Xylem SSW-07 User Manual [en, es]

Motors | Automation | Energy | Transmission & Distribution | Coatings

Soft-Starter

Arrancador Suave

Soft-Starter

SSW-07

User's Manual

Manual del Usuario

Manual do Usuário

SOFT-STARTER

USER’S MANUAL

MANUAL DEL

USUARIO DEL

ARRANCADOR

SUAVE

English

Español

MANUAL DO

USUÁRIO DA

SOFT-STARTER

Series: SSW-07

Document: 0899.5832 / 10

English - Español - Português

Português

07/2012

Summary of revisions / Sumario de las revisiones / Sumário das revisões

The information below describes the revisions in this manual.

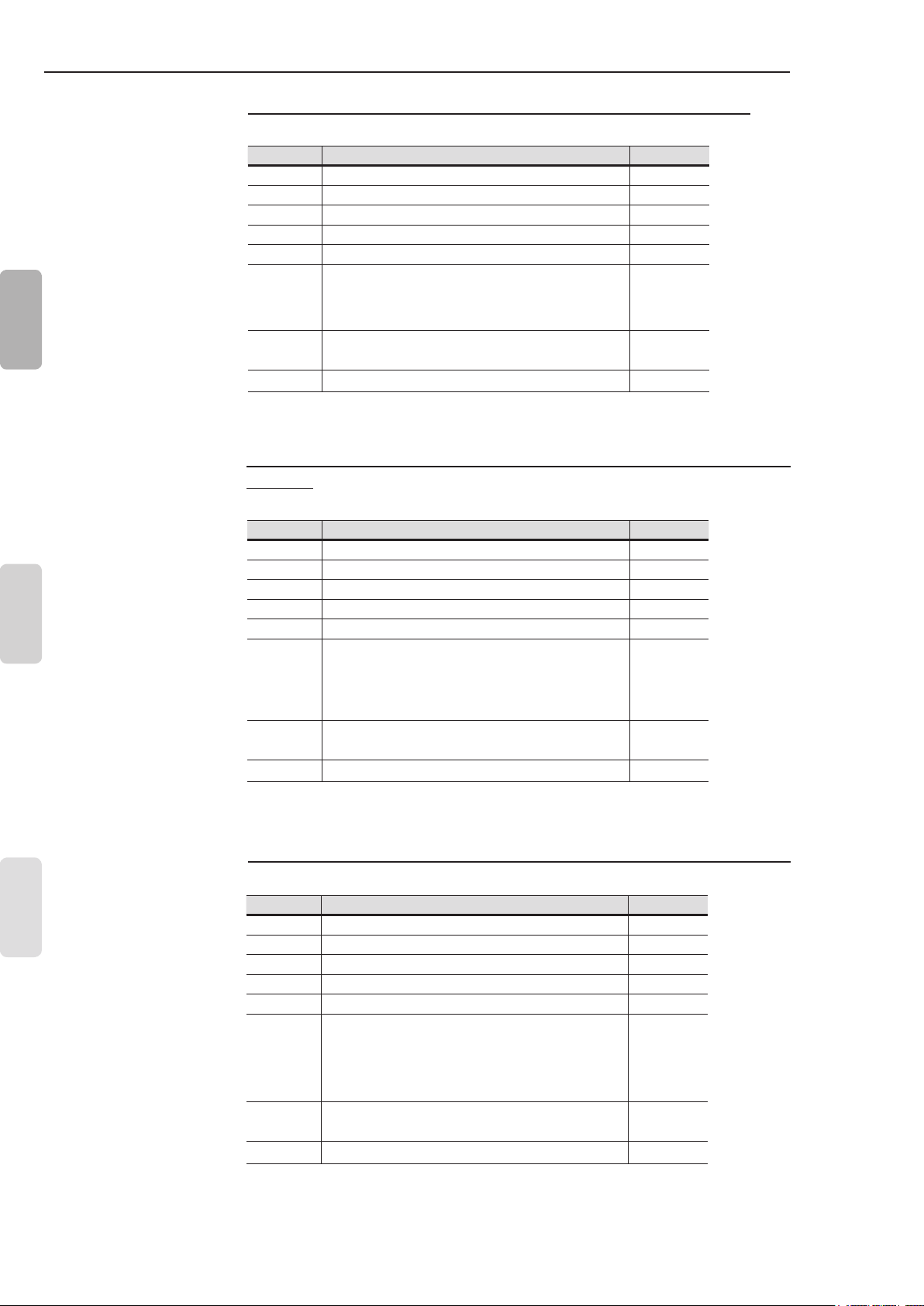

Revision Description Chapter

1 First Edition 2 General Revision 3 General Revision 4 Size 4 Included -

5 and 6 Table 3.1 and 8.2 corrected 3 and 8

English

Revision after the Size 4 UL certication.

7

Changed: item 3.2.3; 3.2.4.1; 3.2.4.2; 3.2.7;

4.8; 5.2; E77 in the table 6.1; table 8.1

8

9 General Revision -

Included new functions of

software version V1.4x

3, 4, 5, 6

and 8

3,4

and 5

La información abajo describe las revisiones ocurridas en este

manual.

Español

Português

Revisión Descripción Capítulo

1 Primer Edición 2 Revisión General 3 Revisión General 4 Inclusión Mecánica 4 -

5 y 6 Correción de las tablas 3.1 y 8.2 3 y 8

Corrección luego de la certicación UL de la

Mecánica 4. Modicado: ítem 3.2.3; 3.2.4.1;

7

8

9 Revisión General -

3.2.4.2; 3.2.7; 4.8; 5.2; E77 en la tabla 6.1;

tabla 8.1

Inclusión de las nuevas funciones de la

version de software V1.4x

3, 4, 5, 6

y 8

3, 4 y 5

A informação abaixo descreve as revisões ocorridas neste manual.

Revisão Descrição Capítulo

1 Primeira Edição 2 Revisão Geral 3 Revisão Geral 4 Inclusão da mecânica 4 -

5 e 6 Correções das tabelas 3.1 e 8.2 3 e 8

Correção depois da certicação UL da

7

8

9 Revisão Geral -

Mecânica 4. Alterado: item 3.2.3; 3.2.4.1;

3.2.4.2; 3.2.7; 4.8; 5.2; E77 na tabela 6.1;

tabela 8.1

Inclusão das novas funções da versão

de software V1.4x

3, 4, 5,

6 e 8

3, 4 e 5

Summary

CHAPTER 1

Safety Instructions

1.1 Safety Notices in the Manual ................................................5

1.2 Safety Notices on the Product ..............................................5

1.3 Preliminary Recommendations .............................................5

CHAPTER 2

General Information

2.1 About this Manual ................................................................7

2.2 About the Soft-Starter SSW-07 ............................................7

2.3 Soft-Starter SSW-07 Identication Plate ............................8

2.4 Receiving and Storage .......................................................11

CHAPTER 3

Installation and Connection

3.1 Mechanical Installation .......................................................12

3.1.1 Environmental Conditions ............................................12

3.1.2 Soft-Starter SSW-07 Dimensions ................................12

3.1.3 Mounting Specications ...............................................13

3.1.3.1 Mounting Inside a Panel .....................................14

3.1.3.2 Mounting on Surface ..........................................15

3.2 Electrical Installation ...........................................................15

3.2.1 Power Terminals ...........................................................16

3.2.2 Location of the Grounding, Control and Power

Connections ..................................................................17

3.2.3 Recommended Power and Grounding Cables ............18

3.2.4 Power Supply Connection to the Soft-Starter SSW-07 18

3.2.4.1 Power Supply Capacity .......................................19

3.2.4.2 Recommended Fuses .........................................19

3.2.4.3 Recommended Contactors .................................20

3.2.5 Soft-Starter SSW-07 Connection to the Motor .............20

3.2.5.1 Standard Three-Wire Connection .......................21

3.2.6 Grounding Connections ...............................................21

3.2.7 Control and Signal Connections ...................................22

3.3 Recommended Set-ups ......................................................23

3.3.1 Recommended Set-up with Command via Two-wire

Digital Inputs and Isolation Contactor ..........................24

3.3.2 Recommended Set-up with Command via Three-wire

Digital Inputs and Circuit-Breaker ................................24

3.3.3 Recommended Set-up with Command via Two-wire

Digital Inputs and Direction of Rotation .......................25

3.3.4 Recommended Set-up with Command via Two-wires

Digital Inputs and DC-Braking .....................................26

3.3.5 Symbols .......................................................................27

English

Summary

English

CHAPTER 4

Setting the SSW-07

4.1 Control Type Setting ...........................................................28

4.2 Kick Start ............................................................................29

4.3 Initial Voltage Setting ..........................................................29

4.4 Current Limit Setting ...........................................................30

4.5 Acceleration Ramp Time Setting ........................................31

4.6 Deceleration Ramp Time Setting ........................................31

4.7 Motor Current Setting .........................................................32

4.8 Motor Electronic Overload Protection ................................33

4.9 Reset ..................................................................................36

4.10 DI2 Digital Input Setting ....................................................36

4.11 Output Relay Operation ....................................................37

4.12 Relay Output RL1 Programming ......................................37

CHAPTER 5

Programming Information and Suggestions

5.1 Applications and Programming ...........................................38

5.1.1 Voltage Ramp Starting .................................................39

5.1.2 Current Limit Starting ...................................................40

5.1.3 Starting with Pump Control (P202 = 2) ........................40

5.1.4 Programming the control type in pump control ............42

5.2 Protections and Programming ............................................43

5.2.1 Suggestion on How to Program the Thermal Class .....43

5.2.2 Service Factor ..............................................................45

CHAPTER 6

Solution and Troubleshooting

6.1 Faults and Possible Causes ...............................................47

6.2 Troubleshooting ..................................................................50

6.3 Preventive Maintenance .....................................................51

CHAPTER 7

Options and Accessories

7.1 IP20 Kit ...............................................................................52

CHAPTER 8

Technical Characteristics

8.1 Nominal Powers and Currents According to UL508 ...........53

8.2 Nominal Powers and Currents for Standard IP55,

IV Pole Weg Motor .............................................................53

8.3 Power Data .........................................................................54

8.4 Electronics and Programming Data ....................................54

CHAPTER 1

SAFETY INSTRUCTIONS

This Manual contains the necessary information for the correct use

of the Soft-Starter SSW-07.

It was written to be used by qualied personnel with suitable training

or technical qualications to operate this type of equipment.

1.1 SAFETY NOTICES IN THE MANUAL

1.2 SAFETY NOTICES ON THE PRODUCT

The following safety notices will be used in the text.

DANGER!

The nonobservance of the procedures recommended in this warning

can lead to death, serious injuries and considerable material damage.

ATTENTION!

Failure to observe the recommended procedures in this notice may

lead to material damage.

NOTE!

The text intents to supply important information for the correct

understanding and good operation of the product.

The following symbols may be attached to the product as a safety

notice.

English

1.3 PRELIMINARY RECOMMENDATIONS

High Voltages.

Components are sensitive to electrostatic discharge.

Do not touch them.

Mandatory connection to ground protection (PE).

DANGER!

Only personnel with suitable qualication and familiar with the

Soft-Starter SSW-07 and associated equipment should plan or

implement the installation, start-up, operation and maintenance of

this equipment.

These personnel must follow all safety instructions in this manual

and/ or dened by local regulations.

Failure to follow these safety instructions may result in personnel

injury and/or equipment damage.

5

CHAPTER 1 - SAFETY INSTRUCTIONS

NOTE!

In this Manual, qualied personnel are those trained to:

1. Install, ground, power-up, and operate the Soft-Starter SSW-07

according to this manual and the required safety procedures;

2. Use protection equipment according to established regulations;

3. Give First Aid.

DANGER!

Always disconnect the general power supply before touching any

electrical component associated to the Soft-Starter SSW-07.

English

High voltage may be present even after the power supply is

disconnected. Wait at least 3 minutes for the total discharge of the

capacitors.

Always connect the equipment’s heatsink to the protection ground

(PE), at the proper connection point.

ATTENTION!

All electronic boards have components that are sensitive to

electrostatic discharges. Do not touch these components or

connectors directly.

If necessary, rst touch the grounded metallic heatsink or use a

suitable grounded wrist strap.

Do not apply any high voltage test on the Soft-Starter SSW-07!

If necessary, contact the manufacturer.

NOTE!

Soft-Starters SSW-07 may interfere with other electronic equipment.

Follow the measures in Chapter 3 to reduce these effects.

NOTE!

Read this manual completely before installing or operating the

Soft-Starter SSW-07.

6

GENERAL INFORMATION

Tampa para

Trifásica

Opcionais Plug-In

Ajustes e Habilitar as

Proteções

DIP Swith para

LED's para Indicação

Entrada de Alimentação

de Status da SSW-07

Saída para Motor

Saida a Relé

(13,14/23 e 24)

CHAPTER 2

2.1 ABOUT THIS MANUAL

2.2 ABOUT THE

SOFT-STARTER

SSW-07

This manual presents the Soft-Starter installation, how to start it up,

its main technical characteristics and how to identify and correct the

most common problems. The manuals listed next must be consulted

in order to get more information regarding the functions, accessories

and working conditions:

Programming Manual, with a detailed description of the

parameters and its functions;

RS232 / RS485 Communication Manual.

DeviceNet Communication Manual.

These manuals are supplied in electronic format on the CD-ROM

that accompanies the Soft-Starter, or can be obtained at WEG’s

web site: http://www.weg.net.

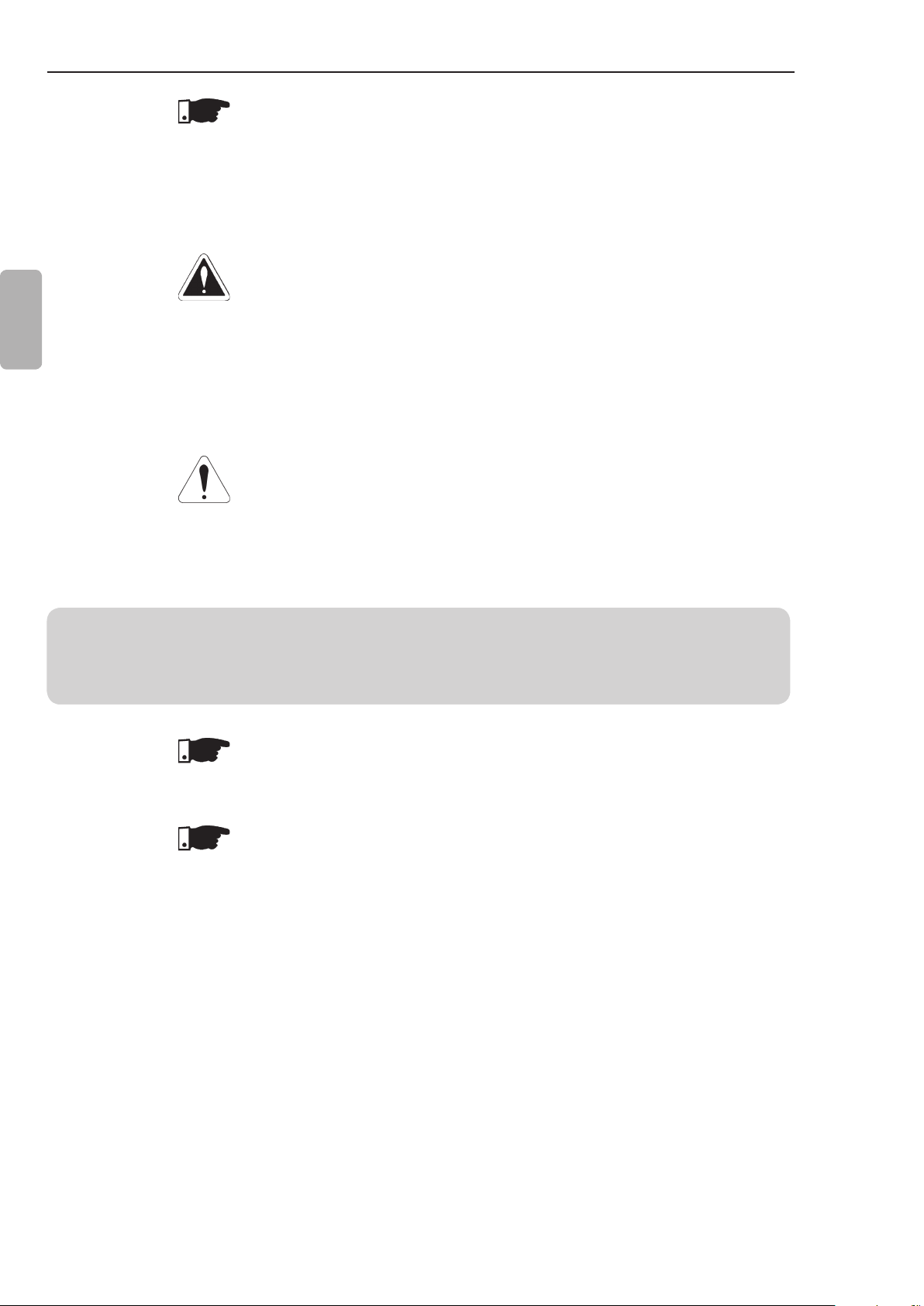

The Soft-Starter SSW-07 is a high performance product that permits

the start control of the three phase AC induction motors. Thus, it

prevents mechanical shocks on the load and current peaks in the

supply line.

Three-phase

Power Supply

English

Trimpots to adjust

DIP switch to adjust

the Thermal Class

Electronic Power Supply

(A1 and A2)/

Start/Stop Command

of the Motor (D1) and

Reset (DI2 and DI3)

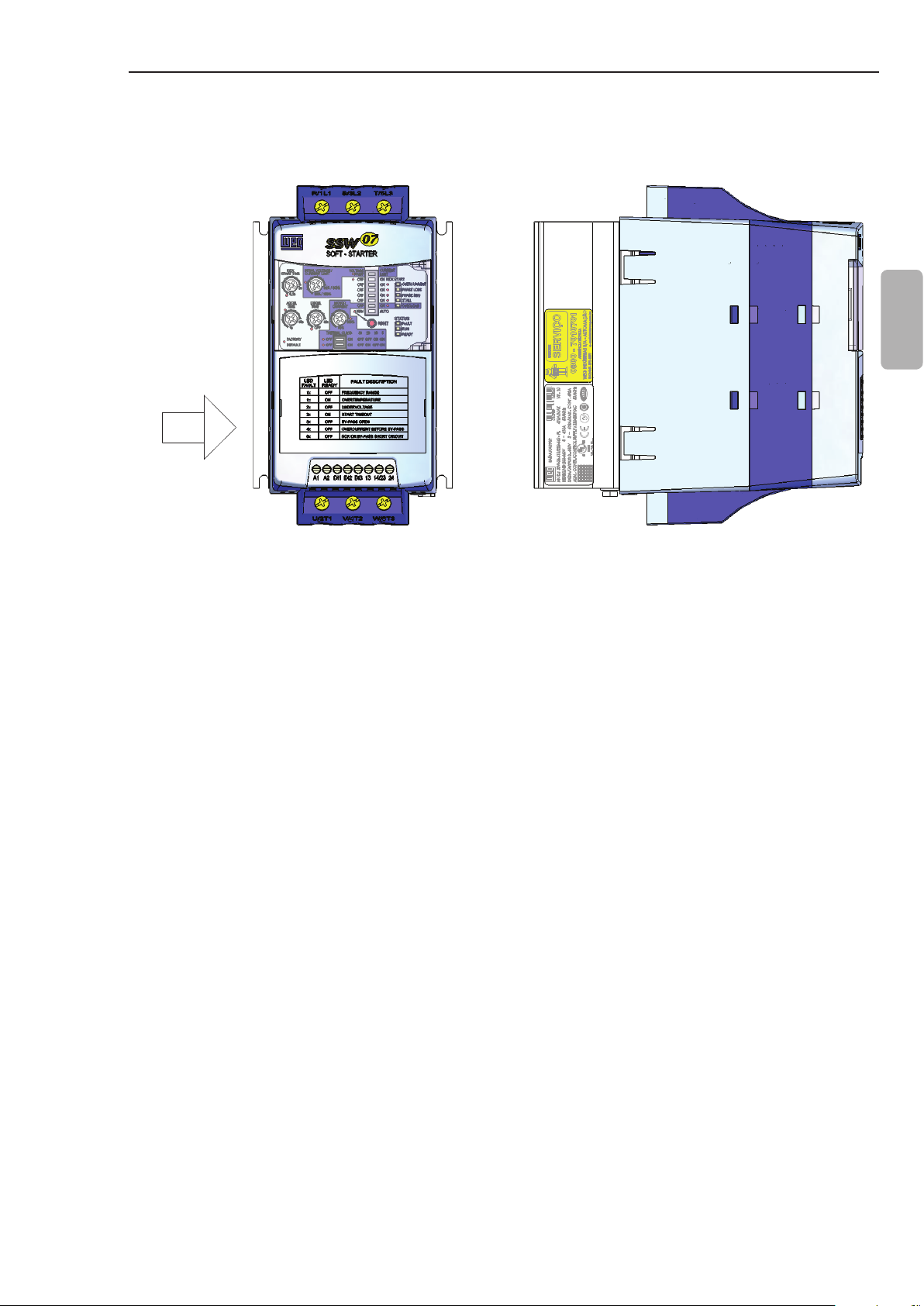

Figure 2.1 - Frontal view of the SSW-07

DIP Switch for

Soft-Starter adjustment

and protection enabling

Status Indication LEDs

of the SSW-07

Lid for optional Plug-in

Modules

Relay Output

(13, 14/23 and 24)

Motor Output

7

CHAPTER 2 - GENERAL INFORMATION

English

Three-Phase

Power Supply

R S

U

V W

Three-Phase Motor

Programmable

Digital Inputs

Dl1

Dl2

Dl3

T

Control

Power Supply

A1

A2

3 x

Digital Signal

2 x

Processor

DSP

PE

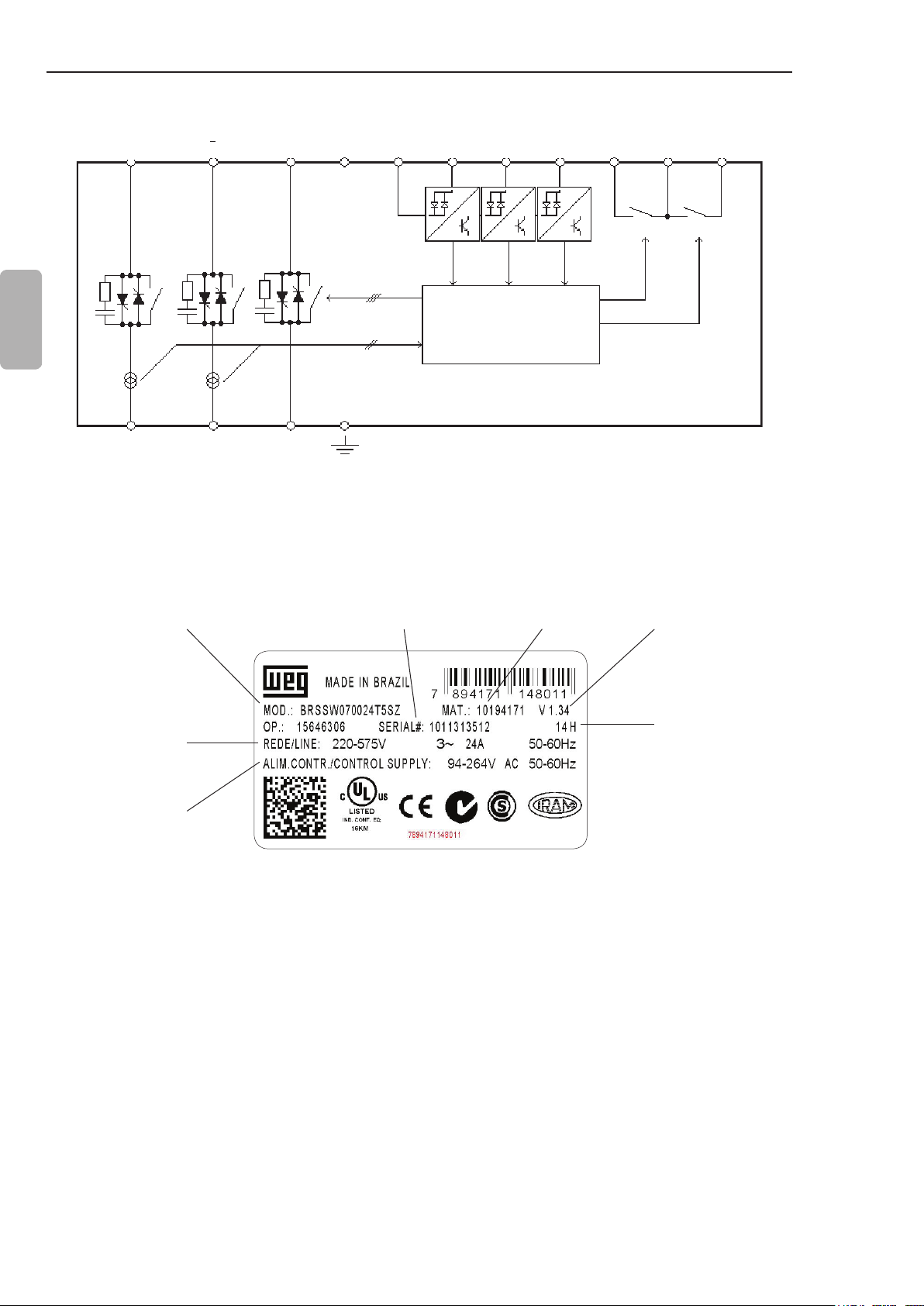

Figure 2.2 - Soft-Starter SSW-07 block diagram

Programmable Digital

Outputs

13

14/23 24

RL1

RL2

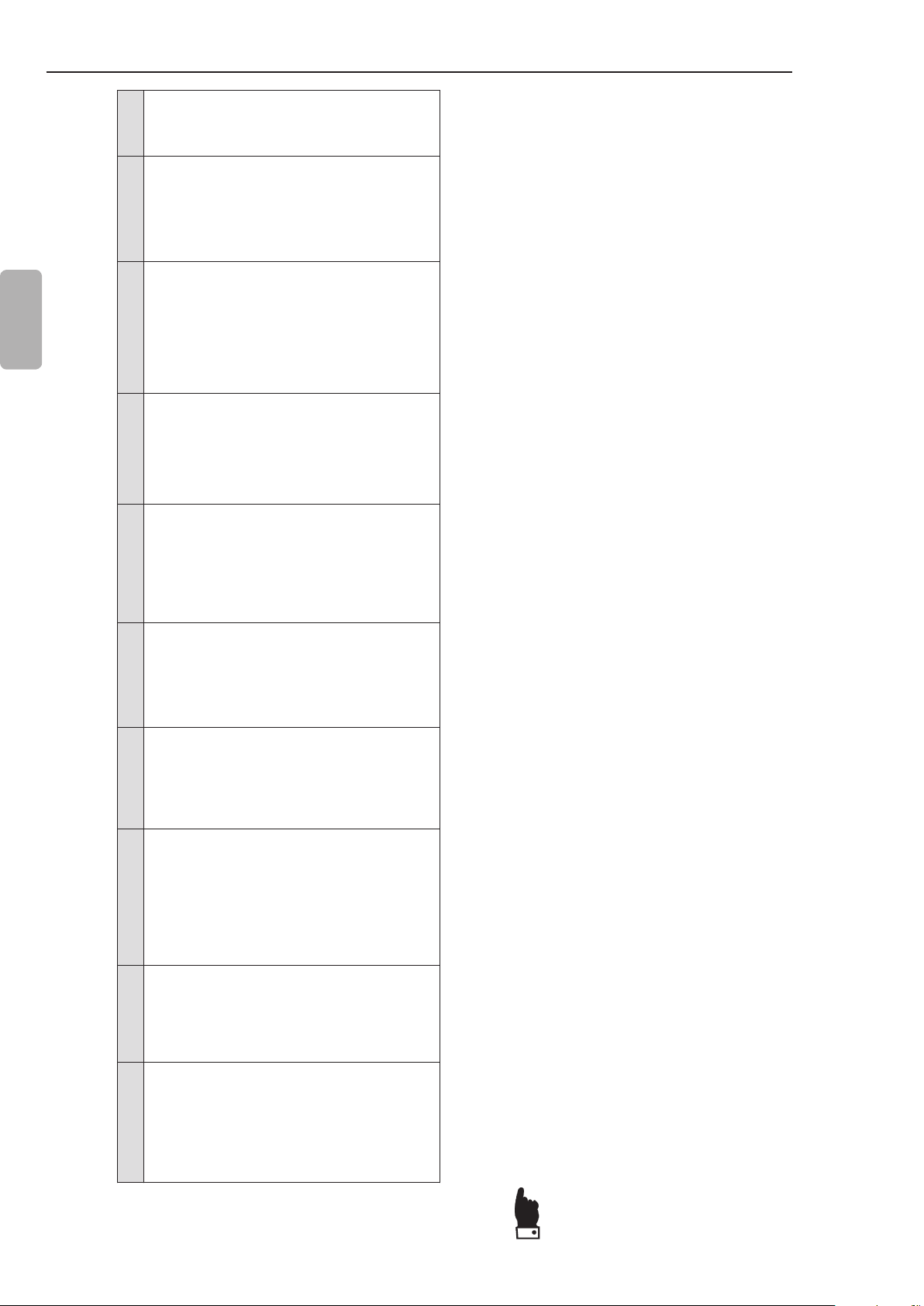

2.3 SOFT-STARTER SSW-07 IDENTIFICATION PLATE

WEG Stock

SSW-07 Model

Input Data (Voltage,

Number of Phases,

Current and Frequency)

Control Power Supply

Data (Voltage, Frequency)

Serial Number

Figure 2.3 - Soft-Starter SSW-07 identication plate

Item Number

Software

Version

Manufacturing date

(14 corresponds to

week and H to year)

8

CHAPTER 2 - GENERAL INFORMATION

VISTA FRONTAL

VISTA DE X

Position of the Identication Plate on the Soft-Starter SSW-07:

FRONTAL VIEW X VIEW

English

X

Figure 2.4 - Location of the labels

9

CHAPTER 2 - GENERAL INFORMATION

End of

Code

Special

Software

Blank =

Standard

S1 = Special

Software

English

Special

Hardware

Blank =

Degree of

Protection

Blank =

S = Standard

O = with

220-575 Vac Optional:

(2)

Standard

H1 = Electronics

supply: 110 to

130 Vac

H2 = Electronics

(1)

Standard

IP=IP20

Optional

(2)

supply: 208 to

240 Vac

10

HOW TO SPECIFY THE SSW-07 MODEL:

Three-

Phase

SSW-07

Nominal Current

WEG Soft-

Starter

EX SSW-07 0017 T 5 S _ _ _ _ _ _ Z

Market

Power

Supply

0017 = 17 A

0024 = 24 A

0030 = 30 A

Series

SSW-07

BR = Brazil

EX = Export

0045 = 45 A

0061 = 61 A

0085 = 85 A

0130 = 130 A

0171 = 171 A

0200 = 200 A

0255 = 255 A

0312 = 312 A

0365 = 365 A

0412 = 412 A

(1) Only for models 130 A to 412 A.

(2) Only for the 255 A to 412 A models.

NOTE!

The option eld (S or O) denes if the Soft-Starter SSW-07 will be a standard version or if it will include any optional. If standard, the

code ends here.

Always put the letter Z at the end. For example:

EXSSW070017T5SZ = Standard Soft-Starter SSW-07 with 17 A and 220 V to 575 V to three-phase input with the User’s Guide in

English, Spanish and Portuguese.

If there is any optional, the elds must be lled out in the correct sequence until the code is completed with the letter Z.

The standard product as dened by this code is described as:

Degree of Protection: IP20 from 17 A to 85 A and IP00 from 130 A to 412 A.

CHAPTER 2 - GENERAL INFORMATION

2.4 RECEIVING AND STORAGE

The Soft-Starter SSW-07 is supplied in a cardboard box. On the

outside of the package there is an identication plate which is

identical to the one placed on the Soft-Starter SSW-07.

To open the package:

1- Put it on a table;

2- Open the package;

3- Take out the Soft-Starter.

Check if:

The Identication plate of the Soft-Starter SSW-07 matches the

model purchased:

Damage has occurred during transport. If so, contact the carrier

immediately.

If the Soft-Starter SSW-07 is not installed immediately, store it in

its package in a clean and dry place with temperature between

-25 °C (-13 °F) and 65 °C (149 °F). 1 hour at -40 °C (-40 °F) is

permitted.

English

SSW-07

Model

17 A

24 A

30 A

45 A

61 A

85 A

130 A

171 A

200 A

255 A

312 A

365 A

412 A

Height

H

mm

(in)

221

(8.70)

260

(10.24)

356

(14.02)

415

(16.34)

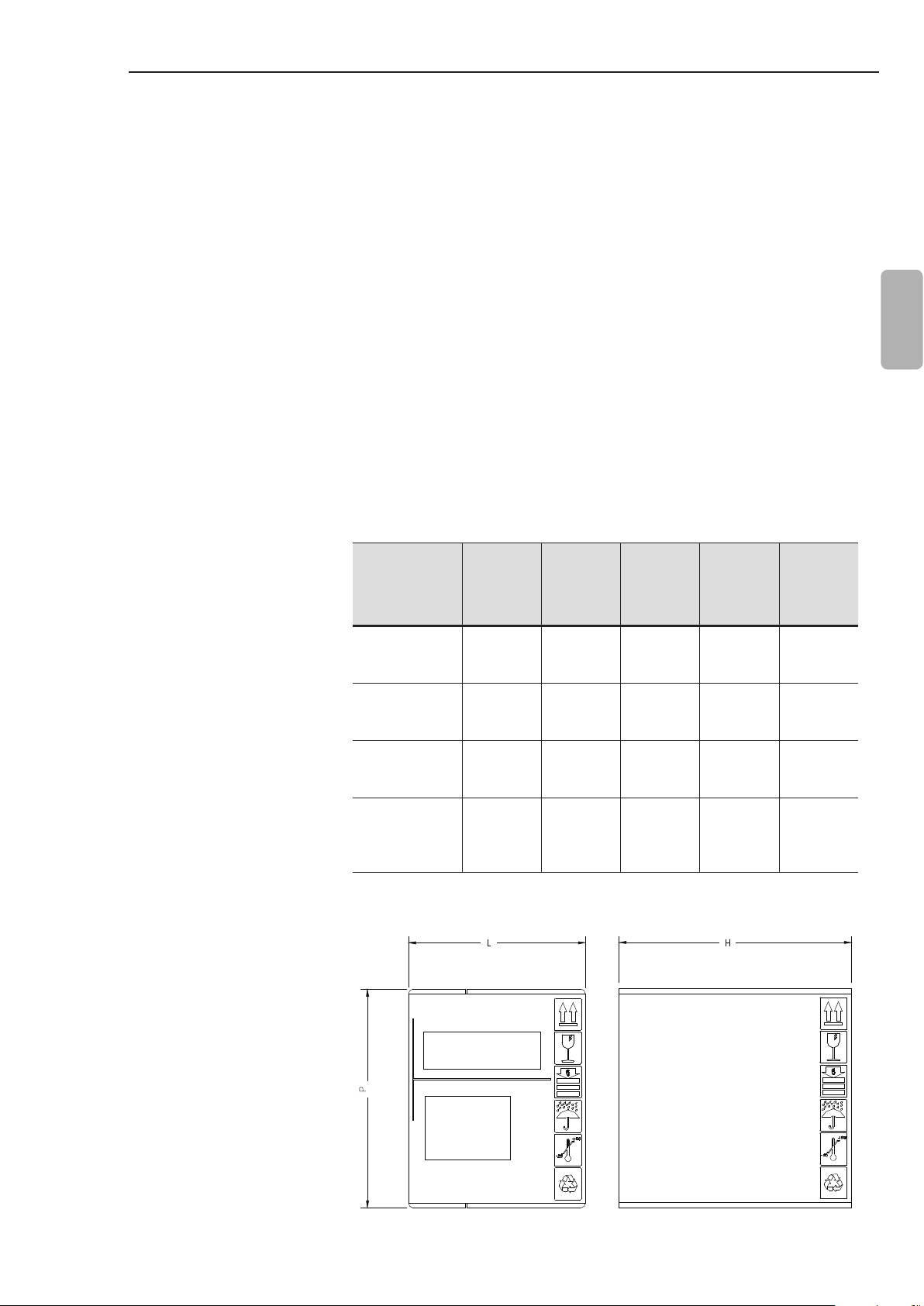

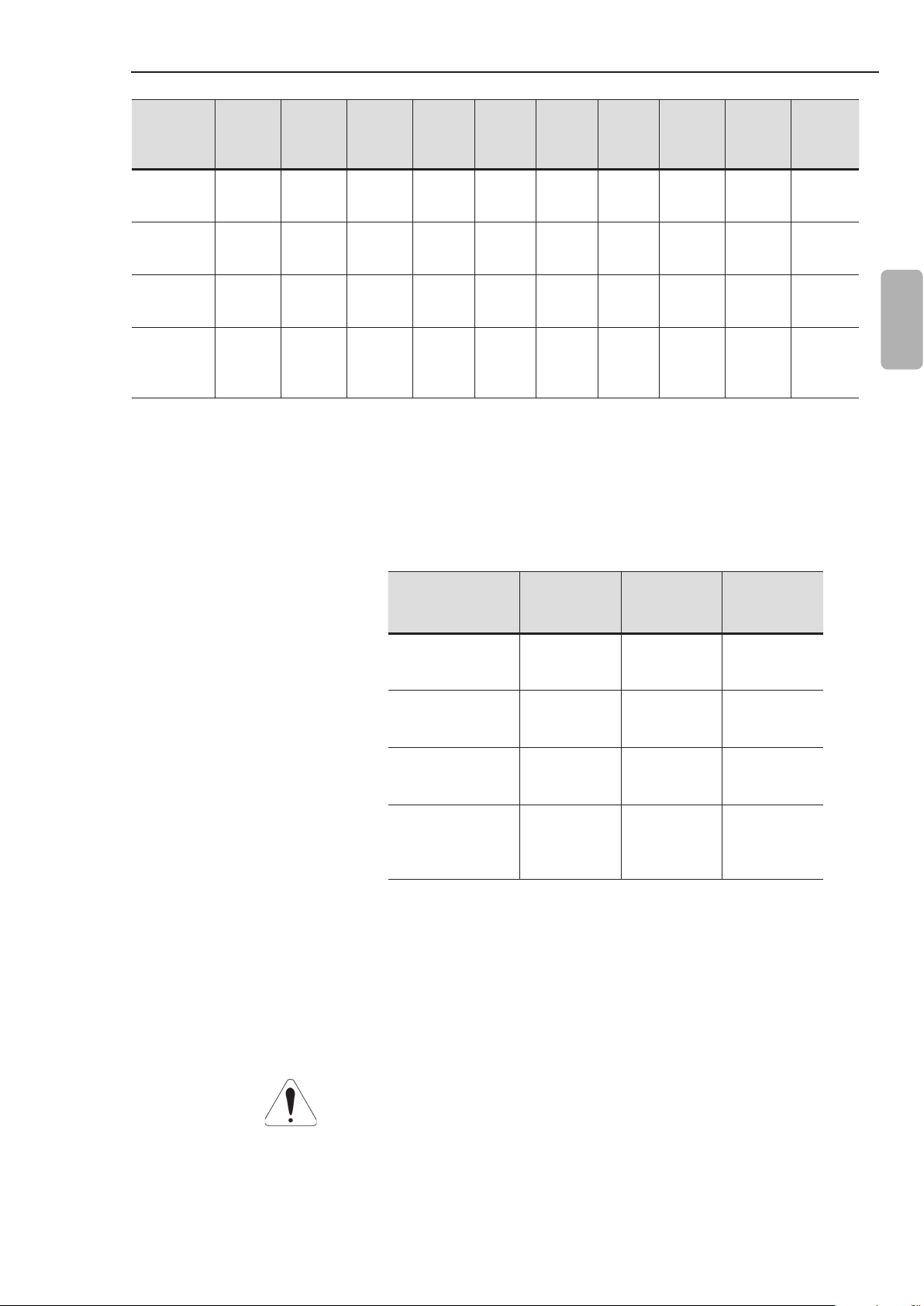

Table 2.1 - Dimensions of the package in mm (in)

Width

L

mm

(in)

180

(7.09)

198

(7.80)

273

(10.75)

265

(10.43)

Depth

P

mm

(in)

145

(5.71)

245

(9.65)

295

(11.61)

320

(12.6)

Volume

3

cm

(in3)

5768

(352.2)

12613

(770.8)

28670

(1750)

35192

(2147)

Weight

kg

(lb)

1.65

(3.64)

3.82

(8.42)

8.36

(18.43)

12.8

(28.2)

Figure 2.5 - Dimensions of the package

11

C

A

B

P

L

3.1 MECHANICAL INSTALLATION

CHAPTER 3

INSTALLATION AND CONNECTION

This chapter describes the procedures for the electrical and

mechanical installation of the Soft-Starter SSW-07. The guidelines

and suggestions must be followed for the correct operation of the

Soft-Starter SSW-07.

3.1.1 Environmental

English

Conditions

The location of the Soft-Starters SSW-07 is an important factor to

assure the correct operation and high product reliability.

Avoid:

Direct exposure to sunlight, rain, high moisture and sea air ;

Exposure to explosive or corrosive gases and liquids;

Exposure to excessive vibration, dust or any metallic and/or oil

particles in the air.

Allowed Environmental Conditions:

Surrounding air Temperature: 0 ºC to 55 ºC (32 ºF to 131 ºF) -

nominal conditions.

Relative air moisture: 5 % to 90 %, with no-condensation.

Maximum altitude: 1,000 m (3,300 ft) above sea level - nominal

conditions.

From, 1,000 m to 4,000 m (3,300 ft to 13,200 ft) above sea level -

current reduction of 1 % for each 100 m (330 ft) above 1,000 m

(3,300 ft).

From 2000 m to 4000 m (6,600 ft to 13,200 ft) above sea level -

voltage reduction of 1.1 % for each 100m (330 ft) above 2,000 m

(6,600 ft).

Pollution degree: 2 (according to the UL508).

Normally, only non conductive pollution. Condensation must not

cause conduction in the particles in the air.

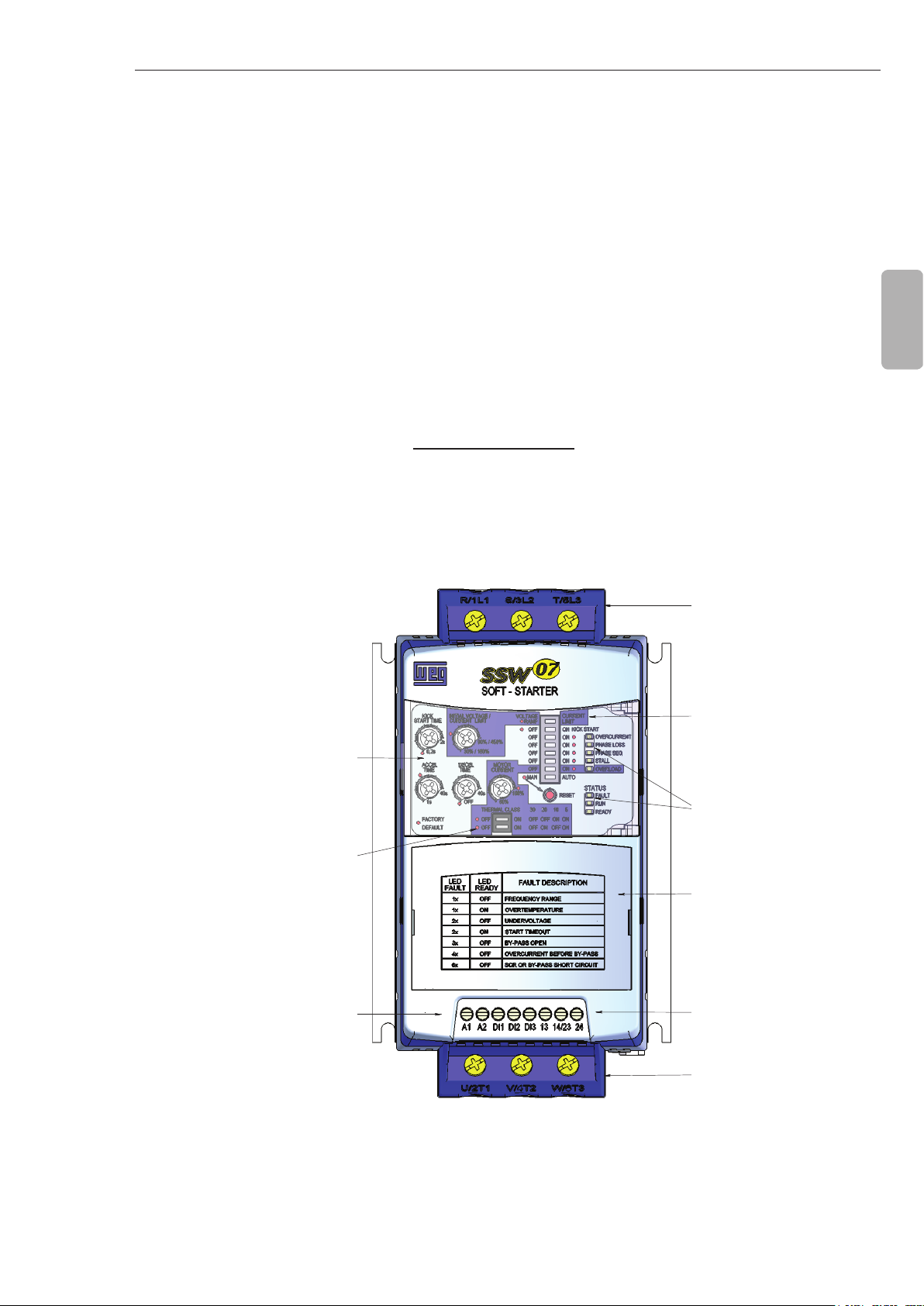

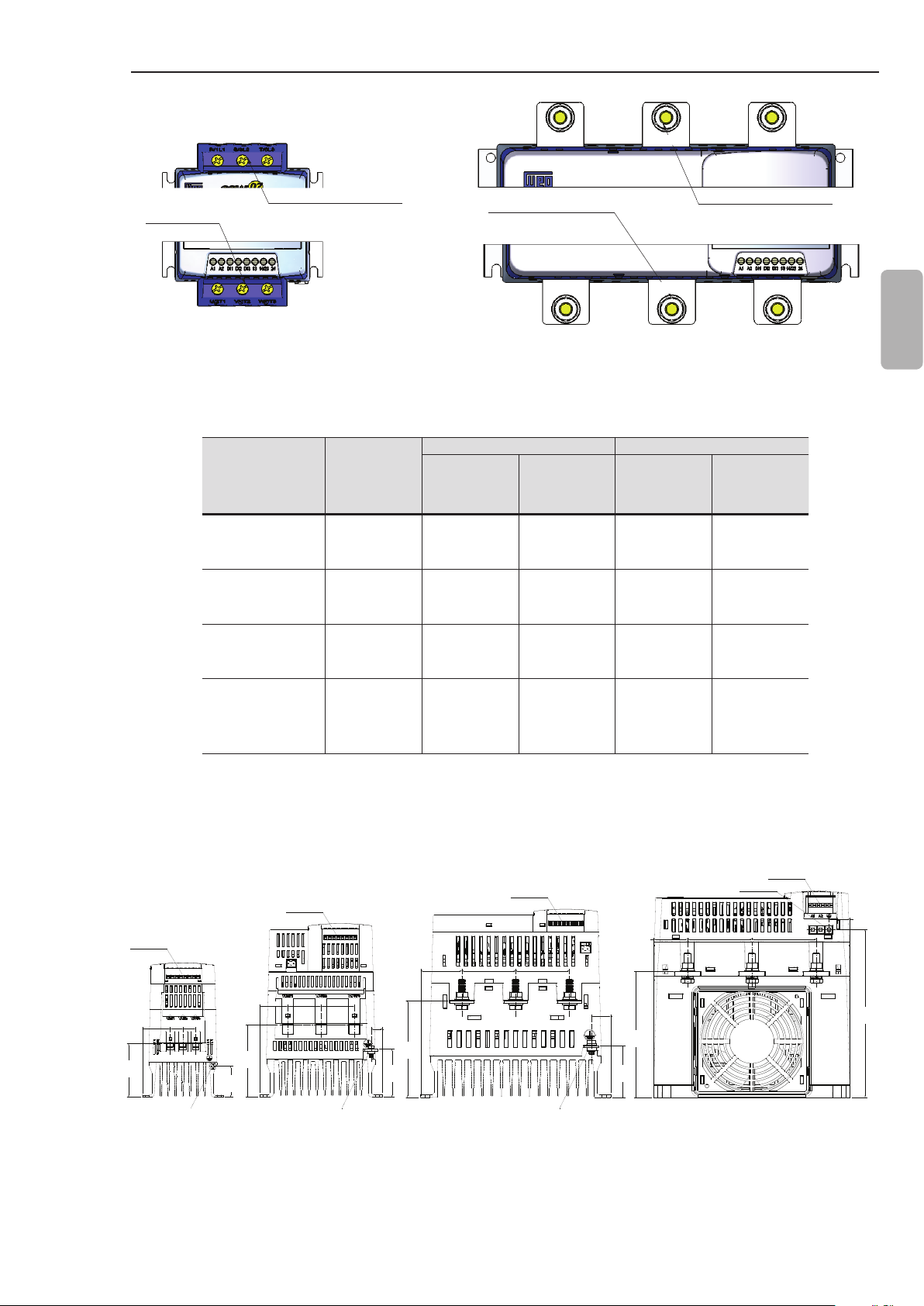

3.1.2 Soft-Starter SSW-07 Dimensions

B

D

D

C

12

The external dimensions and mounting holes are shown in gure

3.1 and table 3.1 below.

A

Figure 3.1 - SSW-07 dimensions

L

H

H

P

CHAPTER 3 - INSTALLATION AND CONNECTION

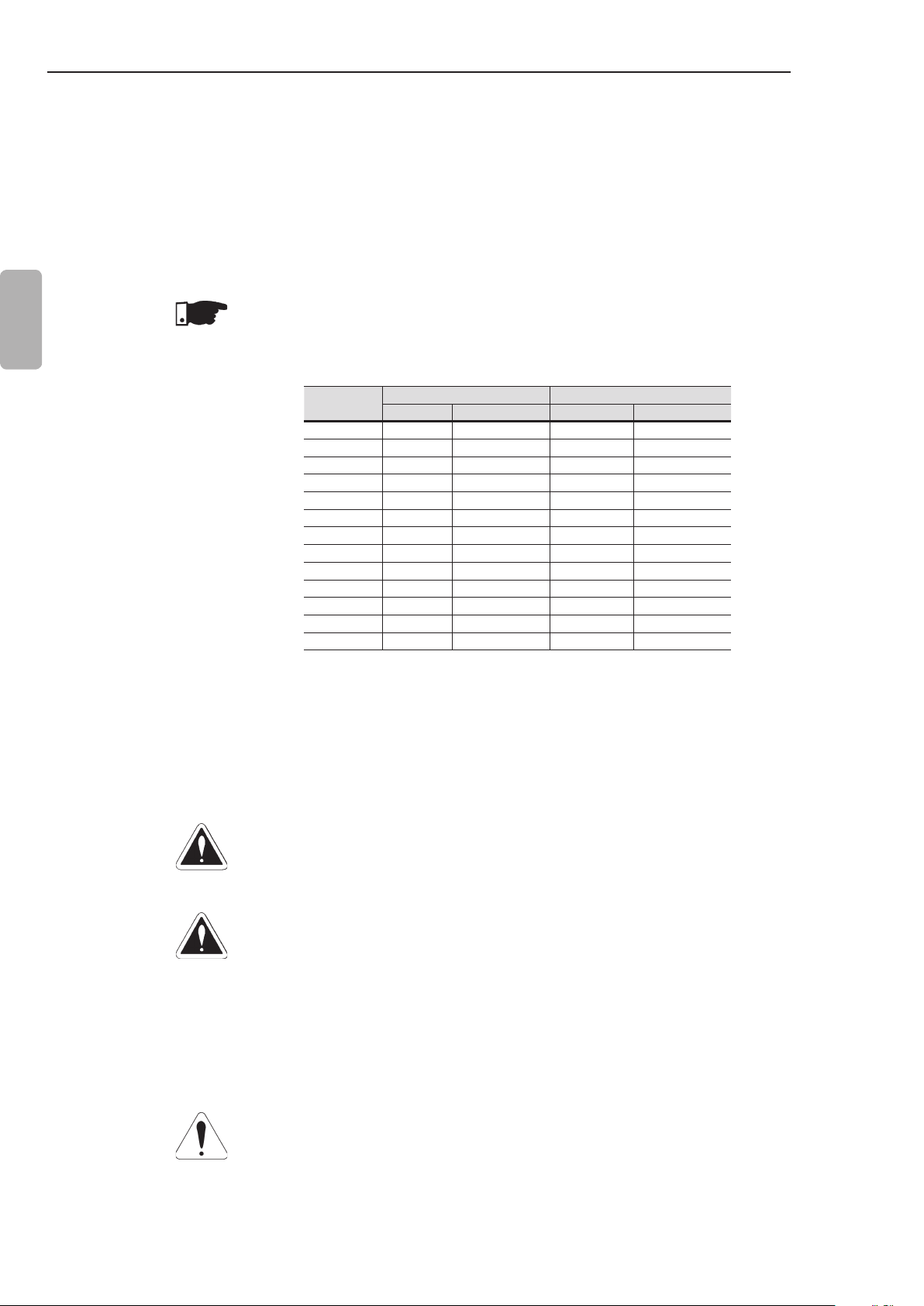

Height

SSW-07

Model

17 A

24 A

30 A

45 A

61 A

85 A

130 A

171 A

200 A

255 A

312 A

365 A

412 A

H

mm

(in)

162

(6.38)95(3.74)

208

(8.19)

276

(10.9)

331

(13.0)

* IP20 with optional.

3.1.3 Mounting

Specications

Width

L

mm

(in)

144

(5.67)

223

(8.78)

227

(8.94)

Depth

P

mm

(in)

157

(6.18)85(3.35)

203

(7.99)

220

(8.66)

242

(9.53)

A

mm

(in)

132

(5.2)

208

(8.19)

200

(7.87)

B

mm

(in)

120

(4.72)5(0.20)4(0.16) M4

148

(5.83)6(0.24)

210

(8.27)

280

(11.0)15(0.59)9(0.35)

C

mm

(in)

7.5

(0.3)

D

Mounting

mm

(in)

3.4

(0.13) M4

5

(0.2) M5

Screw

M8

Weight

kg

(lb)

1.3

(2.9) IP20

3.3

(7.28) IP20

7.6

(16.8)

11.5

(25.4)

Table 3.1 - Installation data with dimensions in mm (in)

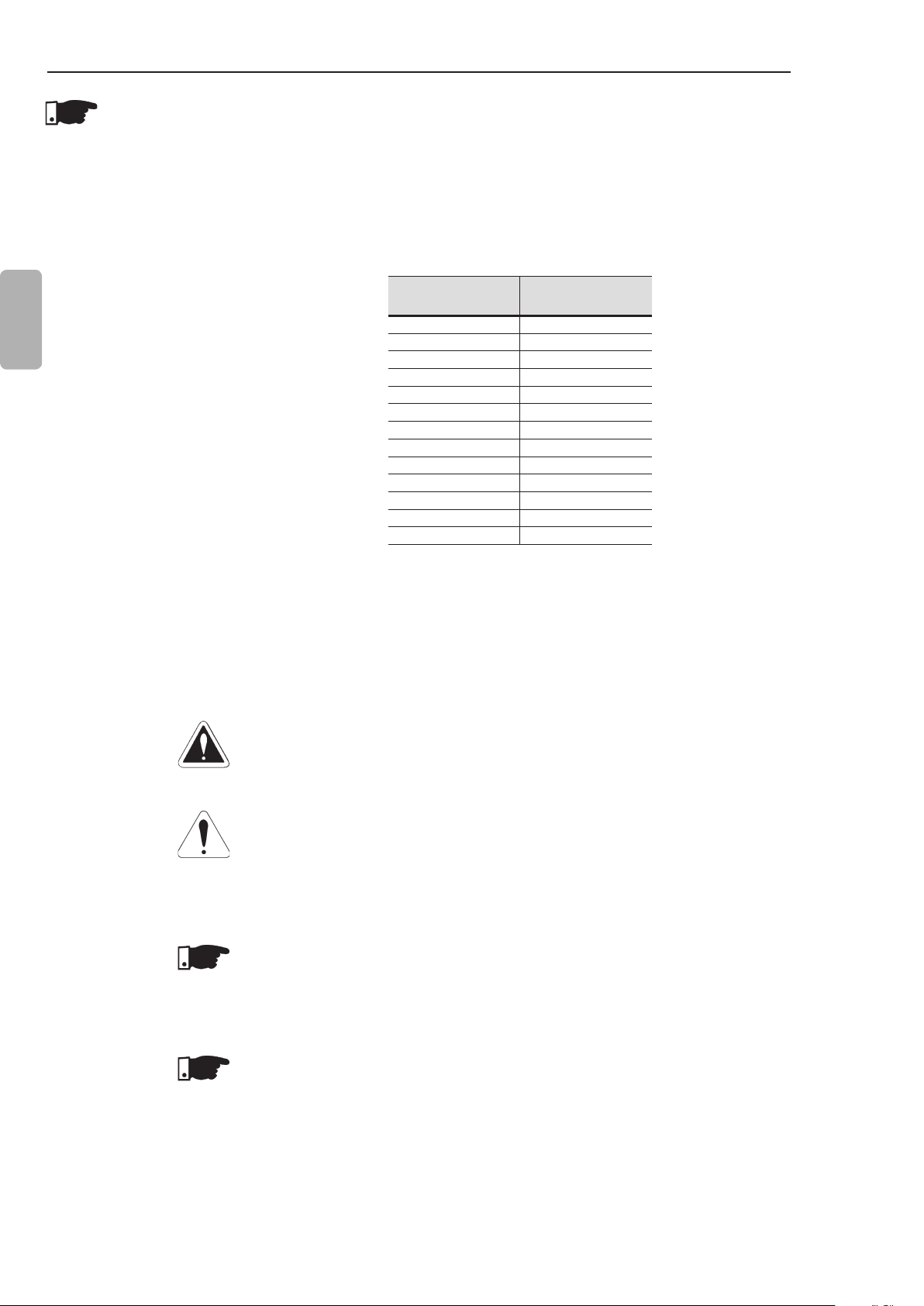

To install the Soft-Starter SSW-07 leave at least the free spaces

surrounding the Soft-Starter as in gure 3.2 below. The dimensions

of these free spaces are described in table 3.2.

Degree

of

Protection

IP00 *

English

IP00 *

SSW-07 Model

17 A

24 A

30 A

45 A

61 A

85 A

130 A

171 A

200 A

A

mm

(in)

50

(2)

80

(3.2)

100

(4)

B

mm

(in)

50

(2)

80

(3.2)

100

(4)

C

mm

(in)

30

(1.2)

30

(1.2)

30

(1.2)

255 A

312 A

365 A

150

(6)

150

(6)

30

(1.2)

412 A

Table 3.2 - Recommended free spaces

Install the Soft-Starter SSW-07 in the vertical position according to

the following recommendations:

1) Install on a reasonably at surface;

2) Do not put heat sensitive components immediately above the

Soft-Starter SSW-07.

ATTENTION!

If a Soft-Starter SSW-07 is installed on top of another use the

minimum distance A + B and diverge from the top Soft-Starter the

hot air that comes from the one beneath it.

13

CHAPTER 3 - INSTALLATION AND CONNECTION

ATTENTION!

Independent conduits or cable trays must be planned for physic

separation of signal, control and power cables. (Refer to item 3.2

Electrical Installation).

A

A

English

SAIDA

Air Flow

FLUXO DE AR

Outlet

C

C

3.1.3.1 Mounting Inside a Panel

SSW-07

Model

130 A 12 117 129

171 A 12 154 166

200 A 12 180 192

255 A 12 230 242

312 A 12 281 293

365 A 12 329 341

412 A 12 371 383

Air Flow

B

B

Figure 3.2 - Free spaces for ventilation

ENTRADA

FLUXO DE AR

Inlet

For Soft-Starters SSW-07 installed in panels or closed metallic

boxes exhaustion/cooling is required so the temperature does not

exceed the maximum allowed. Refer to dissipated nominal power

in table 3.3.

Average Power

Dissipated Power

in the electronics

(W)

17 A 12 15.3 27.3

24 A 12 21.6 33.6

30 A 12 27 39

45 A 12 41 53

61 A 12 55 67

85 A 12 77 89

dissipated

10 starts/h

3 x In @ 30 s

(W)

Total Average Power

dissipated

10 starts/h

3 x In @ 30 s

(W)

14

Table 3.3 - Dissipated power for ventilator panel dimensioning

CHAPTER 3 - INSTALLATION AND CONNECTION

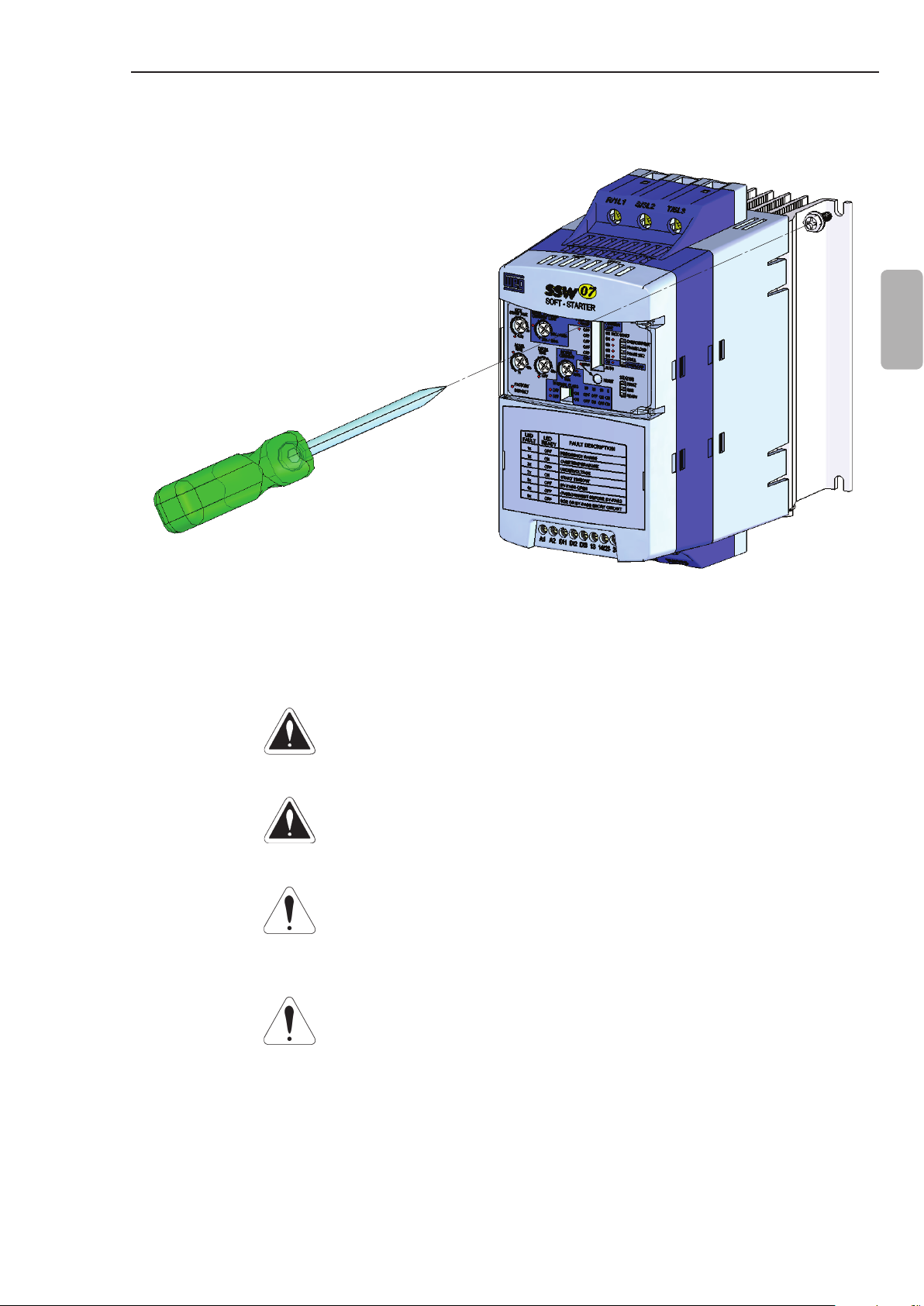

3.1.3.2 Mounting on Surface

Figure 3.3 shows the installation of the Soft-Starter SSW-07 on the

surface of a mounting plate.

English

Figure 3.3 - Installation procedures of the Soft-Starter SSW-07 on a surface

3.2 ELECTRICAL

INSTALLATION

DANGER!

The Soft-Starter SSW-07 cannot be used as an emergency stop

device.

DANGER!

Be sure that the AC input power is disconnected before making any

terminal connection.

ATTENTION!

The information below may be used as a guide to achieve a proper

installation. Follow also the applicable local standards for electrical

installations.

ATTENTION!

If a power isolating contactor or circuit breaker with minimum voltage

coil is not used at the rst power on, then power up the electronics

rst, adjust the trimpots that are necessary to put the SSW-07 into

operation and only after this energize the power section.

15

CHAPTER 3 - INSTALLATION AND CONNECTION

Circuit-breaker

T

S

R

Line

English

Fuses

R/1L1 S/3L2 T/5L3

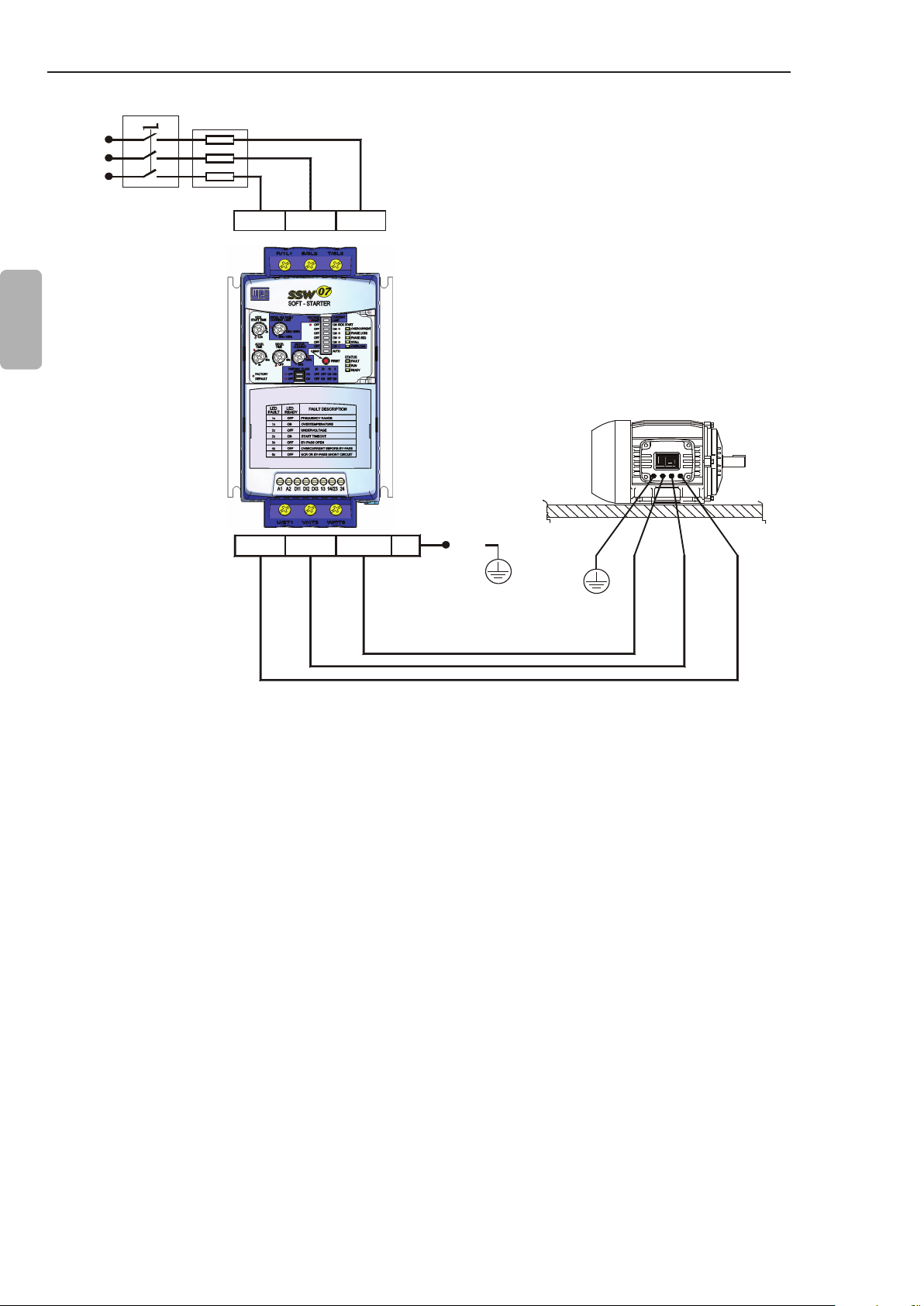

3.2.1 Power Terminals

U/2T1 V/4T2 W/6T3 PE

Figure 3.4 - Standard power/grounding connections

PE

PE

The power terminal blocks vary in size and conguration, depending

on the SSW-07 soft-starter model, as can be observed at the gures

3.5 and 3.6.

Terminals:

R / 1L1, S / 3L2 and T / 5L3: AC supply line.

U / 2T1, V / 4T2 and W / 6T3: Motor connection.

16

CHAPTER 3 - INSTALLATION AND CONNECTION

R/1L1 S/3L2 T/5L3

Output Power

BORNE DE SAIDA

POTENCIA

Terminal

Models 17 A to 85 A Models 130 A to 412 A

Input

BORNE DE ENTRADA

Power Terminal

POTENCIA

SSW-07

Model

17 A

24 A

30 A

45 A

61 A

85 A

130 A

171 A

200 A

255 A

312 A

365 A

412 A

Figure 3.5 - Power terminals

Enclosure

Size

Screw/

Terminal

Size 01 Terminal

Size 02 Terminal

Size 03

Size 04

M8

(5/16”)

M10

(3/8”)

R/1L1

Output

BORNE DE SAIDA

POTENCIA

Power Terminal

U/2T1

S/3L2

V/4T2

Input

BORNE DE ENTRADA

POTENCIA

Power Terminal

Line / Motor Grounding

Torque

Nm

Screw

(in lb)

3

(27)

5.5

(49)

19

(168)

37

(328)

M4

(5/32”)

M5

(3/16”)

M6

(1/4”)

Terminal

T/5L3

W/6T3

English

Torque

Nm

(in lb)

4.5

(40)

6

(53)

8.3

(73)

0.5

(4.5)

Table 3.4 - Maximum torque for power connection

3.2.2 Location of the Grounding, Control and Power Connections

Control

Control

CONTROLE

Control

CONTROLE

48.2

(1.90)

39.0

(1.54)

ATERRAMENTO

39.0

(1.54)

13.3

(0.52)

114

(4.48)

56.3

(2.22)

62.8

(2.48)

32.7

(1.29)

ATERRAMENTO

33.0

36.3

84,8

(3.34)

(1.30)

14.8

14.8

(0.59)

(0.59)

(1.43)

Grounding Grounding Grounding

Dimensions in mm (in).

Figure 3.6 - Location of the grounding, control and power connections

CONTROLE

63.0

(2.48)

(2.48)

ATERRAMENTO

63.0

22.7

(0.89)

60.5

(2.38)

39.7

(1.56)

148

(5.81)

Grounding

ATERRAMENTO

75.5

(2.97)

Control

CONTROLE

75.5

(2.97)

25.1

(0.99)

197

(7.75)

17

CHAPTER 3 - INSTALLATION AND CONNECTION

3.2.3 Recommended Power and Grounding Cables

English

The described specications in table 3.5 are valid only for the

following conditions:

Copper wires for 70 ºC (158 ºF) with PVC insulation for ambient

temperature of 40 ºC (104 ºF), installed in perforated and not

agglomerated conduits.

Naked or silver coated copper busbars with round edges with 1

mm radius with ambient temperature of 40 ºC (104 ºF) and bus

temperature of 80 °C (176 °F).

NOTE!

For correct cable dimensioning, consider the installation condition

and the maximum permitted line voltage drop.

SSW-07

Model

17 A 4 12 4 12

24 A 6 10 6 10

30 A 6 10 6 10

45 A 10 8 6 10

61 A 16 6 10 8

85 A 25 4 10 8

130 A 50 1 25 4

171 A 70 2/0 35 2

200 A 95 3/0 50 1

255 A 120 250 kcmil 2.5 14

312 A 185 350 kcmil 2.5 14

365 A 240 500 kcmil 2.5 14

412 A 300 600 kcmil 2.5 14

Power Cable Grounding Cable

2

) AWG (mm2) AWG

(mm

3.2.4 Power Supply Connection to the Soft-Starter SSW-07

18

Table 3.5 - Minimum cable gauge specication

DANGER!

The AC input must be compatible with the voltage range of the

Soft-Starter SSW-07.

DANGER!

Provide a power supply disconnecting switch for the Soft-Starter

SSW-07. This disconnecting switch must disconnect the AC input

voltage to the Soft-Starter SSW-07 whenever necessary (for

example: during maintenance services).

If a disconnected switch or a contactor is inserted in the motor supply

line never operate these devices with the motor running or when

the Soft-Starter SSW-07 is enabled.

ATTENTION!

The overvoltage control in the line that feeds the soft-starter must

be done using overvoltage suppressors with a clamping voltage of

680 Vac (phase-to-phase connection) and an energy absorption

capability of 40 joules (17 A to 200 A models) and 80 joules (255 A

to 412 A models).

CHAPTER 3 - INSTALLATION AND CONNECTION

NOTE!

Use the wire sizes and fuses recommended in tables 3.5 and 3.7.

The connector tightening torque is indicated in table 3.4. Use only

copper wires 70 °C (158 °F).

3.2.4.1 Power Supply Capacity

The Soft-Starter SSW-07 is suitable to be used in a circuit capable

of supplying not more than X (according to table 3.6) symmetrical

rms amperes, Y maximum volts when protected by ultra-rapid fuses.

SSW-07 Model

17 A 5

24 A 5

30 A 5

45 A 5

61 A 5

85 A 10

130 A 10

171 A 10

200 A 10

255 A 25

312 A 25

365 A 25

412 A 25

Table 3.6 - Maximum current capacity of the power supply

Y = 220-575 V

X (kA)

The SSW-07 can be installed on power supplies with a higher

fault level, if it is protected by ultra-rapid fuses with an adequate

2

interrupting current and an I

t according to item 3.2.4.2.

English

3.2.4.2 Recommended Fuses

The fuses to be used on the input must be high speed semiconductor

fuses with l2t lower or equal to 75 % of the SCR value indicated in

2

table 3.7 (A

s). The fuse rated current should preferably be equal or

greater than the motor starting current to avoid cyclic overloads and

fuse opening in the forbidden region of the Time x Current curve.

These fuses will protect the SSW-07 in case of a short-circuit.

Normal fuses can also be used, instead of the high speed, which will protect

the installation from short-circuits, but the SSW-07 will not be protected.

For the electronic supply protection of the SSW-07 must be used

fuse type D, or circuit breaker type C as specied in table 3.7.

I²t of

SSW-07

Model

17 A 720 63 FNH1-63-K-A 10806688 50 6.6URD30TTF0050 170M2611

24 A 4000 80 FNH00-80-K-A 10705995 80 6.6URD30TTF0080 170M1366

30 A 4000 100 FNH00-100-K-A 10707110 80 6.6URD30TTF0080 170M1366

45 A 8000 125 FNH00-125-K-A 10707231 100 6.6URD30TTF0100 170M1367

61 A 10500 160 FNH00-160-K-A 10701724 125 6.6URD30TTF0125 170M1368

85 A 51200 250 FNH00-250-K-A 10711445 200 6.6URD30TTF0200 170M1370

130 A 97000 400 FNH1-400-K-A 10815073 315 6.6URD31TTF0315 170M1372

171 A 168000 500 FNH2-500-K-A 10824109 450 6.6URD32TTF0450 170M3170

200 A 245000 630 FNH2-630-K-A 10824110 500 6.6URD32TTF0500 170M3171

255 A 90000 500 FNH3-500-K-A 10833056 400 6.6URD32TTF0400 170M5158

312 A 238000 710 FNH3-710-K-A 10833591 500 6.6URD33TTF0500 170M3171

365 A 238000 710 FNH3-710-K-A 10833591 550 6.6URD33TTF0550 170M5161

412 A 320000 2 x 500 A FNH3-500-K-A 10833056 700 6.6URD33TTF0700 170M6161

the

SCR

(A²s)

WEG Fuses with CE Certication Fuses with UL Certication (A)

Fuse

Nominal

Current

(A)

Fuse Model

(Blade Contacts)

Part

Number

WEG

Fuse

Nominal

Current

(A)

Ferraz Shawmut/

Mersen

Flush End Contacts

Cooper

Bussmann

Bolted

Contacts

Control

Fuse

2 A

(D Type)

or

2 A

Circuit

Breakers

(C Type)

Table 3.7 - Recommended fuses

19

CHAPTER 3 - INSTALLATION AND CONNECTION

NOTE!

The maximum I2t of the SSW-07 255 A fuse is smaller than 200 A

because of the thyristor constructive type used on this soft-starter.

3.2.4.3 Recommended Contactors

English

3.2.5 Soft-Starter

SSW-07

Connection to

the Motor

When the SSW-07 is used in applications that require an isolator

contactor, according to the gure 3.10 (K1), the use of WEG

contactors is recommended.

SSW-07 Model WEG Contactor

17 A CWM18

24 A CWM25

30 A CWM32

45 A CWM50

61 A CWM65

85 A CWM95

130 A CWM150

171 A CWM180

200 A CWM250

255 A CWM250

312 A CWM300

365 A CWME400

412 A CWME400

Table 3.8 - Recommended contactors

DANGER!

Power factor correction capacitors must never be installed at the

output of the Soft-Starter SSW-07. (U / 2T1, V / 4T2 and W / 6T3).

ATTENTION!

To ensure that the protections based on the current reading and

display operate correctly, for example the overload, the motor

nominal current must not be lower than 50 % of the nominal SoftStarter SSW-07 current.

NOTE!

Use the wire sizes and fuses recommended in tables 3.5, 3.6 and

3.7. The connector tightening torque is indicated in table 3.4. Use

only copper wires.

NOTE!

The Soft-Starter SSW-07 is provided with electronic protection

against motor overload. This protection must be set according to

the specic motor. When several motors are connected to the same

Soft-Starter SSW-07 use individual overload relays for each motor.

20

CHAPTER 3 - INSTALLATION AND CONNECTION

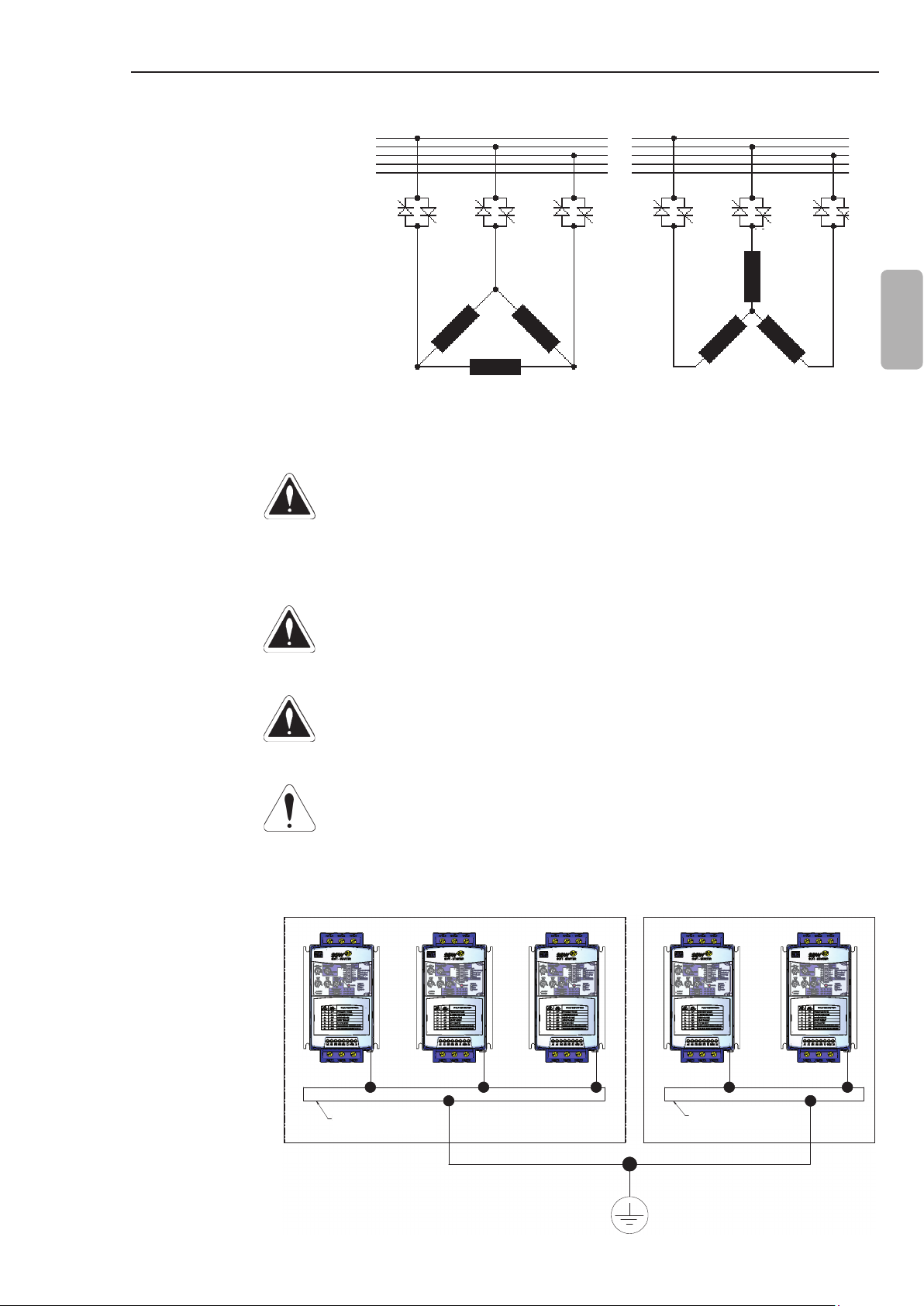

3.2.5.1 Standard Three-Wire Connection

3.2.6 Grounding

Connections

Line current of the Soft-Starter SSW-07 is equal to the motor current.

R

S

T

N

PE

R

U

1/U1

S

V

4/U2

6/W2

3/W1

T

2/V1

5/V2

Figure 3.7 - Soft-Starter SSW-07 with standard connection

R

S

T

N

PE

R

W

U

1/U1

2/V1

4/U2

S

5/V2

6/W2

T

WV

3/W1

DANGER!

The Soft-Starter must be grounded for safety purposes (PE).

The ground connection must comply with the local regulations.

Make the ground connection to a grounding bar or to the general

grounding point (resistance ≤10 ohms).

English

DANGER!

The AC input for the Soft-Starter SSW-07 must have a ground

connection.

DANGER!

Do not use the neutral conductor for grounding purpose. Use

dedicated ground conductor.

ATTENTION!

Do not share the ground wiring with other equipment that operate

with high current (for examples: high voltage motors, welding

machines, etc.). When several Soft-Starters SSW-07 are used,

observe the connections in the gure 3.8.

GROUNDING BAR

BARRA DE ATERRAMENTO

INTERNAL TO THE PANEL

INTERNA AO PAINEL

GROUNDING BAR

BARRA DE ATERRAMENTO

INTERNAL TO THE PANEL

INTERNA AO PAINEL

Figure 3.8 - Grounding connections for more than one Soft-Starter SSW-07

21

CHAPTER 3 - INSTALLATION AND CONNECTION

EMI - Electronic Interference

The Soft-Starter SSW-07 is developed to be used in industrial

systems (Class A) according to Standard EN60947-4-2.

It’s necessary to have a distance of 0.25 m (10 in) between the

Soft- Starter SSW-07 control cables and motor cables.

Example: PLC wiring, temperature controllers, thermocouple cables, etc.

Grounding of the Motor frame

Always ground the motor frame. The Soft-Starter SSW-07 output

wiring to the motor must be installed separately from the input wiring

as well as from the control and signal wiring.

English

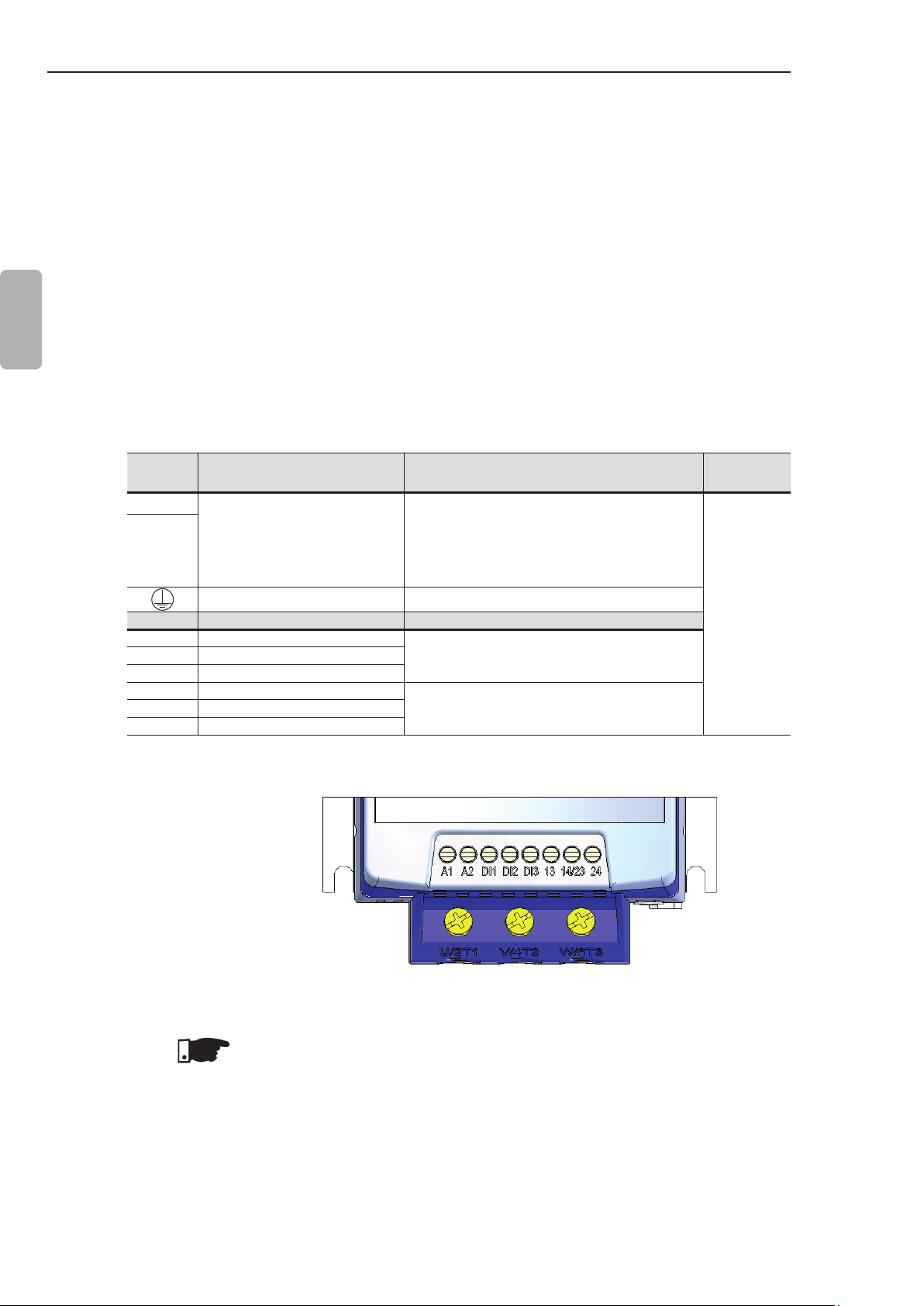

3.2.7 Control and Signal Connections

Terminal Description Specications

A1

A2

Terminal Factory Default Specications

DI1 Starts/Stops Motor

DI2 Fault reset

DI3 Fault reset

13 Relay 1 output - Operation

14/23 Relay common point

24 Relay 2 output - Full voltage

The control connections (digital inputs and relay outputs) are made

through the terminals (refer to gure 3.9).

Voltage: 110 to 240 Vac (-15 % to +10 %)

(models from 17 A to 200 A)

Electronics Supply

Grounding Only for the 255 to 412 A models

Table 3.9 - Description of the control connector pins

110 to 130 Vac or 208 to 240 Vac

(-15 % to 10 %) (models from 255 A

to 412 A).

3 isolated digital inputs

Voltage: 110 to 240 Vac (-15 % to +10 %)

Current: 2 mA Max.

Contact capacity:

Voltage: 250 Vac

Current: 1 A

Torque Nm

(in lb)

0.5 (4.5)

22

Figure 3.9 - Control terminals of the Soft-Starter SSW-07

NOTE!

It is recommended to use shielded cables for the Dix inputs when

using long cables (above 30 m) in noisy environments. The metallic

shield and A2 must be grounded.

CHAPTER 3 - INSTALLATION AND CONNECTION

3.3 RECOMMENDED SET-UPS

Some recommended set-ups are shown here and they can be

completely or partly used.

The main warning notes for all the recommended set-ups are

shown below and are described in the schemes by their respective

numbers.

NOTES!

The use of fuses or circuit breakers at the input circuit is

1

necessary for the entire installation protection. It is not necessary

to use ultra-fast fuses for the SSW-07 operation; however, their

use is recommended for the soft-starter complete protection.

The transformer “T1” is optional and must be used when there

2

is a difference between the line voltage and the electronic power

voltage.

In case that damage at the SSW-07 Soft-Starter power circuit

3

keeps the motor running (e.g., shorted thyristors), the motor

protection is obtained with the use of the power isolating

contactor (K1) or circuit breaker (Q1).

English

Start push-button.

4

Stop push-button.

5

Start/Stop switch. Bear in mind that when using two-wire digital

6

input command (normally open switch with retention), in case

of a power interruption, upon return of power, the motor will be

started immediately if the switch remains closed.

In case of maintenance of the Soft-Starter SSW-07 or the motor

7

it is necessary to remove the input fuses or disconnect the power

supply to ensure the complete equipment disconnection from

the power supply.

The emergency stop can be used by disconnecting the

8

electronics power supply.

Undervoltage release for the Q1 power isolation circuit breaker.

9

23

CHAPTER 3 - INSTALLATION AND CONNECTION

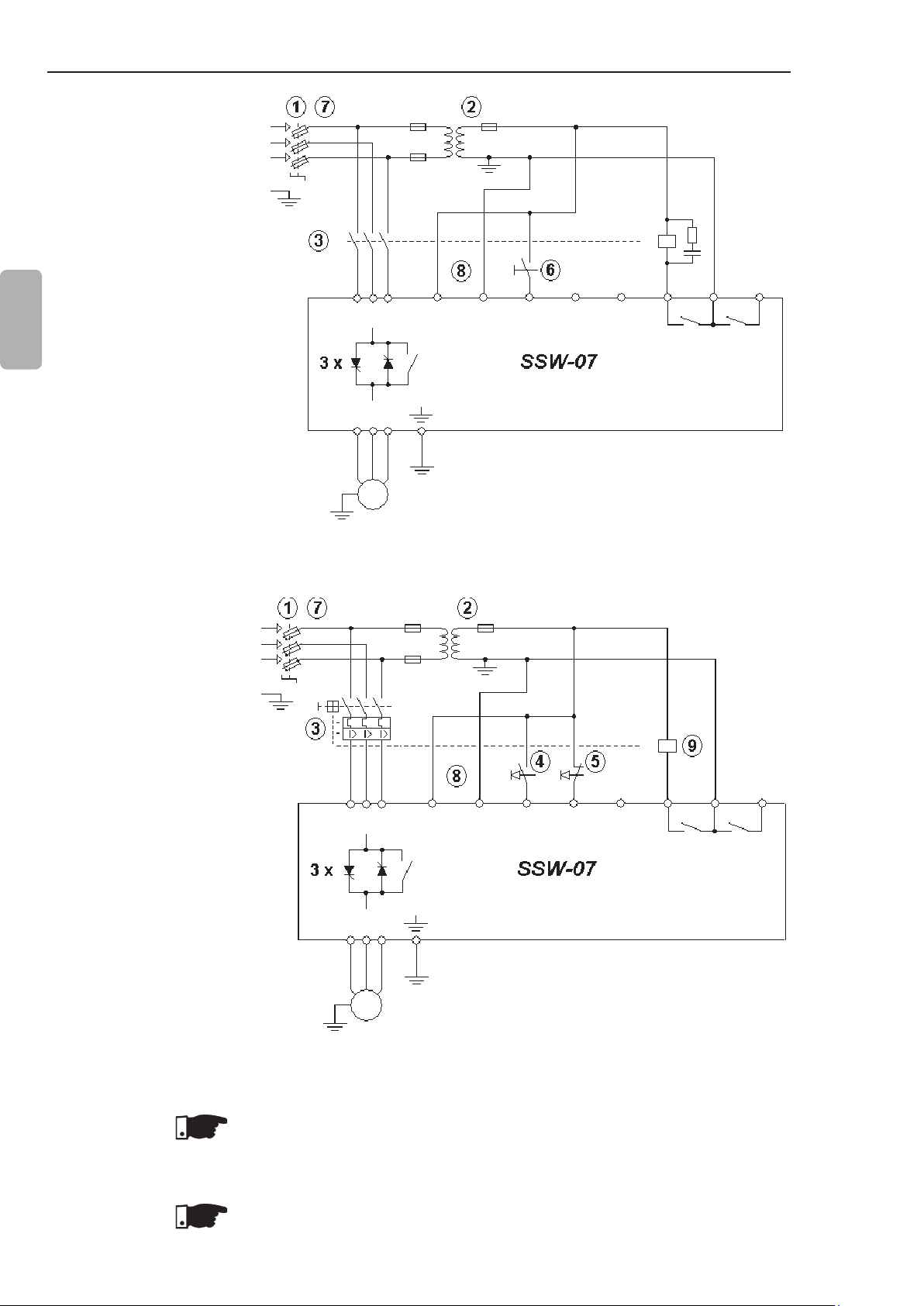

3.3.1 Recommended Set-up with Command via Two-wire Digital Inputs and Isolation Contactor

English

Refer to notes in item 3.3.

R

S

T

PE

K1

R S T

U V W

M

3~

T1

K1

RL1

23

14

24

RL2

DI1A2A1

DI2

DI3

13

Figure 3.10 - Recommended set-up with commands via two-wire digital inputs

and isolation contactor

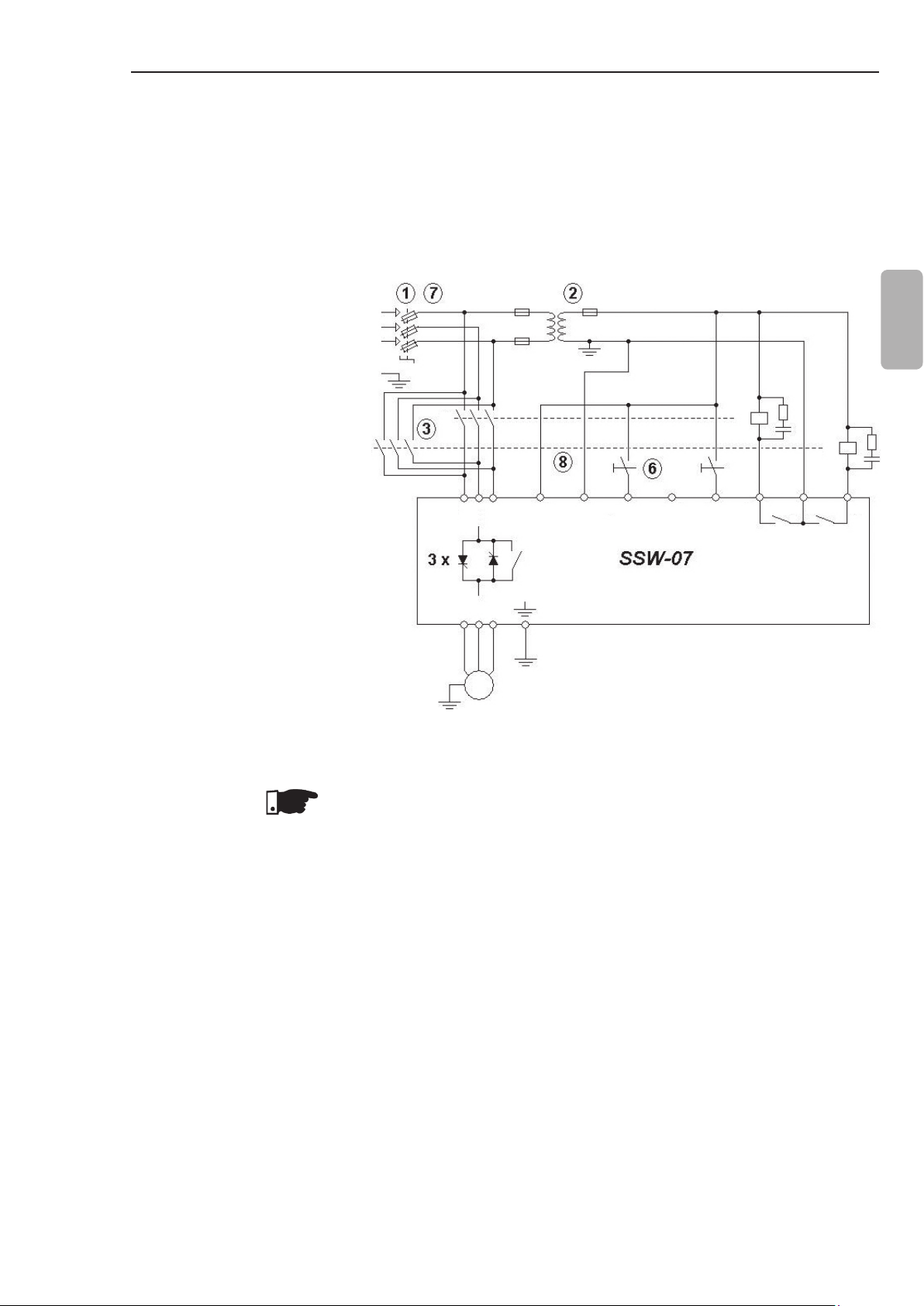

3.3.2 Recommended

Set-up with

Command

via Threewire Digital

Inputs and

Circuit- Breaker

Refer to notes in item 3.3.

R

S

T

PE

Q1

R S T

U V W

M

3~

T1

Q1

DI1A2A1

DI2

DI3

13

14

23

RL1 RL2

24

24

Figure 3.11 - Recommended set-up with commands via three-wire digital

inputs and a circuit-breaker

NOTE!

It’s necessary to program the digital input DI2 for the three-wire

command function. Refer to item 4.10.

NOTE!

The RL1 shall be set to the “No fault” function. Refer to item 4.12.

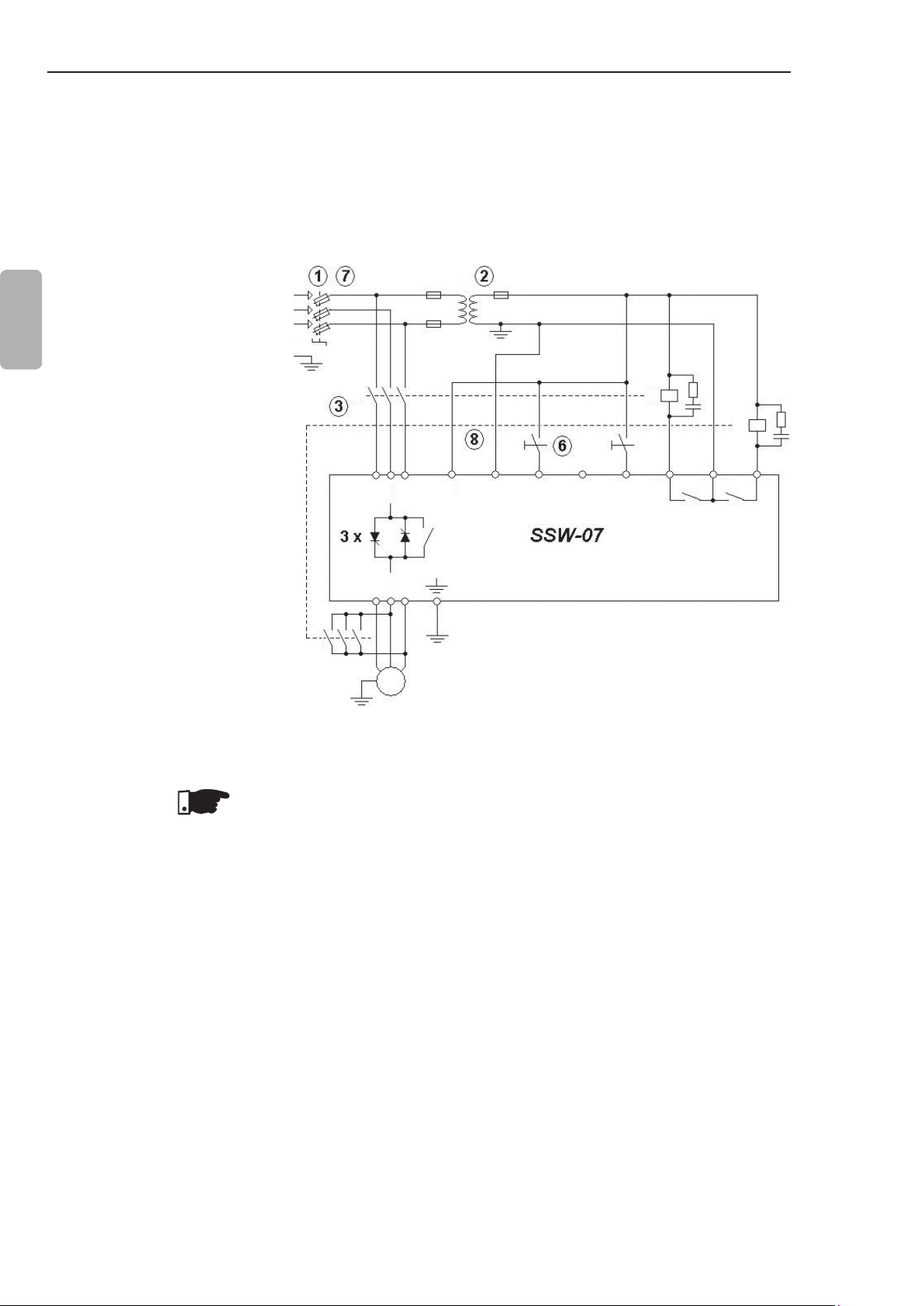

3.3.3 Recommended Set-up with Command via Two-wire Digital Inputs and Direction of Rotation

P220 = 1

P230 = 1

P263 = 1 (DI1 = Start/Stop two

wires)

P265 = 4 (DI3 = Rotation

Direction)

P277 = 4 (RL1 = FWD/REV - K1)

P278 = 4 (RL2 = FWD/REV - K2)

CHAPTER 3 - INSTALLATION AND CONNECTION

R

S

T

PE

K1

K2 K2

T1

K1

English

Refer to notes in item 3.3.

Figure 3.12 - Recommended Set-up with Command via Two-wire Digital

NOTE!

To program the parameters shown above, is necessary the use of

keypad or serial communication. See the Programming Manual for

more information.

R S T

U V W

M

3~

DI1A2A1

Inputs and Direction of Rotation

DI2

DI3

RL1

23

14

24

RL2

13

25

CHAPTER 3 - INSTALLATION AND CONNECTION

3.3.4 Recommended

Set-up with

Command via

Two-wires Digital

Inputs and DCBraking

P220 = 1

P230 = 1

P263 = 1 (DI1 = Start/Stop two

wires)

English

P265 = 5 (DI3 = Brake Off)

P277 = 1 (RL1 = Running)

P278 = 5 (RL2 = DC-Braking)

P501 ≥ 1 (DC Braking Time ≥ 1s)

R

S

T

PE

K1

T1

K1

K2

Refer to notes in item 3.3.

NOTE!

To program the parameters shown above, is necessary the use of

keypad or serial communication. See the Programming Manual for

more information.

K2

R S T

U V W

M

3~

DI1A2A1

DI2

DI3

13

RL1

23

14

24

RL2

Figure 3.13 - Recommended Set-up with Command via Two-wires Digital

Inputs and DC-Braking

26

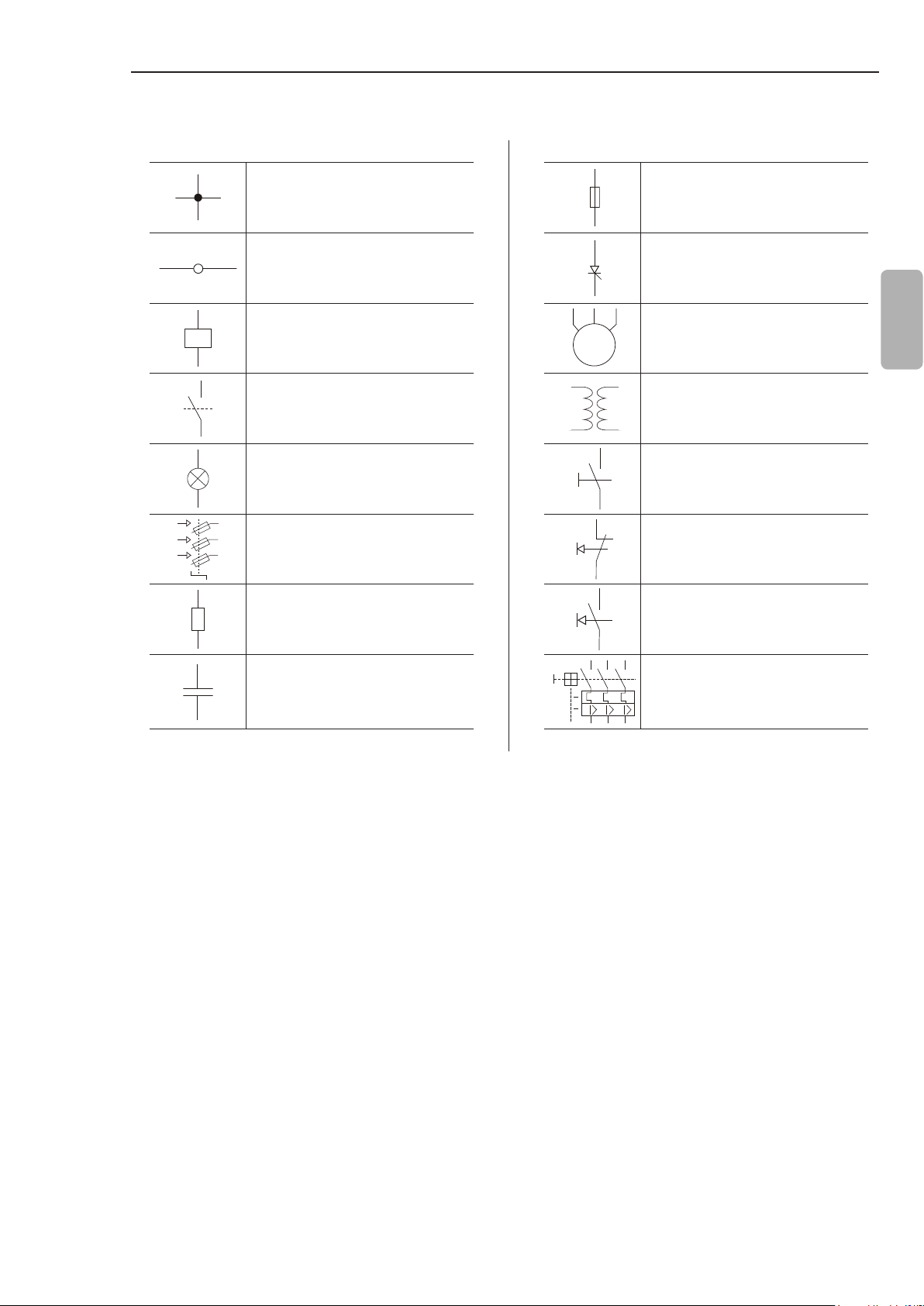

3.3.5 Symbols

CHAPTER 3 - INSTALLATION AND CONNECTION

Electrical connection between

two signals

Connection terminals Thyristor/SCR

Relay or contactor coil

M

3~

Normally open contact (NO) Transformer

Indicator light N.O Contact (with retention)

Circuit-breaker

(opens under load)

Resistor Normally open (NO)

Fuse

Three-phase motor

Normally closed (NC)

push-button

push-button

English

Capacitor Circuit-breaker with

undervoltage release

27

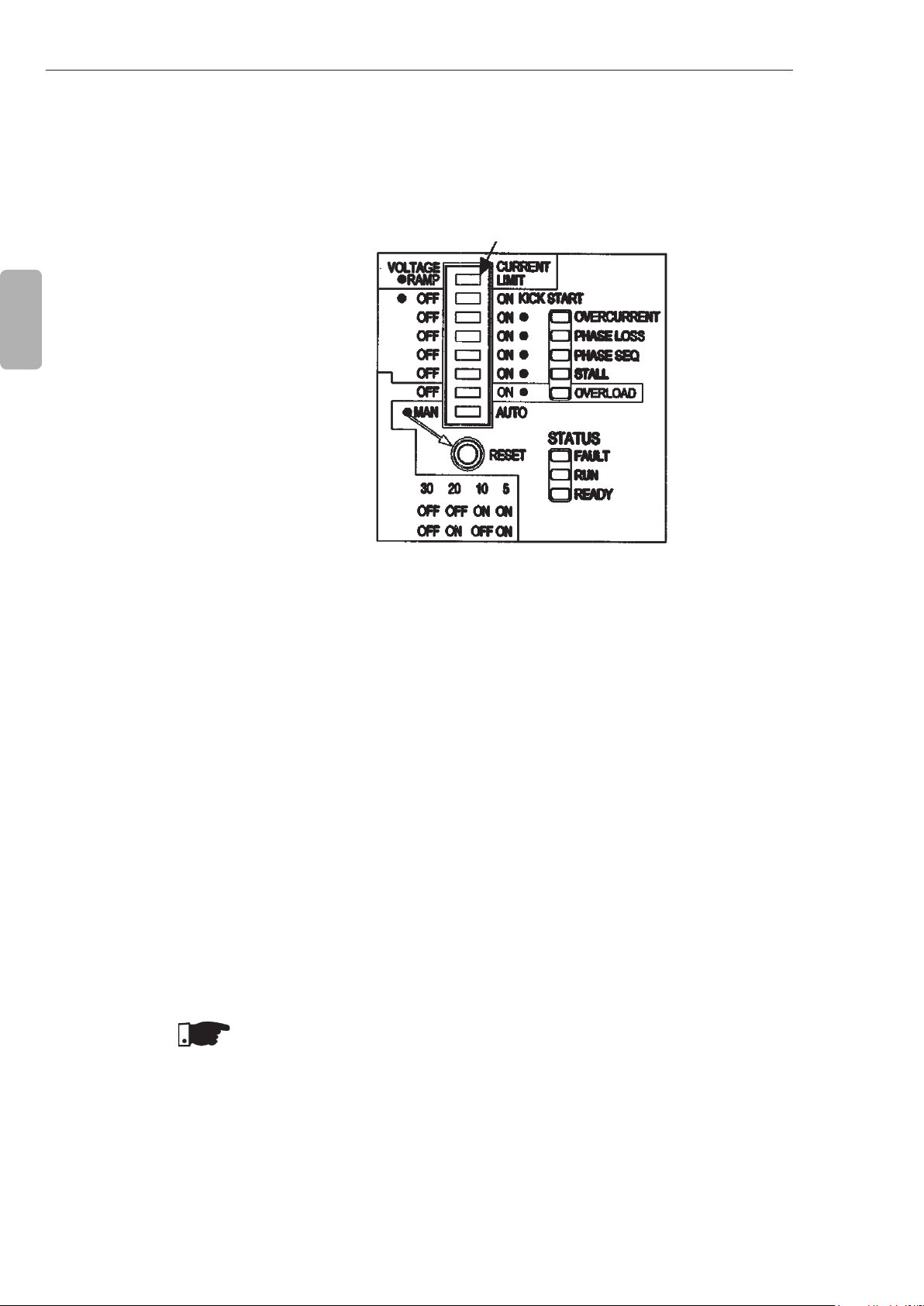

CHAPTER 4

SETTING THE SSW-07

This chapter describes how to make the necessary settings for the

correct functioning of the SSW-07.

4.1 CONTROL TYPE SETTING

English

DIP Switch Control

Type Setting

Figure 4.1 - Control type setting

Select the type of starting control that best adapts to the application.

Voltage Ramp Starting:

This is the most commonly used method. Very easy to program

and set.

The Soft-Starter SSW-07 imposes the voltage applied to the motor.

Generally applied to loads with a lower initial torque or a square

torque.

This kind of control can be used as an initial working test.

Current Limit Starting:

The maximum current level is maintained during the start, being set

according to the application necessities.

Generally applied to loads with a higher initial torque or a constant

torque.

This kind of control is used to adapt the start to the capacity limits

of the supply network.

NOTES!

1. The Current Ramp control type, is only programmed using keypad

or serial communication. See the Programming Manual for more

details.

2. To program the control type in Pump control, see the Programming

Manual or item 5.1.4.

28

CHAPTER 4 - SETTING THE SSW-07

4.2 KICK START

Kick Start Enabling

DIP Switch

English

Figure 4.2 - Kick Start enabling

Soft-Starter SSW-07 offers a Kick Start function for loads that

present a large initial resistance to movement.

This function is enabled through the Kick Start DIP Switch. The

duration of the voltage pulse is set through the trimpot Kick Start

Time.

The voltage pulse applied is of 80 % Un during the programmed

trimpot Kick Start Time.

4.3 INITIAL VOLTAGE SETTING

NOTE!

Use this function only for specic applications and where necessary.

Set the initial voltage to a value that the motor starts to run as soon

as the start command is given to the SSW-07.

Initial Voltage

Setting Trimpot

The dot indicates

the factory default

setting

Figure 4.3 - Initial voltage setting

29

Loading...

Loading...