XICOR X25C02SM, X25C02SI, X25C02S, X25C02PM, X25C02PI Datasheet

...

APPLICATION NOTES

A V A I L A B L E

AN9 • AN18 • AN31 • AN37 • AN40 |

|

|

X25C02 |

|

|

2K |

X25C02 |

256 x 8 Bit |

|

|

|

|

SPI Serial E2PROM |

|

FEATURES |

DESCRIPTION |

|

•1MHz Clock Rate

•256 X 8 Bits

—4 Byte Page Mode

•Low Power CMOS

—150 μA Standby Current

—2mA Active Current

•5V Power Supply

•Built-in Inadvertent Write Protection —Power-Up/Power-Down protection circuitry —Write Latch

—Write Protect Pin

•Self-Timed Write Cycle

—5ms Write Cycle Time (Typical)

•High Reliability

—Endurance: 100,000 cycles per byte —Data Retention: 100 Years

—ESD protection: 2000V on all pins

•Available Packages —8-Lead MSOP —8-Lead PDlP —8-Lead SOIC

The X25C02 is a CMOS 2048-bit serial E2PROM, internally organized as 256 x 8. The X25C02 features a serial interface and software protocol allowing operation on a simple three-wire bus. The bus signals are a clock input (SCK) plus separate data in (SI) and data out (SO) lines. Access to the device is controlled through a chip select (CS) input, allowing any number of devices to share the same bus.

The X25C02 also features two additional inputs that provide the end user with added flexibility. By asserting the HOLD input, the X25C02 will ignore transitions on its inputs, thus allowing the host to service higher priority interrupts. The WP input can be used as a hardwire input to the X25C02 disabling all write attempts, thus providing a mechanism for limiting end user capability of altering the memory.

The X25C02 utilizes Xicor’s proprietary Direct Write™ cell, providing a minimum endurance of 100,000 cycles per byte and a minimum data retention of 100 years.

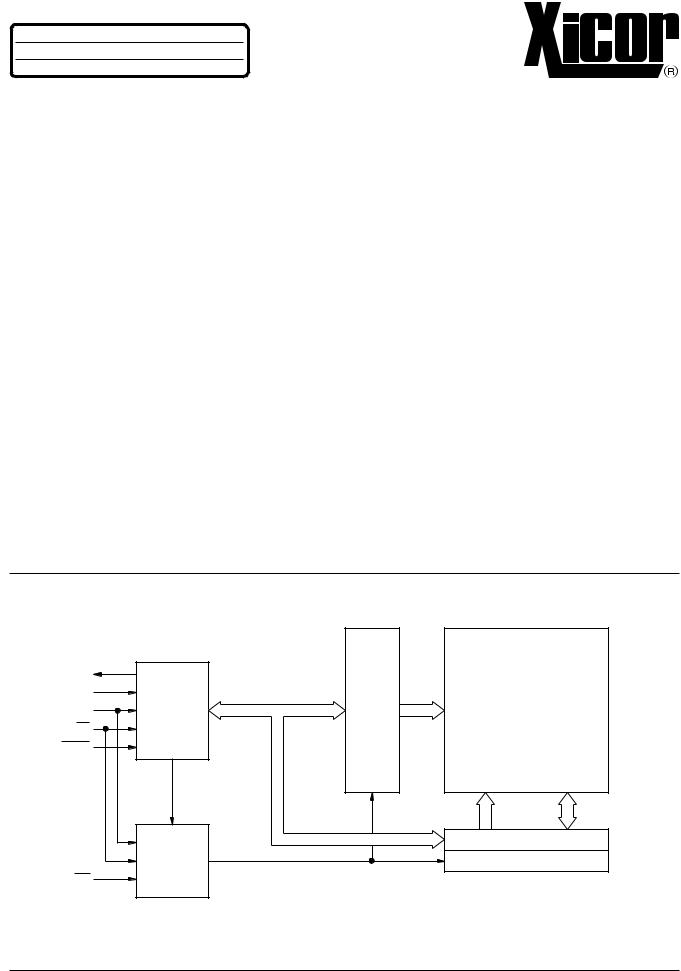

FUNCTIONAL DIAGRAM

SO |

|

|

|

|

SI |

COMMAND |

X |

64 |

|

DECODE |

||||

SCK |

DECODE |

256 BYTE ARRAY |

||

AND |

||||

(64 X 32) |

||||

CS |

CONTROL |

LOGIC |

||

|

||||

|

|

|||

HOLD |

LOGIC |

|

|

|

|

|

|

|

4 |

8 |

|

WRITE |

Y DECODE |

|

CONTROL |

|

|

|

|

|

AND |

DATA REGISTER |

WP |

TIMING |

|

LOGIC |

|

|

|

|

3843 FHD F01

Direct Write™ is a trademark of Xicor, Inc.

©Xicor, Inc. 1994, 1995, 1996 Patents Pending |

Characteristics subject to change without notice |

3843-1.6 6/10/96 T5/C1/D1 NS |

1 |

X25C02

PIN DESCRIPTIONS

Serial Output (SO)

SO is a push/pull serial data output pin. During a read cycle, data is shifted out on this pin. Data is clocked out by the falling edge of the serial clock.

Serial Input (SI)

SI is the serial data input pin. All data, opcodes, byte addresses, and data to be written to the memory are input on this pin. Data is latched by the rising edge of the serial clock.

Serial Clock (SCK)

The Serial Clock controls the serial bus timing for data input and output. Opcodes, addresses, or data present on the SI pin are sampled or latched on the rising edge of the clock input, while data on the SO pin change after the falling edge of the clock input.

Chip Select (CS)

When CS is HIGH, the X25C02 is deselected and the SO output pin is at HIGH impedance and unless an internal write operation is underway, the X25C02 will be

PIN CONFIGURATION

|

|

|

|

|

|

MSOP/DIP/SOIC |

|

|

|

|

|

|

|

|

1 |

8 |

|

|

|

||

|

|

CS |

|

|

|

|

VCC |

|||

|

|

|||||||||

|

|

|||||||||

|

SO |

|

2 |

7 |

|

|

|

|||

|

|

|

HOLD |

|||||||

|

|

|||||||||

|

|

|

|

|

|

|

X25C02 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WP |

|

3 |

6 |

|

SCK |

|||||

VSS |

|

4 |

5 |

|

SI |

|||||

|

|

|||||||||

|

|

|||||||||

3843 FHD F02.2

in the standby power mode. CS LOW enables the X25C02, placing it in the active power mode. It should be noted that after power-up, a HIGH to LOW transition on CS is required prior to the start of any operation.

Write Protect (WP)

When WP is LOW, nonvolatile writes to the X25C02 are disabled, but the part otherwise functions normally. When WP is held HIGH, all functions, including nonvolatile writes operate normally. WP going LOW while CS is still LOW will interrupt a write to the X25C02. If the internal write cycle has already been initiated, WP going LOW will have no affect on a write.

Hold (HOLD)

HOLD is used in conjunction with the CS pin to select the device. Once the part is selected and a serial sequence is underway, HOLD may be used to pause the serial communication with the controller without resetting the serial sequence. To pause, HOLD must be brought LOW while SCK is LOW. To resume communication, HOLD is brought HIGH, again while SCK is LOW. If the pause feature is not used, HOLD should be held HIGH at all times.

PIN NAMES

Symbol |

Description |

|

|

CS |

Chip Select Input |

|

|

SO |

Serial Output |

|

|

SI |

Serial Input |

SCK |

Serial Clock Input |

|

|

WP |

Write Protect Input |

|

|

VSS |

Ground |

VCC |

Supply Voltage |

HOLD |

Hold Input |

|

|

3843 PGM T01

2

X25C02

PRINCIPLES OF OPERATION

The X25C02 is a 256 x 8 E2PROM designed to interface directly with the synchronous serial peripheral interface (SPI) of many popular microcontroller families.

The X25C02 contains an 8-bit instruction register. It is

accessed via the SI input, with data being clocked in on the rising SCK. CS must be LOW and the HOLD and WP

inputs must be HIGH during the entire operation.

Table 1 contains a list of the instructions and their opcodes. All instructions, addresses and data are transferred MSB first.

Data input is sampled on the first rising edge of SCK after CS goes LOW. SCK is static, allowing the user to stop

Table 1. Instruction Set

the clock and then resume operations. If the clock line is shared with other peripheral devices on the SPI bus, the user can assert the HOLD input to place the X25C02 into a “PAUSE” condition. After releasing HOLD, the X25C02 will resume operation from the point when HOLD was first asserted.

Write Enable (WREN) and Write Disable (WRDI)

The X25C02 contains a “write enable” latch. This latch must be SET before a write operation will be completed internally. The WREN instruction will set the latch and the WRDI instruction will reset the latch. This latch is automatically reset upon a power-up condition and after the completion of a byte or page write cycle. The latch is also reset if WP is brought LOW.

Instruction Name |

Instruction Format* |

Operation |

||

|

|

|

|

|

WREN |

0000 |

0110 |

Set the Write Enable Latch (Enable Write Operations) |

|

|

|

|

|

|

WRDI |

0000 |

0100 |

Reset the Write Enable Latch (Disable Write Operations) |

|

READ |

0000 |

0011 |

Read Data from Memory Array beginning at selected ad- |

|

dress |

||||

|

|

|

||

|

|

|

|

|

WRITE |

0000 |

0010 |

Write Data to Memory Array beginning at Selected Address |

|

(1 to 4 Bytes) |

||||

|

|

|

||

|

|

|

|

|

|

|

|

3843 PGM T02 |

|

*Instructions are shown MSB in leftmost position. Instructions are transferred MSB first.

3

X25C02

DEVICE OPERATION

Clock and Data Timing

Data input on the SI line is sampled and latched on the rising edge of SCK. Data is output on the SO line by the falling edge of SCK.

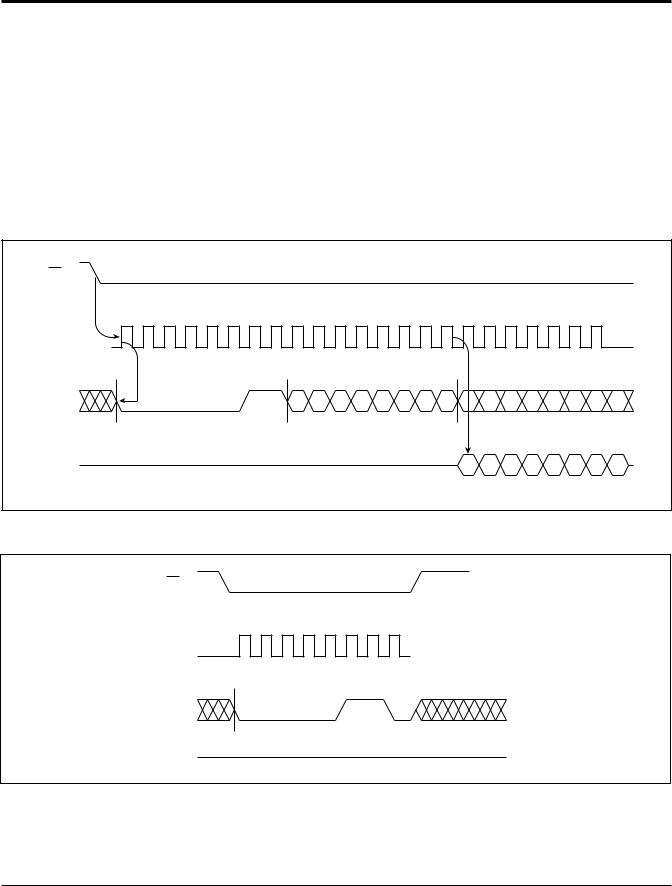

Read Sequence

The CS line is first pulled LOW to select the device. The 8-bit read opcode is transmitted to the X25C02, followed by the 8-bit address. After the READ opcode and byte address are sent, the data stored in the memory at the selected address is shifted out on the SO line. The data stored in memory at the next address can be read sequentially by continuing to provide clock pulses. The byte address is automatically incremented to the next higher address after each byte of data is shifted out. When the highest address is reached ($FF) the address counter rolls over to address $00 allowing the read cycle to be continued indefinitely. The read operation is terminated by taking CS HIGH. Refer to the read operation sequence illustrated in Figure 1.

Write Sequence

Prior to any attempt to write data into the X25C02, the “write enable” latch must first be set by issuing the WREN instruction (See Fig. 2). CS is first taken LOW, then the instruction is clocked into the X25C02. After all eight bits of the instruction are transmitted, CS must then be taken HIGH. If the user continues the write operation without taking CS HIGH after issuing the WREN instruction, the write operation will be ignored.

Once the “write enable” latch is set, the user may proceed by issuing the write instruction, followed by the address and then the data to be written. This is minimally a twenty-four clock operation. CS must go LOW and remain LOW for the duration of the operation. The host may continue to write up to four bytes of data to the X25C02. The only restriction is the four bytes must reside on the same page. A page address begins with address XXXX XX00 and ends with XXXX XX11. If the byte address counter reaches XXXX XX11 and the clock continues the counter will “roll over” to the first address of the page and overwrite any data that may have been written.

For the write operation (byte or page write) to be completed, CS can only be brought HIGH after the twenty-fourth, thirty-second, fourtieth or fourty-eighth clock. If it is brought HIGH at any other time, the write operation will not be completed. Refer to Figure 4 for a detailed illustration of the page write sequence and time frames in which CS going HIGH are valid.

Hold Operation

The HOLD input should be HIGH (at VIH) under normal operation. If a data transfer is to be interrupted HOLD can be pulled LOW to suspend the transfer until it can be

resumed. The only restriction is the SCK input must be LOW when HOLD is first pulled low and SCK must also

be LOW when HOLD is released.

The HOLD input may be tied HIGH either directly to VCC or tied to VCC through a resistor.

4

X25C02

Operational Notes

The X25C02 powers-up in the following state:

•The device is in the low power standby state.

•A HIGH to LOW transition on CS is required to enter an active state and receive an instruction.

•SO pin is high impedance.

•The “write enable” latch is reset.

Data Protection

The following circuitry has been included to prevent inadvertent writes:

•The “write enable” latch is reset upon power-up.

•A WREN instruction must be issued to set the “write enable” latch.

•CS must come HIGH at the proper clock count in order to start a write cycle.

The “write enable” latch is reset when WP is brought LOW.

Figure 1. Read Operation Sequence

CS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

22 |

|

SCK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INSTRUCTION |

|

|

|

|

|

BYTE ADDRESS |

|

|

|

|

|

|

|

|

|

|

||||||

SI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HIGH IMPEDANCE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DATA OUT |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

6 |

5 |

4 |

3 |

2 |

1 |

0 |

|||

SO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MSB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3843 FHD F04.1 |

Figure 2. Set Write Enable Latch Sequence

CS

0 |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

SCK

SI

HIGH IMPEDANCE

SO

3843 FHD F05.1

5

Loading...

Loading...