |

|

|

|

|

ESP |

Energy Savings Predictor for E7 |

|

|

|

|

Flyers, Bulletins, Pricebook, Binders, And Specifications |

||

|

|

|

Document Number |

|

Description |

|

|

|

FL.E7.01 |

Flyer, 2 page, E7 Drives and Bypass Packages |

|

|

|

|

BL.E7.01 |

Bulletin, Multi-page, E7 Drives and Bypass Packages |

|

|

|

|

PB.E7.01 |

E7 |

Price Book |

|

|

|

DRG.E7 |

E7 |

Drives Resources Guide Binder for Building Automation |

|

|

|

SG.E7.01 EngSpec15172 |

E7 |

Specification Guide, Section 15172 for Consulting Engineers |

|

|

|

SG.E7.10 SubmittalSpec |

E7 |

Submittal Specification |

|

|

|

SG.E7B.10 SubmittalSpec |

E7 |

Bypass Submittal Specification |

|

|

|

SG.E7C.10 SubmittalSpec |

E7 |

Configured Submittal Specification |

|

|

|

SG.E7E.10 SubmittalSpec |

E7 |

Engineered Submittal Specification |

|

|

|

See also www.drives.com.

Introduction v

Notes:

Introduction vi

Table of Contents |

|

Quick Reference Parameter List ........................................................ |

Inside front cover |

Warnings and Cautions ................................................................................................ |

i |

Introduction.................................................................................................................. |

iii |

Chapter 1 - Physical Installation ............................................................................... |

1-1 |

Bypass Model Number and Enclosure Style .............................................................. |

2 |

Enclosure Data ........................................................................................................... |

4 |

Confirmations upon Delivery ...................................................................................... |

7 |

Bypass Product Options ............................................................................................. |

9 |

Bypass Component Descriptions ............................................................................. |

11 |

Exterior and Mounting Dimensions .......................................................................... |

17 |

Checking and Controlling Installation Site ................................................................ |

24 |

Chapter 2 - Electrical Installation.............................................................................. |

2-1 |

Termination Configuration - Power Wiring ................................................................. |

2 |

Control Wiring ............................................................................................................. |

9 |

Wiring Diagram ......................................................................................................... |

20 |

Logic Diagram .......................................................................................................... |

22 |

Chapter 3 - Control Panel .......................................................................................... |

3-1 |

Digital Operator and Control Panel Display ............................................................... |

2 |

Drive Main Menus ...................................................................................................... |

8 |

Example of Changing a Parameter .......................................................................... |

16 |

Chapter 4 - Start Up and Operation .......................................................................... |

4-1 |

Start Up Introduction .................................................................................................. |

2 |

Bypass Start Up Preparation....................................................................................... |

3 |

Bypass Unit Start Up Procedure ................................................................................. |

4 |

Bypass Operation Description..................................................................................... |

8 |

Chapter 5 - Programming .......................................................................................... |

5-1 |

Bypass Basic Programming Parameters ................................................................... |

2 |

Table of Contents vii

Chapter 6 - Diagnostics & Troubleshooting ........................................................... |

6-1 |

Bypass Diagnostics .................................................................................................... |

2 |

Drive Diagnostics ....................................................................................................... |

3 |

Drive Troubleshooting .............................................................................................. |

17 |

Drive Main Circuit Test Procedure ............................................................................ |

23 |

Drive Date Stamp Information .................................................................................. |

27 |

Chapter 7 - Maintenance ............................................................................................ |

7-1 |

Maintenance ............................................................................................................... |

2 |

Removing and Replacing Drive in a Bypass Unit ....................................................... |

9 |

Appendix A - Parameters.......................................................................................... |

A-1 |

Parameter List ............................................................................................................ |

2 |

Monitor List ............................................................................................................... |

26 |

Fault Trace List ........................................................................................................ |

28 |

Fault History List ...................................................................................................... |

29 |

Appendix B - Capacity Related Parameters............................................................ |

B-1 |

Drive Capacity ............................................................................................................ |

2 |

Appendix C - Specifications ..................................................................................... |

C-1 |

Standard Drive and Bypass Specifications ................................................................. |

2 |

Appendix D - Communication .................................................................................. |

D-1 |

Using Modbus Communication .................................................................................. |

2 |

Modbus Function Code Details .................................................................................. |

7 |

Modbus Data Tables .................................................................................................. |

9 |

Modbus Self-Diagnosis ............................................................................................ |

14 |

Metasys N2 Point Database...................................................................................... |

15 |

APOGEE FLN Point Database.................................................................................. |

19 |

Appendix E - Peripheral Devices ............................................................................. |

E-1 |

Drive Input Fuse Selection for I2t Protection ............................................................... |

2 |

General Peripheral Devices ....................................................................................... |

4 |

Table of Contents viii

Appendix F - Replacement Parts ............................................................................. |

F-1 |

Bypass Replacement Parts......................................................................................... |

2 |

Index .................................................................................................................... |

Index-1 |

Table of Contents ix

Notes:

Table of Contents x

Chapter 1

Physical Installation

This chapter describes the checks required upon receiving and the installation process for a Drive and Bypass unit.

Bypass Model Number and Enclosure Style .................................. |

2 |

Enclosure Data ............................................................................... |

4 |

Confirmations upon Delivery .......................................................... |

7 |

Receiving Checks ...................................................................... |

7 |

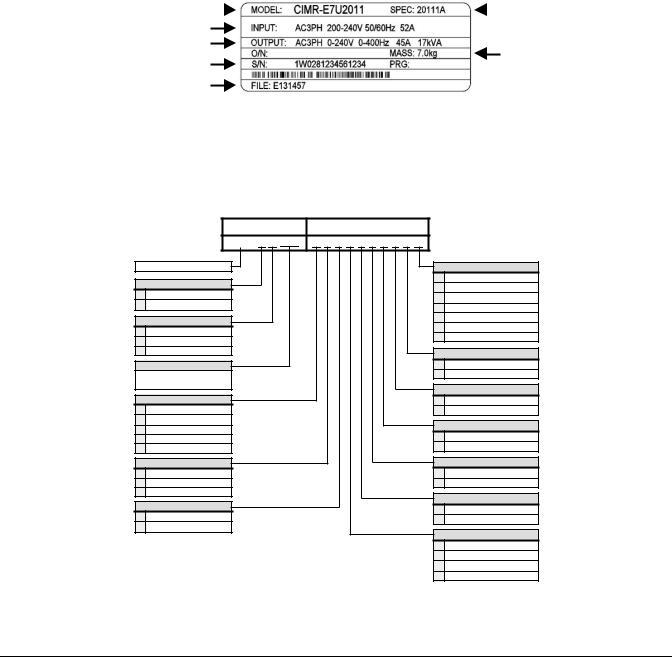

Bypass Nameplate Information .................................................. |

7 |

Bypass Unit Enclosures ............................................................. |

8 |

Bypass Product Options ................................................................. |

9 |

Bypass Component Descriptions ................................................. |

11 |

Bypass Unit Front Control Panel ............................................ |

11 |

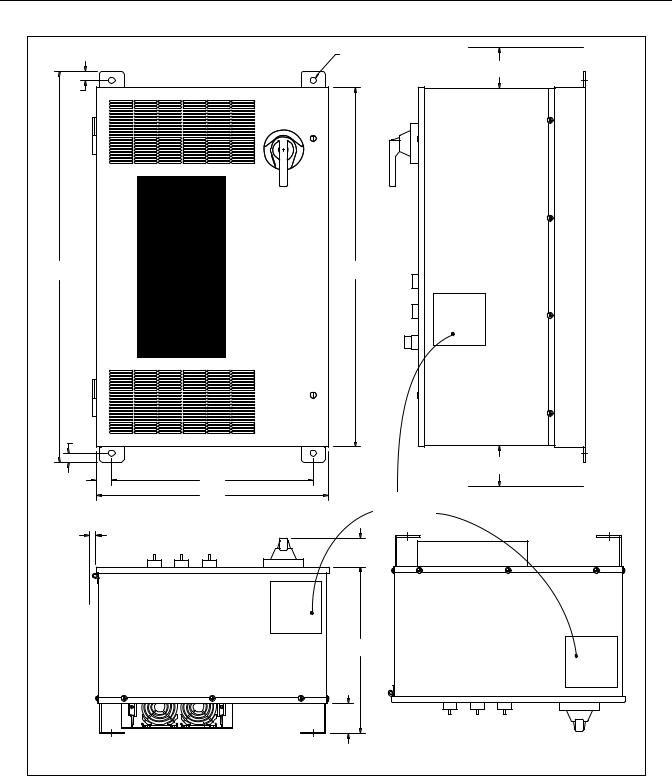

Exterior and Mounting Dimensions .............................................. |

17 |

Bypass Unit 30 HP and Below, 480 VAC; |

|

15 HP and Below, 208V/240V ................................................. |

17 |

Bypass Unit 30 HP and Below, 480 VAC; |

|

15 HP and Below, 208V/240V With Add-On Box ................... |

18 |

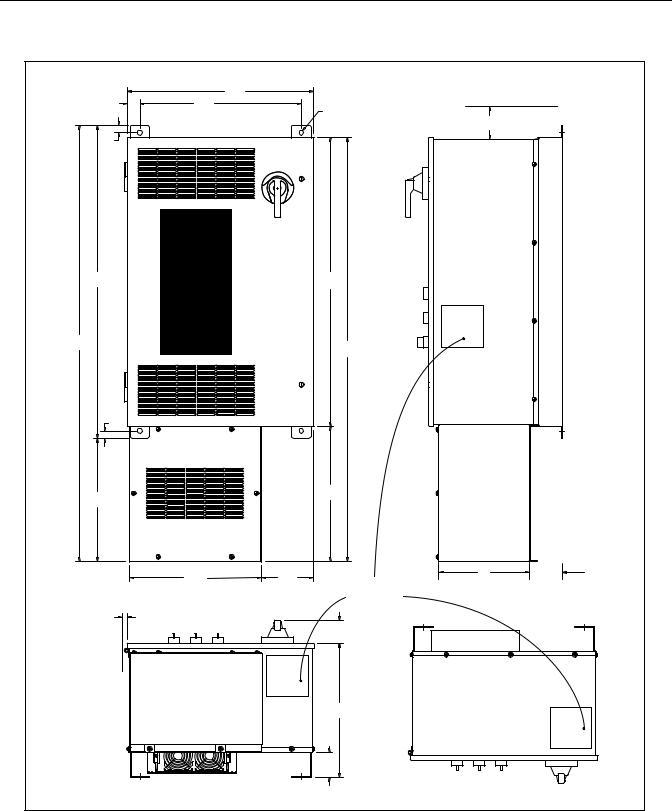

Bypass Unit 40 HP to 100 HP, 480 VAC; |

|

20 HP to 40 HP, 208V/240V .................................................... |

19 |

Bypass Unit 40 HP to 100 HP, 480 VAC; |

|

20 HP to 40 HP, 208V/240V With Add-On Box ........................ |

20 |

Bypass Unit 125 HP to 250 HP, 480 VAC; |

|

50 HP to 125 HP, 208V ............................................................ |

21 |

Dimensions and Weights ......................................................... |

22 |

Checking and Controlling Installation Site .................................... |

24 |

Installation Site ........................................................................ |

24 |

Controlling the Ambient Temperature ...................................... |

25 |

Protecting the Bypass Unit from Foreign Matter ...................... |

25 |

Installation Orientation and Enclosure Considerations ............ |

26 |

Physical Installation 1 - 1

Bypass Model Number and Enclosure Style

The Bypass covers two voltage ranges: 208-240 VAC and 480 VAC. Ratings applicable are from 1/2 to 500 HP.

|

|

|

Table 1.1 |

Bypass |

|

|

|

|

|

|

|

|

|

|

|

|

|

Bypass |

|

|

Bypass |

|

|

|

Base Model Number |

|

|

Continuous |

Uses |

||

Voltage |

|

|

*NEMA 12 |

|

HP |

Output |

Basic Drive |

|

NEMA 1 |

|

|

|

Current |

Model-Number |

|

|

|

FVFF |

|

|

|||

|

|

|

|

|

(Amps) |

|

|

|

|

|

|

|

|

|

|

|

E7BVD002 |

|

E7BBD002 |

|

0.5 |

2.4 |

CIMR-E7U22P2 |

|

|

|

|

|

|

|

|

|

E7BVD003 |

|

E7BBD003 |

|

0.75 |

3.5 |

CIMR-E7U22P2 |

|

|

|

|

|

|

|

|

|

E7BVD004 |

|

E7BBD004 |

|

1 |

4.6 |

CIMR-E7U22P2 |

|

|

|

|

|

|

|

|

|

E7BVD007 |

|

E7BBD007 |

|

2 |

7.5 |

CIMR-E7U22P2 |

|

|

|

|

|

|

|

|

|

E7BVD010 |

|

E7BBD010 |

|

3 |

10.6 |

CIMR-E7U22P2 |

|

|

|

|

|

|

|

|

|

E7BVD016 |

|

E7BBD016 |

|

5 |

16.7 |

CIMR-E7U23P7 |

|

|

|

|

|

|

|

|

|

E7BVD024 |

|

E7BBD024 |

|

7.5 |

24.2 |

CIMR-E7U27P5 |

|

|

|

|

|

|

|

|

|

E7BVD030 |

|

E7BBD030 |

|

10 |

30.8 |

CIMR-E7U27P5 |

|

|

|

|

|

|

|

|

|

E7BVD046 |

|

E7BBD046 |

|

15 |

46.2 |

CIMR-E7U2011 |

|

|

|

|

|

|

|

|

208 VAC |

E7BVD059 |

|

E7BBD059 |

|

20 |

59.4 |

CIMR-E7U2015 |

|

|

|

|

|

|

|

|

|

E7BVD074 |

|

E7BBD074 |

|

25 |

74.8 |

CIMR-E7U2018 |

|

|

|

|

|

|

|

|

|

E7BVD088 |

|

E7BBD088 |

|

30 |

88 |

CIMR-E7U2022 |

|

|

|

|

|

|

|

|

|

E7BVD114 |

|

E7BBD114 |

|

40 |

114 |

CIMR-E7U2030 |

|

|

|

|

|

|

|

|

|

E7BVD143 |

|

E7BBD143 |

|

50 |

143 |

CIMR-E7U2037 |

|

|

|

|

|

|

|

|

|

E7BVD169 |

|

E7BBD169 |

|

60 |

169 |

CIMR-E7U2045 |

|

|

|

|

|

|

|

|

|

E7BVD211 |

|

E7BBD211 |

|

75 |

211 |

CIMR-E7U2055 |

|

|

|

|

|

|

|

|

|

E7BVD273 |

|

E7BBD273 |

|

100 |

273 |

CIMR-E7U2075 |

|

|

|

|

|

|

|

|

|

E7BVD343 |

|

E7BBD343 |

|

125 |

343 |

CIMR-E7U2090 |

|

|

|

|

|

|

|

|

|

E7BVD396 |

|

E7BBD396 |

|

150 |

396 |

CIMR-E7U2110 |

|

|

|

|

|

|

|

|

|

E7BVA002 |

|

E7BBA002 |

|

0.5 |

2.2 |

CIMR-E7U22P2 |

|

|

|

|

|

|

|

|

|

E7BVA003 |

|

E7BBA003 |

|

0.75 |

3.2 |

CIMR-E7U22P2 |

|

|

|

|

|

|

|

|

|

E7BVA004 |

|

E7BBA004 |

|

1 |

4.0 |

CIMR-E7U22P2 |

|

|

|

|

|

|

|

|

|

E7BVA006 |

|

E7BBA006 |

|

2 |

6.8 |

CIMR-E7U22P2 |

|

|

|

|

|

|

|

|

|

E7BVA009 |

|

E7BBA009 |

|

3 |

9.6 |

CIMR-E7U22P2 |

|

|

|

|

|

|

|

|

|

E7BVA015 |

|

E7BBA015 |

|

5 |

15.2 |

CIMR-E7U23P7 |

|

|

|

|

|

|

|

|

240 VAC |

E7BVA022 |

|

E7BBA022 |

|

7.5 |

22 |

CIMR-E7U25P5 |

|

|

|

|

|

|

|

|

|

E7BVA028 |

|

E7BBA028 |

|

10 |

28 |

CIMR-E7U27P5 |

|

|

|

|

|

|

|

|

|

E7BVA042 |

|

E7BBA042 |

|

15 |

42 |

CIMR-E7U2011 |

|

|

|

|

|

|

|

|

|

E7BVA054 |

|

E7BBA054 |

|

20 |

54 |

CIMR-E7U2015 |

|

|

|

|

|

|

|

|

|

E7BVA068 |

|

E7BBA068 |

|

25 |

68 |

CIMR-E7U2018 |

|

|

|

|

|

|

|

|

|

E7BVA080 |

|

E7BBA080 |

|

30 |

80 |

CIMR-E7U2022 |

|

|

|

|

|

|

|

|

|

E7BVA104 |

|

E7BBA104 |

|

40 |

104 |

CIMR-E7U2030 |

|

|

|

|

|

|

|

|

Physical Installation 1 - 2

|

|

|

Table 1.1 |

Bypass (Continued) |

|

||

|

|

|

|

|

|

|

|

|

|

Bypass |

|

|

Bypass |

Uses |

|

|

Base Model Number |

|

|

Continuous |

|||

Voltage |

|

|

*NEMA 12 |

|

HP |

Output |

Basic Drive |

|

NEMA 1 |

|

|

|

Current |

Model-Number |

|

|

|

FVFF |

|

|

|||

|

|

|

|

|

(Amps) |

|

|

|

|

|

|

|

|

|

|

|

E7BVA130 |

|

E7BBA130 |

|

50 |

130 |

CIMR-E7U2037 |

|

|

|

|

|

|

|

|

|

E7BVA154 |

|

E7BBA154 |

|

60 |

154 |

CIMR-E7U2037 |

|

|

|

|

|

|

|

|

230 VAC |

E7BVA192 |

|

E7BBA192 |

|

75 |

192 |

CIMR-E7U2045 |

|

|

|

|

|

|

|

|

E7BVA248 |

|

E7BBA248 |

|

100 |

248 |

CIMR-E7U2075 |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

E7BVA312 |

|

E7BBA312 |

|

125 |

312 |

CIMR-E7U2075 |

|

|

|

|

|

|

|

|

|

E7BVA360 |

|

E7BBA360 |

|

150 |

360 |

CIMR-E7U2090 |

|

|

|

|

|

|

|

|

|

E7BVB001 |

|

E7BBB001 |

|

0.5 |

1.1 |

CIMR-E7U42P2 |

|

|

|

|

|

|

|

|

|

E7BVB001 |

|

E7BBB001 |

|

0.75 |

1.6 |

CIMR-E7U42P2 |

|

|

|

|

|

|

|

|

|

E7BVB002 |

|

E7BBB002 |

|

1 |

2.1 |

CIMR-E7U42P2 |

|

|

|

|

|

|

|

|

|

E7BVB003 |

|

E7BBB003 |

|

2 |

3.4 |

CIMR-E7U42P2 |

|

|

|

|

|

|

|

|

|

E7BVB004 |

|

E7BBB004 |

|

3 |

4.8 |

CIMR-E7U42P2 |

|

|

|

|

|

|

|

|

|

E7BVB007 |

|

E7BBB007 |

|

5 |

7.6 |

CIMR-E7U43P7 |

|

|

|

|

|

|

|

|

|

E7BVB011 |

|

E7BBB011 |

|

7.5 |

11 |

CIMR-E7U45P5 |

|

|

|

|

|

|

|

|

|

E7BVB014 |

|

E7BBB014 |

|

10 |

14 |

CIMR-E7U47P5 |

|

|

|

|

|

|

|

|

|

E7BVB021 |

|

E7BBB021 |

|

15 |

21 |

CIMR-E7U49P0 |

|

|

|

|

|

|

|

|

|

E7BVB027 |

|

E7BBB027 |

|

20 |

27 |

CIMR-E7U4011 |

|

|

|

|

|

|

|

|

480 VAC |

E7BVB034 |

|

E7BBB034 |

|

25 |

34 |

CIMR-E7U4015 |

|

|

|

|

|

|

|

|

|

E7BVB040 |

|

E7BBB040 |

|

30 |

40 |

CIMR-E7U4018 |

|

|

|

|

|

|

|

|

|

E7BVB052 |

|

E7BBB052 |

|

40 |

52 |

CIMR-E7U4024 |

|

|

|

|

|

|

|

|

|

E7BVB065 |

|

E7BBB065 |

|

50 |

65 |

CIMR-E7U4030 |

|

|

|

|

|

|

|

|

|

E7BVB077 |

|

E7BBB077 |

|

60 |

77 |

CIMR-E7U4037 |

|

|

|

|

|

|

|

|

|

E7BVB096 |

|

E7BBB096 |

|

75 |

96 |

CIMR-E7U4045 |

|

|

|

|

|

|

|

|

|

E7BVB124 |

|

E7BBB124 |

|

100 |

124 |

CIMR-E7U4055 |

|

|

|

|

|

|

|

|

|

E7BVB156 |

|

E7BBB156 |

|

125 |

156 |

CIMR-E7U4075 |

|

|

|

|

|

|

|

|

|

E7BVB180 |

|

E7BBB180 |

|

150 |

180 |

CIMR-E7U4090 |

|

|

|

|

|

|

|

|

|

E7BVB240 |

|

E7BBB240 |

|

200 |

240 |

CIMR-E7U4110 |

|

|

|

|

|

|

|

|

|

E7BVB302 |

|

E7BBB302 |

|

250 |

302 |

CIMR-E7U4160 |

|

|

|

|

|

|

|

|

*The Nema 12 FVFF Enclosure is ventilated and filtered with gaskets. UL does not recognize NEMA 12 ventilated enclosures, therefore, for UL purposes, these units are designated NEMA 1.

Physical Installation 1 - 3

Enclosure Data

Table 1.2 208V Enclosure Data

Input |

|

1 |

Drive |

Bypass |

2 |

NEC |

OL |

Heat |

3 |

Enclosure Dimensions |

4 |

Weight |

5 |

Enclosure Dimensions w/Add-on4 |

Weight5 of |

Electrical |

||||

HP |

Model |

|

110% |

|

|

|

NEMA 1 & NEMA 12-FVFF |

Assembly |

||||||||||||

Volts |

|

Model |

|

FLA |

Loss |

NEMA 1 & NEMA 12 -FVFF |

of |

|

Schematic |

|||||||||||

|

|

|

CIMR- |

Number |

1 min |

Watts |

H |

W |

D |

|

Assembly |

H |

W |

D |

+Add-on |

|

||||

|

|

|

|

|

|

inches |

|

Box |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

inches |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5 |

E7U22P21 |

E7B_D002 |

2.4 |

2.6 |

68 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

0.75 |

E7U22P21 |

E7B_D003 |

3.5 |

3.8 |

68 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

29.48 |

19.06 |

13.66 |

|

|

|

|

|

|

|

||

|

1 |

|

E7U22P21 |

E7B_D004 |

4.6 |

5.1 |

78 |

|

|

|

43.35 |

19.06 |

13.66 |

|

|

|||||

|

2 |

|

E7U22P21 |

E7B_D007 |

7.5 |

8.2 |

110 |

|

|

|

|

|

115 lbs |

|

|

|

156 lbs |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

E7U22P21 |

E7B_D010 |

10.6 |

11.7 |

141 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

E7U23P71 |

E7B_D016 |

16.7 |

18.4 |

202 |

|

Dimension Drawing6 |

|

|

|

|

Dimension Drawing |

|

|

|

|||

|

7.5 |

E7U27P51 |

E7B_D024 |

24.2 |

26.6 |

273 |

|

|

S-5512 |

|

|

|

|

|

S-5513 |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

10 |

E7U27P51 |

E7B_D030 |

30.8 |

33.9 |

365 |

|

|

|

|

|

127 lbs |

|

|

|

164 lbs |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

15 |

E7U20111 |

E7B_D046 |

46.2 |

50.8 |

578 |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

208 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E7B-00 |

||

20 |

E7U20151 |

E7B_D059 |

59.4 |

65.3 |

653 |

|

40.48 |

25.63 |

14.66 |

208 lbs |

|

|

|

291 lbs |

||||||

|

25 |

E7U20181 |

E7B_D074 |

74.8 |

82.3 |

746 |

|

55.35 |

25.63 |

14.66 |

|

|||||||||

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

Dimension Drawing |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

Dimension Drawing7 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

30 |

E7U20221 |

E7B_D088 |

88.0 |

96.8 |

939 |

|

|

221 lbs |

|

S-5515 |

|

307 lbs |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

S-5514 |

|

|

|

|

|

|

|||

|

40 |

E7U20301 |

E7B_D114 |

114.0 |

125.4 |

1340 |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

50 |

E7U20370 |

E7B_D143 |

143.0 |

157.3 |

1523 |

|

|

|

|

847 lbs |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

60 |

E7U20450 |

E7B_D169 |

169.0 |

185.9 |

1762 |

84.00 |

25.63 |

26.258 |

943 lbs |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

75 |

E7U20550 |

E7B_D211 |

211.0 |

232.1 |

2244 |

|

NOT REQUIRED |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

Dimension Drawing9 |

|

|

|

|

|

|

||||

|

100 |

E7U20750 |

E7B_D273 |

273.0 |

300.3 |

3003 |

|

1214 lbs |

|

|

|

|||||||||

|

|

|

|

|

|

|

||||||||||||||

|

|

S-5525 |

|

|

|

|

|

|

|

|||||||||||

|

125 |

E7U20900 |

E7B_D343 |

343.0 |

377.3 |

3296 |

|

|

|

1330 lbs |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

150 |

E7U21100 |

E7B_D396 |

396.0 |

435.6 |

4029 |

|

|

|

|

1423 lbs |

|

|

|

|

|

||||

Note 1: Horsepower rating is based on a standard NEMA B 4-pole motor. |

|

|

|

|

|

|

|

|

|

|

||||||||||

Note 2: The underscore position in these model numbers codes for the enclosure type: V = NEMA1, B = NEMA12 FVFF.

Note 3: Heat loss is the amount of heat dissipated by the drive at full load with all standard options available inside the enclosure. Drive heat sink losses are included in the heat loss data. Heat loss data is for the enclosure without the add-on enclosure.

Note 4: Height dimension (H) excludes the mounting screw tabs. Depth dimension (D) excludes MCP disconnect handle.

Note 5: This data represents the total weight with all possible standard options. Weight could be less depending on the options specified.

Note 6: All standard options are available in this size enclosure except options E (RFI Filter) and K (5% Output Reactor). Options E and K require the add-on enclosure.

Note 7: All options are available in this size enclosure except E (RFI Filter), R (3% Line Reactor), and K (5% Output Reactor). Only option E combined with either option R or option K can be installed in the add-on enclosure. Options R and K together require an increase in the size of the E7 Bypass Enclosure.

Contact the factory if all three options are required. Options D (2 Motor “OR”) or A (2 Motor “AND”) for 30 Hp and 40 Hp, or for 75 Hp and 100 Hp, require the next size enclosure.

Note 8: Heat sink mounted externally varies the depth dimension depending on the drive size. Depth will not exceed dimension shown.

Note 9: All options are available in this size enclosure except options D (2 Motor “OR”) or A (2 Motor “AND”) for 75 Hp and 100 Hp require the next size enclosure.

Physical Installation 1 - 4

Table 1.3 240/230V Enclosure Data

Input |

|

1 |

Drive |

Bypass |

2 |

NEC |

OL |

Heat |

3 |

Enclosure Dimensions |

4 |

Weight |

5 |

Enclosure Dimensions w/Add-on4 |

Weight5 of |

Electrical |

||||

HP |

Model |

|

110% |

|

|

|

NEMA 1 & NEMA 12-FVFF |

Assembly |

||||||||||||

Volts |

|

Model |

|

FLA |

Loss |

NEMA 1 & NEMA 12 -FVFF |

of |

|

Schematic |

|||||||||||

|

|

|

CIMR- |

Number |

1 min |

Watts |

H |

W |

D |

|

Assembly |

H |

W |

D |

+Add-on |

|

||||

|

|

|

|

|

|

inches |

|

Box |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

inches |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5 |

E7U22P21 |

E7B_A002 |

2.2 |

2.4 |

68 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

0.75 |

E7U22P21 |

E7B_A003 |

3.2 |

3.5 |

68 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

1 |

|

E7U22P21 |

E7B_A004 |

4.0 |

4.4 |

78 |

|

29.48 |

19.06 |

13.66 |

|

|

43.35 |

19.06 |

13.66 |

|

|

||

|

2 |

|

E7U22P21 |

E7B_A006 |

6.8 |

7.5 |

110 |

|

|

|

|

|

115 lbs |

|

|

|

156 lbs |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

E7U22P21 |

E7B_A009 |

9.6 |

10.6 |

141 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

E7U23P71 |

E7B_A015 |

15.2 |

16.7 |

202 |

|

Dimension Drawing6 |

|

|

|

|

Dimension Drawing |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

240 |

7.5 |

E7U25P51 |

E7B_A022 |

22.0 |

24.2 |

273 |

|

|

S-5512 |

|

|

|

|

|

S-5513 |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

10 |

E7U27P51 |

E7B_A028 |

28.0 |

30.8 |

365 |

|

|

|

|

|

127 lbs |

|

|

|

164 lbs |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

15 |

E7U20111 |

E7B_A042 |

42.0 |

46.2 |

578 |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E7B-00 |

||

|

20 |

E7U20151 |

E7B_A054 |

54.0 |

59.4 |

653 |

|

40.48 |

25.63 |

14.66 |

208 lbs |

|

|

|

291 lbs |

|||||

|

25 |

E7U20181 |

E7B_A068 |

68.0 |

74.8 |

746 |

|

55.35 |

25.63 |

14.66 |

|

|||||||||

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

Dimension Drawing7 |

|

|

|

|

Dimension Drawing |

|

|

|

||||

|

30 |

E7U20221 |

E7B_A080 |

80.0 |

88.0 |

939 |

|

|

221 lbs |

|

|

307 lbs |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

S-5514 |

|

|

|

S-5515 |

|

|

|||

|

40 |

E7U20301 |

E7B_A104 |

104.0 |

114.4 |

1340 |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

50 |

E7U20370 |

E7B_A130 |

130.0 |

143.0 |

1523 |

|

|

|

|

847 lbs |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

60 |

E7U20370 |

E7B_A154 |

154.0 |

169.4 |

1544 |

84.00 |

25.63 |

26.258 |

943 lbs |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

230 |

75 |

E7U20450 |

E7B_A192 |

192.0 |

211.2 |

1860 |

|

NOT REQUIRED |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

Dimension Drawing9 |

|

|

|

|

|

|

|||||

100 |

E7U20750 |

E7B_A248 |

248.0 |

272.8 |

3003 |

|

1214 lbs |

|

|

|

||||||||||

|

|

|

|

|

|

|

||||||||||||||

|

|

S-5525 |

|

|

|

|

|

|

|

|||||||||||

|

125 |

E7U20750 |

E7B_A312 |

312.0 |

343.2 |

3045 |

|

|

|

1330 lbs |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

150 |

E7U20900 |

E7B_A360 |

360.0 |

396.0 |

3440 |

|

|

|

|

1423 lbs |

|

|

|

|

|

||||

Note 1: Horsepower rating is based on a standard NEMA B 4-pole motor. |

|

|

|

|

|

|

|

|

|

|

||||||||||

Note 2: The underscore position in these model numbers codes for the enclosure type: V = NEMA1, B = NEMA12 FVFF.

Note 3: Heat loss is the amount of heat dissipated by the drive at full load with all standard options available inside the enclosure. Drive heat sink losses are included in the heat loss data. Heat loss data is for the enclosure without the add-on enclosure.

Note 4: Height dimension (H) excludes the mounting screw tabs. Depth dimension (D) excludes MCP disconnect handle.

Note 5: This data represents the total weight with all possible standard options. Weight could be less depending on the options specified.

Note 6: All standard options are available in this size enclosure except options E (RFI Filter) and K (5% Output Reactor). Options E and K require the add-on enclosure.

Note 7: All options are available in this size enclosure except E (RFI Filter), R (3% Line Reactor), and K (5% Output Reactor). Only option E combined with either option R or option K can be installed in the add-on enclosure. Options R and K together require an increase in the size of the E7 Bypass Enclosure. Contact the factory if all three options are required. Option A (2 Motor “AND”) for 30 Hp and 40 Hp, or for 75 Hp and 100 Hp, require the next size enclosure. Option D (2 Motor “OR”) for 40 Hp, or for 75 Hp and 100 Hp, require the next size enclosure.

Note 8: Heat sink mounted externally varies the depth dimension depending on the drive size. Depth will not exceed dimension shown.

Note 9: All options are available in this size enclosure except options D (2 Motor “OR”) or A (2 Motor “AND”) for 75 Hp and 100 Hp require the next size enclosure.

Physical Installation 1 - 5

Table 1.4 480V Enclosure Data

Input |

|

1 |

Drive |

Bypass |

2 |

NEC |

OL |

Heat |

3 |

Enclosure Dimensions |

4 |

Weight |

5 |

Enclosure Dimensions w/Add-on4 |

Weight5 of |

Electrical |

||||

HP |

Model |

|

110% |

|

|

|

NEMA 1 & NEMA 12-FVFF |

Assembly |

||||||||||||

Volts |

|

Model |

|

FLA |

Loss |

NEMA 1 & NEMA 12 -FVFF |

of |

|

Schematic |

|||||||||||

|

|

|

CIMR- |

Number |

1 min |

Watts |

H |

W |

D |

|

Assembly |

H |

W |

D |

+Add-on |

|

||||

|

|

|

|

|

|

inches |

|

Box |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

inches |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5 |

42P21 |

E7B_B001 |

1.1 |

1.2 |

57 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

0.75 |

42P21 |

E7B_B001 |

1.6 |

1.8 |

57 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

1 |

|

42P21 |

E7B_B002 |

2.1 |

2.3 |

62 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

115 lbs |

|

|

|

156 lbs |

|

||

|

2 |

|

42P21 |

E7B_B003 |

3.4 |

3.7 |

89 |

|

|

|

|

|

|

|

|

|

||||

|

3 |

|

42P21 |

E7B_B004 |

4.8 |

5.3 |

121 |

|

29.48 |

19.06 |

13.66 |

|

|

43.35 |

19.06 |

13.66 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

43P71 |

E7B_B007 |

7.6 |

8.4 |

155 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7.5 |

45P51 |

E7B_B011 |

11.0 |

12.1 |

217 |

|

Dimension Drawing6 |

|

|

|

|

Dimension Drawing |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

10 |

47P51 |

E7B_B014 |

14.0 |

15.4 |

318 |

|

|

S-5512 |

|

|

127 lbs |

|

S-5513 |

|

164 lbs |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

15 |

49P01 |

E7B_B021 |

21.0 |

23.1 |

404 |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

20 |

40111 |

E7B_B027 |

27.0 |

29.7 |

408 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

189 lbs |

|

|||

|

25 |

40151 |

E7B_B034 |

34.0 |

37.4 |

485 |

|

|

|

|

|

142 lbs |

|

|

|

|

||||

|

30 |

40181 |

E7B_B040 |

40.0 |

44.0 |

618 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

480 |

40 |

40241 |

E7B_B052 |

52.0 |

57.2 |

1040 |

|

|

|

|

203 lbs |

|

|

|

281 lbs |

E7B-00 |

||||

|

|

|

|

|

|

|

40.48 |

25.63 |

14.66 |

|

|

|

|

|

|

|

||||

|

50 |

40301 |

E7B_B065 |

65.0 |

71.5 |

1045 |

232 lbs |

55.35 |

25.63 |

14.66 |

|

|

||||||||

|

60 |

40371 |

E7B_B077 |

77.0 |

84.7 |

1197 |

Dimension Drawing7 |

|

|

Dimension Drawing |

|

319 lbs |

|

|||||||

|

|

|

|

|

|

|

||||||||||||||

|

75 |

40451 |

E7B_B096 |

96.0 |

105.6 |

1357 |

|

S-5514 |

|

|

241 lbs |

|

S-5515 |

|

332 lbs |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

100 |

40551 |

E7B_B124 |

124.0 |

136.4 |

1749 |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

125 |

40750 |

E7B_B156 |

156.0 |

171.6 |

2032 |

84.00 |

25.63 |

26.258 |

943 lbs |

|

|

|

|

|