Wolf ICBCT15G/S, ICBCT15G/S-LP, ICBCT30G/S-LP, ICBCT36G/S, ICBCT36G/S-LP Installation Instructions Manual

...

GAS COOKTOPS

INSTALLATION INSTRUCTIONS

INSTRUCCIONES DE INSTALACIÓN

INSTRUCTIONS D’INSTALLATION

ISTRUZIONI PER L’INSTALLAZIONE

INSTALLATIONSANWEISUNGEN

N G L I S H 4

E

S P Ã N O L 1 8

E

F R A N Ç A I S 3 2

I TA L I AN O 4 6

D E U T S C H 6 0

3

C O N TA C T

I N F O R M A T IO N

Website:

wolfappliance.com

As you follow these instruc tions, you will

notice WARNING and CAUTION symbols. This

blocked information is impor tant for the safe

and efficient installation of Wolf equipment.

There are two types of potential hazards that

may occur during installation.

WOLF®is a registered trademark of Wolf Appliance, Inc.

signals a situation where minor injury or

product damage may occur if you do not

follow instructions.

states a hazard that may cause serious

injury or death if precautions are not

followed.

Another footnote we would like to identify is

IMPORTANT NOTE: This highlights information that is especially relevant to a problemfree installation.

W O L F GAS CO O KTO P S

IN S TA LL AT I ON R E Q U I R E M E N T S

WHAT TO DO IF YOU SMELL GAS:

This appliance shall be installed

in accordance with the regulations in force and only used in a

well ventilated space. Read the

instructions before installing or

using this appliance.

IMPORTANT NOTE:

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Do not store or use gasoline or

other flammable vapors and liquids

in the vicinity of this or any other

appliance.

The use of a gas cooking appliance

results in the production of heat and

moisture in the room in which it is

installed. Ensure that the kitchen is

well ventilated; keep natural ventilation holes open or install a mechanical ventilation device (mechanical

extractor hood)

Do not try to light any appliance.

Do not touch any electrical switch.

Do not use any phone in your

building.

Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

If you cannot reach your gas

supplier, call the fire department.

Prolonged intensive use of the appliance may for additional ventilation,

for example opening of a window, or

more effective ventilation, for

example increasing the level of

mechanical ventilation where

present.

5

W O L F GAS C OO K TOP S

AT I NG P LAT E

R

I N FO R M AT IO N

Model Number

Serial Number

IN S TA LL AT I ON R E Q U I R E M E N T S

IMPORTANT NOTE: This installation must

be completed by a qualified installer,

service agency or gas supplier.

IMPORTANT NOTE:

Save these Installation

Instructions for the local inspector’s use.

Please read the entire Installation Instructions prior to installation.

Installer:

please retain these instructions

for local inspector’s reference, then leave

them with the homeowner.

Homeowner:

please read and keep these

instructions for future reference and be sure

to read the entire Use & Care Information

prior to use.

IMPORTANT NOTE:

This appliance must be

installed in accordance with local codes. The

correct voltage, frequency and amperage must

be supplied to the appliance from a dedicated,

grounded circuit which is protected by a

properly sized circuit breaker or time delay

fuse. The proper voltage, frequency, and

amperage ratings are listed on the product

rating plate.

BE F OR E YO U S TA RT

Proper installation is your responsibility.

Have a qualified technician install this

cooktop. You must also assure that electrical installation is adequate and in compliance with all local codes and ordinances.

Prior to installation, ensure that the local

distribution conditions (nature of the gas

and gas pressure) and the adjustment of

the appliance are compatible.

Proper gas supply connection must be

available; refer to Gas Supply Requirements

on page 12. Electrical ground is required;

see Electrical Requirements on page 13.

The adjustment conditions for this appliance are stated on the label (or rating

plate). The data plate can be found on the

underside of the cooktop.

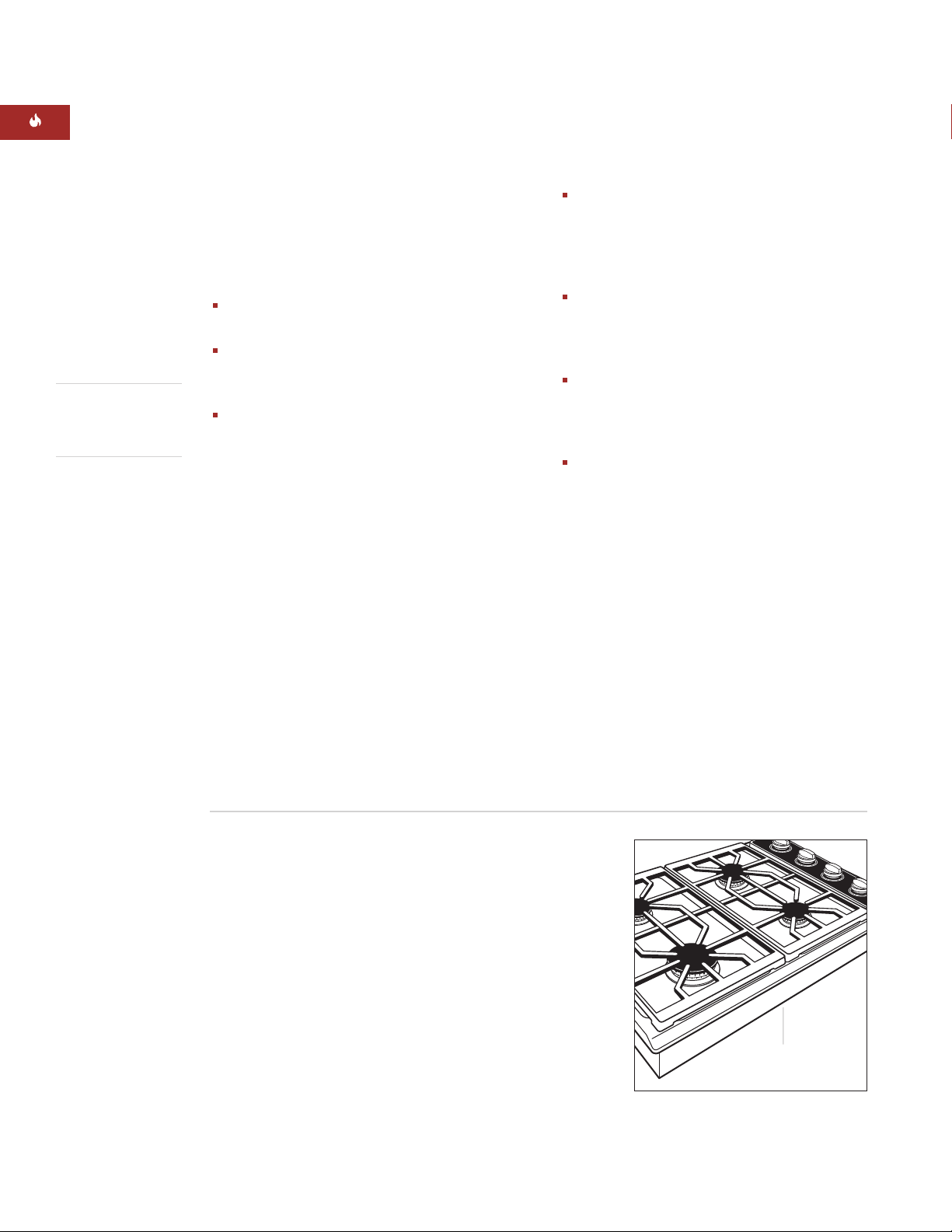

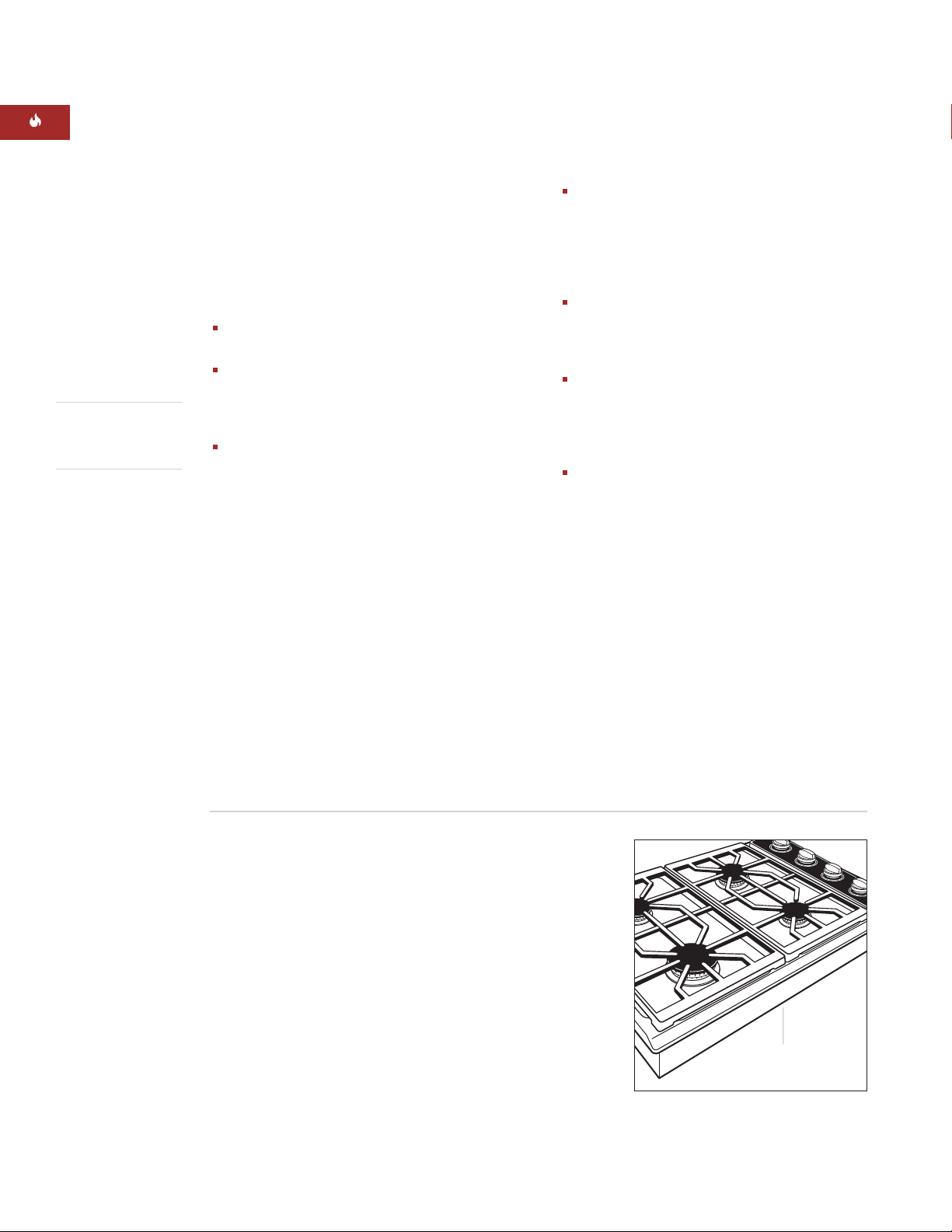

Record the model and serial numbers before

installing the cooktop. Both numbers are listed

on the rating plate, located on the underside of

the cooktop. Refer to the illustration below.

Location of rating

plate under cooktop

Rating plate location

6

IN S TA LL AT I ON I N S T R U C T I O N S

BE F OR E YO U S TA RT

Check the location where the cooktop will

be installed. The location should be away

from strong draft areas, such as windows,

doors and strong heating vents or fans. Do

not obstruct flow of combustion and

ventilation air.

This appliance is not connected to a

combustion products evacuation device. It

shall be installed and connected in accordance with current installation regulations.

Particular attention shall be given to the

relevant requirements regarding ventilation.

This cooktop is intended for indoor use.

SI T E P R EP A R AT I O N

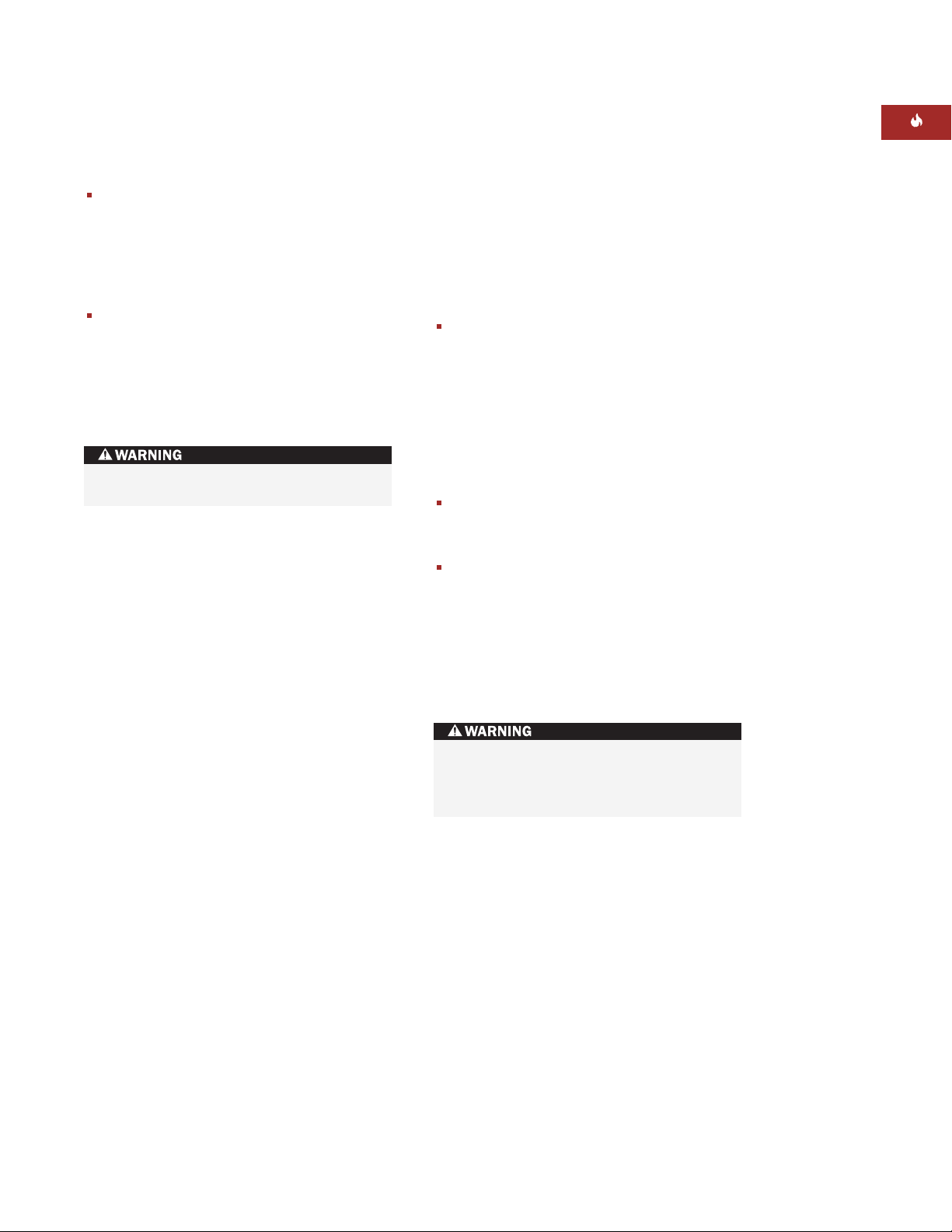

C O U N T E R T O P C U T- O UT D I M E N S I O N S

IMPORTANT NOTE:

Countertop opening

dimensions shown on the following pages

must be used. The dimensions shown provide

for required clearances.

These cooktops are designed to fit a standard

610 mm deep base cabinet with a 635 mm

deep countertop. Before making the countertop cut-out, verify that the cooktop will clear

the side walls of the base cabinet below. There

should be at least 140 mm clearance between

the countertop and any combustible surface

directly below the unit.

L O C AT I O N R EQ U I RE M E NT S

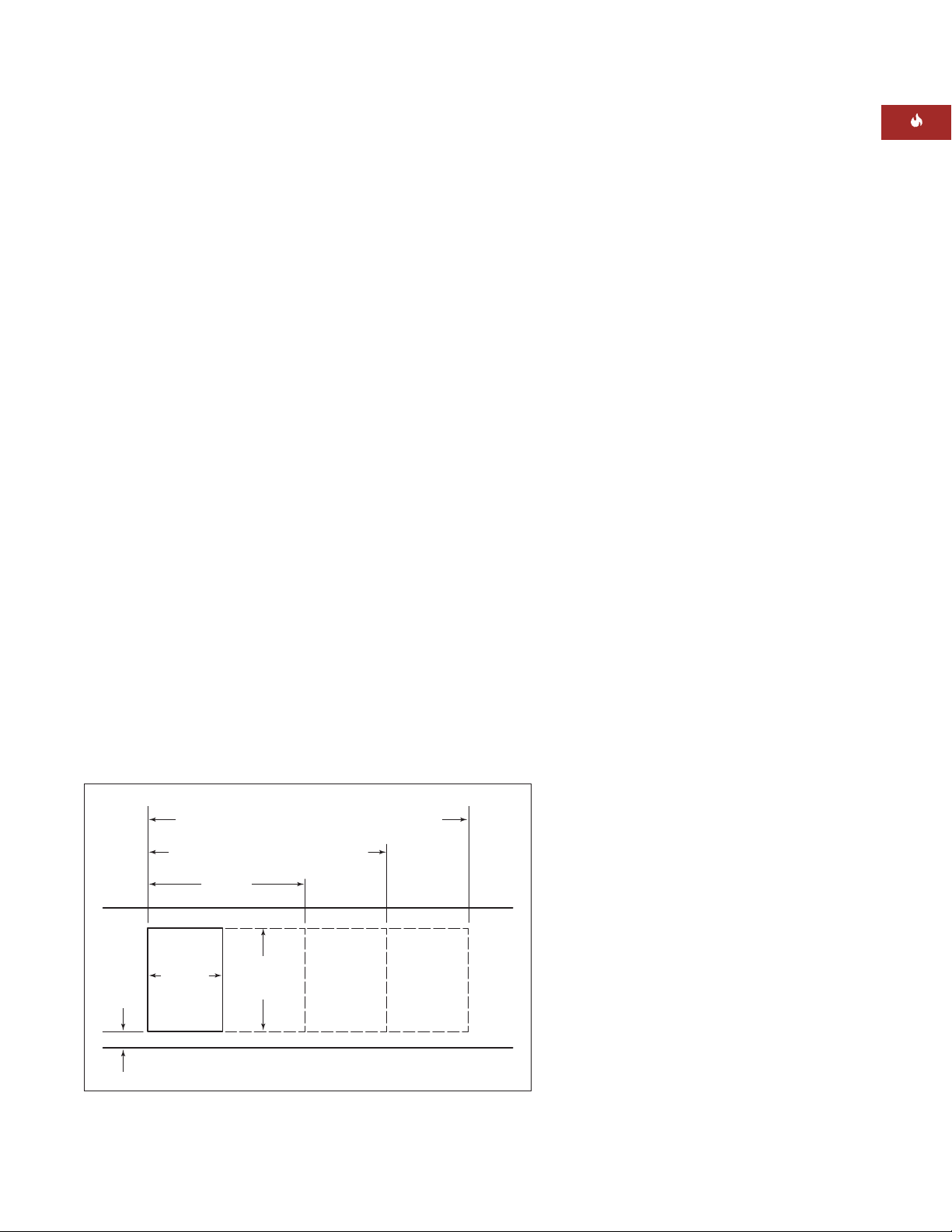

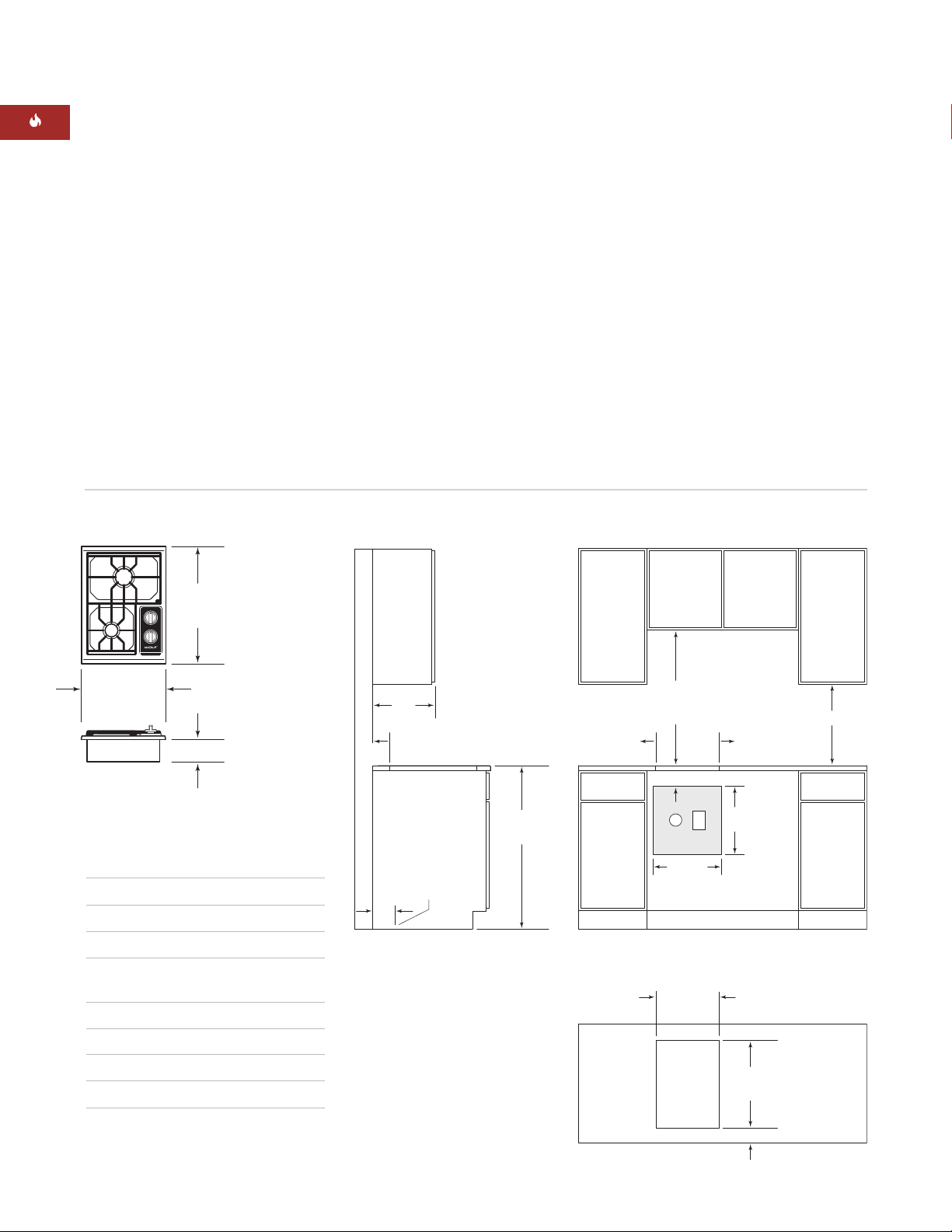

Illustrations on the following pages provide the

overall dimensions, countertop cut-out and

installation specifications for Wolf gas

cooktops. Maintain the following minimum

installation dimensions:

Minimum horizontal clearance from the

sides and back of the cooktop cut-out to

adjacent vertical combustible construction,

extending a minimum of 457 mm above the

countertop, is as follows: 178 mm from side

edges of cut-out for the 381 mm cooktop;

229 mm from side edges of cut-out for the

762 mm and 914 mm cooktops; 64 mm

from rear edge of cut-out.

Minimum vertical distance between the

countertop and combustible materials

above the cooktop must be 762 mm.

Maximum 330 mm depth of overhead side

cabinets directly above and within side

clearance.

IMPORTANT NOTE:

When installing a ventilation hood, refer to the specific requirements

of the hood for the minimum dimension to

countertop.

Failure to locate the cooktop without the

proper clearances will result in a fire

hazard.

IMPORTANT NOTE:

Do not seal the cooktop

to the countertop. It must be removed if

service is necessary.

7

914 mm

FLOOR TO

COUNTERTOP

762 mm min

COUNTERTOP

TO COMBUSTIBLE

MATERIALS

SEE COUNTERTOP

CUT-OUT BELOW

356 mm

CUT-OUT

WIDTH

COUNTERTOP CUT-OUT

FRONT

489 mm

CUT-OUT

DEPTH

64 mm min

178 mm TO

COMBUSTIBLE*

178 mm TO

COMBUSTIBLE*

SIDE

CABINET

330 mm

max

*Minimum clearance from cooktop cut-out to combustible materials up to 457 mm above countertop.

NOTE: Application shown allows for installation of two 381 mm modules side by side.

E

381 mm

381

mm

102 mm

457 mm min

127

mm

LOCATION OF GAS

AND ELECTRICAL

EXTENDS ON FLOOR

G

64

mm*

W O L F GAS C OO K TOP S

381 mm

OVER ALL WID TH

533 mm

OVERALL

DEPTH

102 mm

IN S TA LL AT I ON S P E C I F I C AT I O N S

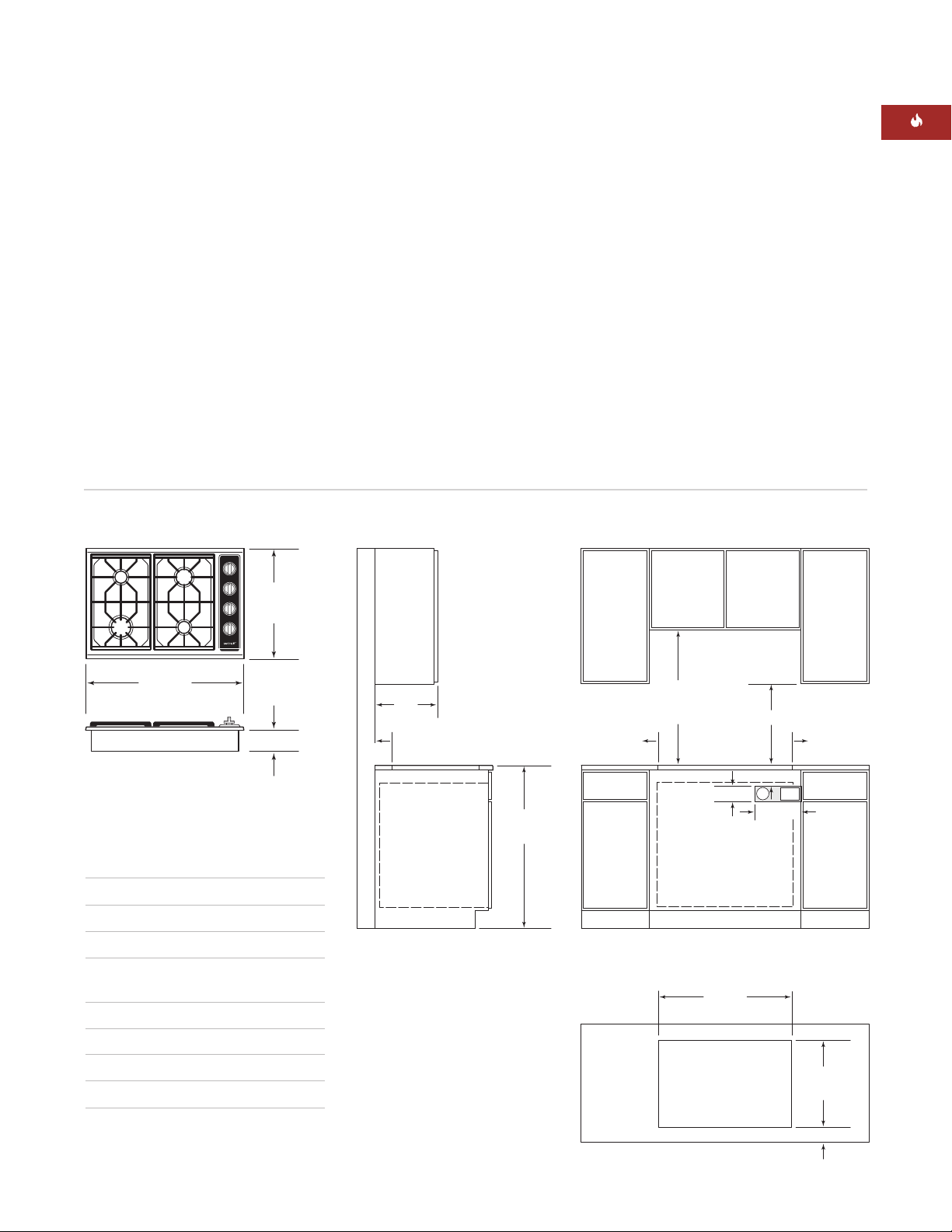

The illustrations below provide the overall

dimensions, countertop cut-out and installation

specifications for Model ICBCT15G.

For Model ICBCT15G, the gas service may be

supplied through the floor if the cooktop is not

installed above an oven. Refer to the illustration

for specifics on placement of gas and electrical.

I N S TA LL AT I O N SP E C IF I C AT I O N S – M O DE L I C BC T 1 5G

IMPORTANT NOTE:

When multiple cooktop

units are installed side by side, refer to the

countertop cut-out dimensions on page 11.

Overall Dimensions

M O D E L I CB C T 15 G

D I M E N S I O N S

Overall Width 381 mm

Overall Height 102 mm

Overall Depth 533 mm

Recommended

Cabinet Width 838 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance 102 mm

Cut-Out Width 356 mm

Cut-Out Depth 489 mm

Unit dimensions may vary to ±3 mm.

8

457 mm min

914 mm

FLOOR TO

COUNTERTOP

762 mm

min

C

OUNTERTOP

TO COMBUSTIBLE

MATERIALS

762 mm OVEN OPENING

102 mm

254 mm

89 mm

E

SEE COUNTERTOP

CUT-OUT BELOW

229 mm TO

COMBUSTIBLE*

229 mm TO

COMBUSTIBLE*

64

mm*

SIDE

CABINET

330 mm

m

ax

737 mm

CUT-OUT WIDTH

COUNTERTOP CUT-OUT

FRONT

489 mm

CUT-OUT

DEPTH

64 mm min

*Minimum clearance from cooktop cut-out to combustible materials up to 457 mm above countertop.

NOTE: Gas and electrical location applies only to installation with built-in oven.

G

IN S TA LL AT I ON I N S T R U C T I O N S

533 mm

FONDO

T

OTAL

762 mm

ANCHURA TOTAL

102 mm

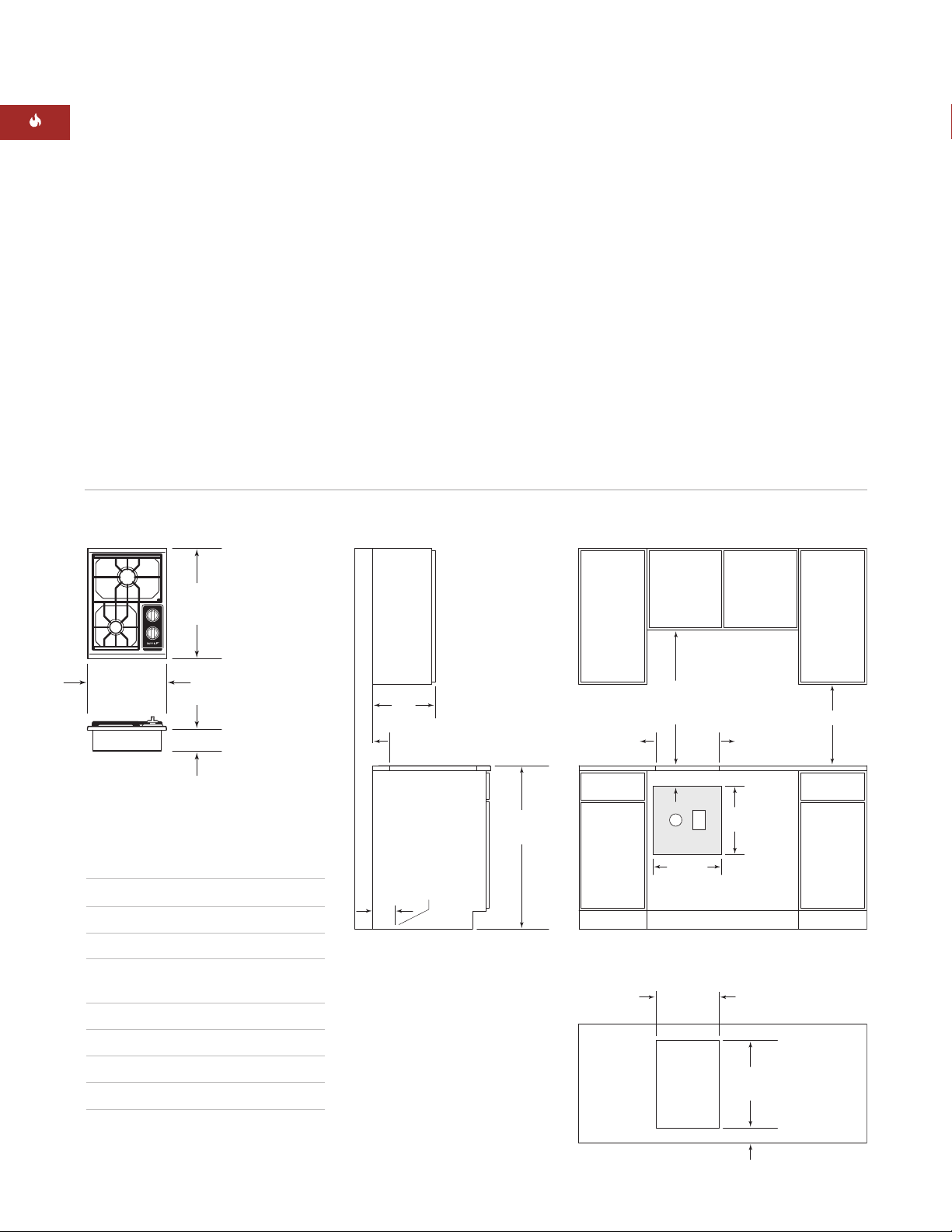

IN S TA LL AT I ON S P E C I F I C AT I O N S

The illustrations below provide the overall

dimensions, countertop cut-out and installation

specifications for Model ICBCT30G.

IMPORTANT NOTE:

838 mm wide cabinets are

recommended for installation of Model

ICBCT30G.

A Wolf 762 mm single built-in oven may be

If the Model ICBCT30G is installed above

cabinets, the gas and electrical placement is not

critical. A grounded outlet needs to be placed

within 1.2 m of the right rear of the cooktop.

IMPORTANT NOTE:

units are installed side by side, refer to the

countertop cut-out dimensions on page 11.

installed below Model ICBCT30G. For this

installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical and gas supply be placed in the

base cabinet to the right of the oven. Refer to

installation instructions provided with the builtin oven for additional specifications.

I N S TA LL AT I O N SP E C IF I C AT I O N S – M O DE L I C BC T 3 0G

When multiple cooktop

Overall Dimensions

M O D E L I CB C T 30 G

D I M E N S I O N S

Overall Width 762 mm

Overall Height 102 mm

Overall Depth 533 mm

Recommended

Cabinet Width 838 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance 102 mm

Cut-Out Width 737 mm

Cut-Out Depth 489 mm

Unit dimensions may vary to ±3 mm.

9

W O L F GAS C OO K TOP S

102 mm

E

G

457 mm min

914 mm

FLOOR TO

COUNTERTOP

762 mm min

COUNTERTOP

TO COMBUSTIBLE

MATERIALS

914 mm OVEN OPENING

254 mm

89 mm

SEE COUNTERTOP

CUT-OUT BELOW

889 mm

CUT-OUT WIDTH

COUNTERTOP CUT-OUT

FRONT

489 mm

CUT-OUT

DEPTH

64 mm min

229 mm TO

COMBUSTIBLE

*

229 mm TO

COMBUSTIBLE

*

SIDE

CABINET

330 mm

m

ax

*Minimum clearance from cooktop cut-out to combustible materials up to 457 mm above countertop.

NOTE: Gas and electrical location applies only to installation with built-in oven.

64

mm*

533 mm

OVERALL

DEPTH

914 mm

OVER ALL WID TH

102 mm

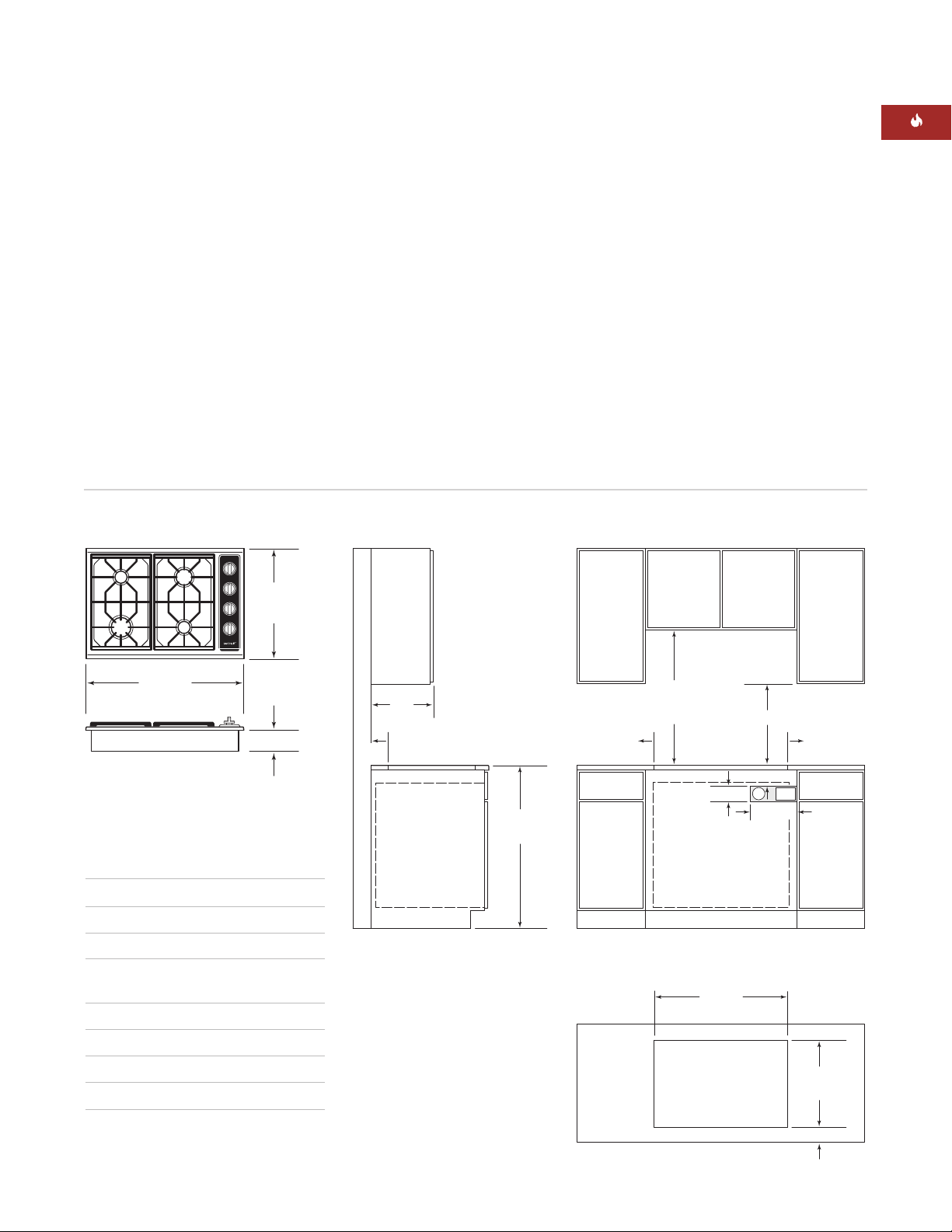

IN S TA LL AT I ON S P E C I F I C AT I O N S

The illustrations below provide the overall

dimensions, countertop cut-out and installation

specifications for Model ICBCT36G.

IMPORTANT NOTE:

991 mm wide cabinets are

recommended for installation of Model

ICBCT36G.

A Wolf 914 mm built-in oven may be installed

below Model ICBCT36G. For this installation,

unless you are using cabinets deeper than 610

mm, it is recommended that the electrical and

gas supply be placed in the base cabinet to the

right of the oven. Refer to installation instructions provided with the built-in oven for additional specifications.

I N S TA LL AT I O N SP E C IF I C AT I O N S – M O DE L I C BC T 3 6G

If the Model ICBCT36G is installed above

cabinets, the gas and electrical placement is not

critical. A grounded outlet needs to be placed

within 1.2 m of the right rear of the cooktop.

When a 914 mm built-in oven is installed below

Model ICBCT36G, it is recommended that the

rough opening for the oven be 197 mm from

the floor to ease the use of the oven door.

IMPORTANT NOTE:

When multiple cooktop

units are installed side by side, refer to the

countertop cut-out dimensions on page 11.

Overall Dimensions

M O D E L I CB C T 36 G

D I M E N S I O N S

Overall Width 914 mm

Overall Height 102 mm

Overall Depth 533 mm

Recommended

Cabinet Width 991 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance 102 mm

Cut-Out Width 889 mm

Cut-Out Depth 489 mm

Unit dimensions may vary to ±3 mm.

10

IN S TA LL AT I ON I N S T R U C T I O N S

64 mm

min

FRONT OF COUNTERTOP

489 mm

CUT-OUT

DEPTH

743 mm

TWO MODULES WIDTH

1130 mm – THREE MODULES WIDTH OR

1124 mm – 762 mm COOKTOP AND ONE MODULE

1518 mm – FOUR MODULES WIDTH OR

1511 mm – 762 mm COOKTOP AND TWO MODULES OR

1276 mm – 914 mm COOKTOP AND ONE MODULE

356 mm

CUT-OUT

WIDTH

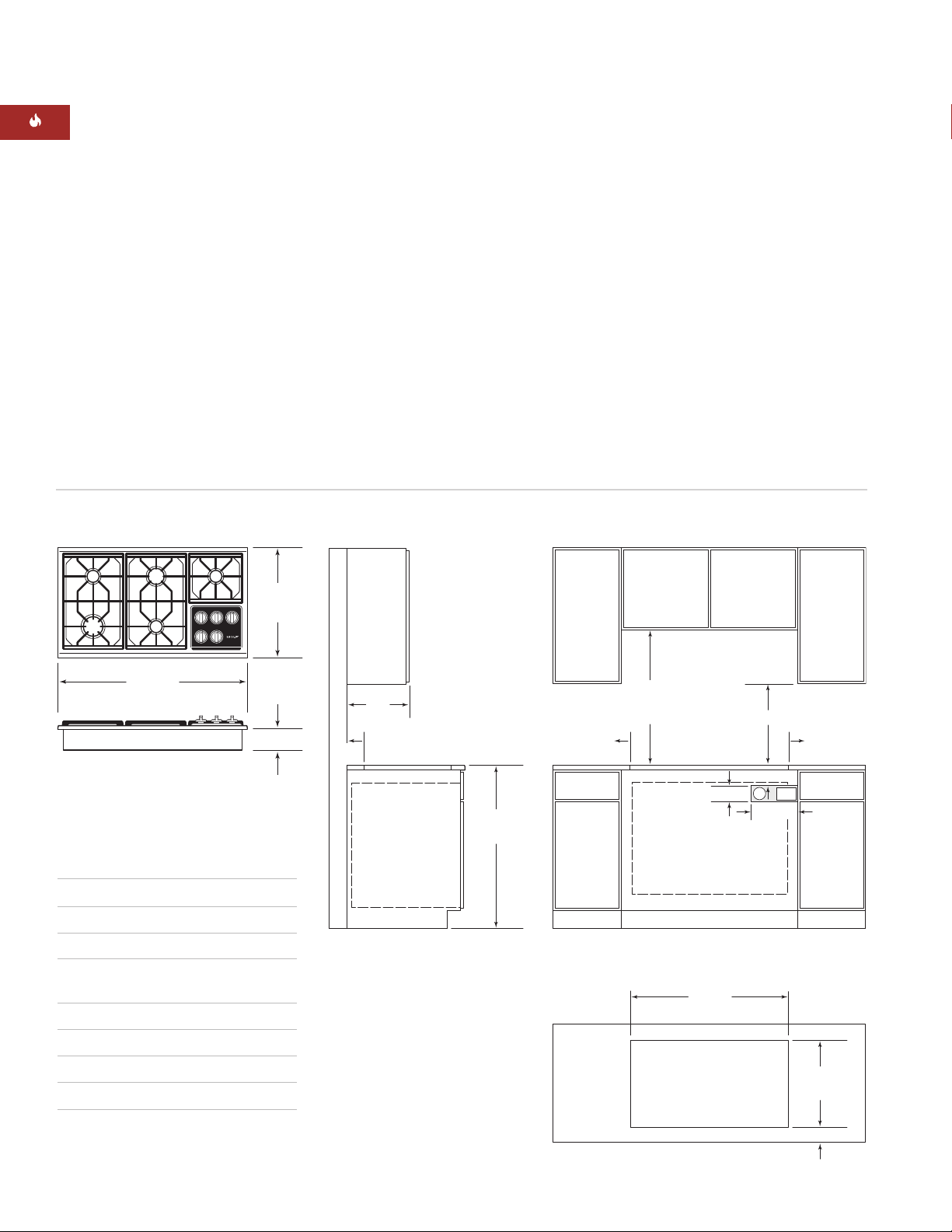

IN S TA LL AT I ON O P T I O N S

M U LT I P LE C O O K TO P I N S TA LL AT I O N

If the gas cooktop is to be used with any

combination of additional cooktop units or

modules with a filler strip, the cut-out width is

calculated by adding the corresponding units'

cut-out dimensions plus 32 mm for each additional unit. Refer to the illustration below.

P T I O N A L

O

I N S TA LL AT I O N S

IMPORTANT NOTE:

When multiple units are

installed side by side, each unit must have its

own separate recommended electrical circuit.

When two or more modules are installed

together, an integrated module filler strip

(IFILLER/S) is recommended. Contact your

Wolf dealer for information on these accessory

components.

Dimensions will

vary according to

the specific installation.

Countertop cut-out dimensions for installation of multiple cooktops

11

M P O RTA N T

I

N O T E

This installation

must conform with

local codes and

ordinances.

W O L F GAS C OO K TOP S

GA S S U PP LY R E Q U I R E M E NT S

EXPLOSION HAZARD—

Securely tighten all external gas

connections.

Failure to do so can result in explosion,

fire or death.

IMPORTANT NOTE:

The gas cooktop must be

connected to a regulated gas supply.

IMPORTANT NOTE:

This installation must

conform with local codes and ordinances.

IMPORTANT NOTE:

The natural gas cooktop

is rated for elevations up to 2438 m without

adjustment. Install a high altitude kit for elevations from 2438 to 3084 m. The LP gas cooktop

is rated for 3084 m.

The rating plate, located on the underside of

the burner box, has information on the type of

gas that should be used. If this information

does not agree with the type of gas available,

check with the local gas supplier.

Provide a gas supply line of 19 mm rigid pipe

to the cooktop location. A smaller size pipe on

long runs may result in insufficient gas supply.

Pipe joint compounds, suitable for use with LP

gas should be used. For LP gas, piping or

tubing size can be 13 mm minimum. LP gas

suppliers usually determine the size and materials used on the system.

If local codes permit, a flexible metal appliance

connector is recommended for connecting this

cooktop to the gas supply line. Do not kink or

damage the flexible connector when moving

the cooktop. You will need to determine the

fittings required, depending on the size of your

gas supply line, flexible metal connector and

shut-off valve.

If rigid pipe is used as a gas supply line, a

combination of pipe fittings must be used to

obtain an in-line connection to the cooktop. All

strains must be removed from the supply and

gas lines so the cooktop will be level and in

line.

12

GA S R AT I N G

Total Heat Electrical Types and

Output Gas Rating Appliance Pressures

Model # (Gas) Units (Watts) Category (mbar) Country of Destination

I2H G20 at 20

ICBCT15G/S 6.8 kW 230

ICBCT15G/S-LP 494 g/h 230 I3P G31 at 37

ICBCT30G/S 14.7 kW 230

ICBCT30G/S-LP 1069 g/h 230 I3P G31 at 37

ICBCT36G/S 17.7 kW 230

ICBCT36G/S-LP 1287 g/h 230 I3P G31 at 37

I2E G20 at 20 DE, PL

I2E+ G20 at 20/25 BE, FR

I2H G20 at 20

I2E G20 at 20 DE, PL

I2E+ G20 at 20/25 BE, FR

I2H G20 at 20

I2E G20 at 20 DE, PL

I2E+ G20 at 20/25 BE, FR

AT, DK, EE, FI, GR, IE, IT, LT,

NO, PT, ES, SE, SI, SK, GB, CH

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

AT, DK, EE, FI, GR, IE, IT, LT,

NO, PT, ES, SE, SI, SK, GB, CH

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

AT, DK, EE, FI, GR, IE, IT, LT,

NO, PT, ES, SE, SI, SK, GB, CH

BE, CZ, FR, GR, IE, NL, NO, PT,

ES, GB, CH

IN S TA LL AT I ON I N S T R U C T I O N S

EL E CT R I C AL RE Q U IR E M E N T S

ELECTRICAL SHOCK HAZARD—

Plug into a grounded 3-prong adapter.

Do not remove ground prong.

o not use an adapter.

D

Failure to follow these instructions can

result in electric shock, fire or death.

IMPORTANT NOTE:

If codes permit and a

separate ground wire is used, it is recommended that a qualified electrician determine

that the ground path is adequate.

IMPORTANT NOTE:

Check with a qualified

electrician if you are not sure whether the

cooktop is properly grounded.

IMPORTANT NOTE:

Do not ground to a gas

pipe.

A 220-240 VAC, 50/60 Hz, fused electrical

supply is required. A time-delay fuse or circuit

breaker is recommended. It is recommended

that a separate circuit serving only this appliance be provided.

Electronic ignition systems operate within

wide voltage limits, but proper ground and

polarity are necessary. In addition to checking

that the outlet provides 220-240 VAC power

and is correctly grounded, the outlet must be

checked by a qualified electrician to see if it is

wired with correct polarity. A wiring diagram is

provided in the literature package.

IMPORTANT NOTE:

Connection of this appliance should be through a fused connection

unit or a suitable isolator, which complies with

national and local safety regulations. The

on/off switch should be easily accessible after

the appliance has been installed. If the switch

is not accessible after installation (depending

on country) an additional means of disconnection must be provided for all poles of the

power supply. When switched off there must

be an all pole contact gap of 3 mm in the

isolator switch. This 3 mm contact disconnect

gap must apply to any isolator switch, fuses

and/or relays according to EN60335.

R E C O M M E N D E D GR O U N D M ET H O D

IMPORTANT NOTE:

For your personal safety,

this cooktop must be grounded. This cooktop

is equipped with a 3-prong ground plug. To

minimize possible shock hazard, a 85C

minimum rated cord must be plugged into a

mating 3-prong ground-type outlet, grounded

in conformance with all local codes and ordinances. If a mating outlet is not available, it is

the obligation of the customer to have a

properly grounded, 3-prong outlet installed by

a qualified electrician.

IMPORTANT NOTE:

If product is connected to

a GFCI protected outlet, nuisance tripping of

power supply may occur, resulting in loss of

product operation.

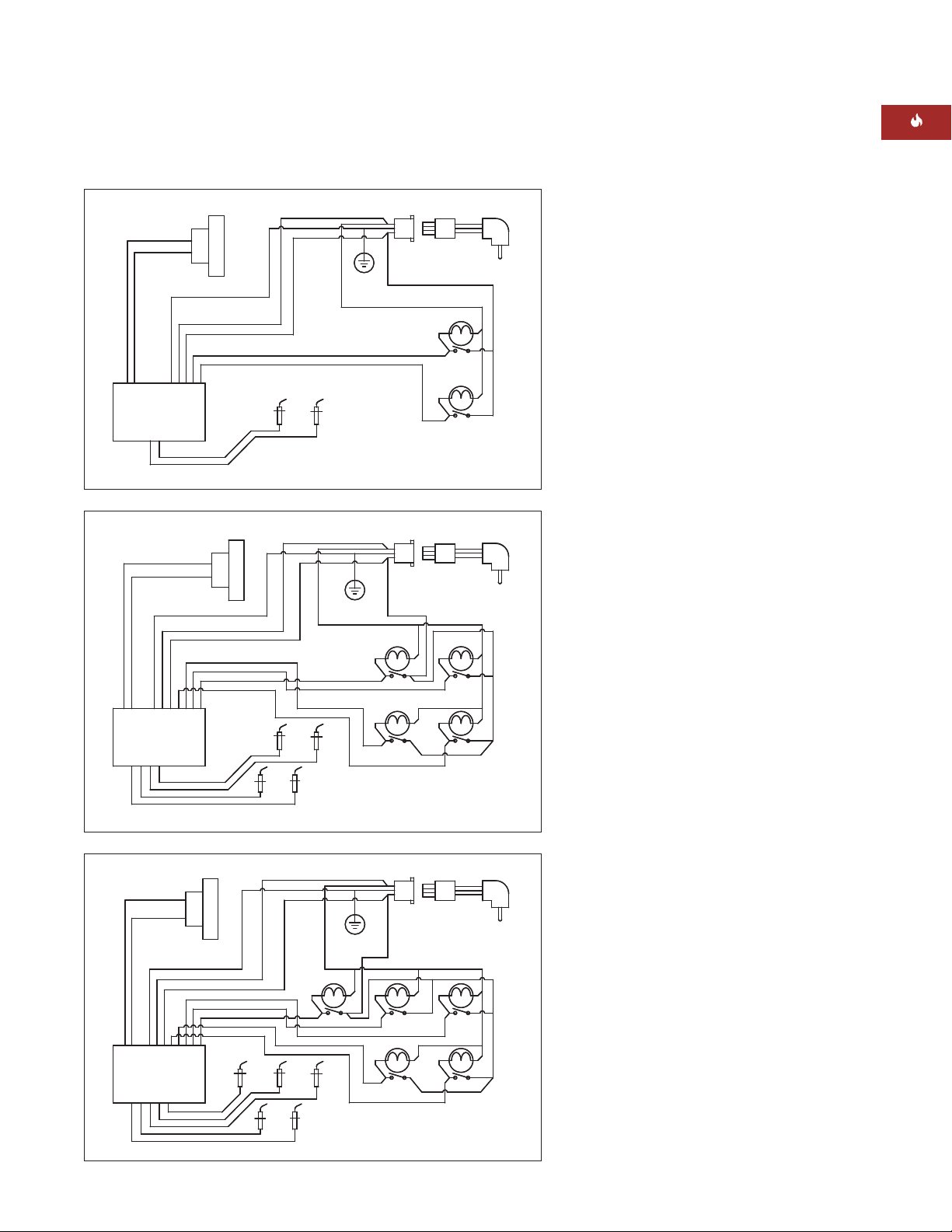

W I R I N G D IA GR A M

This appliance, when installed, must be electrically grounded in accordance with local codes.

A wiring diagram covering the control circuit

for each Wolf gas cooktop model can be found

on page 17.

13

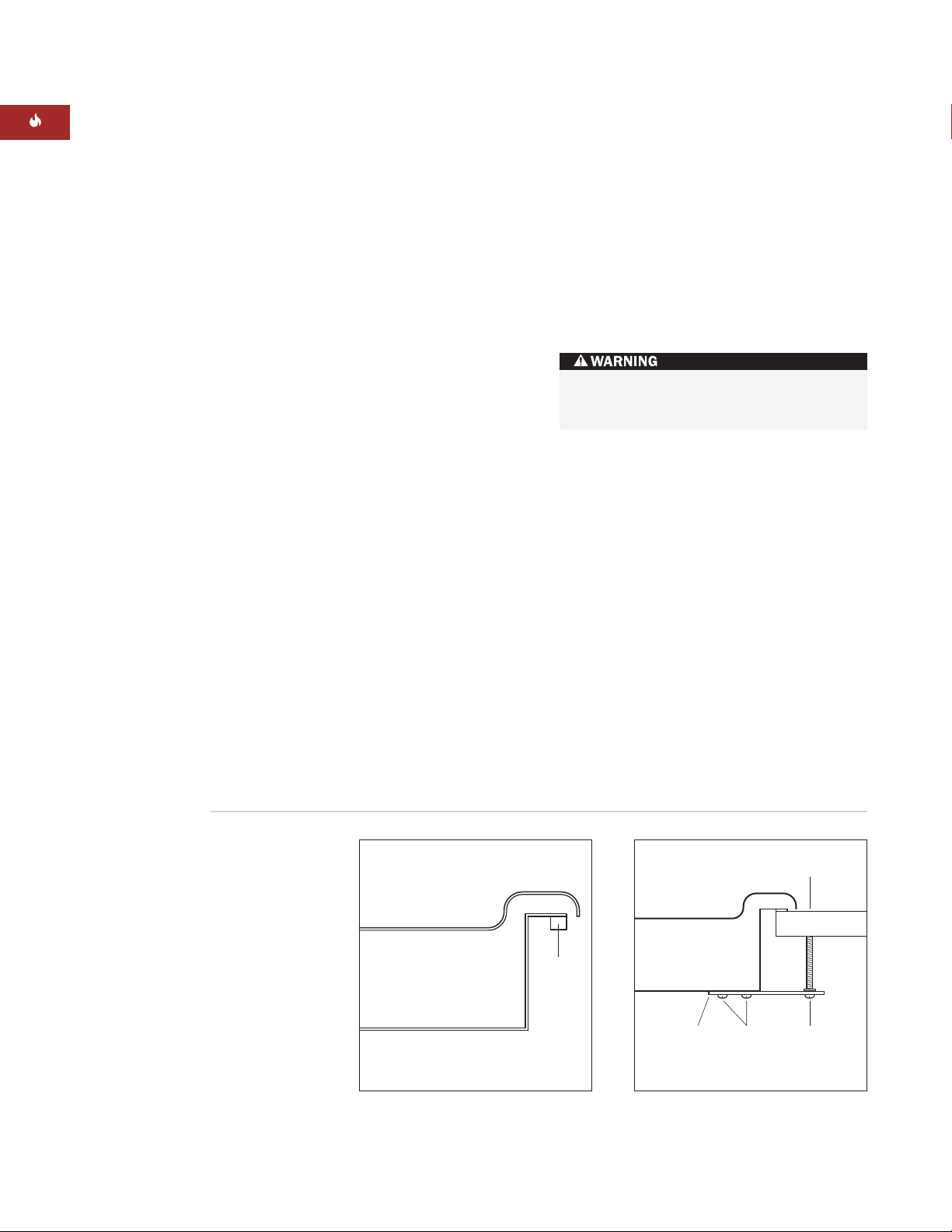

Cooktop

Burner Box

Foam

Strip

W O L F GAS C OO K TOP S

89 mm

Clamping

Screw

Burner Box

Countertop

Bracket

Screws

Bracket

C O O K T O P IN S TA L LATI O N

Remove the cooktop, burner grates and burner

caps from the shipping package.

Lower the cooktop into the countertop cut-out

opening. Center the cooktop in the opening

and check that the front edge of cooktop is

parallel to the front edge of the countertop.

Check that all required clearances are met. Use

a pencil to outline the rear edge of the cooktop

on the countertop. Remove the cooktop from

the countertop opening.

IMPORTANT NOTE:

When repositioning the

cooktop in the countertop cut-out opening, lift

the entire cooktop up from the opening to

prevent scratching the countertop.

Remove the foam strip from the hardware

package. Apply the foam strip around the

bottom of the burner box flush with the edge

as shown in the illustration below.

Reinsert the cooktop into the countertop

opening. Check that the cooktop is parallel to

the front edge of the countertop. Lift the entire

cooktop to make adjustments and align the

rear edge with the pencil line.

G A S L E A K T E S TI N G

Use a brush and liquid detergent to test all gas

connections for leaks. Bubbles around connections will indicate a leak. If a leak appears, shut

off gas valve controls and adjust connections.

Then check connections again. Clean all the

detergent solution from the cooktop.

Never test for a gas leak with a match or

other flame.

Attach the brackets to the burner box. Insert

the 89 mm clamping screws into the brackets.

Use a screwdriver to tighten the clamping

screws against the underside of the countertop. Refer to the illustration below. Do not

overtighten screws.

Foam strip application

Bracket installation

14

IN S TA LL AT I ON I N S T R U C T I O N S

SU R FAC E B U RN E R S

I N I T I A L LI G H TI N G

The surface burners use electronic igniters in

place of standing pilots. When the cooktop

control knob is pushed in and turned to the

position, the system creates a spark to

light the burner. This sparking continues until

the electronic ignition senses a flame. If the

burner fails to ignite after 10 seconds, return

the knob to the position and attempt to

ignite by turning the knob back to the

position.

Be sure to place the burner heads and caps on

each burner base and position the burner

grates over the burner bases and heads before

lighting.

To check operation of the surface burners,

push in and turn each control knob to the

position. The flame should light within four

seconds.

If the burners do not light properly, turn

control knob to the position. Check that

the burner heads and caps are in the proper

position. Check that the power supply cord is

plugged in and that the circuit breaker or

house fuse has not blown. Check operation

again, if the burners do not light properly at

this point, contact a Wolf authorized service

center.

IMPORTANT NOTE:

Initial lighting of the

surface burners may take slightly longer, as air

in the system must be purged before gas can

be supplied to the burner.

CO O KTO P R E MO VA L

If it is necessary to remove the cooktop for

cleaning or service, shut off the gas supply.

Disconnect the gas and electric supply.

Remove the mounting brackets on the right

and left side of the burner box and remove the

cooktop. Reinstall in the reverse order and

check the gas connection for leaks.

TR O U BL ES H O OT I N G

IMPORTANT NOTE:

If the cooktop does not

operate properly, follow these troubleshooting

steps:

Verify that power is being supplied to the

cooktop.

Check that gas valves are turned to the ON

position.

Check the gas supply and electrical

connections to ensure that the installation

has been completed correctly.

Follow troubleshooting procedures as

described in the Wolf Gas Cooktops

Use & Care Information.

If the cooktop still does not work, contact

a Wolf authorized service center. Do not

attempt to repair the cooktop yourself. Wolf

is not responsible for service required to

correct a faulty installation.

15

W O L F GAS C OO K TOP S

I F Y O U N EE D SE RVI C E

For service in your area, contact either your

Wolf dealer or visit the Showroom Locator

section of our website, wolfappliance.com

to find the regional distributor by country.

C O N TA C T

I N F O R M A T IO N

Website:

wolfappliance.com

When calling for service, you will need the

cooktop model and serial numbers. Both

numbers are listed on the rating plate,

located on the underside of the cooktop.

Refer to the illustration on page 6 for

location of the rating plate.

16

The information and images in this book are the

copyright property of Wolf Appliance, Inc., an affiliate of Sub-Zero, Inc. Neither this book nor any

information or images contained herein may be

copied or used in whole or in part without the

express written permission of Wolf Appliance,

Inc.,an affiliate of Sub-Zero, Inc.

©Wolf Appliance, Inc. all rights reserved.

IN S TA LL AT I ON I N S T R U C T I O N S

P

OWER CORD

FRONT

R

IV

GAS VALVE

RED

RED

B

LACK

WHITE

G

RN/YEL

B

LACK

REAR

BLACK

BLACK

WHITE

WHITE

POWER CORD

WHITE

RIGHT

FRONT

BLACK

RIV

GAS VALVE

RED

RED

RED

RED

WHITE

GRN/YEL

B

LACK

RIGHT

REAR

LEFT

REAR

LEFT FRONT

B

LACK

WHITE

WHITE

BLACK

LEFT FRONT

POWER CORD

RED

RIV

GAS VALVE

WHITE

BLACK

RIGHT

REAR

LEFT REAR

RIGHT

FRONT

CTR REAR

GRN/YEL

BLACK

RED

RED

RED

BLACK

WHITE

WI R IN G D I AG RA M S

Model ICBCT15G

Model ICBCT30G

Model ICBCT36G

17

PRECAUCIÓN

I NF O R M A C I Ó N

D E C O NTA C TO

ágina Web:

P

www.sub-

ero.eu.com

z

Cuando consulte las instrucciones que aparecen en

esta guía, encontrará símbolos de ADVERTENCIA y

PRECAUCIÓN. Esta información en recuadros es

importante para instalar el equipo de Wolf de forma

segura y eficaz. Existen dos tipos de posibles riesgos

que pueden producirse durante una instalación.

WOLF®es una marca comercial registrada de Wolf Appliance, Inc.

indica una situación en la que se pueden sufrir

heridas leves o provocar daños secundarios al

producto si no se siguen las instrucciones.

indica peligro de que se produzcan heridas

personales graves o incluso puede provocar

la muerte si no se siguen las precauciones

especificadas.

Otro tipo de anotación que es importante resaltar es

la que se incluye en NOTA IMPORTANTE: En esta

nota se resalta la información que resulta especialmente importante para que la instalación se realice

sin problemas.

PL ACA S DE G A S DE W O LF

R EQ U I S I TO S DE IN STA LA C IÓ N

QUÉ SE DEBE HACER SI HUELE A GAS:

Este aparato debe instalarse de

acuerdo con las normativas vigentes

y sólo puede ser utilizado en un

lugar que esté bien ventilado. Lea las

instrucciones antes de instalar o

utilizar este aparato.

NOTA IMPORTANTE:

La instalación y el mantenimiento

deben ser realizados por un insta-lador

cualificado, por un centro de asistencia

técnica o por el proveedor de gas.

No almacene ni utilice gasolina ni otros

vapores ni líquidos infla-mables cerca

de éste o de otros aparatos.

La utilización de un aparato de cocción

de gas produce calor y vaho en la

habitación en la que está instalado.

Asegúrese que la cocina está bien ventilada; mantenga despejados los agujeros

de ventilación natural o instale un

dispositivo de ventilación mecánico

(campana extractora mecánica).

No encienda ningún aparato.

No toque ningún interruptor eléctrico.

No utilice ningún teléfono dentro

del edificio.

Llame inmediatamente a su proveedor

de gas desde el teléfono de un vecino.

Siga las instrucciones que le proporcione el proveedor de gas.

Si no le es posible ponerse en

contacto con el proveedor de gas,

llame a los bomberos.

Si utiliza mucho el aparato y lo hace de

manera prolongada, es posible que

necesite ventilación adicional, por

ejemplo, puede abrir una ventana, o si

quiere que la ventilación sea más eficaz,

aumente el nivel de la ventilación

mecánica, si dispone de ella.

19

PL ACA S DE G A S DE W O LF

I N FO RM AC I Ó N

D E L A P L A C A

D E DAT O S

Referencia del

odelo

m

úmero de serie

N

R EQ U I S I TO S DE IN STA LA C IÓ N

NOTA IMPORTANTE: Esta instalación debe ser

realizada por un instalador cualificado, por un

centro de asistencia técnica o por el proveedor

de gas.

NOTA IMPORTANTE:

Guarde estas instrucciones

de instalación para que el inspector local pueda

utilizarlas.

Lea las instrucciones de instalación antes de

llevar a cabo la instalación.

Instalador:

guarde estas instrucciones para que

el inspector local pueda utilizarlas como referencia y, a continuación, entréguelas el propietario

del aparato.

Propietario:

lea y guarde estas instrucciones

para que pueda utilizarlas como referencia en el

futuro y asegúrese de leer la guía de uso y

manteni-miento antes de utilizar el aparato.

NOTA IMPORTANTE:

Este aparato debe instalarse

siguiendo las normativas nacionales correspondientes. Se debe aplicar al aparato el voltaje, la

frecuencia y el amperaje adecuados desde una instalación eléctrica resistente con toma de tierra protegida por un fusible de retardo. El voltaje, la frecuencia y el amperaje se muestran en la placa de datos

del producto.

Apunte la referencia del modelo y el número de

serie antes de instalar el aparato. Esta información

se muestra en la placa de datos del producto situada

en la parte inferior de la placa. Observe la siguiente

ilustración.

AN TE S DE C OM E N Z A R

Es responsabilidad del propietario asegurarse de

que la instalación se realiza de manera correcta.

Esta placa debe ser instalada por un técnico cualificado. Debe asegurarse de que la instalación

eléctrica es la correcta y que cumple todos los

códigos y normativas nacionales.

Antes de llevar a cabo la instalación, asegúrese

de que las condiciones de distribución locales

(tipo y presión del gas) y el ajuste del aparato

son compatibles.

Debe disponer de una entrada de suministro de

gas; consulte la sección Requisitos del suministro

de gas en la página 26. También debe disponer de

una conexión eléctrica a tierra; consulte la sección

Requisitos eléctricos en la página 27.

Las condiciones de ajuste de este aparato se

especifican en la etiqueta (o en la placa de datos

del producto). La placa de datos está ubicada en

la parte inferior del aparato.

20

Ubicación de la placa

de datos debajo

de la placa

Ubicación de la placa de datos

I NS T R U C C I ON E S DE IN STA LA C IÓ N

AN TE S DE C OM E N Z A R

Inspeccione el lugar en el que va a instalar la

placa. El lugar en el que va a instalarla debe estar

alejado de áreas en las que pueda haber corrientes fuertes, por ejemplo, ventanas, puertas

y salidas de aire caliente o ventiladores. No

debe obstruir el flujo de combustión ni el aire

de ventilación.

Este aparato no está conectado a ningún dispositivo de evacuación de productos de combustión.

El aparato debe ser instalado y conectado siguiendo las normativas de instalación vigentes.

Debe prestar especial atención a los requisitos

relevantes correspondientes a la ventilación.

Esta placa está diseñada para que se utilice en

spacios interiores.

e

P RE PA R A C I ÓN D EL SI TI O

D IM E N S I ON E S DE C ORT E D E

L A E N CI M E R A

NOTA IMPORTANTE:

Se deben utilizar las medidas

de las cavidades de la encimera que se muestran en

la página siguiente. Las medidas que se especifican

mantienen los espacios requeridos.

Esta placa está diseñada para que se adapte a un

armario de base estándar de 610 mm de fondo con

una encimera de 635 mm de fondo. Antes de cortar

la encimera, compruebe que la placa va a quedar

separada de las paredes laterales del armario

inferior. Deberá dejar al menos una distancia de

140 mm entre la encimera y cualquier superficie

combustible que esté justo debajo de la unidad.

NOTA IMPORTANTE:

No selle la placa a la

encimera. Es posible que necesite quitarla para

realizar alguna tarea de mantenimiento.

R EQ U I S I TO S DE UB I C A C I ÓN

Las ilustraciones que se incluyen en las páginas

siguientes proporcionan las medidas totales, las

medidas del corte de la encimera y las especificaciones de la instalación de las placas de gas de Wolf.

Mantenga las siguientes medidas de instalación

mínimas:

Distancia horizontal mínima desde los lados y la

parte trasera del corte de la encimera a material

combustible vertical adyacente, extendiéndose

un mínimo de 457 mm por encima de la

encimera, de la siguiente manera: 178 mm

desde los bordes laterales de la cavidad para la

placa de 381 mm; 229 mm desde los bordes

laterales de la cavidad para las placas de 762 mm

y 914 mm; 64 mm para el borde trasero de la

cavidad.

La distancia vertical mínima entre la encimera y

los materiales combustibles situados por encima

de la placa debe ser de 762 mm.

El fondo máximo de los armarios superiores

laterales situados por encima de la placa debe

ser de 330 mm con una distancia lateral mínima.

NOTA IMPORTANTE:

Cuando instale una campana

extractora, consulte los requisitos específicos de la

campana para obtener las medidas mínimas que

debe mantener respecto a la encimera.

Si no coloca la placa siguiendo las distancias

de separación correctas, es posible que se

produzca un incendio.

21

914 mm

DEL SUELO A

LA ENCIMERA

762 mm mín.

ENCIMERA HASTA

LOS MATERIALES

INFLAMABLES

CONSULTAR CORTE DE

LA ENCIMERA A CONT.

356 mm

ANCHO DE

CORTE

CORTE DE LA ENCIMERA

FRONTAL

489 mm

FONDO DE

CORTE

64 mm mín.

178 mm HASTA

LOS MATERIALES

INFLAMABLES*

178 mm HASTA

LOS MATERIALES

INFLAMABLES*

ARMARIO

LATERAL

330 mm

máx.

*Espacio de separación mínimo desde el corte de la superficie de cocción hasta los materiales inflamables hasta un máximo

de 457 mm sobre la encimera.

NOTA: la instalación detallada permite montar dos módulos de 381 mm contiguos.

E

381 mm

381

mm

102 mm

457 mm mín.

127

mm

LA UBICACIÓN DE LA TOMA

ELÉCTRICA Y DE GAS SE

EXTIENDE EN EL SUELO

G

64

mm*

PL ACA S DE G A S DE W O L F

381 mm

ANCHURA TOTAL

5

33 mm

FONDO

T

OTAL

102 mm

E SP E C I F IC AC I O N ES D E L A INS TA L AC I ÓN

Las ilustraciones que se muestran a continuación

proporcionan las medidas totales, las medidas de

corte de la encimera y las especificaciones de instalación que corresponden al modelo ICBCT15G.

Para el modelo ICBCT15G, el servicio de gas debe

suministrarse a través del suelo si la placa no se ha

instalado encima de un horno. Consulte la ilustración

para obtener información específica sobre la colocación de la toma de gas y de electricidad.

E SP E C I F IC AC I O N ES D E L A I N S TA LA CI Ó N – MO D E L O I C B CT 1 5 G

NOTA IMPORTANTE:

Cuando instale varias placas

juntas, consulte las dimensiones de corte de la

encimera en la página 25.

Medidas totales

M OD E L O I C B C T1 5 G

M ED I D AS

Anchura total 381 mm

Altura total 102 mm

Fondo total 533 mm

Anchura del armario

recomendada 838 mm

Fondo mínimo del armario 578 mm

Espacio mínimo de altura 102 mm

Ancho del corte 356 mm

Fondo del corte 489 mm

Las dimensiones de la unidad pueden

variar ±3 mm.

22

457 mm mín.

914 mm

DEL SUELO A

LA ENCIMERA

762 mm mín.

ENCIMERA HASTA

L

OS MATERIALES

INFLAMABLES

762 mm APERTURA DEL HORNO

102 mm

254 mm

89 mm

E

CONSULTAR CORTE DE

LA ENCIMERA A CONT.

229 mm HASTA

LOS MATERIALES

INFLAMABLES

*

229 mm HASTA

LOS MATERIALES

INFLAMABLES

*

64

mm*

ARMARIO

LATERAL

330 mm

máx.

737 mm

ANCHO DE CORTE

CORTE DE LA ENCIMERA

PARTE DELANTERA

489 mm

FONDO

DE CORTE

64 mm mín.

*Espacio de separación mínimo desde el corte de la superficie de cocción hasta los materiales inflamables hasta un máximo

de 457 mm sobre la encimera.

NOTA: la instalación detallada permite montar dos módulos de 381 mm contiguos.

G

I NS T R U C C I ON E S DE L A IN S TALAC IÓ N

5

33 mm

FONDO

TOTAL

762 mm

ANCHURA TOTAL

102 mm

E SP E C I F IC AC I O N ES D E L A INS TA L AC I ÓN

Las ilustraciones que se muestran a continuación

proporcionan las medidas totales, las medidas de

corte de la encimera y las especificaciones de instalación que corresponden al modelo ICBCT30G.

NOTA IMPORTANTE:

Para la instalación del modelo

ICBCT30G se recomienda utilizar armarios con un

ancho de 838 mm.

Se puede instalar un horno integrable sencillo de

Si instala el modelo ICBCT30G encima de los

armarios, la colocación de la toma eléctrica y de gas

no es importante. Es necesario colocar una toma de

corriente conectada a tierra a una distancia de 1,2 m

de la parte trasera derecha de la placa.

NOTA IMPORTANTE:

juntas, consulte las dimensiones de corte de la

encimera en la página 25.

762 mm debajo del modelo ICBCT30G. Para esta

instalación, a menos que vaya a utilizar armarios

con un fondo superior a 610 mm, se recomienda que

la toma eléctrica y de gas se coloque en un armario

base situado a la derecha del horno. Consulte las

instrucciones de instalación que se proporcionan con

el horno integrable para obtener más información.

E SP E C I F IC AC I O N ES D E L A I N S TA LA CI Ó N – MO D E L O I C B CT 3 0 G

Cuando instalen varias placas

Medidas totales

M OD E L O I C B C T3 0 G

M ED I D AS

Anchura total 762 mm

Altura total 102 mm

Fondo total 533 mm

Anchura del armario

recomendada 838 mm

Fondo mínimo del armario 578 mm

Espacio mínimo de altura 102 mm

Ancho del corte 737 mm

Fondo del corte 489 mm

Las dimensiones de la unidad pueden

variar ±3 mm.

23

Loading...

Loading...