Xantrex HPD 15-20, HPD 30-10, HPD 60-5 User Guide

Operating Manual

HPD 300 Watt Series

Programmable DC

Power Supply

HPD 15-20

HPD 30-10

HPD 60-5

Operating Manual for

HPD Series

Programmable DC

Power Supply

ii Operating Manual for HPD Series Power Supply

Limited

Warranty

What does this warranty cover and how long does it last?

This Limited Warranty is provided by Xantrex Technology, Inc. (“Xantrex”) and

covers defects in workmanship and materials in your HPD 300 Watt Series DC

Power Supply. This warranty lasts for a Warranty Period of 5 years from the date

of purchase at point of sale to you, the original end user customer.

What will Xantrex do?

Xantrex will, at its option, repair or replace the defective product free of charge,

provided that you notify Xantrex of the product defect within the Warranty Period,

and provided that Xantrex through inspection establishes the existence of such a

defect and that it is covered by this Limited Warranty.

Xantrex will, at its option, use new and/or reconditioned parts in performing

warranty repair and building replacement products. Xantrex reserves the right to use

parts or products of original or improved design in the repair or replacement. If

Xantrex repairs or replaces a product, its warranty continues for the remaining

portion of the original Warranty Period or 90 days from the date of the return

shipment to the customer, whichever is greater. All replaced products and all parts

removed from repaired products become the property of Xantrex.

Xantrex covers both parts and labor necessary to repair the product, and return

shipment to the customer via a Xantrex-selected non-expedited surface freight

within the contiguous United States and Canada. Alaska and Hawaii are excluded.

Contact Xantrex Customer Service for details on freight policy for return shipments

outside of the contiguous United States and Canada.

How do you get service?

If your product requires troubleshooting or warranty service, contact your merchant.

If you are unable to contact your merchant, or the merchant is unable to provide

service, contact Xantrex directly at:

Phone: 604 422 8595

Toll Free North America: 1 800 667 8422

Fax: 604 421 3056

Email: info@xantrex.com

Release 1.2 iii

Direct returns may be performed according to the Xantrex Return Material

Authorization Policy described in your product manual. For some products, Xantrex

maintains a network of regional Authorized Service Centers. Call Xantrex or check

our website to see if your product can be repaired at one of these facilities.

In any warranty claim, dated proof of purchase must accompany the product and the

product must not have been disassembled or modified without prior written

authorization by Xantrex.

Proof of purchase may be in any one of the following forms:

• The dated purchase receipt from the original purchase of the product at point of

sale to the end user, or

• The dated dealer invoice or purchase receipt showing original equipment

manufacturer (OEM) status, or

• The dated invoice or purchase receipt showing the product exchanged under

warranty

What does this warranty not cover?

This Limited Warranty does not cover normal wear and tear of the product or costs

related to the removal, installation, or troubleshooting of the customer’s electrical

systems. This warranty does not apply to and Xantrex will not be responsible for any

defect in or damage to:

a. the product if it has been misused, neglected, improperly installed, physically

damaged or altered, either internally or externally, or damaged from improper

use or use in an unsuitable environment;

b. the product if it has been subjected to fire, water, generalized corrosion,

biological infestations, and high input voltage from lightning strikes;

c. the product if repairs have been done to it other than by Xantrex or its authorized

service centers (hereafter “ASCs”);

d. the product if it is used as a component part of a product expressly warranted by

another manufacturer;

e. the product if its original identification (trade-mark, serial number) markings

have been defaced, altered, or removed.

iv Operating Manual for HPD Series Power Supply

Disclaimer Product

THIS LIMITED WARRANTY IS THE SOLE AND EXCLUSIVE WARRANTY PROVIDED

BY XANTREX IN CONNECTION WITH YOUR XANTREX PRODUCT AND IS, WHERE

PERMITTED BY LAW, IN LIEU OF ALL OTHER WARRANTIES, CONDITIONS,

GUARANTEES, REPRESENTATIONS, OBLIGATIONS AND LIABILITIES, EXPRESS

OR IMPLIED, STATUTORY OR OTHERWISE IN CONNECTION WITH THE PRODUCT,

HOWEVER ARISING (WHETHER BY CONTRACT, TORT, NEGLIGENCE, PRINCIPLES

OF MANUFACTURER’S LIABILITY, OPERATION OF LAW, CONDUCT, STATEMENT

OR OTHERWISE), INCLUDING WITHOUT RESTRICTION ANY IMPLIED WARRANTY

OR CONDITION OF QUALITY, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE TO THE EXTENT REQUIRED UNDER

APPLICABLE LAW TO APPLY TO THE PRODUCT SHALL BE LIMITED IN DURATION

TO THE PERIOD STIPULATED UNDER THIS LIMITED WARRANTY.

IN NO EVENT WILL XANTREX BE LIABLE FOR ANY SPECIAL, DIRECT, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOSSES, COSTS OR EXPENSES

HOWEVER ARISING WHETHER IN CONTRACT OR TORT INCLUDING WITHOUT

RESTRICTION ANY ECONOMIC LOSSES OF ANY KIND, ANY LOSS OR DAMAGE TO

PROPERTY, ANY PERSONAL INJURY, ANY DAMAGE OR INJURY ARISING FROM OR

AS A RESULT OF MISUSE OR ABUSE, OR THE INCORRECT INSTALLATION,

INTEGRATION OR OPERATION OF THE PRODUCT.

Exclusions If this product is a consumer product, federal law does not allow an exclusion of

implied warranties. To the extent you are entitled to implied warranties under federal

law, to the extent permitted by applicable law they are limited to the duration of this

Limited Warranty. Some states and provinces do not allow limitations or exclusions

on implied warranties or on the duration of an implied warranty or on the limitation

or exclusion of incidental or consequential damages, so the above limitation(s) or

exclusion(s) may not apply to you. This Limited Warranty gives you specific legal

rights. You may have other rights which may vary from state to state or province to

province.

Release 1.2 v

Information WITHOUT LIMITING THE GENERALITY OF THE FOREGOING, UNLESS

SPECIFICALLY AGREED TO BY IT IN WRITING, XANTREX

a. MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY

OF ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN MANUALS OR

OTHER DOCUMENTATION PROVIDED BY IT IN CONNECTION WITH THE

PRODUCT; AND

b. ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES,

COSTS OR EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF

SUCH INFORMATION.

THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

WARNING:

Limitations

on Use

Please refer to your product user manual for limitations on uses of the product.

Specifically, please note that this power supply is not intended for use in connection

with life support systems and Xantrex makes no warranty or representation in

connection with any use of the product for such purposes.

Xantrex Technology, Inc.

8999 Nelson Way

Burnaby, British Columbia

Canada V5A 4B5

Information

About Your

Power

Supply

Please record the following information when you first open your Power Supply

package:

Release Release 1.2 (2003-04)

Copyright

©

2002 Xantrex Technology Inc. All rights reserved.

Printed in Canada

Model Number ______________________________________________

Serial Number ______________________________________________

Purchased From ______________________________________________

Purchase Date ______________________________________________

vi Operating Manual for HPD Series Power Supply

Warnings

and

Cautions

Warnings and cautions are defined and formatted in this manual as shown below.

Power

Supply

Safety

WARNING

Describes a potential hazard which could result in injury or death, or, a procedure

which, if not performed correctly, could result in injury or death.

!

CAUTION

Describes a procedure which, if not performed correctly, could result in damage

to data, equipment, or systems.

WARNING—High Energy and High Voltage

Exercise caution when using and calibrating a power supply. High energy levels

can be stored at the output voltage terminals on a power supply in normal

operation. In addition, potentially lethal voltages exist in the power circuit and on

the output and sense connectors of a power supply with a rated output greater

than 40 V. Filter capacitors store potentially dangerous energy for some time after

power is removed.

!

CAUTION

Operate the power supply in an environment free of flammable gases or fumes. To

ensure that the power supply’s safety features are not compromised, use the

power supply as specified in this manual and do not substitute parts or make any

unauthorized modifications. Contact the service technician for service and repair

help. Repairs must be made by experienced service technicians only.

!

CAUTION

For Use as a Battery Charger

When you are using any of these power supplies for battery charging applications,

it is essential to provide an appropriately sized fuse or circuit breaker in series

between the power supply output and the battery.

Installation of a protector (fuse or DC circuit breaker) rated for about 115% of the

maximum current rating of the power supply and designed specifically to interrupt

the DC voltage of the battery, will provide adequate reverse polarity current

protection. Where several power supplies are in parallel, it is best to fuse each one,

rather than one large fuse for all.

Release 1.2 vii

About This Manual

This Operating Manual contains operating instructions for the HPD Series of high

performance, switching, laboratory power supplies, available in several voltage

models at 300 watts. It provides information on features and specifications,

installation procedures, and basic functions testing, as well as operating procedures

for using both standard and multiple supply configurations.

Who Should Use This Manual

This manual is designed for the user who is familiar with basic electrical theory,

especially as applied to the operation of power supplies. This implies a recognition

of Constant Voltage and Constant Current operating modes and the control of input

and output power, as well as the observance of safe techniques while calibrating,

making supply connections, and/or making any changes in configuration.

Main Sections

Section 1 Features and Specifications Describes the power supply, lists its

features, and provides tables of specifications.

Section 2 Installation Reviews safety and inspection procedures, and provides

procedures for basic setup. Also includes directions for testing basic functions.

Section 3 Load Operation and Sensing Provides procedures for connecting

the load, grounding, and remote sensing.

Section 4 Operation Describes standard operation (Constant Voltage and

Constant Current), and series, parallel, and split supply operation.

Manual Revisions

The current release of this manual is listed below. Updates may be issued as an

addendum.

Release 1.2 (2003-04)

About This Manual

viii Operating Manual for HPD Series Power Supply

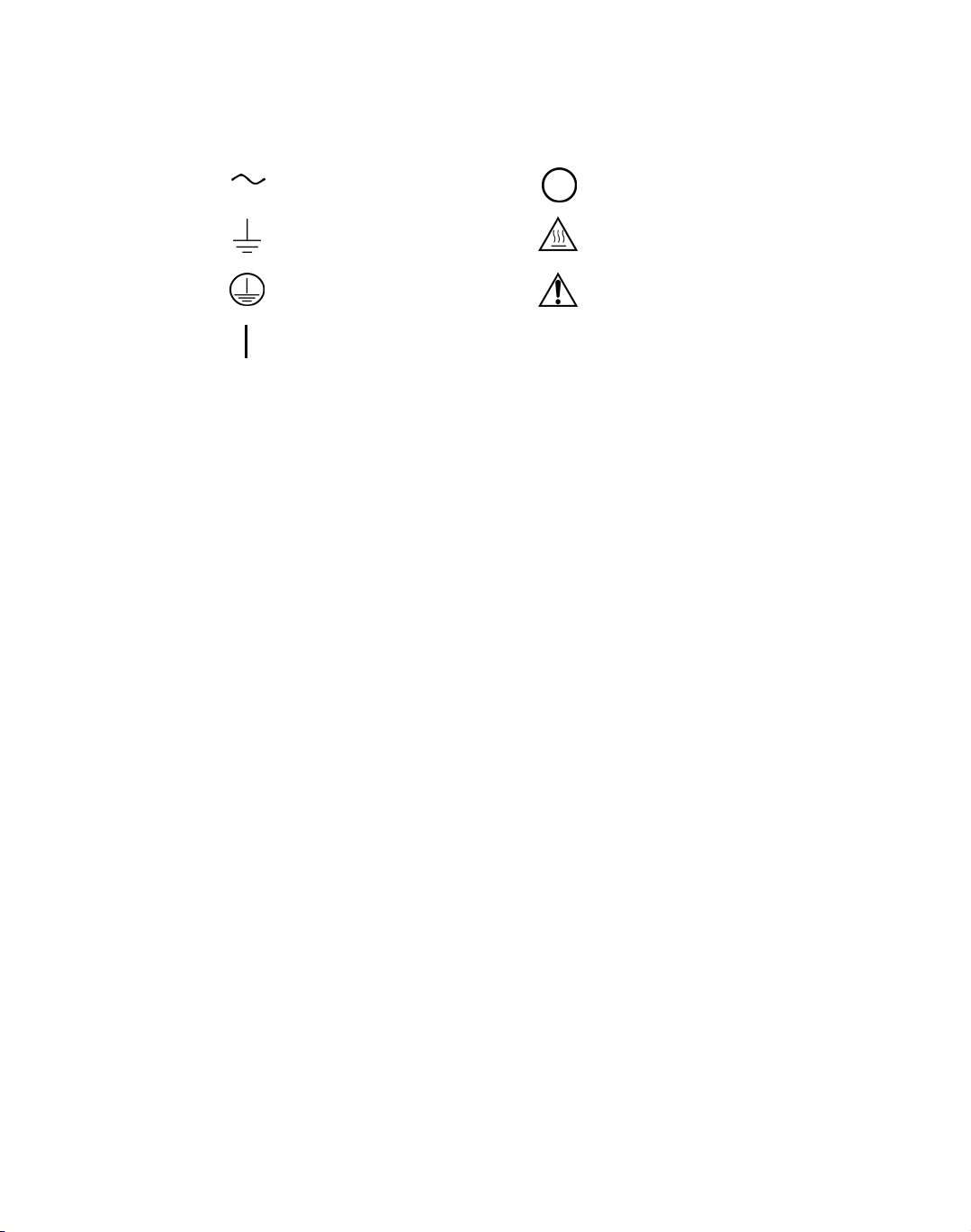

Power Supply Safety Markings

Alternating Current Off (Supply)

Earth (Ground) Terminal Caution (Hot Surface)

Protective Conductor Terminal Caution (Check manual for

additional information.)

On (Supply)

Release 1.2 ix

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Section 1.

Features and

Specifications

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Front Panel Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rear Panel Connectors and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Additional Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Input Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chassis Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Single Output Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dual Output Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Section 2.

Installation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Basic Setup Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Periodic Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Returning Power Supplies to the Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Return Material Authorization Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Packaging for Shipping or Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Location and Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC Input Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

AC Input Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Functional Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power-on Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Voltage Mode Operation Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Current Mode Operation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Section 3.

Load

Connection

and Sensing

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Load Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Load Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Making Load Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Connecting Multiple Loads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Local Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Output Jumpers for Local Sensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Remote Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Contents

x

Operating Manual for HPD Series Power Supply

Section 4.

Operation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Constant Voltage Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Constant Current Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setting the Current Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setting the Supply to Operate in CI Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Automatic Mode Crossover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Constant Power Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Using Multiple Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connecting Multiple Supplies in Series (Voltage Mode Only) . . . . . . . . . . . . . . 36

Connecting Multiple Supplies in Parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Split Supply Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Release 1.2 11

Section 1. Features and Specifications

Introduction

The HPD Series of DC power supplies provides highly stable, variable output

voltage and current for a broad range of development and system requirements.

These units employ high frequency switching regulator technology to achieve high

power density and small package size, as well as a linear post-regulator circuit for

low output noise and fast response. A wide variety of options is available, including

both analog and IEEE-488 controlled programming, to make this series the first

choice in flexible power system design.

Table 1.1 300 Watt Series Models

Features

• High frequency switching technology allows high power density, providing

increased power output in a small, light, package.

• The power supply delivers simultaneous digital displays for both voltage and

current, and bar graph displays for monitoring transient changes, which gives the

user the benefit of continuous, up-to-date information.

• Ten-turn voltage control permits high resolution setting of the output voltage.

• Current limit is fully adjustable from zero to the rated output with a single turn

control.

• The automatic crossover system allows the power supply to automatically

switch operating modes into current or voltage mode.

• Impedance-switched remote sensing lets operators display the voltage at the load

with no switch ambiguity.

• Multiple units can be connected in parallel or series to produce greater diversity.

• Short-circuit-proof power outlets give greater operating safety.

• These power supplies (available in single and dual outputs) can be combined

with one or more 60 watt series power supplies to create mixed units that are

ideal for high precision applications.

Model Output Voltage Output Current

15–20 0–15 V 0–20 A

30–10 0–30 V 0–10 A

60–5 0–60 V 0–5 A

Section 1. Features and Specifications

Options and Accessories

12 Operating Manual for HPD Series Power Supply

Options and Accessories

• Internal Analog Programming (APG) interface for analog signal control of

voltage and current, overvoltage protection (OVP), master/slave output tracking,

and remote ON/OFF.

• Internal RS-232 interface for serial instrument programming using RS-232

protocol.

• Internal GPIB interface for complete remote digital programming. IEEE-488

standard.

• Optional 200–250 Vac input (Option AC200). Standard is 115 Vac. Optional AC

input cords for use in different countries.

• Ten-turn current potentiometer (Option M11). Rack mount kit (Option RM).

• Locking voltage and/or current adjust knobs (Option M13A).

Front Panel Controls

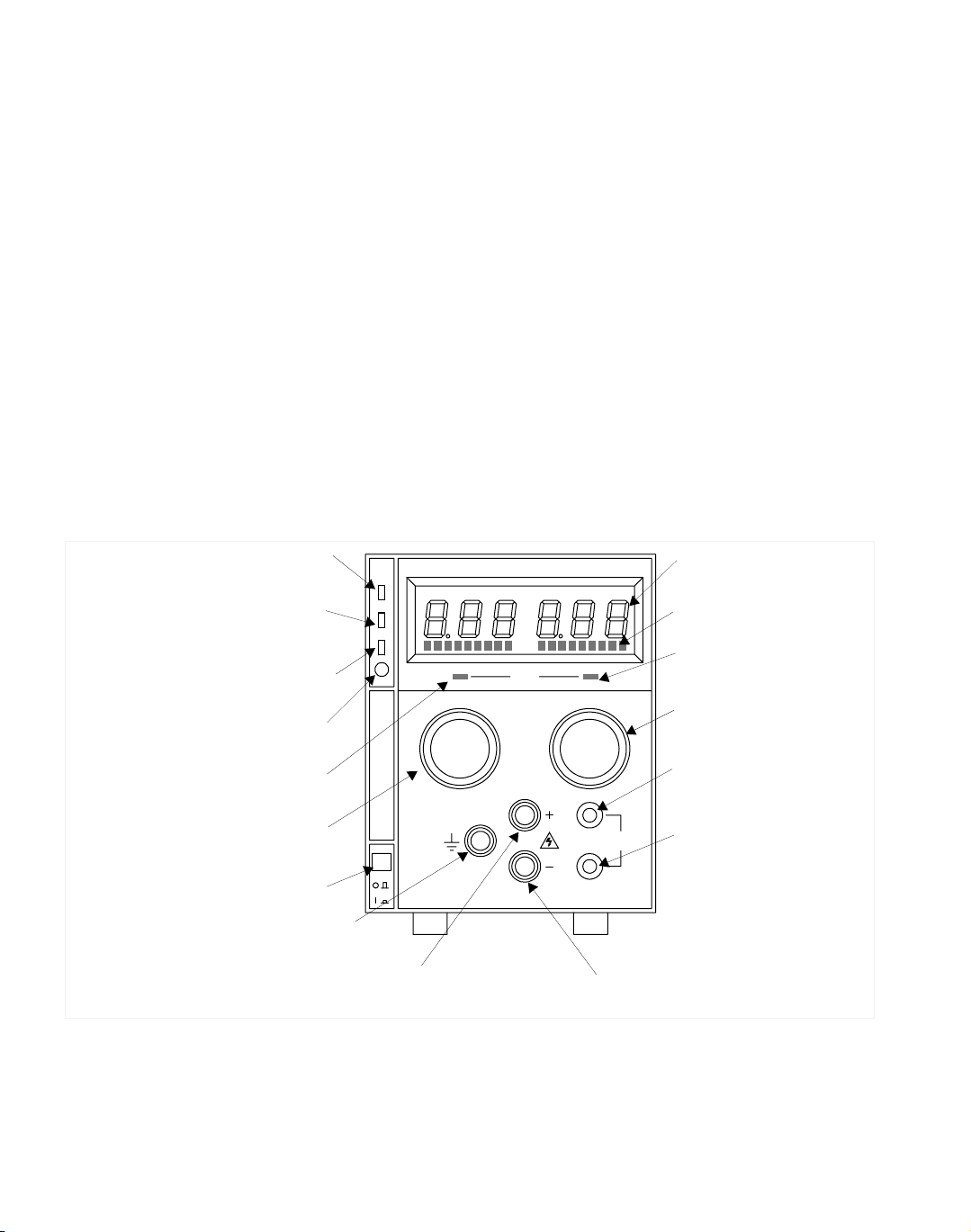

Figure 1.1 shows the controls, LEDs, and meters located on the unit’s front panel.

Figure 1.1 Front Panel Controls

REGULATED DC POWER SUPPLY

MODE

VOLTAGE CURRENT

SENSE

POWER

P

G

S

/

D

O

V

P

OVP

ADJ

M

Shutdown LED (S/D)

(For units with APG installed.)

Voltage Mode

Indicator (Green LED)

Safety Ground

Binding Post (Green)

AC Power Switch

Positive (+) Output Binding Post (Red)

Voltage Control Knob

(10-turn standard)

OVP Shutdown (OVP)

(For units with APG installed.)

OVP Adjust Potentiometer (OVP ADJ)

(For units with APG installed.)

Digital Display of DC Output

(Volts, Amperes)

Analog Bar Graph Display

Current Limit Mode

Indicator (Red LED)

Current Limit Adjust Knob

(1-turn standard)

Positive (+) Sense

Connection

(Banana Jack)

Return (−) Sense

Connection

(Banana Jack)

Return (−) Output Binding

Post (Black)

Remote Programming LED (PGM)

(For units with APG installed.

See also Figure 1.2).

Loading...

Loading...