Wolf ICBCT15I/S Installation Instructions Manual

INDUCTION COOKTOPS

INSTALLATION INSTRUCTIONS

INSTRUCCIONES DE INSTALACIÓN

INSTRUCTIONS D’INSTALLATION

ISTRUZIONI PER L’INSTALLAZIONE

INSTALLATIONSANWEISUNGEN

2

ENGLISH 4

ESPÃNOL 21

FRANÇAIS 38

ITALIANO 55

DEUTSCH 72

3

CONTACT

INFORMATION

Website:

wolfappliance.com

As you follow these instructions, you will

notice WARNING and CAUTION symbols.

This blocked information is important for the

safe and efficient installation of Wolf equipment. There are two types of potential

hazards that may occur during installation.

WOLF®is a registered trademark of Wolf Appliance, Inc.

signals a situation where minor injury or

product damage may occur if you do not

follow instructions.

states a hazard that may cause serious

injury or death if precautions are not

followed.

Another footnote we would like to identify is

IMPORTANT NOTE: This highlights information that is especially relevant to a problemfree installation.

WOLF INDUCTION COOKTOPS

INSTALLATION REQUIREMENTS

IMPORTANT NOTE:

Save these Installation

Instructions for the local inspector’s use.

Please read the entire Installation Instructions prior to installation.

This installation must be completed by a

qualified technician.

Installer:

please retain these instructions

for local inspector’s reference, then leave

them with the homeowner.

Homeowner:

please read and keep these

instructions for future reference and be sure

to read the entire Use & Care Information

prior to use.

IMPORTANT NOTE:

This appliance must be

installed in accordance with local codes. The

correct voltage, frequency and amperage must

be supplied to the appliance from a dedicated,

grounded circuit which is protected by a

properly sized circuit breaker or time delay

fuse. The proper voltage, frequency, and

amperage ratings are listed on the product

rating plate.

BEFORE YO U S TART

Proper installation is your responsibility.

Have a qualified technician install this

cooktop. You must also assure that electrical installation is adequate and in compliance with all local codes and ordinances.

Installations and repairs must be performed

by a qualified or licensed contractor or

electrician qualified or licensed by the state,

province, or region where this appliance is

being installed.

Make sure you have everything necessary

for correct installation. It is the responsibility of the installer to comply with the installation clearances specified on the product

rating plate. The rating plate is located on

the underside of the cooktop.

Electrical ground is required; see Electrical

Requirements on pages 16–17.

This cooktop is intended for indoor use.

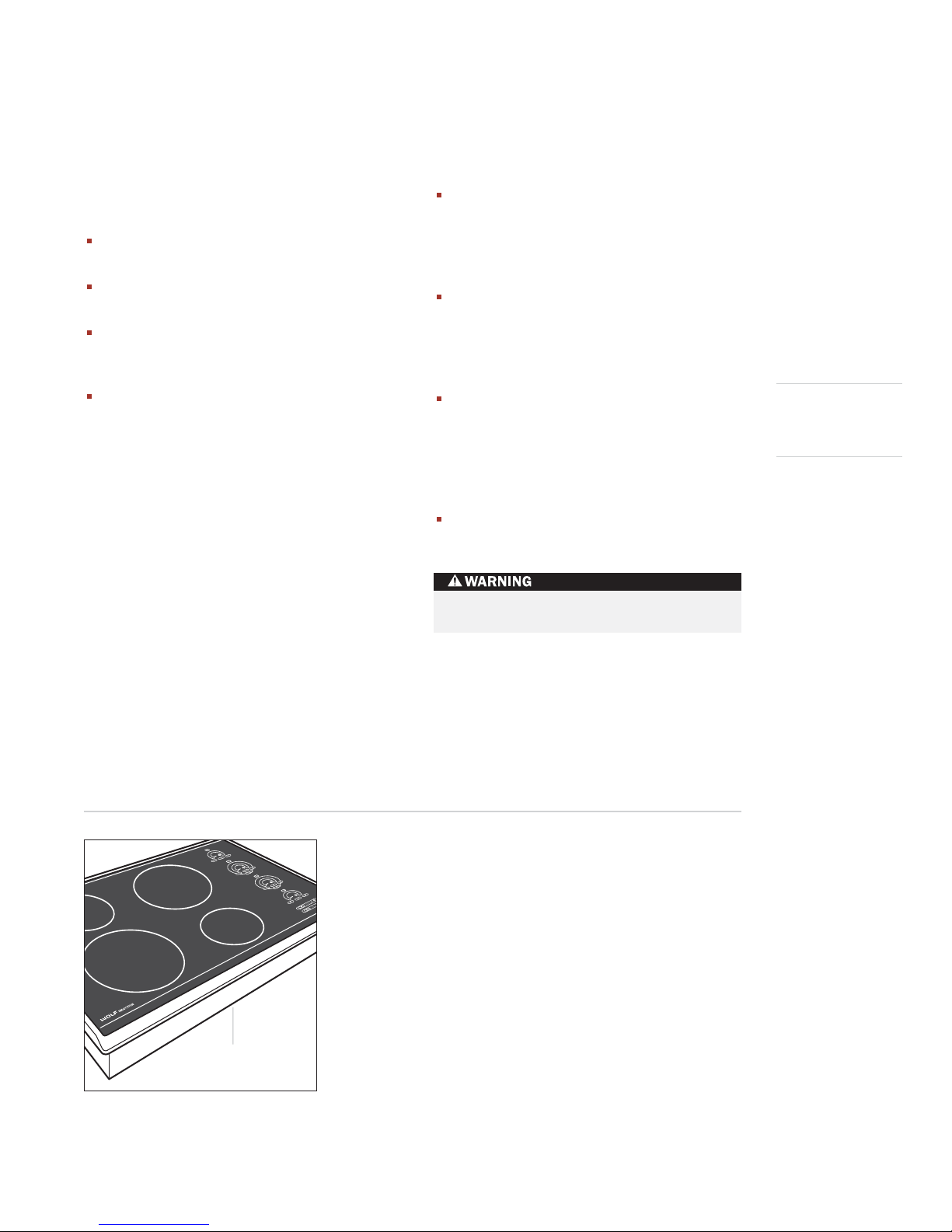

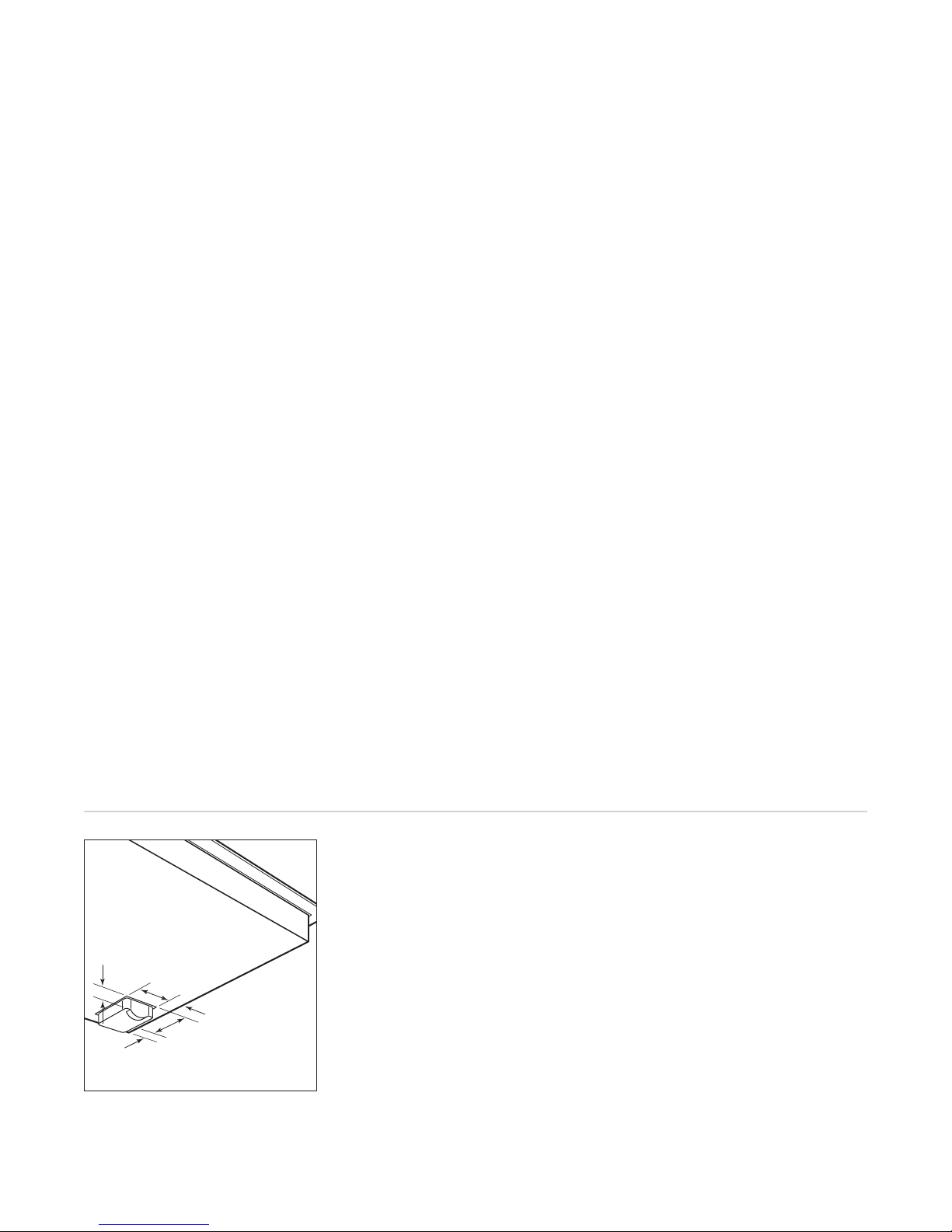

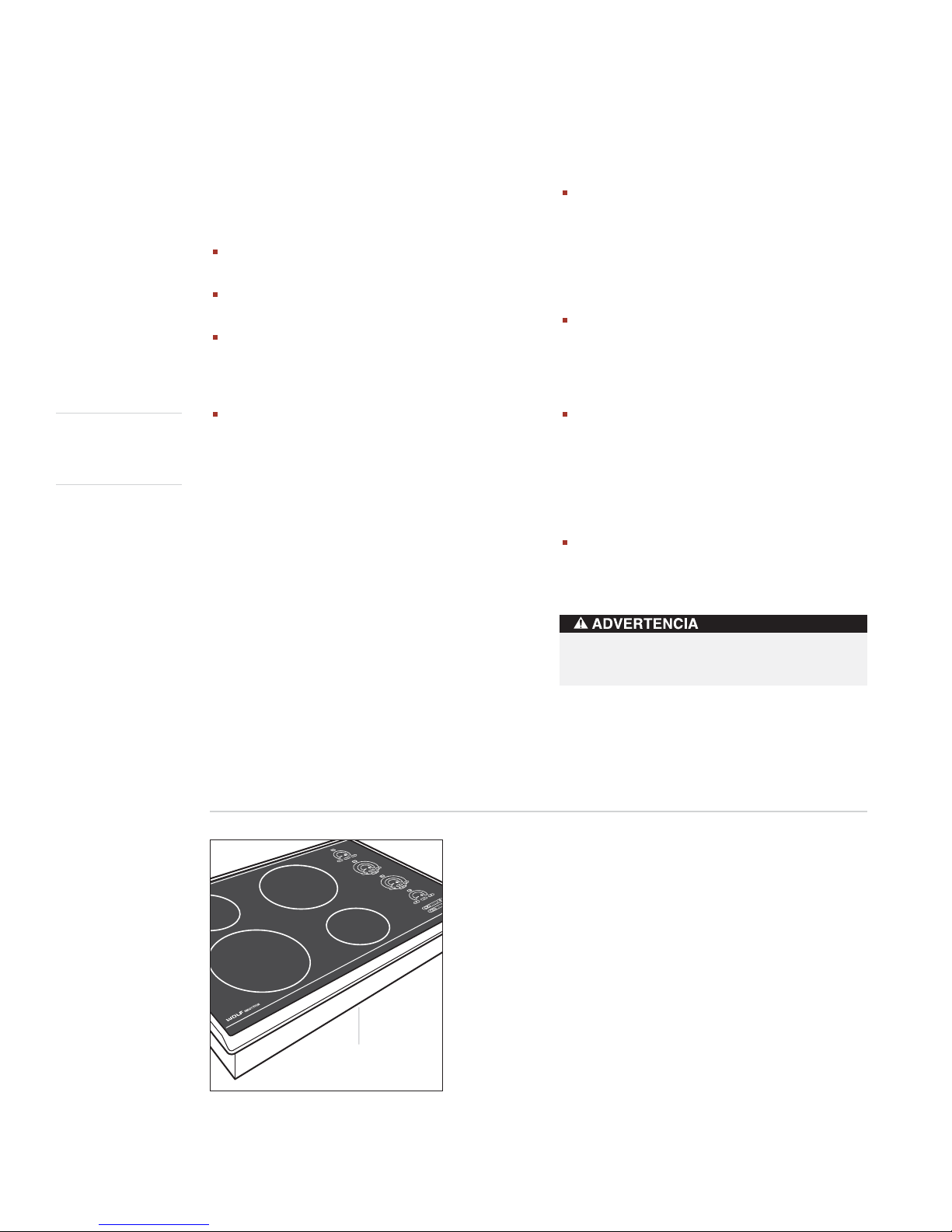

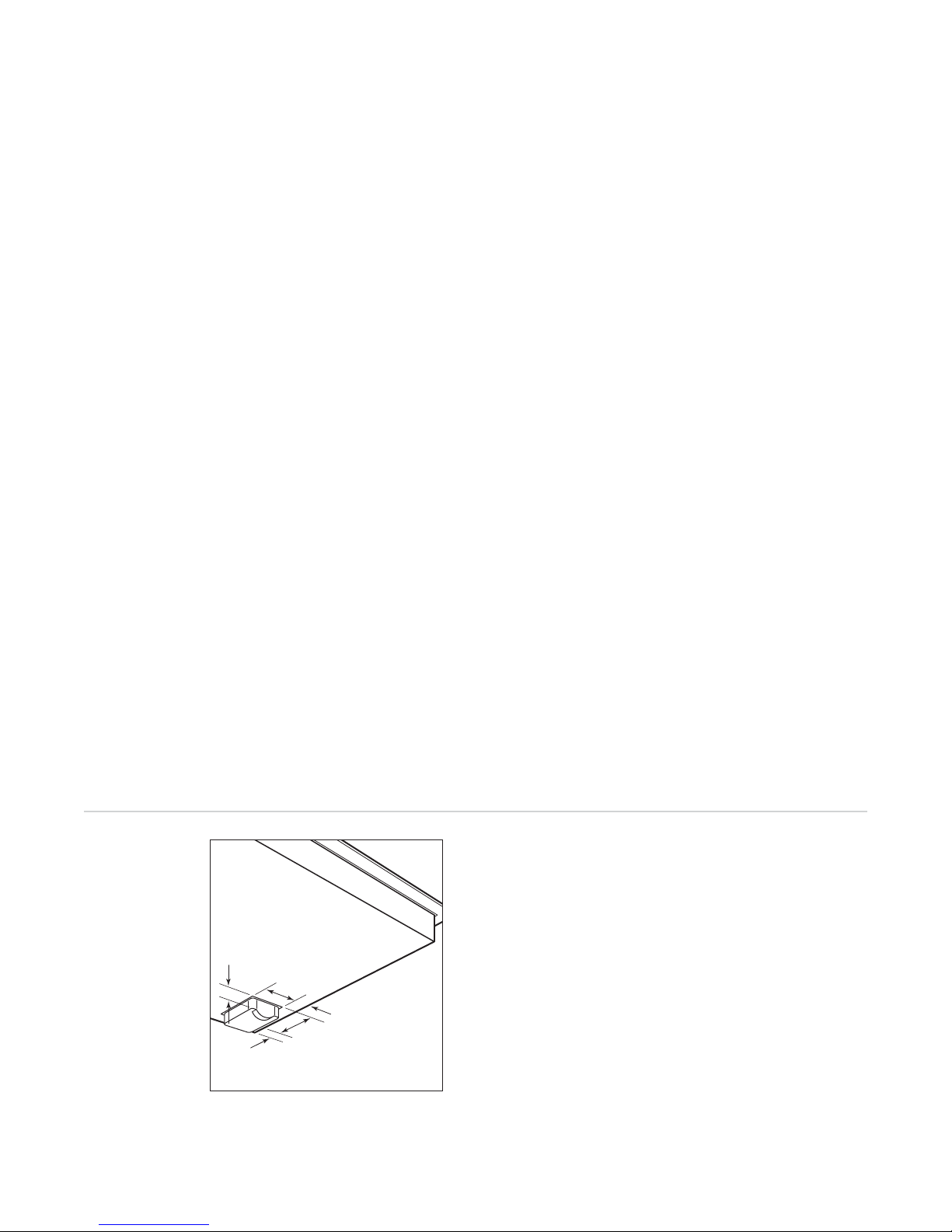

RATING PLATE

INFORMATION

Model Number

Serial Number

Record the model and serial numbers before

installing the cooktop. Both numbers are on

the rating plate, located on the underside of

the cooktop. Refer to the illustration below.

Location of rating

plate under cooktop

Rating plate location

5

WOLF INDUCTION COOKTOPS

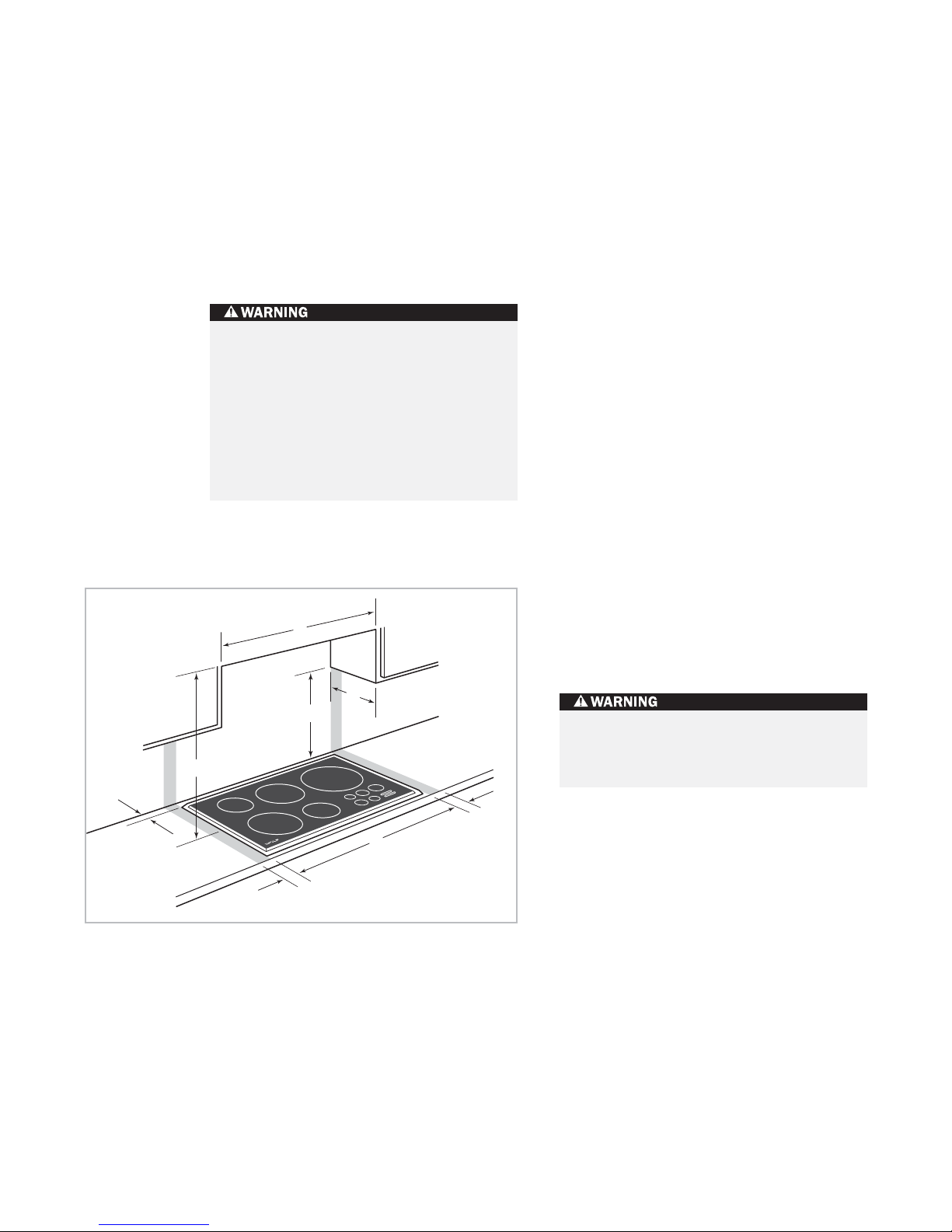

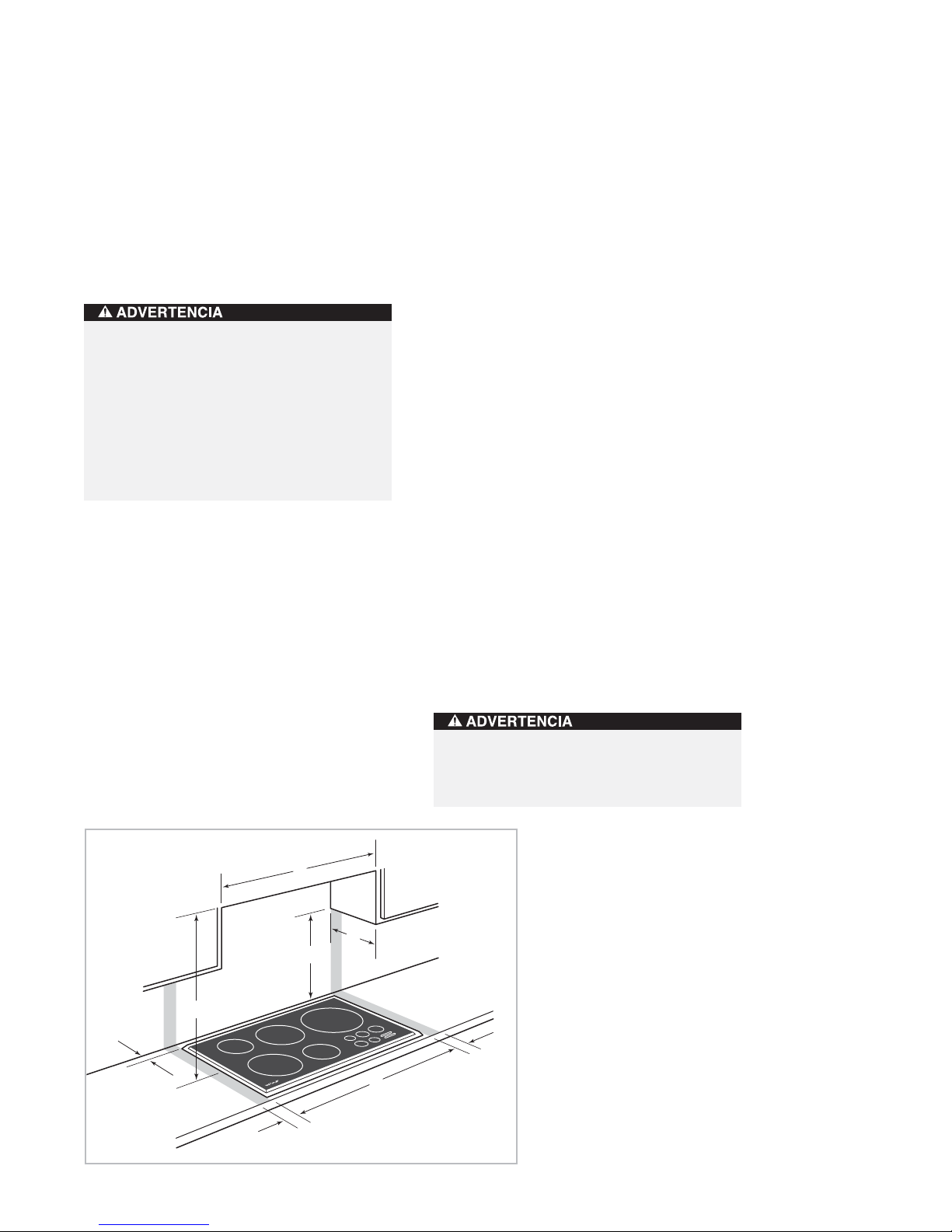

SITE PREPARATION

IMPORTANT NOTE:

Installation of the Wolf

induction cooktop must meet the following

location requirements. All dimensions listed

are minimum requirements for safe operation.

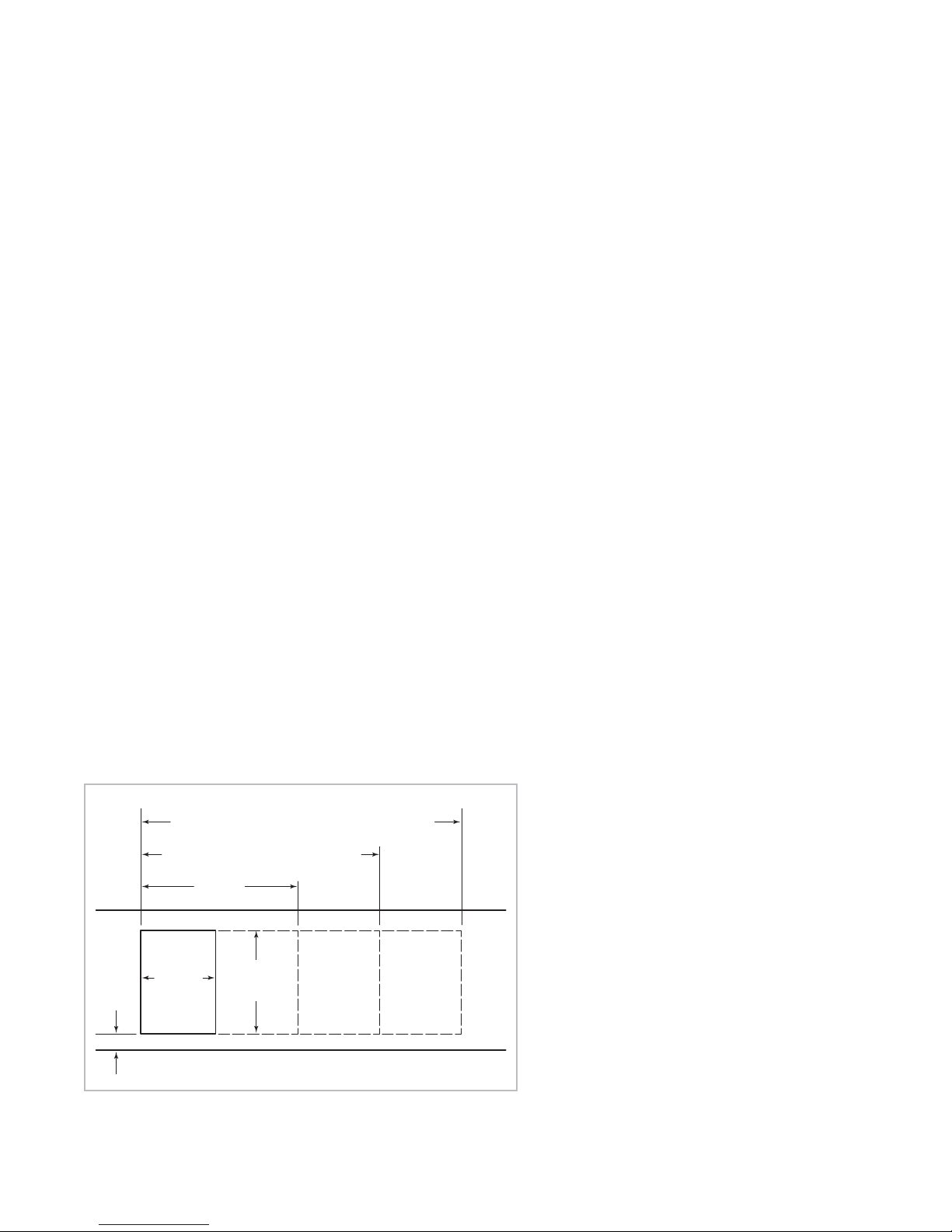

Refer to the illustration below.

To eliminate the risk of burns or fire by

reaching over heated surface units,

cabinet storage space located above the

surface units should be avoided. If

cabinet storage is to be provided, the risk

can be reduced by installing a ventilation

hood that projects horizontally a

minimum of 127 mm beyond the bottom

cabinets.

C

LOCATION IN COUNTERTOP

A)

Minimum flat countertop surface. Must be

equal to or greater than cooktop width.

B)

Minimum 25 mm wide clearance from the

cooktop side edge to any combustible

surface up to 457 mm above the cooktop

(noted by shaded area).

OVERHEAD CABINET DIMENSIONS

C)

Minimum spacing between overhead side

cabinets must be greater than or equal to

the nominal width of the cooktop unit(s).

D)

Minimum 457 mm vertical distance from

the countertop to the bottom of side

cabinets within minimum side clearance.

E)

Minimum vertical distance between the

countertop and combustible materials

above the cooktop must be 762 mm.

F)

Minimum 25 mm from rear wall.

G)

Maximum 330 mm depth of overhead and

side cabinets directly above and within side

clearance.

E

F

B

Minimum installation clearances

G

D

Failure to locate the cooktop without the

proper clearances will result in a fire

hazard.

B

A

6

INSTALLATION INSTRUCTIONS

INSTALLATION SPECIFICATIONS

The illustrations on pages 8–13 provide the

overall dimensions, installation specifications

and countertop cut-out for each of the Wolf

induction cooktop models.

These cooktops are designed to fit a standard

610 mm deep base cabinet with a 635 mm

deep countertop. Before making the countertop cut-out, verify that the cooktop will clear

the side walls of the base cabinet below.

Clearance is required for the terminal block

located at the right rear of the cooktop. Refer

to the illustration below for dimensions.

FRAMED INDUCTION COOKTOPS

IMPORTANT NOTE:

A minimum height clearance of 152 mm is required between the countertop and any combustible surface directly

below the cooktop. This includes upper edges

of drawers located directly below unit. If a

shelf is installed below the unit, a 25 mm gap

at the rear of the cabinet shelf is necessary to

allow for proper ventilation. Failure to do so

could result in decreased performance or

product damage.

Wolf induction cooktops are designed to be

installed in combination with other cooktop

units.

IMPORTANT NOTE:

When multiple cooktops

and/or modules are installed side by side, refer

to countertop cut-out dimensions on page 11.

Wolf induction cooktops can accommodate a

Wolf downdraft ventilation system. Refer to

installation instructions provided with the

downdraft for additional specifications.

UNFRAMED INDUCTION COOKTOPS

IMPORTANT NOTE:

A minimum height clearance of 165 mm is required between the countertop and any combustible surface directly

below the cooktop. This includes upper edges

of drawers located directly below unit. If a

shelf is installed below the unit, a 25 mm gap

at the rear of the cabinet shelf is necessary to

allow for proper ventilation. Failure to do so

could result in decreased performance or

product damage.

IMPORTANT NOTE:

Unframed induction

cooktops are not designed to be installed in

combination with other cooktops.

IMPORTANT NOTE:

Unframed induction

cooktops cannot be installed with a downdraft

ventilation system.

For installation options of the unframed induction cooktops, refer to Unframed Installation

on pages 14–15.

32 mm

56

mm

22 mm

84

24

mm

Terminal block dimensions

mm

7

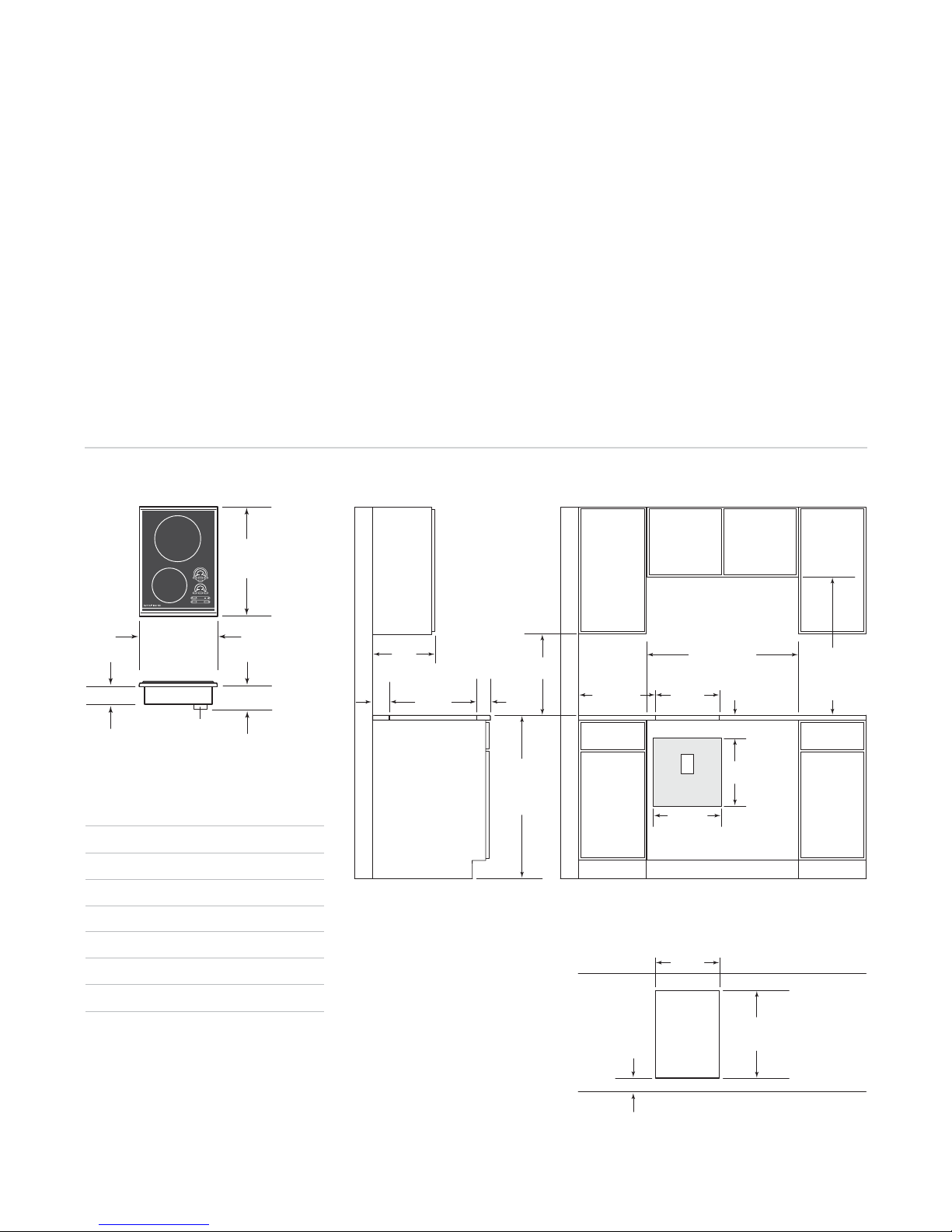

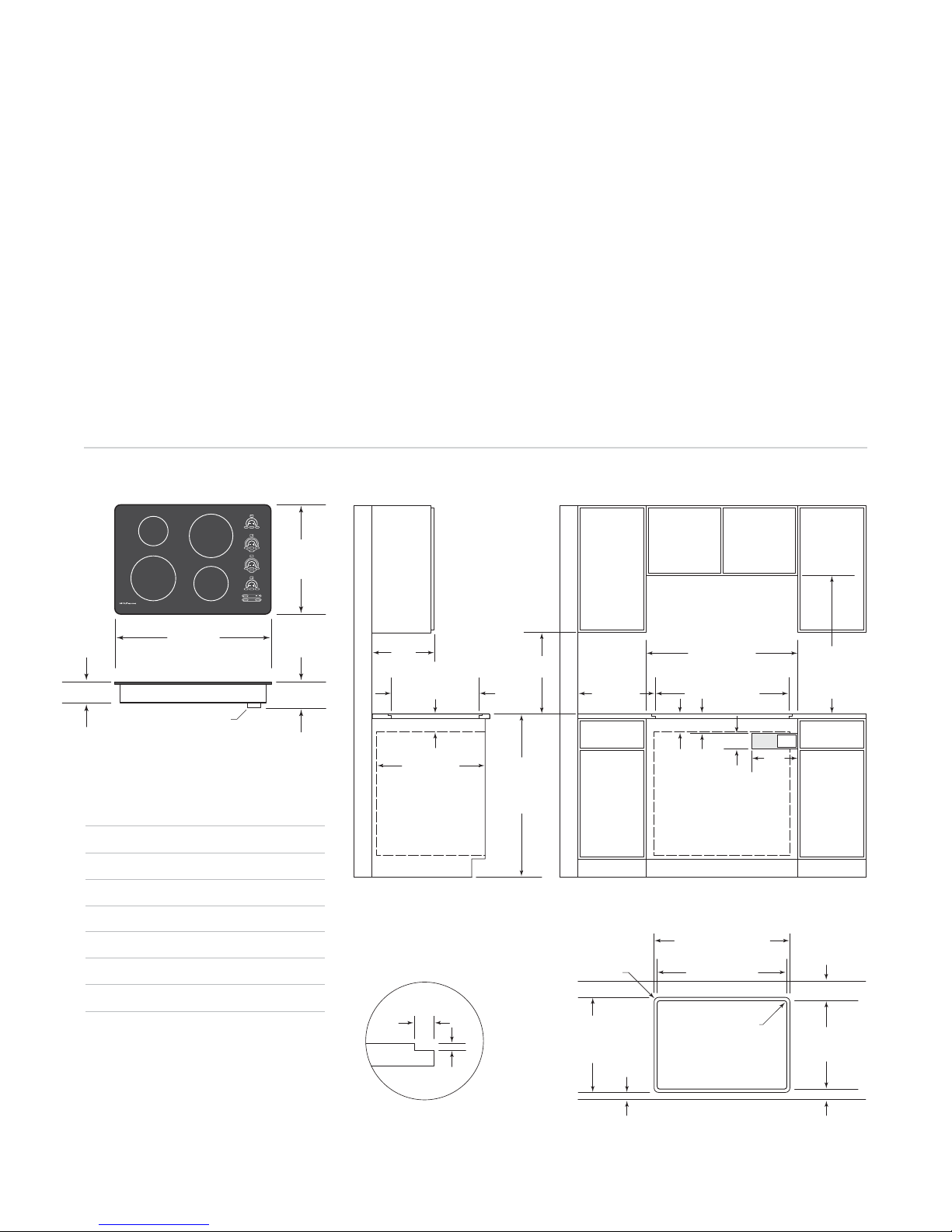

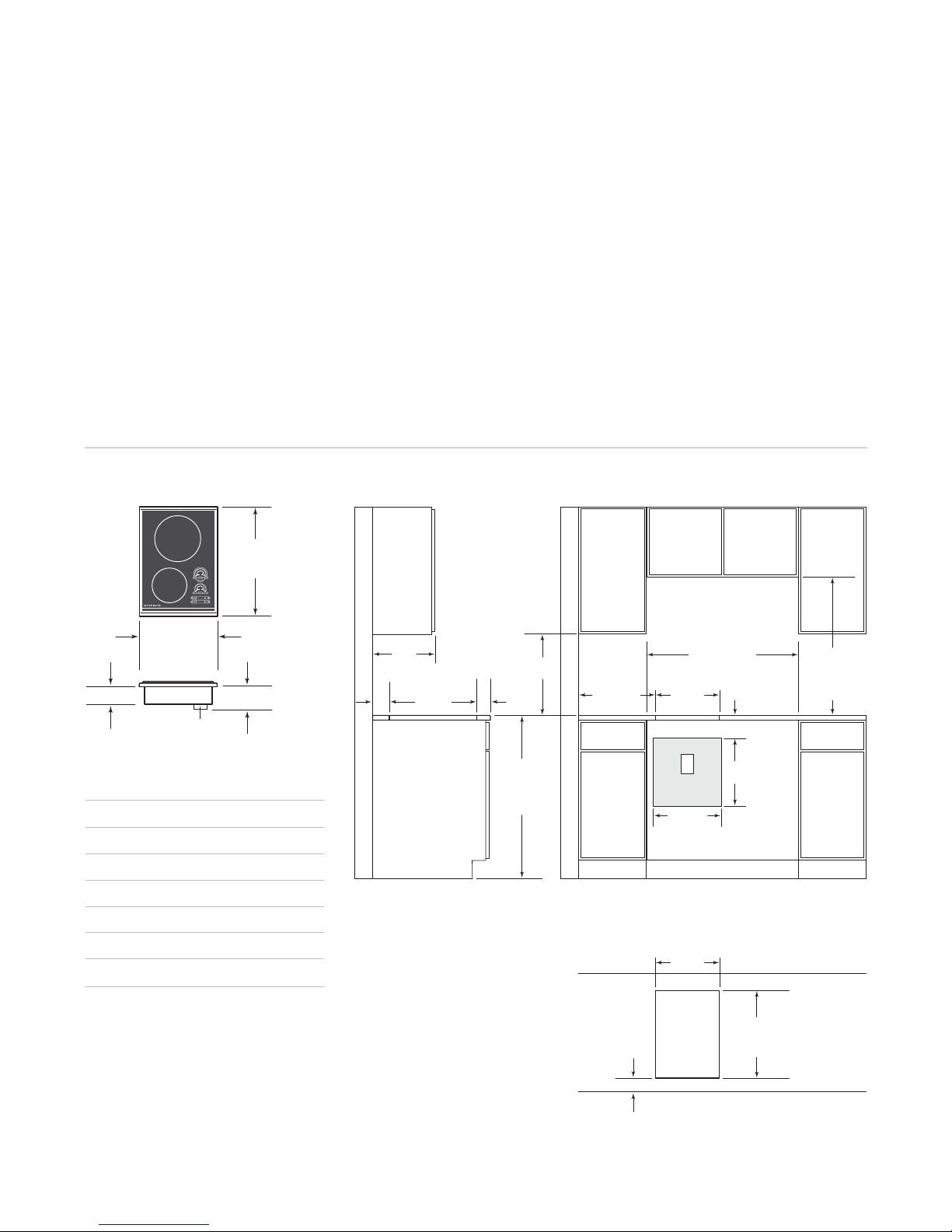

WOLF INDUCTION COOKTOPS

FRAMED MODEL ICBCT15I/S

The illustrations below provide installation

specifications for Model ICBCT15I/S.

INSTALLATION SPECIFICATIONS – MODEL ICBCT15I/S

533 mm

OVERALL

DEPTH

381 mm

OVERALL WIDTH

89 mm

TERMINAL BOX

114 mm

Overall Dimensions

MODEL ICBCT15I/S

Overall Width 381 mm

Overall Height 89 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance* 114 mm

Cut-Out Width 340 mm

Cut-Out Depth 489 mm

*Minimum 152 mm clearance is required

between countertop and any combustible

surface directly below the cooktop.

For detailed terminal block dimensions,

refer to the illustration on page 7.

Dimensions may vary to±3mm.

330 mm

max

51**

489 mm

mm

COOKTOP CUT-OUT

DEPTH

NOTE: Application shown allows for installation of two 381 mm modules side-by-side with 838 mm recommended cabinet width. 457 mm

recommended cabinet width for installation of single 381 mm cooktop or module. *Minimum clearance from both side edges of cooktop cut-out

to combustible materials up to 457 mm above countertop. **Minimum clearance from rear edge of cooktop cut-out to combustible mater ials up

to 457 mm above countertop.

64 mm

min

914 mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

Countertop Cut-Out

If Model ICBCT15I/S is installed above

cabinets, the electrical placement is not critical.

The appliance shall be installed in such a way

to allow disconnection of the appliance from

the supply mains after installation.

838 mm

RECOMMENDED

457

mm

min

51 mm*

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

64 mm

min

CABINET WIDTH

340 mm

COOKTOP CUT-OUT

WIDTH

E

381 mm

340 mm

COOKTOP CUT-OUT

WIDTH

FRONT OF COUNTERTOP

114 mm

381

mm

489 mm

COOKTOP

CUT-OUT DEPTH

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

762 mm

8

INSTALLATION INSTRUCTIONS

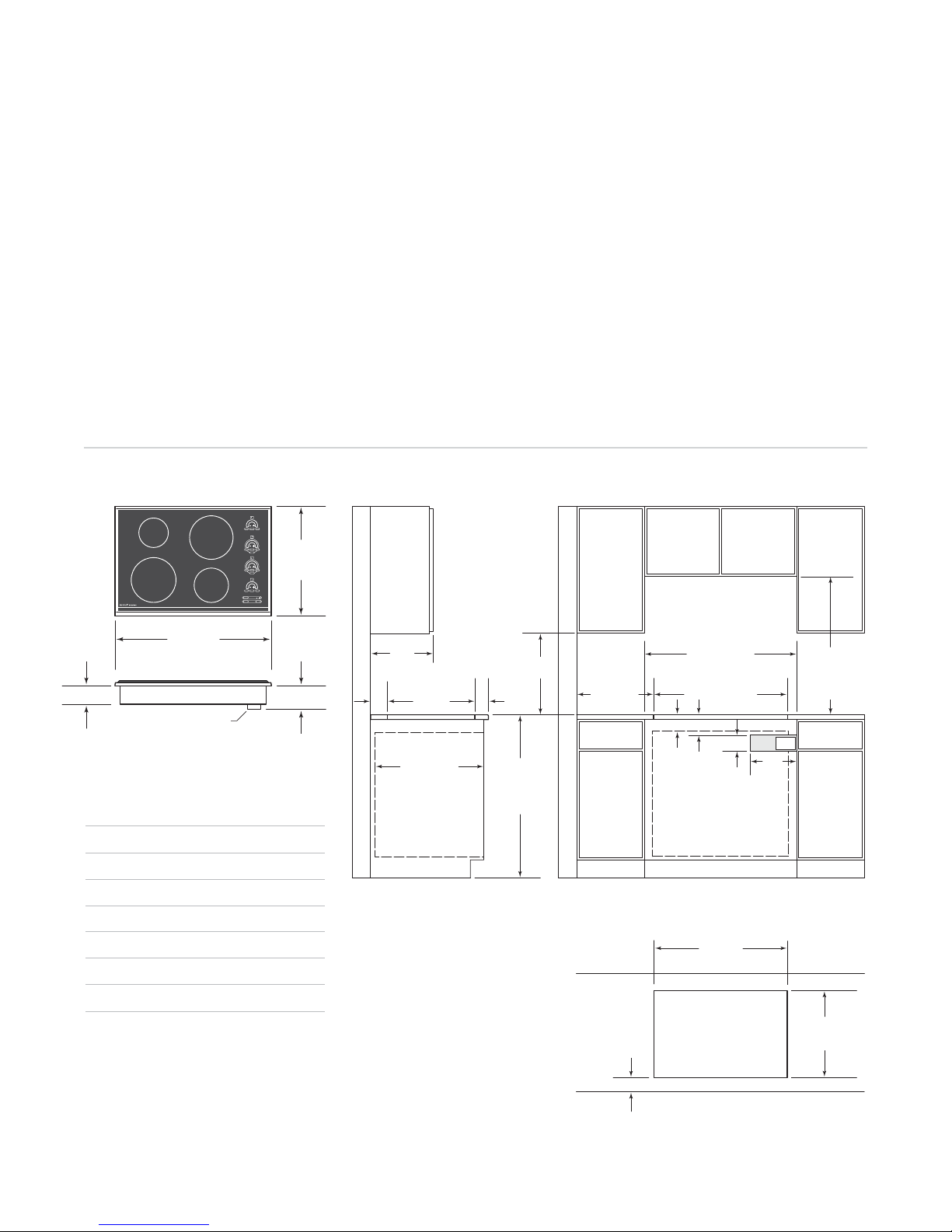

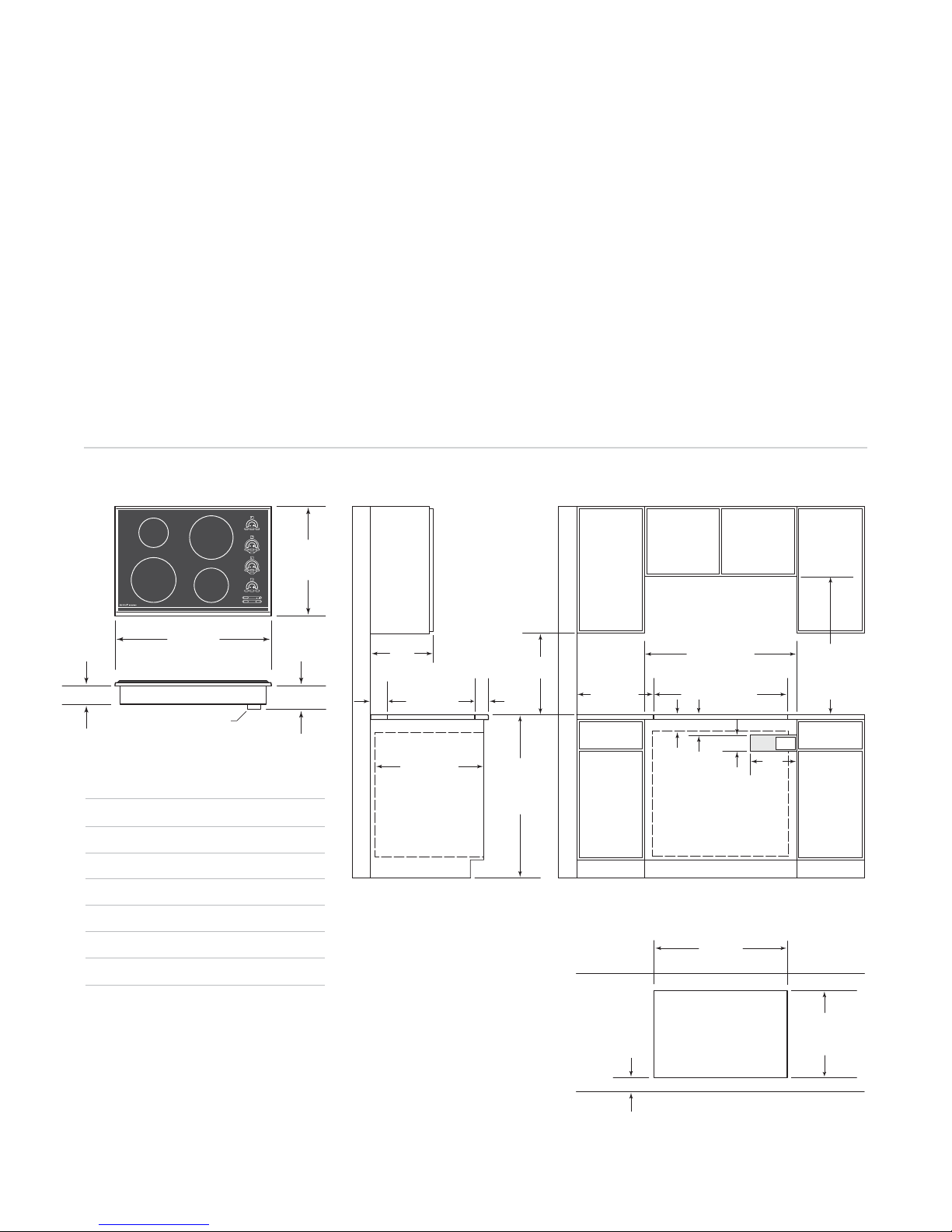

FRAMED MODEL ICBCT30I/S

The illustrations below provide installation

specifications for Model ICBCT30I/S.

For ease of installation, 838 mm cabinets are

recommended for installation of Model

ICBCT30I/S.

A Wolf 762 mm or 914 mm built-in single oven

may be installed below Model ICBCT30I/S. For

Refer to installation instructions provided with

the built-in oven for additional specifications.

If Model ICBCT30I/S is installed above

cabinets, the electrical placement is not critical.

The appliance shall be installed in such a way

to allow disconnection of the appliance from

the supply mains after installation.

this installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical supply be placed in the base

cabinet to the right of the oven.

INSTALLATION SPECIFICATIONS – MODEL ICBCT30I/S

533 mm

OVERALL

DEPTH

89 mm

762 mm

OVERALL WIDTH

TERMINAL BOX

114 mm

330 mm

max

51**

489 mm

mm

COOKTOP CUT-OUT

DEPTH

64 mm

Overall Dimensions

610 mm min

STANDARD

FLOOR TO

COUNTERTOP

MODEL ICBCT30I/S

min

914 mm

HEIGHT

457

mm

51 mm*min

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

838 mm

RECOMMENDED

CABINET WIDTH

762 mm min

721 mm COOKTOP

CUT-OUT WIDTH

114 mm

95 mm

89 mm

min

762 mm OVEN OPENING

254

mm

E

762 mm

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

Overall Width 762 mm

Overall Height 89 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance* 114 mm

Cut-Out Width 721 mm

Cut-Out Depth 489 mm

*Minimum 152 mm clearance is required

between countertop and any combustible

surface directly below the cooktop.

For detailed terminal block dimensions,

refer to the illustration on page 7.

Dimensions may vary to±3mm.

*Minimum clearance from both side edges of cooktop cut-out to combustible materials up to 457 mm above countertop. **Minimum clearance

from rear edge of cooktop cut-out to combustible materials up to 457 mm above countertop.

721 mm

COOKTOP CUT-OUT WIDTH

Countertop Cut-Out

489 mm

64 mm

min

FRONT OF COUNTERTOP

COOKTOP

CUT-OUT DEPTH

9

WOLF INDUCTION COOKTOPS

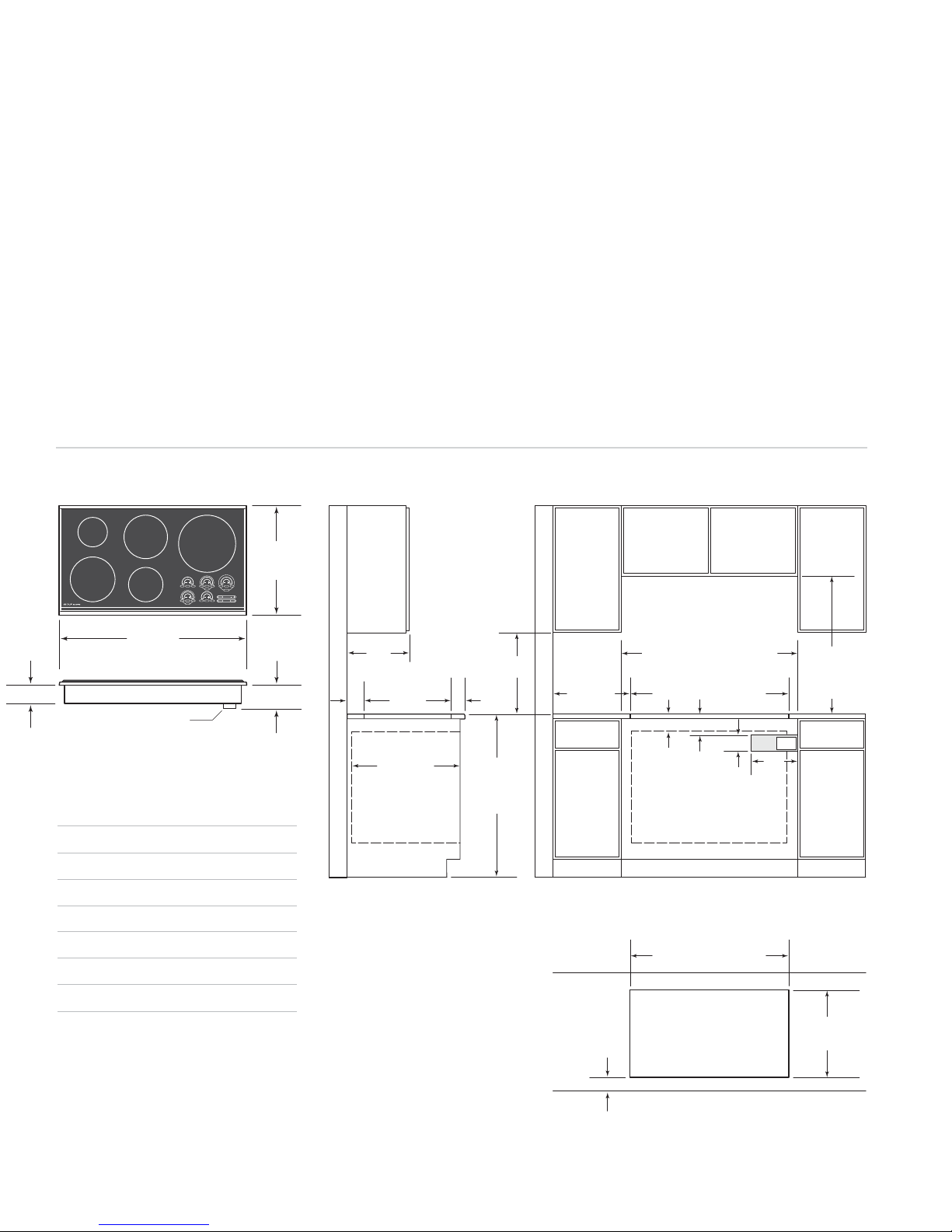

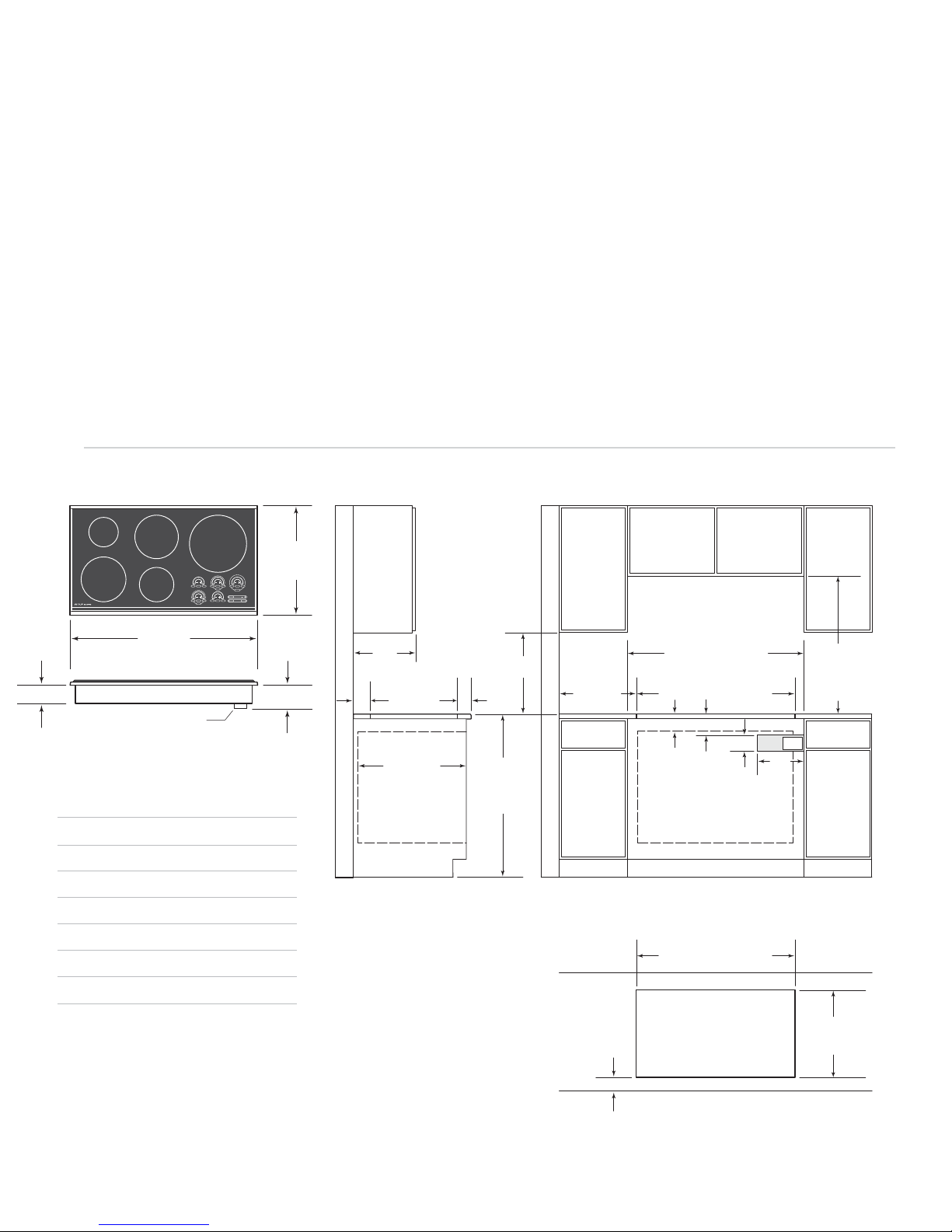

FRAMED MODEL ICBCT36I/S

The illustrations below provide installation

specifications for Model ICBCT36I/S.

For ease of installation, 991 mm cabinets are

recommended for installation of Model

ICBCT36I/S.

A Wolf 762 mm or 914 mm built-in single oven

may be installed below Model ICBCT36I/S. For

this installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical supply be placed in the base

cabinet to the right of the oven.

INSTALLATION SPECIFICATIONS – MODEL ICBCT36I/S

533 mm

OVERALL

DEPTH

89 mm

914 mm

OVERALL WIDTH

TERMINAL BOX

114 mm

330 mm

max

51**

489 mm

mm

COOKTOP CUT-OUT

DEPTH

Overall Dimensions

610 mm min

MODEL ICBCT36I/S

457

mm

64 mm

min

914 mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

Refer to installation instructions provided with

the built-in oven for additional specifications.

If Model ICBCT36I/S is installed above

cabinets, the electrical placement is not critical.

The appliance shall be installed in such a way

to allow disconnection of the appliance from

the supply mains after installation.

51 mm*min

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

RECOMMENDED CABINET WIDTH

991 mm

914 mm min

873 mm

COOKTOP CUT-OUT WIDTH

114 mm

95 mm

min

914mmOVENOPENING

89 mm

254

mm

762 mm

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

E

Overall Width 914 mm

Overall Height 89 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance* 114 mm

Cut-Out Width 873 mm

Cut-Out Depth 489 mm

*Minimum 152 mm clearance is required

between countertop and any combustible

surface directly below the cooktop.

For detailed terminal block dimensions,

refer to the illustration on page 7.

Dimensions may vary to±3mm.

10

*Minimum clearance from both side edges of cooktop cut-out to combustible materials up to 457 mm above countertop. **Minimum clearance from

rear edge of cooktop cut-out to combustible materials up to 457 mm above countertop.

873 mm

COOKTOP CUT-OUT WIDTH

Countertop Cut-Out

489 mm

64 mm

min

FRONT OF COUNTERTOP

COOKTOP

CUT-OUT DEPTH

INSTALLATION INSTRUCTIONS

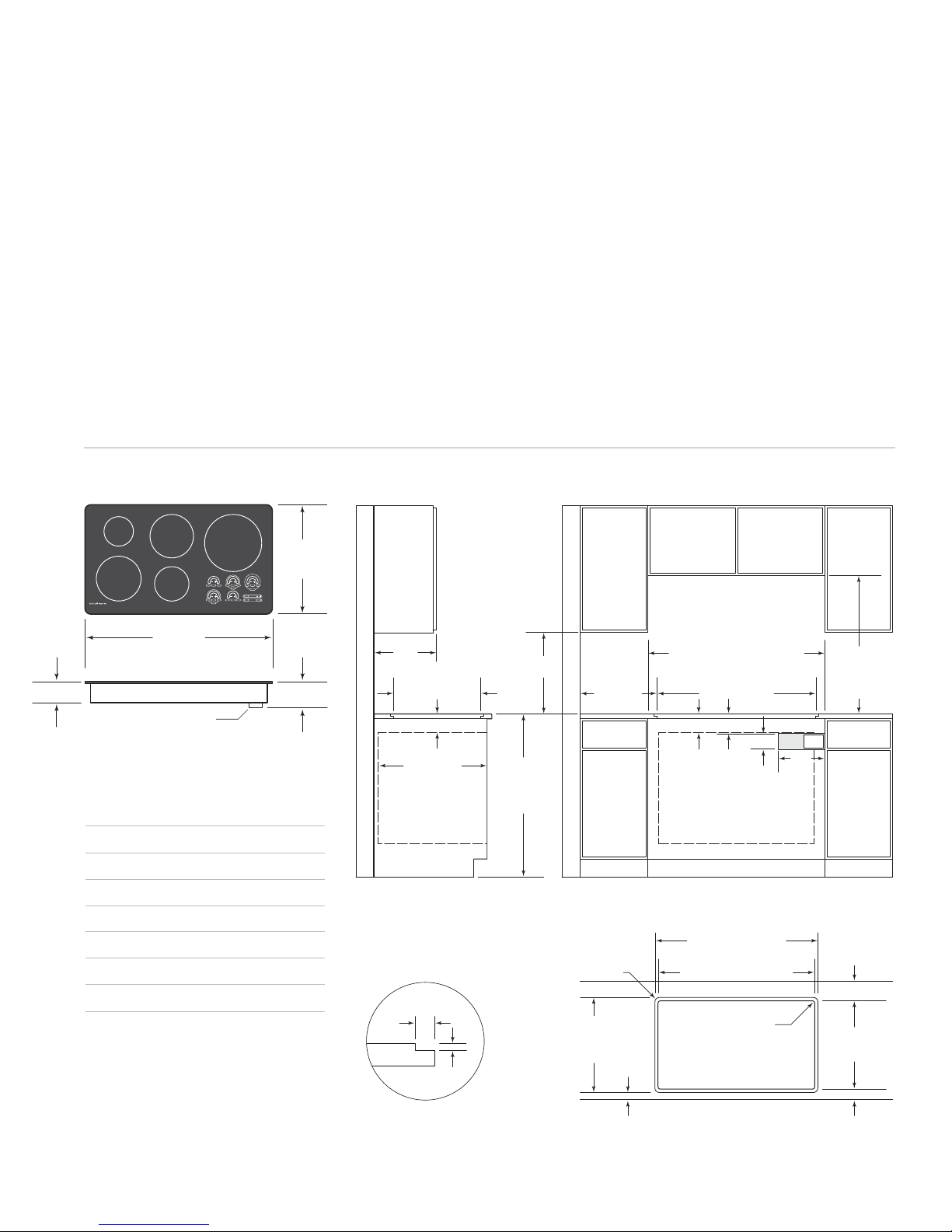

MULTIPLE COOKTOP INSTALLATION

If the framed induction cooktop is to be used

with any combination of additional cooktop

units or modules with a filler strip, the cut-out

width is calculated by adding the corresponding units’ cut-out dimensions plus 32 mm for

each additional unit. Refer to the illustration

below.

IMPORTANT NOTE:

For Model ICBCT15I/S,

the cut-out width should be increased from

340 mm to 356 mm when installed with

multiple units.

IMPORTANT NOTE:

Unframed induction

cooktops are not designed to be installed in

combination with other cooktops.

IMPORTANT NOTE:

When multiple units are

installed side by side, each unit must have its

own separate recommended electrical circuit.

When two or more modules are installed

together, an integrated module filler strip

(IFILLER/S) is recommended. If a 762 mm

downdraft ventilation system is also installed,

an integrated module support for downdraft

ventilation (ISUPPORT) is also required.

Contact your Wolf dealer for information on

these accessory components.

ACCESSORIES

Optional accessories are available

through your

Wolf dealer. To

obtain local dealer

information, visit

our website,

wolfappliance.com.

1518 mm – FOUR MODULES WIDTH OR

1511 mm – 762 mm COOKTOP AND TWO MODULES OR

1276 mm – 914 mm COOKTOP AND ONE MODULE

1130 mm – THREE MODULES WIDTH OR

1124 mm – 762 mm COOKTOP AND ONE MODULE

743 mm

TWO MODULES WIDTH

356 mm

64 mm

min

Countertop cut-out dimensions for installation of multiple cooktops

CUT-OUT

WIDTH

FRONT OF COUNTERTOP

489 mm

CUT-OUT

DEPTH

11

WOLF INDUCTION COOKTOPS

UNFRAMED MODEL ICBCT30IU

The illustrations below provide installation

specifications for Model ICBCT30IU.

For ease of installation, 838 mm cabinets are

recommended for installation of Model ICBCT30IU.

A Wolf 762 mm built-in single oven may be

installed below Model ICBCT30IU. For this

installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical supply be placed in the base

cabinet to the right of the oven. Refer to installation instructions provided with the built-in

oven for additional specifications.

INSTALLATION SPECIFICATIONS – MODEL ICBCT30IU

533 mm

OVERALL

DEPTH

104 mm

762 mm

OVERALL WIDTH

TERMINAL BOX

127 mm

330 mm

max

SEE COUNTERTOP

CUT-OUT BELOW

102 mm min

Overall Dimensions

610 mm min

MODEL ICBCT30IU

457

mm

914 mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

If Model ICBCT30IU is installed above cabinets,

electrical placement is not critical. The appliance shall be installed in such a way to allow

disconnection of the appliance from the supply

mains after installation.

For Model ICBCT30IU installation options, refer

to Unframed Installations on pages 14–15.

IMPORTANT NOTE:

For flush mount applications, it is recommended to measure the

cooktop glass before cutting the countertop to

ensure a proper fit. Small variances may exist

between the template and the cooktop.

838 mm

51 mm*min

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

RECOMMENDED

CABINET WIDTH

762 mm min

SEE COUNTERTOP

CUT-OUT BELOW

114 mm

102 mm

TO OVEN

OPENING

89 mm

min

762mmOVENOPENING

254

mm

762 mm

COUNTERTOP TO

COMBUSTIBLE

MATERIALS

ABOVE COOKTOP

E

Overall Width 762 mm

Overall Height 102 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance*

127 mm

Cut-Out Width 721 mm

Cut-Out Depth 492 mm

*Minimum 165 mm clearance is required

between countertop and any combustible

surface directly below the cooktop.

For detailed terminal block dimensions,

refer to the illustration on page 7.

Dimensions may vary to±3mm.

12

*Minimum clearance from both side edges and back edge of cooktop cut-out to combustible materials up to 457 mm above countertop.

Countertop Cut-Out

RECESSED AREA FOR

FLUSH MOUNT INSTALLATION ONLY

COUNTERTOP

PROFILE

22

max

mm

8mm

**Minimum dimension, but may be exceeded by up to 3 mm.

FOR FLUSH MOUNT

INSTALLATION ONLY

33 mm

RADIUS

537 mm**

RECESSED AREA

40 mm

765 mm**

RECESSED AREA FOR

FLUSH MOUNT INSTALLATION ONLY

721 mm COOKTOP

CUT-OUT WIDTH

11 mm RADIUS

FRONT OF COUNTERTOP

51 mm*

492 mm

COOKTOP

CUT-OUT DEPTH

62 mm

INSTALLATION INSTRUCTIONS

UNFRAMED

The illustrations below provide installation

specifications for Model ICBCT36IU.

For ease of installation, 991 mm cabinets are

recommended for installation of Model ICBCT36IU.

A Wolf 914 mm built-in single oven may be

installed below Model ICBCT36IU. For this

installation, unless you are using cabinets

deeper than 610 mm, it is recommended that

the electrical supply be placed in the base

cabinet to the right of the oven. Refer to installation instructions provided with the built-in

oven for additional specifications.

MODEL ICBCT36IU

If Model ICBCT36IU is installed above cabinets,

electrical placement is not critical. The appliance shall be installed in such a way to allow

disconnection of the appliance from the supply

mains after installation.

For Model ICBCT36IU installation options, refer

to Unframed Installations on pages 14–15.

IMPORTANT NOTE:

tions, it is recommended to measure the

cooktop glass before cutting the countertop to

ensure a proper fit. Small variances may exist

between the template and the cooktop.

INSTALLATION SPECIFICATIONS – MODEL ICBCT36IU

533 mm

OVERALL

DEPTH

For flush mount applica-

914 mm

OVERALL WIDTH

104 mm

TERMINAL BOX

Overall Dimensions

MODEL ICBCT36IU

Overall Width 914 mm

Overall Height 102 mm

Overall Depth 533 mm

Minimum Cabinet Depth 578 mm

Minimum Height Clearance*

Cut-Out Width 873 mm

Cut-Out Depth 492 mm

*Minimum 165 mm clearance is required

between countertop and any combustible

surface directly below the cooktop.

For detailed terminal block dimensions,

refer to the illustration on page 7.

Dimensions may vary to±3mm.

127 mm

127 mm

330 mm

max

SEE COUNTERTOP

CUT-OUT BELOW

min

102 mm

610 mm min

*Minimum clearance from both side edges and back edge of cooktop cut-out to combustible materials up to 457 mm above countertop.

457

mm

914 mm

STANDARD

FLOOR TO

COUNTERTOP

HEIGHT

51 mm*min

CUT-OUT TO

COMBUSTIBLE

MATERIALS

(BOTH SIDES)

Countertop Cut-Out

RECESSED AREA FOR

FLUSH MOUNT INSTALLATION ONLY

COUNTERTOP

PROFILE

22

mm max

8mm

**Minimum dimension, but may be exceeded by up to 3 mm.

RECESSED AREA

FOR FLUSH MOUNT

INSTALLATION ONLY

33 mm

RADIUS

537 mm**

40 mm

FLUSH MOUNT INSTALLATION ONLY

991 mm

RECOMMENDED CABINET WIDTH

914 mm min

SEE COUNTERTOP

CUT-OUT BELOW

114 mm

102 mm min

TO OVEN

OPENING

914 mm OVEN OPENING

RECESSED AREA FOR

COOKTOP CUT-OUT WIDTH

FRONT OF COUNTERTOP

89 mm

918 mm**

873 mm

11 mm RADIUS

254

mm

E

COUNTERTOP TO

ABOVE COOKTOP

CUT-OUT DEPTH

762 mm

COMBUSTIBLE

MATERIALS

51 mm*

492 mm

COOKTOP

62 mm

13

WOLF INDUCTION COOKTOPS

UNFRAMED

Flush mount installations are intended

for granite, solid surface or stone countertop surfaces only. Failure to use high

heat resistant surface will result in countertop damage if hot cooking utensils are

accidentally moved off the cooking

surface.

INSTALLATIONS

MODELS ICBCT30IU AND ICBCT36IU

Unframed induction cooktop Models

ICBCT30IU and ICBCT36IU can be mounted

flush with the top of the countertop or as a

frameless installation with the glass mounted

on top of the countertop surface.

IMPORTANT NOTE:

The materials required

for a flush mount installation are provided with

the unframed Models ICBCT30IU and

ICBCT36IU. Refer to the instructions provided

with the unframed cooktop installation kit

(#811358) for additional specifications.

FLUSH MOUNT INSTALLATION

There are two options for a flush mount

installation of the unframed induction cooktop;

Option 1 and Option 2.

OPTION 1:

For this flush mount installation, a

recessed area surrounding the standard countertop cut-out is required. Fabrication of the

recessed area must take place before the final

countertop installation. A template of the countertop cut-out is provided with the unframed

cooktop for fabrication purposes.

IMPORTANT NOTE:

This fabrication method is

not recommended for molded backsplash style

countertops (triple cove).

For countertop cut-out dimensions, refer to

the Installation Specifications illustration on

page 12 for Model ICBCT30IU and page 13 for

Model ICBCT36IU.

In order to rout the required recessed area for

this flush mount installation, a second

template must be made from 13 mm plywood.

The template will be used as a guide for a top

bearing router bit.

Make the wood template wide enough so that

clamps used to hold this template to the countertop do not interfere with the router base.

The cut-out dimension of the wood template

should match the outer perimeter of the

template supplied with the cooktop.

Center the wood template over the existing

cut-out in the countertop and clamp. It may be

helpful to use medium-strength double-sided

tape to adhere the template to the countertop;

this will keep the template from shifting during

the routing operation. Make sure that the

adhesive can be easily removed by testing it

on a scrap piece of the countertop. Using a top

bearing router bit with the wood template as a

guide, rout out a 8 mm deep recessed area in

the countertop cut-out.

14

INSTALLATION INSTRUCTIONS

UNFRAMED INSTALLATIONS

FLUSH MOUNT INSTALLATION

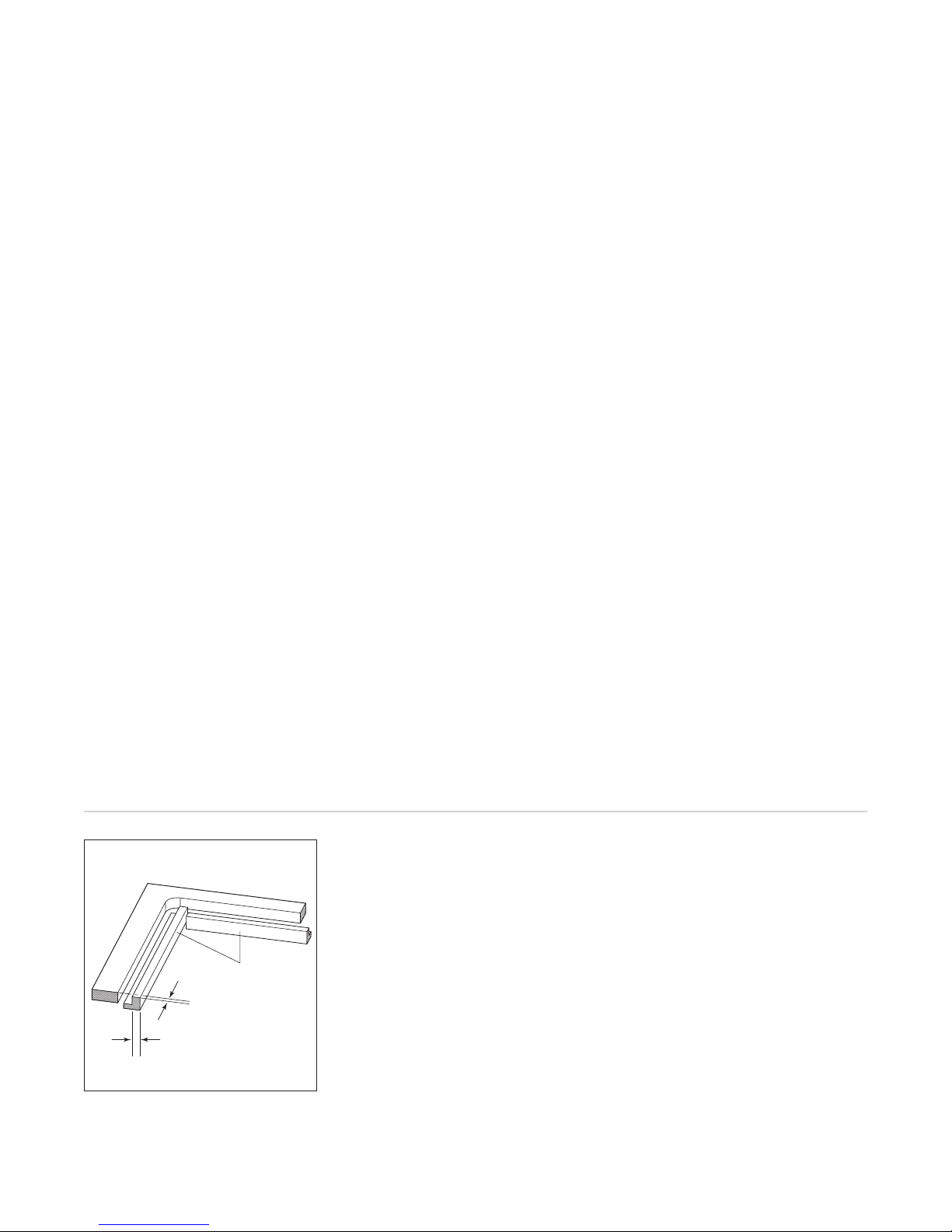

OPTION 2:

For this flush mount installation,

the countertop cut-out will be the same size as

the outer edge of the glass top. It is recommended that cooktop itself be used as the

template for the cut-out. Turn the cooktop over

and mark the opening using the glass top as a

template.

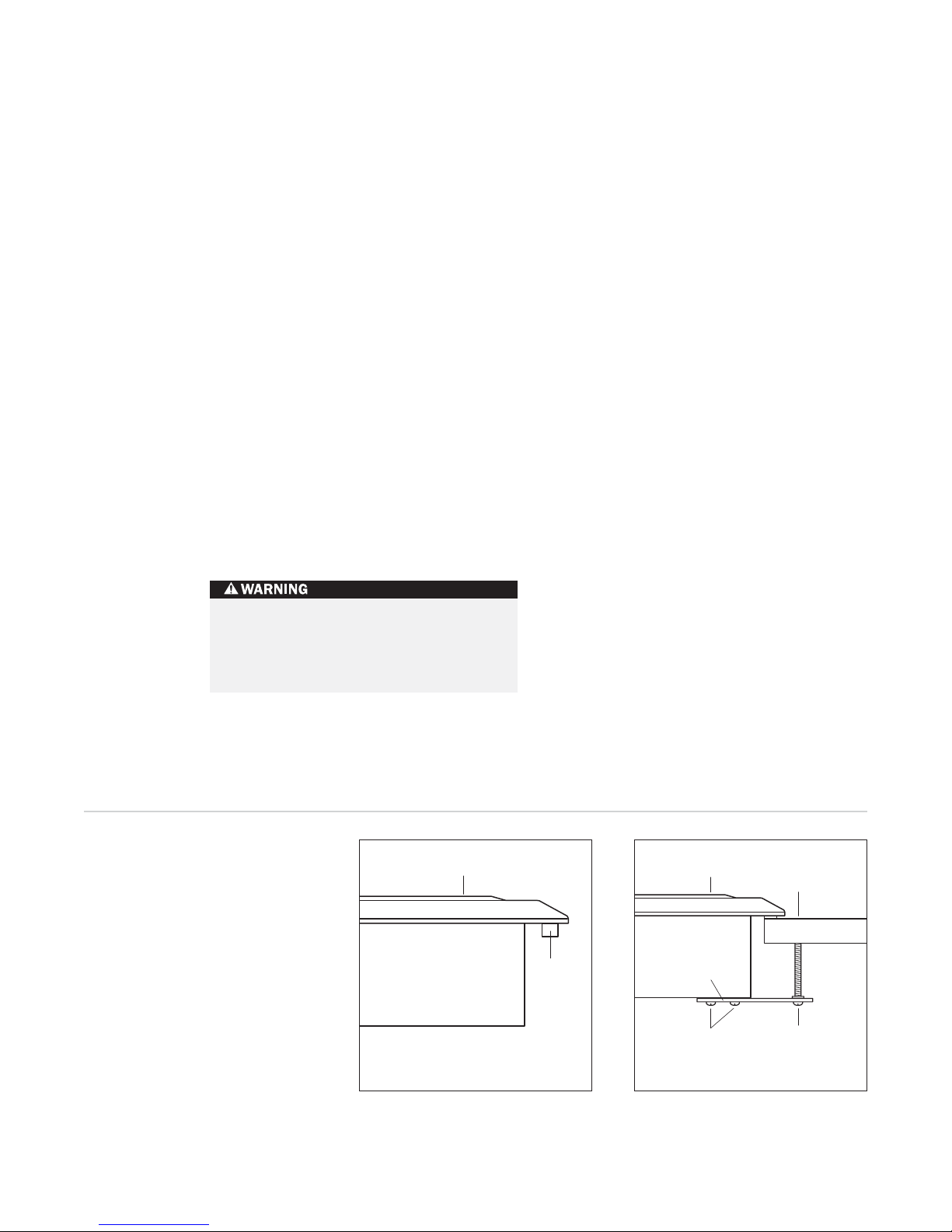

It will be necessary to attach L-shaped brackets

or cleats to the inner perimeter of the cut-out

to support the cooktop. The top edge of the

bracket can be no wider than 22 mm and will

be attached 8 mm below the surface of the

countertop. Refer to the illustration below.

Attachment of the brackets is up to the

installer's discretion, wherever enough countertop material is present.

For additional support in the cut-out area,

adhere scrap countertop material to the

bottom side of the countertop. Consult your

countertop supplier for the proper methods of

attachment.

FRAMELESS INSTALLATION

Unframed induction cooktop Models

ICBCT30IU and ICBCT36IU can be installed as a

frameless application, with the glass mounted

on top of the countertop surface. For countertop cut-out dimensions, refer to the Installation

Specifications illustration on page 12 for Model

ICBCT30IU and page 13 for Model ICBCT36IU.

8mm

22 mm

Flush mount installation brackets

L-Shaped

Brackets

15

IMPORTANT

NOTE

WOLF INDUCTION COOKTOPS

ELECTRICAL REQUIREMENTS

Verify that power is disconnected from

the electrical box before proceeding.

REQUIRED POWER SUPPLY

FOR SINGLE PHASE CIRCUITS

Wolf induction cooktops require a separate,

grounded 3-wire service for single phase

circuits or 5-wire service for three phase

circuits with its own circuit breaker. Locate the

electrical supply within the shaded area shown

in the Installation Specifications illustration for

your specific model on pages 8–13.

This appliance

must be installed

in accordance

with local codes.

Model ICBCT15I/S

220-240 V AC, 50/60 Hz, 3.6 kW,

20 amp service

Model ICBCT30I/S and ICBCT30IU

220-240 V AC, 50/60 Hz, 7.2 kW,

40 amp service

Model ICBCT36I/S and ICBCT36IU

220-240 V AC, 50/60 Hz, 10.2 kW,

50 amp service

REQUIRED POWER SUPPLY

FOR THREE PHASE CIRCUITS

Model ICBCT15I/S

220-240 V AC, 50/60 Hz, 3.6 kW,

25 amp service per line

Model ICBCT30I/S and ICBCT30IU

220-240 V AC, 50/60 Hz, 7.2 kW,

25 amp service per line

Model ICBCT36I/S and ICBCT36IU

220-240 V AC, 50/60 Hz, 10.2 kW,

25 amp service per line

16

INSTALLATION INSTRUCTIONS

ELECTRICAL REQUIREMENTS

This appliance must be installed in accordance

with local codes. The correct voltage,

frequency and amperage must be supplied to

the appliance from a dedicated, grounded

circuit which is protected by a properly sized

circuit breaker or time delay fuse. The proper

voltage, frequency and amperage ratings are

listed on the product rating plate, located on

the underside of the cooktop.

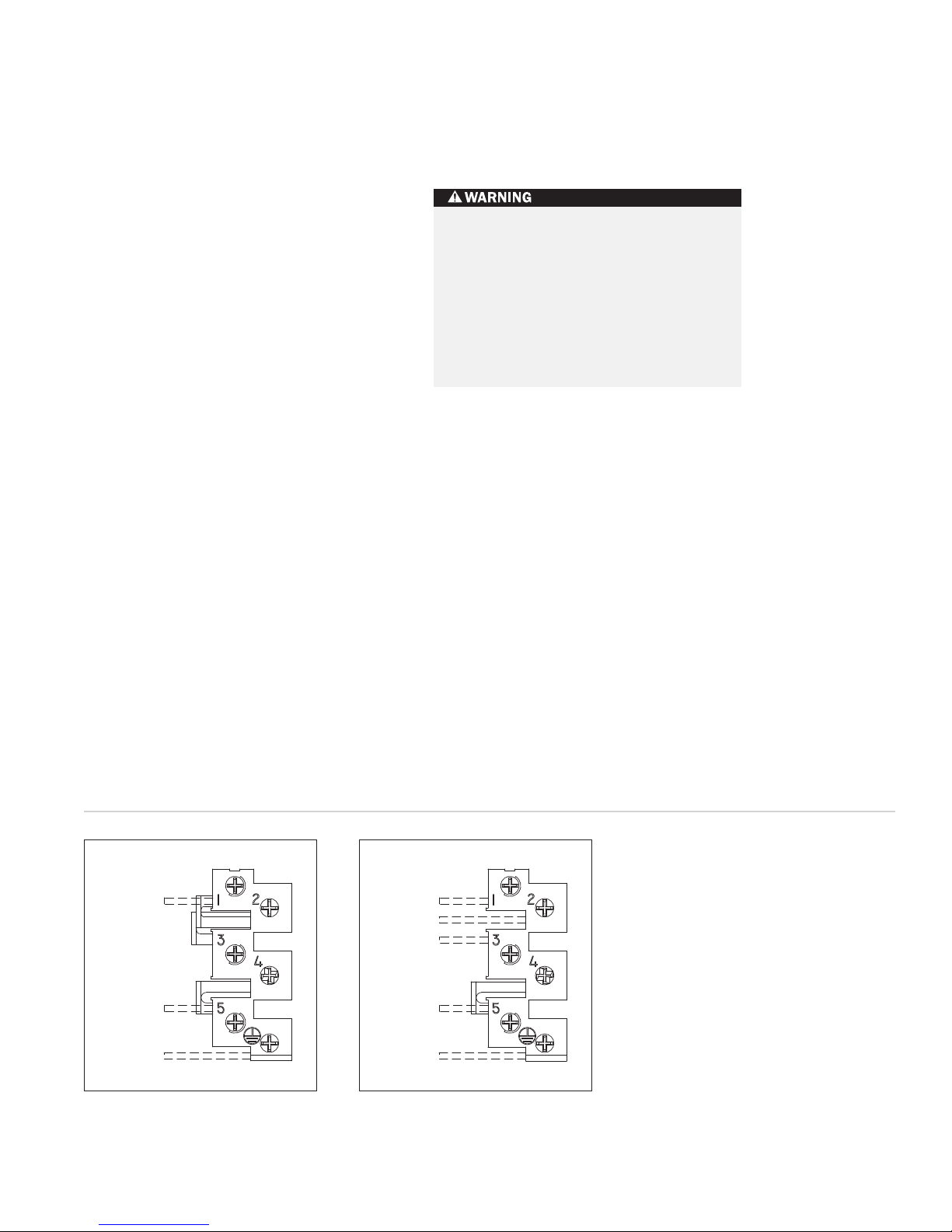

The cooktop is provided with a terminal box.

Refer to the wiring diagram below.

The complete appliance must be properly

grounded at all times when electrical

power is applied.

Do not ground the appliance with the

neutral (white) house supply wire. A

separate ground wire must be utilized.

Improper connection can result in a fire

hazard!

N

L1

GROUND

Single phase wiring diagram

L1

L2

L3

N

GROUND

Three phase wiring diagram

17

WOLF INDUCTION COOKTOPS

ACCESSORIES

Optional accessories are available

through your

Wolf dealer. To

obtain local dealer

information, visit

our website,

wolfappliance.com.

COOKTOP

INSTALLATION

Attach the foam strip to the underside of the

cooktop frame. Refer to the illustration below.

IMPORTANT NOTE:

For unframed installation,

adhere foam strip to the outer edge of the

glass, not the support frame.

Gently lower the cooktop into the cut-out area

in the countertop and center. Check that the

front edge of the cooktop is parallel to the

front edge of the countertop. Check that all

required clearances are met.

Attach the brackets to the bottom of the unit,

as shown in the illustration below. Install the

clamping screws into the bracket and tighten

until the screws contact the underside of the

countertop.

IMPORTANT NOTE:

Do not over tighten the screws.

Do not seal the cooktop

to the countertop. It must be removed if

service is necessary.

If the ceramic glass top of the cooktop is

broken, turn off power to the unit. Do

not operate until glass has been replaced

by a Wolf authorized service center.

BEFORE OPERATING

Clean the ceramic glass surface carefully using

the Cooktop Cleaning Crème provided with the

cooktop. Remove all cleaning residue.

Read the entire Wolf Induction Cooktops

Use & Care Information included with the

cooktop. Important safety and service information is contained within the book.

COOKTOP

IMPORTANT NOTE:

REMOVAL

This procedure should

only be performed by a Wolf authorized

service center.

If it is necessary to remove the cooktop for

cleaning or service, disconnect the electrical

supply. Remove the mounting brackets on the

right and left side of the unit and remove the

cooktop. Reinstall in the reverse order.

IMPORTANT NOTE:

For flush mount installations, use a razor blade to cut around the RTV

seal. A new RTV installation kit (811358) will be

required to reinstall the cooktop. This kit is

available through your Wolf dealer. To obtain

local dealer information, visit our website,

wolfappliance.com.

18

COOKTOP

FOAM

STRIP

Foam strip Installation brackets

COOKTOP

BRACKET

BRACKET

SCREWS

COUNTERTOP

89 mm

CLAMPING

SCREW

INSTALLATION INSTRUCTIONS

TROUBLESHOOTING

IF COOKTOP DOES NOT OPERATE

IMPORTANT NOTE:

If the induction cooktop

does not operate properly, follow these

troubleshooting steps:

Verify that power is being supplied to the

cooktop.

Check electrical connections to ensure that

the installation has been completed

correctly.

Follow troubleshooting procedures as

described in the Wolf Induction Cooktops

Use & Care Information.

If the power bar indicator lights operate but

the unit shows that it is in Lock mode, the

unit is in Showroom mode. Contact your

localWolfdealer.

If the cooktop still does not work, contact

a Wolf authorized service center. Do not

attempt to repair the cooktop yourself.

Wolf is not responsible for service required

to correct a faulty installation.

The unit must be disconnected from

power prior to service.

19

CONTACT

INFORMATION

Website:

wolfappliance.com

WOLF INDUCTION COOKTOPS

IF YOU NEED SERVICE

If service is necessary, maintain the quality

built into your induction cooktop by calling

a Wolf authorized service center.

To obtain the name and number of a

Wolf authorized service center, visit our

website,

wolfappliance.com

.

When calling for service, you will need the

cooktop model and serial numbers. Both

numbers are listed on the rating plate,

located on the underside of the cooktop.

Refer to the illustration on page 5 for

location of the rating plate.

20

The information and images in this book are the

copyright property of Wolf Appliance, Inc., an

affiliate of Sub-Zero, Inc. Neither this book nor any

information or images contained herein may be

copied or used in whole or in part without the

express written permission of Wolf Appliance, Inc.,

an affiliate of Sub-Zero, Inc.

©Wolf Appliance, Inc. all rights reserved.

INFORMACIÓN

DE CONTACTO

Página web:

wolfappliances.com

Cuando consulte las instrucciones que aparecen

en esta guía, encontrará símbolos de ADVERTENCIA y PRECAUCIÓN. Esta información en

recuadros es importante para instalar el equipo

de Wolf de forma segura y eficaz. Existen dos

tipos de posibles riesgos que pueden producirse

durante una instalación.

WOLF®es una marca comercial registrada de Wolf Appliance, Inc.

indica una situación en la que se pueden

sufrir heridas leves o provocar daños

secundarios al producto si no se siguen

las instrucciones.

indica peligro de que se produzcan heridas

personales graves o incluso puede provocar

la muerte si no se siguen las precauciones

especificadas.

Otro tipo de anotación que es importante

resaltar es la que se incluye en NOTA

IMPORTANTE: En esta nota se resalta la

información que resulta especialmente

importante para que la instalación se

realice sin problemas.

PLACAS DE INDUCCIÓN DE WOLF

INFORMACIÓN

DE LA PLACA

DE DATOS

Referencia del

modelo

Número de serie

REQUISITOS DE INSTALACIÓN

NOTA IMPORTANTE:

Guarde estas instrucciones

de instalación para que el inspector local pueda

utilizarlas.

Lea las instrucciones de instalación antes de

llevar a cabo la instalación.

Esta instalación debe ser realizada por un

técnico cualificado.

Instalador:

guarde estas instrucciones para

que el inspector local pueda utilizarlas como

referencia y, a continuación, entréguelas al

propietario del aparato.

Propietario:

lea y guarde estas instrucciones

para que pueda utilizarlas como referencia en

el futuro y asegúrese de leer la guía de uso y

mantenimiento antes de utilizar el aparato.

NOTA IMPORTANTE:

Este aparato debe instalarse siguiendo las normativas nacionales correspondientes. Se debe aplicar al aparato el voltaje,

la frecuencia y el amperaje adecuados desde una

instalación eléctrica resistente con toma de tierra

protegida por un fusible de retardo. El voltaje, la

frecuencia y el amperaje se muestran en la placa

de datos del producto.

Apunte la referencia del modelo y el número

de serie antes de instalar el aparato. Esta información se muestra en la placa de datos del

producto situada en la parte inferior de la

placa. Observe la siguiente ilustración.

ANTES DE COMENZAR

Es responsabilidad del propietario asegurarse

de que la instalación se realiza de manera

correcta. Esta placa debe ser instalada por un

técnico cualificado. Debe asegurarse de que la

instalación eléctrica es la correcta y que

cumple todos los códigos y normativas

nacionales.

Las instalaciones y reparaciones deben ser

realizadas por un contratista cualificado o

autorizado o por un electricista cualificado o

autorizado por el estado, provincia o región

en la que se va a instalar este aparato.

Compruebe que tiene todo lo necesario para

que la instalación se lleve a cabo de la manera

correcta. Es responsabilidad del instalador

dejar los espacios necesarios para la instalación que se especifican en la placa de datos

del producto. La placa de datos está ubicada

en la parte inferior del aparato.

Este aparato necesita una conexión a tierra;

consulte la sección Requisitos eléctricos en las

páginas 33 y 34.

Esta placa está diseñada para que se utilice

en espacios interiores.

placa de datos debajo

Ubicación de la placa de datos

22

Ubicación de la

de la placa

PLACAS DE INDUCCIÓN DE WOLF

PREPARACIÓN DEL

NOTA IMPORTANTE:

SITIO

La instalación de la placa

de inducción de Wolf debe cumplir los siguientes

requisitos de colocación. Las medidas que se

especifican son las mínimas para que el funcionamiento de la placa sea seguro. Observe la siguiente ilustración.

Para eliminar el riesgo de sufrir quemaduras

o de que se produzca un incendio al

alcanzar las superficies calientes, debe

evitar colocar armarios por encima de los

módulos de superficie. Si va a colocar

armarios, el riesgo se puede reducir al

instalar una campana de extracción que

sobresalga horizontalmente un mínimo de

127 mm de la parte inferior de los armarios.

COLOCACIÓN EN LA ENCIMERA

A)

Superficie mínima de encimera plana. Debe

ser igual o superior al ancho de la placa.

B)

Espacio mínimo de 25 mm desde el borde

lateral de la placa a cualquier superficie

combustible situada a 457 mm por encima de

la placa (área sombreada de la ilustración).

MEDIDAS DE LOS ARMARIOS

SUPERIORES

C)

El espacio mínimo entre los armarios laterales

superiores debe ser igual o superior al ancho

nominal de la placa o placas.

D)

Debe existir una distancia vertical mínima de

457 mm desde la encimera hasta la parte

inferior de los armarios laterales con una

distancia lateral mínima.

E)

La distancia vertical mínima entre la encimera

y los materiales combustibles situados por

encima de la placa debe ser de 762 mm.

F)

Distancia mínima de 25 mm a la pared trasera.

G)

El fondo máximo de los armarios superiores

laterales situados por encima de la placa

debe ser de 330 mm con una distancia

lateral mínima.

E

F

B

Distancias mínimas de instalación

Si no coloca la placa siguiendo las

distancias de separación correctas, es

posible que se produzca un incendio.

C

G

D

B

A

23

INSTRUCCIONES DE INSTALACIÓN

ESPECIFICACIONES DE

LA

INSTALACIÓN

Las ilustraciones de las páginas 25–30 proporcionan las medidas totales, las especificaciones de la

instalación y las medidas del corte de la encimera

para cada uno de los modelos de placas de

inducción de Wolf.

Esta placa está diseñada para que se adapte a un

armario de base estándar de 610 mm de fondo

con una encimera de 635 mm de fondo. Antes de

cortar la encimera, compruebe que la placa va a

quedar separada de las paredes laterales del

armario inferior.

Se necesita dejar un espacio para el bloque de

terminales en la parte trasera derecha de la placa.

Observe la siguiente ilustración para ver las

medidas.

PLACAS DE INDUCCIÓN CON MARCO

NOTA IMPORTANTE:

Es necesario dejar un

espacio mínimo de altura de 152 mm entre la

placa y cualquier superficie combustible que se

encuentre justo debajo de la placa. Esto incluye

los bordes superiores de los cajones situados

directamente debajo de la unidad. Si instala un

estante debajo del aparato, debe dejar un espacio

de 25 mm en la parte trasera del armario para

que la ventilación sea correcta. Si no deja este

espacio, es posible que se reduzca el rendimiento

del aparato o que se produzcan daños en el

mismo.

Las placas de inducción de Wolf están diseñadas

para que se puedan instalar junto con otras

placas.

NOTA IMPORTANTE:

Cuando instale varias

placas juntas y /o módulos, consulte las dimensiones de corte de la encimera en la página 28.

Las placas de inducción de Wolf pueden

instalarse con un sistema de ventilación de tiro

ascendente de Wolf. Consulte las instrucciones de

instalación que se proporcionan con el sistema

de ventilación de tiro ascendente para obtener

más información.

PLACAS DE INDUCCIÓN SIN MARCO

NOTA IMPORTANTE:

Es necesario dejar un

espacio mínimo de altura de 165 mm entre la

placa y cualquier superficie combustible que se

encuentre justo debajo de la placa. Esto incluye

los bordes superiores de los cajones situados

directamente debajo de la unidad. Si instala un

estante debajo del aparato, debe dejar un espacio

de 25 mm en la parte trasera del armario para

que la ventilación sea correcta. Si no deja este

espacio, es posible que se reduzca el rendimiento

del aparato o que se produzcan daños en el

mismo.

NOTA IMPORTANTE:

Las placas de inducción

sin marco de Wolf están diseñadas para que se

puedan instalar junto con otras placas.

NOTA IMPORTANTE:

Las placas de inducción

sin marco no se pueden instalar con un sistema

de ventilación de tiro ascendente.

Si desea consultar las opciones de instalación

de las placas de inducción sin marco, consulte

la sección Instalación sin marco en las

páginas 31–32.

32 mm

56

mm

84

24

mm

Medidas del bloque de terminales

24

mm

22 mm

PLACAS DE INDUCCIÓN DE WOLF

MODELO ICBCT15I/S CON MARCO

Las siguientes ilustraciones proporcionan las

especificaciones de instalación del modelo

ICBCT15I/S.

Si instala el modelo ICBCT15I/S encima de los

armarios, la colocación de la toma eléctrica no es

importante. El aparato se instalará de tal forma

que se pueda desconectar de la red después de

su instalación.

ESPECIFICACIONES DE LA INSTALACIÓN – MODELO ICBCT15I/S

533 mm

PROFUNDIDAD

TOTAL

89 mm

381 mm

ANCHURA TOTAL

114 mm

mm

51**

330 mm

máx

489 mm

PROFUNDIDAD

DE CORTE DE LA

SUPERFICIE

DE

COCCIÓN

64 mm

mín

457

mm

CAJA PARA TERMINAL

Medidas totales

914 mm

ALTURA

MODELO ICBCT15I/S

Anchura total 381 mm

ESTÁNDAR DEL

SUELO

ALA

ENCIMERA

Altura total 89 mm

Profundidad total 533 mm

Fondo mínimo del armario 578 mm

Espacio de altura mínimo* 114 mm

NOTA: La aplicación que se muestra permite la instalación de dos módulos contiguos de 381 mm con un armario con una anchura recomendada

de 838 mm. 457 mm de anchura de armario recomendada para la instalación de un solo módulo o superficie de cocción de 381 mm. *Espacio mínimo

desde ambos bordes laterales del corte de la superficie de cocción hasta la superficie inflamable situada a 457 mm por encima de la encimera. **Espacio

mínimo desde el borde trasero del corte de la superficie de cocción a la superficie inflamable situada a 457 mm sobre la encimera.

Ancho del corte 340 mm

Profundidad del corte 489 mm

*Es necesario dejar un espacio mínimo de

altura de 152 mm entre la encimera y

cualquier superficie combustible que se

encuentre justo encima de la placa.

Si desea obtener las medidas detalladas

del bloque de terminales, consulte la

ilustración en la página 24.

Las medidas pueden variar±3mm.

Corte de la encimera

51 mm* mín

DESDE CORTE A

LOS MATERIALES

INFLAMABLES

(AMBOS

LADOS)

64 mm

mín

838 mm ANCHURA RECOMENDADA

DEL ARMARIO

340 mm ANCHURA

DE CORTE DE

LA SUPERFICIE

DE

COCCIÓN

114 mm

E

381

mm

381 mm

340 mm ANCHURA DE CORTE

DE LA SUPERFICIE

DE

COCCIÓN

PROFUNDIDAD

DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

PARTE DELANTERA DE LA ENCIMERA

489 mm

762 mm

ENCIMERA

A MATERIALES

COMBUSTIBLES

SOBRE

LA SUPERFICIE

DE COCCIÓN

25

INSTRUCCIONES DE INSTALACIÓN

MODELO ICBCT30I/S CON MARCO

Las siguientes ilustraciones proporcionan las

especificaciones de instalación del modelo

ICBCT30I/S.

Para que la instalación le resulte más sencilla,

cuando instale el modelo ICBCT30I/S le

recomendamos que utilice armarios de 838 mm.

Debajo del modelo ICBCT30I/S se puede instalar

un horno sencillo de Wolf integrado de 762 mm

o 914 mm. Para realizar esta instalación, a menos

que utilice armarios con una profundidad mayor

a 610 mm, se recomienda colocar la alimentación

eléctrica en el armario de la base a la derecha

del horno.

ESPECIFICACIONES DE LA INSTALACIÓN – MODELO ICBCT30I/S

533 mm

PROFUNDIDAD

TOTAL

89 mm

762 mm

ANCHURA TOTAL

CAJA PARA TERMINAL

114 mm

330 mm

máx

PROFUNDIDAD

51**

mm

DE LA SUPERFICIE

489 mm

DE CORTE

DE COCCIÓN

64 mm

mín

457

mm

Medidas totales

610 mm mín

MODELO ICBCT30I/S

Anchura total 762 mm

914 mm

ALTURA

ESTÁNDAR

DEL

SUELO A LA

ENCIMERA

Altura total 89 mm

Profundidad total 533 mm

Fondo mínimo del armario 578 mm

*Espacio mínimo desde ambos bordes laterales del corte de la superficie de cocción hasta la superficie inflamable situada a 457 mm por encima de

la encimera. **Espacio mínimo desde el borde trasero del corte de la superficie de cocción a la superficie inflamable situada a 457 mm sobre la encimera.

Espacio de altura mínimo* 114 mm

Ancho del corte 721 mm

Profundidad del corte 489 mm

Cortedelaencimera

Consulte las instrucciones de instalación que

se proporcionan con el horno integrable para

obtener más información.

Si instala el modelo ICBCT30I/S encima de los

armarios, la colocación de la toma eléctrica no

es importante. El aparato se instalará de tal

forma que se pueda desconectar de la red

después de su instalación.

51 mm* mín

DESDE CORTE A

LOS MATERIALES

INFLAMABLES

(AMBOS

LADOS)

838 mm ANCHURA RECOMENDADA

DEL ARMARIO

762 mm mín

721 mm ANCHURA

DE CORTE

DE LA SUPERFICIE

DE

COCCIÓN

114 mm

95 mm

mín

762 mm APERTURA DEL HORNO

DE LA SUPERFICIE DE COCCIÓN

89 mm

721 mm

ANCHURA DE CORTE

254

mm

A MATERIALES

COMBUSTIBLES

SUPERFICIE

DE COCCIÓN

E

762 mm

ENCIMERA

SOBRE LA

*Es necesario dejar un espacio mínimo de

altura de 152 mm entre la encimera y

cualquier superficie combustible que se

encuentre justo encima de la placa.

Si desea obtener las medidas detalladas

del bloque de terminales, consulte la

ilustración en la página 24.

Las medidas pueden variar±3 mm.

26

64 mm

mín

PARTE DELANTERA DE LA ENCIMERA

489 mm

PROFUNDIDAD

DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

PLACAS DE INDUCCIÓN DE WOLF

MODELO ICBCT36I/S CON MARCO

Las siguientes ilustraciones proporcionan las

especificaciones de instalación del modelo

ICBCT36I/S.

Para que la instalación le resulte más sencilla,

cuando instale el modelo ICBCT36I/S le

recomendamos que utilice armarios de 991 mm.

Debajo del modelo ICBCT36I/S se puede instalar

un horno sencillo de Wolf integrado de 762 mm

o 914 mm. Para realizar esta instalación, a menos

que utilice armarios con una profundidad mayor

a 610 mm, se recomienda colocar la alimentación

eléctrica en el armario de la base a la derecha

del horno.

ESPECIFICACIONES DE LA INSTALACIÓN – MODELO ICBCT36I/S

914 mm

ANCHURA TOTAL

89 mm

CAJA PARA TERMINAL

Medidas totales

MODELO ICBCT36I/S

533 mm

PROFUNDIDAD

TOTAL

114 mm

330 mm

máx

PROFUNDIDAD

51**

mm

DE LA SUPERFICIE

Consulte las instrucciones de instalación que

se proporcionan con el horno integrable para

obtener más información.

Si instala el modelo ICBCT36I/S encima de los

armarios, la colocación de la toma eléctrica no

es importante. El aparato se instalará de tal

forma que se pueda desconectar de la red

después de su instalación.

489 mm

DE CORTE

DE COCCIÓN

610 mm mín

64 mm

mín

914 mm

ALTURA

ESTÁNDAR

DEL SUELO

ALA

ENCIMERA

457

mm

51 mm* mín

DESDE CORTE A

LOS MATERIALES

INFLAMABLES

(AMBOS

LADOS)

991 mm

ANCHURA RECOMENDADA

DEL ARMARIO

ANCHURA DE CORTE DE

LA SUPERFICIE DE COCCIÓN

95 mm

mín

762 mm APERTURA DEL HORNO

914 mm mín

873 mm

114 mm

89 mm

254

mm

ENCIMERA A

MATERIALES

COMBUSTIBLES

SUPERFICIE

DE COCCIÓN

E

762 mm

SOBRE LA

Anchura total 914 mm

Altura total 89 mm

Profundidad total 533 mm

Fondo mínimo del armario 578 mm

Espacio de altura mínimo* 114 mm

Ancho del corte 873 mm

Profundidad del corte 489 mm

*Es necesario dejar un espacio mínimo de

altura de 152 mm entre la encimera y

cualquier superficie combustible que se

encuentre justo encima de la placa.

Si desea obtener las medidas detalladas

del bloque de terminales, c onsulte la

ilustración en la página 24.

Las medidas pueden variar±3mm.

*Espacio mínimo desde ambos bordes laterales del corte de la superficie de cocción hasta la superficie inflamable situada a 457 mm por encima de la encimera.

**Espacio mínimo desde el borde trasero del corte de la superficie de cocción a la superficie inflamable situada a 457 mm sobre la encimera.

873 mm

ANCHURA DE CORTE

DE LA SUPERFICIE DE COCCIÓN

Corte de la encimera

489 mm

PROFUNDIDAD

64 mm

mín

PARTE DELANTERA DE LA ENCIMERA

DE CORTE

DE LA SUPERFICIE

DE COCCIÓN

27

Loading...

Loading...