Wolf ICBDD, CTWH30, CTWH36, IH4227, CTEWH30I Installation And Operation Manual

...

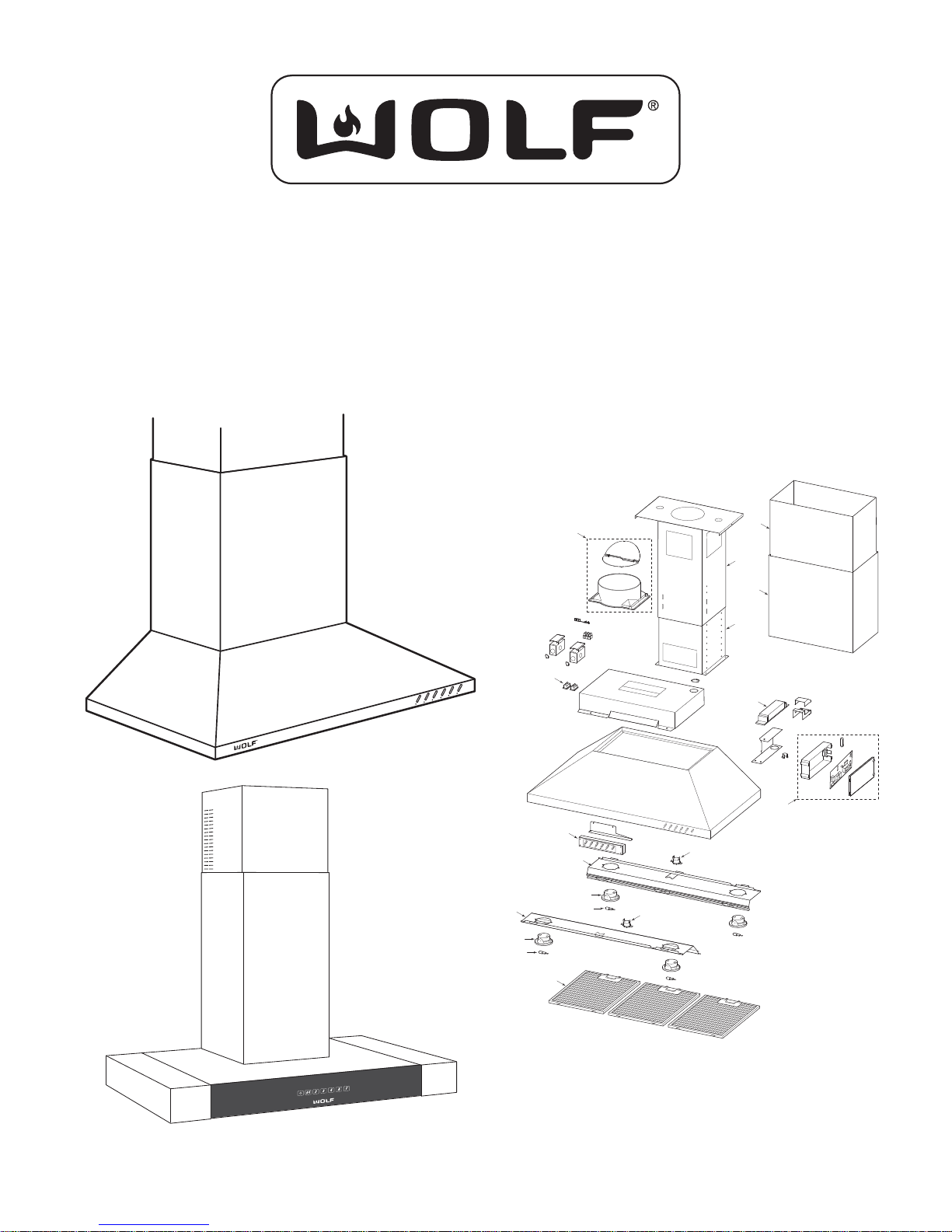

CT & CTE HOODS

DD & ICBDD VENTILATION

(Including Parts Lists and Exploded Views)

1

10

15

9

14

8

13

5

R

E

T

L

I

H

F

G

I

M

H

U

I

D

E

M

W

O

L

Y

A

L

E

T

D

H

G

I

2

12

L

6

3

11

4

6

3

4

WOLF APPLIANCE, INC 2009 ALL RIGHTS RESERVED JOB AID 810125 REVISION C JAN. 2009

7

General Information CT Hoods and DD Ventilation

SECTION 1

GENERAL INFORMATION

1-1

General InformationCT Hoods and DD Ventilation

INTRODUCTION

This Wolf Cooktop and Downdraft Ventilation Technical Service Manual, has been compiled with information provided

by Broan-Nu Tone LLC. This manual provides the most recent technical service information that will enable the

service technician to troubleshoot and diagnose malfunctions, perform necessary repairs and return a Wolf Ventilation

product to proper operational condition.

The service technician should read the complete instructions contained in this Service Manual before initiating any

repairs on a Wolf Appliance.

IMPORTANT SAFETY INFORMATION

Below are the Product Safety Labels used in this manual.

The “Signal Words” used are WARNING & CAUTION.

Please note that these safety labels are placed in areas

where awareness of personal safety and product safety

should be taken and lists the precautions to be taken when

the signal word is observed.

INDICATES THAT HAZARDOUS OR UNSAFE

PRACTICES COULD RESULT IN SEVERE

PERSONAL INJURY OR DEATH

Indicates that hazardous or unsafe practices

could result in minor personal injury or product

and/or property damage

In addition, please pay attention to the signal

word “NOTE”, which highlights especially

important information within each section.

TECHNICAL ASSISTANCE

If you should have any questions regarding a Wolf

appliance and/or this manual, please contact:

Wolf Appliance, Inc.

ATTN.: Service Department

P.O. Box 44988

Madison, WI 53744-4988

Customer Service

Phone #: (800) 332 - 9513

T echnical Assistance

Phone #: (800) 919 - 8324

Parts / Warranty Claims

Phone #: (800) 332 - 9513

Customer Service E-mail Address

customerservice@wolfappliance.com

Customer Service & Technical Assistance

Facsimile #: (608) 441 - 5887

Parts / Warranty Claims

Facsimile #: (608) 441 - 5886

This manual is designed to be used by Authorized Service Personnel only. Wolf Appliance, Inc. assumes no

responsibility for any repairs made to Wolf appliances by anyone other than Authorized Service Technicians.

The information and images contained in this manual are the copyright property of Wolf Appliance, Inc., an affi liate of Sub-Zero,

Inc. Neither this manual nor any information or images contained herein may be copied or used in whole or in part without the

express written permission of Wolf Appliance, Inc., an affi liate of Sub-Zero, Inc. © Wolf Appliance, Inc., all rights reserved.

Offi ce Hours:

7:00 AM to 7:00 PM Central Standard Time

Monday through Friday

1-2

General Information CT Hoods and DD Ventilation

TABLE OF CONTENTS

Page #

Section 1 - General Information ...................... 1-1

Introduction ........................................................ 1-2

Important Safety Information ............................. 1-2

T echnical Assistance ......................................... 1-2

Table of Contents ............................................... 1-3

Warranty Information ......................................... 1-4

Model Descriptions ............................................ 1-5

Section 2 - Installation Information ............... 2-1

CT & Island Hood Overall Dimensions .............. 2-2

CTEWH Overall Dimensions ............................. 2-3

CTEIH Overall Dimensions ................................ 2-4

CT Hood Placement ........................................... 2-5

CT Wall Hood Installation Considerations ......... 2-6

CT Wall Hood Installation .................................. 2-7

Ductwork Installation ......................................... 2-8

Island Hood Installation Considerations ............ 2-9

Island Hood Installation ..................................... 2-10

Hood Internal Blower Installation ...................... 2-12

CTE Hood Installation Considerations .............. 2-13

CTEW Hood Installation Specifi cations ............ 2-14

CTEW Hood Electrical Requirements ............... 2-15

CTEW Hood Installation .................................... 2-15

CTEI Hood Installation Specifi cations ............ 2-17

CTEI Hood Electrical Requirements ............... 2-18

CTEI Hood Installation .................................... 2-18

Hood Remote Blower Installation ....................... 2-20

Downdraft Dimensions ...................................... 2-21

Downdraft Installation Specifi cations ................ 2-22

Downdraft Installation Requirements ................ 2-23

Downdraft Ducting Considerations ................... 2-24

Downdraft Blower Discharge ............................ 2-25

Downdraft Installation ....................................... 2-25

DD Internal Blower Installation .......................... 2-26

DD Remote Blower Installation ......................... 2-26

Section 3 - Controls & Operation ................... 3-1

Electronic Control for CT Wall Hoods ............... 3-2

Heat Sentry Mode ............................................. 3-2

Electronic Control for Downdraft ....................... 3-3

Cleaning ............................................................ 3-3

Electronic Control for Low Profi le Hoods .......... 3-4

Section 4 - Access and Removal ................... 4-1

CT Hoods:

Filter Removal ................................................... 4-2

Bulb and Light Assembly ................................... 4-3

Heat Sentry ....................................................... 4-4

Control Interface ................................................ 4-4

Power Outlet ...................................................... 4-5

Transformer ........................................................ 4-6

Fuse ................................................................... 4-6

Page #

Section 4 - Access and Removal (continued)

CTE Hoods:

Bulb Removal .......................................................... 4-7

Filter Removal ......................................................... 4-7

Inside Panel ............................................................. 4-7

Lamp Socket ............................................................ 4-8

Control Panel Removal ............................................ 4-8

Internal Blower Removal .......................................... 4-9

Control Board Removal ............................................ 4-10

Downdrafts:

Filter Removal .......................................................... 4-11

Internal Blower Removal .......................................... 4-12

Cam Switch Removal ............................................... 4-13

Front Air Box Removal ............................................. 4-13

Gear Motor Removal ................................................ 4-14

Power Control Board Removal ................................. 4-15

Section 5 - Troubleshooting .................................. 5-1

Ventilation Troubleshooting Chart ............................ 5-3

Downdraft Troubleshooting Chart ............................ 5-4

Low Profi le Troubleshooting Chart ........................... 5-5

Downdraft Cam Switch Operation ............................ 5-6

Downdraft Seal Damage Flow Chart ........................ 5-7

Section 6 - Technical Data ..................................... 6-1

Voltage and Temperature Parameters (CT & DD) .... 6-2

Voltage Parameters (CTE) ........................................ 6-3

Section 7 - Wiring Diagram ................................... 7-1

CTWH30 Wiring Diagram ........................................ 7-2

CTWH36 Wiring Diagram ....,................................... 7-3

IH4227 Wiring Diagram ........................................... 7-4

Low Profi le Hood Wiring Diagram ............................ 7-5

Downdraft Schematic .............................................. 7-6

Downdraft Wiring Diagram ...................................... 7-7

ICBDD Schematic .................................................... 7-8

ICBDD Wiring ........................................................... 7-9

Downdraft Control Schematic .................................. 7-10

Downdraft Power Supply Wiring .............................. 7-11

CT & IH Hood Power Supply Wiring ........................ 7-12

Blower Wiring ........................................................... 7-13

Section 8 - Parts List and Exploded Views ......... 8-1

CT Hood Parts List .................................................. 8-2

CT Hood Exploded View ......................................... 8-3

IH4227 Parts List ..................................................... 8-4

IH4227 Exploded View ............................................ 8-5

CTEWH30I, 36I, 45I Parts List ................................ 8-6

CTEWH30I, 36I, 45I Exploded View ....................... 8-7

CTEWH36, 45 Parts List ......................................... 8-8

CTEWH36, 45 Exploded View ................................ 8-9

CTEIH42 Parts List ................................................. 8-10

CTEIH42 Exploded View ........................................ 8-11

Downdraft Parts List ................................................ 8-12

Downdraft Exploded View ........................................ 8-13

ICBDD Parts List ...................................................... 8-14

ICBDD Exploded View ............................................. 8-15

1-3

WARRANTY INFORMATION

This page contains a summary of the Warranty supplied

with every Domestic Wolf ventilation product, followed by

details about the warranty.

NOTE: “ICB” warranties vary by Country and Distributor.

Contact selling Distributor for warranty coverage.

2 & 5 Y

EAR WARRANTY SUMMARY

2 YEAR TOTAL PRODUCT WARRANTY, • Parts and Labor.

3-5 • LIMITED *PARTS ONLY WARRANTY (Including Blower

motors).

General InformationCT Hoods and DD Ventilation

DETAILS:

Warranty applies to products installed in United States •

or Canada, for residential use only.

Warranty begins at time of unit’s initial installation.•

This Warranty does not cover Wolf Appliances installed •

in a demonstration kitchen, test kitchen, culinary school

kitchen, or similar installations. (See Special Warranty

below)

Warranty and Service information collected by Wolf •

Appliance, Inc. is arranged and stored under unit serial

number and/or customer’s name. Please note that Wolf

Appliance, Inc requests that you have model and serial

number available whenever contacting factory or parts

distributor.

SPECIAL WARRANTY SUMMARY

2 YEAR TOTAL PRODUCT WARRANTY, • Part and Labor.

DETAILS:

This Warranty applies to products installed in United •

States or Canada, for use in a demonstration kitchen,

test kitchen, culinary school kitchen, and similar installations that will help promote Wolf Appliance brand and

its products.

Warranty begins at time of unit’s initial installation.•

Warranty and Service information collected by Wolf •

Appliance, Inc. is arranged and stored under unit serial

number and/or customer’s name. Please note that

Wolf Appliance, Inc. requests that you have model and

serial number available whenever contacting factory or

parts distributor.

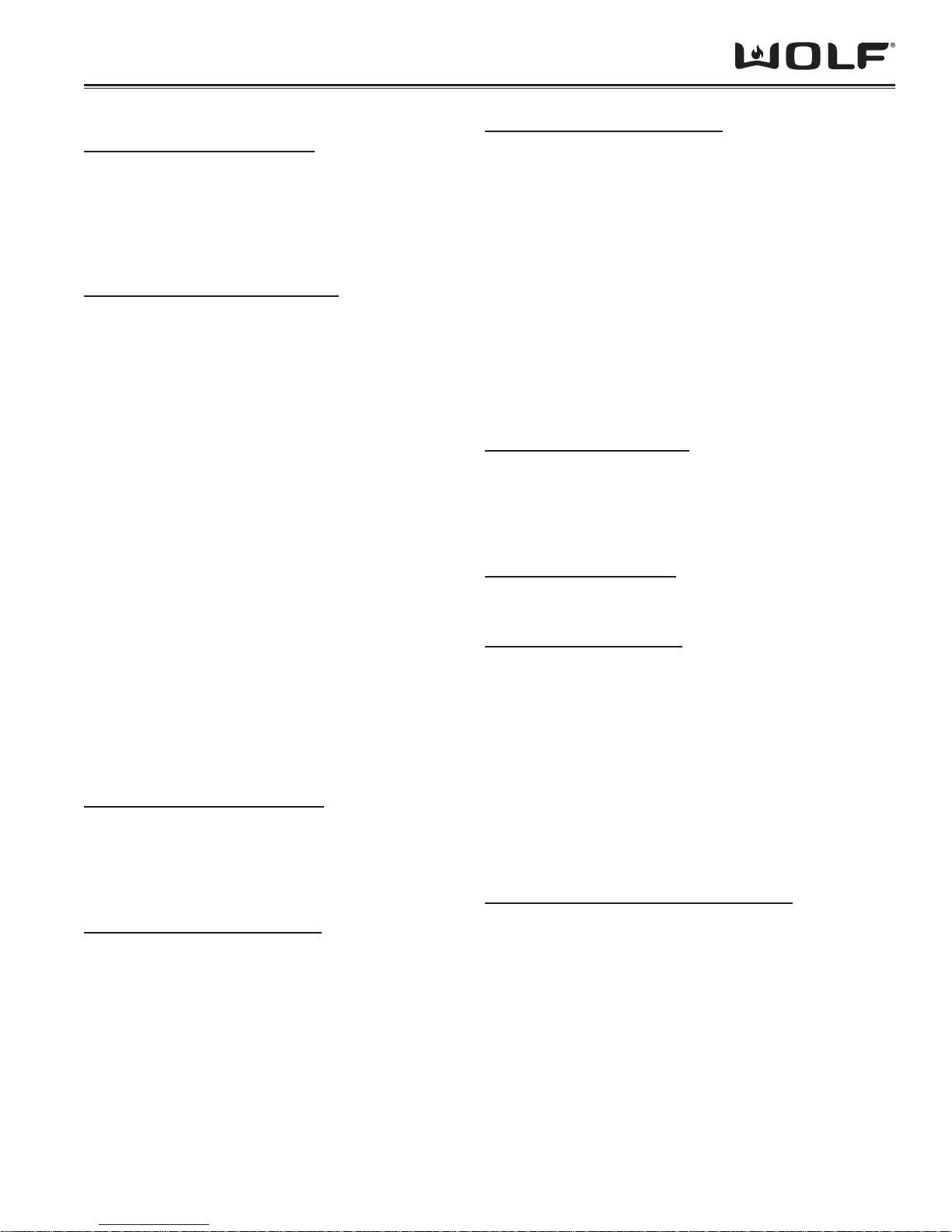

Figure 1-1 Serial Plate Layout

Unit Serial Number

Figure 1-2 Serial Plate Location (CT Hoods)

xxxxxxxxxxx

Unit Serial Number

INFORMATION PLATE AND SERIAL NUMBER

See Figure 1-1 for typical Information Plate layout. •

See Figures 1-2 & 1-3 for Serial Number location. •

Figure 1-3 Serial Plate Location (DD Ventilation)

1-4

General Information CT Hoods and DD Ventilation

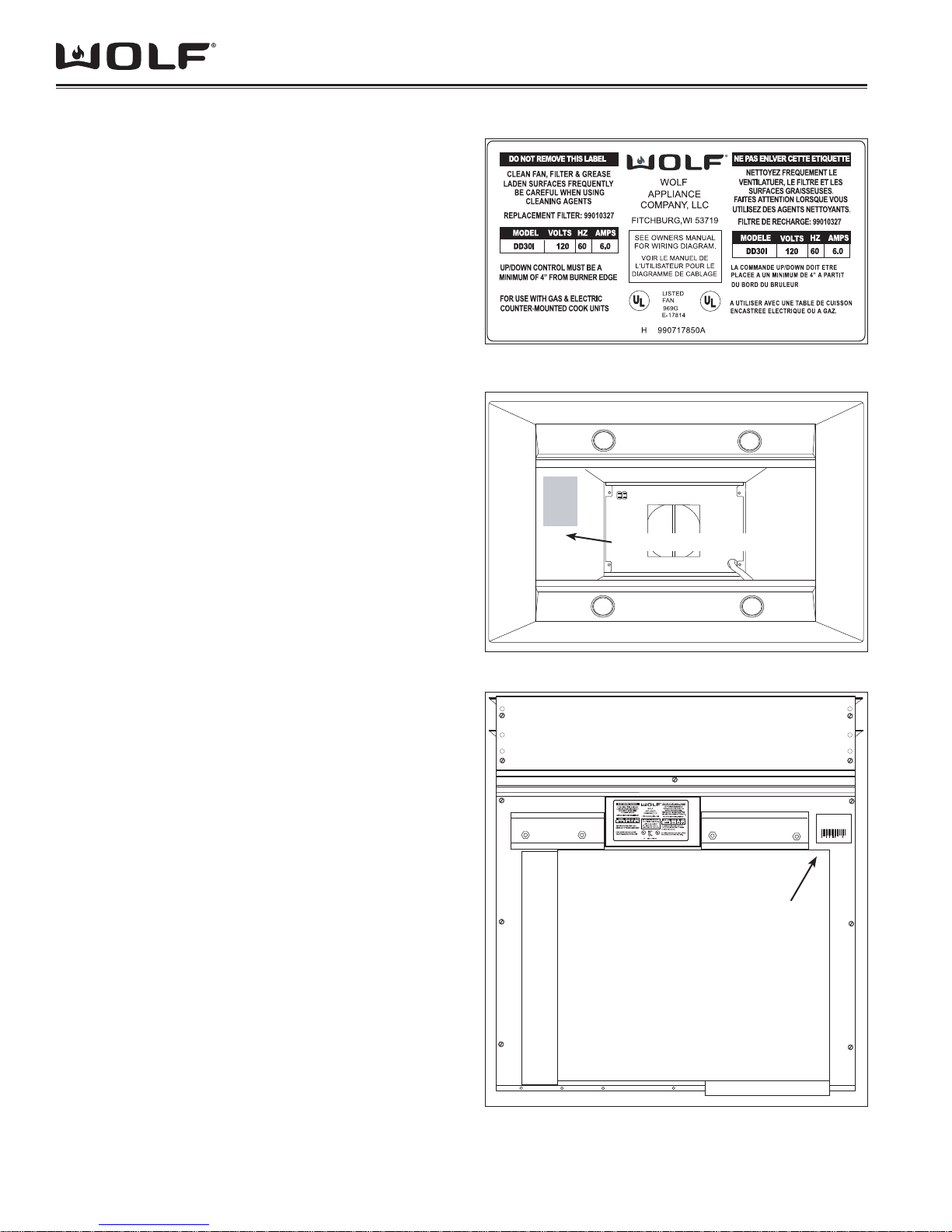

MODEL DESCRIPTIONS

This section explains the model numbering system for the CT Hoods and Downdraft models covered in this manual.

EXAMPLE MODEL # ICB CTWH 30 I

INTERNATIONAL

PRODUCT TYPE

SIZE

BLOWER

PRODUCT TYPE

CTWH COOKTOP (OR CHIMNEY) WALL HOOD

CTEWH COOKTOP (OR CHIMNEY) LOW PROFILE WALL HOOD

CTEIH COOKTOP (OR CHIMNEY) LOW PROFILE ISLAND HOOD

IH ISLAND HOOD

DD DOWN DRAFT

SIZE

30 30 INCH WIDE UNIT

36 36 INCH WIDE UNIT

42 42 INCH WIDE X 27 INCH DEEP

(ONLY ON ISLAND HOOD)

45 45 INCH WIDE UNIT

(ONLY ON DOWN DRAFT)

BLOWER TYPE

I INTERNAL BLOWER

R REMOTE BLOWER

1-5

NOTES

General InformationCT Hoods and DD Ventilation

1-6

Installation Information CT Hoods and DD Ventilation

SECTION 2

INSTALLATION

INFORMATION

2-1

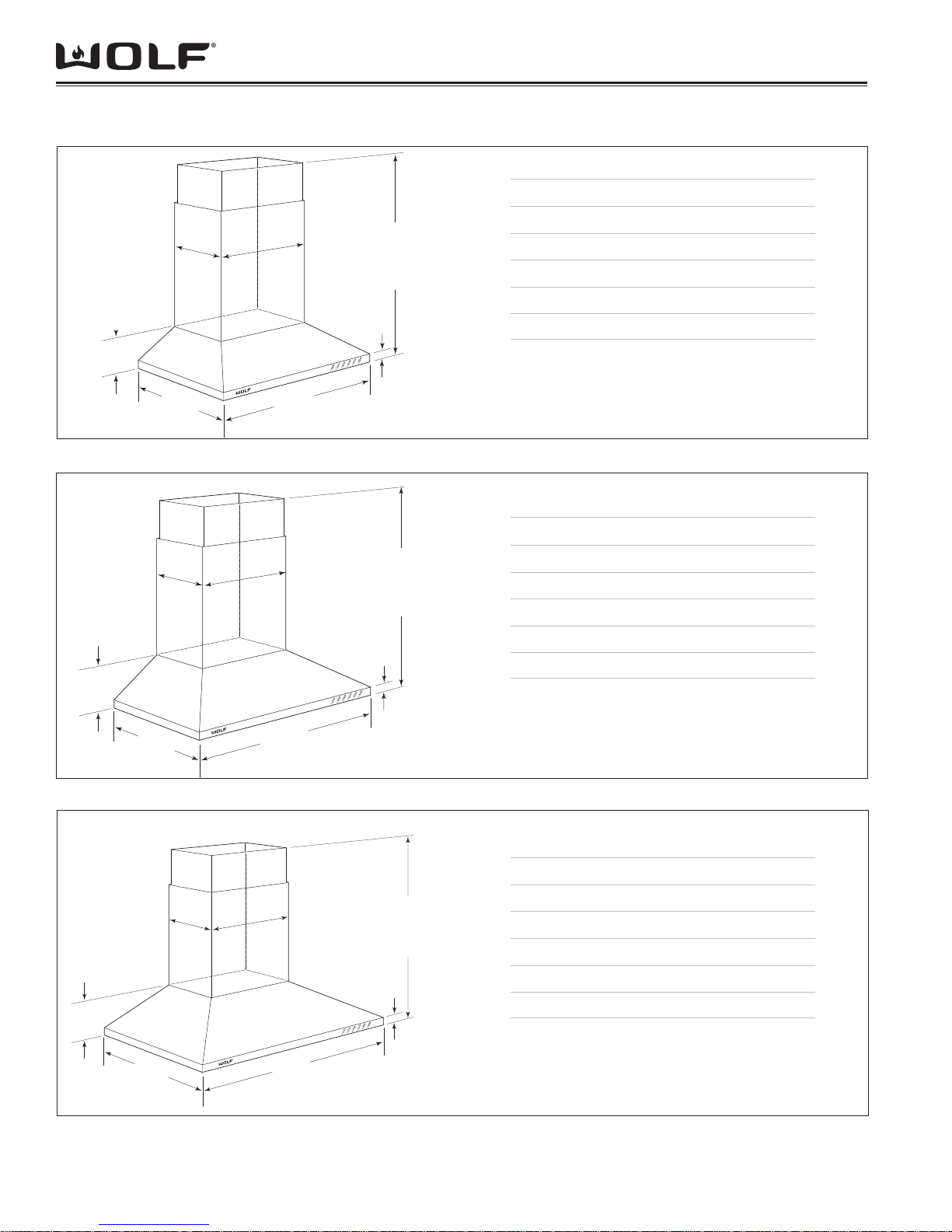

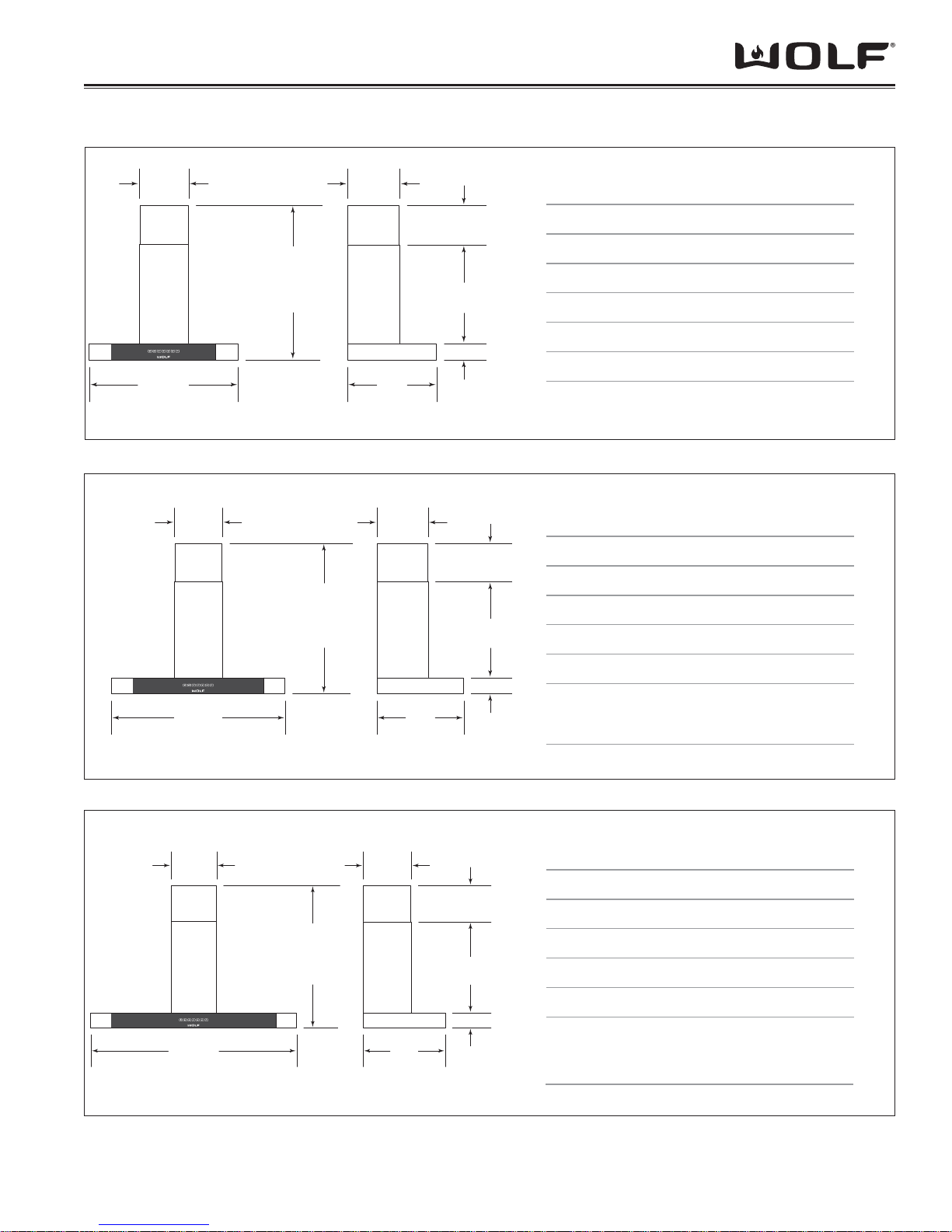

CT & ISLAND HOOD OVER-ALL DIMENSIONS

Installation InformationCT Hoods and DD Ventilation

MODEL CTWH30

)267("03htdiW llarevO

(175mm)

91/4"

(235 mm)

67/8"

(533mm)

(305 mm)

21"

(533 mm)

(305mm)

21"

12"

12"

(457mm)

18"

(457 mm)

357/16"

(900 mm)

18"

30"

(762mm)

301/2"min

(775mm)

TO

481/2"max

(1232mm)

Overall Height (excluding chimney)

Overall Height (including chimney)

Max Height (full extension) 481/2" (1232)

Shipping Weight (shell only) 85 lbs (39 kg)

Dimensions may vary to

9

1

/16 " (40)

Figure 2-1 CTWH30 Dimensions

MODEL CTWH36

3211/16"min

(829 mm)

TO

507/8"max

(1292 mm)

9

1

/16 " (40)

Overall Height (excluding chimney) 91/4"(235)

Overall Height (including chimney) 3211/16"(830)

Max Height (full extension) 50

Shipping Weight (shell only) 100 lbs (45 kg)

Dimensions may vary to

1

+

/8"(3).

–

1

+

/8"(3).

–

67/8" (175)

301/2" (775)

7

53htdiW llarevO

/16" (900)

7

/8" (1292)

)335( "12htpeD llarevO

)335( "12htpeD llarevO

18"

(457 mm)

42"

(1067 mm)

91/4"

(235 mm)

27"

(686 mm)

12"

(305 mm)

Figure 2-2 CTWH36 Dimensions

MODEL IH4227

339/16"min

(851 mm)

TO

471/16"max

(1197 mm)

Overall Height (excluding chimney)

Overall Height (including chimney)

Max Height (full extension) 471/16" (1195)

Overall Depth 27" (686)

Shipping Weight (shell only) 110 lbs (50 kg)

9

1

/16 " (40)

Dimensions may vary to

Figure 2-3 IH4227 Dimensions

2-2

1

+

/8"(3).

–

)7601("24htdiW llarevO

91/4"(235)

339/16"(853)

Installation Information CT Hoods and DD Ventilation

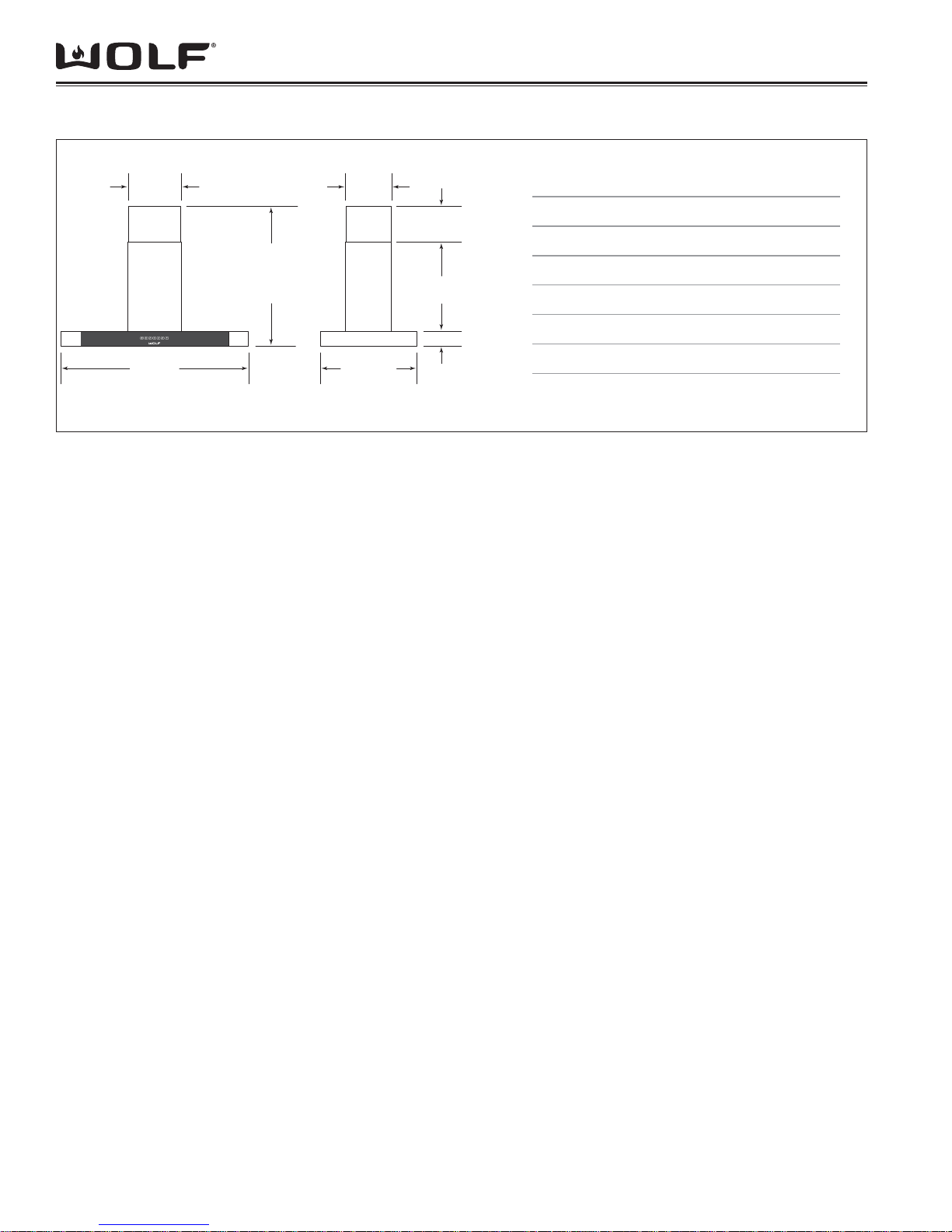

CTEW HOOD OVER-ALL DIMENSIONS

`

97/8"

(251)

30" (762)

OVERALL WIDTH

97/8"

(251)

29 1/8” (740)

TO

41 1/2” (1054)

OVERALL

HEIGHT

29 1/8” (740)

41 1/2” (1054)

OVERALL

TO

HEIGHT

107/8"

(276)

5 7/8” (149)

TO

18 3/8” (467)

MODEL CTEWH30I

Overall Width

Height (excluding chimney)

Min Height (including chimney)

201/8"

(511)

Max Height (full extension)

Overall Depth

173/4"

(451)

OVERALL DEPTH

31/8" (79)

Shipping Weight

Figure 2-4 CTEWH30 Dimensions

107/8"

(276)

5 7/8” (149)

TO

18 3/8” (467)

201/8"

(511)

MODEL CTEWH36(I)

Overall Width

Height (excluding chimney)

Min Height (including chimney)

Max Height (full extension)

30” (762)

3 1/8” (79)

29 1/8”(740)

41 1/2”(1054)

17 3/4”(451)

53 lbs (24kg)

36” (914)

3 1/8” (79)

29 1/8”(740)

41 1/2”(1054)

36" (914)

OVERALL WIDTH

97/8"

(251)

45" (1143)

OVERALL WIDTH

29 1/8” (740)

TO

41 1/2” (1054)

OVERALL

HEIGHT

Overall Depth

173/4"

(451)

OVERALL DEPTH

31/8" (79)

Shipping Weight

Figure 2-5 CTEWH36 Dimensions

107/8"

(276)

173/4"

(451)

OVERALL DEPTH

5 7/8” (149)

TO

18 3/8” (467)

201/8"

(511)

31/8" (79)

MODEL CTEWH45(I)

Overall Width

Height (excluding chimney)

Min Height (including chimney)

Max Height (full extension)

Overall Depth

Shipping Weight

CTEWH36

CTEWH36(I)

CTEWH45

CTEWH45I

17 3/4” (451)

51 lbs (23 kg)

57 lbs (26 kg)

45” (1143)

3 1/8” (79)

29 1/8” (740)

41 1/2” (1054)

17 3/4” (451)

55 lbs (25 kg)

63 lbs (29 kg)

Figure 2-6 CTEWH45 Dimensions

2-3

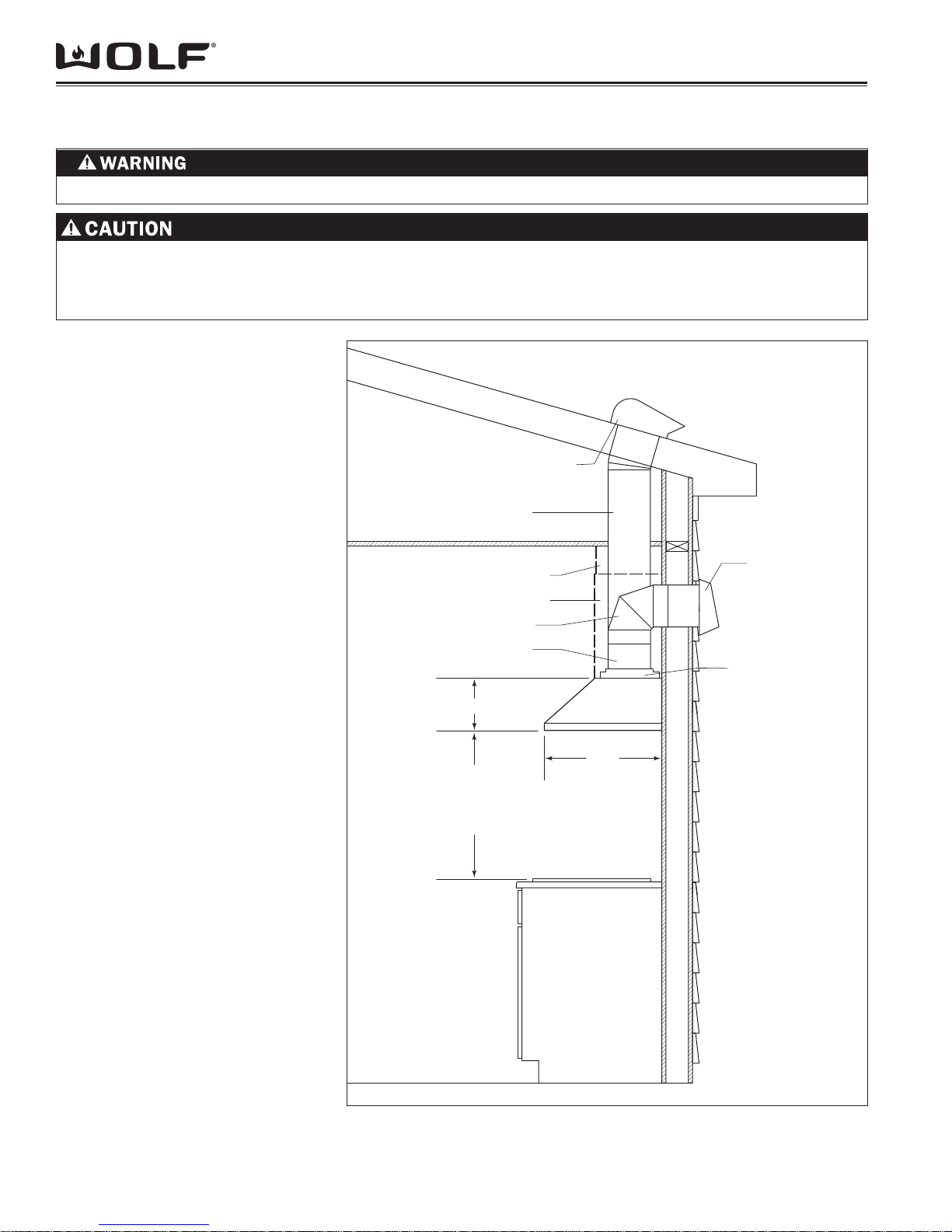

CTEI HOOD OVER-ALL DIMENSIONS

Installation InformationCT Hoods and DD Ventilation

12 1/8”

(308)

42" (1067)

OVERALL WIDTH

28 1/4” (718)

TO

41 1/2” (1054)

OVERALL

HEIGHT

10 7/8”

(276)

215/8" (549)

OVERALL DEPTH

2 1/8” (54)

TO

15 1/2” (394)

22 7/8”

(581)

31/8" (79)

MODEL CTEIH42

Overall Width

Height (excluding chimney)

Min Height (including chimney)

Max Height (full extension)

Overall Depth

Shipping Weight

Figure 2-7 CTEIH42 Dimensions

42” (1067)

3 1/8” (79)

28 1/4” (718)

41 1/2” (1054)

21 5/8” (549)

92 lbs (42 kg)

2-4

Installation Information CT Hoods and DD Ventilation

HOOD PLACEMENT

Flue Extension

Model Minimum Maximum

CTWH30

CTWH36

IH4227

301/2" (775) 481/2" (1232)

3211/16" (830) 507/8" (1292)

339/16" (853) 471/16" (1195)

D

EXTENSION

MINIMUM

FLUE

D

EXTENSION

MINIMUM

FLUE

CTEWH30I

CTEWH36(I)

CTEWH45(I)

CTEIH42I

29 1/8” (740)

29 1/8” (740)

29 1/8” (740)

28 1/4” (718)

41 1/2” (1054)

41 1/2” (1054)

41 1/2” (1054)

41 1/2” (1054)

A C

Figure 2-8 Hood Placement Dimensions

HOOD PLACEMENT

Wolf cooktop wall and island hoods come with a

telescopic chimney fl ue that allows you to reach ceiling

heights of 8’ (2.4m) to 9’ (2.7m) with a fi nished look.

A fl ue extension to accommodate 10’ (3m) ceilings is

available as a sales accessory for cooktop chimney

hoods only.

Installation of the cooktop wall or island hood should be

24” (610) to 30” 762) from the bottom of the hood to the

countertop.

To determine placement of the wall or island hood, you

must calculate the heights of the telescopic chimney

fl ue. Refer to the chart in Figure 2-8 above for the

minimum and maximum fl ue extension for specifi c

hood.

NOTE: Both sections of the telescopic chimney fl ue

must be installed in order for the chimney to be lifted

for service.

NOTE: If the height of the upper fl ue section is less

than 1/2” (13), you will need to modify the fl ue to affi x

to the fl ue attachment brackets.

A C

B

B

sdooH eliforP-woL potkooCsdooH yenmihC potkooC

CALCULATING CHIMNEY FLUE HEIGHT

Measure A (total kitchen height from fi nished fl oor to 1.

fi nished ceiling height).

Measure B (height from fi nished fl oor to countertop). 2.

Determine the desired distance from counter-top to 3.

bottom of hood (C). This dimension must be between

24” (610) and 30” (762).

NOTE: 8’ (2.4m) ceilings may not permit installation of the

wall or island hood at 30” (762) above the countertop.

To calculate the chimney fl ue height (D): D = A – (B 4.

+ C). This dimension must be between the minimum

and maximum fl ue extension for your specifi c hood as

shown in the chart.

2-5

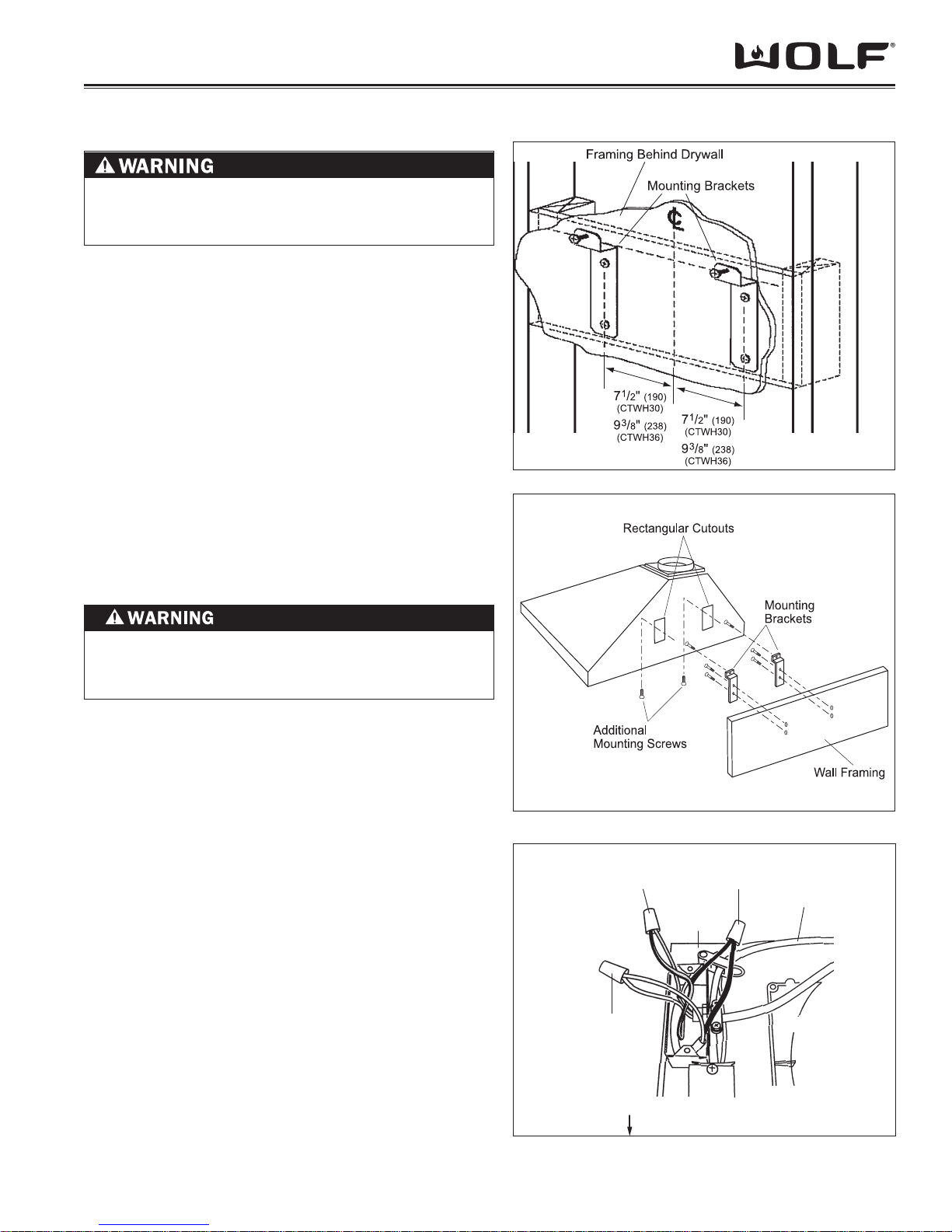

Installation InformationCT Hoods and DD Ventilation

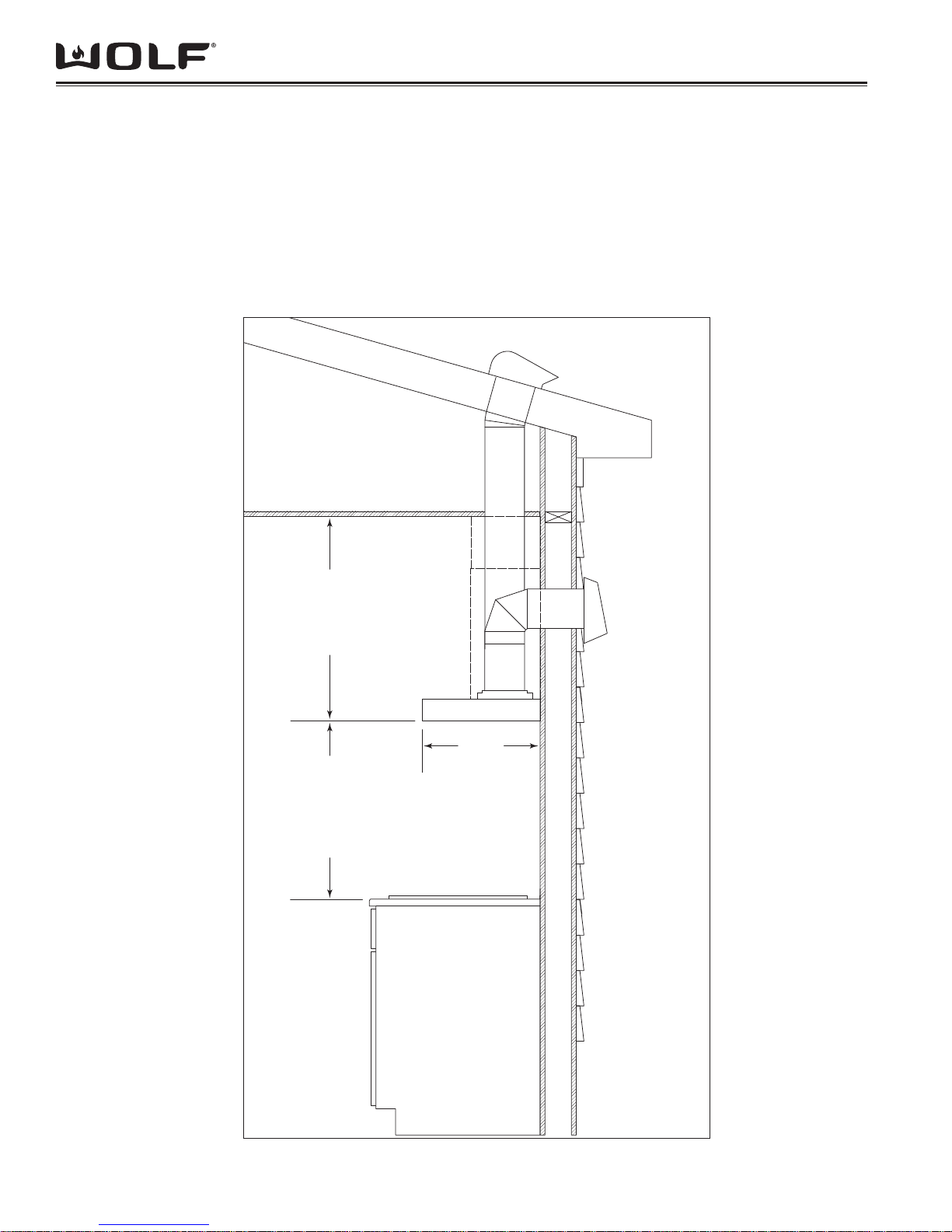

CT WALL HOOD INSTALLATION CONSIDERATIONS

TO REDUCE THE RISK OF FIRE, USE ONLY RIGID METAL DUCTWORK.

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK, THIS VENTILATION HOOD SHOULD ONLY BE

INSTALLED WITH BLOWERS MANUFACTURED BY WOLF APPLIANCE INC. AND SPECIFIED FOR USE WITH

THESE VENTILATION MODELS.

COUNTERTOP WALL HOODS INSTALLATION

SPECIFICATIONS AND PREPARATIONS FOR

MODELS CTWH30 & CTWH36

A straight, short duct run will allow 1.

the hood to perform more effi ciently.

Limit the number of elbows and transitions to as few as possible. Long

duct runs, elbows and transitions will

reduce the performance of the hood.

NOTE: All hoods must exhaust to the

outdoors.

NOTE: There is a possibility of noise issues, if a short duct run is coupled with a

remote blower.

Always use metal ducting. Do not 2.

use fl ex ducting.

Wolf recommends installing a back-3.

draft damper in all installations

(included with hood). In cold weather

installations a back-draft damper is

necessary to minimize the back-fl ow

of cold air into the room.

Wolf recommends the hood be in-4.

stalled 24” (610 mm) to 30” (762 mm)

above the cooking surface.

NOTE: Local building codes may require

the use of make-up air. Consult a local

HVAC professional for specifi c require-

ments.

ELECTRICAL REQUIREMENTS

Wolf cooktop wall hoods require a

separate, grounded, 110/120 VAC, 60 Hz

power supply. The service should have its

own 15 amp circuit breaker.

NOTE: You must follow all National

Electrical Code regulations. In addition,

be aware of local codes and ordinances

when installing your service.

ROOF CAP OR REMOTE BLOWER –

TRANSITION FROM 8" (203) TO 10" (254) DUCT

REQUIRED FOR REMOTE BLOWER

8" (203) ROUND DUCT

CHIMNEY FLUE EXTENSION

TELESCOPIC CHIMNEY FLUE

8" (203) ROUND ELBOW

8" (203) ROUND DUCT

67/8" (175) OR 91/4" (235)

24" TO 30"

(610–762)

COUNTERTOP

TO BOTTOM OF

VENTILATION HOOD

Figure 2-9 CT Wall Hood Installation Considerations

COOKTOP

WALL HOOD

21"

(535)

DUCTWORK INSTALLATION

THROUGH ROOF

WALL CAP

OR REMOTE BLOWER

DUCTWORK INSTALLATION

THROUGH WALL

8" (203) ROUND

VERTICAL DISCHARGE

2-6

Installation Information CT Hoods and DD Ventilation

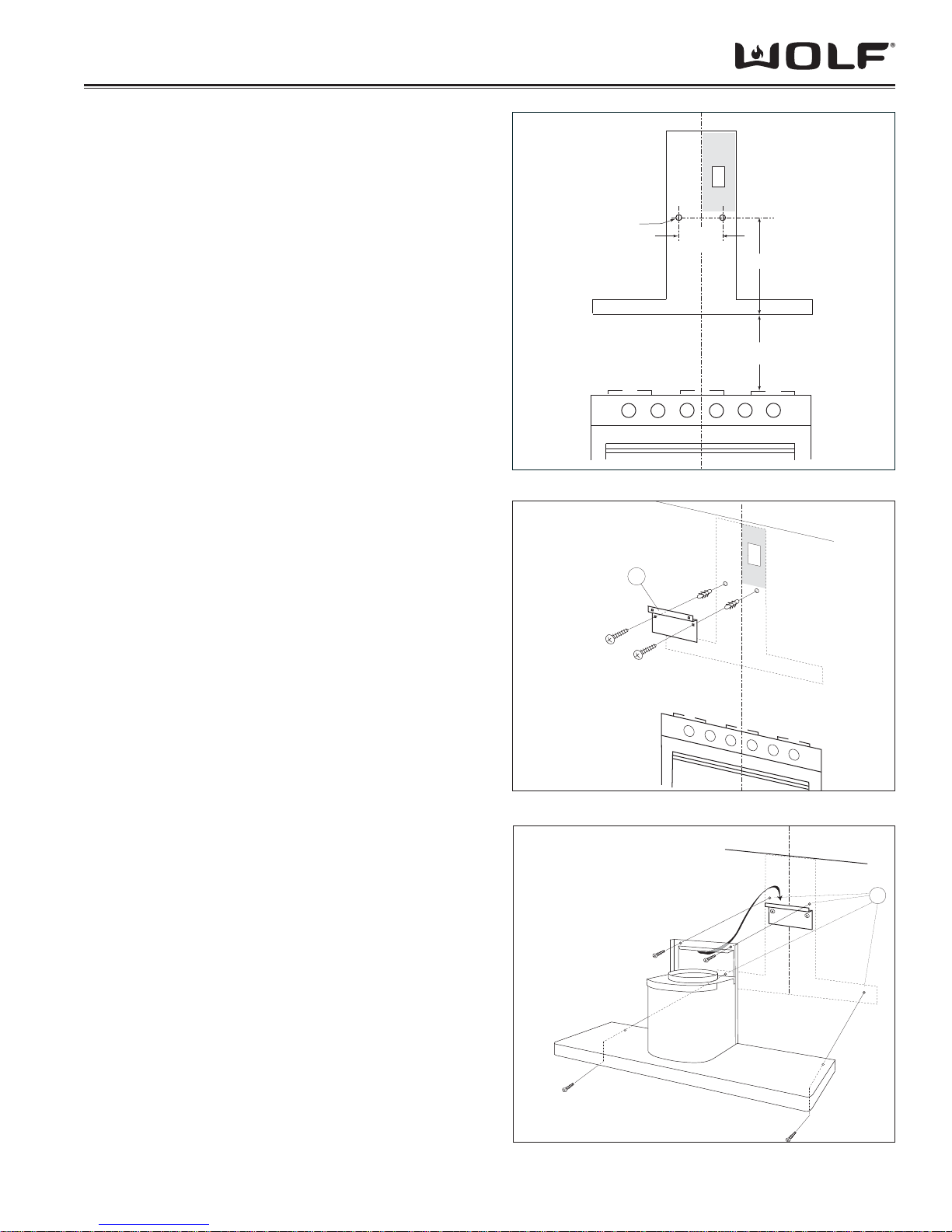

CT WALL HOOD INSTALLATION

DUE TO THE WEIGHT OF SOME HOODS, SEVERAL

PEOPLE MAN BE REQUIRED FOR A SAFE AND

PROPER INSTALLATION.

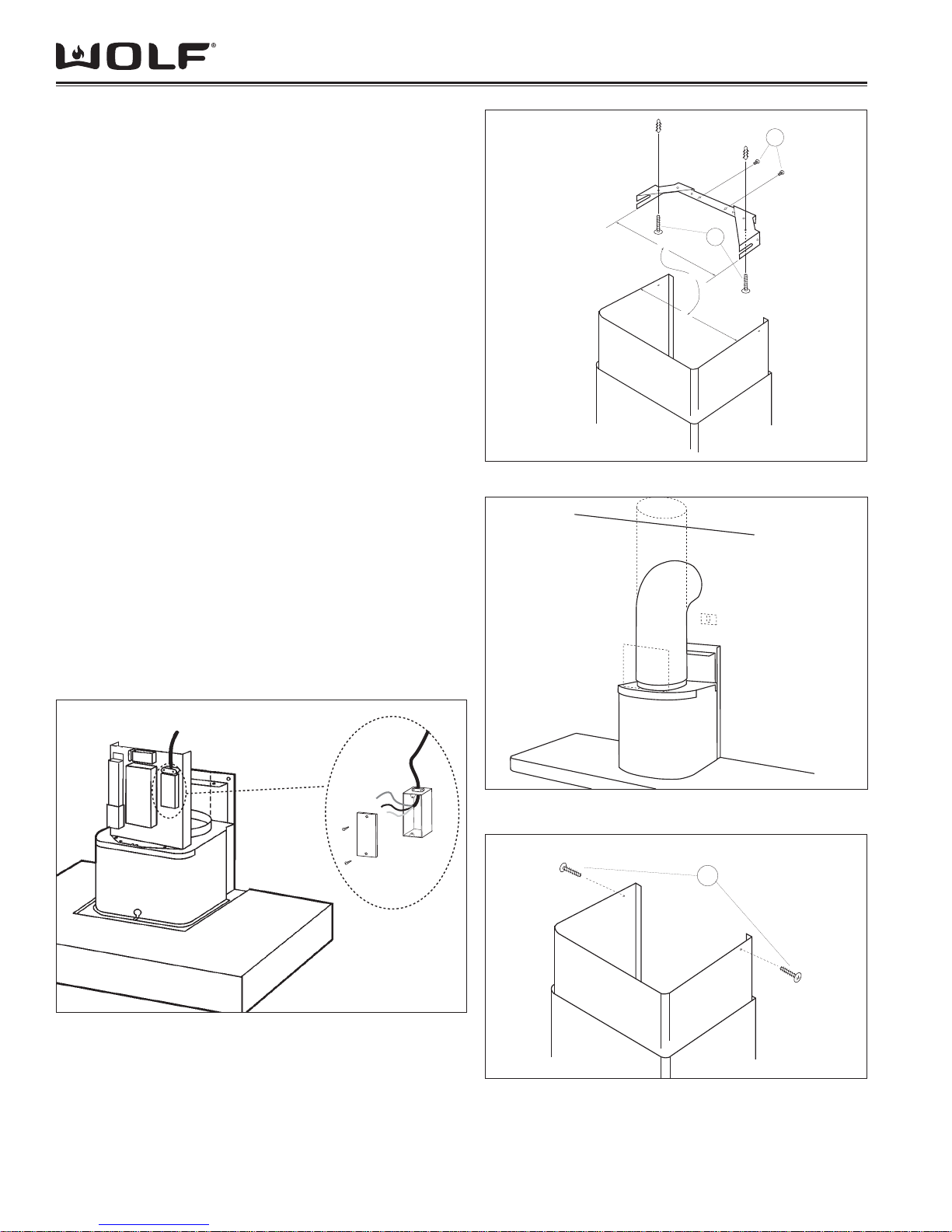

INSTALL MOUNTING BRACKETS

Construct wood wall framing that is fl ush with the interior

surface of the wall studs. Make sure that the framing is

centered in the hood installation location, and that the

height of the framing will allow the mounting brackets to

be secured to the framing within the dimension shown in

Figure 2-10.

After the wall surface is fi nished, secure the mounting

brackets to the framing using the dimensions shown.

INSTALL THE HOOD

Hang the hood from the brackets through the rectangular

cut-outs on the back of the hood. The cut-outs are larger

than the brackets to allow for vertical and horizontal

adjustment. (See Figure 2-11)

Keep in mind that the bottom of the hood should be 24”

(610) to 30” (762) above the countertop.

Figure 2-10 Mounting Bracket Installation

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

THIS VENTILATION HOOD MUST BE PROPERLY

GROUNDED.

Use height adjustment screws to adjust the hood vertically

and the depth adjustment screws to adjust the hood

horizontally.

Secure the hood with additional mounting screws. If wall

studs or framing are not available in the proper location,

use the drywall anchors provided with the hood.

ELECTRICAL CONNECTIONS

NOTE: This unit should be install by a qualifi ed electrician

in accordance with all applicable national and local codes.

Remove the cover from the rear electrical box knockout 1.

that faces the hood’s discharge collar.

Insert 6” (152) of 120 VAC power cable through the 2.

knockout opening. Secure the cable to the electrical

box with an appropriate connector.

Make electrical connections. Connect black to black, 3.

white to white and green/yellow to green or bare wire.

(See Figure 2-12)

Reinstall the electrical box cover and screws. Make 4.

sure that all wires are secure and that no wires are

pinched between the cover and box.

Figure 2-11 Hood Installation

Green/Yellow to

Green or

Bare Wire

White

to White

HOOD FRONT TOP OF HOOD SHELL

Rear

Electrical

Box

Black to

Black

120 V AC

Power Cable

Discharge

Collar

Figure 2-12 Electrical Connections

2-7

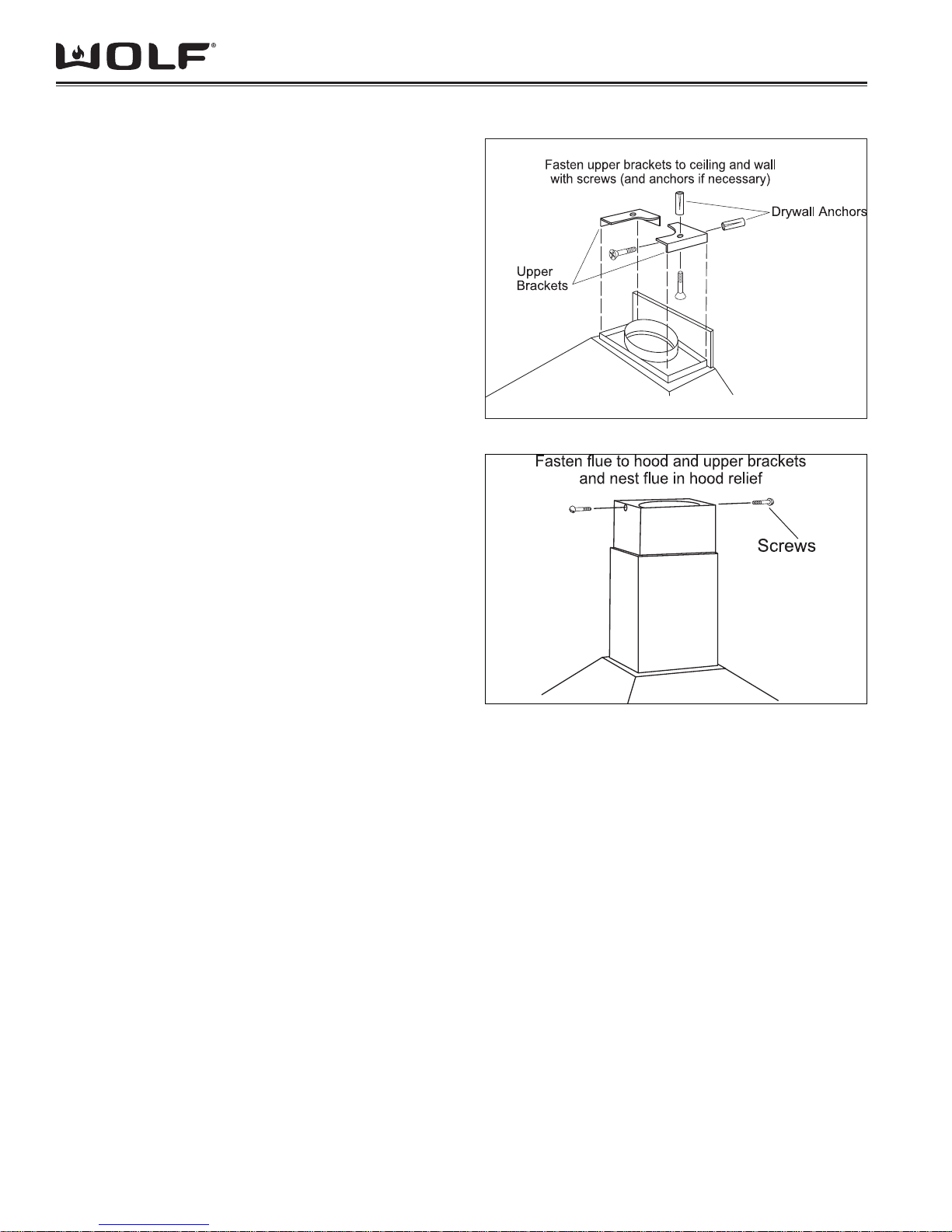

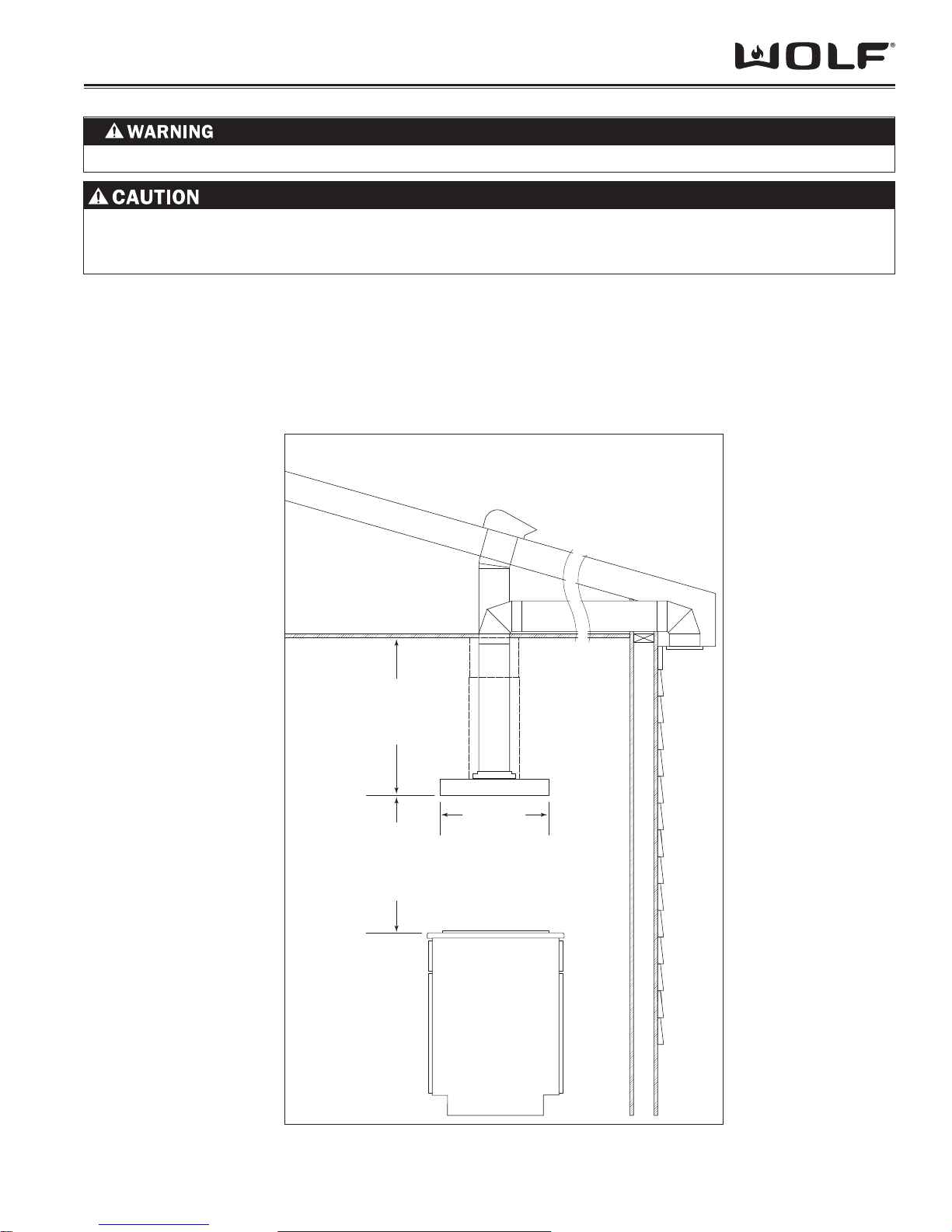

CT WALL HOOD DUCTWORK INSTALLATION

CONNECT DUCTWORK

Use the screws and wall anchors provided to secure the

upper brackets to the ceiling. Position the upper brackets

based on the dimension of the telescopic chimney fl ue.

(See Figure 2-13)

Use an 8” (203) round metal duct to connect the duct collar

on the hood to the ductwork above. Use duct tape to make

all joints secure and air tight.

Connect the upper section of the telescopic chimney fl ue to

the brackets with the screws provided. (See Figure 2-14)

Nest the bottom of the telescopic chimney fl ue into the

relief in the hood shell.

Installation InformationCT Hoods and DD Ventilation

Figure 2-13 Upper Flue Bracket Installation

Figure 2-14 Securing Inner Flue to Upper Flue Bracket

2-8

Installation Information CT Hoods and DD Ventilation

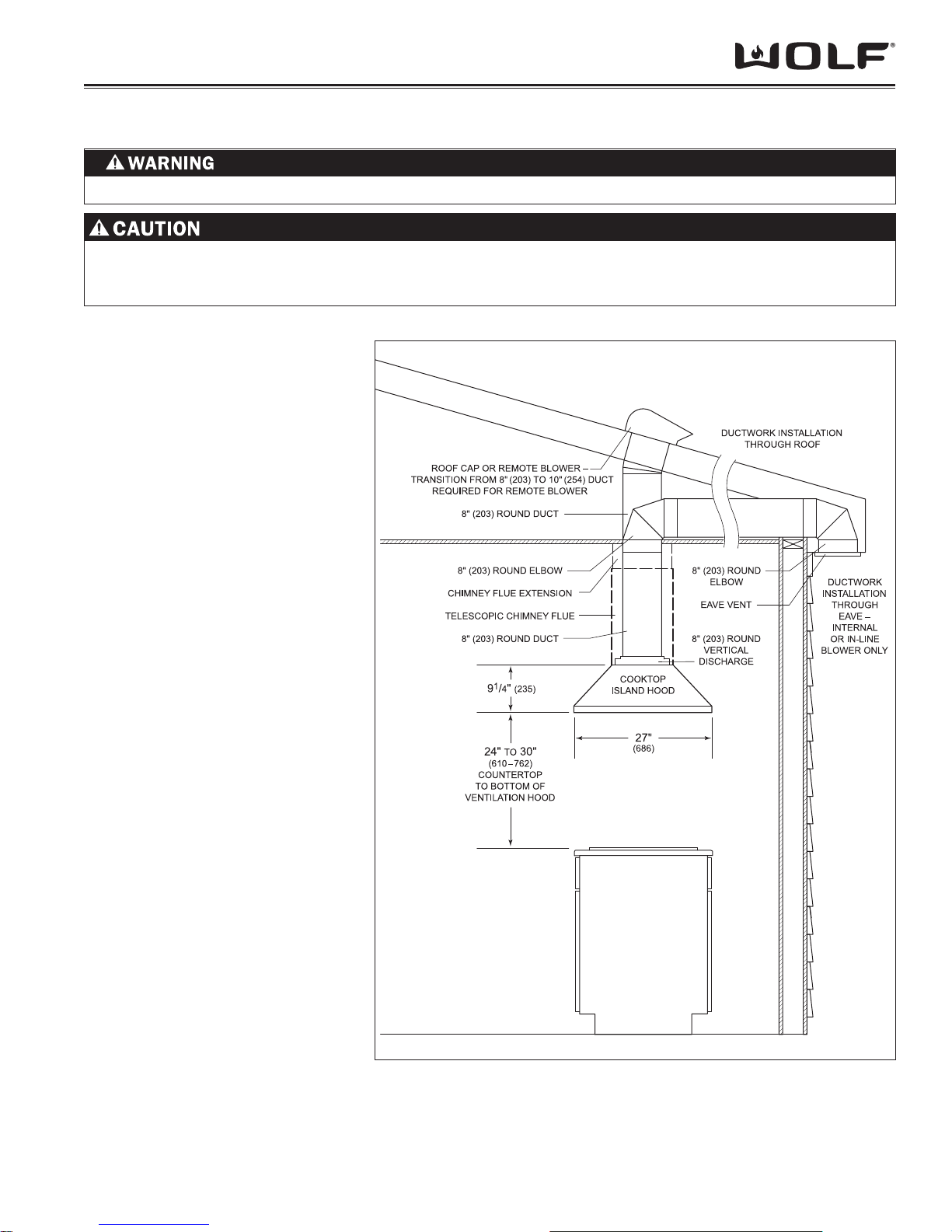

COOKTOP ISLAND HOOD INSTALLATION CONSIDERATIONS

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK, THIS VENTILATION HOOD SHOULD ONLY BE

INSTALLED WITH BLOWERS MANUFACTURED BY WOLF APPLIANCE INC. AND SPECIFIED FOR USE WITH

THESE VENTILATION MODELS.

ISLAND HOOD INSTALLATION SPECIFICATIONS

AND PREPARATION FOR

MODEL IH4227

A straight, short duct run will allow 1.

the hood to perform more effi ciently.

Limit the number of elbows and transitions to as few as possible. Long

duct runs, elbows and transitions will

reduce the performance of the hood.

NOTE: All hoods must exhaust to the

outdoors.

NOTE: There is a possibility of noise issues, if a short duct run is coupled with a

remote blower.

Always use metal ducting. Do not 2.

use fl ex ducting.

Wolf recommends installing a back-3.

draft damper in all installations

(included with hood). In cold weather

installations a back-draft damper is

necessary to minimize the back-fl ow

of cold air into the room.

Wolf recommends the hood be in-4.

stalled 24” (610 mm) to 30” (762 mm)

above the cooking surface.

NOTE: Local building codes may require

the use of make-up air. Consult a local

HVAC professional for specifi c require-

ments.

ELECTRICAL REQUIREMENTS

Wolf cooktop wall hoods require a

separate, grounded, 110/120 VAC, 60 Hz

power supply. The service should have its

own 15 amp circuit breaker.

NOTE: You must follow all National

Electrical Code regulations. In addition,

be aware of local codes and ordinances

when installing your service.

Figure 2-15 Island Hood Installation Considerations

2-9

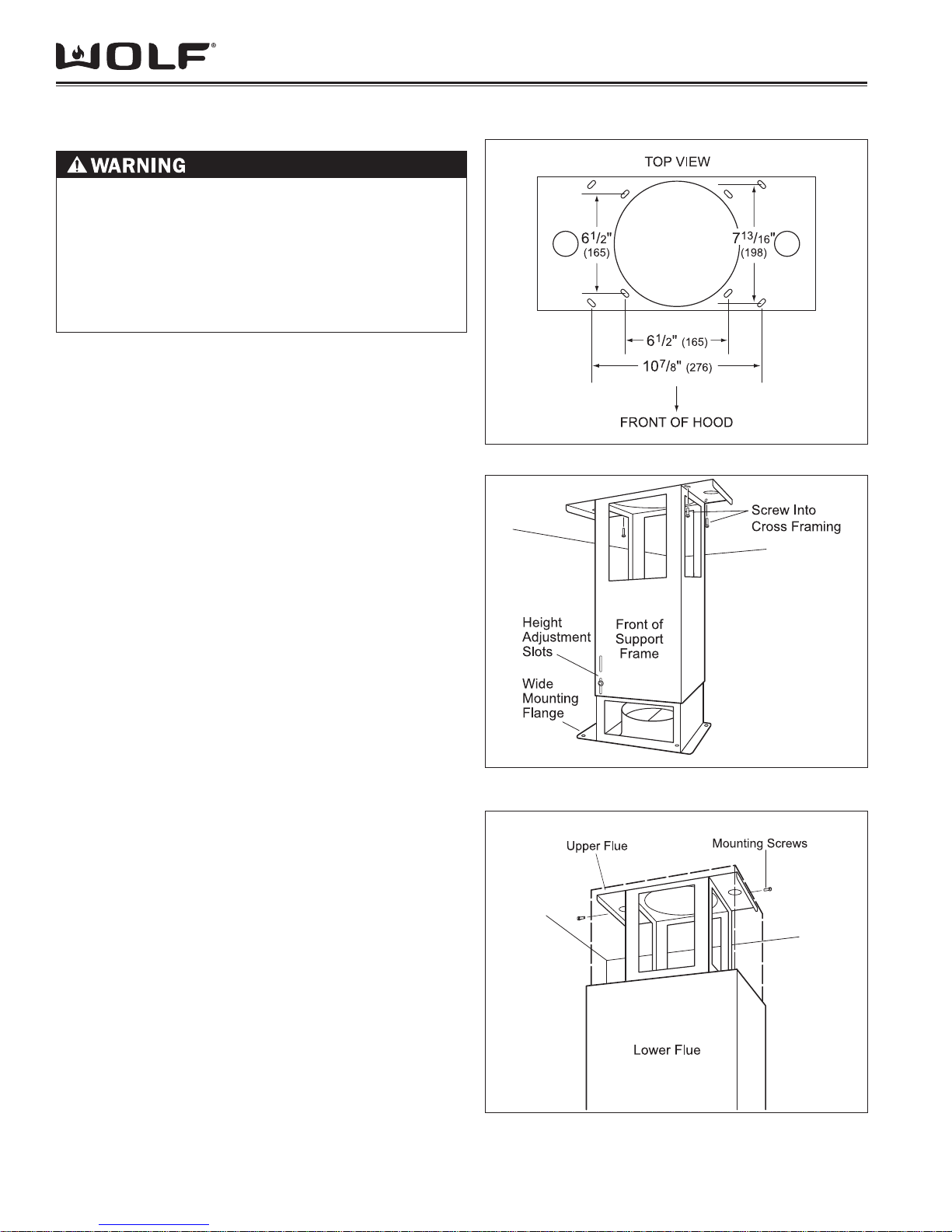

COOKTOP ISLAND HOOD INSTALLATION

DUE TO THE WEIGHT OF SOME HOODS, SEVERAL

PEOPLE MAN BE REQUIRED FOR A SAFE AND

PROPER INSTALLATION.

FRAMING MUST BE STRUCTURALLY TIED TOGETHER

AND TIED TO CEILING JOISTS TO PROVIDE ENOUGH

STRENGTH TO SUPPORT WEIGHT OF THE HOOD

AND INTERNAL BLOWER, IF APPLICABLE.

INSTALL SUPPORT SYSTEM

At the island hood installation location, install two-1.

by-four or 3/4”(19) plywood cross framing between

ceiling joists. Refer to the island hood mounting pattern

dimensions. (See Figure 2-16)

Finish the ceiling surface. Be sure to mark the location 2.

of the ceiling joists and cross framing.

Determine the desired orientation of the island hood. 3.

Note that the front designates the control side of the

hood.

Secure the upper half of the support frame to the joists 4.

and cross framing with four screws provided with your

hood. Make sure that the screws are driven into the

center of the joists and framing for maximum strength.

(See Figure 2-17)

Adjust the overall height of the support frame. Loosen 5.

and retighten the screws in the height adjustment slots

as necessary. (See Figure 2-17)

NOTE: The hood height is 11 1/4”(286) from the support

frame attachment point. The bottom of the hood must

be 24” (610)minimum and 30” (762) maximum from the

countertop.

Secure the upper telescopic chimney fl ue section to the 6.

upper support frame. (See Figure 2-18)

Installation InformationCT Hoods and DD Ventilation

Figure 2-16 Telescopic Flue Mounting

Figure 2-17 Support Frame

Figure 2-18 Upper Chimney Flue Mounting

2-10

Installation Information CT Hoods and DD Ventilation

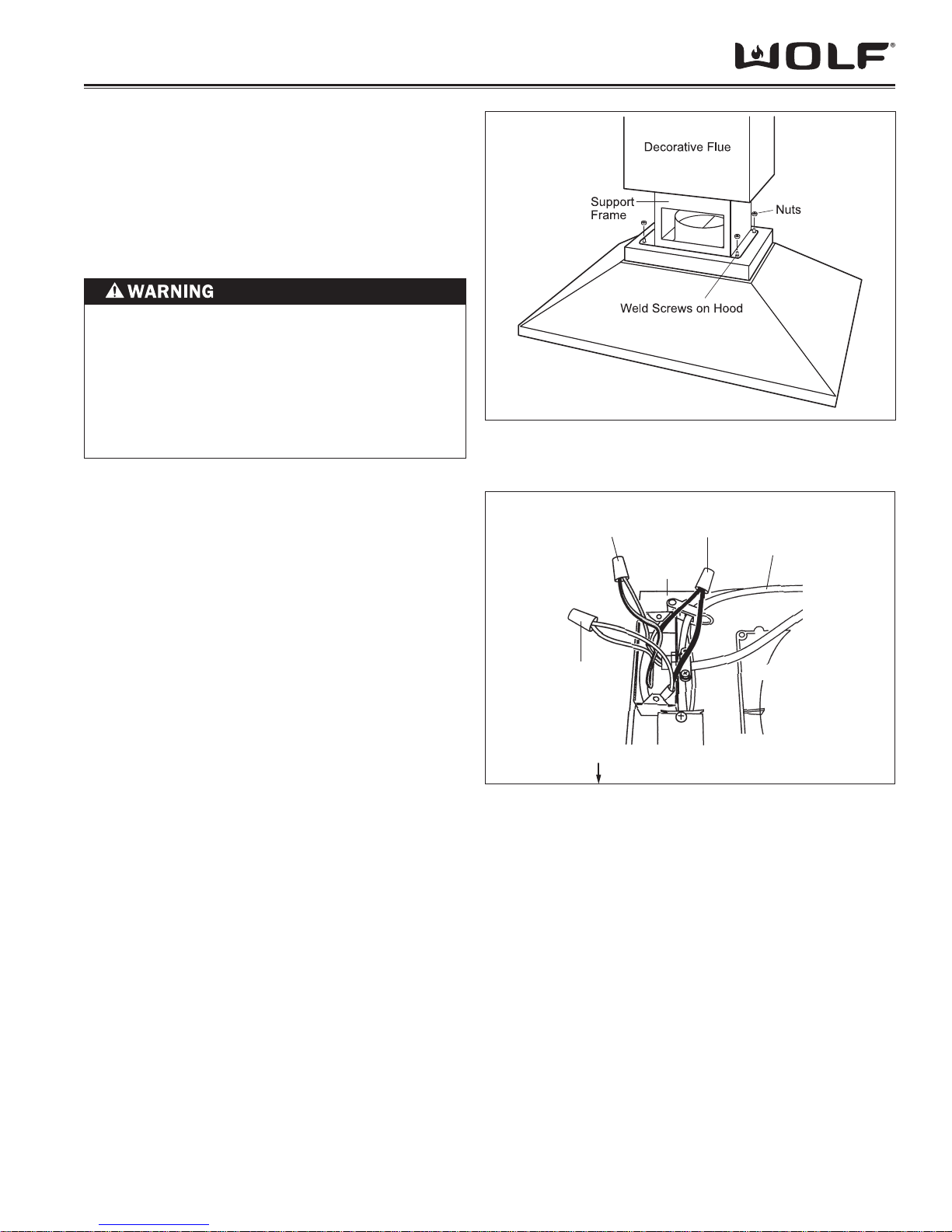

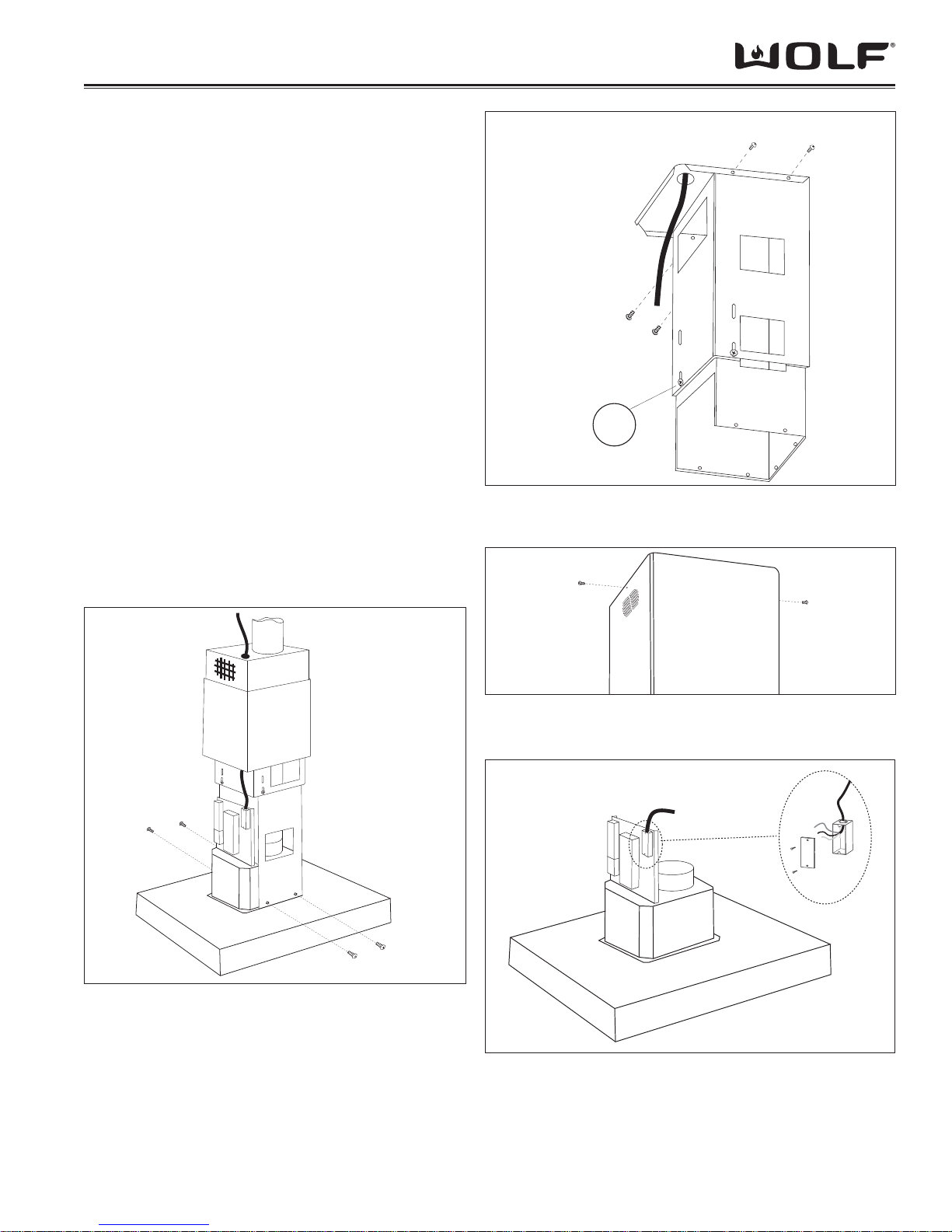

MOUNT HOOD TO SUPPORT FRAME

Temporarily secure the lower telescopic chimney 1.

fl ue section over the upper fl ue section.

Mount the hood to the support frame by aligning 2.

the four weld screws on the hood to the four holes

on the support frame. Use four nuts to secure the

hood to the support frame. (See Figure 2-19).

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

THIS VENTILATION HOOD MUST BE PROPERLY

GROUNDED.

UNIT SHOULD BE CONNECTED ELECTRICALLY

BY A QUALIFIED ELECTRICIAN IN ACCORDANCE

WITH ALL APPLICABLE NATIONAL AND LOCAL

ELECTRICAL CODES.

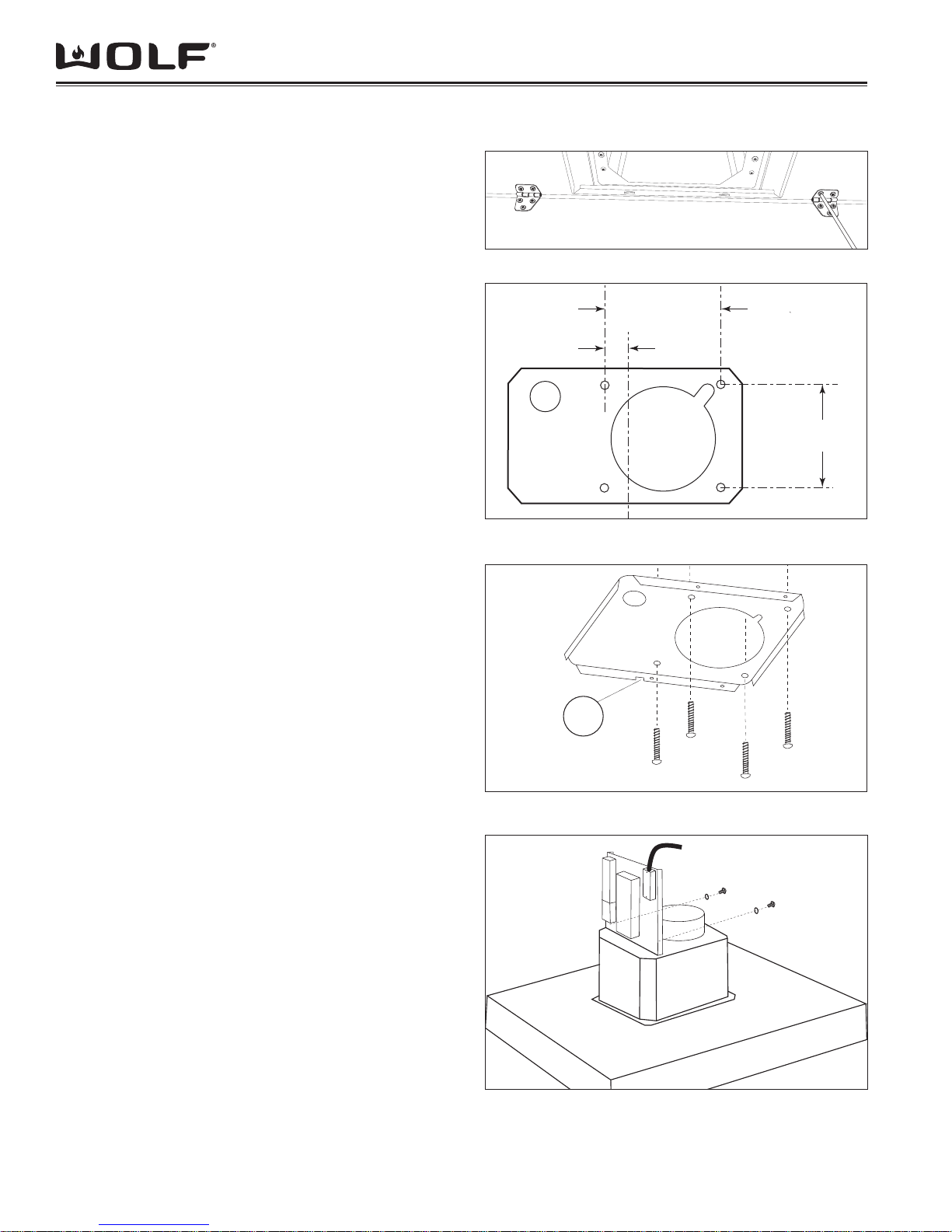

LECTRICAL CONNECTIONS

E

Remove the cover from the rear electrical box 1.

knockout that faces the hood’s discharge collar.

Insert 6” (152) of 120 VAC power cable through 2.

the knockout opening. Secure the cable to the

electrical box with an appropriate connector.

Make electrical connections. Connect black to 3.

black, white to white and green/yellow to green or

bare wire. (See Figure 2-20)

Reinstall the electrical box cover and screws. Make 4.

sure that all wires are secure and that no wires are

pinched between the cover and box.

Use an 8” (203) round metal duct to connect the 5.

duct collar on the hood to the ductwork above. Use

duct tape to make all joints secure and air tight.

Slide the lower telescopic chimney fl ue section 6.

downward until it fi ts properly around the hood

shell.

Figure 2-19 Mounting Hood to Support System

Green/Yellow to

Green or

Bare Wire

White

to White

HOOD FRONT TOP OF HOOD SHELL

Black to

Rear

Electrical

Box

Figure 2-20 Electrical Connections

Black

Power Cable

120 V AC

Discharge

Collar

2-11

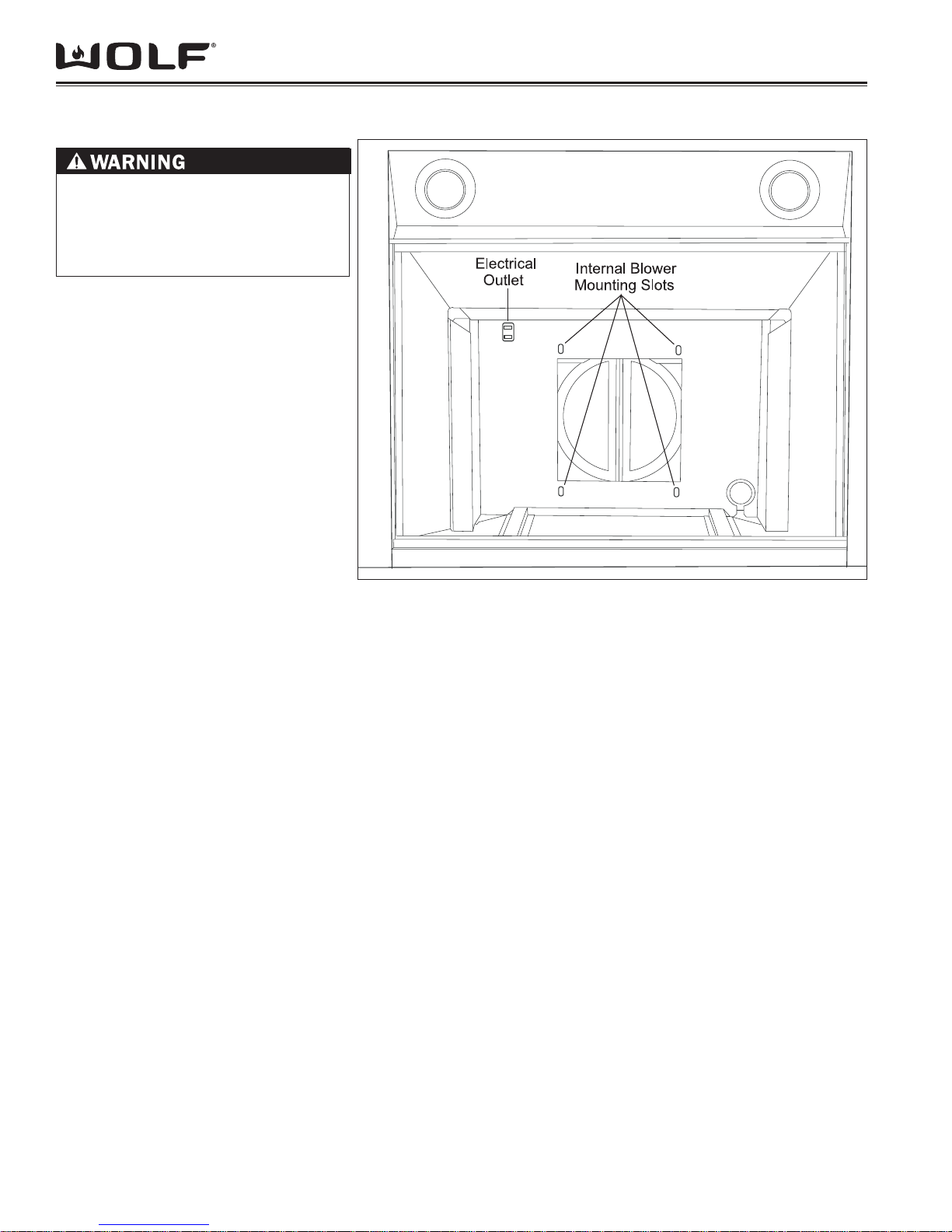

INTERNAL BLOWER INSTALLATION

TO REDUCE THE RISK OF

ELECTRICAL SHOCK, POWER

SHOULD BE TURNED OFF TO

UNIT BEFORE ATTEMPTING THE

FOLLOWING PROCEDURE.

INTERNAL BLOWER INSTALLATION

NOTE: Before turning the power on, make

sure blower control is in the “OFF” position. Use wire connectors or wire nuts

approved by UL or C/UL. Refer to installation instructions provided with each blower

to verify wall or roof cut-outs.

NOTE: Blower options vary with the cooking surface. Use only a Wolf blower with

the cooktop ventilation hood.

NOTE: For mounting and installation of

the internal blower, refer to the specifi c

installation instructions provided with each

blower.

Remove the hood fi lters.1.

Lift the blower into position inside 2.

the hood, the threaded studs on the

blower will slide through the slots provided in the upper panel.

Use four hex nuts provided with 3.

the blower to fasten the unit to four

threaded studs. (See Figure 2-21)

Plug the blowers’ single power cord 4.

(double for some blowers) into the

receptacle(s) inside the hood. Use the

clip on the hood to keep excess power

cord away from moving parts.

Reinstall the hood fi lters.5.

NOTE: Before turning the power on, make

sure the blower control is in the OFF position.

Installation InformationCT Hoods and DD Ventilation

Figure 2-21 Internal Blower Install

2-12

Installation Information CT Hoods and DD Ventilation

CTE WALL HOOD INSTALLATION CONSIDERATIONS

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK, THIS VENTILATION HOOD SHOULD ONLY BE

INSTALLED WITH BLOWERS MANUFACTURED BY WOLF APPLIANCE INC. AND SPECIFIED FOR USE WITH

THESE VENTILATION MODELS.

INSTALLATION OPTIONS:

Ducted Installation. 1.

In a ducted installation, the hood aspirates the kitchen air saturated with fumes and odors, passes it through the

grease fi lter(s) and expels it to the outside through ductwork.

For this installation, a hood with an internal,

in-line or remote blower can be used. In-line blowers are located in ductwork between the hood and the outside.

For wall hoods, the remote blower can be mounted on the roof or an exterior wall. Wolf in-line and remote blower

assemblies are available through your Wolf dealer.

Recirculating Installation.2.

In a recirculating installation, the hood aspirates the kitchen air saturated with fumes and odors, purifi es it through

the grease fi lter(s) and charcoal fi lter and returns clean air into the room. For constant effi ciency, the charcoal fi lter

must be replaced periodically. For this installation, a recirculation kit available through your Wolf dealer will be

required.

NOTE: For Installation instructions for Recirculating Option please see Installation Manual that was provided with

the product.

LOW-PROFILE HOOD INSTALLATION SPECIFICATIONS AND PREPARATIONS

Decide where the ductwork will run between the hood and the outside. A straight, short duct run will allow the hood

to perform more effi ciently. Limit the number of elbows and transitions to as few as possible. Long duct runs, elbows

and transitions will reduce the performance of the hood. Wolf recommends the maximum linear duct run be no greater

than 50’ (15 m).

NOTE: There is a possibility of noise issues, if a short duct run is coupled with a remote blower.

Wolf recommends installing a backdraft damper in all installations. A backdraft damper is included with the hood. It is

built into the transition from the hood to the duct run. Unless you are using a remote blower, a roof or wall cap should

be installed. Connect ductwork to the cap and work back towards the hood. Use duct tape to seal the ductwork joints.

NOTE: Local building codes may require the use of make-up air. Consult a local HVAC professional for specifi c

requirements.

NOTE: Consult a qualifi ed HVAC Engineer for specifi c ducting applications.

2-13

Installation InformationCT Hoods and DD Ventilation

LOW-PROFILE WALL HOODS INSTALLATION SPECIFICATIONS AND PREPARATIONS

NOTE: This installation must be completed by a qualifi ed installer or Wolf authorized service center technician.

NOTE: Low Profi le Hoods are designed for use with a 6” diameter duct.

CTE W

ALL HOOD DUCTED INSTALLATION

Locate the electrical supply through the wall within the shaded area shown in Figure 23.1.

Install ductwork as outlined on page 2-13 & Figure 2-22.2.

If an optional backsplash is to be used, attach it to the fi nished wall. Secure the hood mounting brackets to the 3.

wall studs prior to installing the backsplash.

DUCT WORK

INSTALLATION

THROUGH

ROOF

29 1/8” (740)

TO

41 1/2” (1054)

HEIGHT

OF HOOD

24" (610)

TO

30" (762)

COUNTERTOP

TO B OTTOM

OF HOOD

DUCT WORK

INSTALLATION

THROUGH

WALL

173/4"

(451)

DEPTH OF HOOD

Figure 2-22 CTE Wall Hood Installation Considerations

2-14

Installation Information CT Hoods and DD Ventilation

E

LECTRICAL REQUIREMENTS

Wolf low-profi le hoods require a separate, grounded,

110/120 VAC, 60 Hz power supply. The service should

have its own 15 amp circuit breaker.

NOTE: You must follow all National Electrical Code

regulations. In addition, be aware of local codes and

ordinances when installing your service.

IXING TO THE WALL

F

Draw a line on the wall in vertical line with your hood. 1.

Mark the fi rst two holes to be drilled in the wall, re-

specting the distances indicated in Figure 23. Drill the

two holes and fi t the screw anchors provided.

For best capture of cooking impurities, the bottom 2.

of the hood should be a minimum of 24” (610) and a

maximum of 30” (762) above THE COUNTERTOP.

Fix the metal bracket (A) to the wall using the two 3.

holes just drilled as shown in Figure 24. The screws

for fi xing the bracket are provided. Use the two cut-out

triangles on the bracket to position it exactly along the

vertical axis of the hood.

Hang the hood on the bracket as shown in Figure 4.

25. Adjust the horizontal position moving the hood

to the right or left so that it is aligned with the wall

units. When adjustment has been completed, without

removing the hood, mark the other four holes to be

drilled (C) in the wall. Remove the hood and drill the

holes marked (5/16” diameter). Then use the four

screw anchors and the four screws provided for fi nal

fi xing.

Mount the plate of the electrical system fi xing it with 5.

three screws.

FIXING THE TELESCOPIC FLUE

Adjust the width of the support bracket (D) of the 1.

telescopic fl ue by means of the screws (E) as shown

in Figure 26. Then, by means of the screw anchors

and screws (F) provided, fi x the bracket to the ceiling

in such a way that it is positioned along the axis with

your hood.

Connect the air outlet pipe to the air vent of the hood. 2.

Use a fl exible pipe and lock it to the air vent of the

hood with a metal hose clamp as shown in Figure 27

(pipe and clamp are not provided).

For exhaust hoods, turn the upper fl ue over so that 3.

the air exhaust grid is in the lower section.

Figure 2-23 CTE Wall Hood Mounting Plate Placement

Figure 2-24 CTE Wall Hood Mounting Plate Mounting

5/16"

DIAMETER

4.8 x 38mm

A

5 1/16”

(129)

E

13 3/8” (340)

24" to 30" (610 – 762)

TO COOKING SURFACE

E

C

4.8 x 38 mm

Figure 2-25 CTE Wall Hood Mounting

2-15

WIRING

NOTE: The ventilation hood must be properly grounded. It should be installed by a qualifi ed electrician in ac-

cordance with all applicable national and local electrical

codes.

Run supply conductors to the hood wiring box 1.

marked “120 VAC input”.

Remove the cover from the wiring box and remove 2.

one knockout as shown in Figure 28.

Secure the conduit to the wiring box through a 3.

conduit connector.

Make electrical connections at the hood. Connect 4.

white-to-white, black-to-black and green-to-ground.

Replace the wiring box cover and screws. Make 5.

sure wires are not pinched between the cover and

box.

INAL STEP

F

Insert the fl ue extensions setting them on the hood.

Extend the upper fl ue to the ceiling and secure with the

two screws (H) as shown in Figure 29.

Installation InformationCT Hoods and DD Ventilation

E

F

=

Figure 2-26 CTE Wall Hood Flue Support Bracket

Figure 2-28 CTE Wall Hood Electrical Connection

Figure 2-27 CTE Wall Hood Air Outlet Pipe

3.9 x 9.5mm

H

BOX MARKED

120 VAC INPUT

Figure 2-29 CTE Wall Hood Flue Securing

2-16

Installation Information CT Hoods and DD Ventilation

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK, THIS VENTILATION HOOD SHOULD ONLY BE

INSTALLED WITH BLOWERS MANUFACTURED BY WOLF APPLIANCE INC. AND SPECIFIED FOR USE WITH

THESE VENTILATION MODELS.

LOW-PROFILE ISLAND HOOD INSTALLATION SPECIFICATIONS AND PREPARATION

NOTE: This installation must be completed by a qualifi ed installer or Wolf authorized service center technician.

Locate the electrical supply through the ceiling inside the area of the fl ue.1.

Install ductwork as outlined on page 2-13 & Figure 2-30.2.

DUCT WORK

INS TALLATION

TH ROUGH

28 1/4” (718)

TO

41 1/2” (1054)

HEIGHT

OF HOOD

24" (610)

TO

30" (762)

COUNTERTOP

TO BOTTOM

OF HOOD

ROOF

215/8" (549)

DEPTH OF HOOD

DUCTWORK

INSTALLATION

THROUGH EAVE –

INTERNAL

BLOWER ONLY

Figure 2-30 CTEI Hood Installation Considerations

2-17

CTE ISLAND HOOD INSTALLATION

ELECTRICAL REQUIREMENTS

Wolf low-profi le hoods require a separate, grounded,

110/120 VAC, 60 Hz power supply. The service should

have its own 15 amp circuit breaker.

NOTE: You must follow all National Electrical Code

regulations. In addition, be aware of local codes and

ordinances when installing your service.

FIXING TO THE CEILING

Mount the metal panel with four screws as shown in 1.

Figure 31.

Using the drilling template, drill the holes for fi xing to 2.

the ceiling on the vertical side of your hood. The center

line of the mounting plate (Figure 32) is in line with

the center of the control panel. Carefully observe this

indication to ensure proper alignment of the hood with

the cooking product.

Fix the bracket to the ceiling using the screws and 3.

screw anchors provided as shown in Figure 33.

NOTE: The position of the bracket determines the fi nal

position of the hood. The side with the slot (B) corresponds

to the side opposite the controls.

Assemble the plate of the electrical system fi xing it with 4.

two screws and two metal washers as shown in Figure

34.

Fix the telescopic fl ue to the bracket by means of four 5.

screws (provided), running the air evacuation pipe

through the telescopic fl ue and the electric power cable

through the special hole in the bracket as shown in

Figure 35.

Adjust the height of the telescopic fl ue by means of the 6.

four retaining screws (C) shown in Figure 35. Take into

account that the height of the hood is 3 1/8” (79) and

the bottom of the hood should be a minimum of 24”

(610) and a maximum of 30” (762) above the countertop.

Take the upper fl ue (with the round slots) and slide it on 7.

the telescopic fl ue with the slots facing upwards. Attach

the fl ue to the bracket with two screws as shown in

Figure 36.

Take the lower fl ue and slide it over the upper fl ue, to 8.

the top and secure it in that position using adhesive

tape.

Raise the hood to the telescopic fl ue and connect 9.

the air outlet duct to the hood. Attach the hood to the

telescopic fl ue by means of four screws (provided) as

shown in Figure 37.

Installation InformationCT Hoods and DD Ventilation

Figure 2-31 CTE Island Hood Metal Panel Mounting

5 15/16” (151)

1 3/8” (35)

5 15/16” (151)

Figure 2-32 CTE Island Hood Plate Dimensions

B

4.5 x 60mm

Figure 2-33 CTE Island Hood Ceiling Plate Mounting

3.9 x 9.5mm

Figure 2-34 CTE Island Hood Control Plate

2-18

Installation Information CT Hoods and DD Ventilation

WIRING

NOTE: The ventilation hood must be properly grounded. It should be installed by a qualifi ed electrician in ac-

cordance with all applicable national and local electrical

codes.

Run supply conductors to the hood wiring box 1.

marked “120 VAC input”.

Remove the cover from the wiring box and remove 2.

one knockout as shown in Figure 38.

Secure the conduit to the wiring box through a 3.

conduit connector.

Make electrical connections at the hood. Connect 4.

white-to-white, black-to-black and green-to-ground.

Replace the wiring box cover and screws. Make 5.

sure wires are not pinched between the cover and

box.

INAL STEP

F

Remove the adhesive tape and slide the lower fl ue

downward, placing it gently onto the hood base. Installation is now complete and the grease fi lters can be

installed.

3.9 x 9.5mm

C

Figure 2-35 CTE Island Hood Telescopic Flue Mounting

Figure 2-37 CTE Island Hood to Telescopic Flue

3.9 x 9.5mm

Figure 2-36 CTE Island Hood Upper Flue Mounting

BOX MARKED

120 VAC INPUT

Figure 2-38 CTE Island Hood Electric Hookup

2-19

REMOTE BLOWER INSTALLATION

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

POWER SHOULD BE TURNED OFF TO UNIT

BEFORE A TTEMPTING THE FOLLOWING

PROCEDURE.

REMOTE BLOWER INSTALLATION

NOTE: Before turning the power on, make sure the

blower is in the “OFF” position. Use wire connectors or

wire nuts approved by UL or C/UL..

NOTE: Detailed instructions of Remote Blower

installation are provided with the blower. Refer to

installation instructions provided with each blower to

verify wall or roof cut-outs. The following information is

simply intended to summarize the process.

Locate the blower so the length of the duct run 1.

and number of elbows and transitions are kept to a

minimum.

Where possible, blower should be located between 2.

wall studs or roof rafters.

Avoid pipes, wires or other ductwork that may be 3.

running through the wall.

Be sure that there is enough space for any 4.

transitions that may be needed between the blower

and the connecting ductwork.

For best performance, locate transitions nearest 5.

the blower.

CONNECT REMOTE BLOWER

NOTE: Always refer to all blower installation

instructions provided with the blower for additional

mounting and wiring instructions.

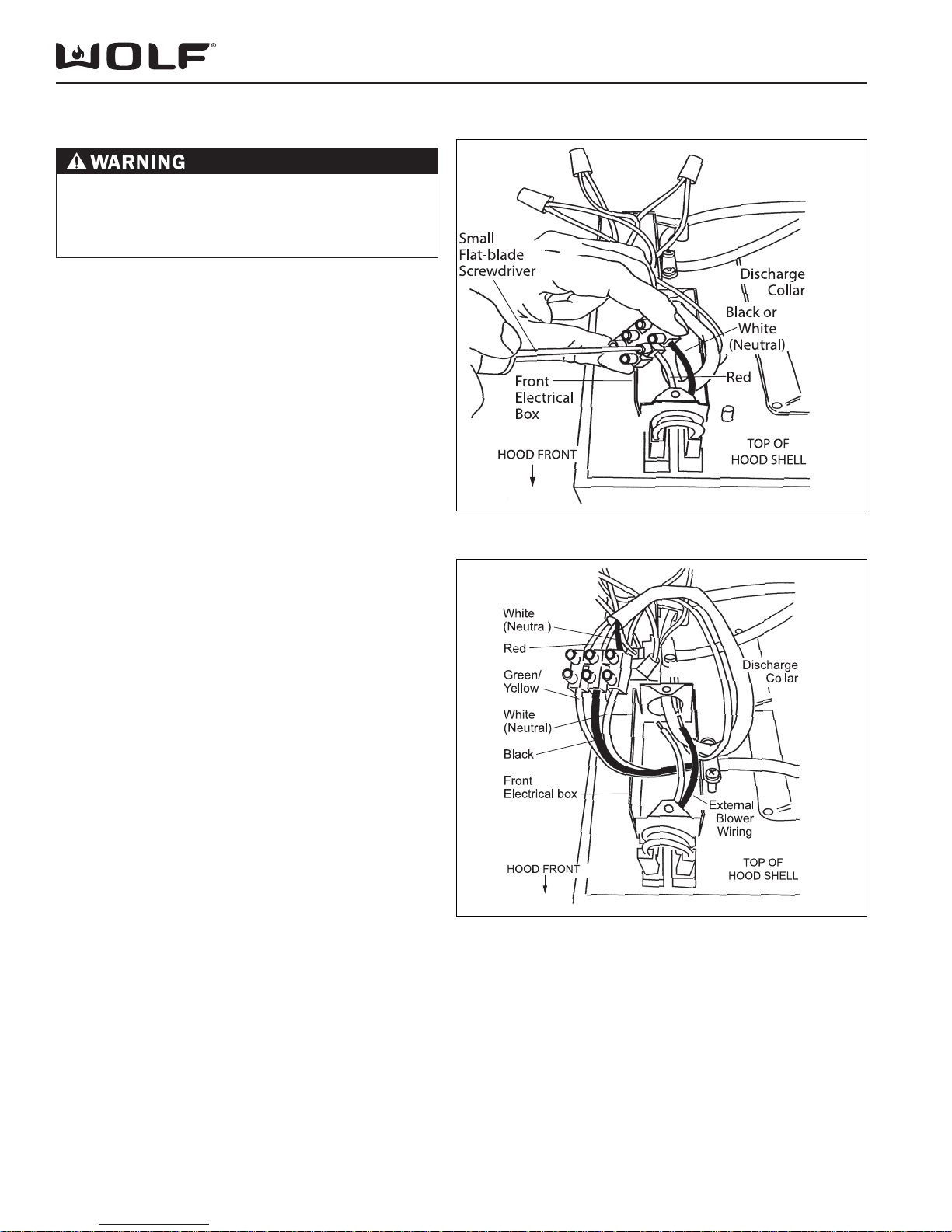

Remove the cover from the front of the electrical 1.

box. Remove the electrical box knockout that

faces the hood’s discharge collar.

Disconnect the red, black or white wires using a 2.

fl at-blade screwdriver. (See Figure 2-39)

Insert 6” (152) of the remote blower wiring through 3.

the knockout opening. Secure the cable to the

electrical box with an appropriate connector. Use

wire connectors or wire nuts approved by UL or C/

UL.

Attach the remote blower wiring where the wires 4.

were removed in step 2. (See Figure 2-40)

Re-install wiring box cover and screws. Make sure 5.

all wires are secure and that no wires are pinched

between cover and box.

NOTE: Before turning the power on to the ventilation

hood, make sure the blower is in the OFF position.

Installation InformationCT Hoods and DD Ventilation

Figure 2-39 Remote Blower Electrical Connections Prepare

Figure 2-40 Remote Blower Electrical Connections

2-20

Installation Information CT Hoods and DD Ventilation

DOWNDRAFT DIMENSIONS

TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK, THIS VENTILATION HOOD SHOULD ONLY BE

INSTALLED WITH BLOWERS MANUFACTURED BY WOLF APPLIANCE INC. AND SPECIFIED FOR USE WITH

THESE VENTILATION MODELS.

NOTE: Wolf downdraft ventilation systems are recommended for use with Wolf framed electric, gas, induction and

multi-function cooktops. They cannot be used with unframed electric cooktops and are not recommended for use with

the electric grill, steamer and fryer modules. A Pro ventilation hood must be used with Wolf dual fuel ranges, gas

ranges and rangetops.

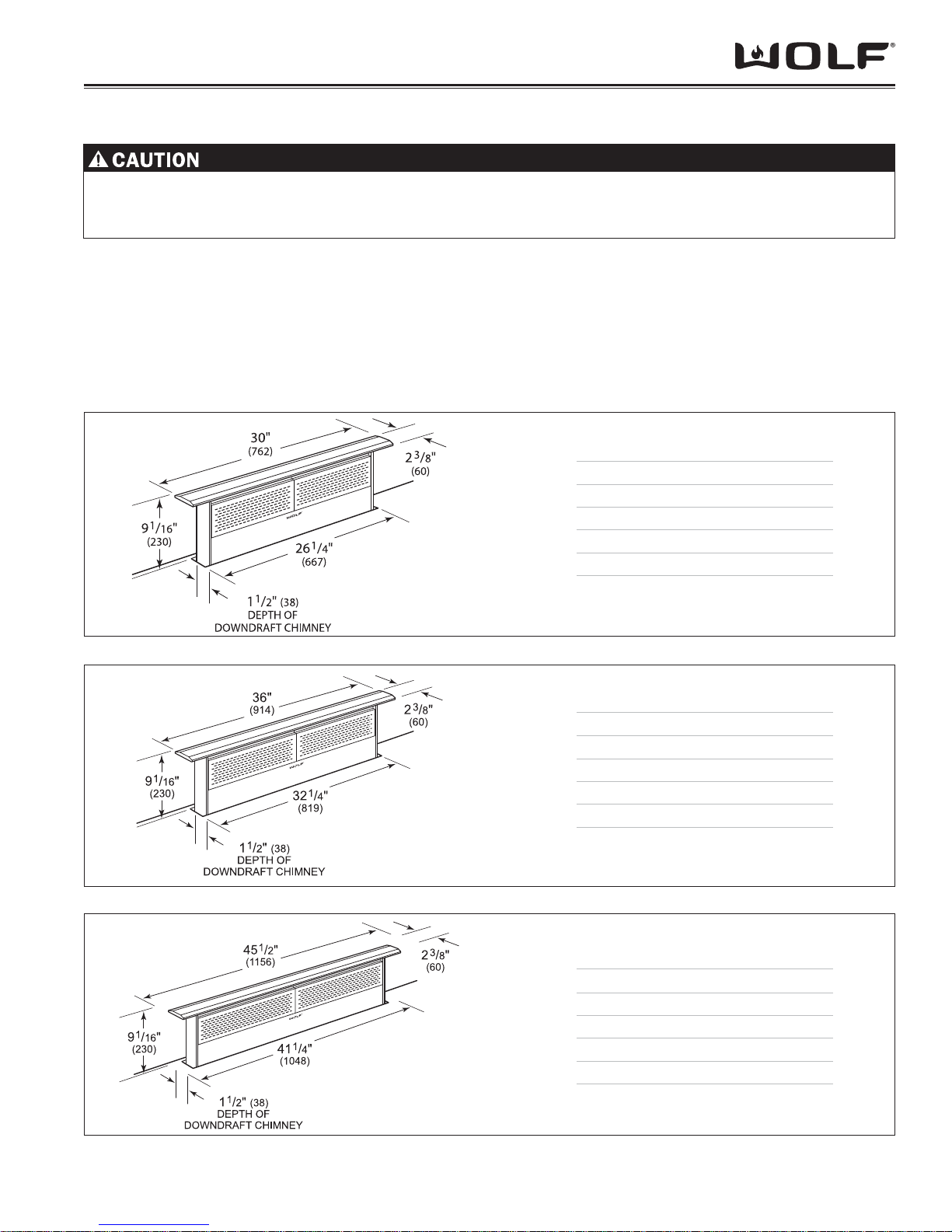

Wolf downdraft ventilation systems are available in 30” (762), 36” (914) and 45-1/2”(1156) widths. The downdraft

should be at least as wide as the cooktop. Models DD30I, DD36I and DD45I include a 500CFM internal blower. Models DD30R, DD36R and DD45R are shipped without a blower assembly.

MODELS DD30I AND DD30R

O )267("03htdiW llarev

Width of Chimney 261/4"(667)

Overall Height

Depth of Chimney 11/2"(38)

(above countertop)

91/16"(230)

3

2htpeD llarevO

/8"(60)

Dimensions may vary to

Figure 2-41 Models DD30I & DD30R

MODELS DD36I AND DD36R

Width of Chimney 321/4"(819)

Overall Height

Overall Depth 23/8"(60)

Depth of Chimney 11/2"(38)

Dimensions may vary to

Figure 2-42 Models DD36I & DD36R

MODELS DD45I AND DD45R

Overall Width 451/2" (1156)

Width of Chimney 411/4" (1048)

Overall Height

Overall Depth 23/8"(60)

Depth of Chimney 11/2"(38)

1

+

/8"(3).

–

(above counter top)

1

+

/8"(3).

–

(above countertop)

)419("63htdiW llarevO

91/16" (230)

91/16" (230)

Dimensions may vary to

Figure 2-43 Models DD45I & DD45R

2-21

1

+

–

/8"(3).

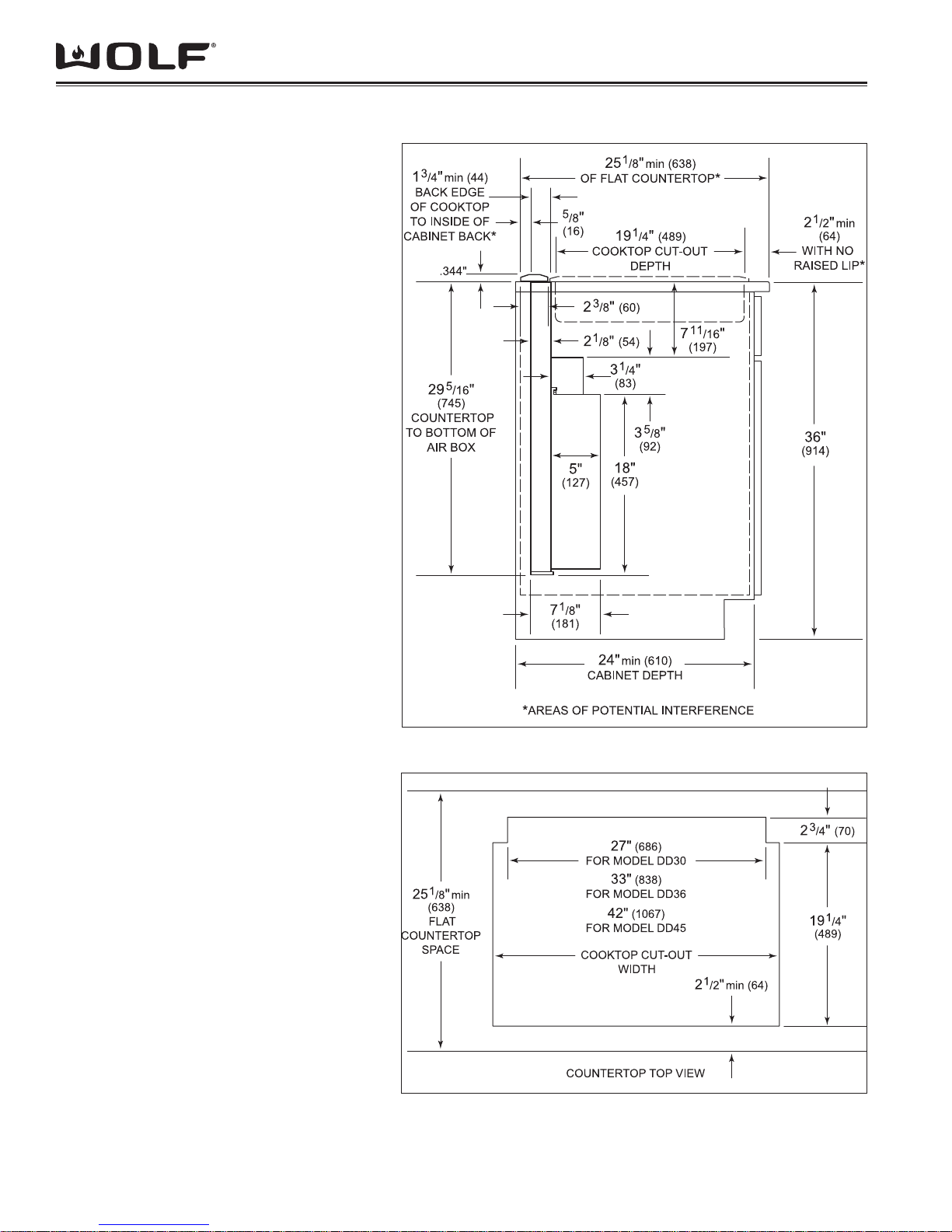

DOWNDRAFT INSTALLATION SPECIFICATIONS

INSTALLATION SPECIFICATIONS

Wolf downdraft Model DD30 will fi t most 30”

(762) wide cabinets, Model DD36 will fi t most

36” (914) wide cabinets and Model DD45 will

fi t most 45-1/2”(1156) wide cabinets. It is

recommended that oversized cabinets be used

for easier installation. Cabinet backs may need

to be removed. Wolf downdraft ventilation

systems can be mounted in an island, peninsula

or standard wall location.

NOTE: To install a downdraft system and a

Wolf cooktop, you must allow for a minimum

25-1/8”(638) fl at counter space from front

to back. A countertop with a raised lip or

backsplash may not allow enough space for

proper installation. 2-3/8”(60) of fl at countertop

is required behind the cooktop and 1-3/4”(44)

is necessary between the back edge of the

cooktop and inside of cabinet back.

If downdraft Model DD30 is installed in

combination with two cooktops or integrated

modules, an integrated module support

(available as a sales accessory) for downdraft

ventilation is required. Model DD45 does not

require this accessory. If optional fi ller strips are

used with the cooktops or modules, be aware

that they are different for the Model DD30 and

DD45. Be sure to use the correct fi ller strip.

For installation of a downdraft system with

a cooktop, refer to the cooktop installation

instructions for the dimensions of the cooktop,

countertop cut-out and cabinet requirements.

The depth of the cooktop may vary and will

affect the location of the downdraft in the

countertop. Figure 2-45 provides countertop

cut-out dimensions for downdraft Models DD30,

DD36 and DD45 installed with a Wolf 30”(762)

or 36” (914) cooktop or combination of cooktop

and/or modules.

Installation InformationCT Hoods and DD Ventilation

Figure 2-44 Side View Installation Dimensions

Figure 2-45 Top View Installation Dimensions

2-22

Loading...

Loading...